Introduction

Wood has served as a fundamental construction material since ancient times (Eder et al. 2021). Compared to steel, concrete, and glass, the use of wood consumes relatively little energy during its manufacturing and disposal (Lin et al. 2023; Sandoli et al. 2021). Consequently, incorporating wood into construction supports the achievement of carbon neutrality (Jang and Kang 2022a; Scouse et al. 2020; Talvitie et al. 2021).

Notably, contemporary architecture has witnessed a rapidly growing interest in the construction of high-rise buildings using wood (Li et al. 2019). In 2019, an 85.4-m tall, 18-story multi-purpose timber building was completed in Brumunddal, Norway (WCN 2019). In 2022, an 86.5-m, 25-story wooden structure was completed in Milwaukee, Wisconsin. It is officially the tallest mass timber building in the world to date (USDA 2022). Furthermore, there is an ongoing project in Japan to construct a 70-story wooden skyscraper in Tokyo, reaching a height of 350 m. The building's inner frame is constructed entirely of timber, while the outer frame utilizes a hybrid structure. This combination ensures the structural integrity of the building, allowing it to withstand strong winds and earthquakes (Harada et al. 2020).

High-rise wooden buildings promote a sustainable building industry and contribute to resource conservation and environmentally friendly construction (Mirzaakbarovna and Sultanbayevich 2021). These structures can also be regarded as artistic expressions that fuse the modern with the traditional.

Wood is inherently vulnerable to fire hazards, making fire safety a critical consideration in the design and use of wooden structures (Jian et al. 2023; Pabeliña et al. 2012). Therefore, flame retardant treatment is required to suppress, significantly reduce, or retard the combustion of wood. These treatment methods typically include surface treatment or coating with flame retardant chemicals and the impregnation of wood with chemical solutions or nanocomposites (Pabeliña et al. 2012; Wang et al. 2022).

This study focused on the vacuum pressure impregnation process for flame retardants. The vacuum pressure impregnation process is commonly known as the Bethel process or full-cell impregnation process (Bryan 1932). This process impregnates the wood with chemicals in a sequence of steps including a vacuum, pressure, soaking time, drainage, and drying (Xu et al. 2020). Originally, this process was used for preserving wood, but it has also become widely used to impregnate wood with fire retardants (Rejeesh and Saju 2017; Xu et al. 2020).

The performance of the vacuum pressure impregnation process is affected by variables such as the species of wood, flow characteristics of chemicals, impregnation pressure, temperature, and impregnation time (Schneider et al. 2003; Yildiz et al. 2012).

Jang and Kang (2023a) investigated the effects of pressure, temperature, and time on larch (Larix kaempferi) and pine (Pinus koraiensis) wood impregnation using multiple regression analysis. Their study revealed that impregnation pressure had the most significant impact on the impregnation process, while time and temperature had comparatively less influence among the variables. This study suggests that controlling and optimizing the impregnation pressure can be crucial in achieving desired results in wood impregnation.

However, these methods alone have limitations in improving the pressure impregnation process for impermeable wood. Thus, physical pre-treatment, such as boring and incision, are typically used to enhance the vacuum pressure impregnation process for impermeable wood species (Park et al. 2017; Yildiz et al. 2010).

Islam et al. (2008) applied laser incisions to Douglas fir (Pseudotsuga menziesii (Mirb.) Franco) under various conditions, and the optimum incision density was found to be 7,500 holes/m2.

Fukuta et al. (2022) reported that improved flame-retardant penetration was observed in wood pretreated by laser micro incisions with depths of 6 mm or less.

Park et al. (2017) conducted experiments involving kerfing and boring combinations under various conditions to improve the permeability of flame retardants. After comprehensively evaluating the permeability and the mechanical strength of the wood treated with flame retardant, they recommended a combination of 5 mm (D) x 3.5 mm (W) kerfing and boring with hole diameter of 12 mm or less.

