Submitted:

31 July 2023

Posted:

03 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Green Infrastructure

1.2. Plastic Waste in Asphalt Mixtures

1.3. Asphalt Mixture Modification in Jordan

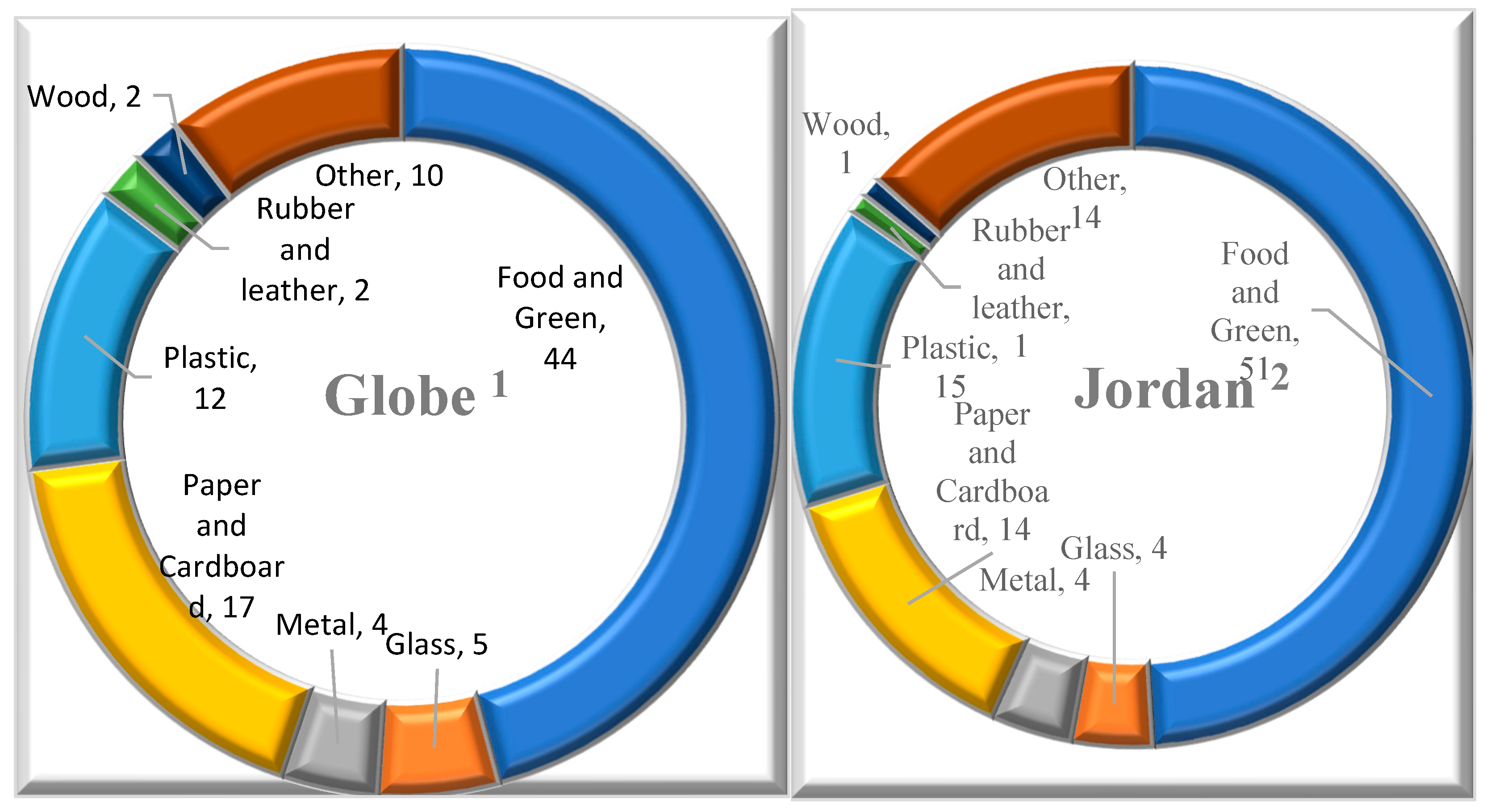

