1. Introduction

Smart textiles offer tremendous potential in healthcare, providing solutions for monitoring vital parameters, facilitating rehabilitation, and improving overall well-being. Various studies have explored the integration of smart textiles into clothing and wearable devices for continuous health monitoring. These devices have demonstrated the ability to collect physiological data, track movement, and provide personalized feedback to patients and healthcare professionals [

1,

2,

3,

4,

5].

A key aspect of this research work are medical smart textiles, for example, motion analysis for rehabilitation applications, or it serves as a signal for electrodes that are intended to stimulate specific muscle groups, e.g., to help people with peroneal nerve paralysis to walk or to train the muscle groups specifically through stimulation [

6]. Pressure sensors are one way of analyzing movement, as shown in studies [

7,

8,

9]. However, all existing solutions for motion detection have been realized via pressure sensors, which were applied to a garment afterwards and not integrally, processed in a manufacturing step and cannot be considered for the knitted piezoresistive strain sensor.

Another option to record the movement is through strain sensors [

10,

11], which work according to the piezoresistive effect [

12,

13]. Using piezoresistive strain sensors, placed on joints, the change in the electrical resistance of the piezoresistive strain sensor during mechanical deformation [

14,

15] can be used to infer the joint bending and, thus, the wearer’s movement [

2,

16,

17]. However, in addition to the position of the sensors, the conductive material, the structural implementation and the design are also important for the sensor functionality. Typical fibre-based conductive materials and their influence on the stability of the sensor signal are analysed in [

15,

18,

19]. It was found that metalized yarns are suitable in principle, but that the elongation of the base material plays a significant role in the sensor signal of a piezoresistive strain sensor and that less stretchable steel yarns are not suitable in contrast to silver-plated polyamide yarns. In [

19,

20,

21,

22] for example the performances of different knitted piezoresistive strain sensors were investigated. The authors explore the optimization of design parameters to achieve enhanced sensitivity and accuracy in strain measurements. The findings demonstrate that the selection of the conductive area and the design of the sensor profile have a significant influence on the performance of knitted piezoresistive strain sensors and are crucial aspects in the development of such sensors. The basic textile structure of the sensors was incorporated exclusively into a mock rib knit (similar to right-right-pattern). [

23] focuses on addressing the challenge of hysteresis, which can negatively impact the accuracy and reliability of strain measurements. Through the utilization of specialized knitting techniques and careful selection of materials, the authors successfully design piezoresistive strain sensors that exhibit minimal hysteresis and provide a linear response to applied strain. The findings demonstrate the potential of weft-knitted piezoresistive strain sensors as reliable and accurate components in smart textiles, opening up opportunities for their integration into various wearables and healthcare applications.

In addition to the essential strain sensor development, various research approaches exist for motion capturing. Weft-knitted piezoresistive strain sensors are already used in various smart textiles for different applications, some of them can be transferred to medical applications. In Ref. [

24], a smart glove was developed to measure the joint angles of the interphalangeal joints. It was shown here that knitted sensors would be suitable for motion capture. The finger movement with a knitted piezoresistive strain sensor was also developed an integrated in a wearable system in [

25]. The new piezoresistive strain sensor has the potential to be used for medical smart textiles and the findings helps to do further research.

In addition to knitted piezoresistive strain sensors, other material approaches to motion sensing have been investigated. In [

26], conductive elastomer sensors made of graphite and silicon rubber and in [

27] carbon filled elastic rubber are coated onto a textile. Study [

28] galvanized an elastic strain sensor made of silver-zinc oxide onto a knitted fabric, creating an electrically conductive sensor surface. These variants are also suitable in principle for joint angle measurement. These alternative material approaches are compared in the paper [

14], and the advantages and disadvantages are discussed. It became clear that the coating variants still have significant weaknesses and must first be eliminated for medical applications.

Due to the enormous advantages of knitted piezoresistive strain sensors, this approach is focused on in this paper.

The studies discussed materials, designs, and the electro-mechanical behavior of knitted piezoresistive strain sensors. The development of knitted strain sensors with low hysteresis is challenging. The main findings from the literature research are:

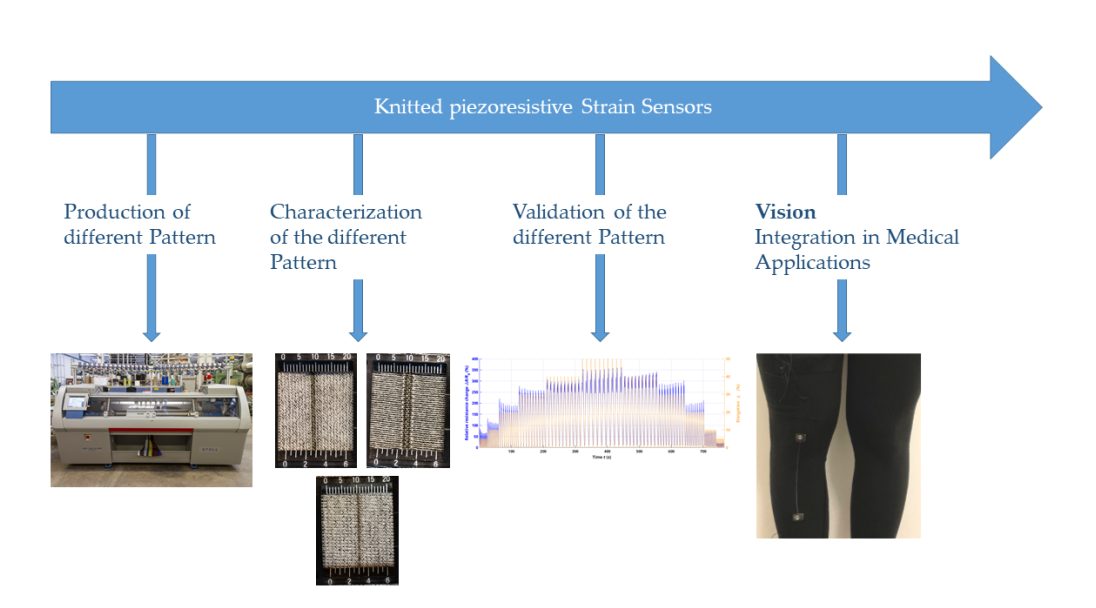

Therefore, in this research the principle of knitted piezoresistive strain sensors for motion capture for medical applications is explored. As shown by the presented studies, knitted textiles have unique properties such as flexibility and stretchability, making them ideal for wearable applications. Knitted textiles additionally have the potential to create a weft-knitted piezoresistive strain sensor with low drift, hysteresis and nonlinearity, high elongation and gauge factor (GF).

