Submitted:

26 July 2023

Posted:

27 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

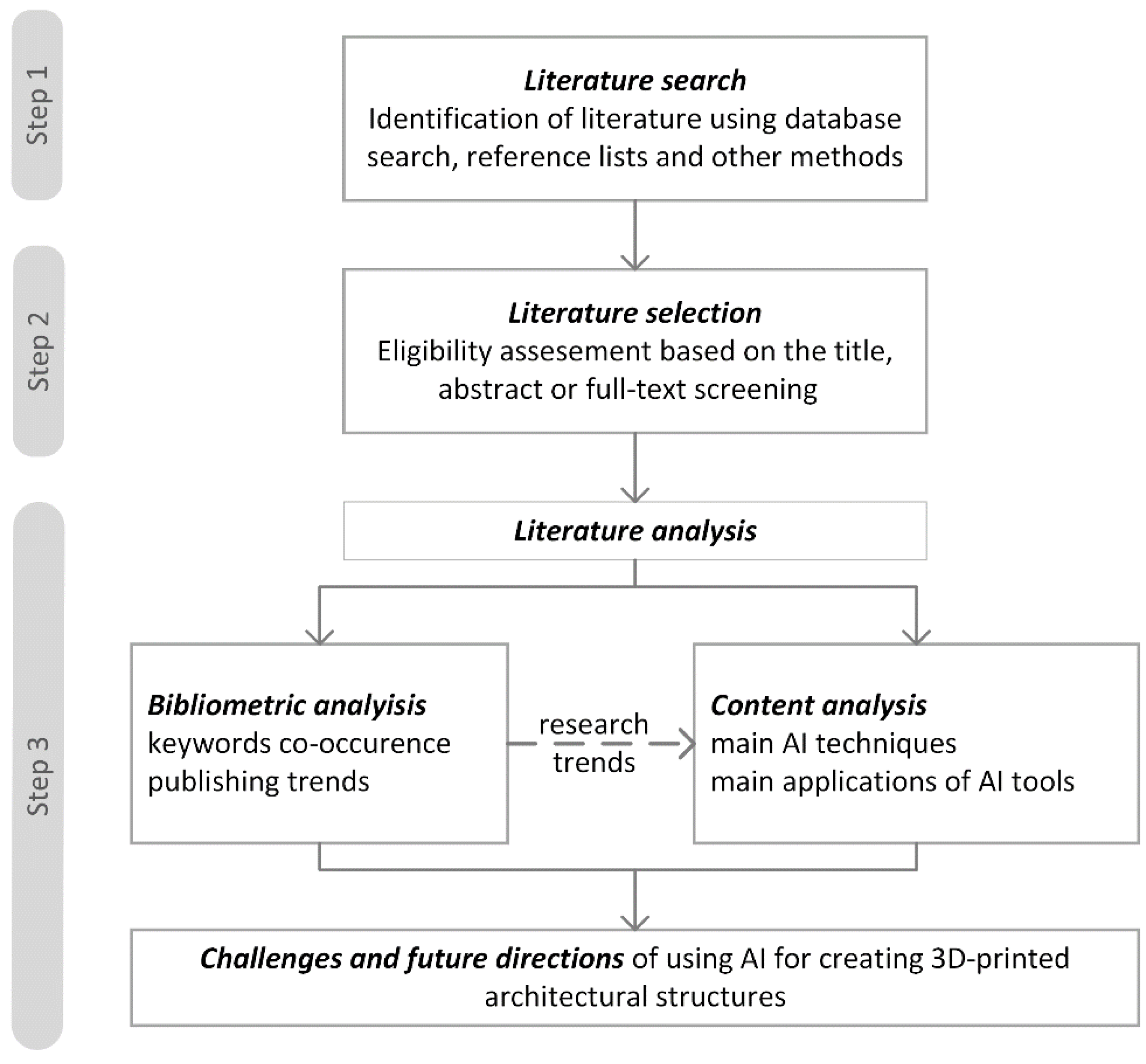

2. Methodology

2.1. Forming Literature Sample

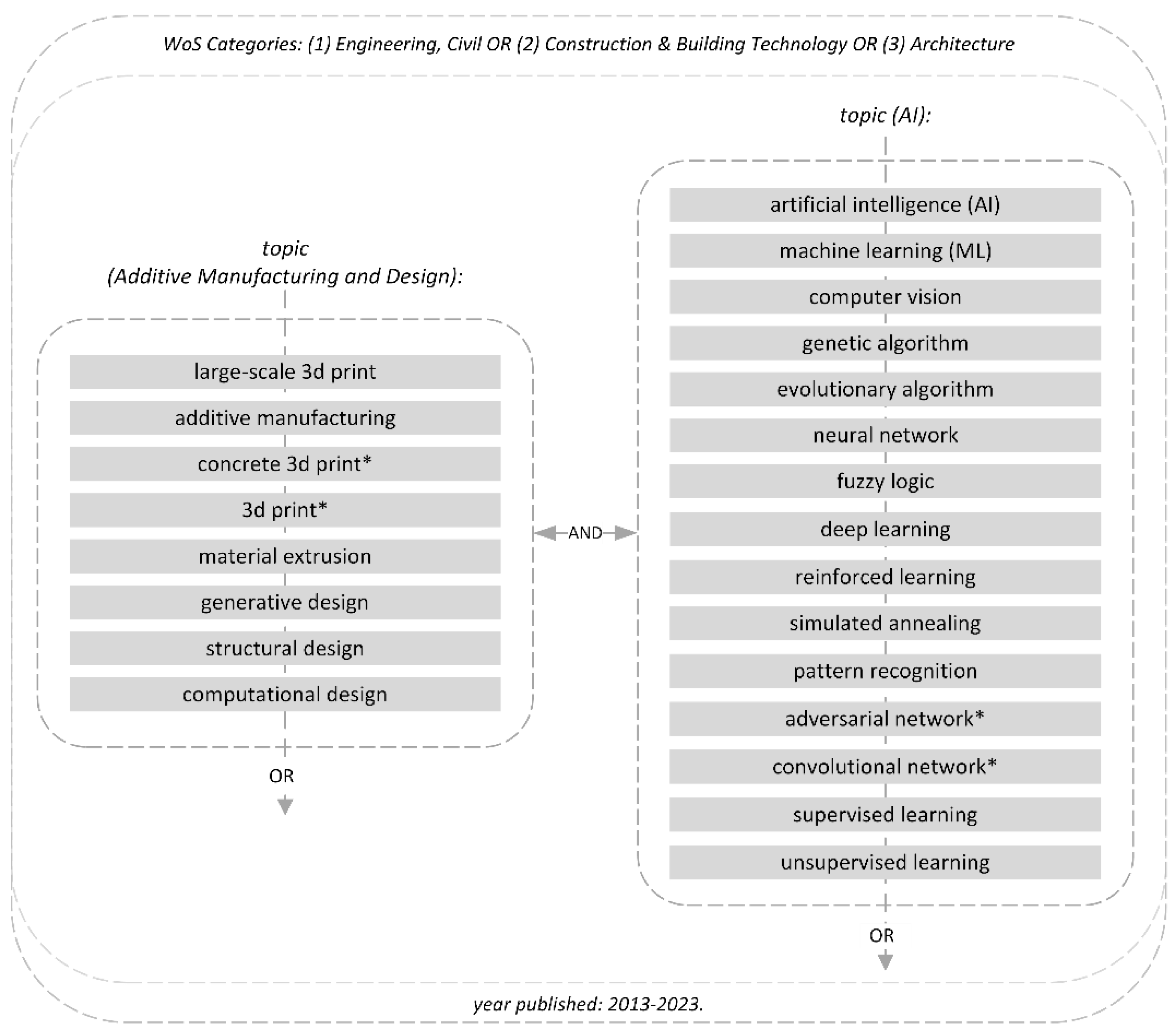

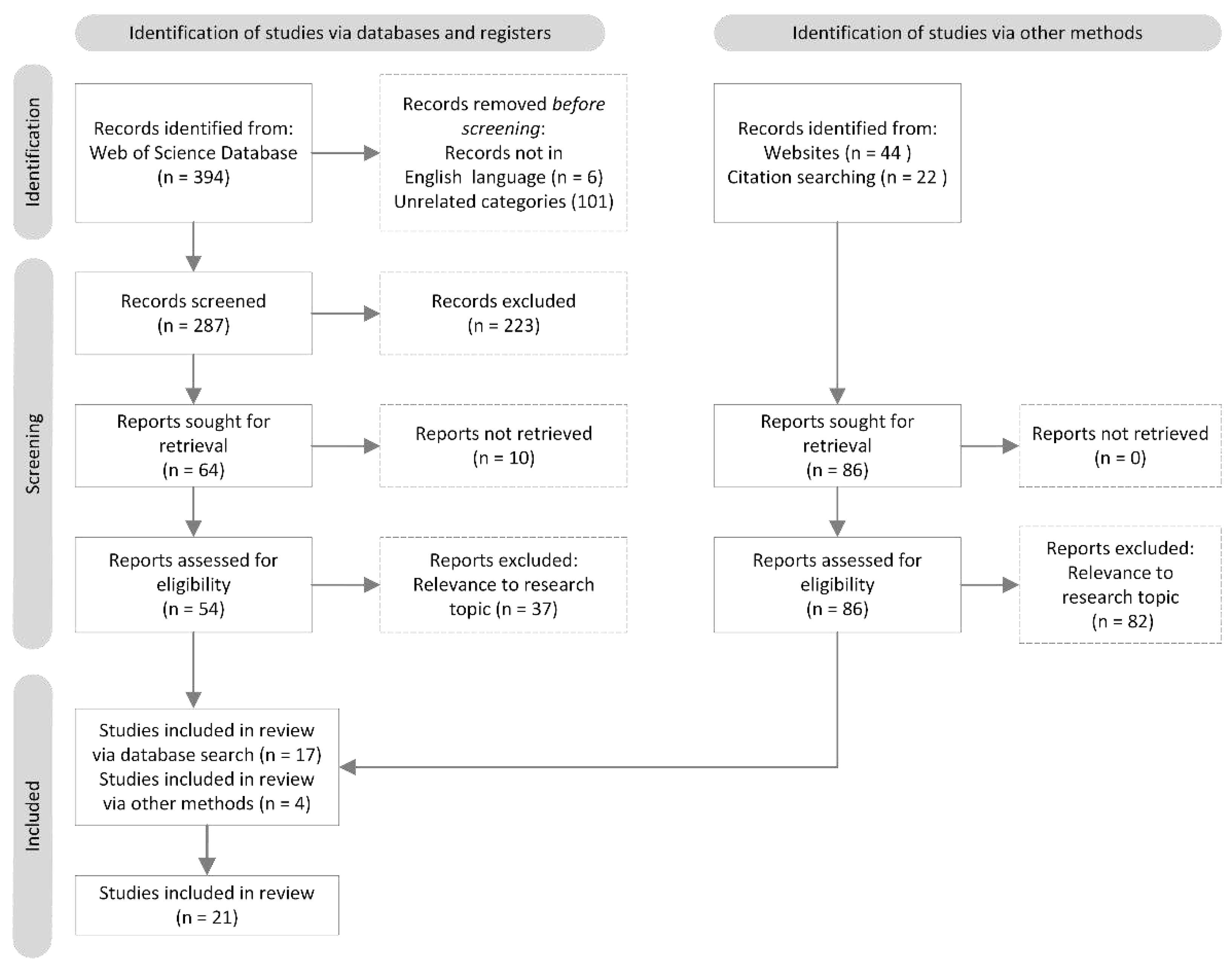

2.1.1. Literature Search

2.1.2. Literature Selection

2.2. Analyzing Literature Sample

2.2.1. Bibliometric Analysis

2.2.2. Content Analysis

3. Results

3.1. Bibliometric Analysis

