Submitted:

12 July 2023

Posted:

13 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

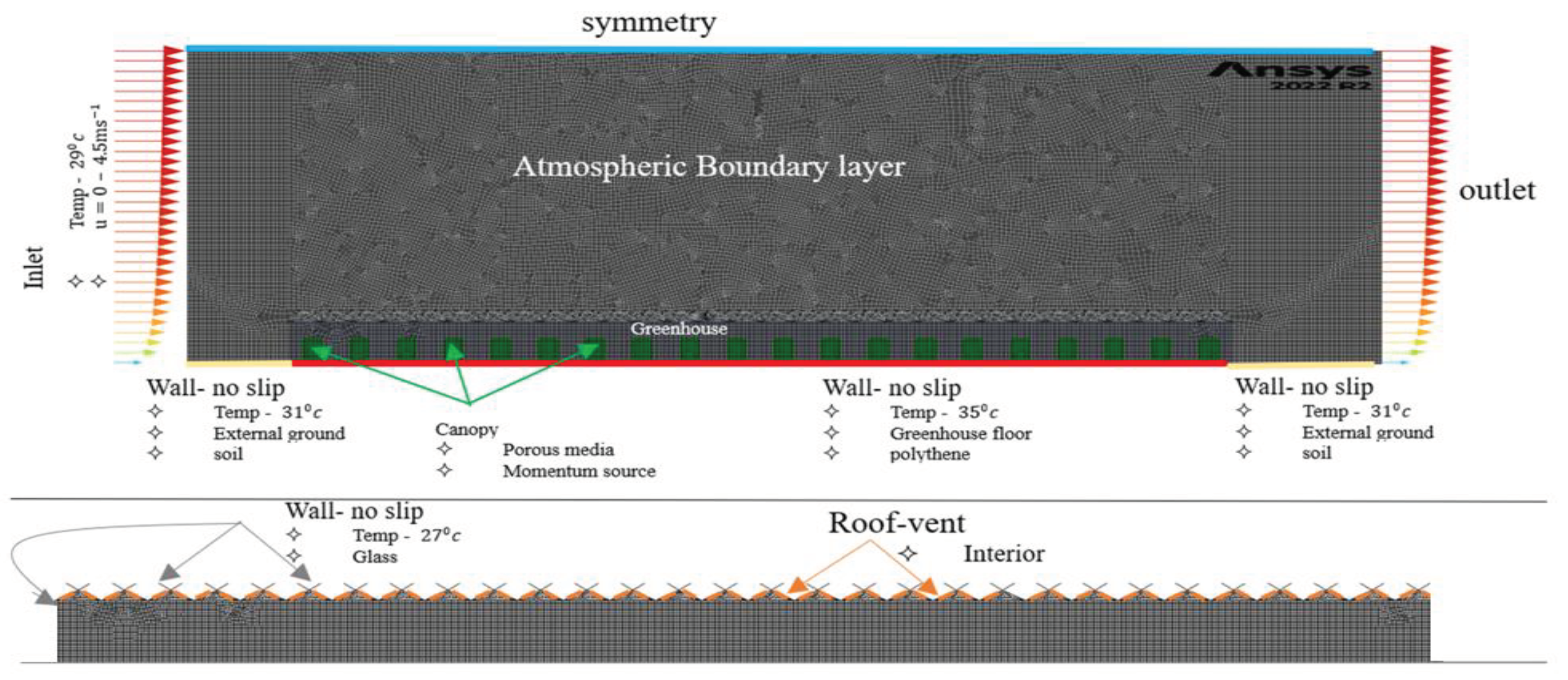

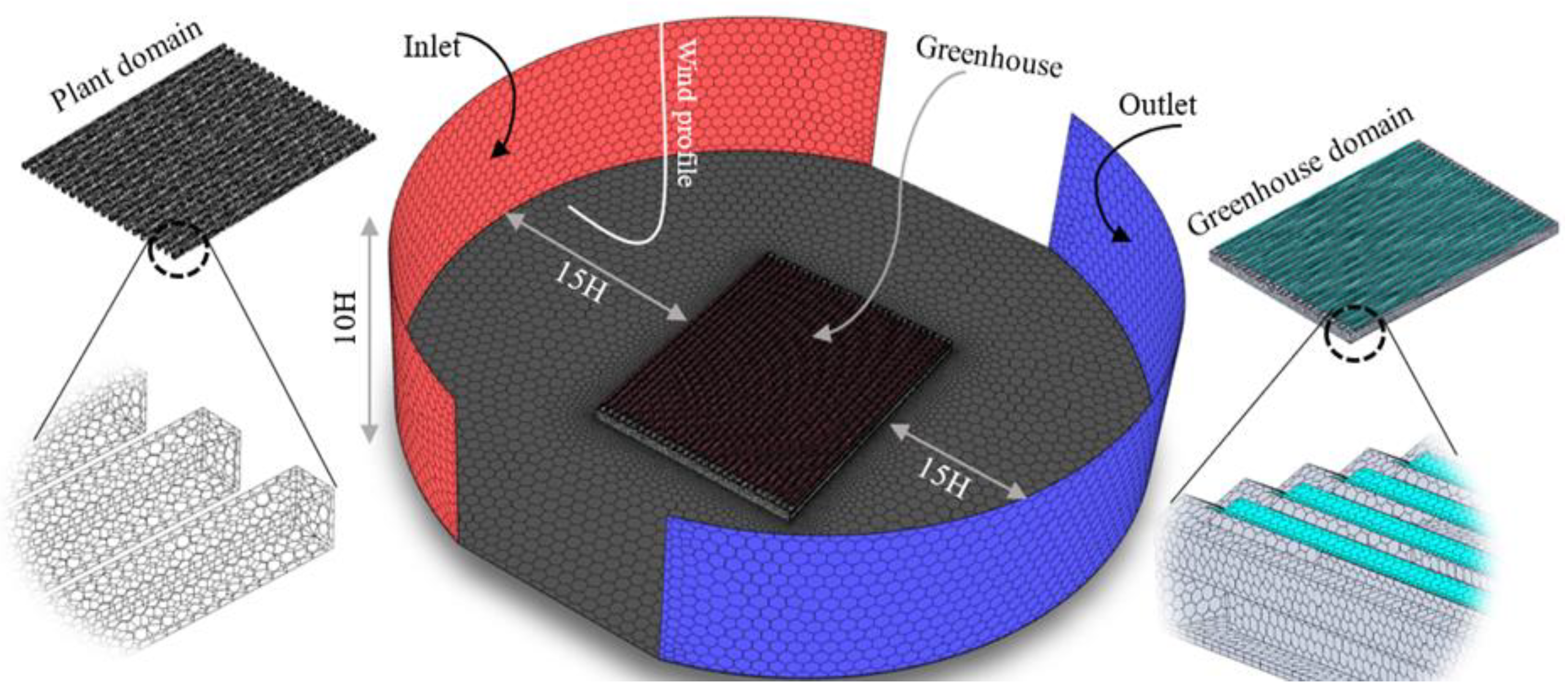

2.1. Computational fluid dynamics

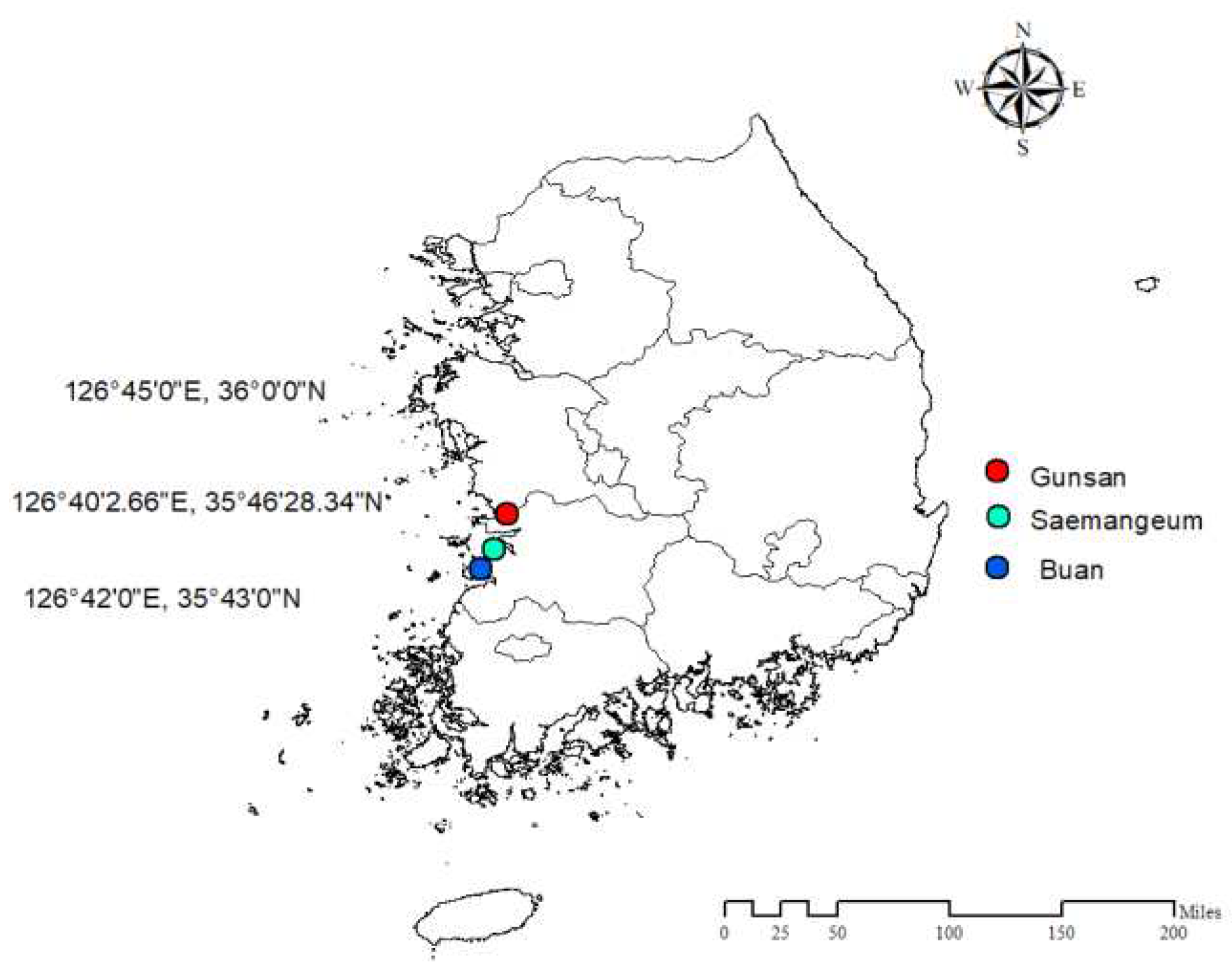

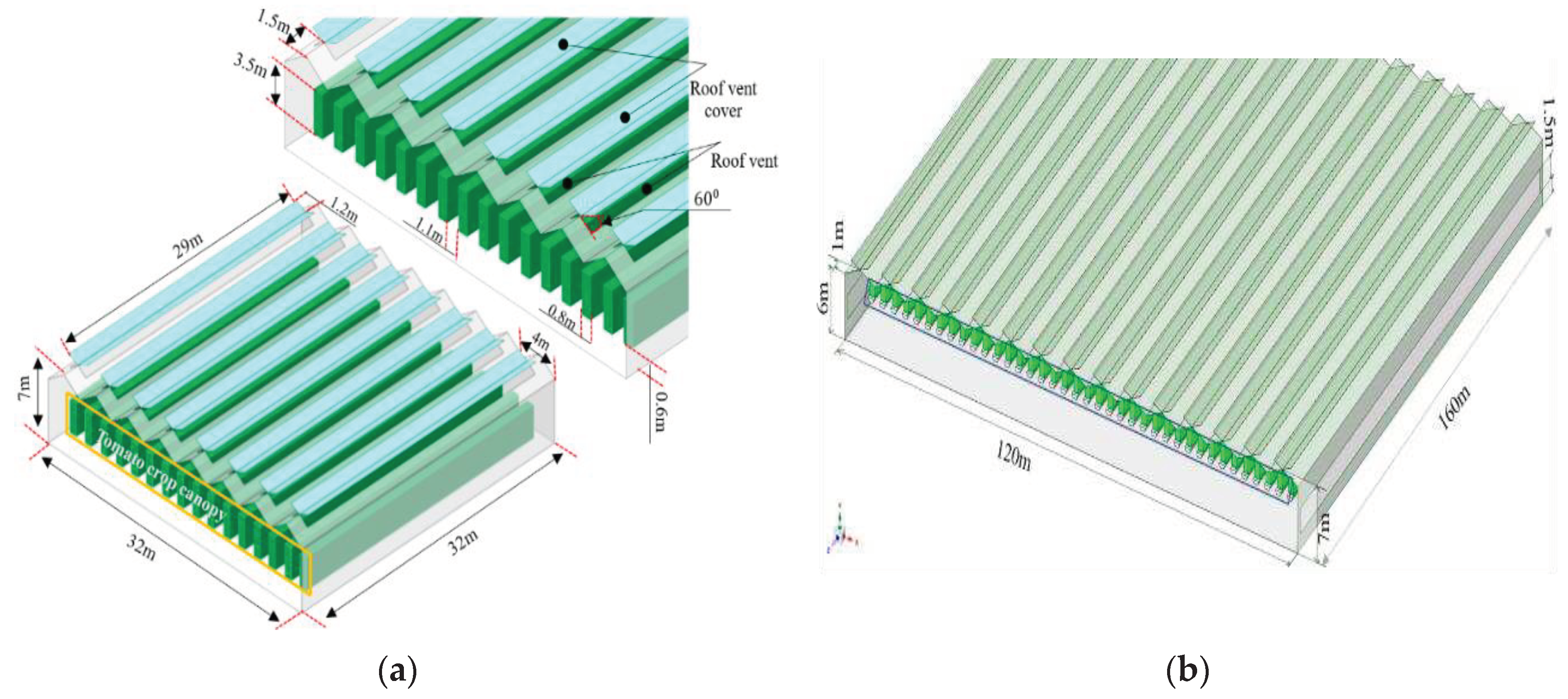

2.2. Target greenhouse type, crop and location