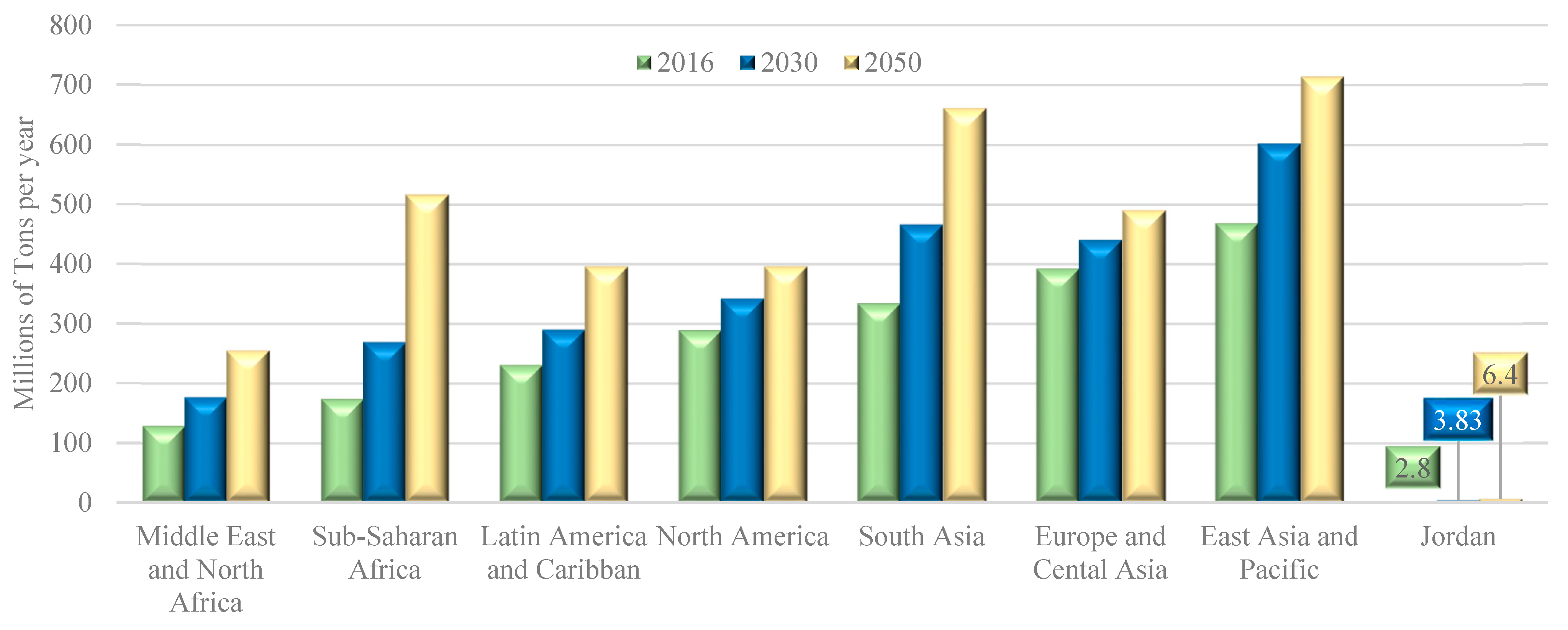

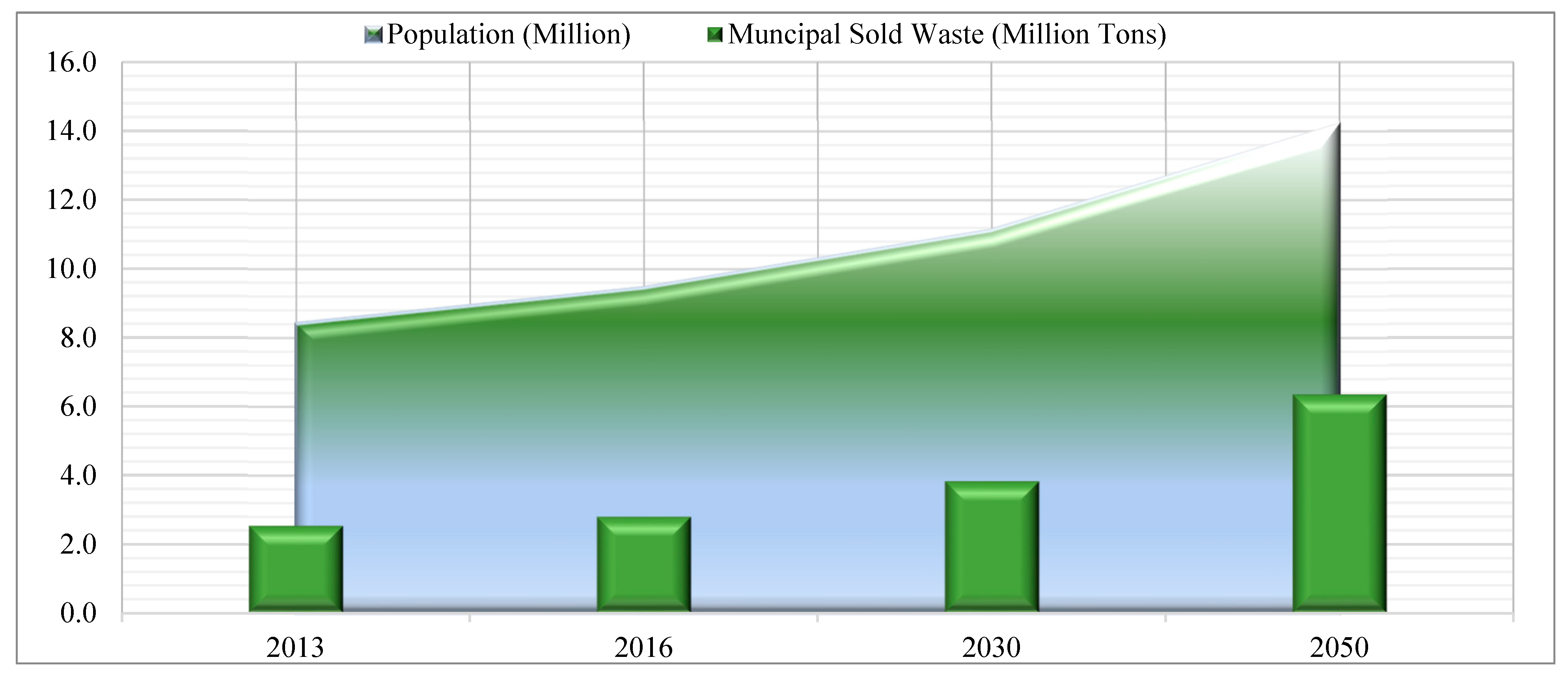

1.4. Municipal Solid Waste in Jordan

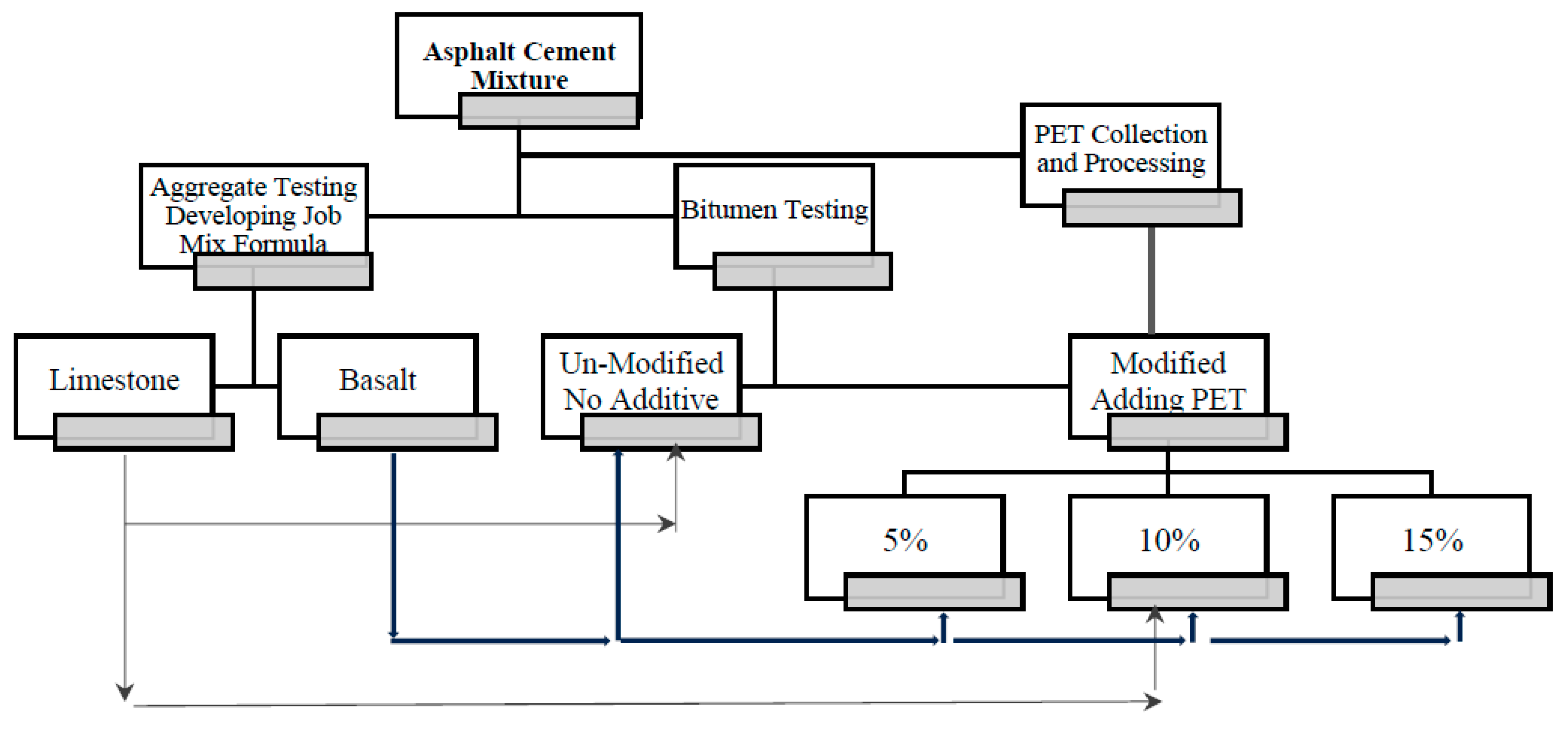

2. Research Methodology

2.1. Material

2.1.1. Bitumen Materials

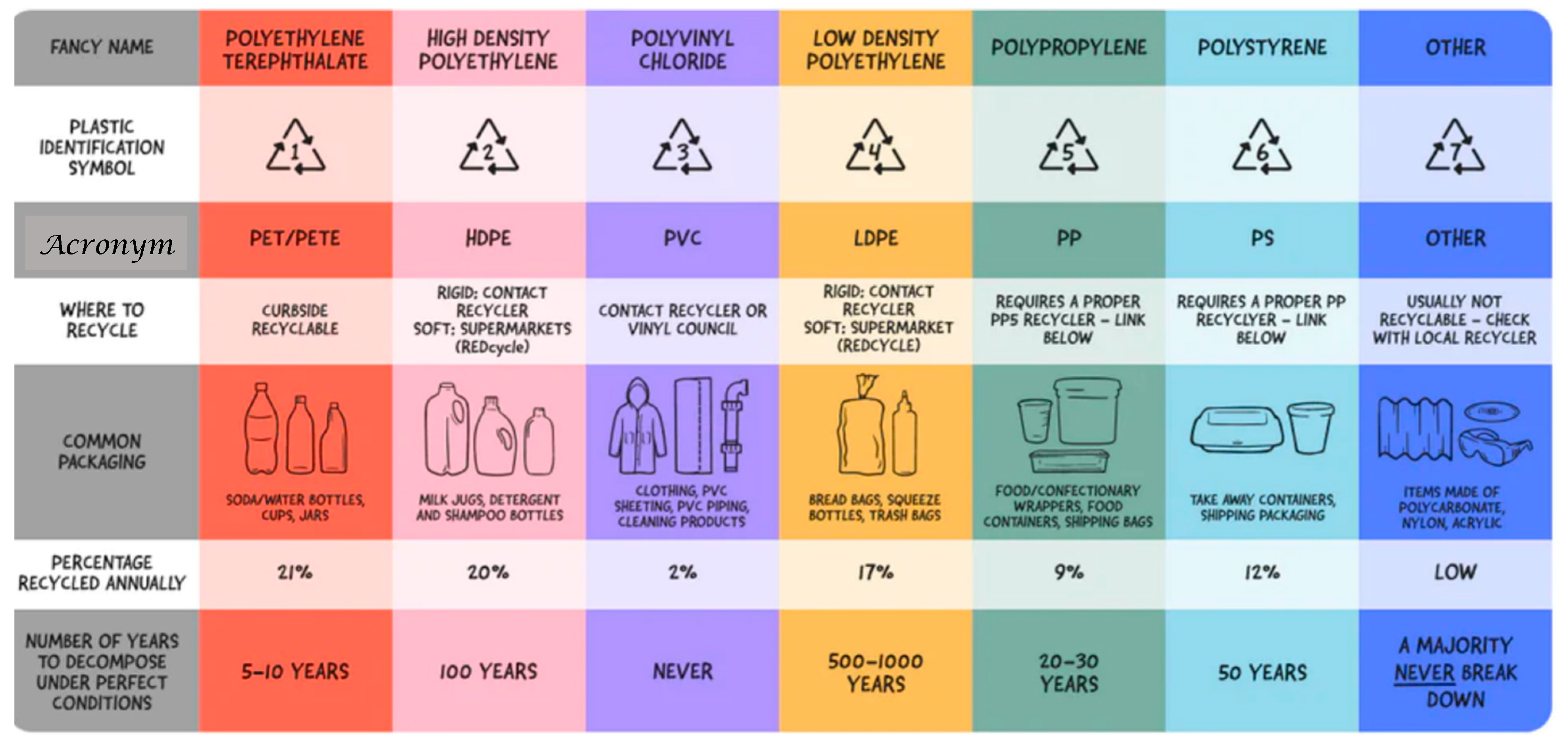

