Submitted:

19 July 2023

Posted:

19 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

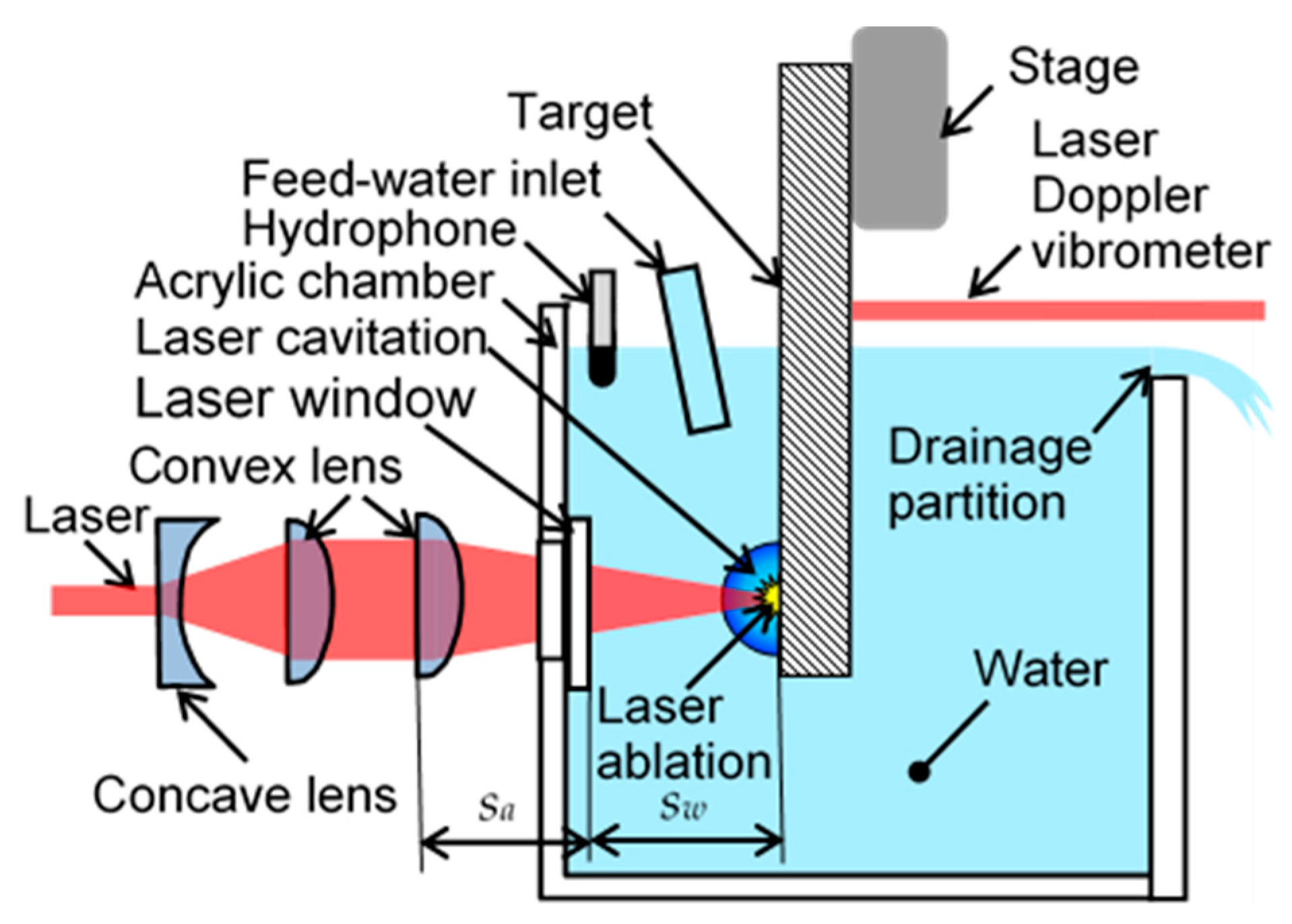

2. Materials and Methods

3. Results

4. Conclusions

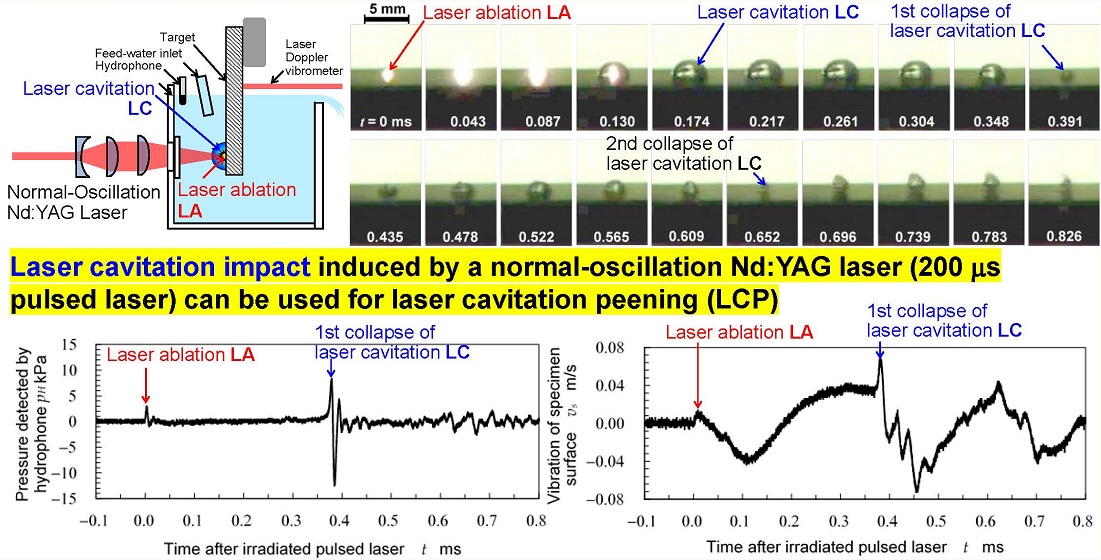

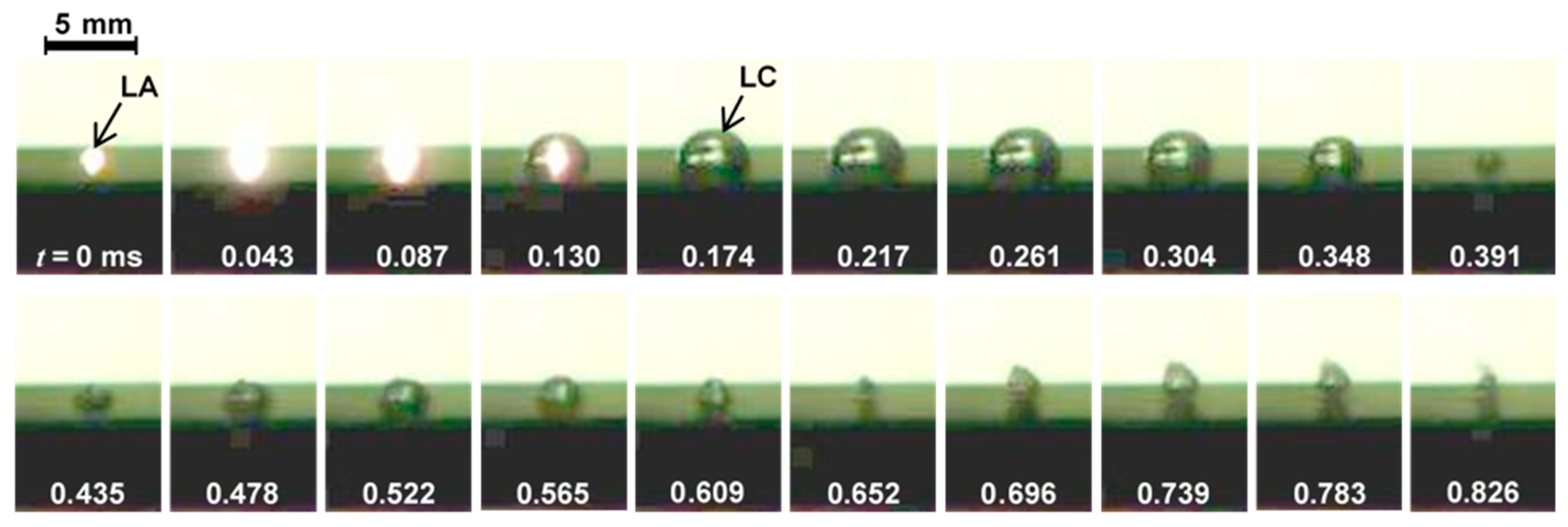

- The laser pulse generated by the normal-oscillation Nd:YAG laser, with a pulse width of about 0.2 ms, produced LC on a black painted surface, similar to that of the Q-switched Nd:YAG laser with a pulse width of several nanoseconds.