2.3. Crop canopy design

2.4. Atmospheric boundary layer (ABL) design

2.5. Model verification theories

2.5.1. GIT

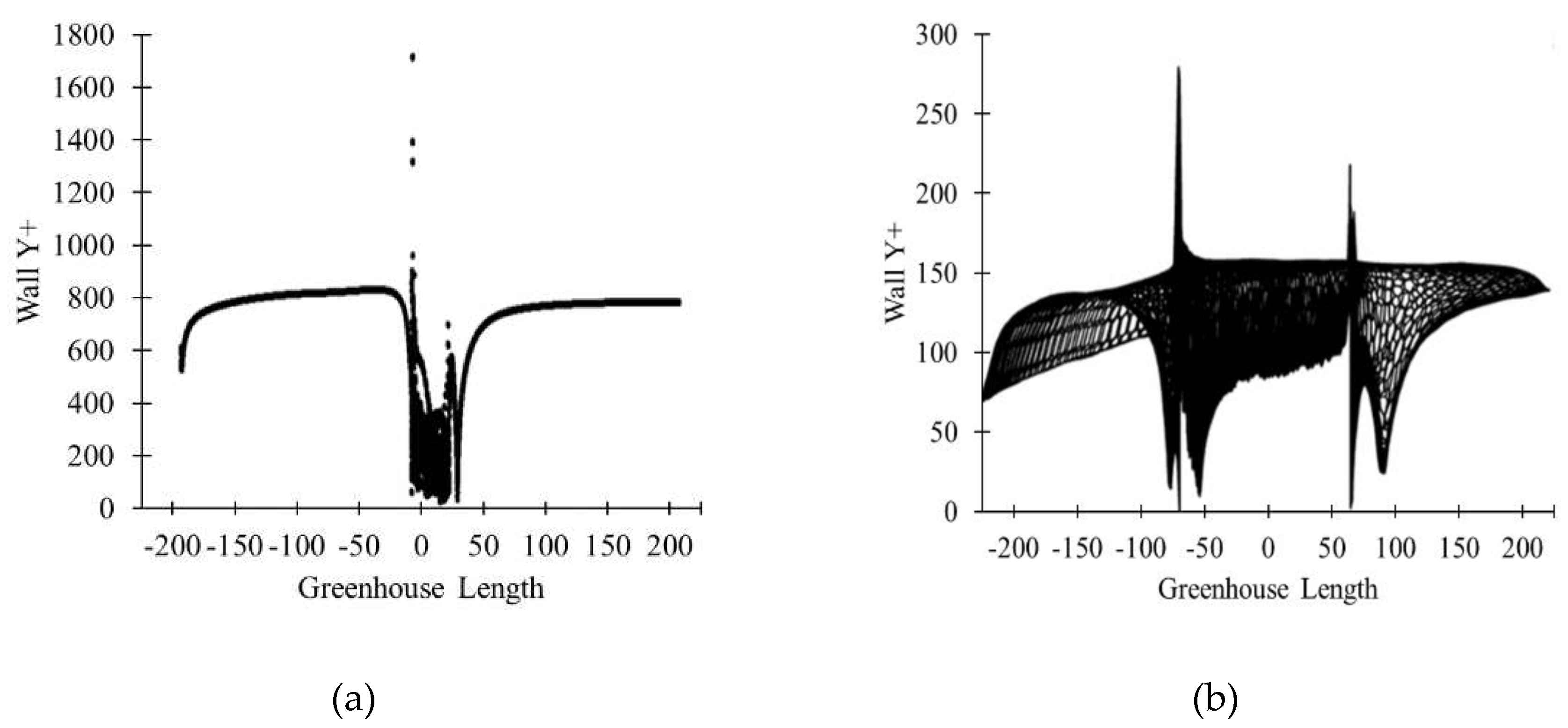

2.5.2. Wall Y+

2.6. Ventilation efficiency theories.

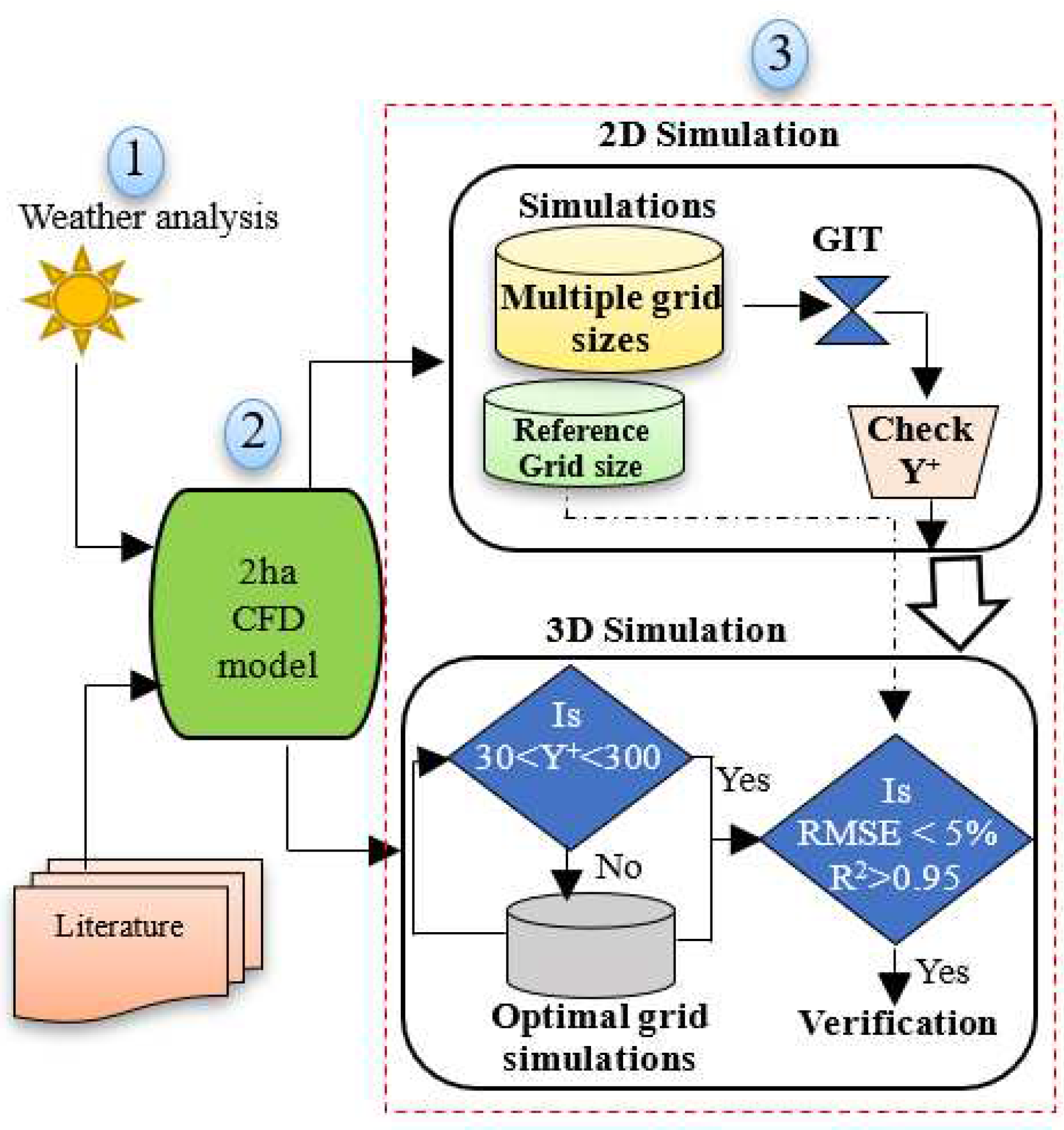

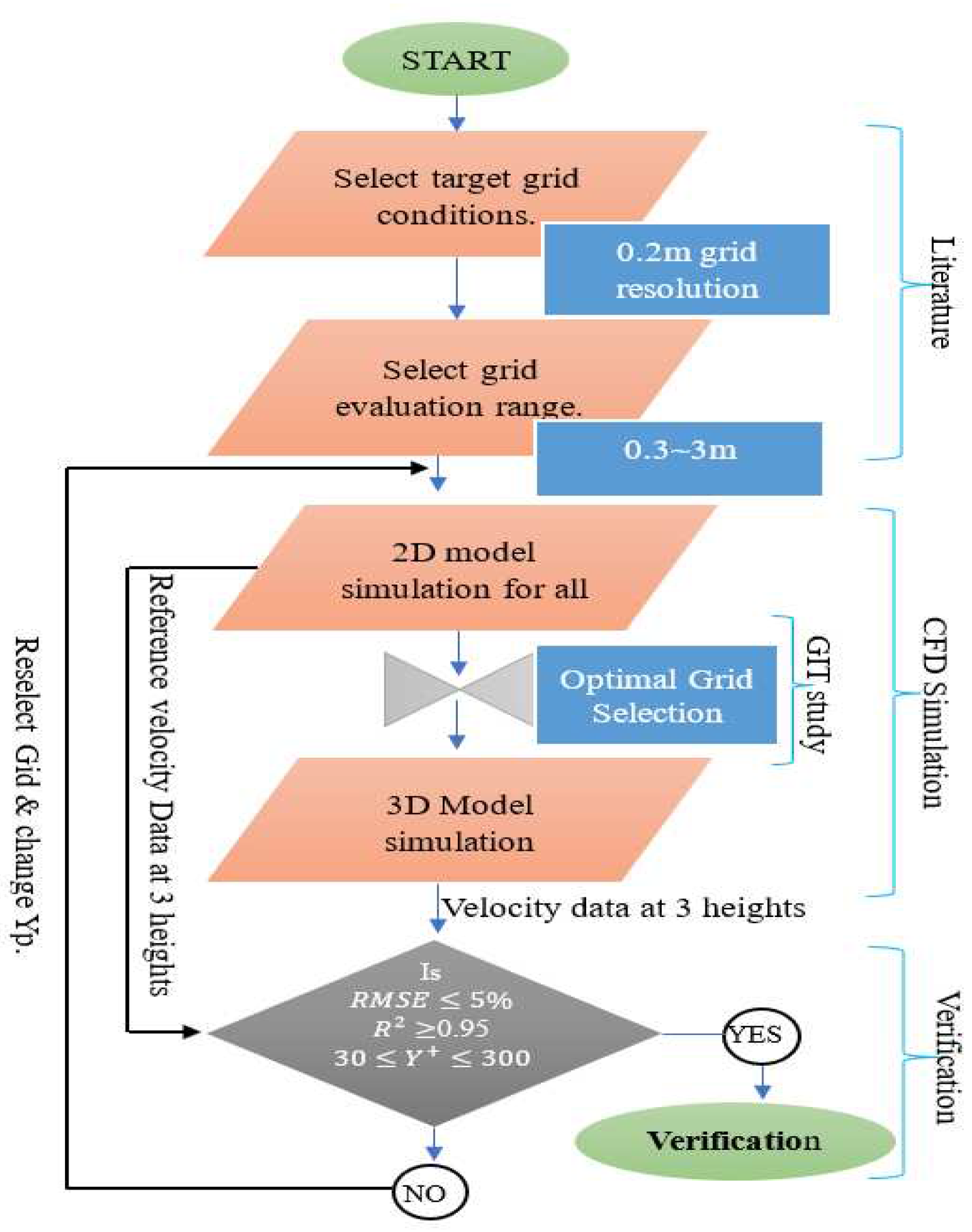

2.7. Study procedure

