Submitted:

10 July 2023

Posted:

11 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

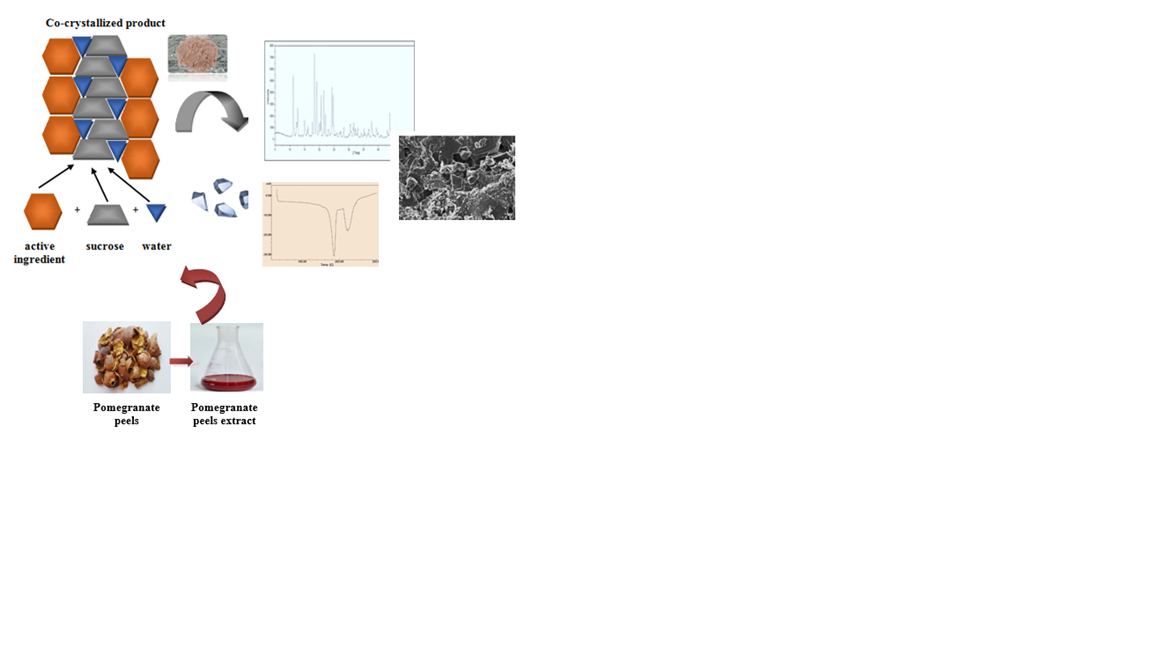

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Phenolic Extract

2.3. Co-Crystallization Procedure

2.4. Characterization of the Product

- Moisture content

- The moisture content (% wet basis) of the co-crystallized product was calculated by drying at 105 °C until constant weight [31].

- Solubility

- The solubility was determined by dissolving 1 g of powder in 25 mL of distilled water at ambient temperature with continuous agitation at 890 rpm [32].

- Bulk density

- The bulk density was calculated by dividing the mass of a co-crystallized powder sample (about 2 g) by its volume in a 50 mL graduated cylinder [33].

- Hygroscopicity

- About 1 g of co-crystallized powder was placed in a desiccator with HNO3 solution at 23 °C and 76% relative humidity on dishes to create a high surface area between air and powder. The increase or decrease of powder weight per gram of its solids was measured [16].

- Color

- A Minolta colorimeter (CR-400, Konica-Minolta Sensing, Japan) was used for the evaluation of color using the CIE-L* a* b* uniform color space. The powder was placed in 5 cm-diameter dishes in a layer with a thickness of approximately 0.5 cm.