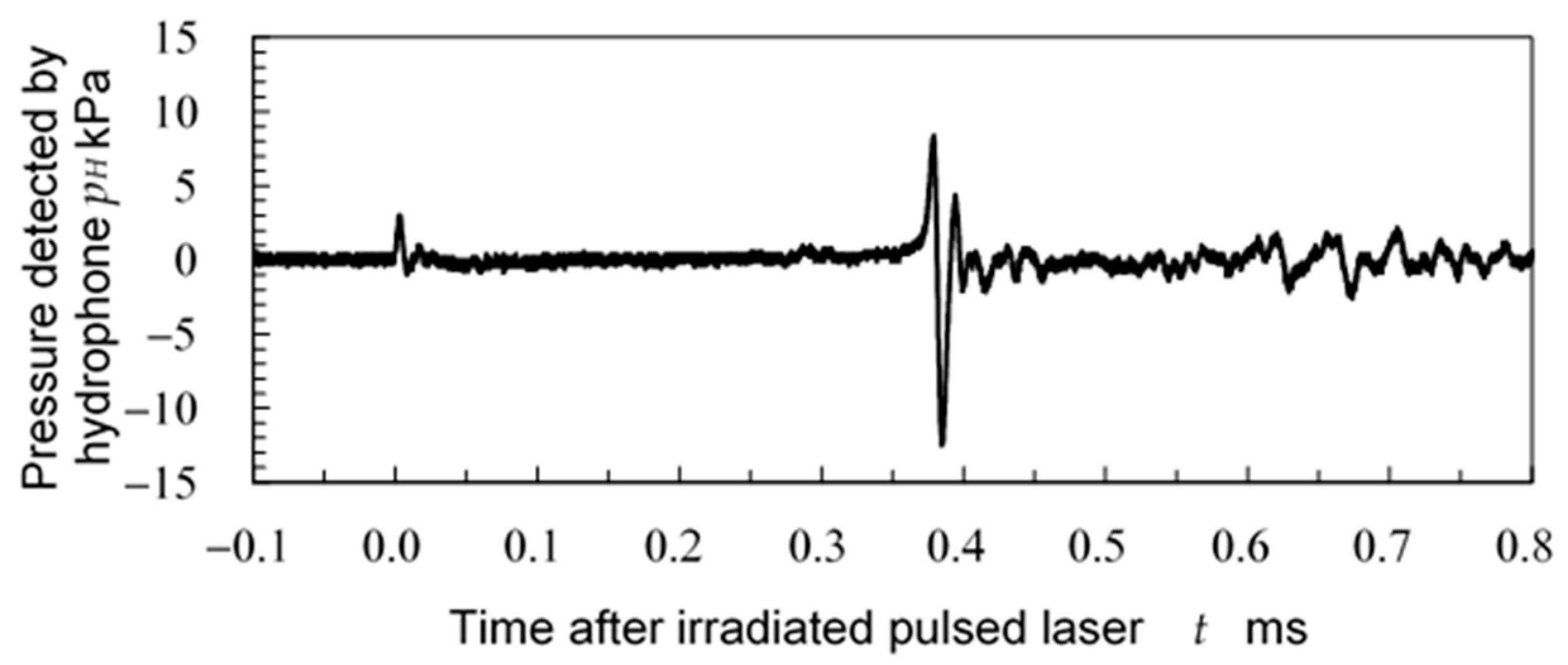

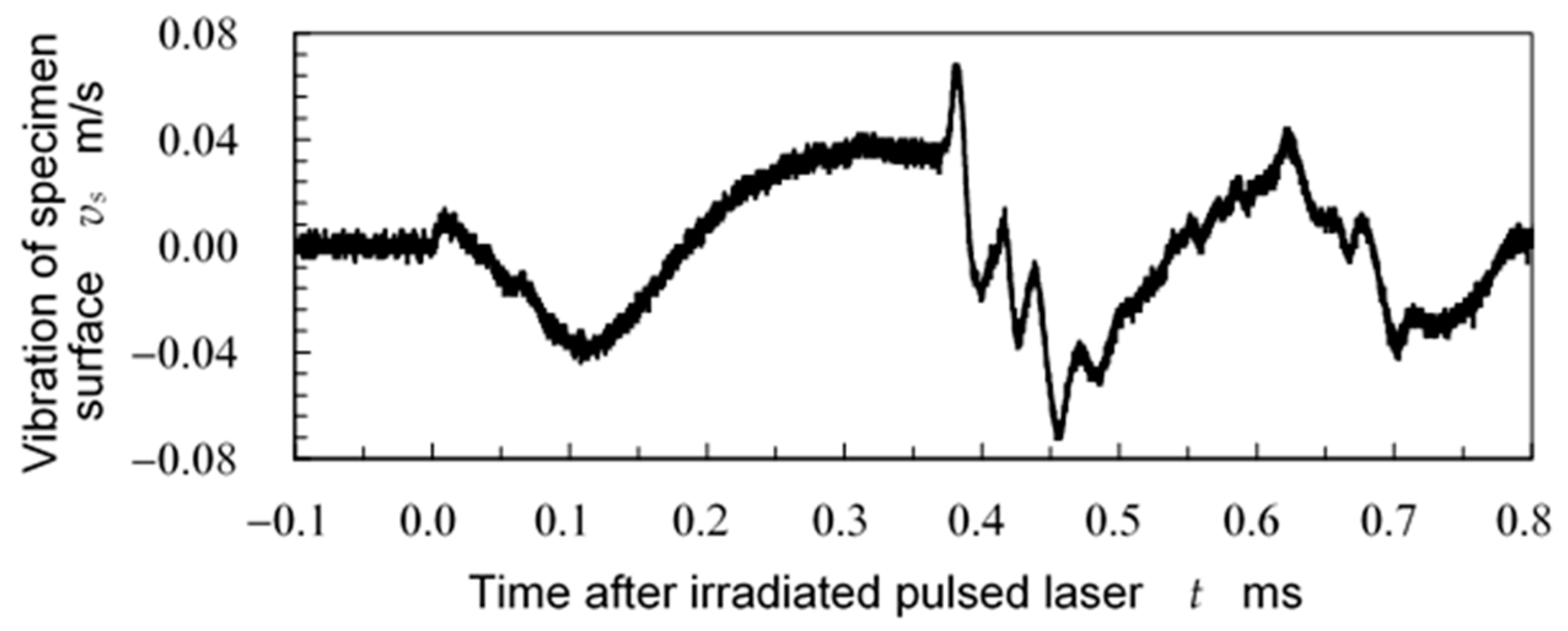

- The first collapse of LC generated the shock pressure wave and impulsive vibration of the target surface, at an intensity 3–4 times larger than LA.