2.7.1. Weather analysis

2.7.2. Greenhouse CFD model design and simulation

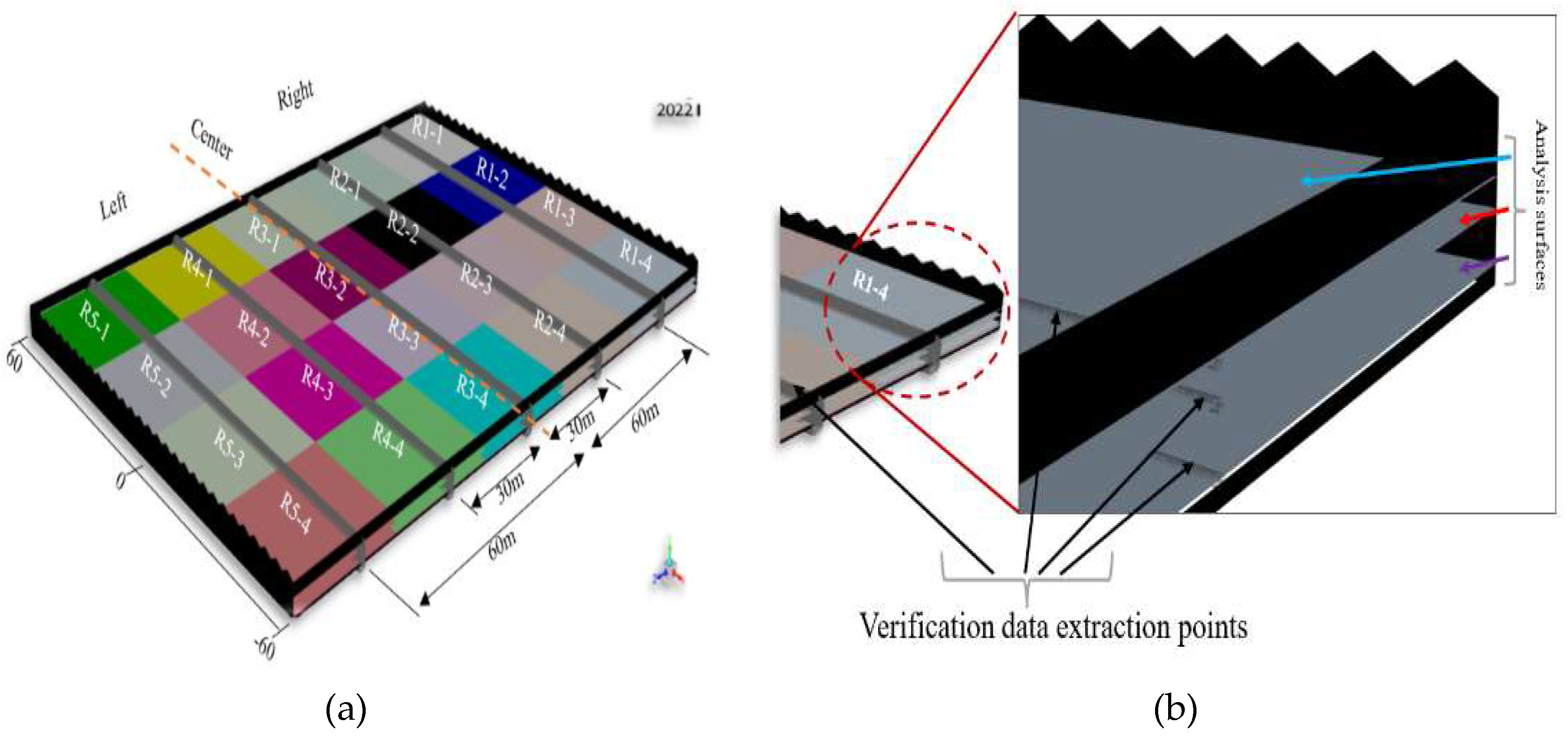

2.7.3. Model verification procedure

- Identifying a recommended grid size. 0.2 m grid resolution and RNG k-ε turbulence model were adapted from literature and used in 2D simulation to generate a reference set of data.