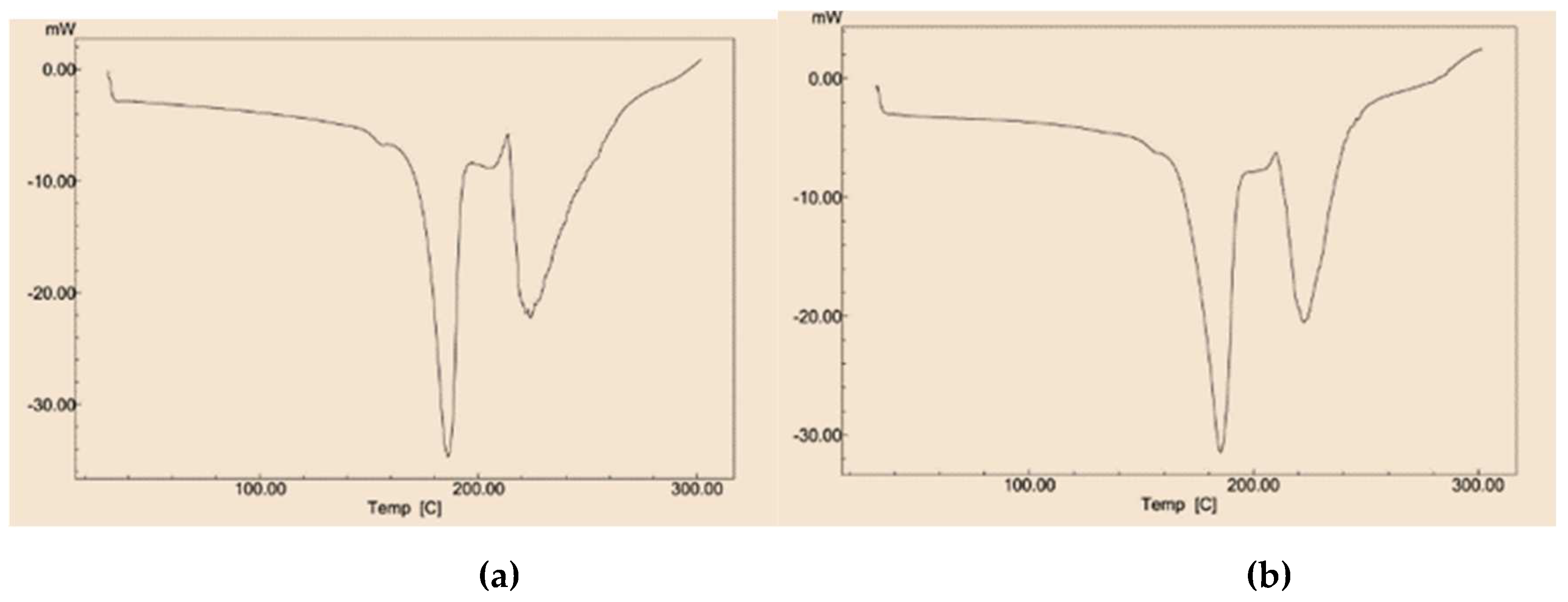

- Differential scanning calorimetry

- Samples (2-10 mg) of pure crystalline sucrose, co-crystallized sucrose without the active ingredient, and co-crystallized sucrose with the encapsulated ingredient are used for differential scanning calorimetry (DSC) analysis with a Perkin–Elmer Pyris 1 differential scanning calorimeter, as described by Kaderides and Goula [34]. The samples were heated from 25 to 250 oC with a rate of 10 oC/min in inert atmosphere. The reference was an empty pan, whereas liquid nitrogen was used for sample cooling before the runs.

