Submitted:

01 August 2023

Posted:

02 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

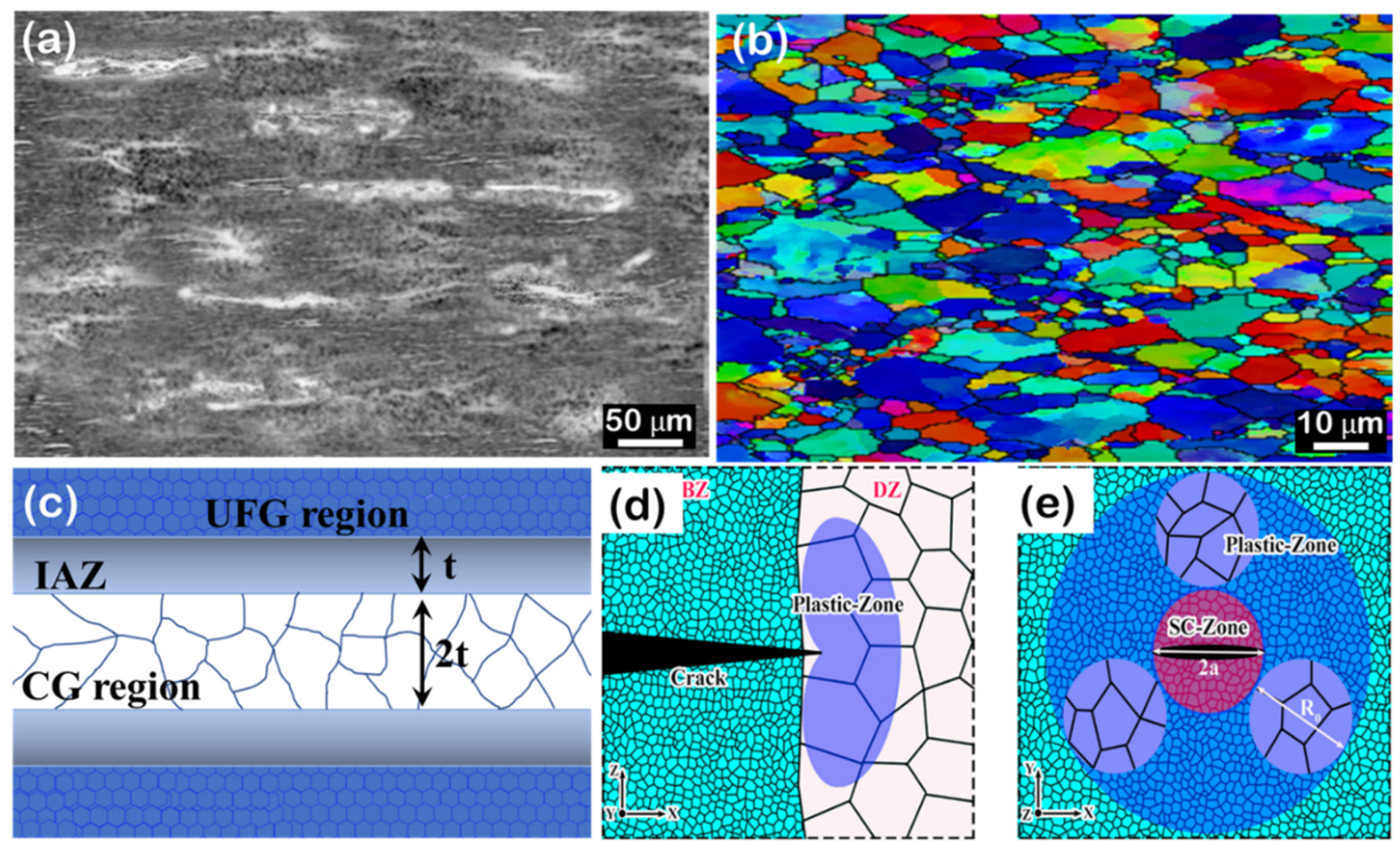

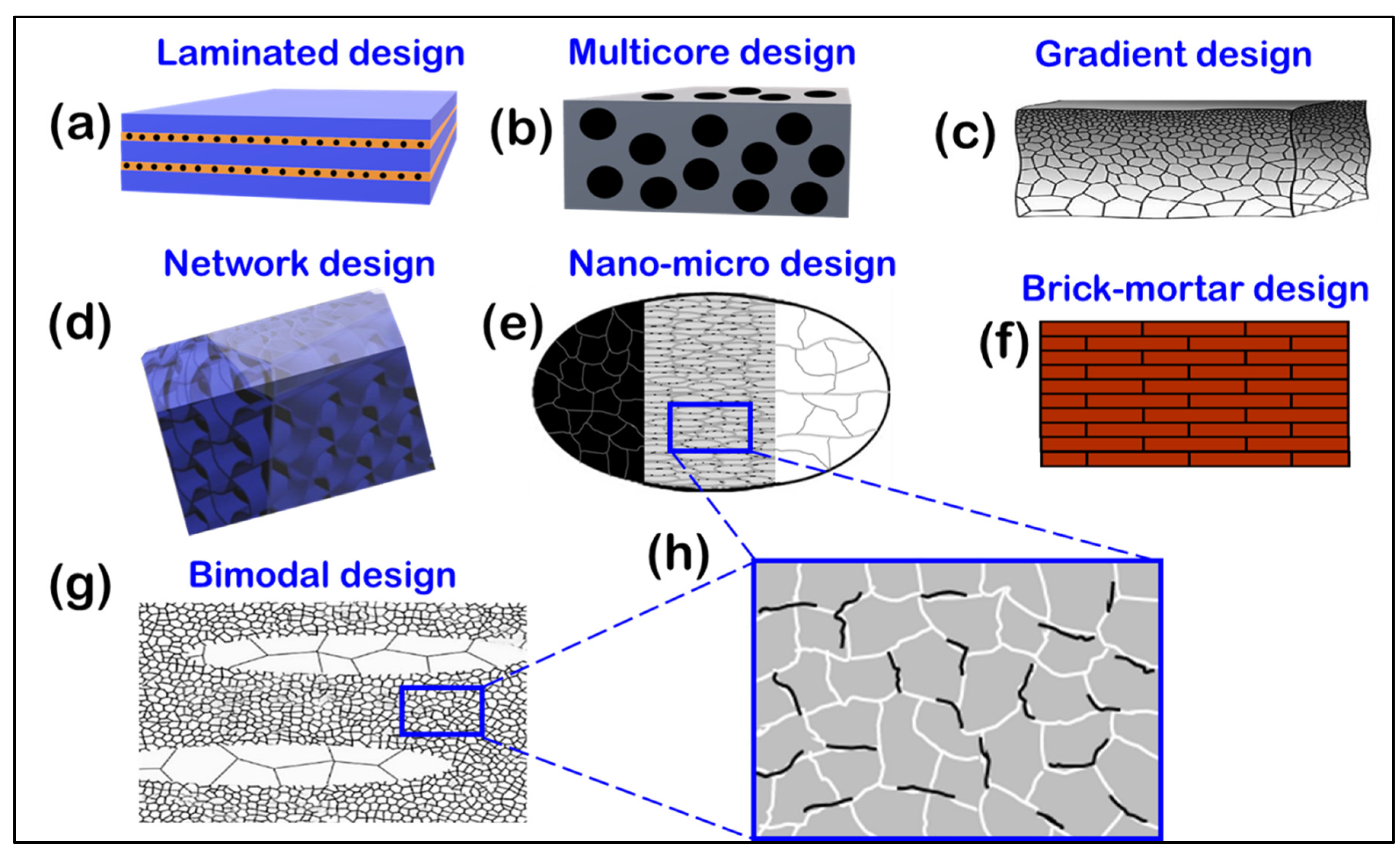

2. Strengthening and Toughening through Macro Heterogeneous Configuration of Reinforcement

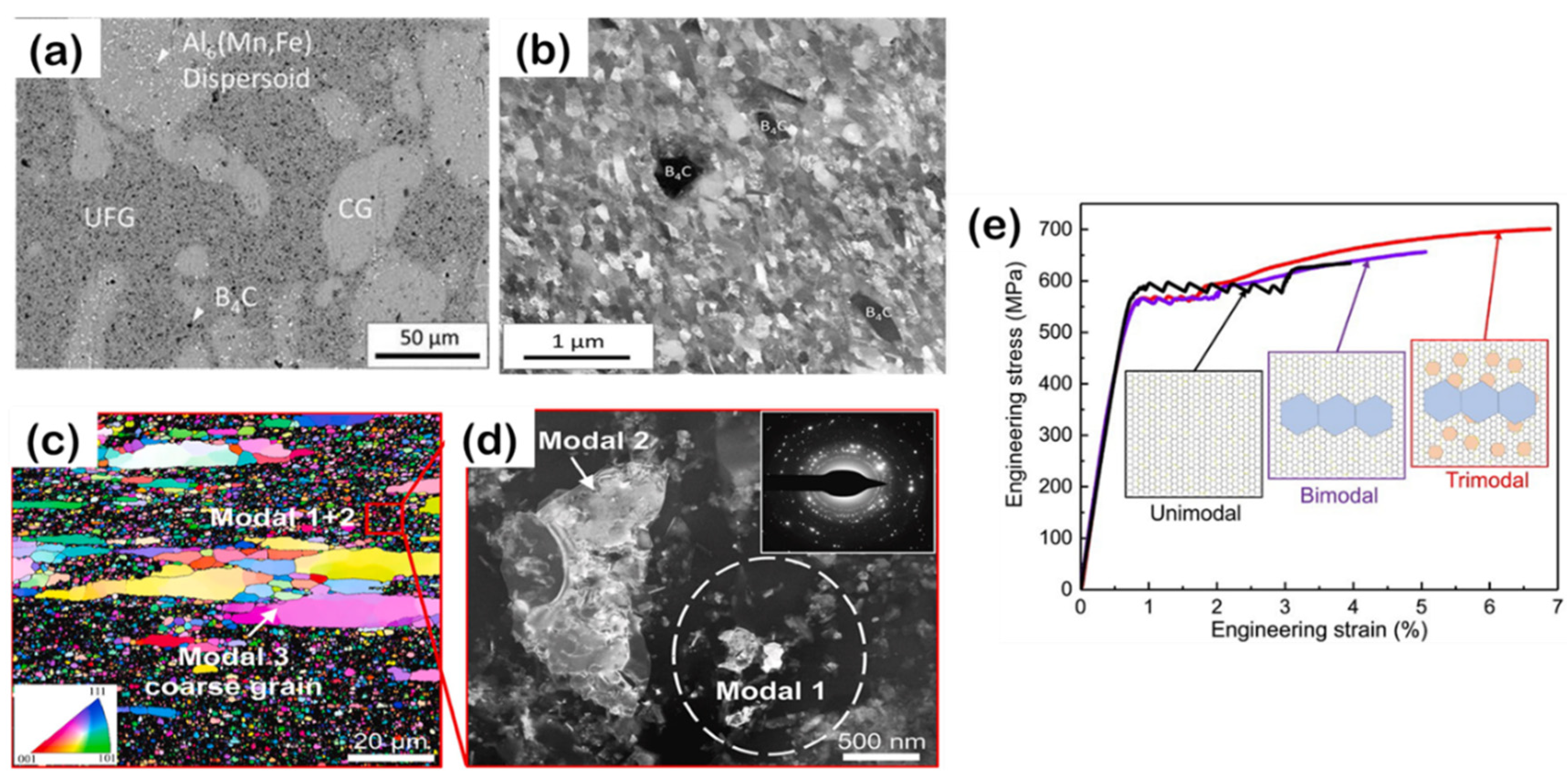

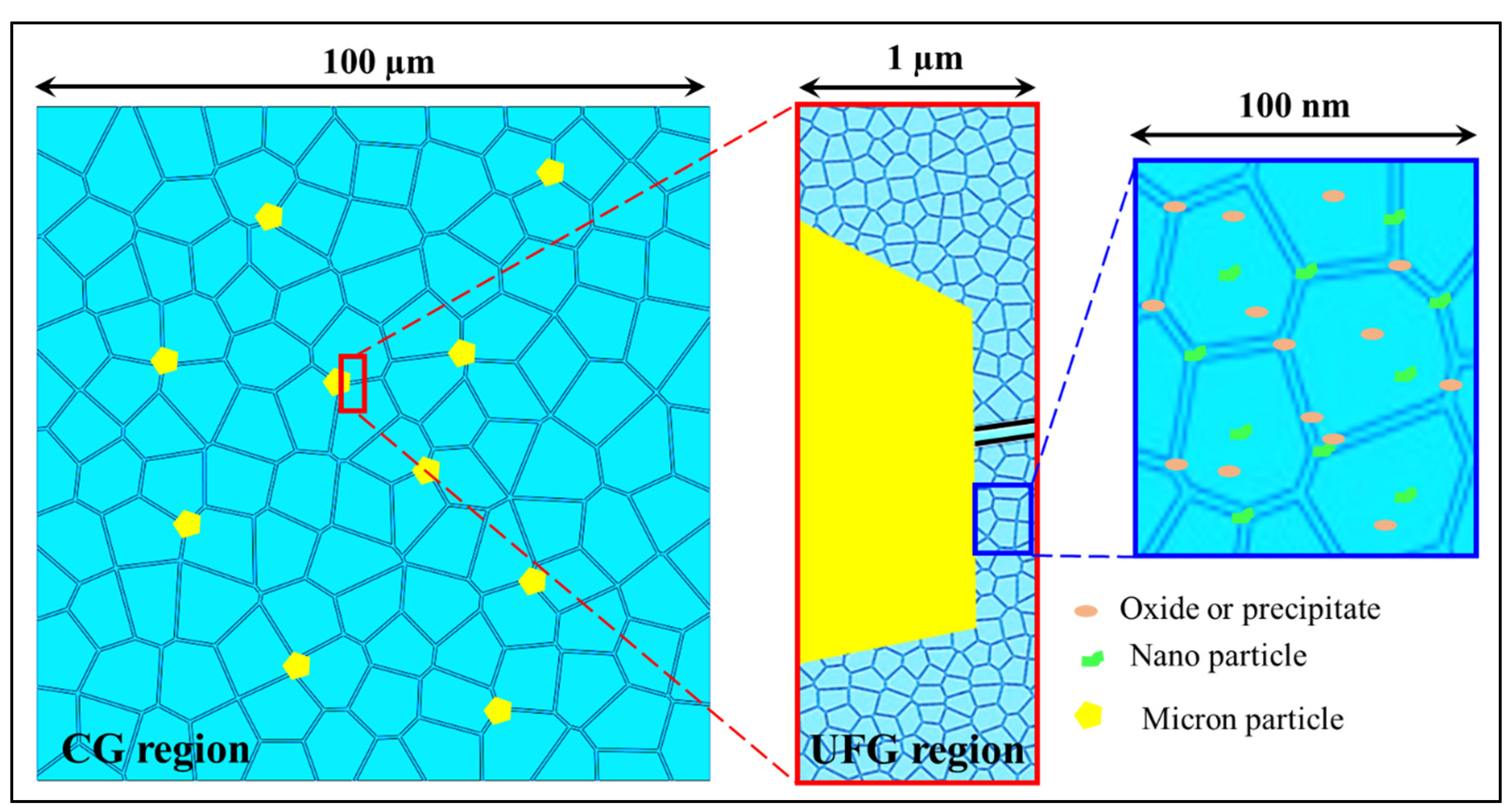

3. Strengthening and Toughening of Microheterogeneous Configurations of Reinforcements

4. Strengthening and Toughening the Matrix through Intrinsic Mechanisms

5. Designing and Fabricating Composite Configurations Based on Energy Dissipation

6. Summary and Outlook

6.1. Summary

6.2. Outlook

References

- Ayar, M.; George, P.; Patel, R. Advanced research progresses in aluminium metal matrix composites: An overview. AIP Conf. Proc. 2021, 2317, 020026. [Google Scholar] [CrossRef]

- Karaoğlu, S.Y.; Karaoğlu, S. Aerospace Industry and Aluminum Metal Matrix Composites. Int. Sustain. Aviat. Res. Soc. 2021, 2, 73–81. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Balog, M.; Pruncu, C.I.; Shabani, A. Microstructure dependent dislocation density evolution in micro-macro rolled Al2O3/Al laminated composite. Mater. Sci. Eng. A 2022, 830, 142317. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Pruncu, C.I. Architecture dependent strengthening mechanisms in graphene/Al heterogeneous lamellar composites. Mater. Charact. 2022, 111913. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Carbon nanotube reinforced aluminum matrix composites produced by spark plasma sintering. J. Mater. Sci. 2017, 52, 8618–8629. [Google Scholar] [CrossRef]

- Sharma, D.K.; Sharma, M.; Upadhyay, G. Boron carbide (B4C) reinforced aluminum matrix composites (AMCs). Int. J. Innov. Technol. Explor. Eng. 2019, 9, 2194–2203. [Google Scholar] [CrossRef]

- He, F.; Han, Q.; Jackson, M.J. Nanoparticulate reinforced metal matrix nanocomposites – a review. Int. J. Nanoparticles 2008, 1, 301. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Miracle, D.J.C.s. ; technology. Metal matrix composites–from science to technological significance. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Miserez, A.; Müller, R.; Rossoll, A.; Weber, L.; Mortensen, A. Particle reinforced metals of high ceramic content. Mater. Sci. Eng. A 2004, 387-389, 822–831. [Google Scholar] [CrossRef]

- Lava Kumar, P.; Lombardi, A.; Byczynski, G.; Narayana Murty, S.V.S.; Murty, B.S.; Bichler, L. Recent advances in aluminium matrix composites reinforced with graphene-based nanomaterial: A critical review. Prog. Mater. Sci. 2022, 128, 100948. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Richardson, M. The soaring potential of AMCs. 2020.

- ROSS, M. Research indicates aluminum matrix composites could deliver weight saving for e-motor rotors. Available online: https://www.electrichybridvehicletechnology.com/news/motor-technology/research-indicates-aluminum-matrix-composites-could-deliver-weight-saving-for-e-motor-rotors.html.