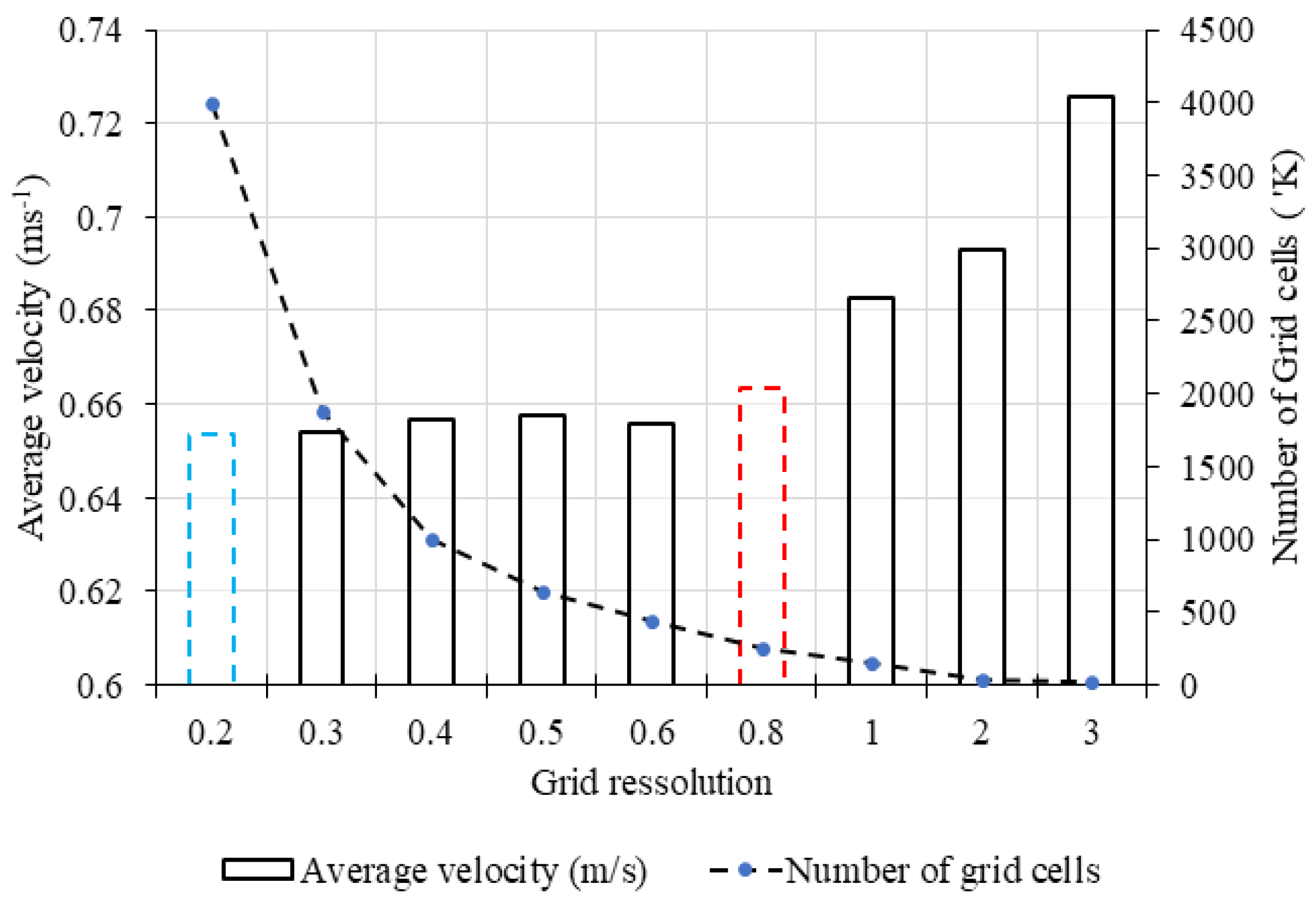

- Selection of grid resolution range for GIT study. With reference to reviewed literature, a range between 0.3 m to 3 m resolution was selected for optimal resolution determination.

