1. Introduction

With the development of electronic science and technology, although the widespread use of electronic equipment has brought great convenience to human life, it also makes people be easily surrounded by a large amount of electromagnetic radiation, and causing great harm to human health [

1]. Electromagnetic interference (EMI) shielding could significantly reduce and sometimes even prevents electromagnetic systems and devices from emitting stray EMI signals into the environment. Therefore, the study of efficient electromagnetic shielding materials is imminent and greatly needed to suppress EMI pollution.

Traditional electromagnetic shielding materials are mainly realized by metal and relevant composite materials [

2,

3]. Although these materials have good electromagnetic shielding performance, there also exist some limitations, such as high density, easy corrosion, and difficulty in adjusting electromagnetic shielding efficiency, which limits their application as multi-functional materials and cannot meet the functional requirements of many devices. With the development of plastics, the disadvantages of metal corrosion, heavy weight and not easy to process are solved. However, plastics are nonconductive and could not meet the requirements of EMI shielding. In this case, the researchers prepared electromagnetic shielding composites by adding conductive fillers [

4], such as MXene [

5], carbon nanotubes (CNTs) [

6,

7], and graphene [

8] to form conductive networks inside the plastic matrix. Han [

7] applied CNTs in reduced GO-CNT vertical edge-rich graphene (rGO-CNT-VG) aerogels, and studied its electromagnetic interference shielding behaviors. The results showed that the rGO-CNT-VG/epoxy composites possessed excellent thermal conductivity, and outstanding EMI shielding effectiveness of 56.65 dB, which 1.9 times higher than that of the pure rGO/epoxy composites. Among various conductive fillers, CNTs were broadly used due to their low percolation threshold, perfect electrical conductivity and excellent aspect ratio aspect ratio.

In order to further meet the requirements of lightweight electromagnetic shielding materials, the foaming technology and aerogel preparation technology were investigated to develop lightweight electromagnetic shielding materials with hole structure [

9,

10,

11]. However, during the preparation process, the unique sized pores are not easy to be controlled, affecting the industrial scale production. 3D printing technology, as an additive manufacturing method also known as additive manufacturing (AM), whose structure can be precisely adjusted, has shown significant advantages in the preparation of EMI shielding materials [

12,

13,

14]. In fact, the feedstock to the 3D printer is commonly a kind of thermoplastic polymer filament which is extruded with a PC-controlled moving nozzle, where it had been heated above its glass transition temperature. With the 3D printing process, the desired 3D structure, layer by layer, are allowed to form and designed. At present, it is known that carbon nanotube polymer composites play an important role in the field of EMI shielding, and the technology for 3D printing carbon nanotube polymer composites is also becoming increasingly mature [

15,

16,

17]. However, the dispersion of CNTs not only determines whether the conductive network in the polymer composite can be effectively constructed, but also whether 3D printing process can be proceeded smoothly. Therefore, it is necessary to explore the effects of the dispersion of CNTs. Polylactic acid (PLA) is a kind of green material with good rheological properties, biocompatibility and biodegradability. Thus, it has quickly become a widely used raw material of 3D printing [

18]. The combination of CNTs and PLA expected to prepare excellent EMI shielding materials.

In the effort to address relevant issue, carbon nanotubes/polylactic acid (CNTs/PLA) composite are prepared by 3D printing technology (fused deposition modeling) to achieve excellent EMI shielding. PLA is used as the substrate, and conductivity network is provided by adding different contents of CNTs. CNTs is directly deposited in PLA using a high volatility solvent (i.e., dichloromethane) as dispersion medium to make sure the fast evaporation. The thorough electrical characterization of the 3D printed samples with increasing CNTs content is performed to evaluate conductivity. In addition, the mechanical behavior of the samples is experimentally investigated and compared made by injection and 3D printing technology. Simultaneously, the Fourier transform infrared spectra (FTIR) and EMI shielding properties are also characterized. The purpose of this study is to prepare 3D printed CNTs/PLA composite with light weight, excellent conductivity and good EMI shielding effect, which is expected to provide a new idea for the development of new EMI shielding materials.

2. Materials and Methods

2.1. Materials

PLA (6060D) was purchased from Nature Works (USA); multi-walled CNTs with the diameter of 10-30 μm and length of 10-30 nm) was bought from Beijing Tiannai Co., LTD.; Dichloromethane (99.5%) was obtained from Taicang Shanghai Test Reagent Co., LTD.