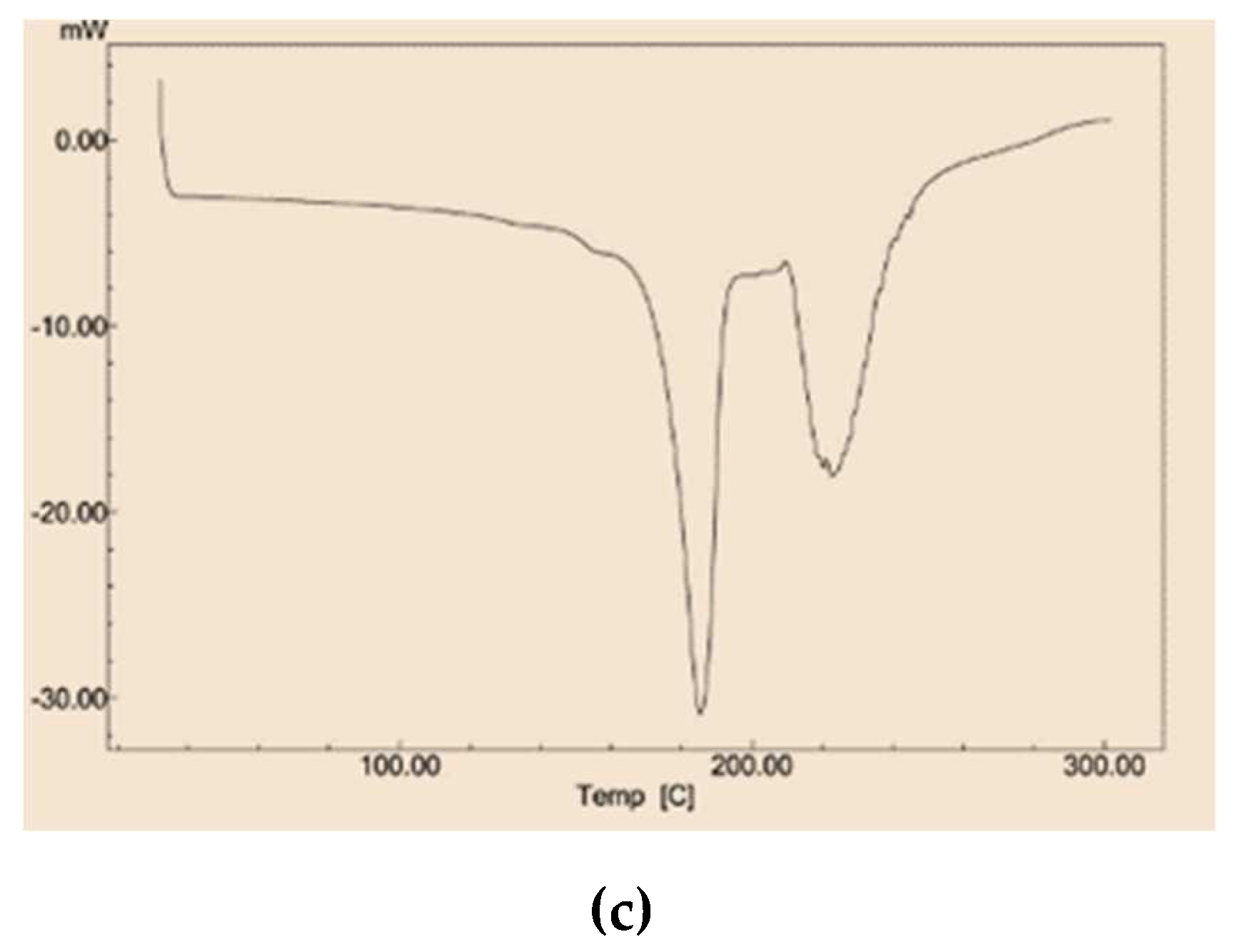

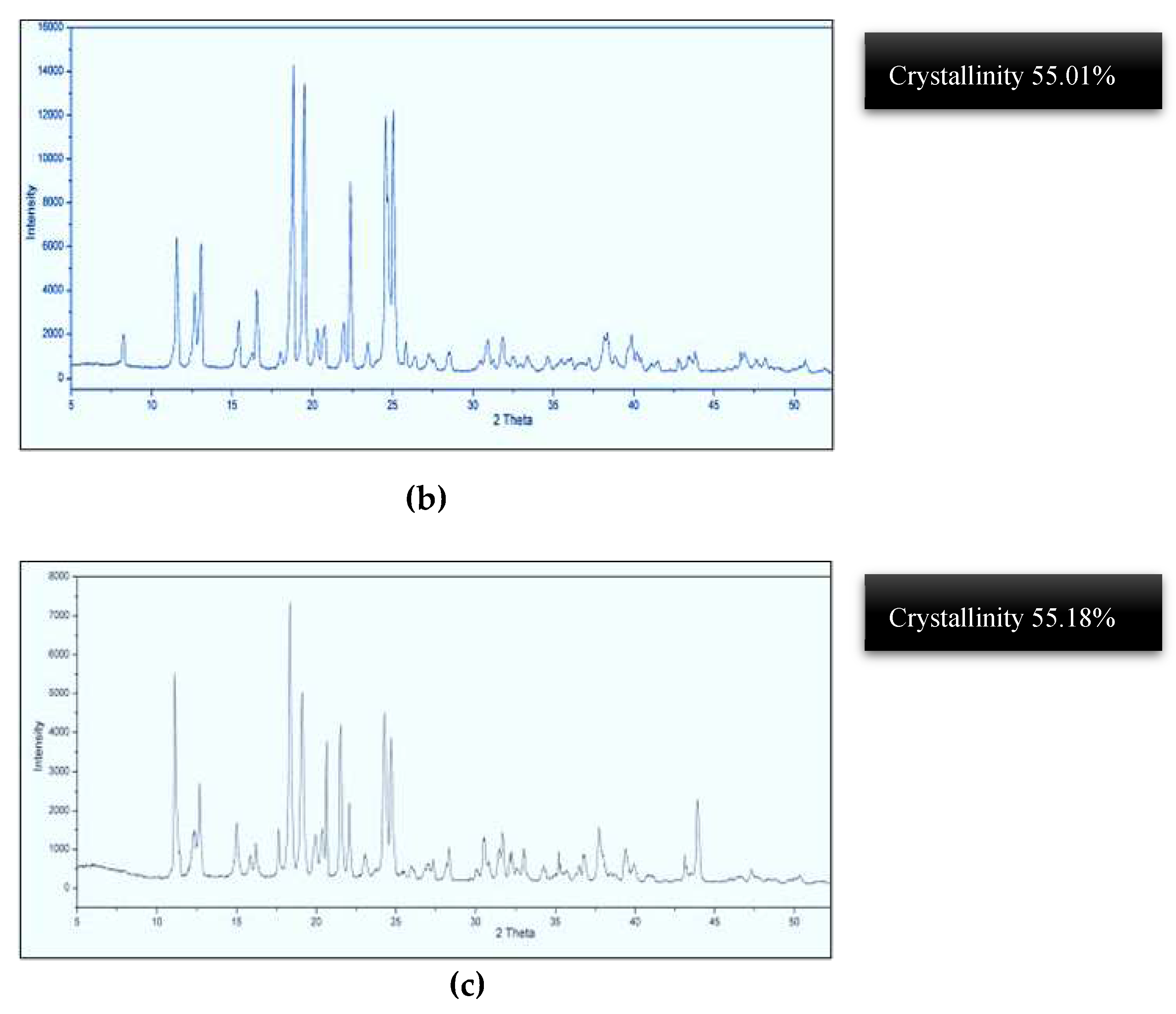

- Degree of crystallinity

- The X-Ray diffraction pattern was determined by using a continuous scan mode (3003 TT, Rich. Seifert) at 40 kV with radiation of wavelength of 40 mÅ and 2θ data between 5 and 60o. All samples were dried at 60 oC before the assay.