Jang and Kang (2023b) introduced a steam explosion treatment as a means to improve the capabilities of wood following pressure impregnation. This treatment subjected the wood to steam and subsequent rapid decompression, which resulted in the creation of microcracks in the cell walls of the wood. This process led to an increased open pore content in the wood, ultimately enhancing the impregnation process. However, the physical properties of the wood treated with this method have not been identified, and there are limitations in applying this method to large-sized timber. Hence, this study proposes a grooving process as a vacuum pressure impregnation pretreatment technique that can be readily implemented for large timber. This method involves creating grooves in the longitudinal and transverse directions. Transverse grooving can increase the exposure of the wood's tracheids compared to the longitudinal direction. We expect that the increased exposure of the tracheids will improve the permeability of the wood and thus improve the impregnation efficiency.

Materials and Methods

Wood species

This study used Korean larch (L. kaempferi), a representative impermeable wood, as the subject material. We sourced dried lumber from a domestic lumber supplier, and samples were cut to 1,030 mm (L) x 100 mm (W) x 19 mm (T). Their air-dried density was 0,57 g/cm3 and their moisture content was 12,9 %.

Grooving process

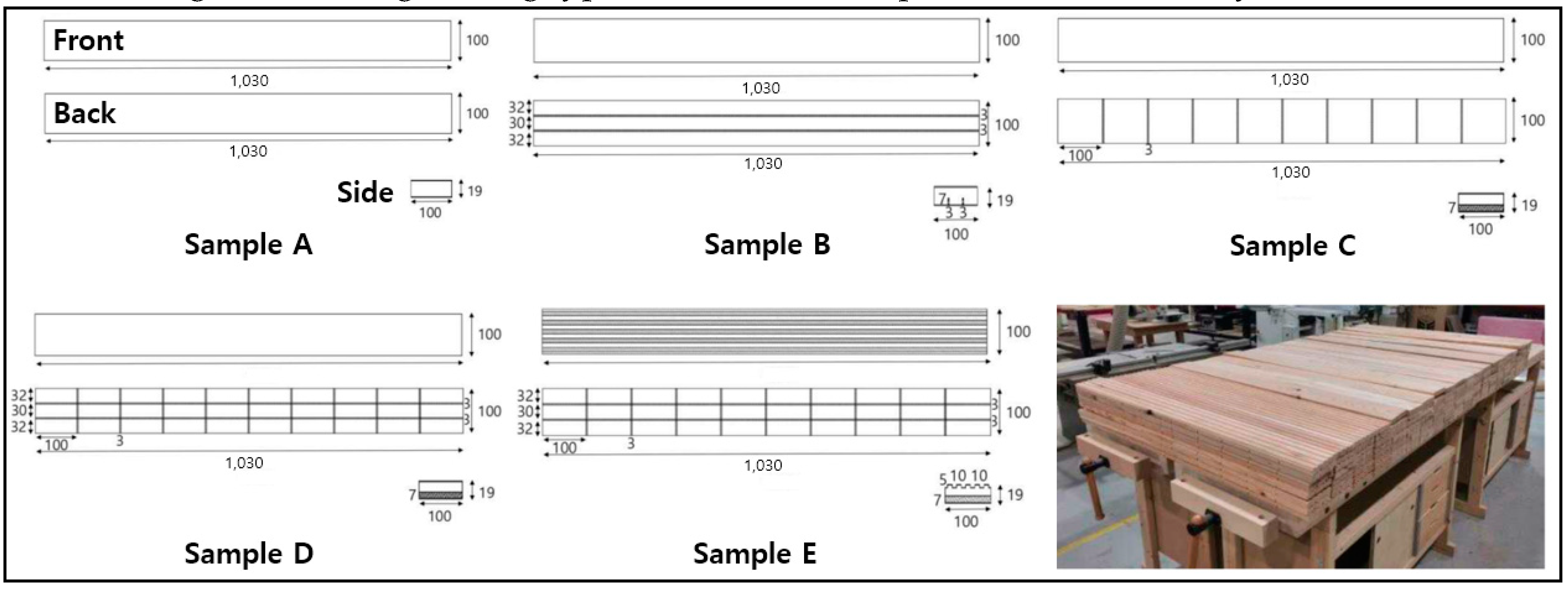

In this study, five types of samples were prepared to compare the efficacy of the flame retardant’s vacuum pressure impregnation by grooving style. Sample A was the control group. Sample B was grooved longitudinally with a width of 3 mm and a depth of 7 mm. Sample C was grooved transversely. Sample D was grooved both longitudinally and transversely. Sample E was grooved both longitudinally and transversely and had additional surface irregularities.