2.1.2. Plastic Material

2.1.3. Aggregate

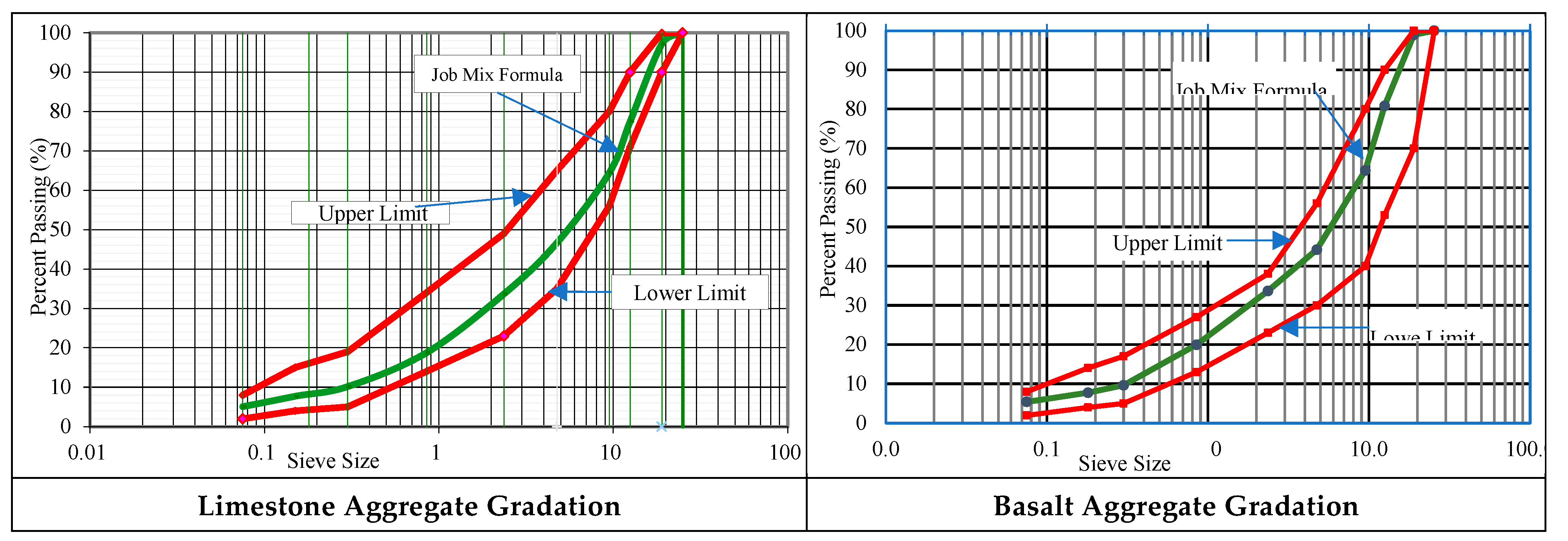

2.2. Asphalt Cement Mixture Design

2.2.1. Asphalt Mixture Design Types

2.2.2. Asphalt Mixture Preparation: Marshall Method

3. Results

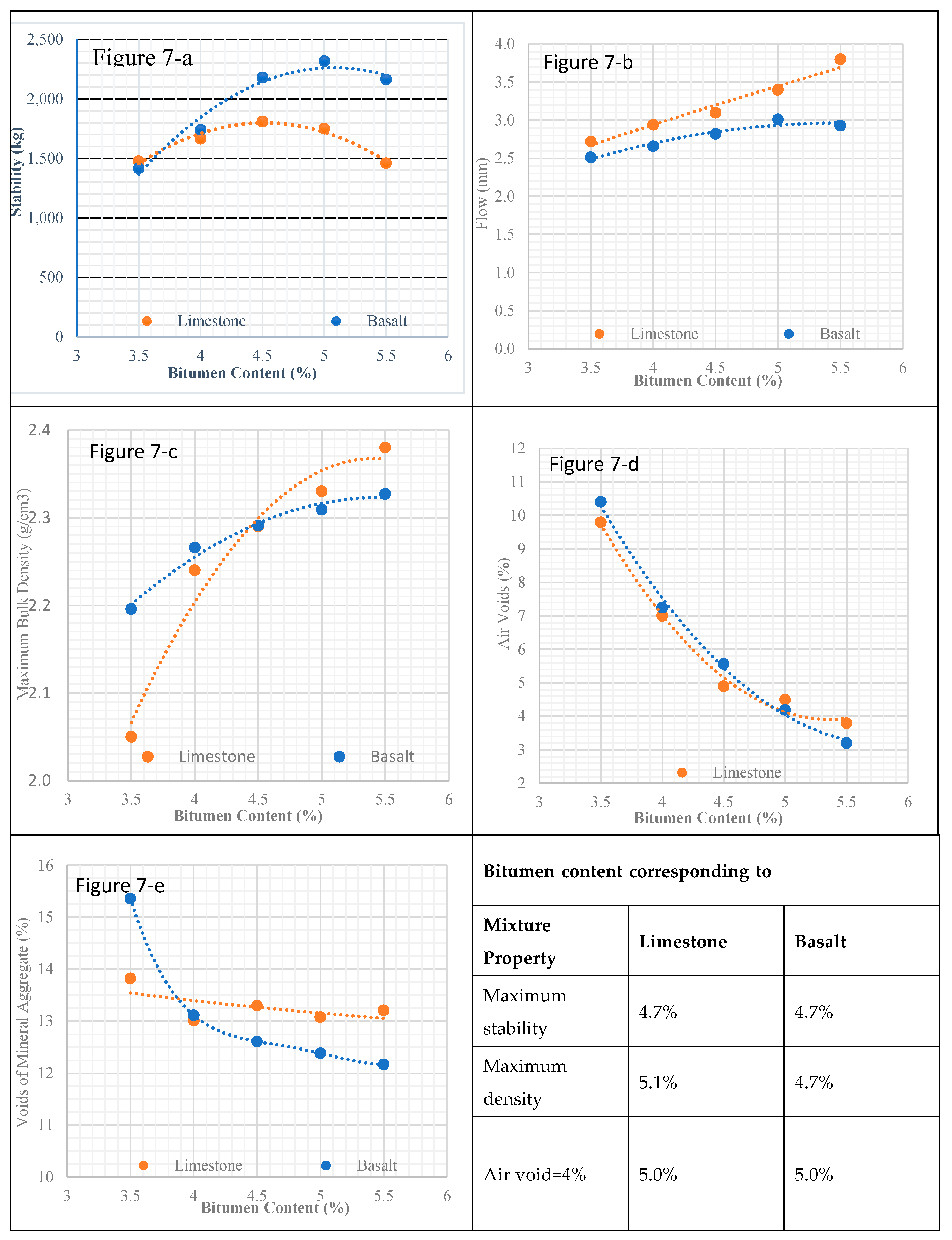