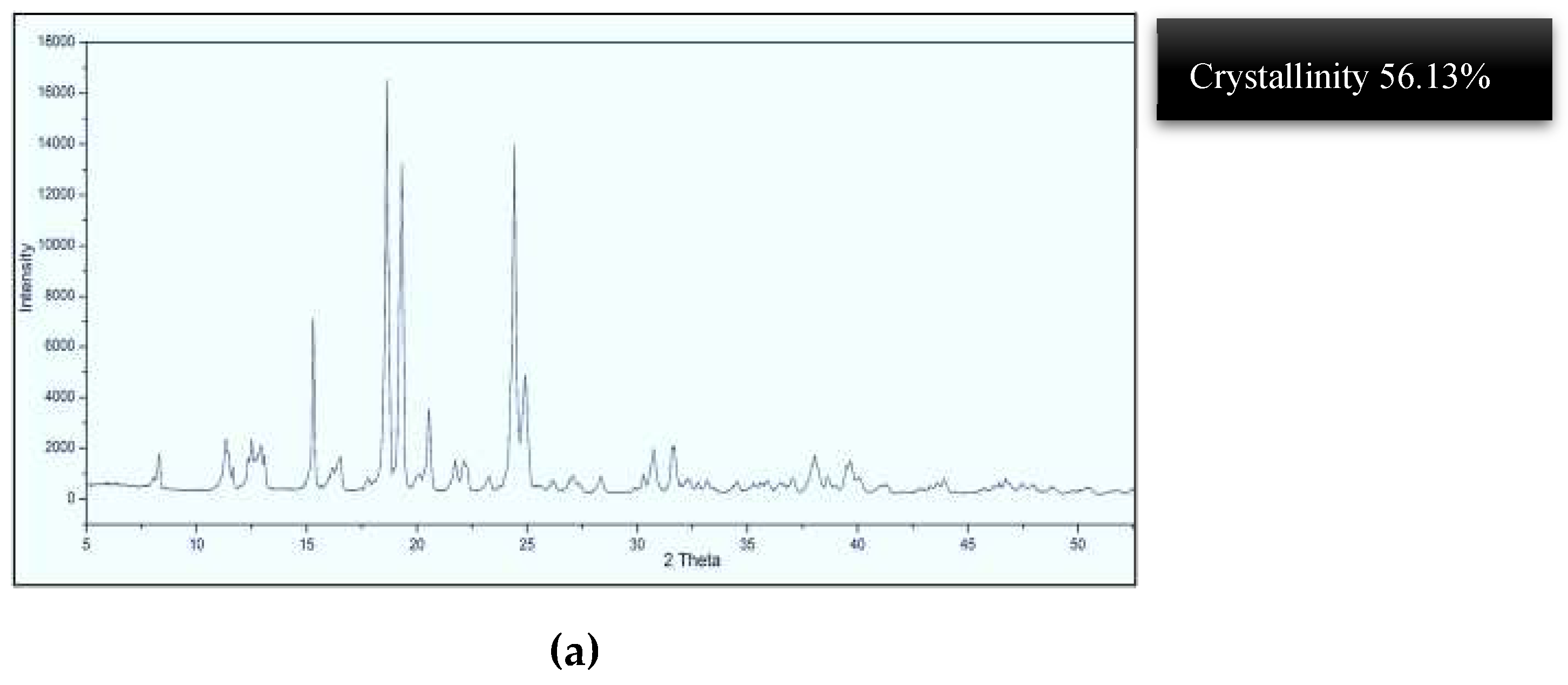

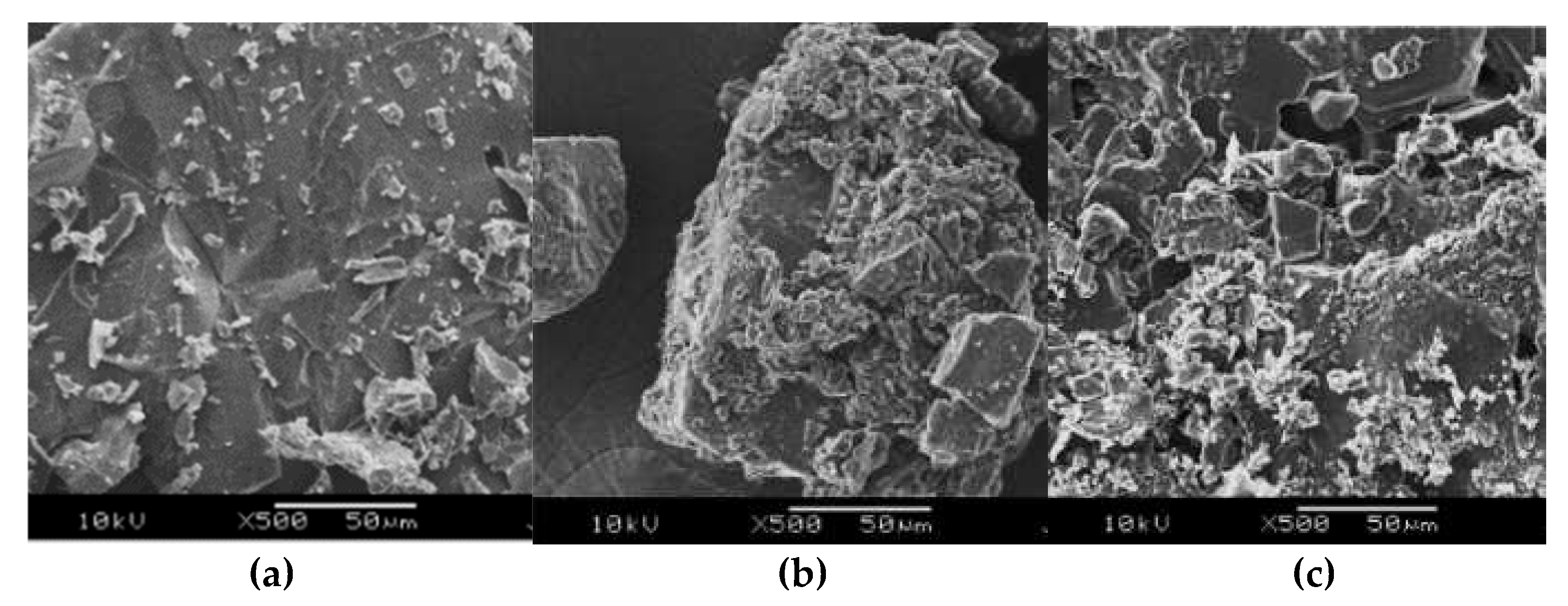

- Morphology

- Particle morphology was evaluated using a Quanta-200 environmental scanning electron microscope system (FEI Company, USA). The samples were examined under high vacuum condition at an accelerating voltage of 10 kV.