Figure 1 provides diagrams of the grooving types of the larch samples used in this study.

Flame retardant

This study used a water-soluble flame retardant (SafeWood Co Ltd., Korea), whose main ingredients were ammonium phosphate dibasic and additives. The resin rate of each sample was about 27 %, the specific gravity was 1,13, and the pH was 7,6. A 3 % dilution of water soluble blue ink was used to easily check the permeability of the flame retardant with the naked eye.

Vacuum pressure impregnation process

This study utilized a wood vacuum pressure impregnation chamber that was developed in house at Jeonbuk National University. The specimens were placed in the chamber and depressurized at -0.1 Mpa for about 5 minutes using a vacuum pump. Then, the flame retardant was added while maintaining a vacuum in the chamber and pressurized at a pressure of 20 kgf/cm² (285 psi) for a range of times up to 720 minutes using a pressurization pump to inject the flame retardant into the test specimen. After the flame retardant was injected, the pressure was released, the flame remaining retardant was recovered, and the vacuum pump was operated to decompress the samples for 5 minutes to recover the flame retardant from the wood surface, completing the flame-retardant impregnation process.

Results and Discussion

Impregnation performance

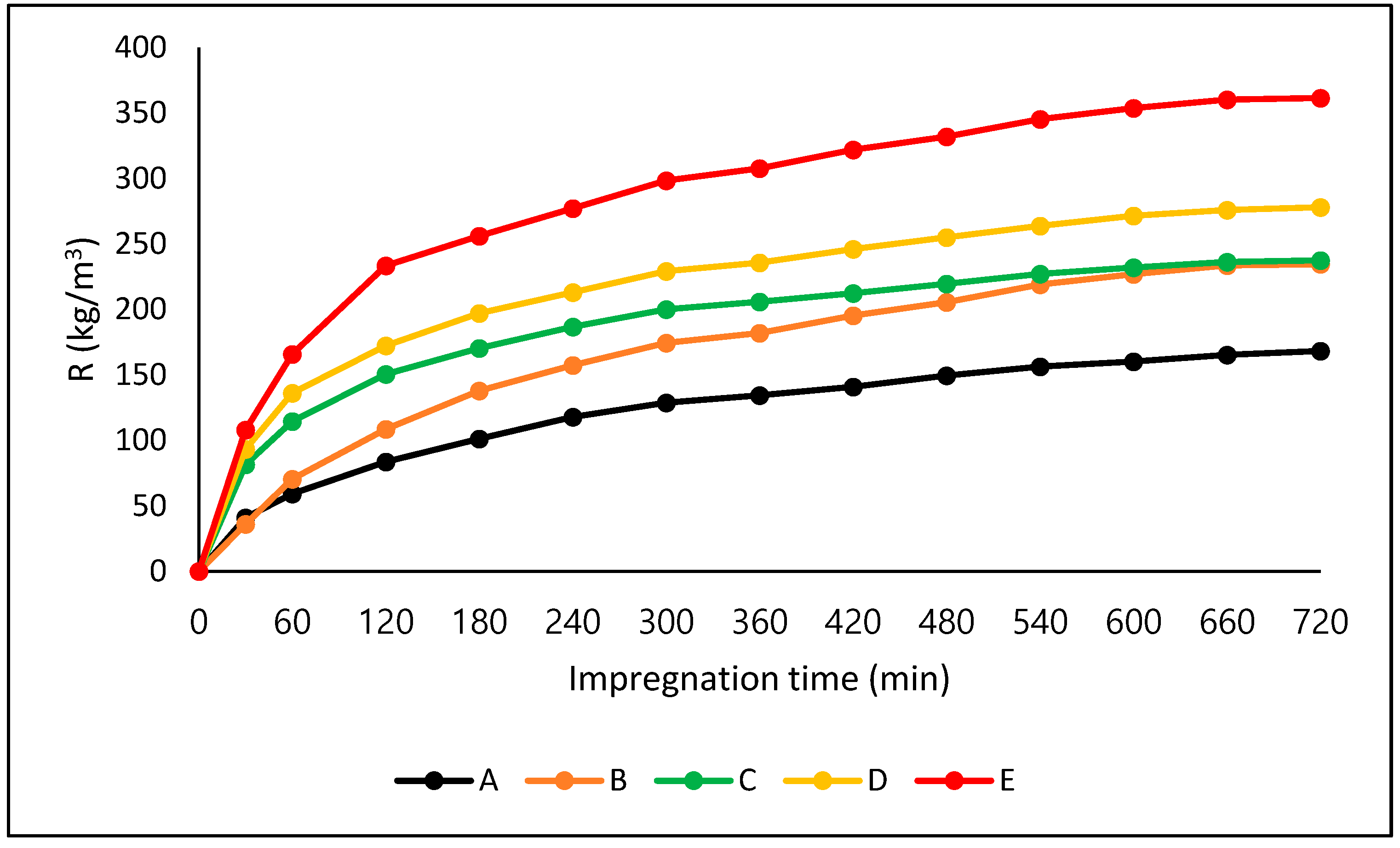