3.1. Control Mix Design Properties

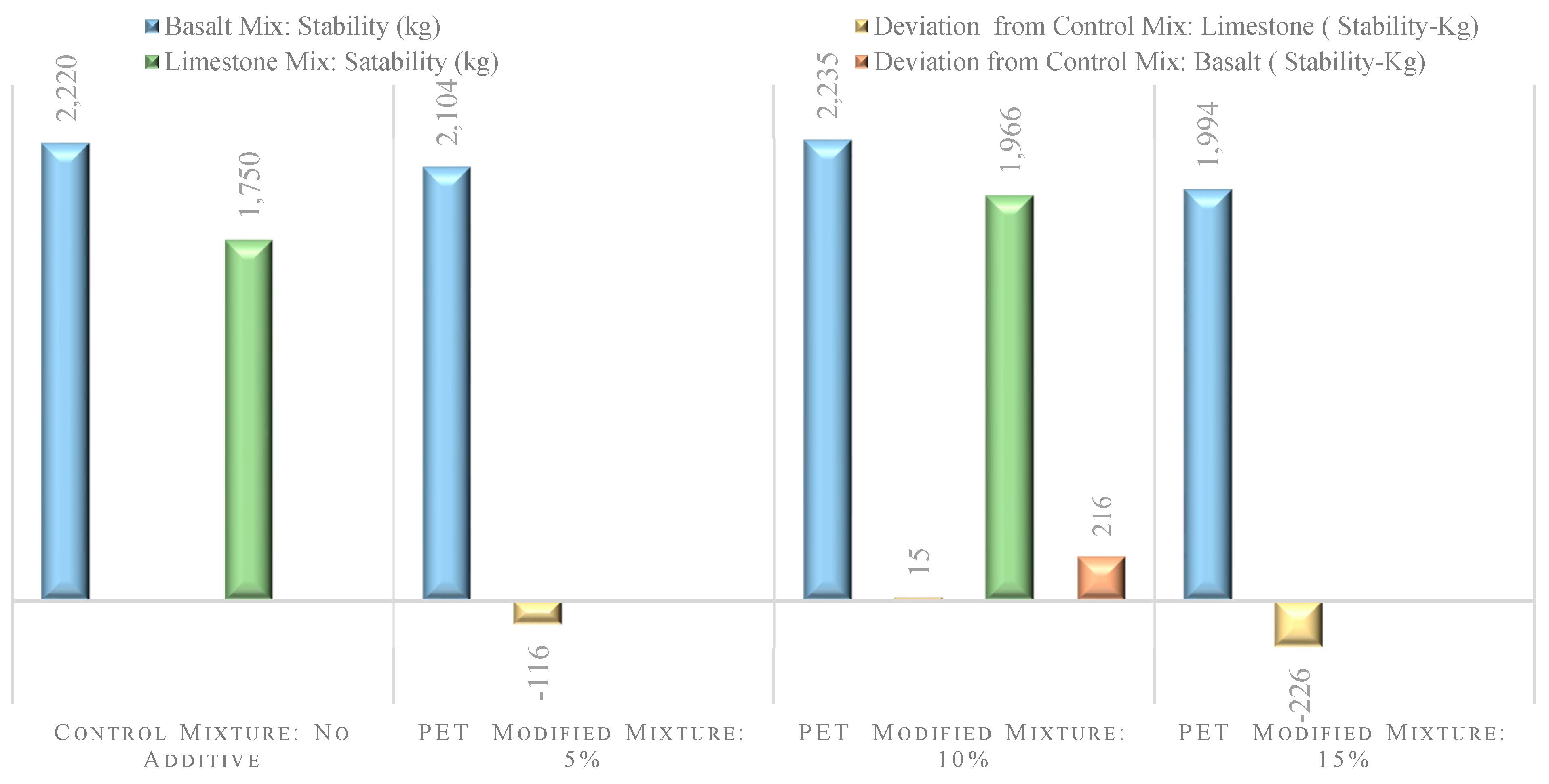

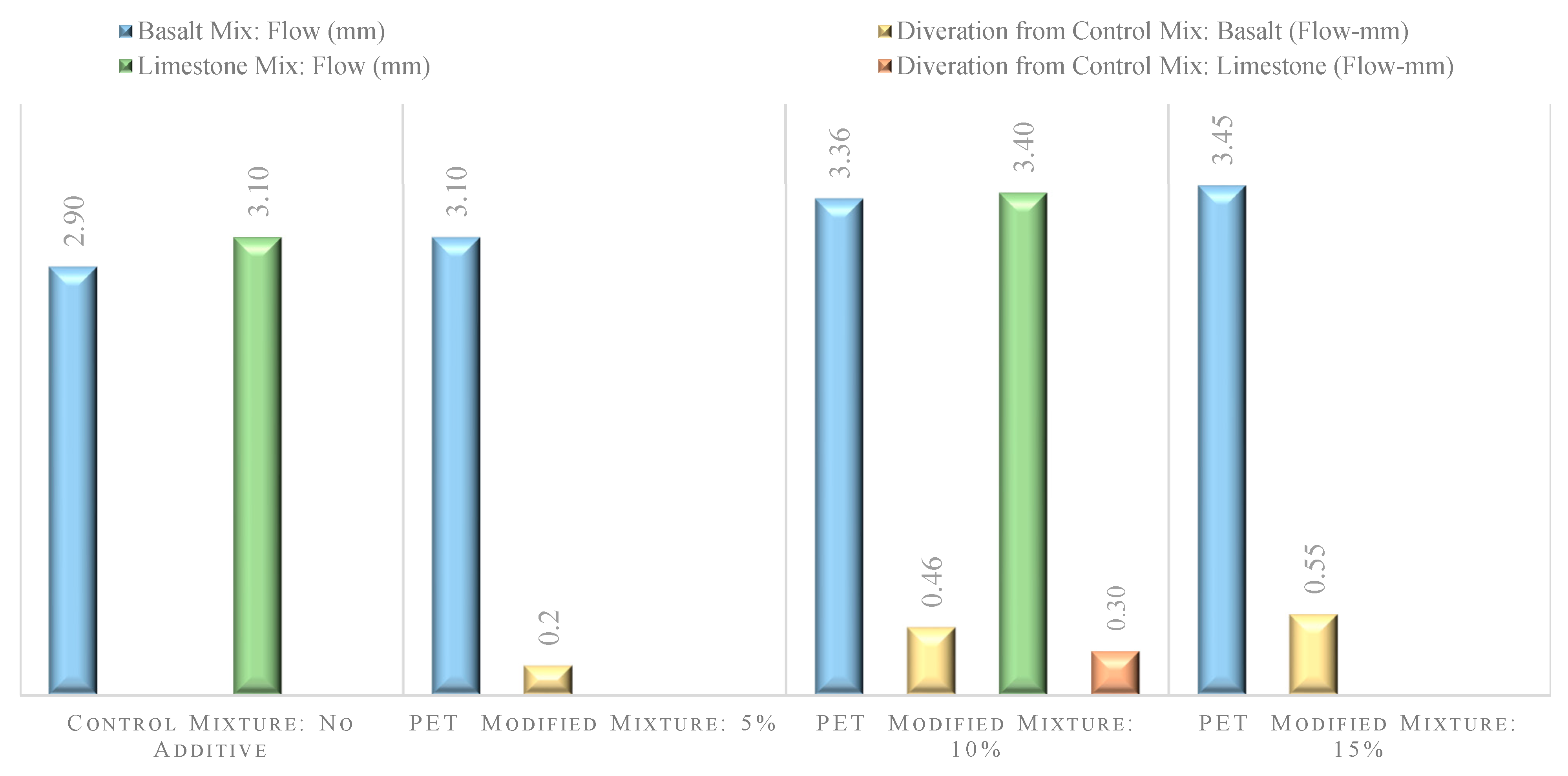

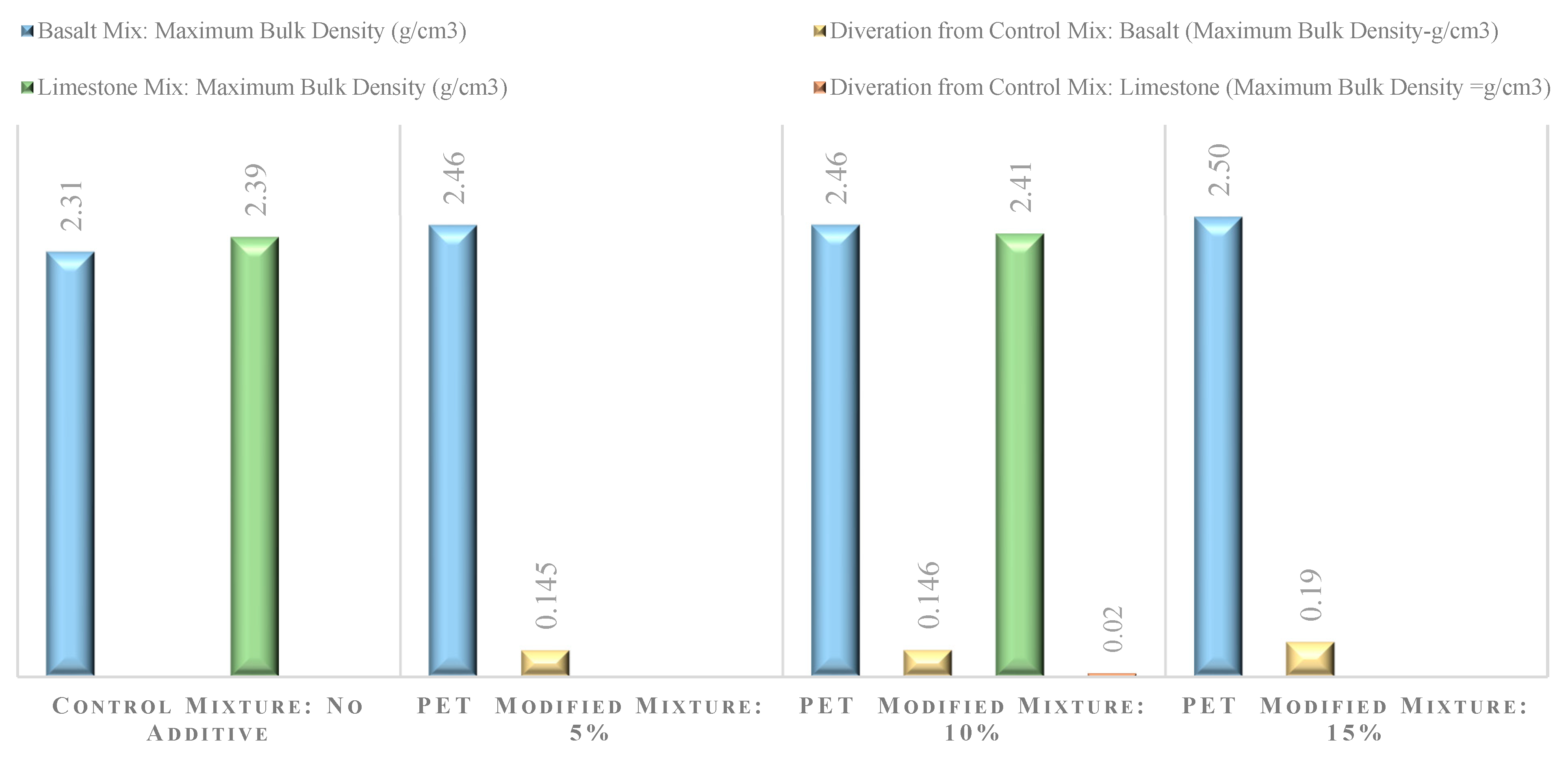

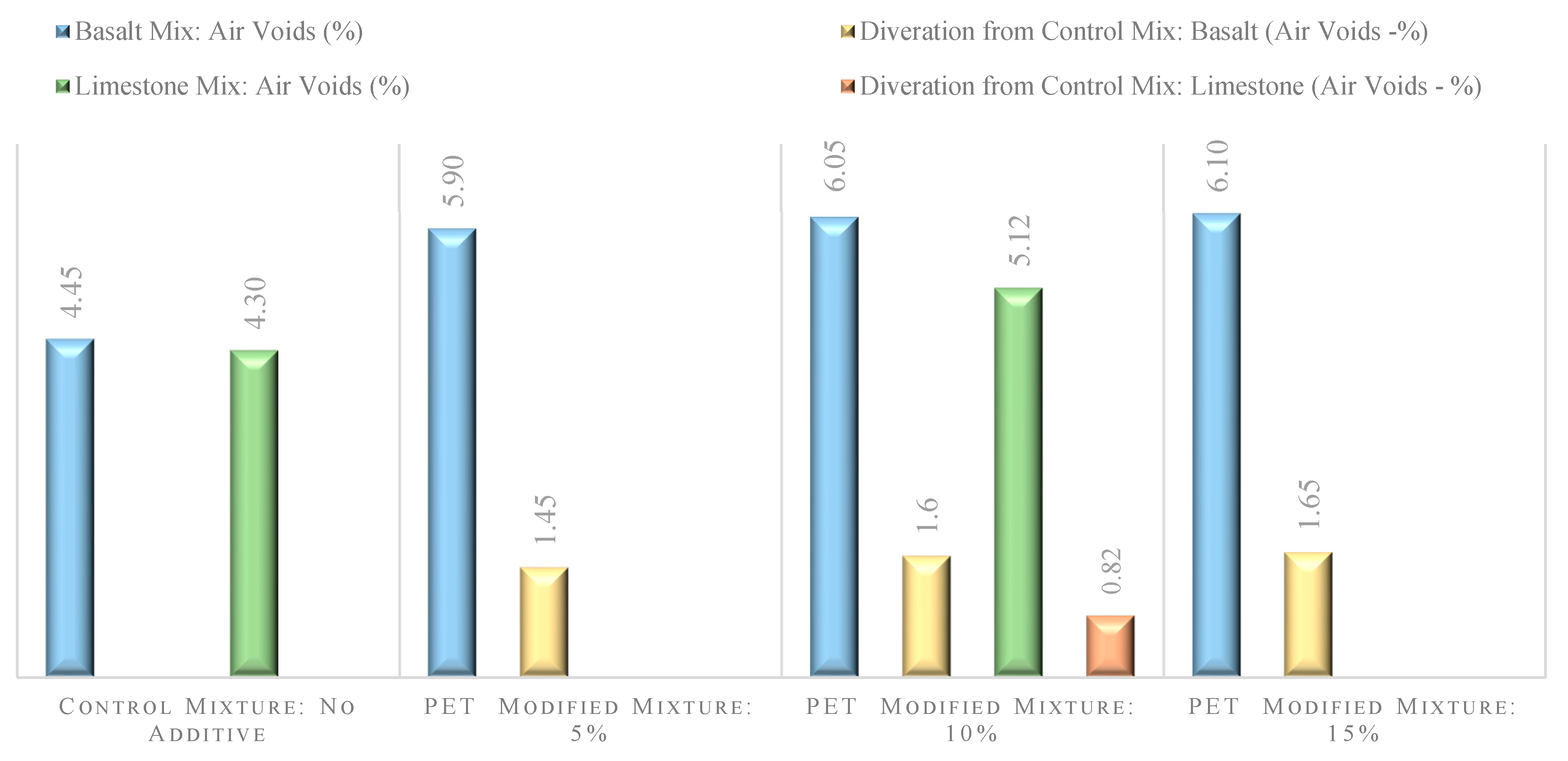

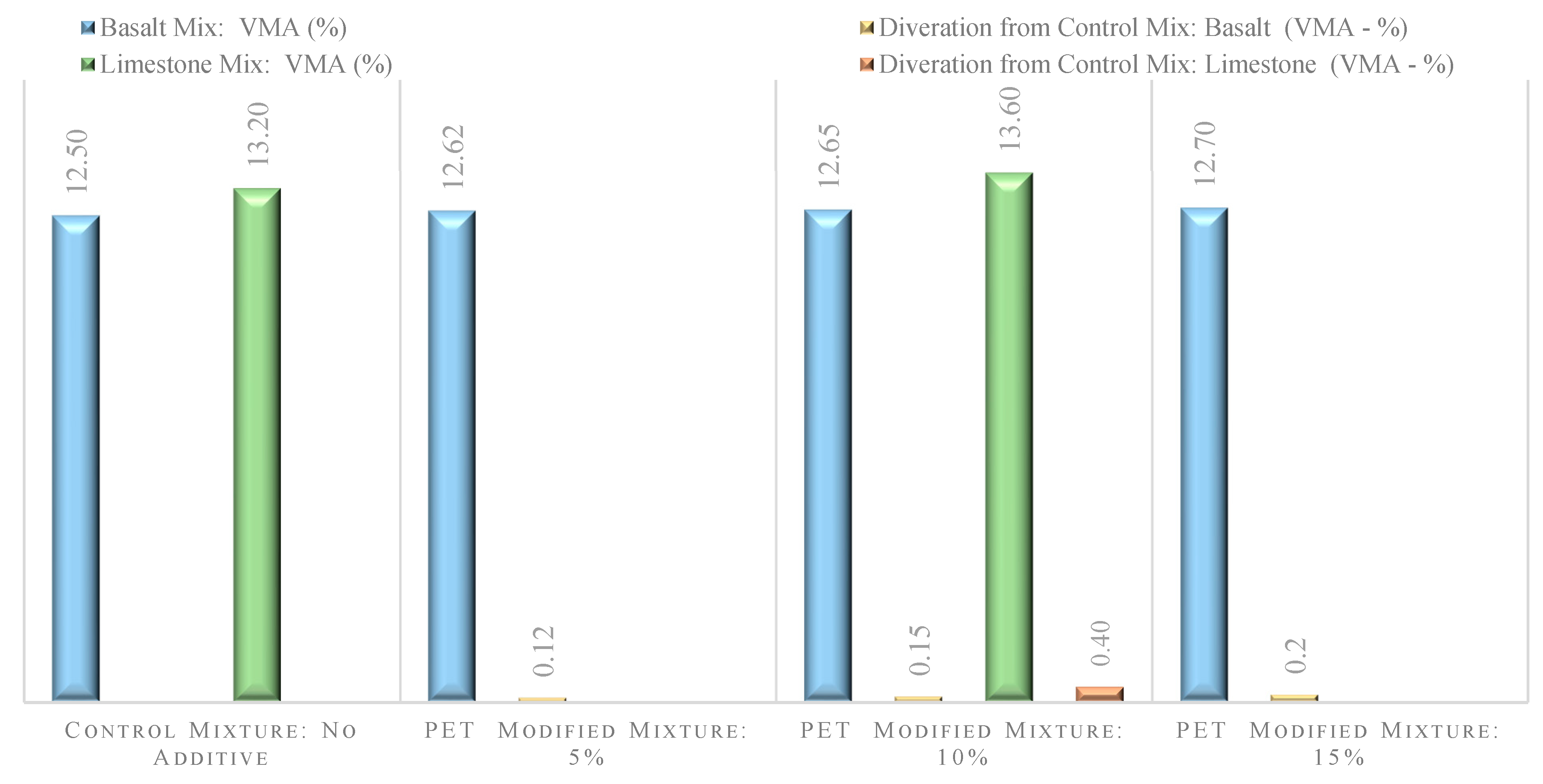