2.2. The Preparation of CNTs/PLA Composites

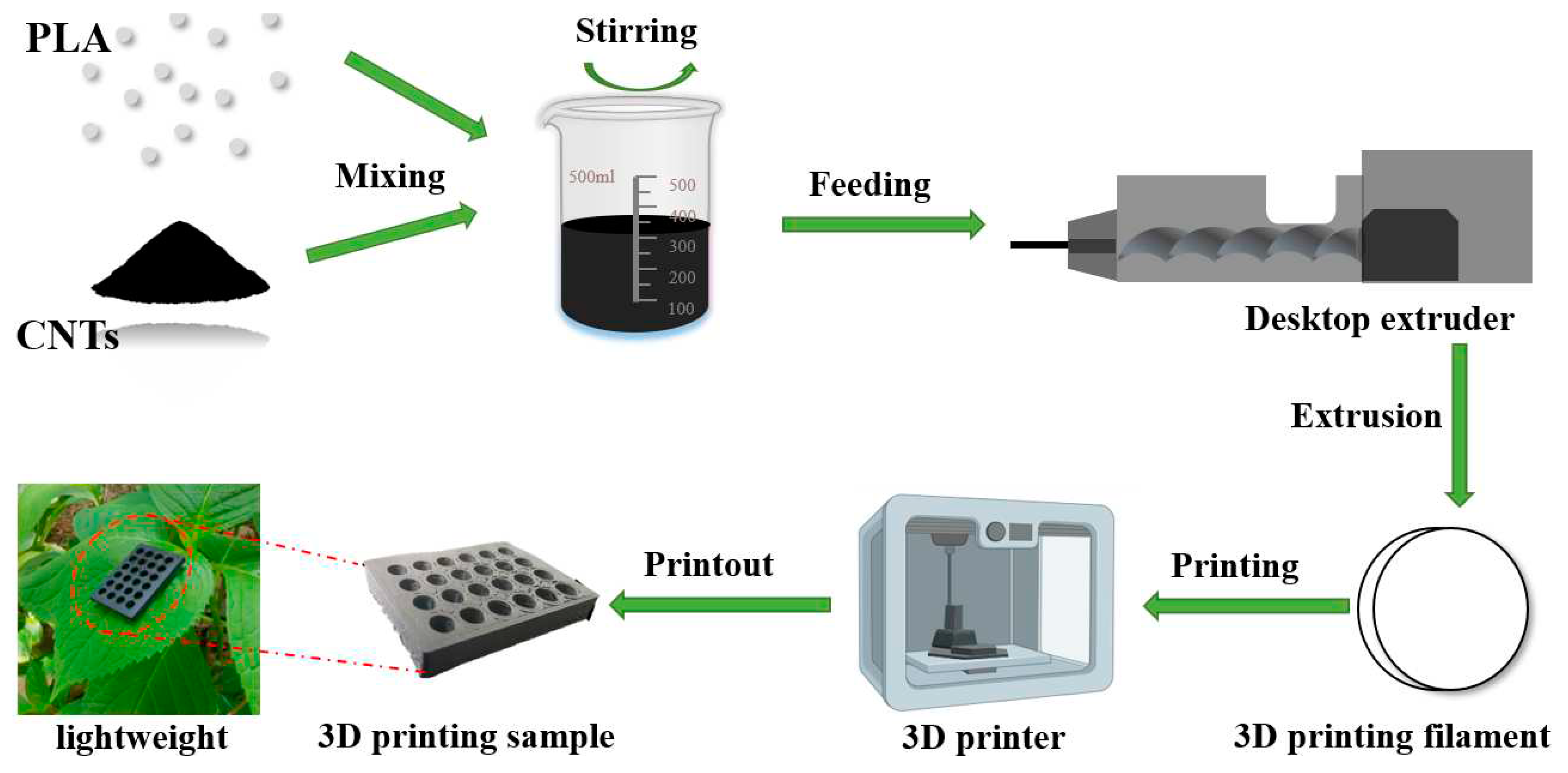

The preparation process flow diagram of CNTs/PLA composites is given in

Figure 1. CNTs and PLA were dried in the oven prior to their use. The mixing process of CNTs and PLA is also a crucial factor which determinates the resulting of electrical properties and EMI shielding properties. Herein, to prepare 50 g 5 wt% CNTs/PLA electromagnetic shielding composites, 2.5 g dried CNTs and 47.5 g PLA were weighted, and then dichloromethane was added to mix them evenly by the magnetic mixer. Then they were dried naturally in the fume hood, cut by the shear machine, and then they are further put into the desktop extruder. Finally, 3D printing filament with the diameter of 1.75 mm were extruded by adjusting the temperature with the range of 170-180

oC and screw speed of 15 rpm. At last, the filaments were put into the 3D printer, and then 5 wt% CNTs/PLA samples could be obtained. Similarly, the CNT/PLA composites with 10 wt%, 15 wt% and 17 wt% CNT were respectively prepared according to above same methods.