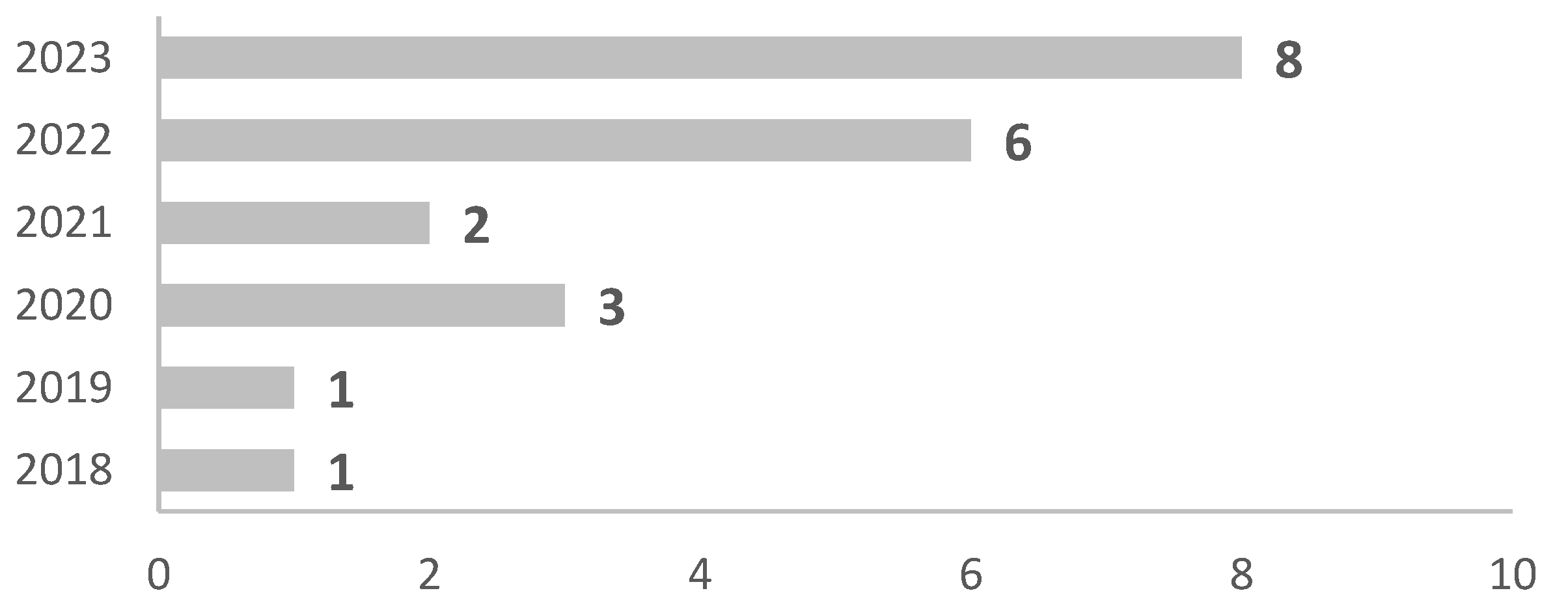

3.1.1. Publishing trends

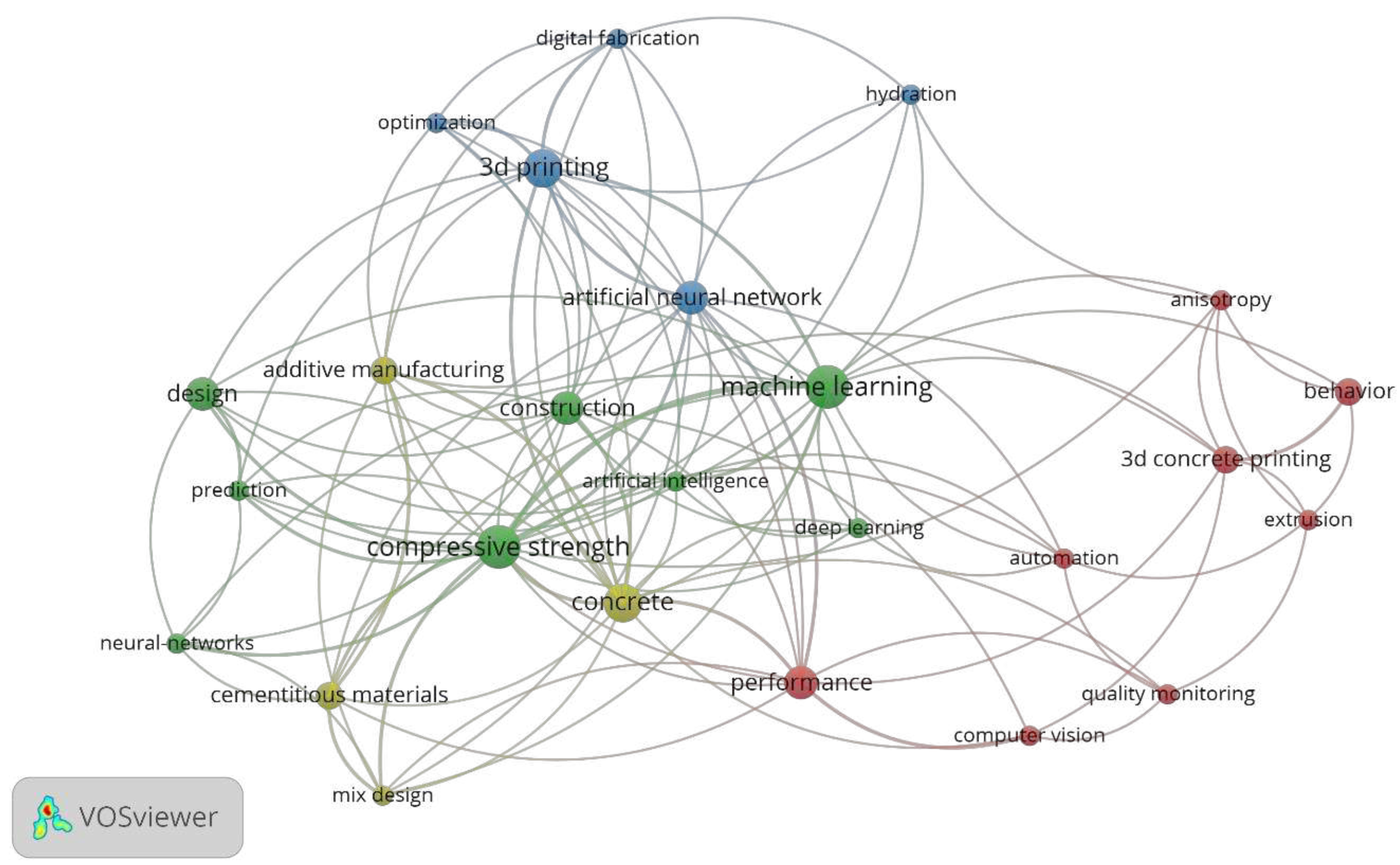

3.1.2. Keywords Analysis

3.2. Content Analysis

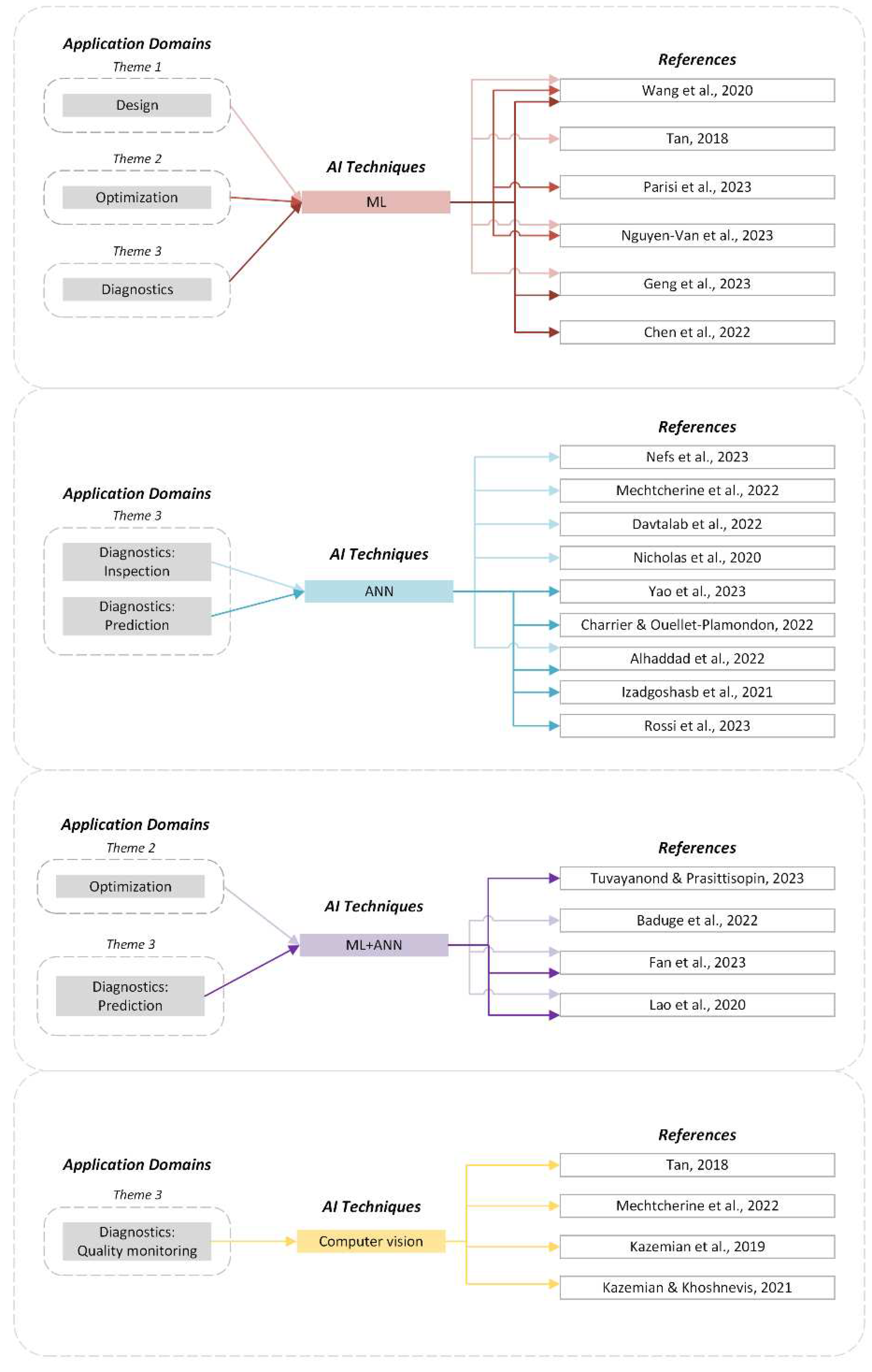

3.2.1. Overview of Techniques

3.2.2. Applications

- Theme 1. AI-driven design of 3DP architectural structures

- Theme 2. AI-driven optimization of 3DP architectural structures

- Theme 3. AI-driven diagnostics for 3DP architectural structures

4. Discussion and Conclusion

4.1. Results Interpretation and Implications

4.2. Research Limitations

4.3. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- The Routledge Companion to Artificial Intelligence in Architecture; Basu, P., As, I., Eds.; 1st Edition.; Routledge: Oxfordshire, UK, 2021; ISBN 978-0-367-82425-9.

- Bernstein, P. Machine Learning: Architecture in the Age of Artificial Intelligence; RIBA Publishing: London, UK, 2022; ISBN 978-1-00-060068-1.

- Campo, M. del Neural Architecture: Design and Artificial Intelligence; G - Reference,Information and Interdisciplinary Subjects Series; 1st ed.; Applied Research & Design: San Francisco, USA, 2022; ISBN 978-1-951541-68-2.

- Chaillou, S. Artificial Intelligence and Architecture: From Research to Practice; Birkhauser Verlag GmbH: Basel [Switzerland] ; Boston [MA], 2022; ISBN 978-3-0356-2400-7.