3.2. PET Modified Mixtures Properties

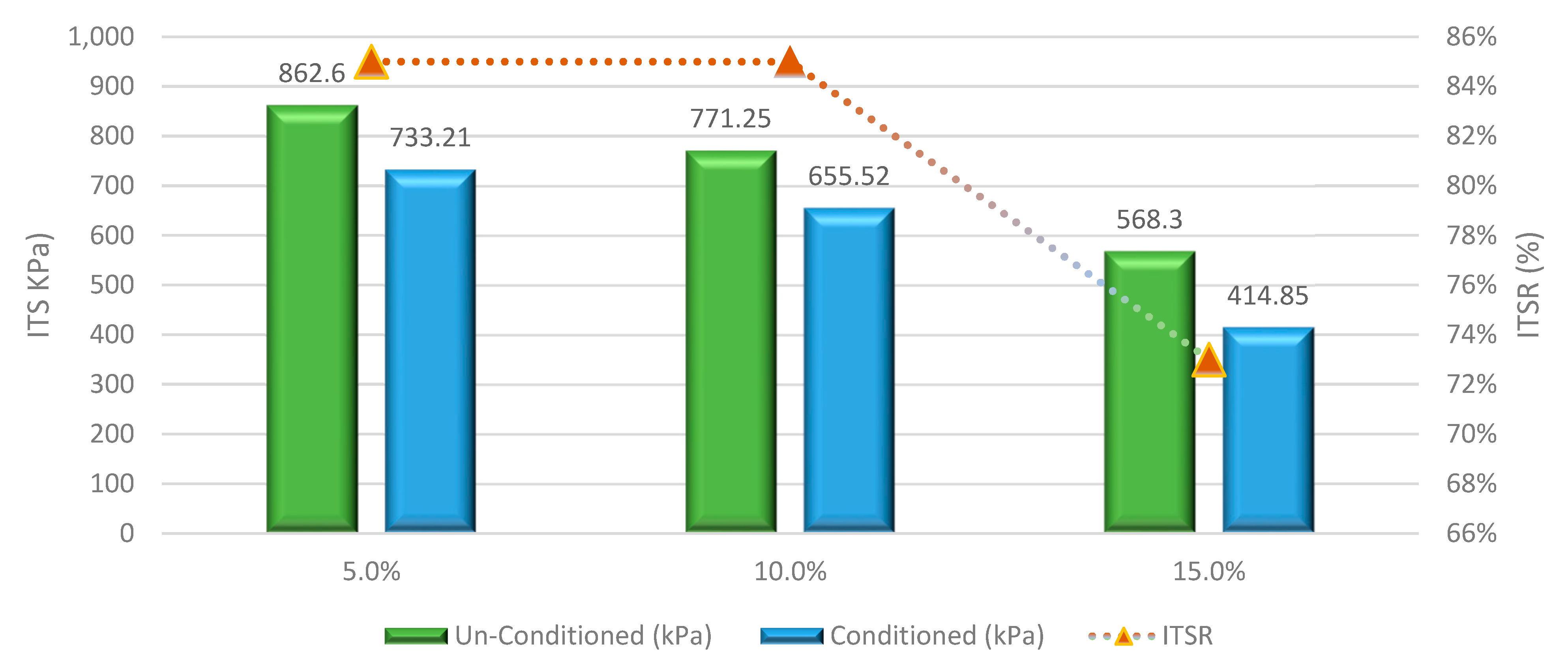

3.3. Modified Asphalt Mixture Tensile Strength

3.4. Economic and Environmental Implications

4. Discussion

4.1. Control Mix Design Properties

4.2. PET Modified Mixtures Properties

5. Conclusion:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Safiuddin, M., Jumaat, M. Z., Salam, M. A., Islam, M. S., & Hashim, R. (2010). Utilization of solid wastes in construction materials. International Journal of the Physical Sciences, 5, 1952–1963.