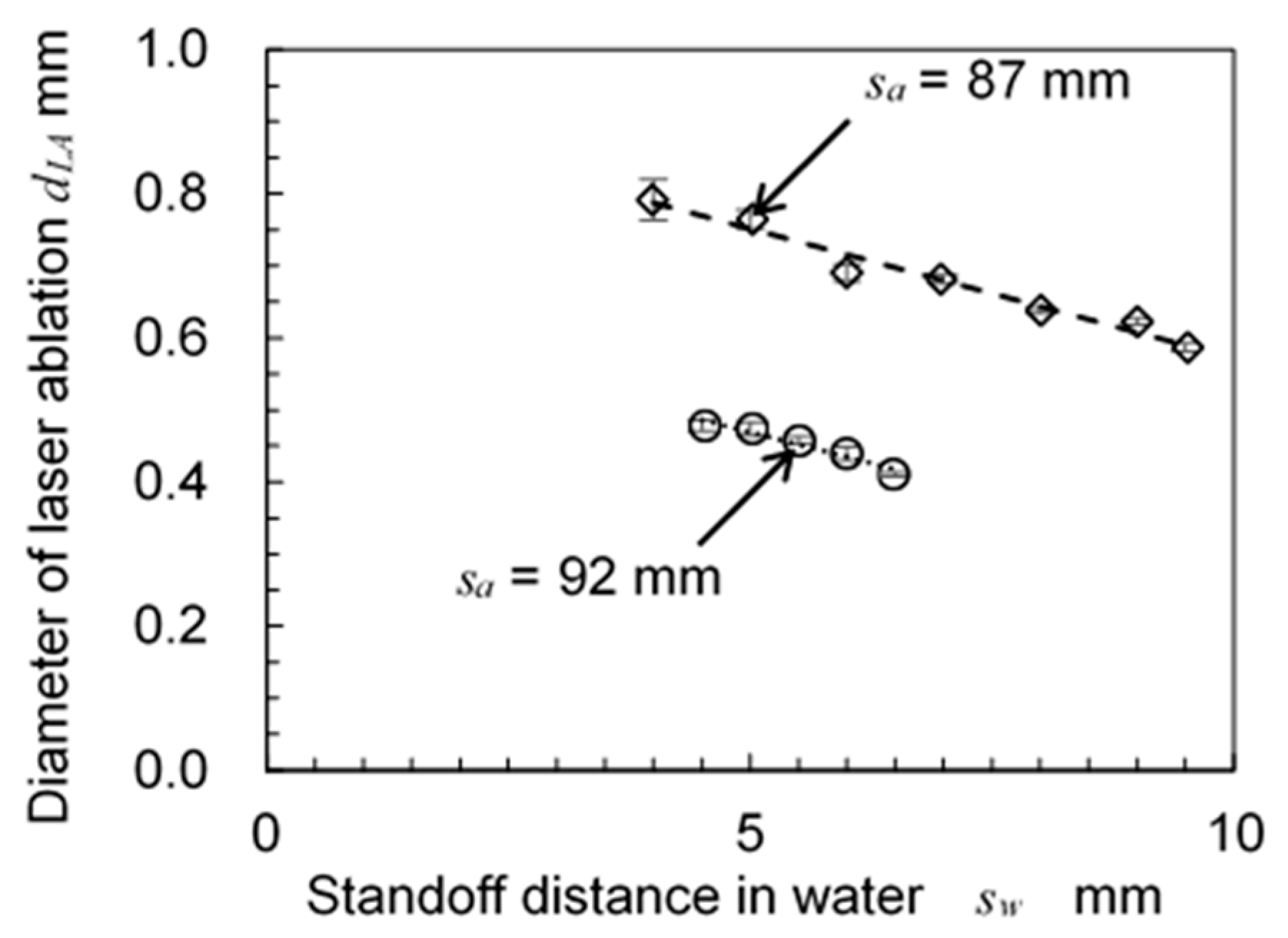

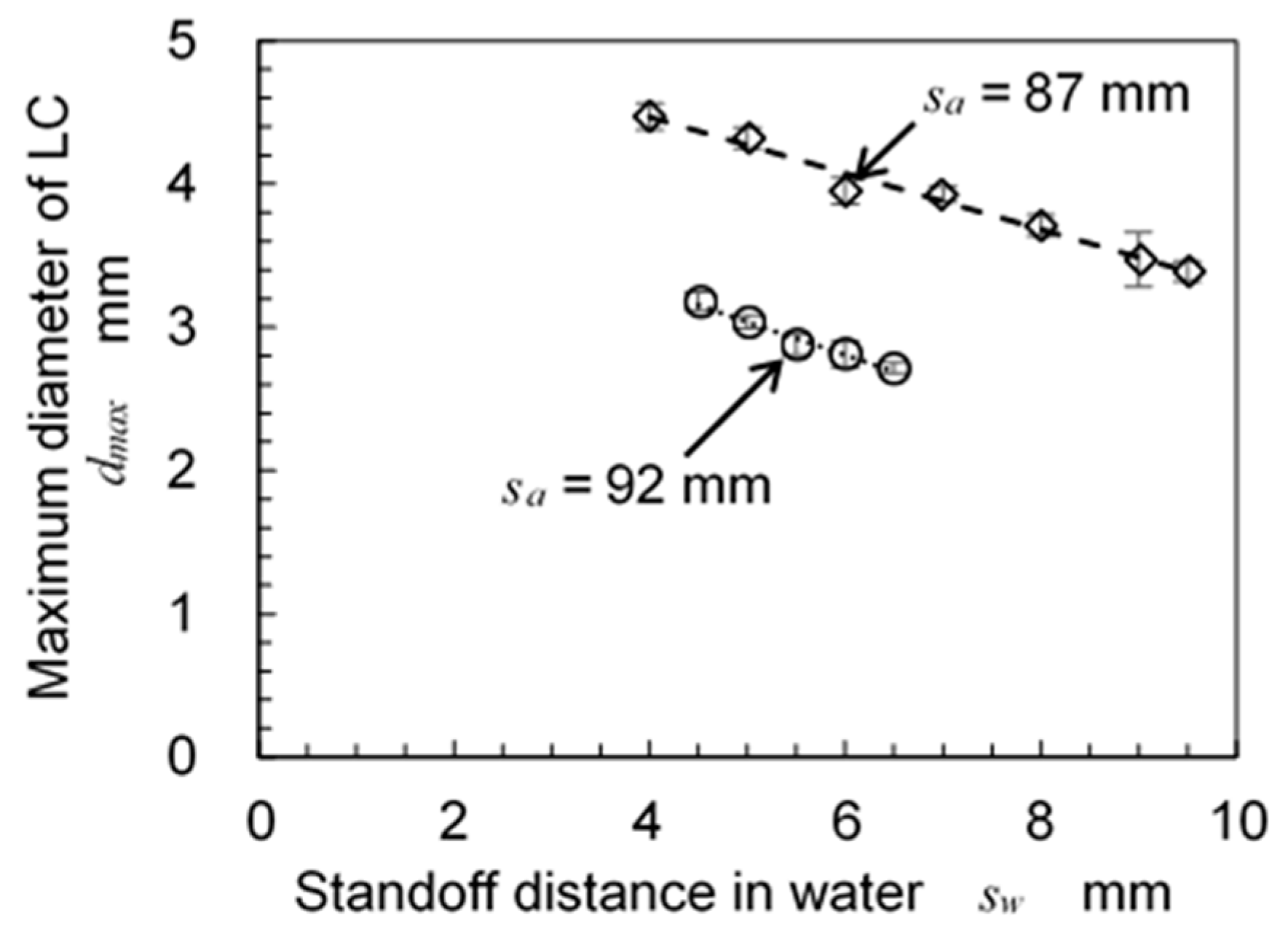

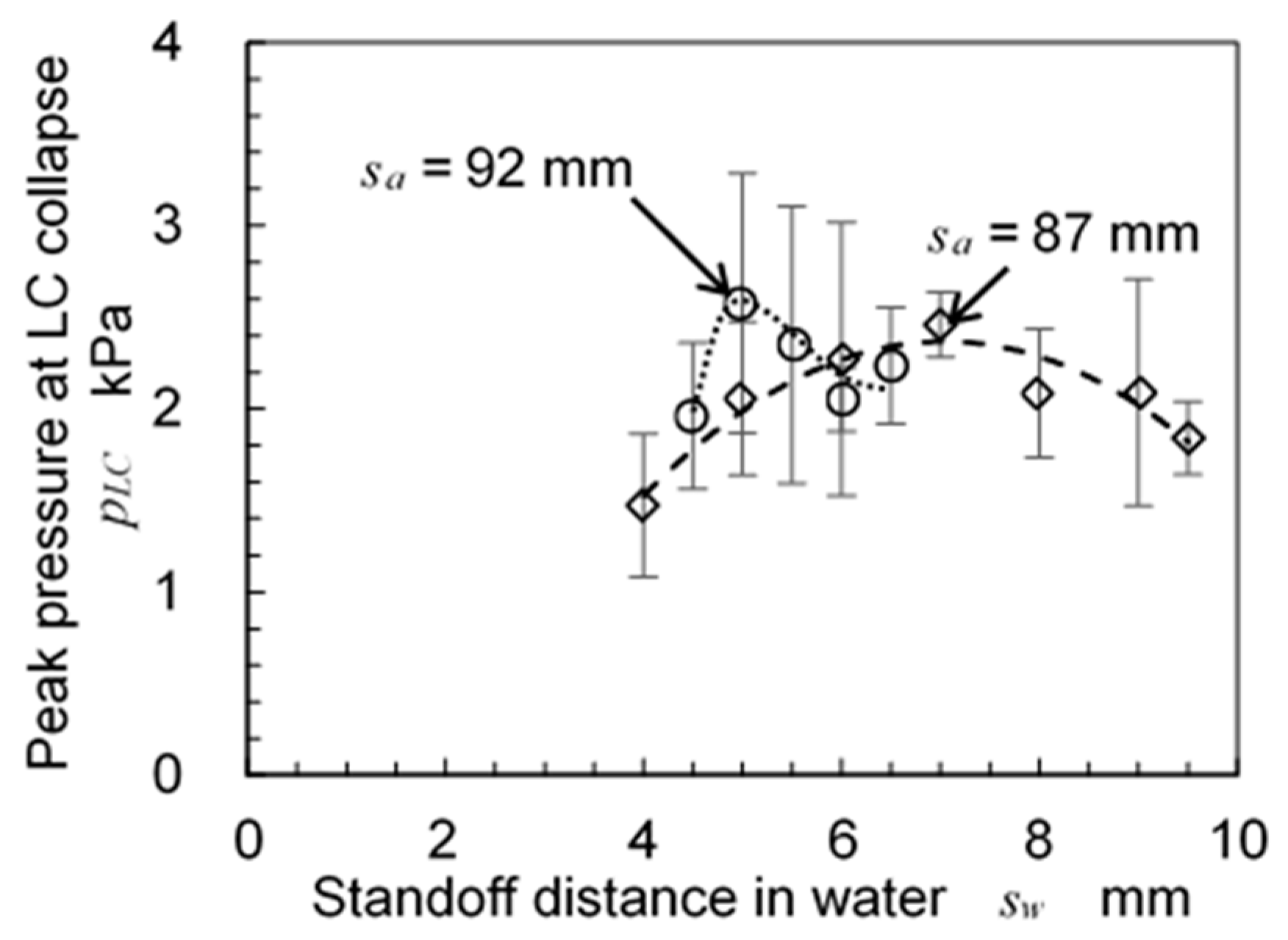

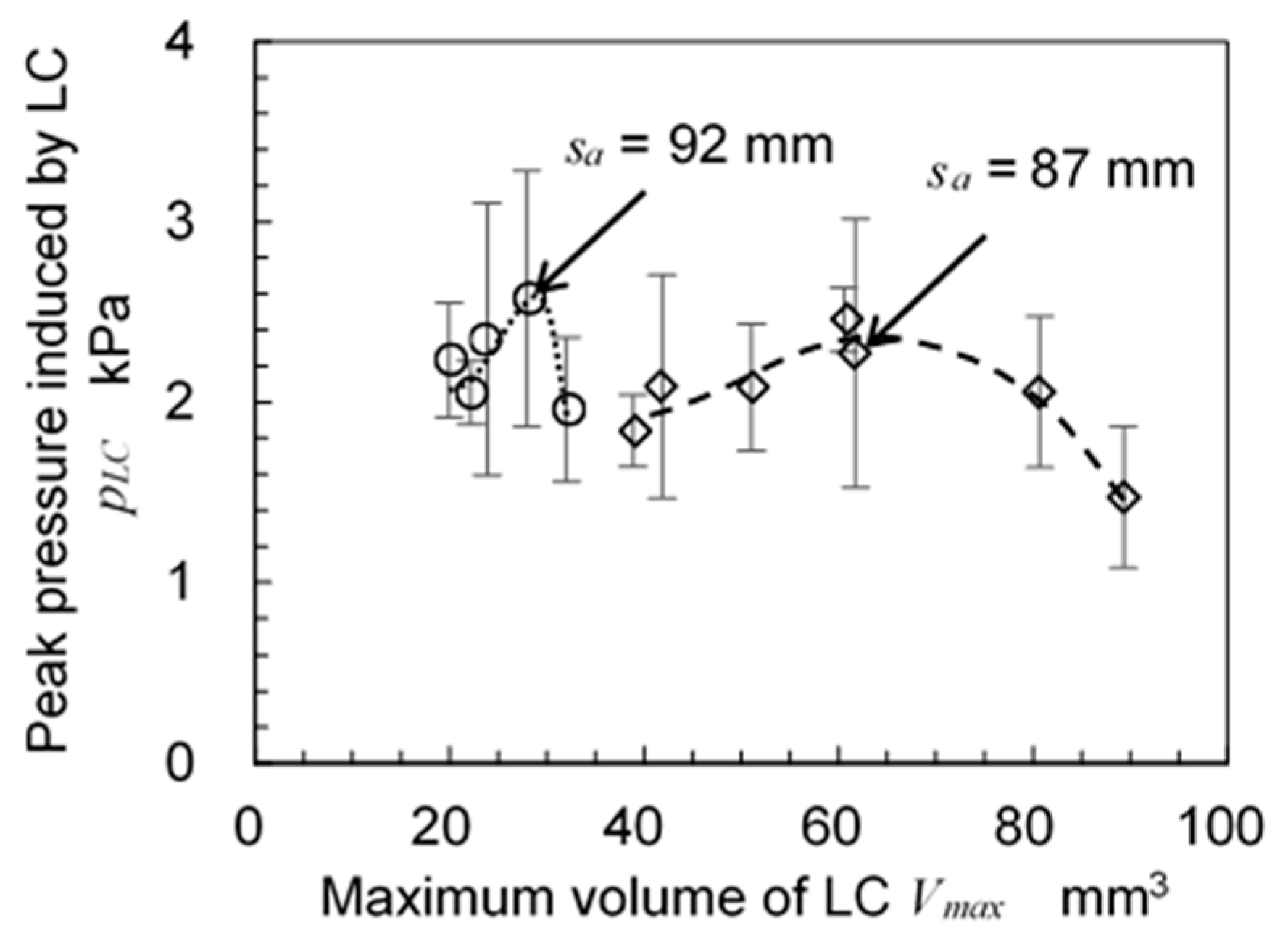

- The amplitude of shock pressure detected by the hydrophone changed with