- Leach, N. Architecture in the Age of Artificial Intelligence: An Introduction to AI for Architects; Architecture in the Age of Art; 1st ed.; Bloomsbury Academic: London, UK, 2022; ISBN 978-1-350-16552-6.

- Brell-Cokcan, S.; Braumann, J. Rob|Arch 2012: Robotic Fabrication in Architecture, Art and Design; SpringerLink : Bücher; Springer Vienna, 2013; ISBN 978-3-7091-1465-0.

- Claypool, M.; Retsin, G.; Jimenez, M.; Garcia, M.J.; Soler, V. Robotic Building: Architecture in the Age of Automation; DETAIL Special; Detail Business Information GmbH, 2019; ISBN 978-3-95553-424-0.

- Habibi, S. Building Automation and Digital Technologies; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier Science: Amsterdam, Netherlands, 2022; ISBN 978-0-12-822129-7.

- Jebelli, H.; Habibnezhad, M.; Shayesteh, S.; Asadi, S.; Lee, S.H. Automation and Robotics in the Architecture, Engineering, and Construction Industry; Springer International Publishing: Cham, Switzerland, 2022; ISBN 978-3-030-77163-8.

- Raphael, B. Construction and Building Automation: From Concepts to Implementation; 1st Edition.; Routledge: Oxfordshire, UK, 2022; ISBN 978-1-00-316562-0.

- Willmann, J.; Block, P.; Hutter, M.; Byrne, K.; Schork, T. Robotic Fabrication in Architecture, Art and Design 2018: Foreword by Sigrid Brell-Çokcan and Johannes Braumann, Association for Robots in Architecture; Springer International Publishing, 2018; ISBN 978-3-319-92294-2.

- Architectural Intelligence: Selected Papers from the 1st International Conference on Computational Design and Robotic Fabrication (CDRF 2019); Yuan, P.F., Xie, Y.M., Leach, N., Yao, J., Wang, X., Eds.; Springer: Singapore, 2020; ISBN 9789811565687.

- van Woensel, R. Printing Architecture: An Overview of Existing and Promising Additive Manufacturing Methods and Their Application in the Building Industry. The International Journal of the Constructed Environment 2018, 9. https://doi.org/10.18848/2154-8587/CGP/v09i01/57-81. [CrossRef]

- Ali, Md.H.; Issayev, G.; Shehab, E.; Sarfraz, S. A Critical Review of 3D Printing and Digital Manufacturing in Construction Engineering. RPJ 2022, pp.1312-1324. https://doi.org/10.1108/RPJ-07-2021-0160. [CrossRef]

- Ning, X.; Liu, T.; Wu, C.; Wang, C. 3D Printing in Construction: Current Status, Implementation Hindrances, and Development Agenda. Adv. Civ. Eng. 2021, 2021, 1–12. https://doi.org/10.1155/2021/6665333. [CrossRef]

- Al Jassmi, H.; Al Najjar, F.; Mourad, A.-H.I. Large-Scale 3D Printing: The Way Forward. IOP Conf. Ser.: Mater. Sci. Eng. 2018, 324, 012088. https://doi.org/10.1088/1757-899X/324/1/012088. [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in Construction-Scale Additive Manufacturing Processes. Autom. Constr. 2012, 21, 262–268. https://doi.org/10.1016/j.autcon.2011.06.010. [CrossRef]

- Bosch-Sijtsema, P.; Claeson-Jonsson, C.; Johansson, M.; Roupe, M. The Hype Factor of Digital Technologies in AEC. CI 2021, 21, 899–916. https://doi.org/10.1108/CI-01-2020-0002. [CrossRef]

- Malaga-Chuquitaype, C. Machine Learning in Structural Design: An Opinionated Review. Front. Built Environ. 2022, 8. https://doi.org/10.3389/fbuil.2022.815717. [CrossRef]

- Sun, H.; Burton, H.; Huang, H. Machine Learning Applications for Building Structural Design and Performance Assessment: State-of-the-Art Review. J. Build. Eng. 2021, 33. https://doi.org/10.1016/j.jobe.2020.101816. [CrossRef]

- Geng, S.; Luo, Q.; Liu, K.; Li, Y.; Hou, Y.; Long, W. Research Status and Prospect of Machine Learning in Construction 3D Printing. Case Stud. Constr. Mater. 2023, 18. https://doi.org/10.1016/j.cscm.2023.e01952. [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A Review on Machine Learning in 3D Printing: Applications, Potential, and Challenges. Artif Intell Rev 2021, 54, 63–94. https://doi.org/10.1007/s10462-020-09876-9. [CrossRef]

- Akhavan, J.; Lyu, J.; Manoochehri, S. A Deep Learning Solution for Real-Time Quality Assessment and Control in Additive Manufacturing Using Point Cloud Data. J Intell Manuf 2023. https://doi.org/10.1007/s10845-023-02121-4. [CrossRef]

- Bhatt, P.M.; Malhan, R.K.; Rajendran, P.; Shah, B.C.; Thakar, S.; Yoon, Y.J.; Gupta, S.K. Image-Based Surface Defect Detection Using Deep Learning: A Review. J. Comput. Inf. Sci. Eng. 2021, 21. https://doi.org/10.1115/1.4049535. [CrossRef]

- Duman, B.; Özsoy, K. A deep learning-based approach for defect detection in powder bed fusion additive manufacturing using transfer learning. J. Fac. Eng. Archit. Gazi Uni. 2022, 37, 361–375. https://doi.org/10.17341/GAZIMMFD.870436. [CrossRef]

- Ho, S.; Zhang, W.; Young, W.; Buchholz, M.; Jufout, S.A.; Dajani, K.; Bian, L.; Mozumdar, M. DLAM: Deep Learning Based Real-Time Porosity Prediction for Additive Manufacturing Using Thermal Images of the Melt Pool. IEEE Access 2021, 9, 115100–115114. https://doi.org/10.1109/ACCESS.2021.3105362. [CrossRef]

- Khanzadeh, M.; Chowdhury, S.; Marufuzzaman, M.; Tschopp, M.A.; Bian, L. Porosity Prediction: Supervised-Learning of Thermal History for Direct Laser Deposition. J Manuf Syst 2018, 47, 69–82. https://doi.org/10.1016/j.jmsy.2018.04.001. [CrossRef]

- Assaad, R.H.; El-Adaway, I.H.; Hastak, M.; Needy, K.L. Smart and Emerging Technologies: Shaping the Future of the Industry and Offsite Construction. In Proceedings of the Computing in Civil Engineering 2021 - Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2021; American Society of Civil Engineers (ASCE), 2021; pp. 787–794.