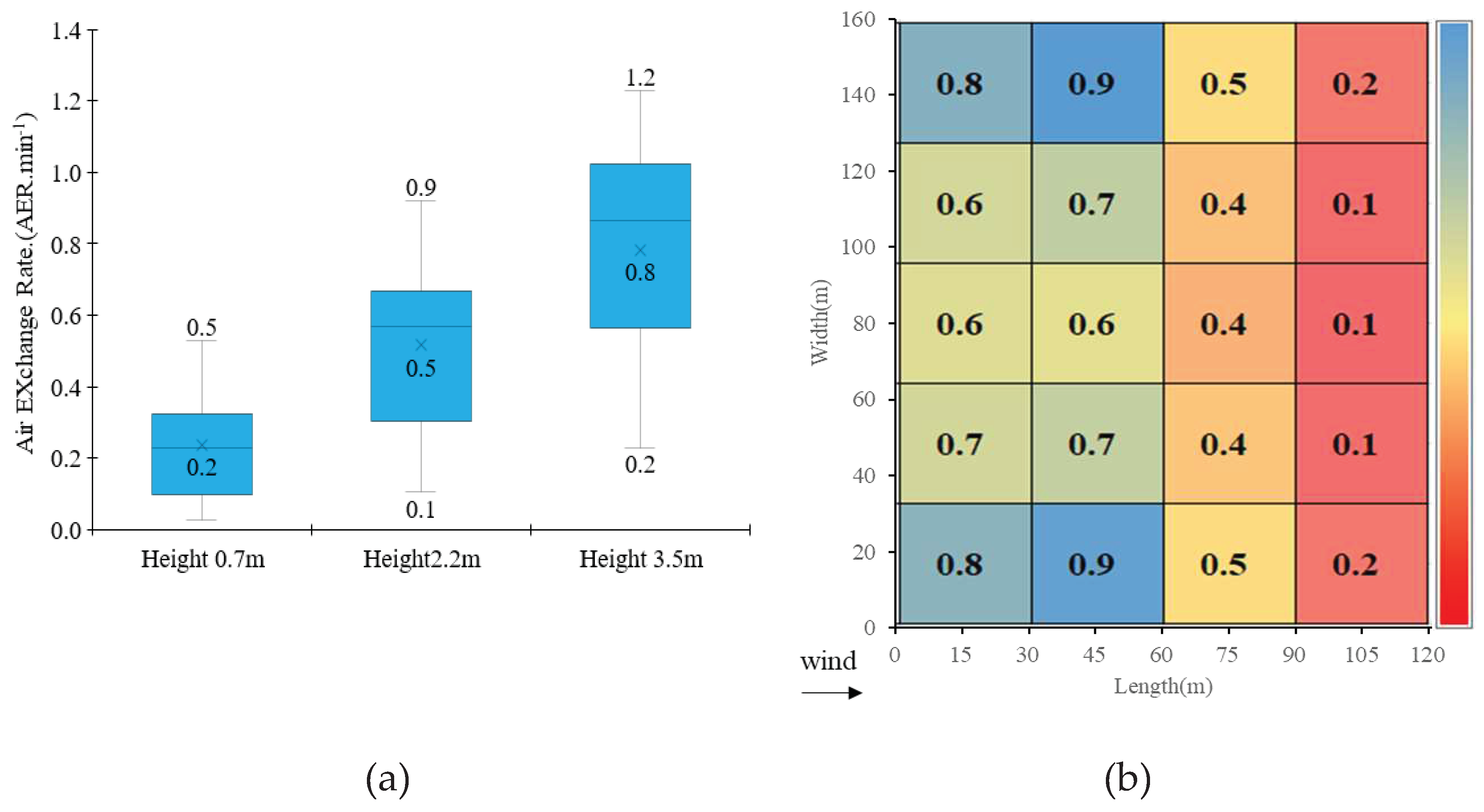

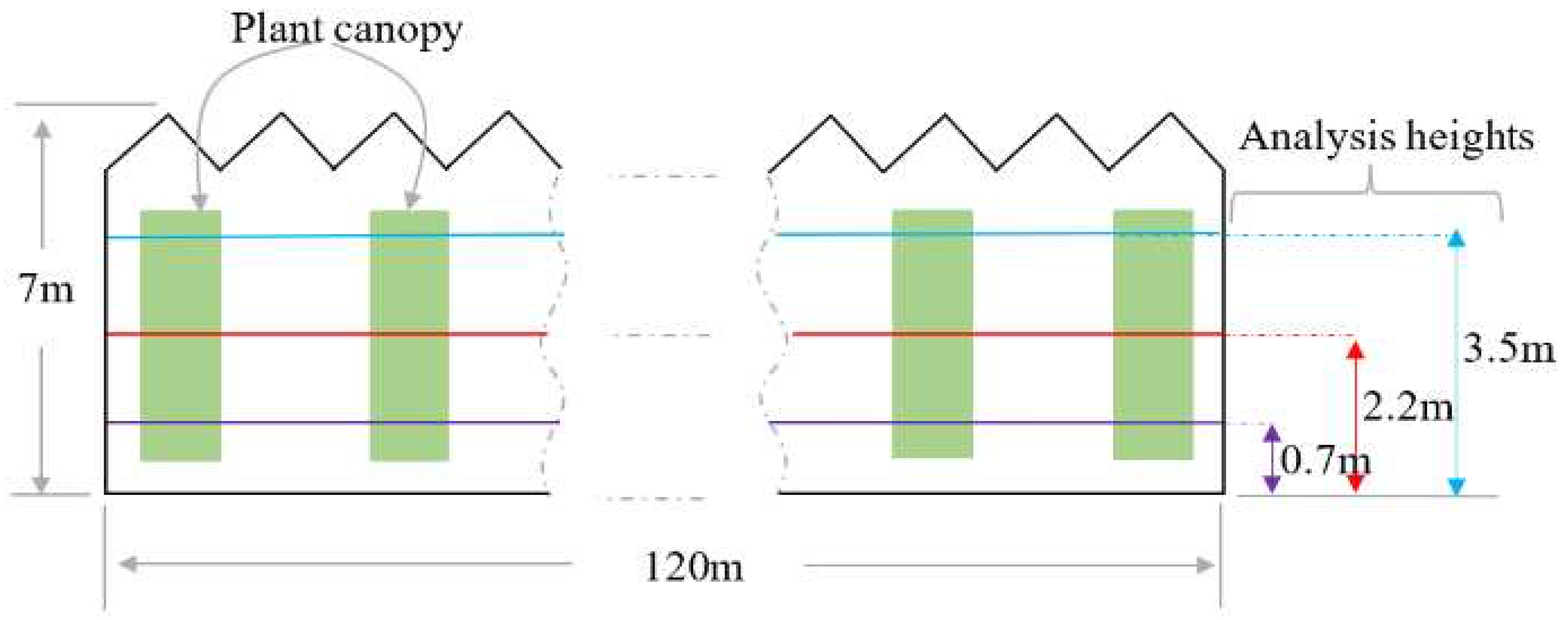

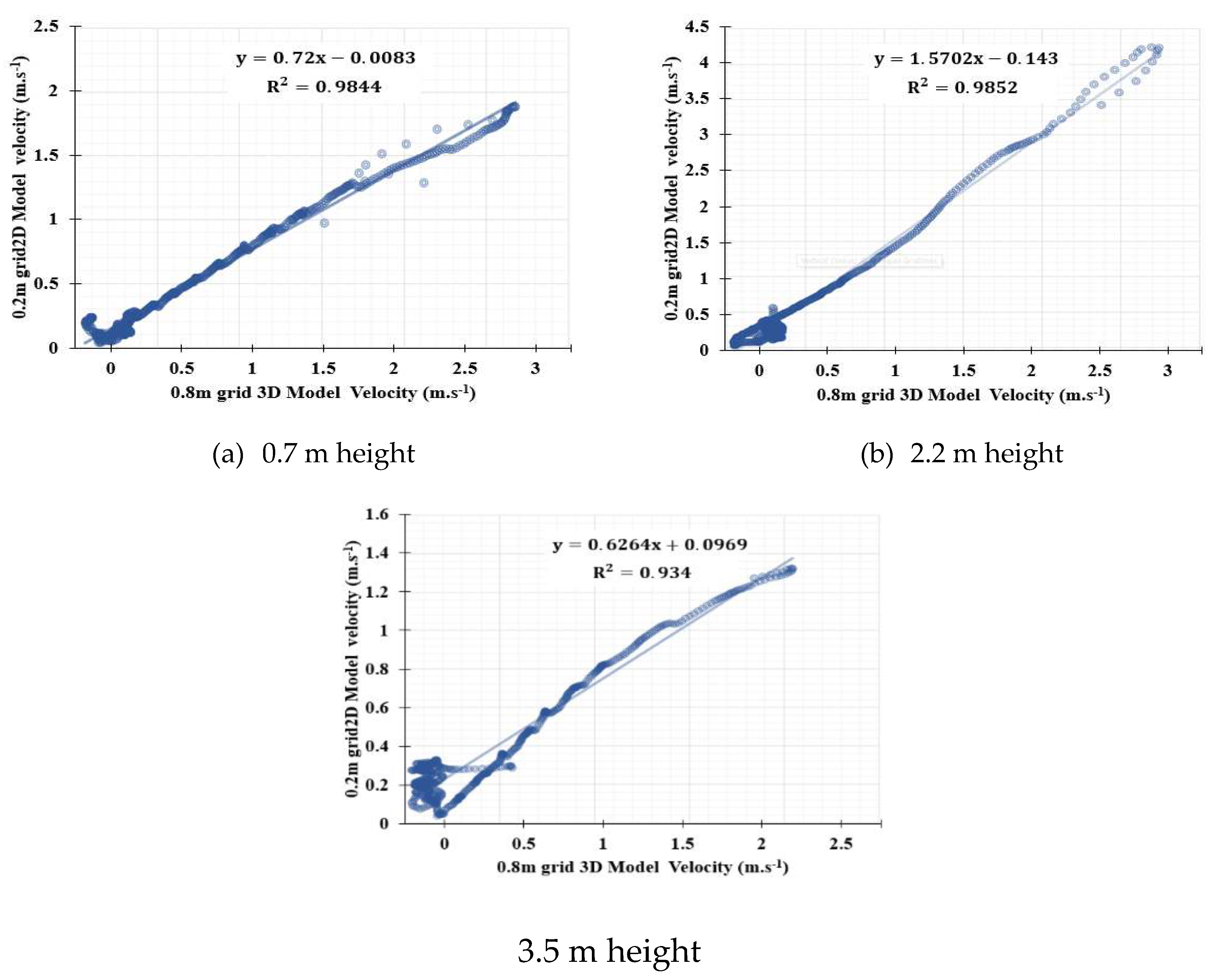

- 2D simulation. The 0.2 m grid resolution model was simulated to generate reference air velocity data. Coarse grid resolution models were also simulated, and average velocity data was extracted at 0.7 m, 2.2 m, and 3.5 m heights.

- GIT study. The average air velocity data for all the coarse grid resolutions was compared to the reference data. The grid resolution above, which the results started to diverge away from the reference data was selected as optimal grid and tested in 3D model.

- 3D simulation. The selected optimal grid was used to make the 3D model and simulated with the same boundary condition with the 2D simulation. Average air velocity was extracted at the study heights and wall Y+ was checked.

- Verification. The 3D results were statistically compared to the reference data by evaluating the R2, RMSE and checking Y+. Near wall mesh refinement using the first layer height of 0.04 m was used to iteratively adjust wall Y+ value into the target range. When the verification procedure was all satisfied, natural ventilation, micro-environment distribution and flow pattern were analyzed to assess the performance of the designed model.