2. Materials and Methods

Yarn Materials. In

Table 1 the yarn materials and their characteristics are presented. Cellulose-based fibres Tencel-Lyocell (TL) and an elastic filament yarn (EY) form the basic pattern. The material is particularly suitable for use in medical devices worn close to the body as TL is kind to the skin, excellent in terms of moisture buffering and sensorial comfort [

29]. The elastic yarn was also used to make the knit-ted fabric even more flexible and close-fitting for optimum skin contact for direct motion capture for therapeutic purposes. The SY was used to manufacture the textile-based piezoresistive strain sensors.

Manufacturing method. A flatbed knitting machine ADF 530-32 BW knit & wear from H. Stoll AG & Co. KG (Reutlingen, Germany) with the machine unit E7.2 was used to manufacture the piezoresistive strain sensors for enabling motion capture for medical and therapeutic applications. The knitted structures produced using the flatbed knitting machine had different textile parameters. These parameters are listed in the following

Table 2.

The nomenclature based on it is composed of Production direction_Pattern_Strain sensor widthxStrain sensor length, such as W_RL_1x200.

Table 3 shows examples of the variants of the different knitted pattern used for the study.

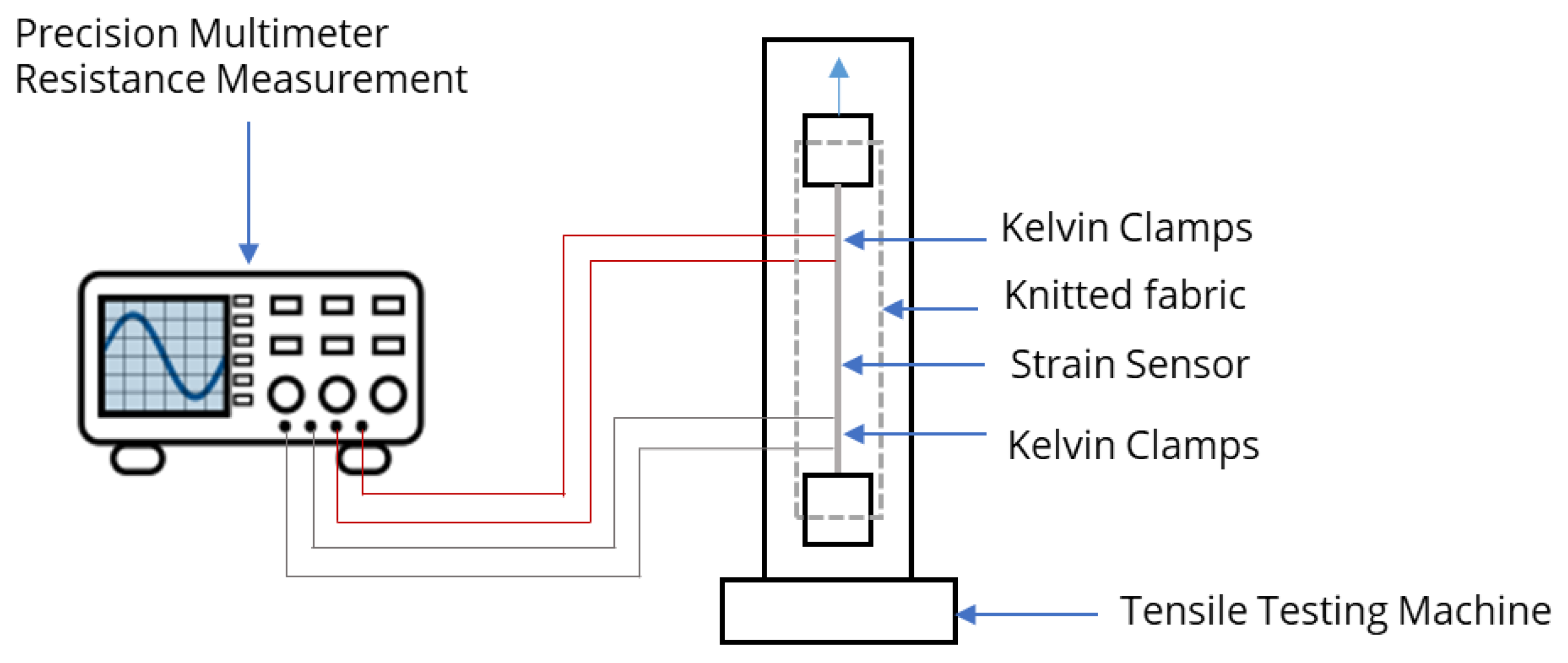

Measurement method. To determine the resistance change during cyclic mechanical elongation of the piezoresistive strain sensor, a four-wire-resistance measurement according to DIN EN 16812 [

30] was used. The four-wire-resistance measuring station consists of a precision multimeter Keithley DAQ 6510 (Tektronix Inc., Beaverton, USA) to determine the measured values and a computer for data storage and processing. To stretch the specimen, the textile was clamped in the tensile testing machine Z2.5 (ZwickRoell GmbH & Co. KG, Ulm, Germany). The test regime is listed in the

Table 4

To measure the piezoresistive strain sensor, it was fixed via four crocodile clips with a distance of 150 mm to each other (

Figure 1).