- Zhang, X.; Zhao, N.; He, C. The superior mechanical and physical properties of nanocarbon reinforced bulk composites achieved by architecture design–a review. Prog. Mater. Sci. 2020, 113, 100672. [Google Scholar] [CrossRef]

- Farkas, D.; Van Petegem, S.; Derlet, P.; Van Swygenhoven, H.J.A.M. Dislocation activity and nano-void formation near crack tips in nanocrystalline Ni. Acta Mater. 2005, 53, 3115–3123. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Laska, A.; Perrone, A.; Blasi, G.; Gopinathan, A.; Shamanian, M.; Ashrafizadeh, F. Effect of processing parameters on the cyclic behaviour of aluminium friction stir welded to spark plasma sintered aluminium matrix composites with bimodal micro-and nano-sized reinforcing alumina particles. Mater. Charact. 2023, 195, 112535. [Google Scholar] [CrossRef]

- Baghad, A.; Mabrouk, K.E. A Brief Review on Additive Manufacturing Processes for Lightweight Metal Matrix Composites. Johns. Matthey Technol. Rev. 2022. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, M. Light Metal Matrix Composites. J. Appl. Biomater. Funct. Mater. 2015, 7–58. [Google Scholar] [CrossRef]

- Meyers, M.A.; McKittrick, J.; Chen, P.-Y.J. Structural biological materials: Critical mechanics-materials connections. Science 2013, 339, 773–779. [Google Scholar] [CrossRef]

- Barthelat, F.; Yin, Z.; Buehler, M.J.J.N.R.M. Structure and mechanics of interfaces in biological materials. Nat. Rev. Mater. 2016, 1, 16007. [Google Scholar] [CrossRef]

- Libonati, F.; Buehler, M.J.J.A.E.M. Advanced structural materials by bioinspiration. Adv. Eng. Mater. 2017, 19, 1600787. [Google Scholar] [CrossRef]

- Estrin, Y.; Beygelzimer, Y.; Kulagin, R.; Gumbsch, P.; Fratzl, P.; Zhu, Y.; Hahn, H. Architecturing materials at mesoscale: Some current trends. Mater. Res. Lett. 2021, 9, 399–421. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Tszeng, T.C. The effects of particle clustering on the mechanical behavior of particle reinforced composites. Compos. Part B Eng. 1998, 29, 299–308. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Xu, H.Y.; Peng, H.X. In situ TiC particles reinforced Ti6Al4V matrix composite with a network reinforcement architecture. Mater. Sci. Eng. A 2011, 528, 2859–2862. [Google Scholar] [CrossRef]

- Nan, C.-W. Physics of inhomogeneous inorganic materials. Prog. Mater. Sci. 1993, 37, 1–116. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, Q.; Li, Z.; Li, Z.; Fan, G.; Xiong, D.-B.; Su, Y.; Zhang, J.; Tan, Z.; Zhang, D. Strain-rate dependent deformation mechanism of graphene-Al nanolaminated composites studied using micro-pillar compression. Int. J. Plast. 2018, 105, 128–140. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Shao, S.; Misra, A. Strength and plasticity of nanolaminated materials. Mater. Res. Lett. 2017, 5, 1–19. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.; Höppel, H.W.; Göken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface affected zone for optimal strength and ductility in heterogeneous laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef]

- Sadeghi, B.; Qi, J.; Min, X.; Cavaliere, P. Modelling of strain rate dependent dislocation behavior of CNT/Al composites based on grain interior/grain boundary affected zone (GI/GBAZ). Mater. Sci. Eng. A 2021, 820, 141547. [Google Scholar] [CrossRef]

- Sadeghi, B.; Tan, Z.; Qi, J.; Li, Z.; Min, X.; Yue, Z.; Fan, G. Enhanced mechanical properties of CNT/Al composite through tailoring grain interior/grain boundary affected zones. Compos. Part B Eng. 2021, 223, 109133. [Google Scholar] [CrossRef]

- Sadeghi, B.; Tan, Z.; Li, Z.; Zhang, D. Strain rate dependent deformation mechanisms of CNT/Al laminated composite based on grain interior/grain boundary affected zone (GI/GBAZ) model. Compos. Struct. Under review. 2020. [Google Scholar]

- Lu, L.; Wu, X.; Beyerlein, I.J.J.S.M. Preface to the viewpoint set on: Heterogeneous gradient and laminated materials. Scripta Mater. 2020, 187, 307–308. [Google Scholar] [CrossRef]

- Barai, P.; Weng, G.J. A theory of plasticity for carbon nanotube reinforced composites. Int. J. Plast. 2011, 27, 539–559. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P. CNTs reinforced Al-based composites produced via modified flake powder metallurgy. J. Mater. Sci. 2022, 57, 2550–2566. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P. Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite. Metals 2021, 11, 1524. [Google Scholar] [CrossRef]

- Fu, X.; Yu, Z.; Tan, Z.; Fan, G.; Li, P.; Wang, M.; Xiong, D.-B.; Li, Z. Enhanced strain hardening by bimodal grain structure in carbon nanotube reinforced Al–Mg composites. Mater. Sci. Eng. A 2021, 803, 140726. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, G. Preparation of high fracture performance SiCp-6061A1/6061A1 composite. Mater. Sci. Eng. A 2000, 279, 231–236. [Google Scholar] [CrossRef]

- Gao, X.; Peng, M.; Zhang, X.; Qian, M.; Li, A.; Geng, L.; Wang, H.; Peng, H.-X. Profound strengthening and toughening effect of reinforcement aspect ratio in composite with network architecture. J. Alloys Compd. 2022, 167444. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, H.; Yee, J.K.; Mo, X.; Topping, T.; Lavernia, E.J.; Schoenung, J.M.J.A.M. Toughening of aluminum matrix nanocomposites via spatial arrays of boron carbide spherical nanoparticles. Acta Mater. 2016, 103, 128–140. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, M.S.; Fang, X.T.; Guo, F.J.; Liu, H.Q.; Scattergood, R.O.; Huang, C.X.; Zhu, Y.T. Extra strengthening in a coarse/ultrafine grained laminate: Role of gradient interfaces. Int. J. Plast. 2019, 123, 196–207. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Gradient and lamellar heterostructures for superior mechanical properties. MRS Bull. 2021, 46, 244–249. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Pruncu, C.I.; Balog, M.; Marques de Castro, M.; Chahal, R. Architectural design of advanced aluminum matrix composites: A review of recent developments. Crit. Rev. Solid State Mater. Sci. 2022, 1–71. [Google Scholar] [CrossRef]

- Luo, X.; Zhao, K.; He, X.; Bai, Y.; De Andrade, V.; Zaiser, M.; An, L.; Liu, J. Evading strength and ductility trade-off in an inverse nacre structured magnesium matrix nanocomposite. Acta Mater. 2022, 228, 117730. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc Natl Acad Sci USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed]

- Imry, Y. Introduction to Mesoscopic Physics; Oxford University Press on Demand: Oxford, UK, 2002. [Google Scholar]