Figure 2 provides impregnation performance depending on the grooving type. All five samples demonstrated that that the flame-retardant impregnation amount increases as the impregnation time increases. This is a typical trend for the vacuum-pressure impregnation process (Jang and Kang 2023a, 2023b).

The impregnation performance varied depending on the grooving type. At 720 minutes, the control (sample A) had an impregnation mass per unit volume of 168,3 kg/m3, while it was 234,5 kg/m3 for sample B, 237,5 kg/m3 for sample C, 278,0 for sample D, and 361,3 kg/m3 for sample E. The impregnation performance of the longitudinally grooved samples was enhanced by approximately 139,3 % compared to the control, while the transversely grooved samples showed an improvement of about 141,1 %. The transversely grooved larch exhibited better impregnation performance due to increased exposure of tracheids, which have higher permeability in the cross-section of the wood. However, the difference between the grooving directions was just 1,8 % due to the larch's pit aspiration. Pit aspiration in conifers is well-known as a cause of reduced permeability (Bao et al. 2001; Comstock and Côté Jr 1968).

When both transverse and longitudinal grooving was applied to the fibers, the impregnation performance was enhanced by around 165.2%. Furthermore, adding surface grooving processing to the longitudinal and transverse grooved sample resulted in a notable improvement of approximately 214.7%. This suggests that the surface grooving processing enhanced flame-retardant absorption by increasing the wood's specific surface area.