the standoff distance in air and water. It peaked at a certain standoff distance in water.

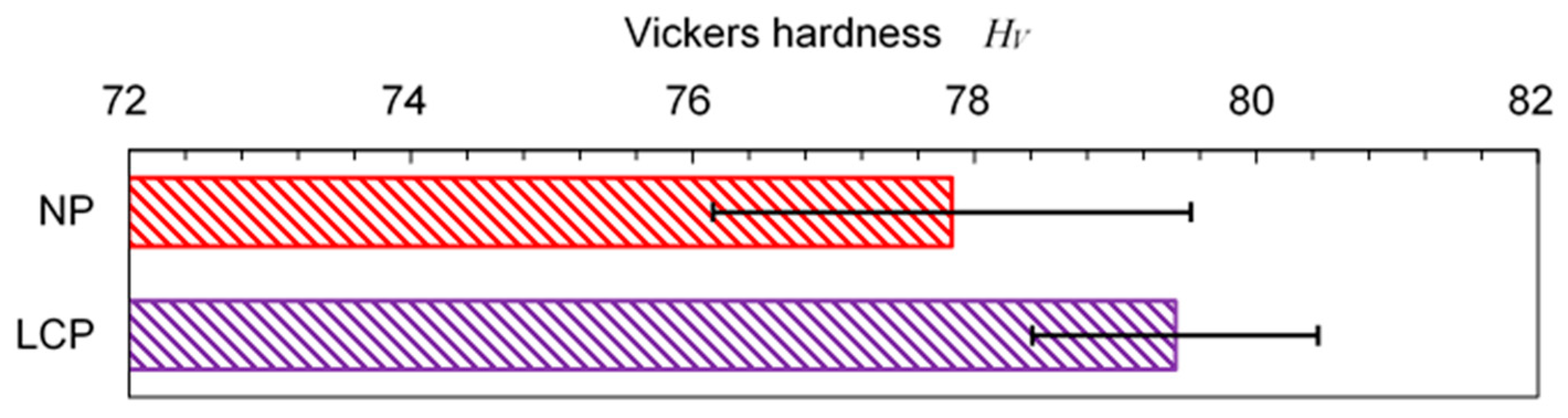

- In the present conditions, LCP using a normal-oscillation Nd:YAG laser could warp the aluminum alloy plate A5052-H34. It also increased the hardness of A5052-H34. Specifically, a laser pulse with 42 mJ energy/pulse and 0.2 ms width can be utilized for LCP.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A5052 | standardaluminum alloy |