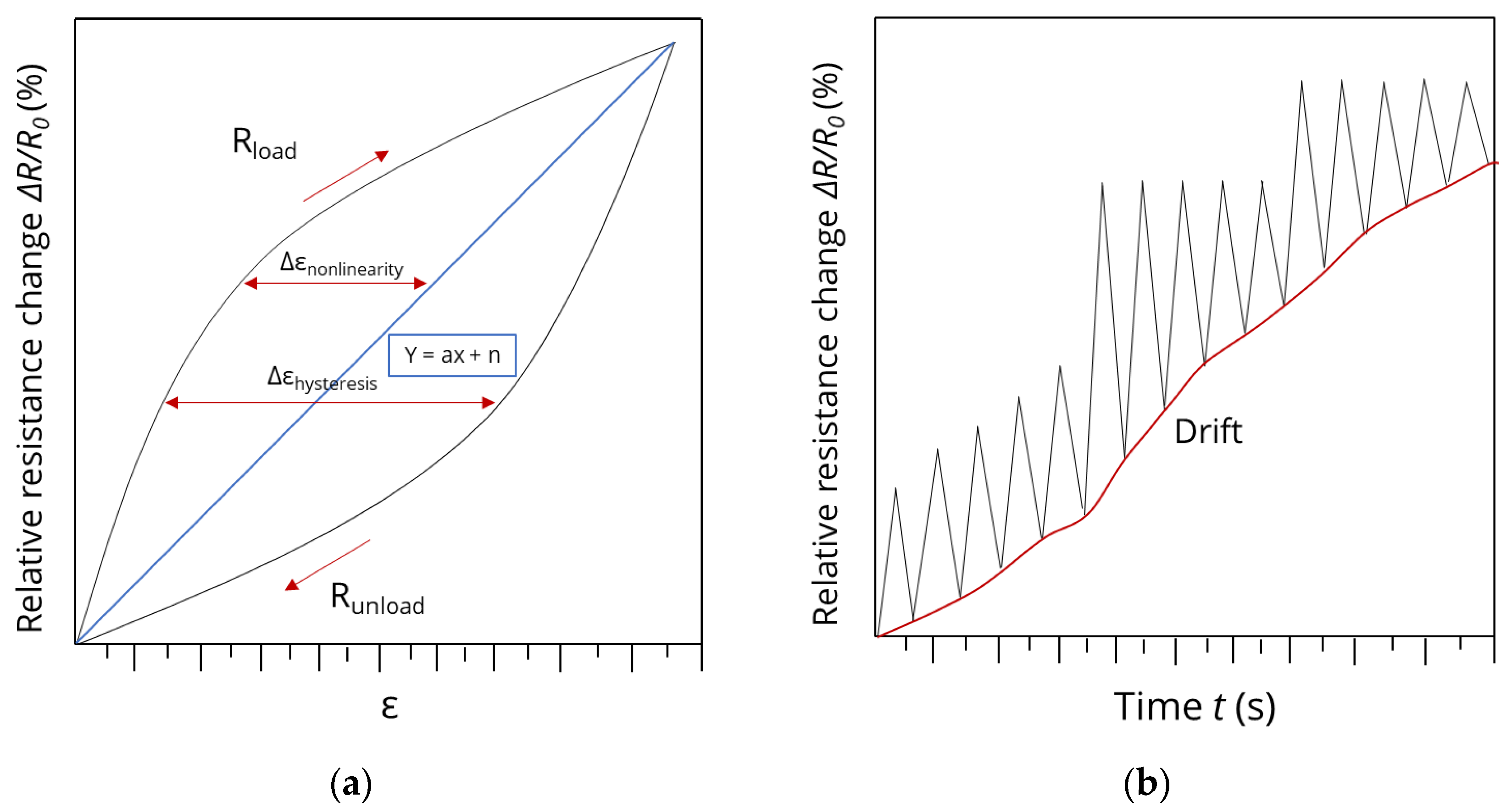

Analysis of electro-mechanical properties. In order to evaluate the sensor quality of differently knitted piezoresistive strain sensors, the electro-mechanical properties were determined. The gauge factor (GF), its nonlinearity, hysteresis, and drift were calculated to analyze the cyclic sensor behavior. The software tool Matlab was used for the analysis. The nonlinearity was determined as the difference between the linear fit line Y and the real averaged result of R

load (

Figure 2a) and was calculated with Equation (1).

The GF were derived from the slope of the linear fit. Equation (2) presents the formulation for determining the gauge factor, where Δ𝑅 denotes the variation in resistance Δ𝑅 = 𝑅

load−𝑅

0, 𝑅

0 represents the initial resistance, and Δ𝜀 signifies the strain alteration within the linear domain of the curve.

The hysteresis values were determined along the strain axis (horizontal), called strain hysteresis. The hysteresis strain, was defined as the maximum difference between the loading and unloading strains (see equation (3)) [

31].

In addition to the hysteresis as a measure of the sensor quality, the drift was determined last. The sensor drift is calculated by determining resistance at 0 % strain for every sample, averaging these values and determining the maximum deviation from 𝑅0.