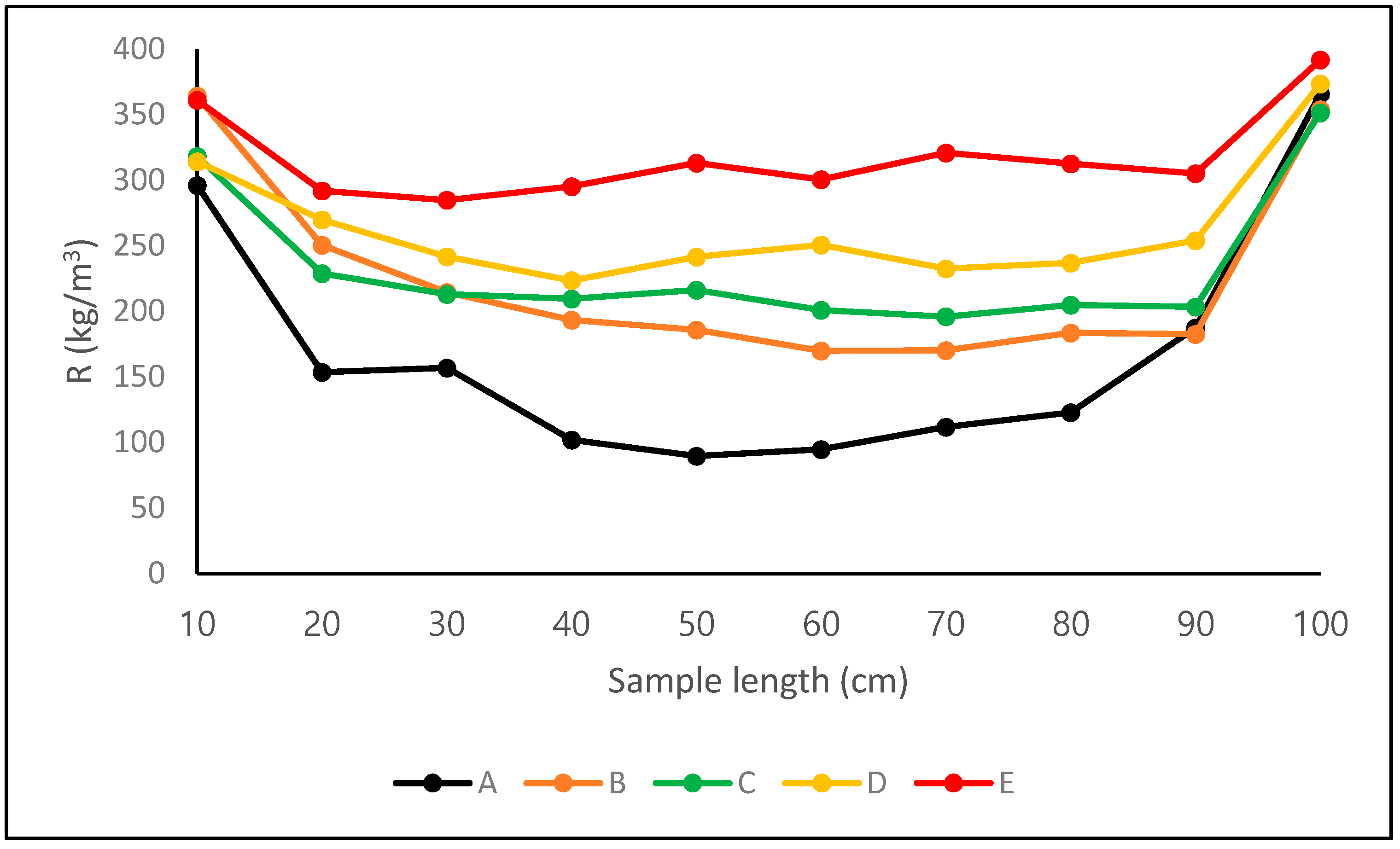

Figure 3 presents a comparison of impregnation performance in the longitudinal direction depending on the grooving type. All larch samples showed high flame-retardant impregnation at both ends but a gradual decrease in impregnation toward the center.

The difference between the maximum and minimum impregnation amounts in the control group was 276.2 kg/m3. On the other hand, it was 194.2 kg/m3 for sample A, 194.2 kg/m3 for sample B, 155.5 kg/m3 for sample C, 150.0 kg/m3 for sample D, and 106.9 kg/m3 for sample E.

As a result, the flame-retardant impregnation performance was more even in the transverse grooving than in the longitudinal grooving, and the flame retardant was more evenly impregnated when grooving in both the longitudinal and transverse directions and when surface roughness processing was added. That is, as the exposure of tracheids increased and the surface area of the wood increased, the flame retardant was impregnated increasingly evenly.