2.8. Analysis procedure

3. Results and discussion

| Parameters (units) | Material | Value |

|---|---|---|

| Refractive index | Polythene (floor cover) | 0.8 |

| Thickness (mm) | Cover glass | 4.0 |

| Density (kgm-3) | Soil | 1900 |

| Glass | 2700 | |

| Specific heat (J.kg-1.0C-1) | Soil | 2200 |

| Glass | 840 | |

| Thermal conductivity (W.m2. 0C) | Soil | 2.0 |

| Glass | 0.78 | |

| Absorption coefficient | Soil | 0.5 |

| Glass | 0.1 | |

| Scattering coefficient | Soil | 1.0 |

| Glass | 0 | |

| Refractive index | Soil | 1.0 |

| Glass | 1900 |

| Variable | CFD Solver setting |

|---|---|

| Time | Steady state (3D, 2D) / Transient state(3D) |

| Solver | Pressure based solver |

| Numerical algorithm | SIMPLE algorithm |

| Discretization | Second order |

| Operating pressure | 101,325 pa |

| Gravity | 9.81 (m·s-2) |

| Air density | Variable (ideal gas) |

| Air viscosity | 1.78994 (kg·m-1·s-1) |

| Turbulence | RNG κ-ε |

| Empirical wall function | Enhanced wall functions |

| Height | R- Square | RMSE |

|---|---|---|

| 0.7 | 0.9844 | 5.61 |

| 2.2 | 0.9852 | 3.96 |

| 3.5 | 0.934 | 2.2 |

| Average | 0.968 | 3.923 |

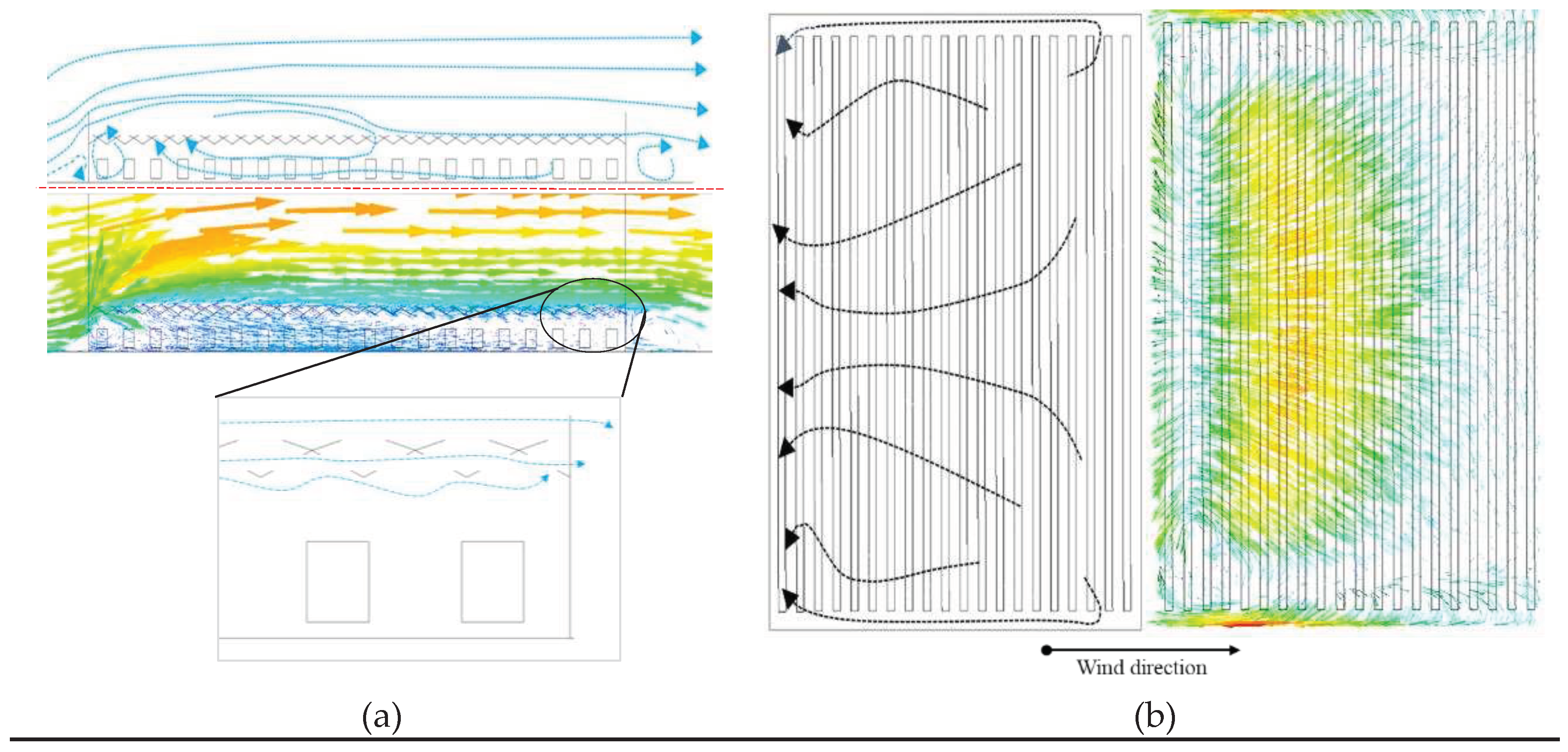

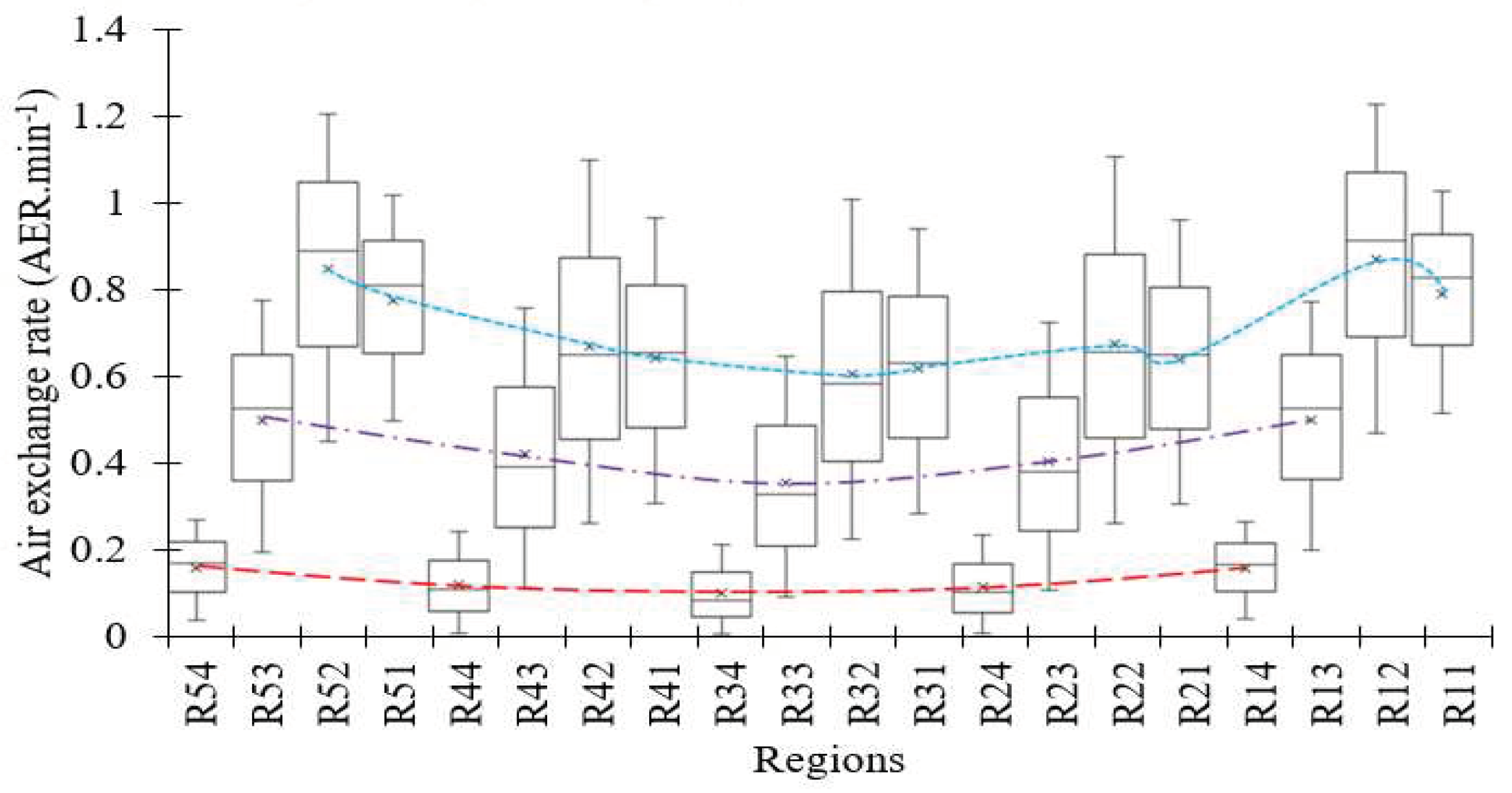

Aerodynamic analysis of 3D greenhouse model

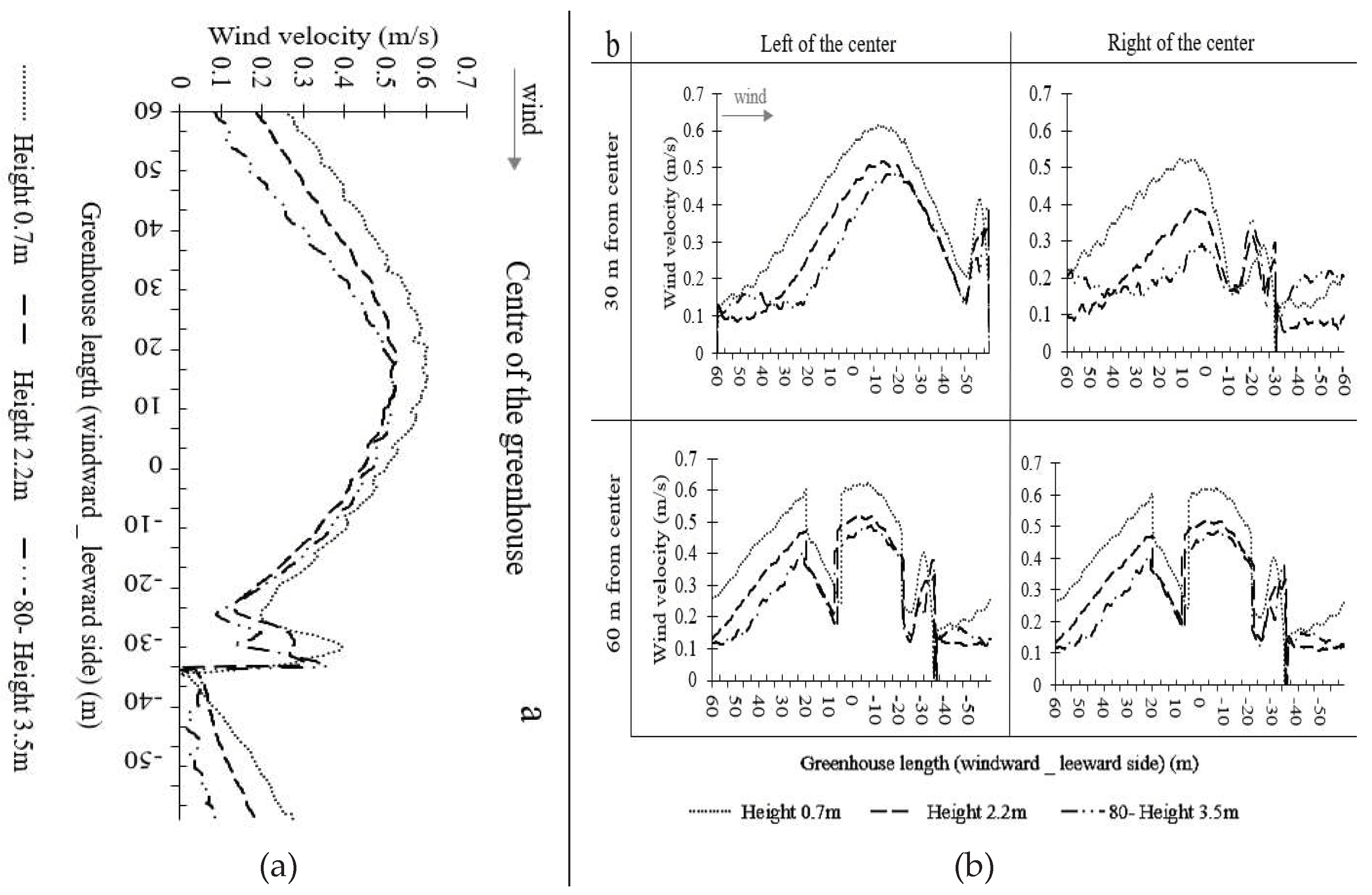

Internal air velocity profile and air flow pattern.