3. Results

3.1. Analyze various piezoresistive strain sensors in stitch wale – and stitch course direction

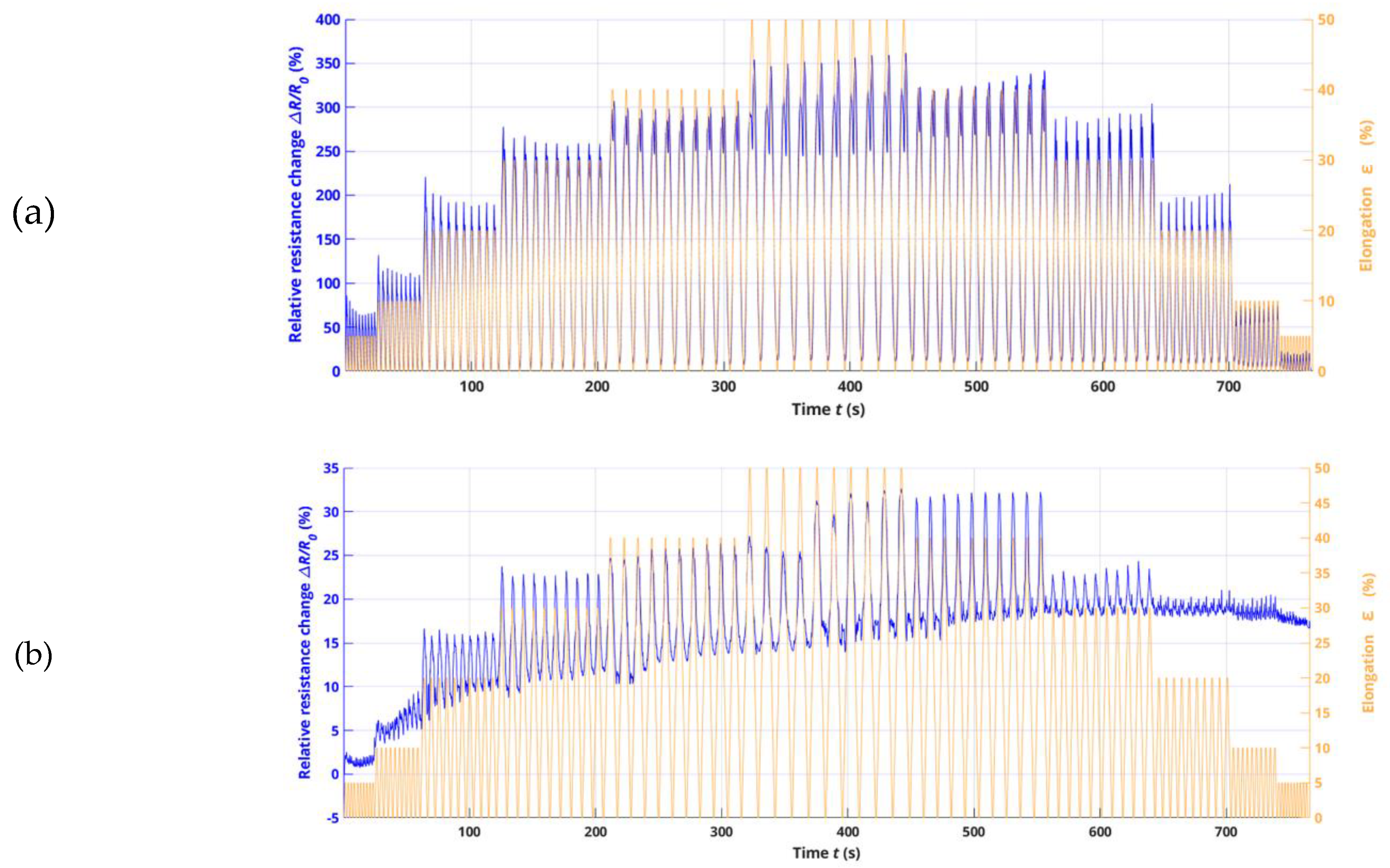

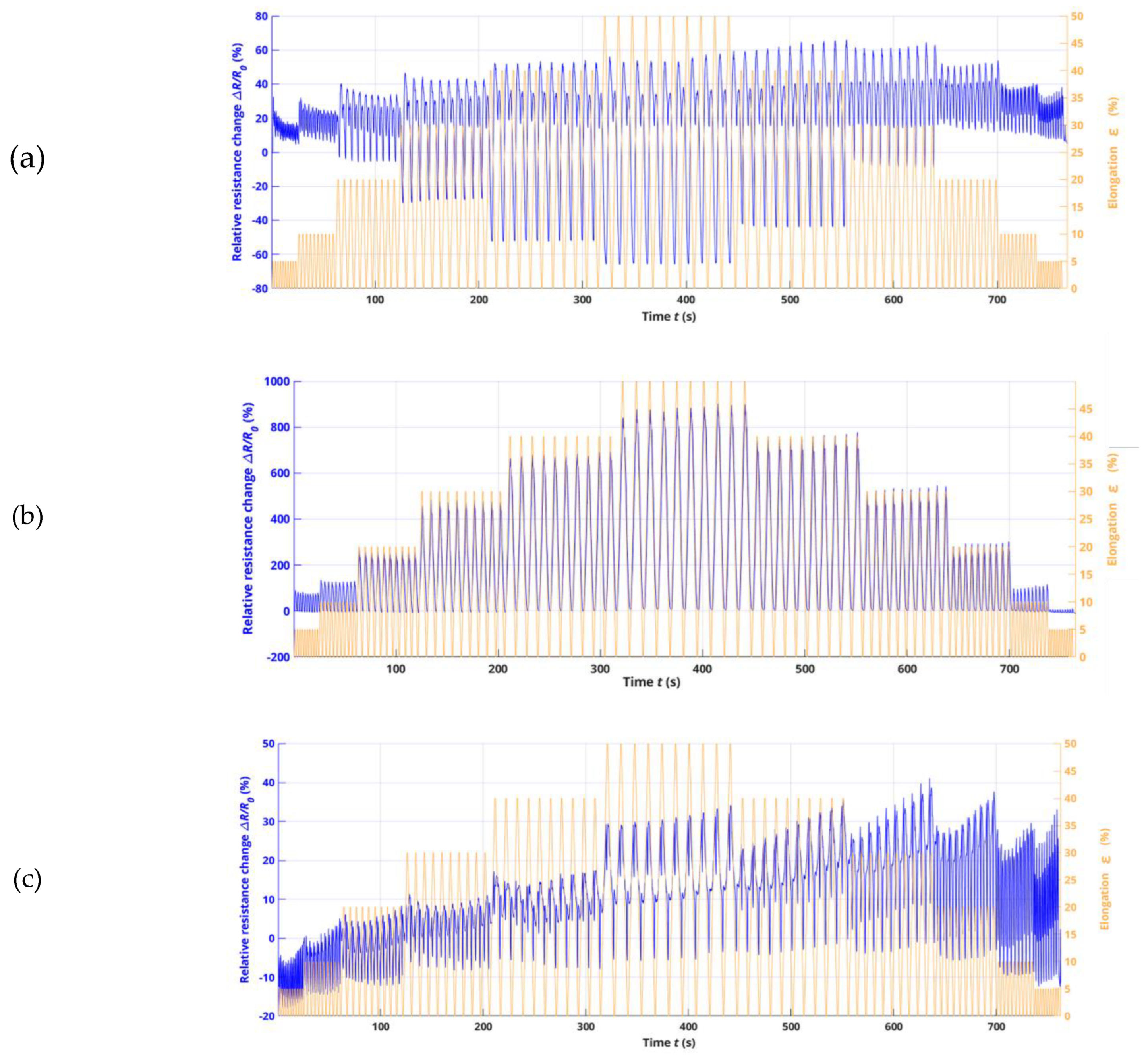

To comprehensively analyze various piezoresistive strain sensors, the initial phase involved assessing the electrical resistance in relation to strain and time. This assessment allowed for qualitative distinctions to be made. To illustrate the range of outcomes, we will focus on the n_nn_2x200 variants as representative examples since these patterns offer the best overview of the differences between sensor designs. The first example is the knit production direction and the differences between stitch wale – and stitch course direction. The results are shown in

Figure 3a,b.

The sensor oriented in stitch wale direction shows significantly better correlation between strain limits and relative resistance change. From a purely qualitative point of view, the sensor’s performance is promising. The quantification of the sensors’ properties will be considered and discussed later. In contrast to W_RL_2x200, the electrical resistance and strain do not correlate, as significantly for the sensors fabricated in stitch course direction and the sensor’s apparent drift and hysteresis over time can be seen in

Figure 3b. Based on this preliminary investigation, the production direction has a decisive influence on the sensor metrics such as nonlinearity, GF, drift, and hysteresis. The results suggest that the knit pattern in stitch course direction, as showed in

Figure 3b, is less suitable for a piezoresistive strain sensor for motion capture. Therefore, the next step is to examine and compare the different pattern variants only in the stitch direction.

3.2. Analyze various pattern and its piezoresistive strain sensors

The analysis is based on the variants W_nn_2x200 (Figures 3a and 4a–c).

Figure 3a W_RL_2x200 and

Figure 4b W_RRI_2x20 again show a correlation between electrical resistance and strain, whereas the sensor signal of (a) W_RR_2x200 and (c) W_LL_2x200 drifts over the cycles.

The results suggest that the knit pattern also influences the sensor quality and that RL and RRI might be more suitable for a piezoresistive strain sensor for motion capture.