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review; Second edition.; Sage: Los Angeles, 2016; ISBN 978-1-4739-1245-8.

- Petticrew, M.; Roberts, H. Systematic Reviews in the Social Sciences: A Practical Guide; Wiley, 2008; ISBN 978-1-4051-5014-9.

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLOS Medicine 2009, 6, e1000097. https://doi.org/10.1371/journal.pmed.1000097. [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, n71. https://doi.org/10.1136/bmj.n71. [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for Conducting Systematic Literature Review and Meta-Analysis for Environmental Science Research. MethodsX 2020, 7, 100777. https://doi.org/10.1016/j.mex.2019.100777. [CrossRef]

- Broadus, R.N. Toward a Definition of “Bibliometrics.” Scientometrics 1987, 12, 373–379. https://doi.org/10.1007/BF02016680. [CrossRef]

- Soomro, S.A.; Casakin, H.; Georgiev, G.V. A Systematic Review on FabLab Environments and Creativity: Implications for Design. Buildings 2022, 12, 804. https://doi.org/10.3390/buildings12060804. [CrossRef]

- Moral-Muñoz, J.A.; Herrera-Viedma, E.; Santisteban-Espejo, A.; Cobo, M.J. Software Tools for Conducting Bibliometric Analysis in Science: An up-to-Date Review. EPI 2020, 29. https://doi.org/10.3145/epi.2020.ene.03. [CrossRef]

- Chen, Q.; García de Soto, B.; Adey, B.T. Construction Automation: Research Areas, Industry Concerns and Suggestions for Advancement. Autom. Constr 2018, 94, 22–38. https://doi.org/10.1016/j.autcon.2018.05.028. [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent Advancements of Robotics in Construction. Autom. Constr. 2022, 144. https://doi.org/10.1016/j.autcon.2022.104591. [CrossRef]

- Rossi, G.; Chiujdea, R.; Hochegger, L.; Lharchi, A.; Harding, J.; Nicholas, P.; Tamke, M.; Thomsen, M. Statistically Modelling the Curing of Cellulose-Based 3d Printed Components: Methods for Material Dataset Composition, Augmentation and Encoding. In Proceedings of the RLUK- Research Libraries UK; Gengnagel, C., Baverel, O., Betti, G., Popescu, M., Thomsen, M., Wurm, J., Eds.; 2023; pp. 487–500.

- Tan, K. The Framework of Combining Artificial Intelligence and Construction 3D Printing in Civil Engineering. In Proceedings of the MATEC Web of Conferences; Lim, C., Zhu, X., Eds.; EDP Sciences: Chengdu, China, 2018; Vol. 206.

- Kazemian, A.; Khoshnevis, B. Real-Time Extrusion Quality Monitoring Techniques for Construction 3D Printing. Constr Build Mater. 2021, 303. https://doi.org/10.1016/j.conbuildmat.2021.124520. [CrossRef]

- Fan, D.; Zhu, J.; Fan, M.; Lu, J.; Chu, S.; Dong, E.; Yu, R. Intelligent Design and Manufacturing of Ultra-High Performance Concrete (UHPC)-A Review. Constr Build Mater. 2023, 385. https://doi.org/10.1016/j.conbuildmat.2023.131495. [CrossRef]

- Nefs, K.; Menkovski, V.; Bos, F.; Suiker, A.; Salet, T. Automated Image Segmentation of 3D Printed Fibrous Composite Micro-Structures Using a Neural Network. Constr Build Mater. 2023, 365. https://doi.org/10.1016/j.conbuildmat.2022.130099. [CrossRef]

- Yao, X.; Lyu, X.; Sun, J.; Wang, B.; Wang, Y.; Yang, M.; Wei, Y.; Elchalakani, M.; Li, D.; Wang, X. AI-Based Performance Prediction for 3D-Printed Concrete Considering Anisotropy and Steam Curing Condition. Constr Build Mater. 2023, 375. https://doi.org/10.1016/j.conbuildmat.2023.130898. [CrossRef]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. https://doi.org/10.3390/buildings12091319. [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. https://doi.org/10.1007/s11192-009-0146-3. [CrossRef]

- Mechtcherine, V.; van Tittelboom, K.; Kazemian, A.; Kreiger, E.; Nematollahi, B.; Nerella, V.; Santhanam, M.; de Schutter, G.; Zijl, G.; Lowke, D.; et al. A Roadmap for Quality Control of Hardening and Hardened Printed Concrete. Cem. Concr. Res. 2022, 157. https://doi.org/10.1016/j.cemconres.2022.106800. [CrossRef]

- Nguyen-Van, V.; Li, S.; Liu, J.; Nguyen, K.; Tran, P. Modelling of 3D Concrete Printing Process: A Perspective on Material and Structural Simulations. Addit. Manuf. 2023, 61, 103333. https://doi.org/10.1016/j.addma.2022.103333. [CrossRef]

- Rebala, G.; Ravi, A.; Churiwala, S. Machine Learning Definition and Basics. In An Introduction to Machine Learning; Springer International Publishing: Cham, 2019; pp. 1–17 ISBN 978-3-030-15728-9.

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN COMPUT. SCI. 2021, 2, 160. https://doi.org/10.1007/s42979-021-00592-x. [CrossRef]

- Deng, L. Deep Learning: Methods and Applications. Found. Trends Signal Process. 2014, 7, 197–387. https://doi.org/10.1561/2000000039. [CrossRef]

- Guresen, E.; Kayakutlu, G. Definition of Artificial Neural Networks with Comparison to Other Networks. Procedia Comput. Sci. 2011, 3, 426–433. https://doi.org/10.1016/j.procs.2010.12.071. [CrossRef]

- Krenker, A.; Bester, J.; Kos, A. Introduction to the Artificial Neural Networks. In Artificial Neural Networks - Methodological Advances and Biomedical Applications; Suzuki, K., Ed.; InTech, 2011 ISBN 978-953-307-243-2.