| CP | cavitationpeening |

| H34 | standard heattreatment |

| HV | Vickershardness |

| JIS | JapaneseIndustrial Standards |

| L | chord length |

| LA | laser ablation |

| LC | lasercavitation |

| LCP | lasercavitation peening |

| PVDF | polyvinylidenefluoride |

| TTL | transistor–transistorlogic |

| Vmax | maximum volumeof LC |

| dh | horizontalstep distance |

| dL | laser pulsedensity |

| dLA | diameter oflaser ablation |

| dmax | maximumdiameter of LC |

| dv | vertical stepdistance |

| h | arc height |

| pH | pressuredetected by hydrophone |

| pLC | peak pressureinduced by first collapse of LC |

| sa | standoffdistance in air |

| sw | standoffdistance in water |

| t | time afterirradiated pulsed laser |

| tD | developingtime of LC |

| vs | vibration ofspecimen surface |

| δ | thickness of plate |

| ρ | radius of curvature |

| 1/ρ | inverse of curvature |

References

- Wagner, L. Mechanical surface treatments on titanium, aluminum and magnesium alloys. Mater. Sci. Eng. A. 1999, 263, 210–216. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue behavior of a low-alloy steel with nanostructured surface obtained by severe shot peening. Eng. Fract. Mech. 2012, 81, 56–68. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K. Study on the surface layer properties and fatigue life of a workpiece machined by centrifugal shot peening and burnishing. Materials 2022, 15, 6677. [Google Scholar] [CrossRef] [PubMed]

- Kikuchi, S.; Minamizawa, K.; Arakawa, J.; Akebono, H.; Takesue, S.; Hayakawa, M. Combined effect of surface morphology and residual stress induced by fine particle and shot peening on the fatigue limit for carburized steels. Int. J. Fatigue 2023, 168, 107441. [Google Scholar] [CrossRef]

- Kang, C.-Y.; Chen, T.-C.; Tsay, L.-W. Effects of micro-shot peening on the stress corrosion cracking of austenitic stainless steel welds. Metals 2022, 13, 69. [Google Scholar] [CrossRef]

- Soyama, H.; Korsunsky, A.M. A critical comparative review of cavitation peening and other surface peening methods. J. Mater. Process. Technol. 2022, 305, 117586. [Google Scholar] [CrossRef]

- Soyama, H. Cavitating jet: A review. Applied Sciences 2020, 10, 7280. [Google Scholar] [CrossRef]

- Saitou, N.; Enomoto, K.; Kurosawa, K.; Morinaka, R.; Hayashi, E.; Ishikwa, T.; Yoshimura, T. Development of water jet peening technique for reactor internal components of nuclear power plant. J. Jet Flow Eng. 2003, No. 1, 4–12. [Google Scholar]

- Soyama, H.; Sanders, D. Use of an abrasive water cavitating jet and peening process to improve the fatigue strength of titanium alloy 6Al-4V manufactured by the electron beam powder bed melting (EBPB) additive manufacturing method. JOM 2019, 71, 4311–4318. [Google Scholar] [CrossRef]

- Sano, Y. Quarter century development of laser peening without coating. Metals 2020, 10, 152. [Google Scholar] [CrossRef]

- Sasoh, A.; Watanabe, K.; Sano, Y.; Mukai, N. Behavior of bubbles induced by the interaction of a laser pulse with a metal plate in water. Applied Physics A 2005, 80, 1497–1500. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Soyama, H.; Iga, Y. Laser cavitation peening: A review. Applied Sciences 2023, 13, 6702. [Google Scholar] [CrossRef]

- Soyama, H.; Kuji, C.; Liao, Y. Comparison of the effects of submerged laser peening, cavitation peening and shot peening on the improvement of the fatigue strength of magnesium alloy AZ31. Journal of Magnesium and Alloys 2023, 11, 1592–1607. [Google Scholar] [CrossRef]

- Soyama, H.; Takeo, F. Effect of various peening methods on the fatigue properties of titanium alloy Ti6Al4V manufactured by direct metal laser sintering and electron beam melting. Materials 2020, 13, 2216. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H.P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-T7351 aluminum alloy joints. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Telang, A.; Gnaupel-Herold, T.; Gill, A.; Vasudevan, V.K. Effect of applied stress and temperature on residual stresses induced by peening surface treatments in alloy 600. J. Mater. Eng. Perform. 2018, 27, 2796–2804. [Google Scholar] [CrossRef]

- Mao, B.; Liao, Y.L.; Li, L. Abnormal twin-twin interaction in an Mg-3Al-1Zn magnesium alloy processed by laser shock peening. Scr. Mater. 2019, 165, 89–93. [Google Scholar] [CrossRef]

- Yang, F.; Liu, P.; Zhou, L.; He, W.; Pan, X.; An, Z. Review on anti-fatigue performance of gradient microstructures in metallic components by laser shock peening. Metals 2023, 13, 979. [Google Scholar] [CrossRef]