3.3. Analyze of the Nonlinearity, Gauge Factor, Drift, and Hysteresis of various pattern and its piezoresistive strain sensors

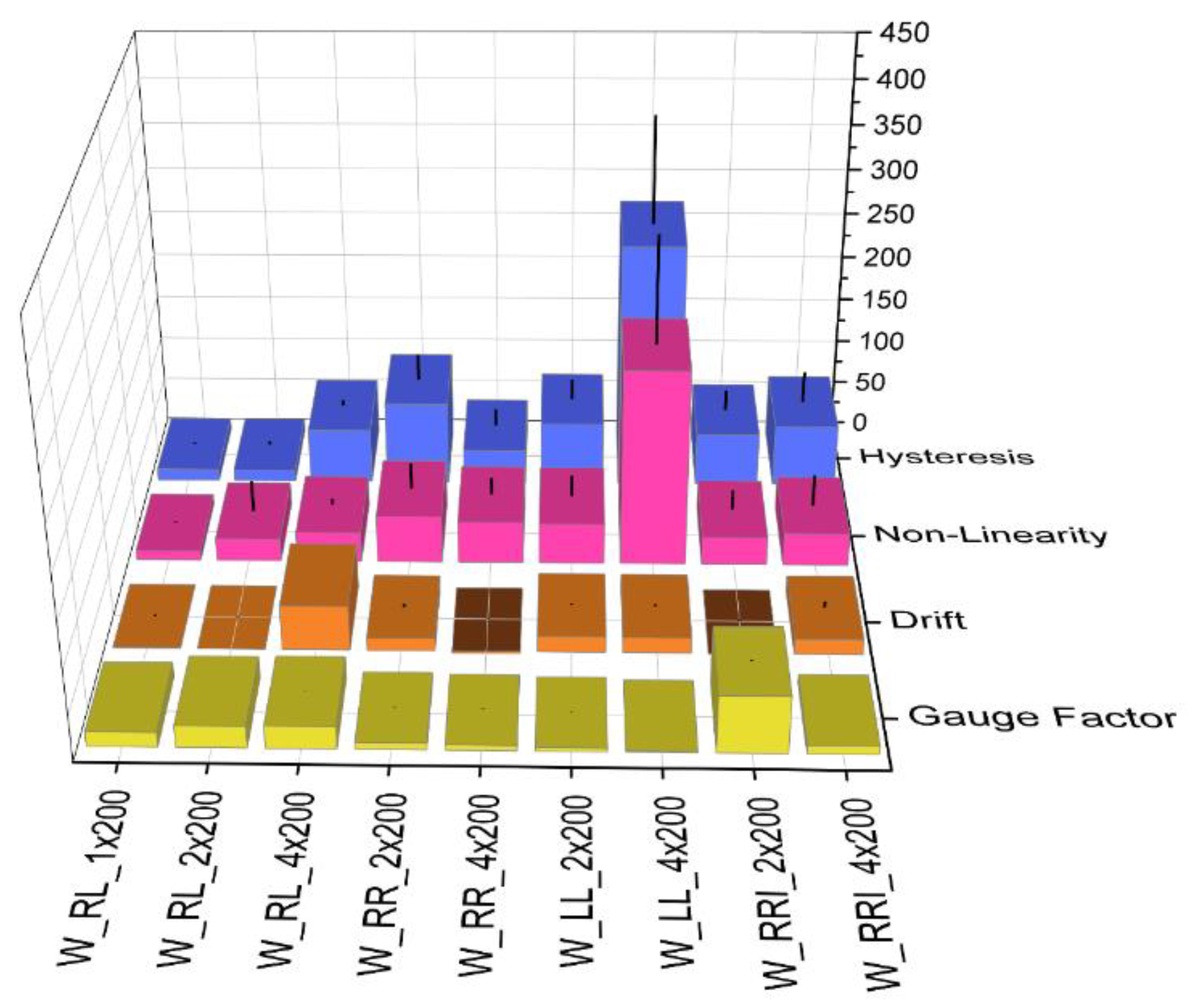

Based on these findings, the nonlinearity, GF, drift, and hysteresis are determined in the next step, and the results are presented in the following.

Figure 5 illustrates the effect of the knitted pattern and the differences be-tween right-left, right-right, right-right-interlock, and left-left patterns. The effect of sensor width and the differences between one, two, and four meshes in a line are also shortly examined.

Upon examining the nonlinearity, it is evident that variant W_LL_4x200 exhibits a deviation of over 200 %. The same observation applies to hysteresis. However, a clear correlation between pattern, sensor width, and the resulting sensor quality cannot be determined based on these results. On the other hand, the analysis of the correlation between strain and electrical resistance in

Figure 4 indicates that the variants LL and RR patterns are unsuitable for the intended purpose. The patterns with the best transmission behavior and the lowest drift are W_RL_4x400, W_RL_2x200, W_RL_1x200, W_RRI_4x200, and W_RRI_2x200. The correlation between strain and resistance over time for the best and the worst versions can be seen for example in the

Figure 3a,

Figure 4b and in

Figure 4c. These samples differ in the RL and RRI patterns and sensor width. The W_RRI_4x200 variant has a GF of 0.9 and a drift of 17 %. The W_RRI_2x200 variant has the highest GF of 6.3 and the lowest drift of 0.15 %. Despite having the same pattern and production direction, the difference can be attributed to the sensor width, which will be further discussed later. The RL pattern with a width of W_RL_4x400 and W_RL_2x200 have a GF of 2.4 and a drift of 50 % and 0.3 % nonlinearity, respectively, while the W_RL_1x200 variant has a GF of 1.6 and a drift of up to 0.8 %. Again, the results differ based on the sensor width rather than the pattern. When considering the sensor width, it can be observed that the variants with four meshes exhibit a nonlinearity of 33.5 % and a hysteresis of 61.5 % for the RL pattern. For the RRI pattern, the values are in a similar range with a nonlinearity of 36 % and a hysteresis of 69 %. Reducing the width to two meshes also reduces the nonlinearity to 25 % and the hysteresis to 12.5 % for the RL pattern. For RRI, the nonlinearity is 31 %, and the hysteresis is 58 %. Despite having a high GF and low drift, the deviations in terms of linearity and hysteresis are more significant for W_RRI_2x200 compared to the RL variants. Although W_RL_1x200 has a lower GF, it exhibits the lowest nonlinearity at 10.7 %.

4. Discussion

Based on the preliminary investigation, the production direction has a decisive influence on the sensor metrics and the C direction is unsuitable as a production direction for a piezoresistive strain sensor. In addition to the production direction, the knit pattern also influences the sensor quality. The results support the hypothesis that LL and RR patterns are unsuitable and that RL and RRI might be more suitable for a piezoresistive strain sensor for motion capture, as indicated by the correlation between strain and resistance change in