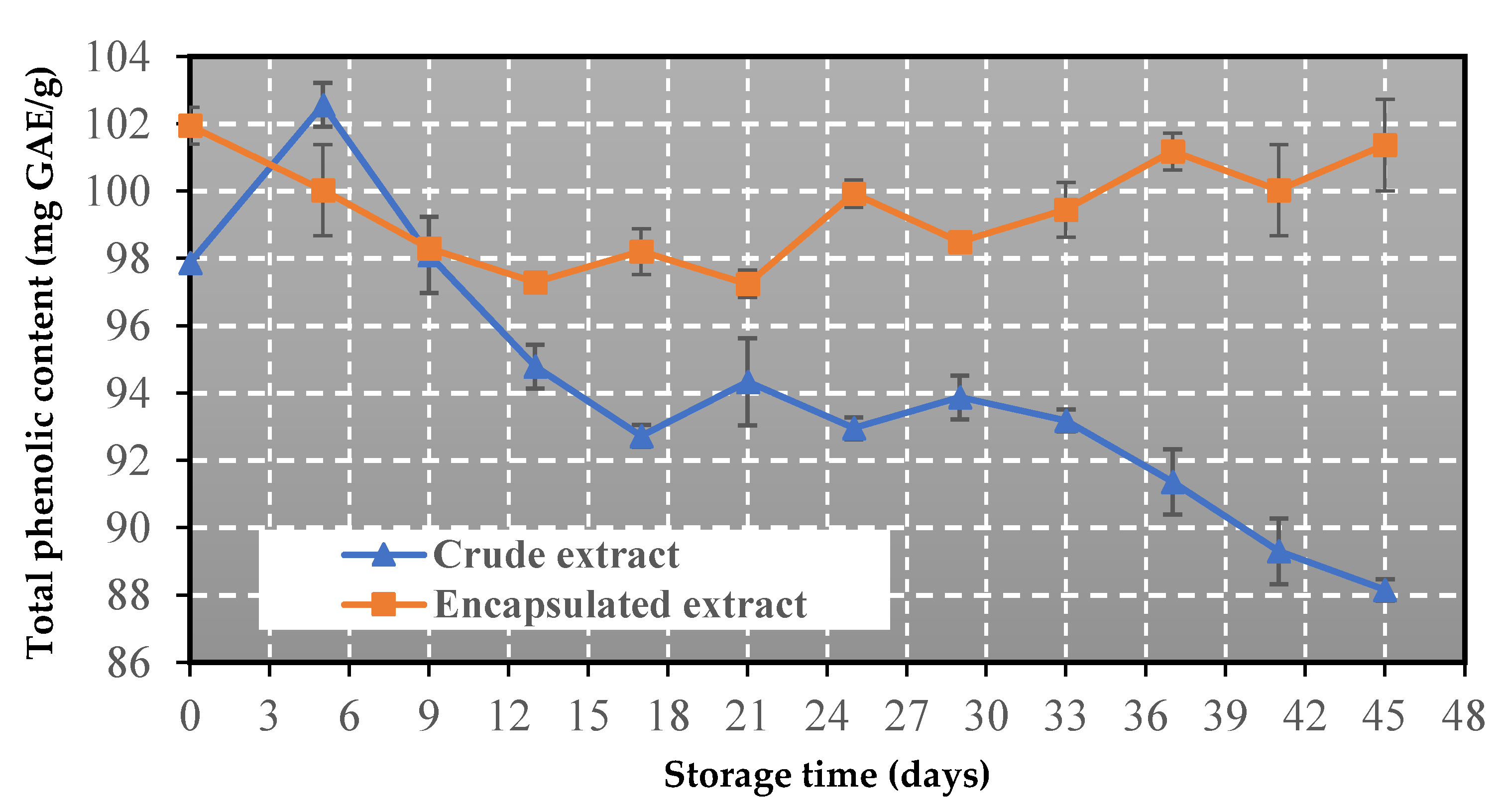

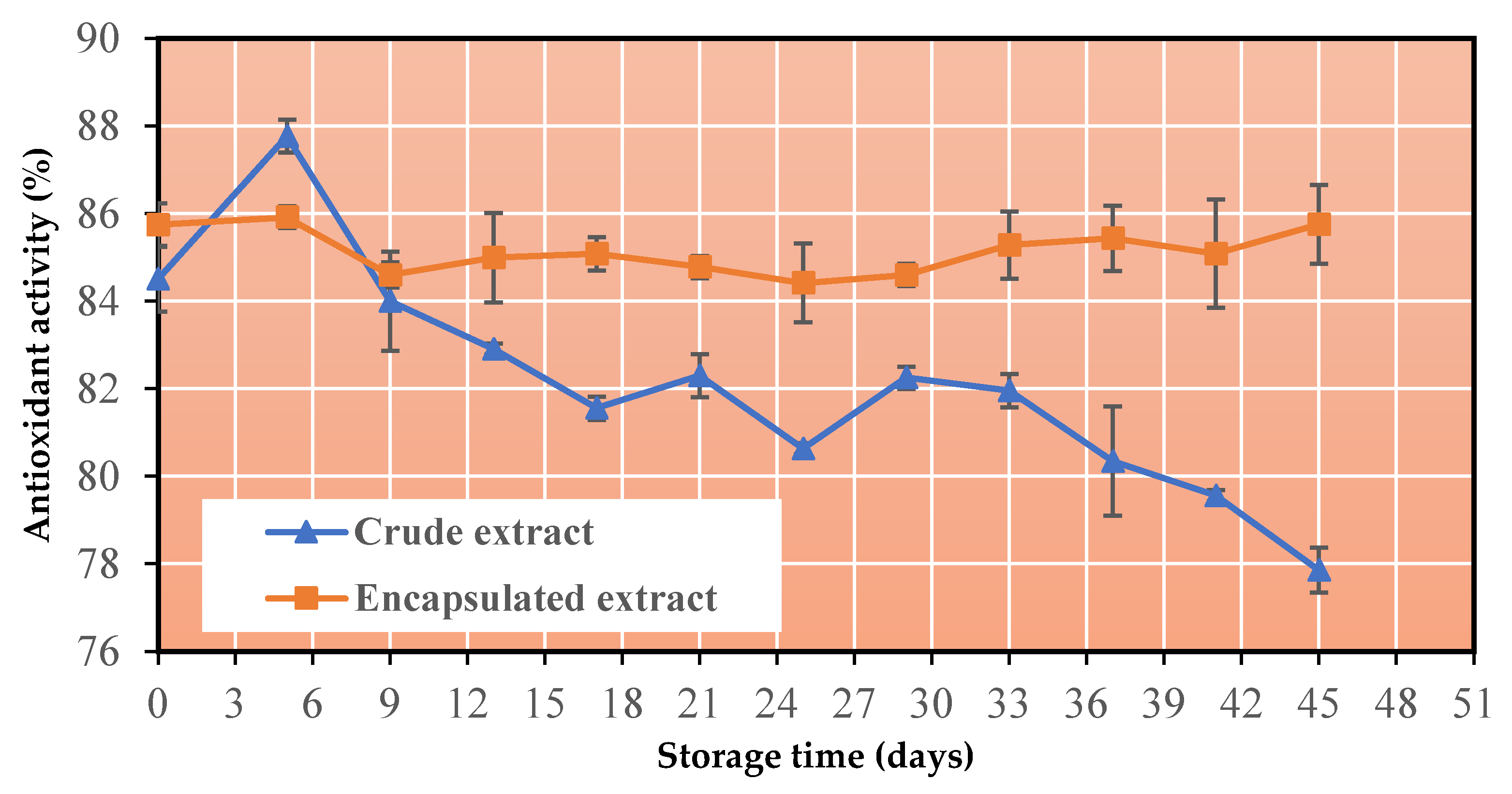

- Storage stability

- The unencapsulated and encapsulated extracts were evaluated for total phenolic content and antiradical activity during storage at 60 °C. Extract samples in vials were stored in the dark in an air oven (Memmert, Schwabach, Germany) at controlled temperature for 45 days. Duplicate samples were collected every 2-3 days for analysis. The total phenolic content (TPC) was determined using the Folin-Ciocalteu method, whereas antiradical activity was measured using the DPPH method [32].

2.5. Statistical Analysis

3. Results and Discussion

3.1. Powder Properties

3.2. Differential Scanning Calorimetry

3.3. Degree of Crystallinity by X-ray Scattering

3.4. Morphology by Scanning Electron Microscope

3.5. Change in Total Phenolic Content

3.6. Change in antioxidant capacity

4. Conclusions

- The moisture content of the co-crystallized product is about 0.59%, a value lower than those reported when spray drying was used.

- The moisture absorption rate for the co-crystallized product is about 0.011%, so the powder cannot be considered to be hygroscopic.

- The co-crystallized powder has a high bulk density (0.803 g/cm3) and solubility (61 s).

- The phenolic extract does not crystallize but is still in an amorphous state between gaps of the sucrose crystals.

- The obtained thermographs indicate both the improvement of the thermal stability of the extract by the co-crystallization and its successful encapsulation in the sucrose matrix.

- The co-crystallized powder has an excellent storage stability, as it preserves its phenolic content and antioxidant activity at high levels after storage at 60°C for 45 days.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Çam, M.; İçyer, N. C., Erdoğan, F. Pomegranate peel phenolics: Microencapsulation, storage stability and potential ingredient for functional food development. LWT 2014, 55, 117–123. [CrossRef]