- Computer Vision and Applications: A Guide for Students and Practitioners; Jähne, B., Haussecker, H., Eds.; Academic Press: San Diego, 2000; ISBN 978-0-12-379777-3.

- Chen, Y.; Zhang, Y.; Pang, B.; Wang, D.; Liu, Z.; Liu, G. Steel Fiber Orientational Distribution and Effects on 3D Printed Concrete with Coarse Aggregate. Mater Struct 2022, 55. https://doi.org/10.1617/s11527-022-01943-7. [CrossRef]

- Parisi, F.; Sangiorgio, V.; Parisi, N.; Mangini, A.; Fanti, M.; Adam, J. A New Concept for Large Additive Manufacturing in Construction: Tower Crane-Based 3D Printing Controlled by Deep Reinforcement Learning. Constr. Innov. 2023. https://doi.org/10.1108/CI-10-2022-0278. [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. https://doi.org/10.3390/buildings10110204. [CrossRef]

- Alhaddad, W.; He, M.; Halabi, Y.; Almajhali, K. Optimizing the Material and Printing Parameters of the Additively Manufactured Fiber-Reinforced Polymer Composites Using an Artificial Neural Network Model and Artificial Bee Colony Algorithm. Structures 2022, 46, 1781–1795. https://doi.org/10.1016/j.istruc.2022.10.134. [CrossRef]

- Charrier, M.; Ouellet-Plamondon, C. Artificial Neural Network for the Prediction of the Fresh Properties of Cementitious Materials. Cem. Concr. Res. 2022, 156. https://doi.org/10.1016/j.cemconres.2022.106761. [CrossRef]

- Davtalab, O.; Kazemian, A.; Yuan, X.; Khoshnevis, B. Automated Inspection in Robotic Additive Manufacturing Using Deep Learning for Layer Deformation Detection. J Intell Manuf 2022, 33, 771–784. https://doi.org/10.1007/s10845-020-01684-w. [CrossRef]

- Izadgoshasb, H.; Kandiri, A.; Shakor, P.; Laghi, V.; Gasparini, G. Predicting Compressive Strength of 3D Printed Mortar in Structural Members Using Machine Learning. Appl. Sci. 2021, 11, 10826. https://doi.org/10.3390/app112210826. [CrossRef]

- Nicholas, P.; Rossi, G.; Williams, E.; Bennett, M.; Schork, T. Integrating Real-Time Multi-Resolution Scanning and Machine Learning for Conformal Robotic 3D Printing in Architecture. Int. J. Archit. Comput. 2020, 18, 371–384. https://doi.org/10.1177/1478077120948203. [CrossRef]

- Baduge, S.; Thilakarathna, S.; Perera, J.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial Intelligence and Smart Vision for Building and Construction 4.0: Machine and Deep Learning Methods and Applications. Autom. Constr 2022, 141. https://doi.org/10.1016/j.autcon.2022.104440. [CrossRef]

- Lao, W.; Li, M.; Wong, T.N.; Tan, M.J.; Tjahjowidodo, T. Improving Surface Finish Quality in Extrusion-Based 3D Concrete Printing Using Machine Learning-Based Extrudate Geometry Control. Virtual Phys. Prototyp. 2020, 15, 178–193. https://doi.org/10.1080/17452759.2020.1713580. [CrossRef]

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13. https://doi.org/10.3390/buildings13020429. [CrossRef]

- Kazemian, A.; Yuan, X.; Davtalab, O.; Khoshnevis, B. Computer Vision for Real-Time Extrusion Quality Monitoring and Control in Robotic Construction. Autom. Constr. 2019, 101, 92–98. https://doi.org/10.1016/j.autcon.2019.01.022. [CrossRef]

- Xu, Y.; Zhang, H. Convergence of Deep Convolutional Neural Networks. Neural Netw 2022, 153, 553–563. https://doi.org/10.1016/j.neunet.2022.06.031. [CrossRef]

- Creswell, A.; White, T.; Dumoulin, V.; Arulkumaran, K.; Sengupta, B.; Bharath, A.A. Generative Adversarial Networks: An Overview. IEEE Signal Process. Mag. 2018, 35, 53–65. https://doi.org/10.1109/MSP.2017.2765202. [CrossRef]

| Source | Search method | Search criteria |

|---|---|---|

| Web of Science | Keyword method |

|

| Online repositories Google Scholar |

Reference list search Internet search |

| Inclusion criteria | Value |

|---|---|

| Papers belong to research categories unrelated to construction industry | Exclude |

| The paper is in the English language | Include |

| The title includes at least one searched keyword | Include |

| The abstract includes at least one searched keyword from each topic | Include |

| An abstract is relevant to the research question | Include |

| Papers that are not accessible in full text | Exclude |

| Full text is relevant to the research question | Include |

| Journal | No. of articles | IF (2022) |

|---|---|---|

| Construction and Building Materials | 4 | 7.4 |

| Cement and Concrete Research | 2 | 11.4 |

| Buildings | 2 | 3.8 |

| Automation in Construction | 2 | 10.3 |

| Additive Manufacturing | 1 | 11.63 |

| Virtual and Physical Prototyping | 1 | 10.96 |

| Journal of Intelligent Manufacturing | 1 | 8.3 |

| Case Studies in Construction Materials | 1 | 6.2 |

| Structures | 1 | 4.1 |

| Materials and Structures | 1 | 3.8 |

| Applied Sciences | 1 | 2.7 |

| International Journal of Architectural Computing | 1 | 1.7 |

| Construction Innovation | 1 | - |

| Keyword | No. occurrences | Link-strength |

|---|---|---|

| compressive strength | 6 | 28 |

| concrete | 5 | 22 |

| machine learning | 6 | 21 |

| 3d printing | 5 | 18 |

| artificial neural networks | 4 | 17 |

| performance | 4 | 15 |

| construction | 4 | 14 |

| additive manufacturing | 3 | 12 |

| cementitious materials | 3 | 11 |

| artificial intelligence | 2 | 11 |

| design | 4 | 10 |

| mix design | 2 | 10 |

| prediction | 2 | 10 |

| No. | Theme topic | Representative keywords |

|---|---|---|

| 1 | AI-driven design of 3DP architectural structures |

Design Construction Machine learning Neural networks Deep learning |

| 2 | AI-driven optimization of 3DP architectural structures |

Optimization Digital fabrication 3D printing Artificial neural networks Concrete Performance |