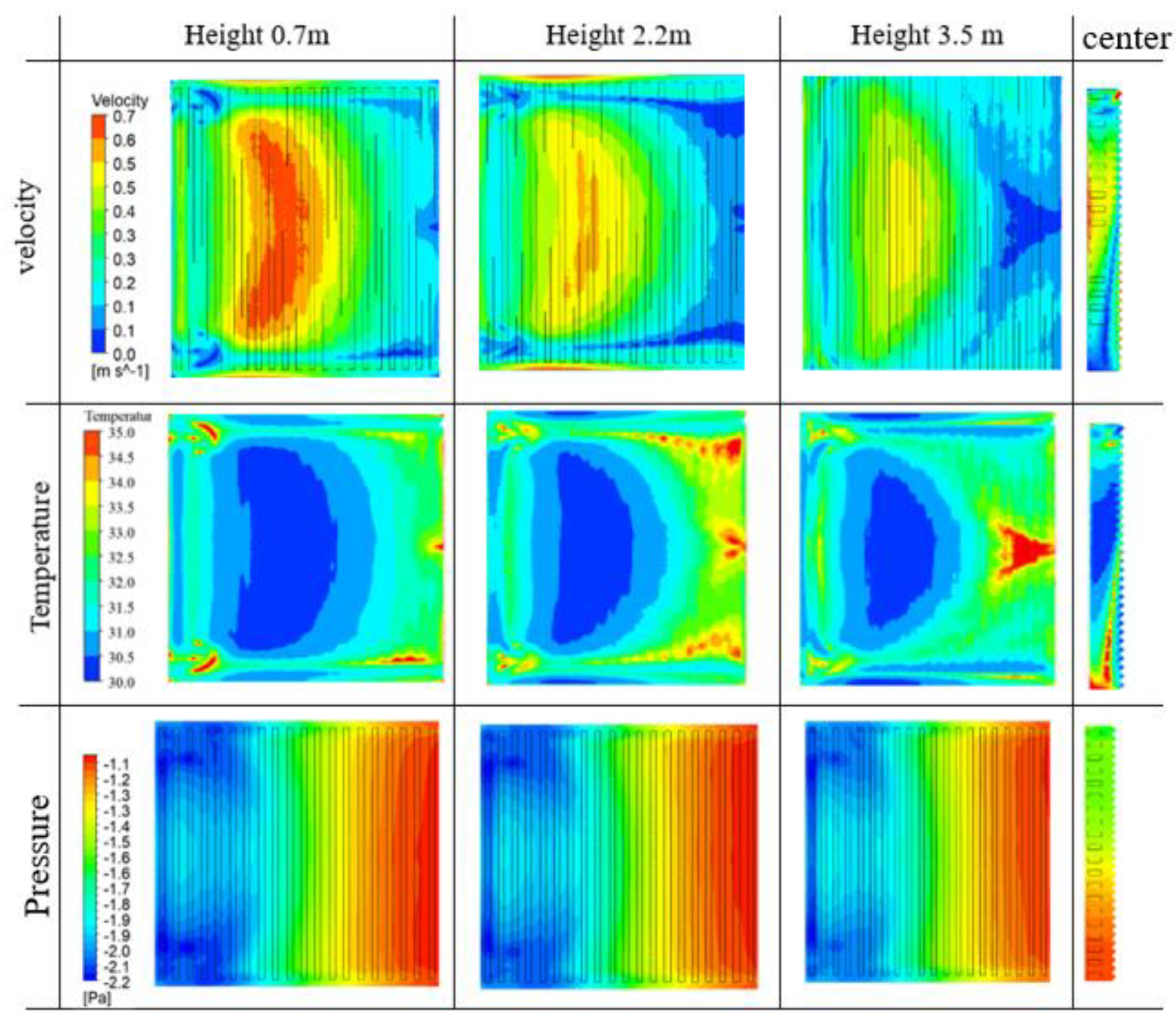

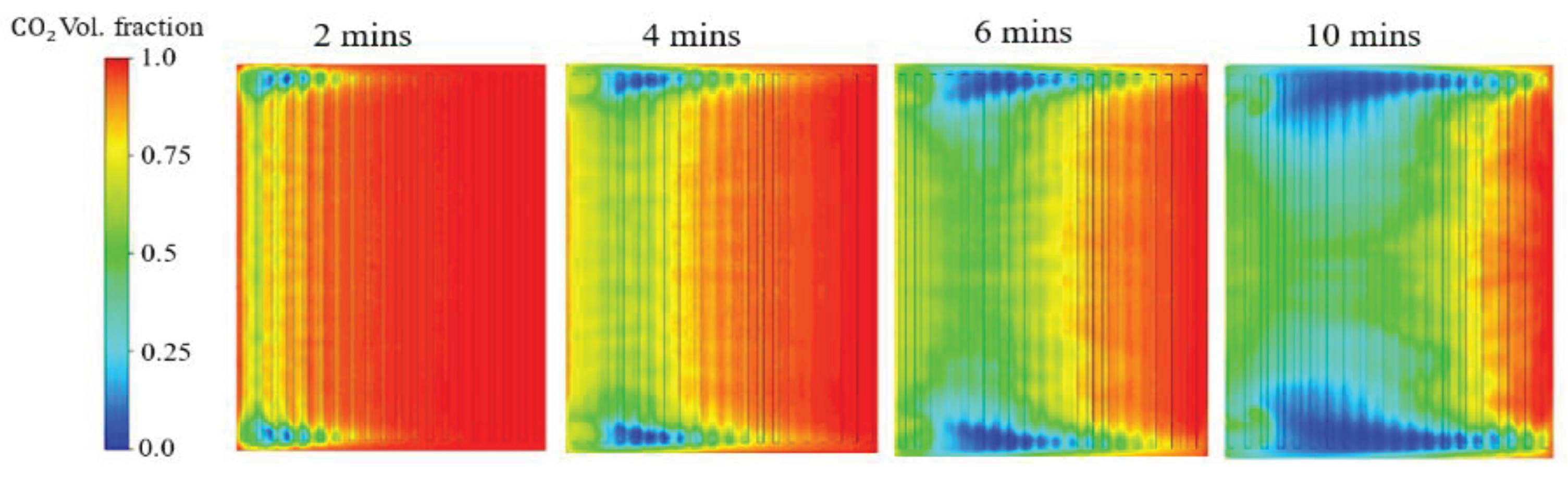

Internal environmental distribution

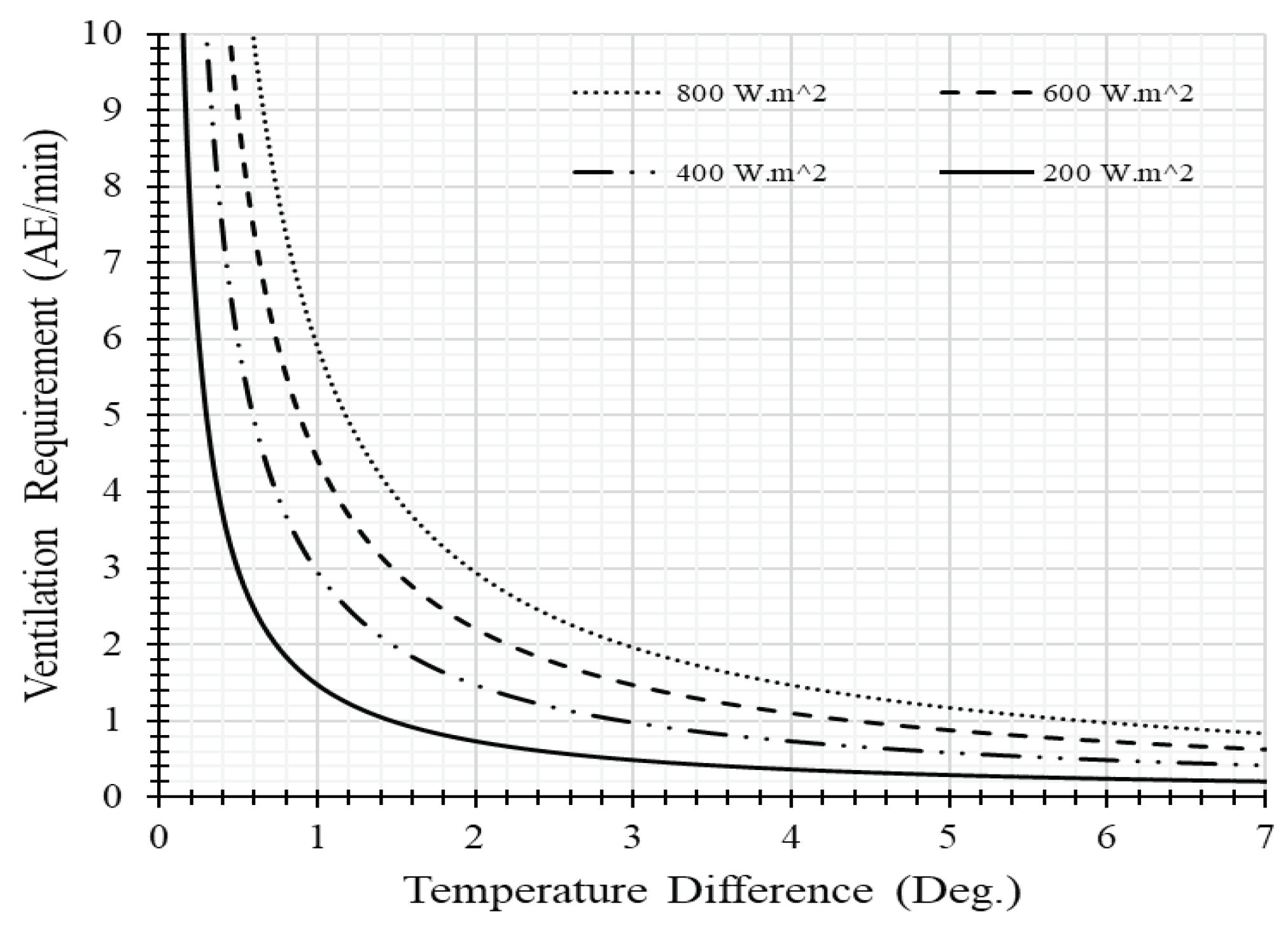

Ventilation efficiency.

4. Conclusions

Acknowledgments

References

- Misra, A.K. Climate change and challenges of water and food security. Int. J. Sustain. Built Environ. 2014, 3, 153–165. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production – A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- Akrami; et al. Study of the effects of vent configuration on mono-span greenhouse ventilation using computational fluid dynamics. Sustain. 2020, 12. [Google Scholar]

- Lin, D.; Zhang, L.; Xia, X. Hierarchical model predictive control of Venlo-type greenhouse climate for improving energy efficiency and reducing operating cost. J. Clean. Prod. 2020, 264, 121513. [Google Scholar] [CrossRef]

- Villagran, E.; Bojacá, C.; Akrami, M. Contribution to the sustainability of agricultural production in greenhouses built on slope soils: A numerical study of the microclimatic behavior of a typical colombian structure. Sustain. 2021, 13. [Google Scholar] [CrossRef]

- Lee, S.-Y.; et al. Analysis of Natural Ventilation Rates of Venlo-type Greenhouse Built on Reclaimed Lands using CFD. J. Korean Soc. Agric. Eng. 2015, 57, 21–33. [Google Scholar]

- Van, E.J. (wageningen university Henten, Greenhouse climate management : An optimal control approach. 1994.