Visual inspection

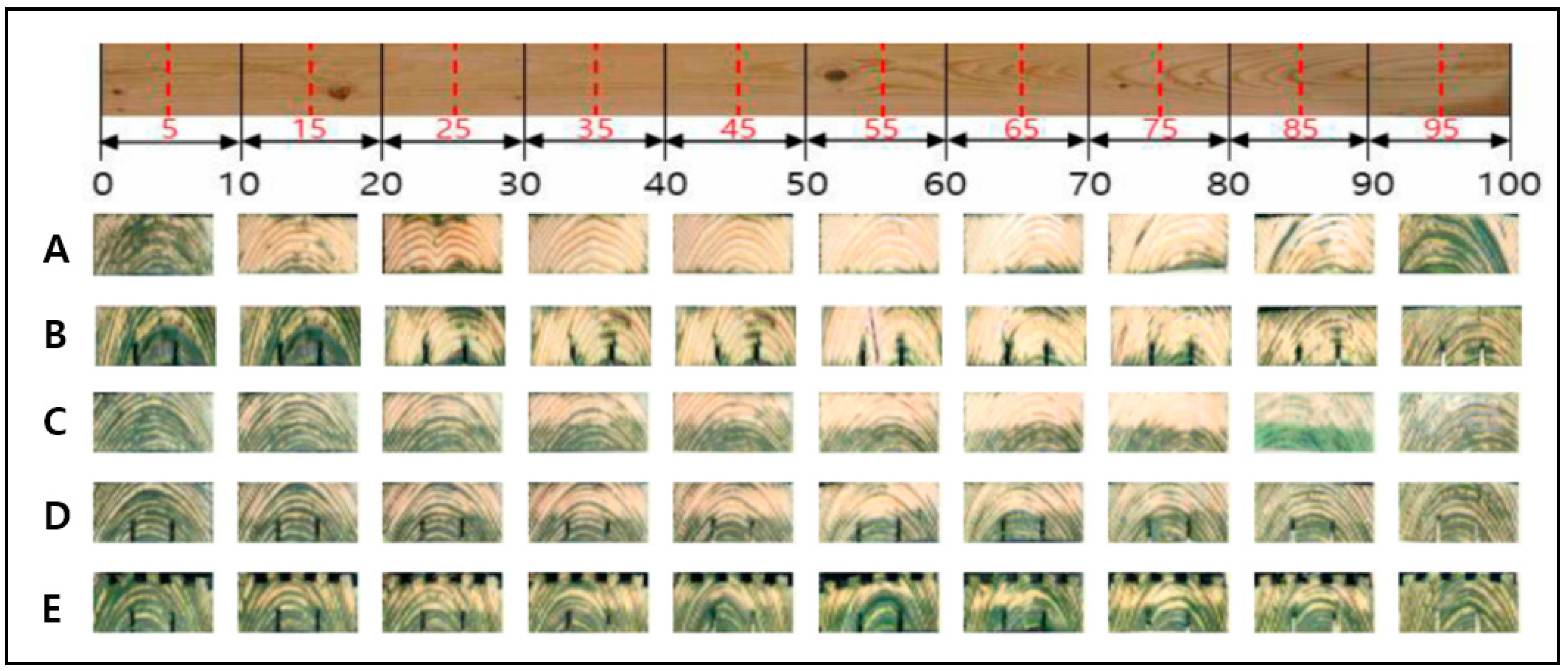

Figure 4 displays the results of visual inspection of impregnation in the longitudinal direction depending on the grooving type. In the untreated wood, the flame retardant was impregnated only at both ends and barely penetrated the center. On the other hand, it was confirmed with the naked eye that the flame retardant penetrated evenly to the central part according to the additional groove processing. This shows the impregnation performance in the order of A<B<C<D<E following the same trend as

Figure 3.

This study served as a fundamental investigation into the impact of grooving on enhancing larch's flame-retardant impregnation performance. In future research, we aim to explore the alterations in physical properties resulting from groove machining. We aim to identify a groove processing technique that optimizes the impregnation performance while minimizing changes in the physical properties of the treated wood. To achieve this, we intend to incorporate not only new grooving processes but also a range of physical and chemical treatment methods to enhance the permeability of wood. Ultimately, we anticipate that this study will contribute to improving the flame-retardant impregnation treatment process for larch, a species known for its low permeability (Jang and Kang 2022b, 2023c).