- Poletti, C.; Balog, M.; Simancik, F.; Degischer, H.P. High-temperature strength of compacted sub-micrometer aluminium powder. Acta Mater. 2010, 58, 3781–3789. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Bajana, O.; Hu, T.; Yang, H.; Schoenung, J.M.; Lavernia, E.J. Influence of grain boundaries with dispersed nanoscale Al2O3 particles on the strength of Al for a wide range of homologous temperatures. J. Alloys Compd. 2019, 772, 472–481. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Nosko, M.; TremboŠovÁ, V.; Nagy, Š. Hot deformation behaviour of bimodal sized Al2O3/Al nanocomposites fabricated by spark plasma sintering. J. Microsc. 2021, 281, 28–45. [Google Scholar] [CrossRef]

- Li, S.; Xiong, D.; Liu, M.; Bai, S.; Zhao, X. Thermophysical properties of SiC/Al composites with three dimensional interpenetrating network structure. Ceram. Int. 2014, 40, 7539–7544. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, L.; Chen, W. Evaluation of Cu-Cr3C2 composite with interpenetrating network. Mater. Sci. Eng. A 2012, 552, 24–30. [Google Scholar] [CrossRef]

- Moon, R.J.; Tilbrook, M.; Hoffman, M.; Neubrand, A. Al–Al2O3 composites with interpenetrating network structures: Composite modulus estimation. J. Am. Ceram. Soc. 2005, 88, 666–674. [Google Scholar] [CrossRef]

- Awotunde, M.A.; Adegbenjo, A.O.; Obadele, B.A.; Okoro, M.; Shongwe, B.M.; Olubambi, P.A. Influence of sintering methods on the mechanical properties of aluminium nanocomposites reinforced with carbonaceous compounds: A review. J. Mater. Res. Technol. 2019, 8, 2432–2449. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.; Liu, E.; Zhao, N.; He, C. High-strength graphene network reinforced copper matrix composites achieved by architecture design and grain structure regulation. Mater. Sci. Eng. A 2019, 762, 138063. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Cavaliere, P.; Ashrafizadeh, F.; Sanayei, M.; Szpunar, J.A. Microstructural and mechanical behavior of bimodal reinforced Al-based composites produced by spark plasma sintering and FSP. Int. J. Adv. Manuf. Technol. 2018, 94, 3903–3916. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P.; Sanayei, M.; Szpunar, J.A. Microstructural behaviour of spark plasma sintered composites containing bimodal micro- and nano-sized Al2O3 particles. Powder Metall. 2018, 61, 50–63. [Google Scholar] [CrossRef]

- Sadeghi, B.; Sadeghian, B.; Taherizadeh, A.; Laska, A.; Cavaliere, P.; Gopinathan, A. Effect of Porosity on the Thermo-Mechanical Behavior of Friction-Stir-Welded Spark-Plasma-Sintered Aluminum Matrix Composites with Bimodal Micro- and Nano-Sized Reinforcing Al2O3 Particles. Metals 2022, 12, 1660. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F. Al-Based Nanocomposites Produced via Spark Plasma Sintering: Effect of Processing Route and Reinforcing Phases. In Spark Plasma Sintering of Materials: Advances in Processing and Applications, Cavaliere, P., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 161–190. [Google Scholar]

- Sadeghi, B.; Cavaliere, P.; Shamanian, M.; Sanayei, M.; Szpunar, J.A.; Nosko, M. Electron backscattered diffraction analysis of friction stir processed nanocomposites produced via spark plasma sintering. J Microsc 2018. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Perrone, A. Effect of Al2O3, SiO2 and carbon nanotubes on the microstructural and mechanical behavior of spark plasma sintered aluminum based nanocomposites. Part. Sci. Technol. 2018, 38, 7–14. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P.; Rizzo, A. Influence of Al2O3 Nanoparticles on Microstructure and Strengthening Mechanism of Al-Based Nanocomposites Produced via Spark Plasma Sintering. J. Mater. Eng. Perform. 2017, 26, 2928–2936. [Google Scholar] [CrossRef]

- Sadeghi, B.; Fan, G.; Tan, Z.; Li, Z.; Kondo, A.; Naito, M. Smart Mechanical Powder Processing for Producing Carbon Nanotube Reinforced Aluminum Matrix Composites. KONA Powder Part. J. 2022, 2022004. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shabani, A.; Heidarinejad, A.; Laska, A.; Szkodo, M.; Cavaliere, P.J.J.o.C.S. A Quantitative Investigation of Dislocation Density in an Al Matrix Composite Produced by a Combination of Micro-/Macro-Rolling. J. Compos. Sci. 2022, 6, 199. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P. Progress of Flake Powder Metallurgy Research. Metals 2021, 11, 931. [Google Scholar] [CrossRef]

- Yuan, C.; Tan, Z.; Fan, G.; Chen, M.; Zheng, Q.; Li, Z. Fabrication and mechanical properties of CNT/Al composites via shift-speed ball milling and hot-rolling. J. Mater. Res. 2019, 34, 2609–2619. [Google Scholar] [CrossRef]

- Jiang, Y.Y.; Tan, Z.Q.; Xu, R.; Fan, G.L.; Xiong, D.B.; Guo, Q.; Su, Y.S.; Li, Z.Q.; Zhang, D. Tailoring the structure and mechanical properties of graphene nanosheet/aluminum composites by flake powder metallurgy via shift-speed ball milling. Compos. Part A-Appl. Sci. Manuf. 2018, 111, 73–82. [Google Scholar] [CrossRef]

- Xie, K.; Nie, J.; Ma, X.; Liu, X. Increasing the ductility of heat-resistant AlNp/Al composites by submicron Al2O3 particles. Mater. Charact. 2020, 170, 110672. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Dvorak, J.; Bajana, O.; Krajcovic, J.; Drienovsky, M. Industrially fabricated in-situ Al-AlN metal matrix composites (part B): The mechanical, creep, and thermal properties. J. Alloys Compd. 2022, 909, 164720. [Google Scholar] [CrossRef]

- Chen, M.; Fan, G.; Tan, Z.; Xiong, D.; Guo, Q.; Su, Y.; Zhang, J.; Li, Z.; Naito, M.; Zhang, D. Design of an efficient flake powder metallurgy route to fabricate CNT/6061Al composites. Mater. Des. 2018, 142, 288–296. [Google Scholar] [CrossRef]

- Fan, G.L.; Xu, R.; Tan, Z.Q.; Zhang, D.; Li, Z.Q. Development of Flake Powder Metallurgy in Fabricating Metal Matrix Composites: A Review. Acta Metall. Sin. -Engl. Lett. 2014, 27, 806–815. [Google Scholar] [CrossRef]