- Yang, S.H.; Rhee, J.Y. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating. Appl. Energy 2013, 105, 244–251. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. An economical analysis on a solar greenhouse integrated solar assisted geothermal heat pump system. J. Energy Resour. Technol. Trans. ASME 2006, 128, 28–34. [Google Scholar] [CrossRef]

- Canakci, M.; Emekli, N.Y.; Bilgin, S.; Caglayan, N. Heating requirement and its costs in greenhouse structures: A case study for Mediterranean region of Turkey. Renew. Sustain. Energy Rev. 2013, 24, 483–490. [Google Scholar] [CrossRef]

- Campen, J.B.; Bot, G.P.A. Determination of greenhouse-specific aspects of ventilation using three-dimensional computational fluid dynamics. Biosyst. Eng. 2003, 84, 69–77. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Ganguly, A.; Ghosh, S. Model development and experimental validation of a floriculture greenhouse under natural ventilation. Energy Build. 2009, 41, 521–527. [Google Scholar] [CrossRef]

- Katsoulas, N.; Bartzanas, T.; Boulard, T.; Mermier, M.; Kittas, C. Effect of Vent Openings and Insect Screens on Greenhouse Ventilation. Biosyst. Eng. 2006, 93, 427–436. [Google Scholar] [CrossRef]

- Kittas, C.; Bartzanas, T. Greenhouse microclimate and dehumidification effectiveness under different ventilator configurations. Build. Environ. 2007, 42, 3774–3784. [Google Scholar] [CrossRef]

- Molina-Aiz, F.D.; Valera, D.L.; Peña, A.A.; Gil, J.A.; López, A. A study of natural ventilation in an Almería-type greenhouse with insect screens by means of tri-sonic anemometry. Biosyst. Eng. 2009, 104, 224–242. [Google Scholar] [CrossRef]

- Molina-Aiz, F.D.; Fatnassi, H.; Boulard, T.; Roy, J.C.; Valera, D.L. Comparison of finite element and finite volume methods for simulation of natural ventilation in greenhouses. Comput. Electron. Agric. 2010, 72, 69–86. [Google Scholar] [CrossRef]

- Khaoua, S.S.A.O.; Bournet, P.E.; Migeon, C.; Boulard, T.; Chassériaux, G. Analysis of Greenhouse Ventilation Efficiency based on Computational Fluid Dynamics. Biosyst. Eng. 2006, 95, 83–98. [Google Scholar] [CrossRef]

- Teitel, M.; Ziskind, G.; Liran, O.; Dubovsky, V.; Letan, R. Effect of wind direction on greenhouse ventilation rate, airflow patterns and temperature distributions. Biosyst. Eng. 2008, 101, 351–369. [Google Scholar] [CrossRef]

- Lee, I.-B.; Yun, N.-K.; Boulard, T.; Roy, J.C.; Lee, S.-H.; Kim, G.-W.; K. S.-H. S-K. Development of an aerodynamic simulation for studying microclimate of plant canopy in greenhouse. J Bio-Environ Contr. 2006, 15, 289–295. [Google Scholar]

- Yu, I.-H.; Yun, N.-K.; Cho, M.-W.; Ryu, H.-R.; Moon, D.-G. Development of CFD model for analyzing the air flow and temperature distribution in greenhouse with air-circulation fans. Korean J. Agric. Sci. 2014, 41, 461–472. [Google Scholar]

- Hong, S.W.; et al. Validation of an open source CFD code to simulate natural ventilation for agricultural buildings. Comput. Electron. Agric. 2017, 138, 80–91. [Google Scholar] [CrossRef]

- Choi, M.K.; Yun, S.W.; Yu, I.H.; Lee, S.Y.; Lee, S.; Yoon, Y.C. Settlement Instrumentation of Greenhouse Foundation in Reclaimed Land. Prot. Hortic. Plant Fact. 2015, 24, 85–92. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, I.B.; Kim, R.W. Evaluation of wind-driven natural ventilation of single-span greenhouses built on reclaimed coastal land. Biosyst. Eng. 2018, 171, 120–142. [Google Scholar] [CrossRef]

- Villagran, E.; Ramirez, R.; Rodriguez, A.; Pacheco, R.L.; Jaramillo, J. Simulation of the thermal and aerodynamic behavior of an established screenhouse under warm tropical climate conditions: A numerical approach. Int. J. Sustain. Dev. Plan. 2020, 15, 487–499. [Google Scholar] [CrossRef]

- Villagrán, E.; Bojacá, C. Study using a CFD approach of the efficiency of a roof ventilation closure system in a multi-tunnel greenhouse for nighttime microclimate optimization. Rev. Ceres 2020, 67, 345–356. [Google Scholar] [CrossRef]

- Washino, K.; Chan, E.L.; Kaji, T.; Matsuno, Y.; Tanaka, T. On large scale CFD–DEM simulation for gas–liquid–solid three-phase flows. Particuology 2021, 59, 2–15. [Google Scholar] [CrossRef]

- Nam, S.-W.; Shin, H.-H. Analysis on the Characteristics of Ventilation and Cooling for Greenhouses Constructed in Reclaimed Lands. Prot. Hortic. Plant Fact. 2017, 26, 181–187. [Google Scholar] [CrossRef]

- ASHRAE, 2021 ASHRAE Handbook- Fundamentals. 2021.

- Majdoubi, H.; Boulard, T.; Fatnassi, H.L. Bouirden. Airflow and microclimate patterns in a one-hectare Canary type greenhouse: An experimental and CFD assisted study. Agric. For. Meteorol. 2009, 149, 1050–1062. [Google Scholar] [CrossRef]

- Boulard, T.; Wang, S. Experimental and numerical studies on the heterogeneity of crop transpiration in a plastic tunnel. Comput. Electron. Agric. 2002, 34, 173–190. [Google Scholar] [CrossRef]

- Bartzanas, T.; Boulard, T.; Kittas, C. Numerical simulation of the airflow and temperature distribution in a tunnel greenhouse equipped with insect-proof screen in the openings. Comput. Electron. Agric. 2002, 34, 207–221. [Google Scholar] [CrossRef]

- Hong, S.W.; Lee, I.B.; Seo, I.H. Modelling and predicting wind velocity patterns for windbreak fence design. J. Wind Eng. Ind. Aerodyn. 2015, 142, 53–64. [Google Scholar] [CrossRef]

- Peng, N.; Hong, S.; Zhang, N.J. Experimental and numerical evaluation of wind-driven natural ventilation and dust suppression effects of coal sheds with porous gables. Build. Environ. 2020, 177. [Google Scholar]

- Canonsburg, T.D. ANSYS FLUENT User ’ s Guide. Knowl. Creat. Diffus. Util. 2012, 15317, 724–746. [Google Scholar]

- Franke. Best practice guideline for the CFD simulation of flows in the urban environment - a summary, 2007.

- Tominaga; et al. AIJ guidelines for practical applications of CFD to pedestrian wind environment around buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Hoxey, R.; Richards, P.; Quinn, A.; Robertson, A.; Gough, H. Measurements of the static pressure near the surface in the atmospheric boundary layer. J. Wind Eng. Ind. Aerodyn. 2021, 209, 104487. [Google Scholar] [CrossRef]

- Boache, P.J. Perspective: A method for uniform reporting of grid refinement studies. J. Fluids Eng. Trans. ASME 1994, 116, 405–413. [Google Scholar]

- Ferziger, J.H.; Peric. Computational Methods for Fluid Dynamics 2002.

- Wilcox, D.C. Turbulence Modelling for CFD 3rd Edition. 1993.

- Utyuzhnikov, S.V. Generalized wall functions and their application for simulation of turbulent flows. Int. J. Numer. Methods Fluids 2005, 47, 1323–1328. [Google Scholar] [CrossRef]

- Craft, T.J.; Gant, S.E.; Gerasimov, A.V.; Iacovides, H.; Launder, B.E. Wall-Function Strategies for Use in Turbulent Flow Cfd. no. January, p. 12, 2019.

- Ariff, M.; Salim, S.; Cheah, S. WALL Y + APPROACH FOR DEALING WITH TURBULENT FLOW OVER A SURFACE MOUNTED CUBE : PART 1 – LOW REYNOLDS NUMBER pertencentes à subcamada viscosa e a regiao buffer para pertencer à y A variavel wall y + é um número adimensional similar ao número de determin. 7th Int. Conf. CFD Miner. Process Ind. 2009; 6. [Google Scholar]

| Parameter | Value |

|---|---|

| Karman constant(k) | 0.42 |

| Roughness length (Z0) | 0.03 m |

| Empirical constant | 0.09 |

| Reference height () | 10 m |

| Summer average wind speed | 3.08 m·s-1 |

| Frictional velocity (u*) | 0.227 m·s-1 |

| Parameter | Symbol | Value |

|---|---|---|

| Volumetric specific heat of air (Wm-3 oC-1) | CV | 0.3 |

| Correction rate of heated area | α | 1.2 |

| Solar transmissivity of greenhouse cover | τ | 0.7 |

| Solar radiation (Wm-2.m-1) | s | 200,400,600,800 |

| Evapotranspiration coefficient (Tomato) | f | 0.5 |

| Temperature difference (℃) | ∆T | 1~7 |

| Overall heat transfer ceff.(Wm2.min-1. oC -1) | K | 0.08 |

| Greenhouse flow area (m2) | Af | 19200 |

| Greenhouse cover area(m2) | Ac | 24,946.3 |

| Greenhouse volume(m3) | V | 124800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).