- Kanatt, S. R.; Chander, R.; Sharma, A. Antioxidant and antimicrobial activity of pomegranate peel extract improves the shelf life of chicken products. Int. J. Food Sci. Techn. 2010, 45, 216–222. [Google Scholar] [CrossRef]

- Çam, M.; Hışıl, Y. Pressurized water extraction of polyphenols from pomegranate peels. Food Chem. 2010, 123, 878–885. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A. M.; Adamopoulos, K. G. A process for turning pomegranate peels into a valuable food ingredient using ultrasound-assisted extraction and encapsulation. IFSET 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Kaderides, K.; Papaoikonomou, L.; Serafim, M.; Goula, A. M. Microwave-assisted extraction of phenolics from pomegranate peels: Optimization, kinetics, and comparison with ultrasounds extraction. Chem. Eng. Process 2019, 137, 1–11. [Google Scholar] [CrossRef]

- López-Córdoba, A.; Navarro, A. Physicochemical properties and stability of sucrose/glucose agglomerates obtained by co-crystallization. J. Food Process Eng. 2018, 41, e12901. [Google Scholar] [CrossRef]

- Desai, K.G.H.; Park, H.J. Recent developments in microencapsulation of food ingredients. Dry. Technol. 2005, 23, 1361–94. [Google Scholar] [CrossRef]

- Karangutkar, A. V.; Ananthanarayan, L. Co-crystallization of Basella rubra extract with sucrose: Characterization of co-crystals and evaluating the storage stability of betacyanin pigments. J. Food Eng. 2020, 271, 109776. [Google Scholar] [CrossRef]

- Sardar, B. R.; Singhal, R. S. Characterization of co-crystallized sucrose entrapped with cardamom oleoresin. J Food Eng. 2013, 117, 521–529. [Google Scholar] [CrossRef]

- Maulny, A. P. E.; Beckett, S. T.; Mackenzie, G. Physical properties of co-crystalline sugar and honey. J. Food Sci. 2005, 70, E567–E572. [Google Scholar] [CrossRef]