- De Rezende, L. R., Camapum-de-Carvalho, J., & Palmeira, E. M. (2015). The use of alternative and improved construction materials and geosynthetics for pavements. In B. Indraratna, J. Chu, & C. Rujikiatkamjorn (Eds.), Ground improvement case histories, (pp. 481–505). San Diego, CA: Butterworth-Heinemann. ISBN 9780081006986.Retrieved from http://www.sciencedirect.com/science/ article/pii/B9780081006986000167. [CrossRef]

- Kaza, S., Yao, L., Bhada-Tata, P., & Van Woerden, F. (2018). What a waste 2.0: a global snapshot of solid waste management to 2050. World Bank Publications.

- OECD (2022).Plastic pollution is growing relentlessly as waste management and recycling fall short, says OECD. https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm.

- FEHRL. (2008). New road construction concepts. Towards reliable, green, safe and smart and human infrastructure in Europe. Retrieved from http://ec.europa.eu/transport/ road_safety/projects/doc/nr2c_final_report.pdf.

- United States Environmental Protection Agency (USEPA). (2009). Using recycled industrial materials in roadways. United States Environmental Protection Agency, EPA-530-F-08-024.

- Wahlstrom, M., Laine-Ylijoki, J., Jarnstrom, H., Kaartinen, T., Erlandsson, M., Cousins, A. P., … Jorgensen, A. (2014). Environmental sustainable construction products and materials—Assessment of release and emissions (Nordic Innovation Report).

- Essawy, A. I., Saleh, A. M. M., Zaky, M. T., Farag, R. K., & Ragab, A. A. (2013). Environmentally friendly road construction. Egyptian Journal of Petroleum, 22, 189–198. http://doi.org/10.1016/j.ejpe.2012.09.010.

- Kamaruddin, M. A., Abdullah, M. M. A., Zawawi, M. H., & Zainol, M. R. R. A. (2017, November). Potential use of plastic waste as construction materials: recent progress and future prospect. In IOP Conference Series: Materials Science and Engineering (Vol. 267, No. 1, p. 012011). Iop Publishing. [CrossRef]

- The State of Queensland - Department of Transport and Main Roads. (SQDTMR) 2020. Use of recycled materials in road construction Technical Note TN193.

- Pouranian, M. R., & Shishehbor, M. (2019). Sustainability assessment of green asphalt mixtures: A review. Environments, 6(6), 73. [CrossRef]

- Souliman, M. I., & Kaloush, K. E. (2011). Assessment of the extended fatigue life for rubber and polymer modified asphalt mixtures using flexural bending beam fatigue test. Jordan Journal of Civil Engineering, 5(2), 210-215.

- Chomicz-Kowalska, A., & Maciejewski, K. (2015). Multivariate optimization of recycled road base cold mixtures with foamed bitumen. Procedia Engineering, 108, 436-444. [CrossRef]

- Jaafar, M. A., Joni, H. H., & Karim, H. H. (2022). Evaluation of Reclaimed Asphalt Mixtures Modified by Nanoclay Powder on Moisture Damage. In IOP Conference Series: Earth and Environmental Science (Vol. 961, No. 1, p. 012047). IOP Publishing. [CrossRef]

- Al Qadi, A. N., Khedaywi, T. S., Haddad, M. A., & Al-Rababa'ah, O. A. (2021, February). Investigating the Effect of Olive Husk Ash on the Properties of Asphalt Concrete Mixture. In Annales de Chimie Science des Materiaux (Vol. 45, No. 1). [CrossRef]

- Kalantar, Z. N., Karim, M. R., & Mahrez, A. (2012). A review of using waste and virgin polymer in pavement. Construction and Building Materials, 33, 55-62. [CrossRef]

- Kashiyani, B., Pitroda, J., & Umrigar, F. S. (2013, December). Plastic waste: Opportunities for eco-friendly material of bituminous road construction. In National Conference CRDCE13 (pp. 1-8).

- Singh, P., Kumar, A., Singh, S., Rajput, R. and Singh, C.L., 2020. Use of Plastic Waste in Flexible Pavement-Green Highway. International Journal of Engineering Research and, 9(09). [CrossRef]

- Rajasekaran, S., Vasudevan, R. and Paulraj, S., 2013. Reuse of waste plastics coated aggregates-bitumen mix composite for road application–green method. American Journal of Engineering and Research, 2(11), pp.1-13.

- Bottenbruch, L. & Anders S. (1996) Engineering Thermoplastics: Polycarbonates, Polyacetals Polyesters, and Cellulose Esters. 1996: Hanser Publishers.

- Webb, H. K., Arnott, J., Crawford, R. J., & Ivanova, E. P. (2012). Plastic degradation and its environmental implications with special reference to poly (ethylene terephthalate). Polymers, 5(1), 1-18. [CrossRef]

- Sinha, V., Patel, M. R., & Patel, J. V. (2010). PET waste management by chemical recycling: a review. Journal of Polymers and the Environment, 18(1), 8-25. [CrossRef]

- Awaja, F., and Pavel, D. (2005). Recycling of PET. European Polymer Journal, 2005. 41(7): p. 1453-1477. [CrossRef]

- Ahmad, A. F., Razali, A. R., & Razelan, I. S. M. (2017, May). Utilization of polyethylene terephthalate (PET) in asphalt pavement: A review. In IOP Conference Series: Materials Science and Engineering (Vol. 203, No. 1, p. 012004). IOP Publishing. [CrossRef]

- Ben Zair, M. M., Jakarni, F. M., Muniandy, R., & Hassim, S. (2021). A brief review: application of recycled polyethylene terephthalate in asphalt pavement reinforcement. Sustainability, 13(3), 1303. [CrossRef]

- Rahman, W.M.N.W.A. and Wahab, A.F.A., 2013. Green pavement using recycled polyethylene terephthalate (PET) as partial fine aggregate replacement in modified asphalt. Procedia Engineering, 53, pp.124-128. [CrossRef]

- Hayat, U., Rahim, A., Khan, A.H. and Rehman, Z.U., 2020. Use of plastic wastes and reclaimed asphalt for sustainable development. Baltic journal of road & bridge engineering (rtu publishing house), 15(2). [CrossRef]

- Movilla-Quesada, D., Raposeiras, A.C. and Olavarría, J., 2019. Effects of recycled polyethylene terephthalate (PET) on stiffness of hot asphalt mixtures. Advances in Civil Engineering, 2019. [CrossRef]

- Usman, A., Sutanto, M.H., Napiah, M., Zoorob, S.E., Abdulrahman, S. and Saeed, S.M., 2021. Irradiated polyethylene terephthalate fiber and binder contents optimization for fiber-reinforced asphalt mix using response surface methodology. Ain Shams Engineering Journal, 12(1), pp.271-282. [CrossRef]

- Mikhailenko, P., Piao, Z., Kakar, M.R., Athari, S., Bueno, M. and Poulikakos, L.D., 2021. Effect of waste PET and CR as sand replacement on the durability and acoustical properties of semi dense asphalt (SDA) mixtures. Sustainable Materials and Technologies, 29, p.e00295. [CrossRef]

- Sojobi, A.O., Nwobodo, S.E. and Aladegboye, O.J., 2016. Recycling of polyethylene terephthalate (PET) plastic bottle wastes in bituminous asphaltic concrete. Cogent engineering, 3(1), p.1133480. [CrossRef]

- Ahmad, M.S. and Ahmad, S.A., 2022. The impact of polyethylene terephthalate waste on different bituminous designs. Journal of Engineering and Applied Science, 69(1), p.53. [CrossRef]

- Almahdi, B.A., Ahmeda, A.G., Adwan, I. and Ladin, M.A., 2021. Feasibility of utilizing waste polyethylene terephthalate as replacement in asphalt binder mixture. Knowledge-Based Engineering and Sciences, 2(1), pp.47-57. [CrossRef]