- Li, N.Y.; Yang, C.; Li, C.J.; Guan, H.D.; Fang, D.; Tao, J.M.; Liu, Y.C.; Yi, J.H. Carbon nanotubes reinforced aluminum matrix composites with high elongation prepared by flake powder metallurgy. Diam. Relat. Mater. 2020, 107, 107907. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.Q.; Fan, G.L.; Ji, G.; Xiong, D.B.; Guo, Q.; Su, Y.S.; Li, Z.Q.; Zhang, D. High-strength CNT/Al-Zn-Mg-Cu composites with improved ductility achieved by flake powder metallurgy via elemental alloying. Compos. Part A-Appl. Sci. Manuf. 2018, 111, 1–11. [Google Scholar] [CrossRef]

- Xiang, Y.; Wang, X.; Hu, X.; Meng, L.; Song, Z.; Li, X.; Sun, Z.; Zhang, Q.; Wu, K. Achieving ultra-high strengthening and toughening efficiency in carbon nanotubes/magnesium composites via constructing micro-nano layered structure. Compos. Part A: Appl. Sci. Manuf. 2019, 119, 225–234. [Google Scholar] [CrossRef]

- Cao, M.; Xiong, D.B.; Tan, Z.Q.; Ji, G.; Amin-Ahmadi, B.; Guo, Q.; Fan, G.L.; Guo, C.P.; Li, Z.Q.; Zhang, D. Aligning graphene in bulk copper: Nacre-inspired nanolaminated architecture coupled with in-situ processing for enhanced mechanical properties and high electrical conductivity. Carbon 2017, 117, 65–74. [Google Scholar] [CrossRef]

- Li, Z.; Guo, Q.; Li, Z.Q.; Fan, G.L.; Xiong, D.B.; Su, Y.S.; Zhang, J.; Zhang, D. Enhanced Mechanical Properties of Graphene (Reduced Graphene Oxide)/Aluminum Composites with a Bioinspired Nanolaminated Structure. Nano Lett. 2015, 15, 8077–8083. [Google Scholar] [CrossRef] [PubMed]

- Vogel, T.; Ma, S.; Liu, Y.; Guo, Q.; Zhang, D. Impact of alumina content and morphology on the mechanical properties of bulk nanolaminated Al2O3-Al composites. Compos. Commun. 2020, 22, 100462. [Google Scholar] [CrossRef]

- Liu, P.; Hou, B.; Wang, A.; Xie, J.; Wang, Z. Balancing the strength and ductility of Ti2AlC/TiAl composite with a bioinspired micro-nano laminated architecture. Mater. Des. 2022, 220, 110851. [Google Scholar] [CrossRef]

- Gao, H.; Ji, B.; Jäger, I.L.; Arzt, E.; Fratzl, P. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc. Natl. Acad. Sci. USA 2003, 100, 5597–5600. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817. [Google Scholar] [CrossRef]

- Sciences, E. Fracture mechanics by three-dimensional crack-tip synchrotron X-ray microscopy. Philos Trans A Math Phys Eng Sci 2015, 373, 20130157. [Google Scholar] [CrossRef]

- Sun, H.; Saba, F.; Fan, G.; Tan, Z.; Li, Z. Micro/nano-reinforcements in bimodal-grained matrix: A heterostructure strategy for toughening particulate reinforced metal matrix composites. Scr. Mater. 2022, 217, 114774. [Google Scholar] [CrossRef]

- Withers, P.J. 3D Crack-tip Microscopy: Illuminating Micro-Scale Effects on Crack-Tip Behavior. Adv. Eng. Mater. 2011, 13, 1096–1100. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 100675. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.; Liu, E.; He, F.; Ma, L.; Li, Q.; Li, J.; Bacsa, W.; Zhao, N.; He, C.J.N. Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network. Nanoscale 2017, 9, 11929–11938. [Google Scholar] [CrossRef] [PubMed]

- Xiao, P.; Gao, Y.; Yang, C.; Li, Y.; Huang, X.; Liu, Q.; Zhao, S.; Xu, F.; Gupta, M. Strengthening and toughening mechanisms of Mg matrix composites reinforced with specific spatial arrangement of in-situ TiB2 nanoparticles. Compos. Part B: Eng. 2020, 198, 108174. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, H.; Yee, J.K.; Mo, X.; Topping, T.; Lavernia, E.J.; Schoenung, J.M. Toughening of aluminum matrix nanocomposites via spatial arrays of boron carbide spherical nanoparticles. Acta Mater. 2016, 103, 128–140. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.D.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat Mater 2013, 12, 344–350. [Google Scholar] [CrossRef]

- Liu, Q.; Fan, G.; Tan, Z.; Guo, Q.; Xiong, D.; Su, Y.; Li, Z.; Zhang, D. Reinforcement with intragranular dispersion of carbon nanotubes in aluminum matrix composites. Compos. Part B Eng. 2021, 217, 108915. [Google Scholar] [CrossRef]

- So, K.P.; Kushima, A.; Park, J.G.; Liu, X.; Keum, D.H.; Jeong, H.Y.; Yao, F.; Joo, S.H.; Kim, H.S.; Kim, H.J.A.S. Intragranular dispersion of carbon nanotubes comprehensively improves aluminum alloys. Adv Sci 2018, 5, 1800115. [Google Scholar] [CrossRef]

- Liu, Q.; Fan, G.; Tan, Z.; Saba, F.; Guo, Q.; Xiong, D.; Su, Y.; Li, Z.; Zhang, D.J.C. Effect of thermomechanical treatment and length-scales on spatial distribution of CNTs in Al matrix. Carbon 2022, 190, 384–394. [Google Scholar] [CrossRef]

- Zhang, D. Ultrafine grained metals and metal matrix nanocomposites fabricated by powder processing and thermomechanical powder consolidation. Prog. Mater. Sci. 2021, 119, 100796. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Roeen, G.A.; Nosko, M.; Shamanian, M.; Trembošová, V.; Nagy, Š.; Ebrahimzadeh, N. Hot rolling of MWCNTs reinforced Al matrix composites produced via spark plasma sintering. Adv. Compos. Hybrid Mater. 2019, 2, 549–570. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Svec, P.; Orovcik, L. Industrially fabricated in-situ Al-AlN metal matrix composites (part A): Processing, thermal stability, and microstructure. J. Alloys Compd. 2021, 883, 160858. [Google Scholar] [CrossRef]