- Khawas, P.; Deka, S. C. Encapsulation of Natural Antioxidant Compounds from Culinary Banana by Cocrystallization. J. Food Process Preserv. 2017, 41, e13033. [Google Scholar] [CrossRef]

- Akbari, M.; Sadeghi Mahoonak, A.; Sarabandi, K.; Ghorbani, A. Physiochemical characterization and antioxidant activities of green tea extract microencapsulated by co-crystallization technique. Food Sci. Technol. 2019, 15, 179–193. [Google Scholar]

- Marpaung, A. M.; Lee, M.; Kartawiria, I. S. The Development of Butterfly pea (Clitoria ternatea) Flower Powder Drink by Co-crystallization. IFSTJ 2020, 3, 34–37. [Google Scholar] [CrossRef]

- Irigoiti, Y.; Yamul, D. K.; Navarro, A. S. Co-crystallized sucrose with propolis extract as a food ingredient: Powder characterization and antioxidant stability. Food Sci. Technol. 2021, 143, 111164. [Google Scholar] [CrossRef]

- Kaur, P.; Elsayed, A.; Subramanian, J.; Singh, A. Encapsulation of carotenoids with sucrose by co-crystallization: Physicochemical properties, characterization and thermal stability of pigments. Food Sci. Technol. 2021, 140, 110810. [Google Scholar] [CrossRef]

- Tzatsi, P.; Goula, A. M. Encapsulation of Extract from Unused Chokeberries by Spray Drying, Co-crystallization, and Ionic Gelation. Waste Biomass Valorization 2021, 12, 1–19. [Google Scholar] [CrossRef]

- Sarabandi, K.; Mohammadi, A. Stabilization of peppermint polyphenols within crystalline sucrose matrix: fortification of gummy candy as a food model system. J. Food Process. Preserv. 2022, 46, e16720. [Google Scholar] [CrossRef]

- Chezanoglou, E.; Kenanidou, N.; Spyropoulos, C.; Xenitopoulou, D.; Zlati, E.; Goula, A. M. Encapsulation of pomegranate peel extract in sucrose matrix by co-crystallization. Sustain. Chem. Pharm. 2023, 31, 100949. [Google Scholar] [CrossRef]

- Bhandari, B. R.; Hartel, R. W. Co-crystallization of sucrose at high concentration in the presence of glucose and fructose. J. Food Sci. 2002, 67, 1797–1802. [Google Scholar] [CrossRef]

- Deladino, L.; Anbinder, P. S.; Navarro, A. S.; Martino, M. N. Co-crystallization of yerba mate extract (Ilex paraguariensis) and mineral salts within a sucrose matrix. J Food Eng. 2007, 80, 573–580. [Google Scholar] [CrossRef]

- Deladino, L.; Navarro, A. S.; Martino, M. N. Microstructure of minerals and yerba mate extract co-crystallized with sucrose. J. Food Eng. 2010, 96, 410–415. [Google Scholar] [CrossRef]

- López-Córdoba, A.; Gallo, L.; Bucalá, V.; Martino, M.; Navarro, A. Co-crystallization of zinc sulfate with sucrose: A promissory strategy to render zinc solid dosage forms more palatable. J. Food Eng. 2016, 170, 100–107. [Google Scholar] [CrossRef]

- Nugroho, D.; Sugih, A. K. Determination of process parameters for curcumin–dextrose cocrystallization. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Malang, East Java, Indonesia, 4-5 November 2017. [Google Scholar]

- Bajaj, S. R.; Singhal, R. S. Enhancement of stability of vitamin B12 by co-crystallization: A convenient and palatable form of fortification. J. Food Eng. 2021, 291, 110231. [Google Scholar] [CrossRef]

- Queiroz, M. B.; Sousa, F. R.; da Silva, L. B.; Alves, R. M. V.; Alvim, I. D. Co-crystallized sucrose-soluble fiber matrix: Physicochemical and structural characterization. Food Sci Technol. 2022, 154, 112685. [Google Scholar] [CrossRef]

- Wang, H.; Gao, S.; Zhang, D.; Wang, Y.; Zhang, Y.; Jiang, S.; Meng, X. Encapsulation of catechin or curcumin in co-crystallized sucrose: Fabrication, characterization and application in beef meatballs. Food Sci. Technol. 2022, 168, 113911. [Google Scholar] [CrossRef]

- Beristain, C. I.; Vazquez, A.; Garcia, H. S.; Vernon-Carter, E. J. Encapsulation of orange peel oil by co-crystallization. Food Sci. Technol. 1996, 29, 645–647. [Google Scholar] [CrossRef]

- Sardar, B. R.; Tarade, K. M.; Singhal, R. S. Stability of active components of cardamom oleoresin in co-crystallized sugar cube during storage. J. Food Eng. 2013, 117, 530–537. [Google Scholar] [CrossRef]

- Federzoni, V.; Alvim, I. D.; Fadini, A. L.; Silva, L. B. D.; Queiroz, M. B. Co-crystallization of paprika oleoresin and storage stability study. Food Sci. Technol. 2019, 39, 182–189. [Google Scholar] [CrossRef]

- Rai, K.; Chhanwal, N.; Shah, N. N.; Singhal, R. S. Encapsulation of ginger oleoresin in co-crystallized sucrose: development, characterization and storage stability. Food Funct. 2021, 12, 7964–7974. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, Vol. II. 2005, Association of Official Analytical Chemists, Arlington, VA.