Figure 4. Based on

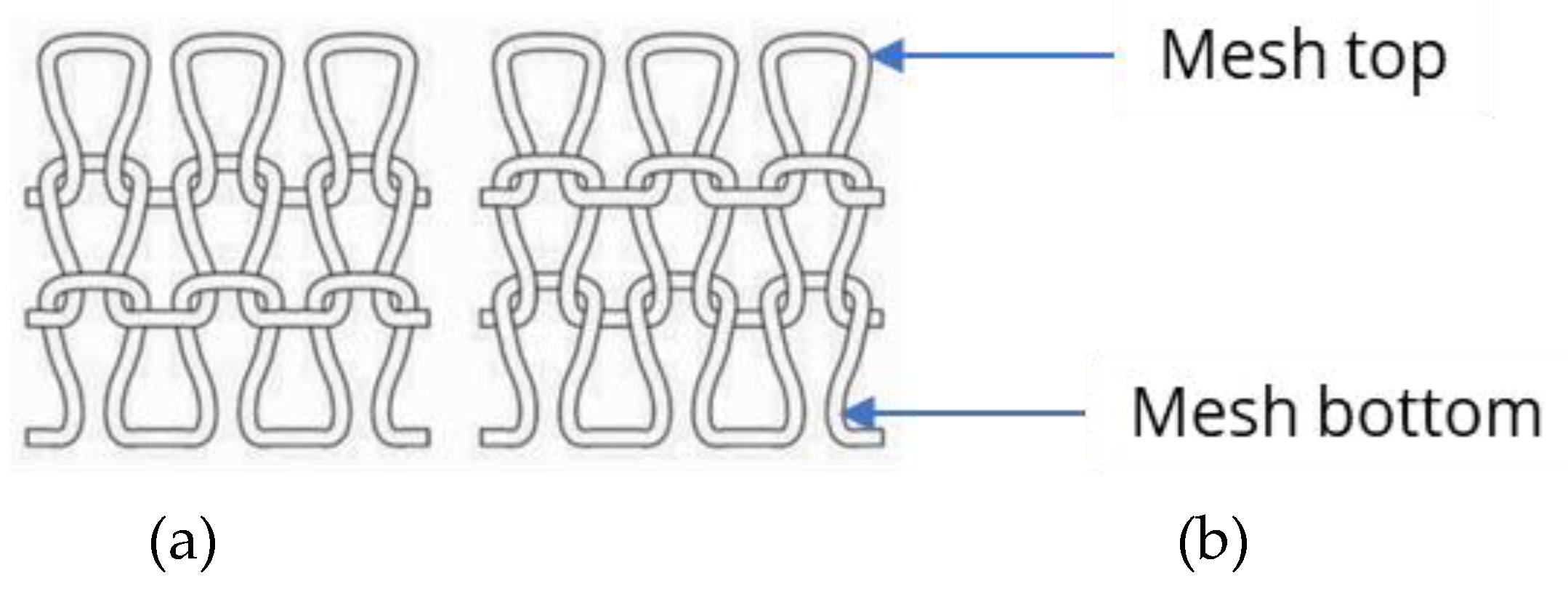

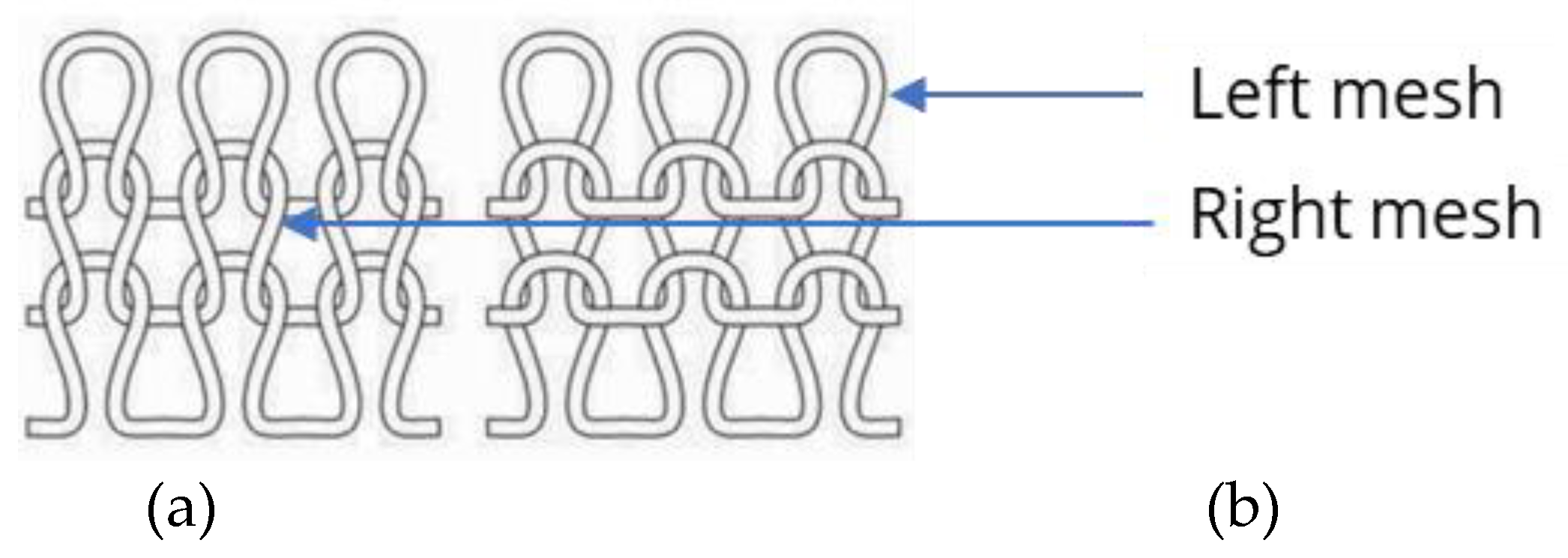

Figure 5 it can be assumed that the LL and the RR pattern might be more unsuitable for a piezoresistive strain sensor because the GF is lower than 0,8 %. In comparison with all four characteristics, it can be summarized that the pattern LL and RR might be less suitable pattern for a piezoresistive strain sensor with reliable properties. The mesh tops are always alternate above or below the mesh bottoms in an LL pattern (

Figure 6).

The alternation between the contact points of the mesh tops and bottoms in the sensor might lead to an indifferent change in resistance when stretched since the mechanical strain and, thus, the electrical resistance has probably a different effect on a crossing point lying above the mesh than on one lying below. As the sensor geometry changes due to strain, the connection points within the sensor also vary, resulting in fluctuations in sensor performance.