Conclusions

The present study focused on utilizing grooving pretreatment processes to enhance the flame-retardant impregnation of larch, a wood species known for its impermeable characteristics. As a result, it was more advantageous to impregnate the flame retardant when grooving in a cross-fiber direction rather than in the longitudinal direction. In addition, when groove processing was performed in both longitudinal and transverse directions for 720 minutes, and groove processing was added to the surface, this resulted in the optimal flame-retardant impregnation performance. This approach yielded approximately 214.7% improved performance compared to untreated larch, a highly encouraging result.

Author Contributions

ESJ: First author, writing (original draft), writing (review & editing), XJK: experiment, formal analysis, writing (review & editing), SUJ: experiment, formal analysis, writing (review & editing), CWK: writing (review & editing), HJP: corresponding author, supervision, conceptualization, methodology, writing (review & editing).

Acknowledgments

This research was supported by the National Research Foundation of Korea (NRF-2019R1I1A3A02059471, NRF-2020K2A9A2A08000181). Also, this research was funded by the R&D Program for Forest Science Technology in Korea (FTIS 2022457A00-2224-AC02, FTIS 2020223A00-2222-AC02). This article was reconstructed by extracting data from Xiao Jia Kang's master's thesis at Jeonbuk National University.

References

- Bao, F.; Lu, J.; Zhao, Y. 2001. Effect of bordered pit torus position on permeability in Chinese yezo spruce. Wood and fiber science 33(2): 193-199. https://wfs.swst.org/index.php/wfs/article/view/1090.

- Bryan, J. 1932. Methods of Applying Antiseptics. Forestry: An International Journal of Forest Research 6(1): 75-81. [CrossRef]

- Comstock, G.; Côté Jr, W. 1968. Factors affecting permeability and pit aspiration in coniferous sapwood. Wood Science and Technology 2: 279-291. [CrossRef]

- Eder, M.; Schäffner, W.; Burgert, I.; Fratzl, P. 2021. Wood and the activity of dead tissue. Advanced Materials 33: 2001412. [CrossRef]

- Fukuta, S.; Nomura, M.; Kurisaki, H.; Okamura, H. 2022. Application of laser micro incisions in the fire-retardant treatment. European Journal of Wood and Wood Products 80: 255-258. [CrossRef]

- Harada, H.; Fukushima, T.; Hatori, T.; Aoyagi, H. 2020. W350-The Roadmap Of Super High-Rise Timber Building. International Journal of High-Rise Buildings 9(3): 255-260. [CrossRef]

- Islam, M.N.; Ando, K.; Yamauchi, H.; Kobayashi, Y.; Hattori, N. 2008. Comparative study between full cell and passive impregnation method of wood preservation for laser incised Douglas fir lumber. Wood Science and Technology 42: 343-350. [CrossRef]

- Jang, E.-S.; Kang, C.-W. 2022a. The relationship between bulk density and thermal conductivity in various korean woods. Wood Research 67(2): 178-186. [CrossRef]

- Jang, E.-S.; Kang, C.-W. 2022b. An experimental study on changes in sound absorption capability of spruce (Picea sitchensis), Douglas fir (Pseudotsuga menziesii), and larch (Larix kaempferi) after microwave treatment. Journal of Wood Science 68(2): 1-6. [CrossRef]

- Jang, E.-S.; Kang, C.-W. 2023a. Effects of Pressure and Temperature on Wood Impregnation–Focusing on Larch (Larix kaempferi) and Korean Pine (Pinus koraiensis). BioResources 18(2): 3208-3216. http://doi.org/0.15376/biores.18.2.3208-3216.

- Jang, E.-S.; Kang, C.-W. 2023b. Effect of Steam Explosion Treatment on Impregnation of Three Species of Softwoods: North American Spruce, Korean Pine, and Japanese Larch. BioResources 18(1): 1454-1464. [CrossRef]

- Jang, E.-S.; Kang, C.-W. 2023c. An experimental study on efficient physical wood modification for enhanced permeability–focusing on ultrasonic and microwave treatments. Wood Material Science & Engineering 18(2): 446-453. [CrossRef]

- Jian, H.; Liang, Y.; Deng, C.; Xu, J.; Liu, Y.; Shi, J.; Wen, M.; Park, H.-J. 2023. Research Progress on the Improvement of Flame Retardancy, Hydrophobicity, and Antibacterial Properties of Wood Surfaces. Polymers 15(4): 951. [CrossRef]