- Casey, D., McNally, C., Gibney, A., & Gilchrist, M. D. (2008). Development of a recycled polymer modified binder for use in stone mastic asphalt. Resources, Conservation and Recycling, 52(10), 1167-1174. [CrossRef]

- Lugeiyamu, L., Kunlin, M., Mensahn, E. S., & Faraz, A. (2021). Utilization of waste polyethylene terephthalate (PET) as partial replacement of bitumen in stone mastic asphalt. Construction and Building Materials, 309, 125176. [CrossRef]

- Awwad, M. T., & Shbeeb, L. (2007). The use of polyethylene in hot asphalt mixtures. American Journal of Applied Sciences, 4, 390–396. [CrossRef]

- Asi, I., Shalabi, F., & Naji, J (2009). Use of basalt in asphalt concrete mixes. Construction and Building Materials, 23(1), 498-506. [CrossRef]

- Asi, I., & Assa’ad, A. (2005). Effect of Jordanian oil shale fly ash on asphalt mixes. Journal of Materials in Civil Engineering, 17(5), 553-559. [CrossRef]

- Shatnawi, A. S., Abdel-Jaber, M. S., Abdel-Jaber, M. S., & Ramadan, K. Z. (2008). Effect of Jordanian steel blast furnace slag on asphalt concrete hot mixes. Jordan Journal of Civil Engineering, 2(3), 197-207.

- Baker, M. B., Abendeh, R., Abu-Salem, Z., & Khedaywi, T. (2016). Production of sustainable asphalt mixes using recycled polystyrene. International Journal of Applied Environmental Sciences, 11(1), 183-192.

- Ghuzlan, K. A., Al-Khateeb, G. G., & Qasem, Y. (2013). Rheological properties of polyethylene-modified asphalt binder. Athens Journal of Technology and Engineering, 10(2013), 1-14.

- Abo-Qudais, S., Ibrahim, A., & Al-Ramahi, E. (2016). Utilizing Reclaimed Asphalt Pavement in Asphalt Mixtures: Laboratory Performance and Environmental and Cost Impacts. J. Geotech. Transp. Eng, 2, 26-32.

- Bani Baker, M. I., Abendeh, R. M., & Khasawneh, M. A. (2022). Freeze and thaw effect on asphalt concrete mixtures modified with natural bentonite clay. Coatings, 12(11), 1664. [CrossRef]

- Khliefat, I., & Msallam, M. (2020). Modification of asphalt mixes using white cement dust and iron filings as a filler. Advances in Civil and Architectural Engineering, 11(21), 67-77. [CrossRef]

- Naser, M., Abdel-Jaber, M. T., Al-Shamayleh, R., Ibrahim, R., Louzi, N., & AlKhrissat, T. (2023). Improving the Mechanical Properties of Recycled Asphalt Pavement Mixtures Using Steel Slag and Silica Fume as a Filler. Buildings, 13(1), 132. [CrossRef]

- Jordan Green Building Council (JGBC) and Friedrich Ebert Stiftung (FES). (2016) Your Guide to Waste management in Jordan: Waste Sorting Informative booklet.

- ASTM D36. (2020). Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus), ASTM International. [CrossRef]

- ASTM D5. (2020). Standard Test Method for Penetration of Bituminous Materials, ASTM International. [CrossRef]

- ASTM D113. (2017), Standard Test Method for Ductility of Asphalt Materials, ASTM International. [CrossRef]

- O'Farrell, K. (2020). 2018–19 Australian Plastics Recycling Survey Report Department of Agriculture, Water and the Environment. R01-03-A21509.

- ASTM D-3515 (2001). Standard Specification for Hot-Mixed, Hot-Laid Bituminous Paving Mixtures.

- ASTM C-127. (2015). Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International. [CrossRef]

- ASTM C128. (2015)., Standard Test Method For Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International. [CrossRef]

- ASTM C-131. (2020). Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International. [CrossRef]

- ASTM D6926. (2020). Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus. ASTM International. [CrossRef]

- ASTM D6927. (2015). Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures, ASTM International. [CrossRef]

- ASTM- D6931. (2020) Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM International.

- Al-Khateeb, G. G., Khedaywi, T. S., Obaidat, T. I. A. S., & Najib, A. M. (2013). Laboratory study for comparing rutting performance of limestone and basalt superpave asphalt mixtures. Journal of Materials in Civil Engineering, 25(1), 21-29. [CrossRef]

- Cao, W., Liu, S., & Feng, Z. (2013). Comparison of performance of stone matrix asphalt mixtures using basalt and limestone aggregates. Construction and Building Materials, 41, 474-479. [CrossRef]

- Xu, G., Fan, J., Ma, T., Zhao, W., Ding, X., & Wang, Z. (2021). Research on application feasibility of limestone in sublayer of Double-Layer permeable asphalt pavement. Construction and Building Materials, 287, 123051. [CrossRef]

- Zaltuom, A. M. (2018). A review study of the effect of air voids on asphalt pavement life. The First Conference for Engineering Sciences and Technology. Al- Mergib University. [CrossRef]

| Characteristics | Test Results | Test Method | Control Limits | |

|---|---|---|---|---|

| Penetration at 25°C, 100 g, 5 s | 0.1 mm | 65.0 | 60 - 70 | ASTM D05 [48] |

| Softening point | Cº | 51.5 | Min. 46 | ASTM D36 [47] |

| Ductility at 25°C, 5 cm/min | cm | 108 | Min. 100 | ASTM D113 [49] |

| Aggregate type | Sieve Designation | Specification Limits [51] | Heavy Traffic | Light Traffic | Design Gradation | |||

| Binder Course | Wearing Course | Binder Course | Wearing Course | Limestone Aggregate | Basalt Aggregate | |||

| Coarse Aggregate | 1 1/2” | - | - | - | - | - | - | - |

| 1” (25.0 mm) | 100 | 100 | 100 | 100 | 100 | 100 | 100.0 | |

| 3/4” (19.0 mm) | 70-100 | 70-100 | 90-100 | 70-100 | 90-100 | 97 | 98.9 | |

| 1/2” (12.5 mm) | 53-90 | 53-90 | 71-90 | 53-90 | 71-90 | 78 | 80.8 | |

| 3/8” (9.5 mm) | 40-80 | 40-80 | 56-80 | 40-80 | 56-80 | 65 | 64.4 | |

| No.4 (4.75 mm) | 30-56 | 30-56 | 35-56 | 30-56 | 35-65 | 47 | 44.2 | |

| Fine Aggregate | No.8 (2.36 mm) | 23-38 | 23-38 | 23-38 | 23-49 | 23-49 | 34 | 33.7 |

| No.20 (1.18 mm) | - | 13-27 | 13-27 | 14-34 | 14-34 | 19 | 20.0 | |

| No.50 (0.300 mm) | 5-14 | 5-17 | 5-17 | 5-19 | 5-19 | 10 | 9.6 | |

| No.80 (0.150 mm) | - | 4-14 | 4-14 | 4-15 | 4-15 | 8 | 7.8 | |

| No.200 (0.075 mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-8 | 5.1 | 5.4 | |

| Test Type | Standards | Limestone | Basalt | |||||||||

| ¾” | ½”-B | No.4 | Filler | Combined | 1" | 3/4 | 1/2" | No.4 | Filler | Combined | ||

| % of Blending | ASTM C127 [52] ASTM C128 [53] |

12 | 44 | 41 | 3 | 0 | 20 | 32 | 43 | 5 | ||

| Bulk Specific gravity (Oven Dry) | 2.38 | 2.42 | 2.63 | 2.69 | 2.50 | 2.83 | 2.85 | 2.84 | 2.74 | 2.75 | 2.71 | |

| Bulk Specific gravity (SSD) | 2.46 | 2.49 | 2.66 | --- | 2.56 | 2.86 | 2.88 | 2.87 | 2.80 | 2.75 | ||

| Absorption % | ASTM-C127 [52] | 3.52 | 2.73 | 1.1 | 0.00 | 2.10 | 1.06 | 1.05 | 1.30 | 1.90 | 0.2 | 1.07 |

| Abrasion | ASTM C131 {54] | 25.0 | 17.7 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).