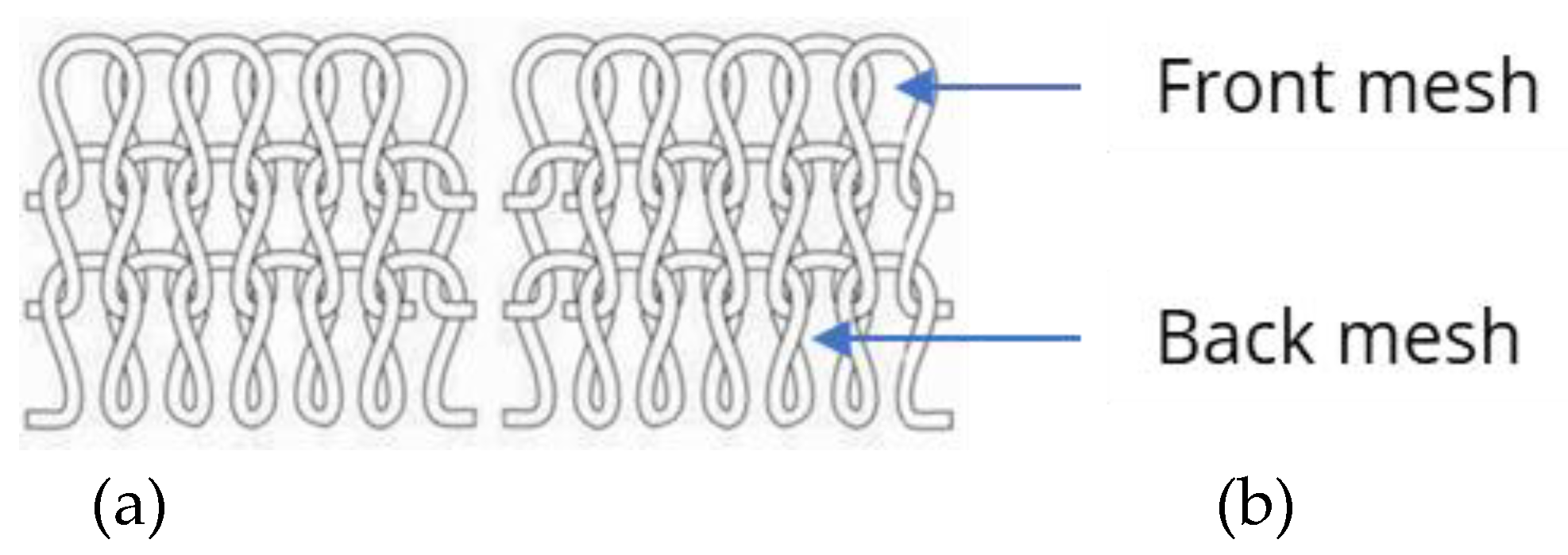

In RR pattern (see

Figure 7), the mesh top and bottom interlock in the same way as in RL pattern (see

Figure 8), with the difference that the meshes are knitted on two needle beds, and the front mesh is continuously interlocked with the back mesh. In this way, the stitch wales from the front and back needle beds always alternate, resulting in a knit with twice as many meshes as in RL.

Therefore, it would be expected that a RR pattern would behave the same way as the RL knit. In both patterns, it can be seen only right meshes on the right side and left meshes on the left side. Because the mesh bottom and mesh top always interlock, the sensor has a high degree of stretch and good transmission behavior, especially with the RL knit. However, twice the number of meshes results in a minor change in sensor geometry and resistance change at the same strain, which leads to poor transmission behavior GF of the sensor.

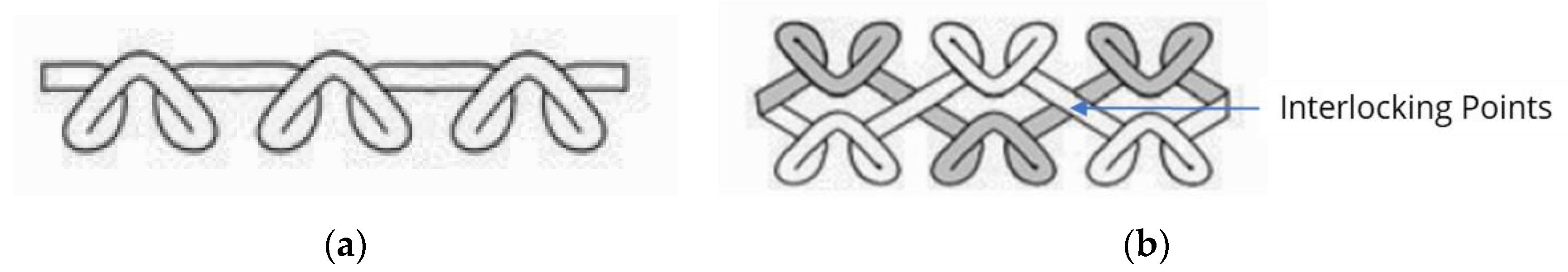

The results show that the two variants W_RL_1x200 and W_RRI_2x200 have a reliable sensor performance but difference in nonlinearity and hysteresis. The distinction between the two pattern variants is due to the interlocking points between mesh tops and

-bottoms. In RRI, the interlocking is always offset by one mesh diagonally (see

Figure 9b), resulting in more significant deviations in electrical resistance within the sensor during stretching in contrast to the RL. In the RL knit, there is only one row of meshes (

Figure 9a), and as already described above, the mesh top and bottom are always in contact without interlocking.

In Addition to the interlocking points, the sensor of the RRI pattern consists of twice as much material as the RL pattern.

The results obtained in this research significantly contribute to the state of the art and tie in directly with the summarized findings from the Introduction. As discussed, the influence of knitted patterns like right-left, left-left, or interlocked ones on the sensor performance still needs to be investigated. Nevertheless, in this systematic study, the influence of the different pattern are discussed, and differences concerning the sensor behavior cloud be elaborated. It was also established that the production direction impacts selecting the correct sensor design. At least the electro-mechanical properties of strain sensors under multi-cyclic mechanical deformation and thereby verified their suitability as strain sensors for motion capture a. o. in medical applications were investigated. It was found that the knitted sensors showed reliable sensor behavior even under high cyclic loading and would be suitable for long-term use under different stresses.

5. Conclusions

In summary, the W_RL_1x200 and W_RRI_2x200 variants are the piezoresistive strain sensors with the highest sensor performance and might be ideal for use in smart textiles for medical applications. For selecting the appropriate knitted sensor, it is necessary to compare all four properties and weigh which parameters need to be fulfilled in each dimension and which ones can be somewhat neglected. Ultimately, right-left and right-right-interlock patterns are most suitable knitted structures for a piezoresistive strain sensor, with RRI exhibiting higher nonlinearity and hysteresis than RL. However, the width of the sensor is more crucial for sensor quality. A sensor width of four results in lower sensor quality regardless of the pattern, while width tow for RRI and width one for RL are the best variants considering all four quality criteria. Unanswered questions remain regarding why adding one or two mesh significantly affects the sensor's performance. Additionally, it remains open within the study why the production direction causes such a sensor drift. For this reason, further studies are needed to investigate what influence the sensors width and the production direction has. The knowledge about these sensors' properties is necessary to design and manufacture different piezoresistive strain sensors to meet the requirements of various medical applications. The findings of this study contribute to the ongoing research and development efforts in the field of smart textiles, particularly in the domain of medical applications.