- Tsali, A.; Goula, A. M. Valorization of grape pomace: Encapsulation and storage stability of its phenolic extract. Powder Technol. 2018, 340, 194–207. [Google Scholar] [CrossRef]

- Goula, A. M.; Adamopoulos, K. G.; Kazakis, N. A. Influence of spray drying conditions on tomato powder properties. Dry. Technol. 2004, 22, 1129–1151. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A. M. Development and characterization of a new encapsulating agent from orange juice by-products. Food Res. Int. 2017, 100, 612–622. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A. M. Encapsulation of pomegranate peel extract with a new carrier material from orange juice by-products. J. Food Eng. 2019, 253, 1–13. [Google Scholar] [CrossRef]

- Sarabandi, K.; Mahoonak, A. S.; Akbari, M. Physicochemical properties and antioxidant stability of microencapsulated marjoram extract prepared by co-crystallization method. J. Food Process Eng. 2019, 42, e12949. [Google Scholar] [CrossRef]

- Kiritsakis, K.; Goula, A.M.; Adamopoulos, K.G.; Gerasopoulos, D. Valorization of olive leaves: spray drying of olive leaf extract. Waste Biomass Valorization 2018, 9, 619–633. [Google Scholar] [CrossRef]

- Kurozawa, L. E.; Park, K. J.; Hubinger, M. D. Effect of carrier agents on the physicochemical properties of a spray dried chicken meat protein hydrolysate. J. Food Eng. 2009, 94, 326–333. [Google Scholar] [CrossRef]

- López-Córdoba, A.; Deladino, L.; Agudelo-Mesa, L.; Martino, M. Yerba mate antioxidant powders obtained by co-crystallization: Stability during storage. J. Food Eng. 2014, 124, 158–165. [Google Scholar] [CrossRef]

- Nik, A. B.; Vazifedoost, M.; Didar, Z.; HajirostamLoo, B. The antioxidant and physicochemical properties of microencapsulated bioactive compounds in Securigera securidaca (L.) seed extract by co-crystallization. Food Qual. Saf. 2019, 3, 243–250. [Google Scholar] [CrossRef]

- Tan, S. P.; Tuyen, C. K.; Parks, S. E.; Stathopoulos, C. E.; Roach, P. D. Effects of the spray-drying temperatures on the physiochemical properties of an encapsulated bitter melon aqueous extract powder. Powder Technol. 2015, 281, 65–75. [Google Scholar] [CrossRef]

- Jones, J. R.; Prime, D.; Leaper, M. C.; Richardson, D. J.; Rielly, C. D.; Stapley, A. G. Effect of processing variables and bulk composition on the surface composition of spray dried powders of a model food system. J. Food Eng. 2013, 118, 19–30. [Google Scholar] [CrossRef]

- Kaderides, K.; Mourtzinos, I.; Goula, A. M. Stability of pomegranate peel polyphenols encapsulated in orange juice industry by-product and their incorporation in cookies. Food Chem. 2020, 310, 125849. [Google Scholar] [CrossRef] [PubMed]

- Flores, F. P.; Singh, R. K.; Kong, F. Physical and storage properties of spray-dried blueberry pomace extract with whey protein isolate as wall material. J. Food Eng. 2014, 137, 1–6. [Google Scholar] [CrossRef]

- Laine, P.; Kylli, P.; Heinonen, M.; Jouppila, K. Does Microencapsulation Improve Storage Stability of Cloudberry (Rubus chamaemorus) Ellagitannins? In Water Properties in Food, Health, Pharmaceutical and Biological Systems, 1st ed.; Reid, D.S., Sajjaanantakul, Τ., Lillford, P.J., Charoenrein, S., Eds.; Blackwell publishing: Iowa, USA, 2010; pp. 563–569. [Google Scholar]

- Lei, Z. Monomeric ellagitannins in oaks and sweetgum. Doctoral dissertation, Virginia Polytechnic Institute and State University, Virginia, 25 April 2022.

- Haslam, E. Plant polyphenols: vegetable tannins revisited, 1st ed.; Cambridge University Press: Cambridge, USA, 1998; pp. 90–139. [Google Scholar]

- Xu, L.; Cheng, J. R.; Liu, X. M.; Zhu, M. J. Effect of microencapsulated process on stability of mulberry polyphenol and oxidation property of dried minced pork slices during heat processing and storage. Lwt 2019, 100, 62–68. [Google Scholar] [CrossRef]

- Negrão-Murakami, A. N.; Nunes, G. L.; Pinto, S. S.; Murakami, F. S.; Amante, E. R.; Petrus, J. C. C.; Prudêncio, E. S.; Amboni, R. D. M. C. Influence of DE-value of maltodextrin on the physicochemical properties, antioxidant activity, and storage stability of spray dried concentrated mate (Ilex paraguariensis A. St. Hil.). Food Sci. Technol. 2017, 79, 561-567.

- Fang, Z.; Bhandari, B. Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem. 2011, 129, 1139–1147. [Google Scholar] [CrossRef]

- Laine, P.; Kylli, P.; Heinonen, M.; Jouppila, K. Storage stability of microencapsulated cloudberry (Rubus chamaemorus) phenolics. J. Agric. Food Chem. 2008, 56, 11251–11261. [Google Scholar] [CrossRef] [PubMed]

- Bors, W.; Michel, C. Chemistry of the antioxidant effect of polyphenols. Ann. N. Y. Acad. Sci. 2002, 957, 57–69. [Google Scholar] [CrossRef] [PubMed]

- Shirode, A. B.; Bharali, D. J.; Nallanthighal, S.; Coon, J. K.; Mousa, S. A.; Reliene, R. Nanoencapsulation of pomegranate bioactive compounds for breast cancer chemoprevention. Int. J. Nanomedicine 2015, 10, 475. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).