- Mokdad, F.; Chen, D.L.; Liu, Z.Y.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Deformation and strengthening mechanisms of a carbon nanotube reinforced aluminum composite. Carbon 2016, 104, 64–77. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, N.R.; Lu, K. Mechanical properties and rolling behaviors of nano-grained copper with embedded nano-twin bundles. Acta Mater. 2008, 56, 2429–2440. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, H.W.; Tao, N.R.; Lu, K. Quantifying the Microstructures of Pure Cu Subjected to Dynamic Plastic Deformation at Cryogenic Temperature. J. Mater. Sci. Technol. 2011, 27, 673–679. [Google Scholar] [CrossRef]

- You, Z.; Luo, S.; Lu, L.J.S.C.T.S. Size effect of deformation nanotwin bundles on their strengthening and toughening in heterogeneous nanostructured Cu. Sci. China Technol. Sci. 2021, 64, 23–31. [Google Scholar] [CrossRef]

- Ni, D.R.; Ma, Z.Y. Shape Memory Alloy-Reinforced Metal-Matrix Composites: A Review. Acta Metall. Sin. (Engl. Lett. ) 2014, 27, 739–761. [Google Scholar] [CrossRef]

- Diffusion and diffusional creep. Deformation of Earth Materials: An Introduction to the Rheology of Solid Earth, Karato, S.-I., Ed.; Cambridge University Press: Cambridge, UK, 2008; pp. 123–142. [Google Scholar]

- Ballo, P.; Kioussis, N.; Lu, G. Grain boundary sliding and migration: Effect of temperature and vacancies. Phys. Rev. B 2001, 64, 024104. [Google Scholar] [CrossRef]

- Langdon, T.G. Identifying creep mechanisms in plastic flow. Int. J. Mater. Res. 2005, 96, 522–531. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X.J.M.R.L. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- AN Zibing, M.S.; Zhang, Z.; Han, X. Strengthening-Toughening Mechanism and Mechanical Properties of Span-Scale Heterostructure High-Entropy Alloy. 2022, 58, 1441–1458. [Google Scholar] [CrossRef]

- Yu, B.; Aranguren van Egmond, D.; Abu Samk, K.; Erb, U.; Wilkinson, D.; Embury, D.; Zurob, H. The design of “Grain Boundary Engineered” architected cellular materials: The role of 5-7 defects in hexagonal honeycombs. Acta Mater. 2023, 243, 118513. [Google Scholar] [CrossRef]

- Schwarze, C.; Darvishi Kamachali, R.; Steinbach, I. Phase-field study of zener drag and pinning of cylindrical particles in polycrystalline materials. Acta Mater. 2016, 106, 59–65. [Google Scholar] [CrossRef]

- Goyal, A.; Doquet, V.; Pouya, A. Grain Boundary Sliding and Strain Rate Sensitivity of Coarse and Fine/Ultrafine Grained 5083 Aluminum Alloys. Metall. Mater. Trans. A 2020, 51, 1109–1122. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P.; Rizzo, A. Friction stir processing of spark plasma sintered aluminum matrix composites with bimodal micro- and nano-sized reinforcing Al 2 O 3 particles. J. Manuf. Process. 2018, 32, 412–424. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Zhang, M.F.; Zheng, M.Y.; Wu, K. Significantly improved strength and ductility in bimodal-size grained microstructural magnesium matrix composites reinforced by bimodal sized SiCp over traditional magnesium matrix composites. Compos. Sci. Technol. 2015, 118, 85–93. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Ma, Z.; Li, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Powder assembly & alloying to CNT/Al–Cu–Mg composites with trimodal grain structure and strength-ductility synergy. Compos. Part B Eng. 2021, 225, 109271. [Google Scholar] [CrossRef]

- Singh, L.K.; Bhadauria, A.; Laha, T. Understanding the effect of bimodal microstructure on the strength–ductility synergy of Al–CNT nanocomposites. J. Mater. Sci. 2021, 56, 1730–1748. [Google Scholar] [CrossRef]

- Hosseiny, N.; Shabani, A.; Toroghinejad, M.R. Effect of bimodal microstructure on texture evolution and mechanical properties of 1050 Al alloy processed through severe plastic deformation and subsequent annealing. Mater. Sci. Eng. A 2021, 820, 141580. [Google Scholar] [CrossRef]

- Liu, Q.; Lomov, S.V.; Gorbatikh, L. Spatial distribution and orientation of nanotubes for suppression of stress concentrations optimized using genetic algorithm and finite element analysis. Mater. Des. 2018, 158, 136–146. [Google Scholar] [CrossRef]

- Yao, B.; Hofmeister, C.; Patterson, T.; Sohn, Y.-h.; van den Bergh, M.; Delahanty, T.; Cho, K. Microstructural features influencing the strength of trimodal aluminum metal-matrix-composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 933–941. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Min, X.; Li, Z.; Yue, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying. Mater. Res. Lett. 2021, 9, 50–57. [Google Scholar] [CrossRef]

- Sun, L.G.; Wu, G.; Wang, Q.; Lu, J. Nanostructural metallic materials: Structures and mechanical properties. Mater. Today 2020, 38, 114–135. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Liu, K.; Chen, X.G.; Xiao, B.L.; Ma, Z.Y. Structure optimization for improving the strength and ductility of heterogeneous carbon nanotube/Al–Cu–Mg composites. Carbon 2021, 178, 190–201. [Google Scholar] [CrossRef]

- Zhang, Y.; Sabbaghianrad, S.; Yang, H.; Topping, T.D.; Langdon, T.G.; Lavernia, E.J.; Schoenung, J.M.; Nutt, S.R. Two-step SPD processing of a trimodal Al-based nano-composite. Metall. Mater. Trans. A 2015, 46, 5877–5886. [Google Scholar] [CrossRef]

- Meng, L.; Wang, X.; Hu, X.; Shi, H.; Wu, K. Role of structural parameters on strength-ductility combination of laminated carbon nanotubes/copper composites. Compos. Part A: Appl. Sci. Manuf. 2019, 116, 138–146. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Ma, K.; Fan, G.H.; Zhao, K.; Zhang, J.F.; Xiao, B.L.; Ma, Z.Y. Enhancement of the strength-ductility relationship for carbon nanotube/Al–Cu–Mg nanocomposites by material parameter optimisation. Carbon 2020, 157, 602–613. [Google Scholar] [CrossRef]