References

- Li, M.; Xiong, W.; Li, Y. Wearable Measurement of ECG Signals Based on Smart Clothing. Int. J. Telemed. Appl. 2020, 2020, 6329360. [Google Scholar] [CrossRef]

- Kubicek, J.; Fiedorova, K.; Vilimek, D.; Cerny, M.; Penhaker, M.; Janura, M.; Rosicky, J. Recent Trends, Construction, and Applications of Smart Textiles and Clothing for Monitoring of Health Activity: A Comprehensive Multidisciplinary Review. IEEE Rev. Biomed. Eng. 2022, 15, 36–60. [Google Scholar] [CrossRef]

- Scilingo, E.P.; Gemignani, A.; Paradiso, R.; Taccini, N.; Ghelarducci, B.; Rossi, D. de. Performance evaluation of sensing fabrics for monitoring physiological and biomechanical variables. IEEE Trans. Inf. Technol. Biomed. 2005, 9, 345–352. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: a review. Smart Mater. Struct. 2014, 23, 53001. [Google Scholar] [CrossRef]

- Miller, L.; Mattison, P.; Paul, L.; Wood, L. The effects of transcutaneous electrical nerve stimulation (TENS) on spasticity in multiple sclerosis. Mult. Scler. 2007, 13, 527–533. [Google Scholar] [CrossRef] [PubMed]

- Holleczek, T.; Ru, A.; Harms, H.; Tro, G. Textile pressure sensors for sports applications. In ; pp 732–737.

- Shu, L.; Hua, T.; Wang, Y.; Qiao Li, Q.; Feng, D.D.; Tao, X. In-shoe plantar pressure measurement and analysis system based on fabric pressure sensing array. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 767–775. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Huang, M.-C.; Amini, N.; Liu, J.J.; He, L.; Sarrafzadeh, M. Smart insole. In ; pp 1–4.

- Park, S.Y.; Lee, J.-H. Machine Embroidered Sensors for Limb Joint Movement-Monitoring Smart Clothing. Sensors (Basel) 2021, 21. [Google Scholar] [CrossRef]

- Kan, C.-W.; Lam, Y.-L. Future Trend in Wearable Electronics in the Textile Industry. Applied Sciences 2021, 11, 3914. [Google Scholar] [CrossRef]

- Huang, C.-T.; Shen, C.-L.; Tang, C.-F.; Chang, S.-H. A wearable yarn-based piezo-resistive sensor. Sensors and Actuators A: Physical 2008, 141, 396–403. [Google Scholar] [CrossRef]

- Taccini, N.; Loriga, G.; Pacelli, M.; Paradiso, R. Wearable monitoring system for chronic cardio-respiratory diseases. Annu. Int. Conf. IEEE Eng. Med. Biol. Soc. 2008, 2008, 3690–3693. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Xie, J.; Long, H.; Miao, M. High sensitivity knitted fabric strain sensors. Smart Mater. Struct. 2016, 25, 105008. [Google Scholar] [CrossRef]

- Watson, A.; Sun, M.; Pendyal, S.; Zhou, G. TracKnee: Knee angle measurement using stretchable conductive fabric sensors. Smart Health 2020, 15, 100092. [Google Scholar] [CrossRef]

- Ancans, A.; Greitans, M.; Cacurs, R.; Banga, B.; Rozentals, A. Wearable Sensor Clothing for Body Movement Measurement during Physical Activities in Healthcare. Sensors (Basel) 2021, 21. [Google Scholar] [CrossRef]

- an Liang; Stewart, R. ; Bryan-Kinns, N. Analysis of Sensitivity, Linearity, Hysteresis, Responsiveness, and Fatigue of Textile Knit Stretch Sensors. Sensors (Basel) 2019, 19. [Google Scholar] [CrossRef]

- Atalay, O.; Tuncay, A.; Husain, M.D.; Kennon, W.R. Comparative study of the weft-knitted strain sensors. Journal of Industrial Textiles 2017, 46, 1212–1240. [Google Scholar] [CrossRef]

- Raji, R.K.; Miao, X.; Zhang, S.; Li, Y.; Wan, A.; Boakye, A. Knitted piezoresistive strain sensor performance, impact of conductive area and profile design. Journal of Industrial Textiles 2020, 50, 616–634. [Google Scholar] [CrossRef]

- Atalay, O.; Kennon, W.R. Knitted strain sensors: impact of design parameters on sensing properties. Sensors (Basel) 2014, 14, 4712–4730. [Google Scholar] [CrossRef] [PubMed]

- Molinaro, N.; Massaroni, C.; Lo Presti, D.; Saccomandi, P.; Di Tomaso, G.; Zollo, L.; Perego, P.; Andreoni, G.; Schena, E. Wearable textile based on silver plated knitted sensor for respiratory rate monitoring. Annu. Int. Conf. IEEE Eng. Med. Biol. Soc. 2018, 2018, 2865–2868. [Google Scholar] [CrossRef] [PubMed]

- Bozali, B.; Ghodrat, S.; Plaude, L.; van Dam, J.J.F.; Jansen, K.M.B. Development of Low Hysteresis, Linear Weft-Knitted Strain Sensors for Smart Textile Applications. Sensors (Basel) 2022, 22. [Google Scholar] [CrossRef] [PubMed]

- Ayodele, E.; Raza Zaidi, S.A.; Scott, J.; Zhang, Z.; Hayajneh, A.; Shittu, S.; Des McLernon. A Weft Knit Data Glove. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Bozali, B.; Ghodrat, S.; Jansen, K.M.B. Development of a Knitted Strain Sensor for Health Monitoring Applications. In E-Textiles 2022. E-Textiles 2022; MDPI: Basel Switzerland; p 10.

- Tognetti, A.; Bartalesi, R.; Lorussi, F.; Rossi, D. de. Body segment position reconstruction and posture classification by smart textiles. Transactions of the Institute of Measurement and Control 2007, 29, 215–253. [Google Scholar] [CrossRef]

- Lorussi, F.; Galatolo, S.; Rossi, D.E. de. Textile-Based Electrogoniometers for Wearable Posture and Gesture Capture Systems. IEEE Sensors J. 2009, 9, 1014–1024. [Google Scholar] [CrossRef]

- Zhao, K.; Niu, W.; Zhang, S. Highly stretchable, breathable and negative resistance variation textile strain sensor with excellent mechanical stability for wearable electronics. J Mater Sci 2020, 55, 2439–2453. [Google Scholar] [CrossRef]

- Abu-Rous, M.; Dabolina, I.; Lapkovska, E. Fabric physical properties and clothing comfort. IOP Conf. Ser.: Mater. Sci. Eng. 2018, 459, 12028. [Google Scholar] [CrossRef]

- Deusches Institut für Normung. Textilien und textile Erzeugnisse- Elektrisch leitfähige Textilien – Bestimmung des linea-ren elektrischen Widerstands von Leiterbahnen (EN 16812:2016); Beuth Verlag, 2016 (16812:2016).

- Bureau International des Poids et Mesures. Evaluation of measurement data — Guide to the expression of uncertainty in measurement: GUM 1995 with minor corrections; France, 2010 (JCGM 100:2008). Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6. /.

-

Textile Materials for Lightweight Constructions: Technologies - Methods - Materials - Properties; Cherif, C., Ed.; Springer: Berlin, Heidelberg, 2016; ISBN 9783662463413. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).