- Li, J.; Rismanchi, B.; Ngo, T. 2019. Feasibility study to estimate the environmental benefits of utilising timber to construct high-rise buildings in Australia. Building and Environment 147: 108-120. [CrossRef]

- Lin, S.; Qin, Y.; Huang, X.; Gollner, M. 2023. Use of pre-charred surfaces to improve fire performance of wood. Fire Safety Journal 136: 103745. [CrossRef]

- Mirzaakbarovna, M.S.; Sultanbayevich, T.N. 2021. Wood Processing For Construction. The American Journal of Applied sciences 3(5): 186-189. [CrossRef]

- Pabeliña, K.G.; Lumban, C.O.; Ramos, H.J. 2012. Plasma impregnation of wood with fire retardants. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 272: 365-369. [CrossRef]

- Park, H.-J.; Wen, M.-Y.; Kang, C.-W.; Sun, Y.-X. 2017. Development of physical pretreatment method for wood fire retardant impregnation. BioResources 12(2): 3778-3789. [CrossRef]

- Rejeesh, C.; Saju, K. 2017. Methods and materials for reducing flammability behaviour of coir fibre based composite boards: a review. Materials Today: Proceedings 4(9): 9399-9407. [CrossRef]

- Sandoli, A.; D’Ambra, C.; Ceraldi, C.; Calderoni, B.; Prota, A. 2021. Sustainable cross-laminated timber structures in a seismic area: Overview and future trends. Applied Sciences 11(5): 2078. [CrossRef]

- Schneider, P.F.; Levien, K.L.; Morrell, J.J. 2003. Internal pressure measurement techniques and pressure response in wood during treating processes. Wood and fiber science: 282-292. https://wfs.swst.org/index.php/wfs/article/view/242/242.

- Scouse, A.; Kelley, S.S.; Liang, S.; Bergman, R. 2020. Regional and net economic impacts of high-rise mass timber construction in Oregon. Sustainable Cities and Society 61: 102154. [CrossRef]

- Talvitie, I.; Vimpari, J.; Junnila, S. 2021. Economic feasibility of wood-based structures—improving urban carbon neutrality strategies. Environmental Research: Infrastructure and Sustainability 1(1): 011002. [CrossRef]

- USDA, 2022. World's tallest timber building opens. https://www.fs.usda.gov/inside-fs/delivering-mission/apply/worlds-tallest-timber-building-opens. Accessed 15-June 2023.

- Wang, K.; Meng, D.; Wang, S.; Sun, J.; Li, H.; Gu, X.; Zhang, S. 2022. Impregnation of phytic acid into the delignified wood to realize excellent flame retardant. Industrial Crops and Products 176: 114364. [CrossRef]

- WCN, 2019. Mjosa Tower. World Construction Network. https://www.worldconstructionnetwork.com/projects/mjosa-tower-mjostarnet/. Accessed 16-June 2023.

- Xu, E.; Zhang, Y.; Lin, L. 2020. Improvement of mechanical, hydrophobicity and thermal properties of Chinese fir wood by impregnation of nano silica sol. Polymers 12(8): 1632. [CrossRef]

- Yildiz, S.; Canakci, S.; Yildiz, U.C.; Ozgenc, O.; Tomak, E.D. 2012. Improving of the impregnability of refractory spruce wood by Bacillus licheniformis pretreatment. BioResources 7(1). https://bioresources.cnr.ncsu.edu/resources/improving-of-the-impregnability-of-refractory-spruce-wood-by-bacillus-licheniformis-pretreatment/.

- Yildiz, S.; Yildiz, Ü.; Dizman, E.; Temiz, A.; Gezer, E. 2010. The effects of preacid treatment on preservative retention and compression strength of refractory spruce wood impregnated with CCA and ACQ. Wood Research 56(3): 93-104. https://www.woodresearch.sk/articles/5-17-143626_WR201003_09Yildiz.pdf.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).