- Lei, Y.; Qiu, G.; Hong, L.; Hehao, C.; Hanyue, X.; Nanpu, C. Fabrication and Properties of Dual-Gradient Nanostructured Copper Matrix Composites Reinforced by Silicon Carbide Particles. Powder Metall. Technol. 2016, 34, 428–433. [Google Scholar] [CrossRef]

- Wu, C.; Shi, R.; Zhang, J.; Luo, G.; Shen, Q.; Gan, Z.; Liu, J.; Zhang, L. Synthesis of functionally graded AA7075-B4C composite with multi-level gradient structure. Ceram. Int. 2019, 45, 7761–7766. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, Q.; Li, Z.; Xiong, D.-B.; Osovski, S.; Su, Y.; Zhang, D. Strengthening and deformation mechanisms in nanolaminated graphene-Al composite micro-pillars affected by graphene in-plane sizes. Int. J. Plast. 2019, 116, 265–279. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Fritz, R.; Kiener, D.; Zhang, J.Y.; Liu, G.; Kolednik, O.; Pippan, R.; Sun, J. Fracture behavior and deformation mechanisms in nanolaminated crystalline/amorphous micro-cantilevers. Acta Mater. 2019, 180, 73–83. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Juster, A.L.; Latourte, F.J.; Loh, O.Y.; Gregoire, D.; Zavattieri, P.D. Tablet-level origin of toughening in abalone shells and translation to synthetic composite materials. Nat. Commun. 2011, 2, 173. [Google Scholar] [CrossRef] [PubMed]

- Shi, P.; Li, R.; Li, Y.; Wen, Y.; Zhong, Y.; Ren, W.; Shen, Z.; Zheng, T.; Peng, J.; Liang, X.J.S. Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys. Science 2021, 373, 912–918. [Google Scholar] [CrossRef]

- Liu, L.; Yu, Q.; Wang, Z.; Ell, J.; Huang, M.X.; Ritchie, R.O. Making ultrastrong steel tough by grain-boundary delamination. Science 2020, eaba9413. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, G.; Tan, Z.; Zhao, H.; Xu, Y.; Xiong, D.; Li, Z. Bioinspired multiscale Al2O3-rGO/Al laminated composites with superior mechanical properties. Compos. Part B Eng. 2021, 217, 108916. [Google Scholar] [CrossRef]

- Cao, M.; Xiong, D.-B.; Tan, Z.; Ji, G.; Amin-Ahmadi, B.; Guo, Q.; Fan, G.; Guo, C.; Li, Z.; Zhang, D. Aligning graphene in bulk copper: Nacre-inspired nanolaminated architecture coupled with in-situ processing for enhanced mechanical properties and high electrical conductivity. Carbon 2017, 117, 65–74. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, D.-B.; Tan, Z.; Fan, G.; Guo, Q.; Su, Y.; Li, Z.; Zhang, D. Enhanced mechanical properties and high electrical conductivity in multiwalled carbon nanotubes reinforced copper matrix nanolaminated composites. Mater. Sci. Eng. A 2018, 729, 452–457. [Google Scholar] [CrossRef]

- Niu, G.; Zurob, H.S.; Misra, R.D.K.; Tang, Q.; Zhang, Z.; Nguyen, M.-T.; Wang, L.; Wu, H.; Zou, Y. Superior fracture toughness in a high-strength austenitic steel with heterogeneous lamellar microstructure. Acta Mater. 2022, 226, 117642. [Google Scholar] [CrossRef]

- Sadeghi, B.; Abbasi, H.; Atapour, M.; Shafiee, S.; Cavaliere, P.; Marfavi, Z. Friction stir spot welding of TiO2 nanoparticle-reinforced interstitial free steel. J. Mater. Sci. 2020, 55, 12458–12475. [Google Scholar] [CrossRef]

- Balog, M.; Orovcik, L.; Nagy, S.; Krizik, P.; Nosko, M.; Oslanec, P.; Zifcak, P. To what extent does friction-stir welding deteriorate the properties of powder metallurgy Al? J. Mater. Res. Technol. 2020, 9, 6733–6744. [Google Scholar] [CrossRef]

- Sadeghi, B.; Shamanian, M.; Ashrafizadeh, F.; Cavaliere, P. FSW of bimodal reinforced Al-based composites produced via spark plasma sintering. Int. J. Mater. Res. 2017, 108, 1045–1054. [Google Scholar] [CrossRef]

- Freeman, R. Friction Stir Welding: The Next Decade. In Proceedings of the 27th Advanced Aerospace Materials and Processes (AeroMat) Conference and Exposition, 23–26 May 2016. [Google Scholar]

- Tang, S.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z. Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review. Adv. Eng. Mater. 2021, 23, 2100053. [Google Scholar] [CrossRef]

- Dadkhah, M.; Mosallanejad, M.H.; Iuliano, L.; Saboori, A. A Comprehensive Overview on the Latest Progress in the Additive Manufacturing of Metal Matrix Composites: Potential, Challenges, and Feasible Solutions. Acta Metall. Sin. (Engl. Lett. ) 2021. [Google Scholar] [CrossRef]

- Tang, S.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z.J.A.E.M. Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review. Adv. Eng. Mater. 2021, 23, 2100053. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, J.; Zhu, R.; Li, S. Effects of strain gradient on the mechanical behaviors of nanocrystalline materials. Mater. Sci. Eng. A 2009, 507, 42–49. [Google Scholar] [CrossRef]

- Hao, S.; Cui, L.; Jiang, D.; Han, X.; Ren, Y.; Jiang, J.; Liu, Y.; Liu, Z.; Mao, S.; Wang, Y.J.S. A transforming metal nanocomposite with large elastic strain, low modulus, and high strength. Science 2013, 339, 1191–1194. [Google Scholar] [CrossRef]

- Zhang, S.; van Dijk, N.; van der Zwaag, S.J.A.M.S. A review of self-healing metals: Fundamentals, design principles and performance. Acta Metall. Sin. 2020, 33, 1167–1179. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Characterization of hybrid aluminum matrix composites for advanced applications – A review. J. Mater. Res. Technol. 2016, 5, 159–169. [Google Scholar] [CrossRef]

- Saheb, N.; Qadir, N.; Siddiqui, M.; Arif, A.; Akhtar, S.; Al-Aqeeli, N. Characterization of Nanoreinforcement Dispersion in Inorganic Nanocomposites: A Review. Materials 2014, 7, 4148–4181. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).