| 3 | AI-driven diagnostics of 3DP architectural structures |

Computer vision Quality monitoring Automation Prediction Behavior |

| Applications | AI techniques | Main challenges and conclusions |

Author(s) References |

|---|---|---|---|

| Design for topology analysis of prefabricated elements | ML | Time consuming preparations of topology analysis | Wang et al. [57] |

| Design automation for 3DP | ML | AI can help establish decision making models, provide various alternatives, compare, and judge various schemes to achieve the maximum benefits | Tan [40] |

| Conceptual design and design optimization | ML, ANN | (1) Small amount of research can be found on the topic of Design for Additive Manufacturing (DfAM) for construction (2) The research which was conducted has not been implemented in the building industry |

Tuvayanond & Prasittisopin [65] |

| Applications | AI techniques | Main challenges and conclusions |

Author(s) References |

|---|---|---|---|

| Printing process optimization through model segmentation and extruder toolpath optimization | ANN | Baduge et al. [63] | |

| DLR | The tower crane 3D printer and the extruder can be properly controlled by AI which allows its effective use in the construction industry | Parisi et al. [56] | |

| ML | Intelligent toolpath generation has potential to reduce printing time, therefore optimizing the printing process | Nguyen-Van et al. [48] | |

| Optimization and prediction of the construction tasks | ML | Large amounts of data needed that is not readily available for prediction methods | Wang et al. [57] |

| Material distribution optimization | ML | The application of AI methods and ML algorithms in practice of AM are still limited to checking printability and modularization for prefabrication techniques | Baduge et al. [63] |

| Optimized material mixture design | ML, ANN | Limited research on the micro characteristics of the UHPC material | Fan et al. [42] |

| SL | SWOT analysis of ML applications for construction 3DP is given in the review article | Geng et al. [21] | |

| ML | Handling large amounts of data in the integration process of ML into AM poses challenges | Nguyen-Van et al. [48] | |

| The advantage of ML algorithms is that the failed experimental data can also be used as input for next, and then the algorithms are refined | Tan, 2018 [40] | ||

| Finding a proper nozzle shape for production of designated extrudate geometries | ML, ANN | The proposed approach offers the improvement of the surface quality on structures with different curvatures | Lao et al. [64] |

| Applications | AI techniques | Main challenges and conclusions |

Author(s) References |

|---|---|---|---|

| Prediction of the construction tasks | ML | Large amounts of data needed that is not readily available for prediction methods | Wang et al. [57] |

| Computer vision | The principal applications of state-of-the-art AI methods in 3DP process are identified | Tan [40] | |

| Identification of the micro-structural objects of 3DP fiber-reinforced materials | DL + U-Net module | U-Net is a newly approved neural network in the ML field where the computer is allowed to segment according to the semantics of the images, used for identification of steel fiber reinforcements based on the X-CT images | Chen et al. [55] |

| DCNN + U-Net module | Successful identification of fibers oriented in arbitrary directions, which eliminates the time-consuming task of a human expert to manually annotate these data | Nefs et al. [43] | |

| Geometrical accuracy and fidelity measurements for 3DP elements | DCNN Computer vision Image processing |

The preliminary data imply the great potential of the shown techniques, both for automated inspection and as-built measurements during the 3DCP process | Mechtcherine et al. [47] |

| Quality monitoring and automated inspection systems | DCNN | Quality monitoring and inspection of large-scale AM have not been as extensively researched as printing material design or software issues | Davtalab et al., [60] |

| Real-time quality control and monitoring | Computer vision | The obtained results revealed the high precision and responsiveness of the developed extrusion monitoring system under the experimental conditions | Kazemian et al. [66] |

| The vision-based technique has the highest precision and responsiveness to material variations | Kazemian & Khoshnevis [41] | ||

| Structural performance simulations and predictions for 3DP structures | cGAN | The workflow proves the ability to use an entirely digital proxy dataset to train a Neural Network that would predict the behavior of physically fabricated panels | Nicholas et al. [62] |

| ANN | (1) The accuracy and performance largely depend on the ANN hyperparameters (2) The construction of a suitable ML model with high precision and dependability is laborious and time-consuming |

Yao et al. [44] | |

| Mechanical properties simulations and predictions for material design | ANN | ANNs can predict the fresh properties of cementitious materials according to different admixtures | Charrier & Ouellet-Plamondon [59] |

| The model can be used as a credible guideline for the designers and researchers to manufacture FRP of optimal mechanical properties, which results in saving efforts and financial resources The developed ANN model accurately predicts the UTS of FRP |

Alhaddad et al. [58] | ||

| (1) The difficulty of this method is that the accuracy of the model depends on the number of patterns (2) Limited amount of research on patterns concerning 3DP concrete’s compressive strength |

Izadgoshasb et al. [61] | ||

| ML, ANN | Insufficient predicting accuracy when using common AI models for predicting UHPC properties | Fan et al. [42] | |

| Prediction of printing errors due to curing conditions | ANN | (1) Instead of having to post-process the prediction to extract fabrication-relevant effects, the authors can target their predictive model towards an application scenario by selecting a processed feature extraction approach coupled with simple ML models as opposed to a raw rich data approach and complex models (2) The dataset size is a constant constraint for getting good predictions out of physically generated datasets, even with straightforward statistical “off the shelf” models |

Rossi et al. [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).