- Li, Y.; Geng, J.; Wang, Z.; Shao, Z.; Zhang, C.; Chen, D.; Wang, H. Thermal evolutions of residual stress and strain hardening of GH4169 Ni-based superalloy treated by laser shock peening. Surface and Coatings Technology 2023, 467, 129690. [Google Scholar] [CrossRef]

- Ye, Y.; Zhang, Y.; Huang, T.; Zou, S.; Dong, Y.; Ding, H.; Vasudevan, V.K.; Ye, C. A critical review of laser shock peening of aircraft engine components. Adv. Eng. Mater. 2023. [Google Scholar] [CrossRef]

- Sano, Y.; Obata, M.; Kubo, T.; Mukai, N.; Yoda, M.; Masaki, K.; Ochi, Y. Retardation of crack initiation and growth in austenitic stainless steels by laser peening without protective coating. Mater. Sci. Eng. A 2006, 417, 334–340. [Google Scholar] [CrossRef]

- Yoda, M.; Chida, I.; Okada, S.; Ochiai, M.; Sano, Y.; Mukai, N.; Komotori, G.; Saeki, R.; Takagi, T.; Sugihara, M.; Yoriki, H. Development and application of laser peening system for pwr power plants. Proc. 14th Inter. Conf. on Nuclear Engineering 2006, 419–424. [Google Scholar]

- Sano, Y.; Akita, K.; Sano, T. A mechanism for inducing compressive residual stresses on a surface by laser peening without coating. Metals 2020, 10, 816. [Google Scholar] [CrossRef]

- Kaufman, J.; Špirit, Z.; Vasudevan, V.K.; Steiner, M.A.; Mannava, S.R.; Brajer, J.; Pína, L.; Mocek, T. Effect of laser shock peening parameters on residual stresses and corrosion fatigue of AA5083. Metals 2021, 11, 1635. [Google Scholar] [CrossRef]

- Sano, T.; Eimura, T.; Kashiwabara, R.; Matsuda, T.; Isshiki, Y.; Hirose, A.; Tsutsumi, S.; Arakawa, K.; Hashimoto, T.; Masaki, K.; Sano, Y. Femtosecond laser peening of 2024 aluminum alloy without a sacrificial overlay under atmospheric conditions. J. Laser Appl. 2017, 29, 012005. [Google Scholar] [CrossRef]

- Sano, T.; Eimura, T.; Hirose, A.; Kawahito, Y.; Katayama, S.; Arakawa, K.; Masaki, K.; Shiro, A.; Shobu, T.; Sano, Y. Improving fatigue performance of laser-welded 2024-T3 aluminum alloy using dry laser peening. Metals 2019, 9, 1192. [Google Scholar] [CrossRef]

- Yoshida, M.; Nishibata, I.; Matsuda, T.; Ito, Y.; Sugita, N.; Shiro, A.; Shobu, T.; Arakawa, K.; Hirose, A.; Sano, T. Influence of pulse duration on mechanical properties and dislocation density of dry laser peened aluminum alloy using ultrashort pulsed laser-driven shock wave. J. Appl. Phys. 2022, 132, 075101. [Google Scholar] [CrossRef]

- Soyama, H.; Sekine, Y.; Saito, K. Evaluation of the enhanced cavitation impact energy using a PVDF transducer with an acrylic resin backing. Measurement 2011, 44, 1279–1283. [Google Scholar] [CrossRef]

- Philipp, A.; Lauterborn, W. Cavitation erosion by single laser-produced bubbles. J. Fluid Mech. 1998, 361, 75–116. [Google Scholar] [CrossRef]

- Soyama, H. Laser cavitation peening and its application for improving the fatigue strength of welded parts. Metals 2021, 11, 531. [Google Scholar] [CrossRef]

- Sano, Y.; Kato, T.; Mizuta, Y.; Tamaki, S.; Yokofujita, K.; Taira, T.; Hosokai, T.; Sakino, Y. Development of a portable laser peening device and its effect on the fatigue properties of HT780 butt-welded joints. Forces in Mechanics 2022, 7, 100080. [Google Scholar] [CrossRef]

- Soyama, H.; Yahata, Y.; Saito, M. Aspect of bubbles in narrow tube imitating root canal induced by Er:YAG laser. Proc. 11th Inter. Symp. Cavitation 2021, 229–232. [Google Scholar]

- Sugimoto, Y.; Obata, S. Behavior of a sphere caused by pulsed laser induced bubble simulating stone crushing with tul. Proc. 11th Inter. Symp. on Cavitation 2021, 614–617. [Google Scholar]

- J442 Test strip, holder, and gage for shot peening. SAE International Standards 2013, 1–5.

- Ward, B.; Emmony, D.C. The energies and pressures of acoustic transients associated with optical cavitation in water. J. Mod. Opt. 1990, 37, 803–811. [Google Scholar] [CrossRef]

- Soyama, H. Luminescence intensity of vortex cavitation in a venturi tube changing with cavitation number. Ultrason. Sonochem. 2021, 71, 105389. [Google Scholar] [CrossRef]

- Ohl, C.D.; Lindau, O.; Lauterborn, W. Luminescence from spherically and aspherically collapsing laser induced bubbles. Phys. Rev. Lett. 1998, 80, 393–396. [Google Scholar] [CrossRef]

| Thickness of plateδ (mm) | Arc height h (mm) | Inverse of curvature 1/ρ (m−1) |

| 1.0 | −0.0950 ± 0.003 | −0.376 ± 0.010 |

| 1.5 | 0.0347 ± 0.004 | 0.137 ± 0.014 |

| 2.0 | 0.0110 ± 0.002 | 0.044 ± 0.007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).