Solidworks software was used to design 3D model of the EMI shielding composite, and the STL format file was exported. Then STL format file was transformed into G-code format file, which is facilitate to the layer-by-layer deposition of CNTs/PLA composites into 3D printing component. The 3D printing process parameters were setting as follows: nozzle diameter 0.4 mm, print layer thickness 0.2 mm, filling density 20%, printing speed 30 mm/s, nozzle temperature 190 oC, and hot bed temperature 55 oC, sample thickness 3 mm.

2.3. Characterization

The morphology and microstructure of the samples were observed by scanning electron microscope (SEM, S-4700, Japan). Micro injection molding machine (SZS-20, Wuhan Ruiming Experimental Instrument Co., LTD.), Desktop extruder (Type B, Shenzhen Misida Technology Co., LTD.) and 3D printer (Sermoon V1, Shenzhen Creative 3D Technology Co., LTD.) were used to prepare 3D printing samples. The infrared spectrometer (FTIR, Nicolet NEXUS-670) was used to characterize the types and changes of organic functional groups of CNTs/PLA composites. The tensile strength of the samples was tested by the tensile tester (CSS-88100, Changchun Testing Machine Research Institute).

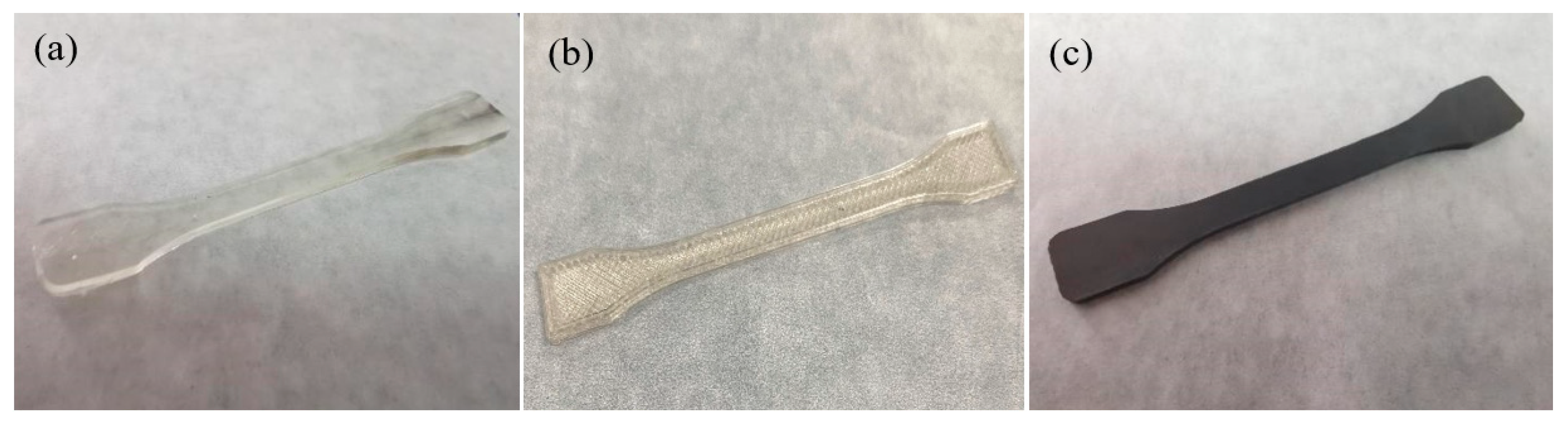

Figure 2 gives tensile samples of PLA and CNTs/PLA fabricated with injection molding and 3D printing technology. The effective length scale of the tensile sample is of 45 mm, width of 5mm and thickness of 2mm. It could be seen 3D printed CNTs/PLA sample came black compared to with that of pure PLA samples which showed white and transparent. Electrical conductivity (σ, S/m) was calculated by equation: σ=L/(R*S), L is the length (m), R is the resistance (Ω), and S is the cross-sectional area of the sample (m

2) [

19]. And the R was measured by digital resistor (Agilent 34401A, USA). Before test the left and right surfaces (length direction) of rectangular were coated with a uniform layer of silver paste to reduce the contact resistance between the probes and 3D printed samples.

The EMI shielding properties of the samples (22.86 mm × 10.86 mm) were characterized by the vector network analyzer (P5004A, Keysight) with the frequency range of 8.2–12.4 GHz (X-band) via the waveguide method. Before EMI SE testing, the accuracy of the equipment was adjusted with the thru-reflect-line (TRL) calibration technique to guarantee of the test. The S-parameters of transmission loss (S

21 or S

12) and forward transmission loss (S

11 or S

22) were measured, and the EMI shielding effectiveness due to reflection (SE

R) and absorption (SE

A) are further calculated according to the following equations [

20]:

where

T,

R,

A are transmission, reflection and absorption coefficient, SE

T is the total shielding effectiveness.

3. Results and Discussion

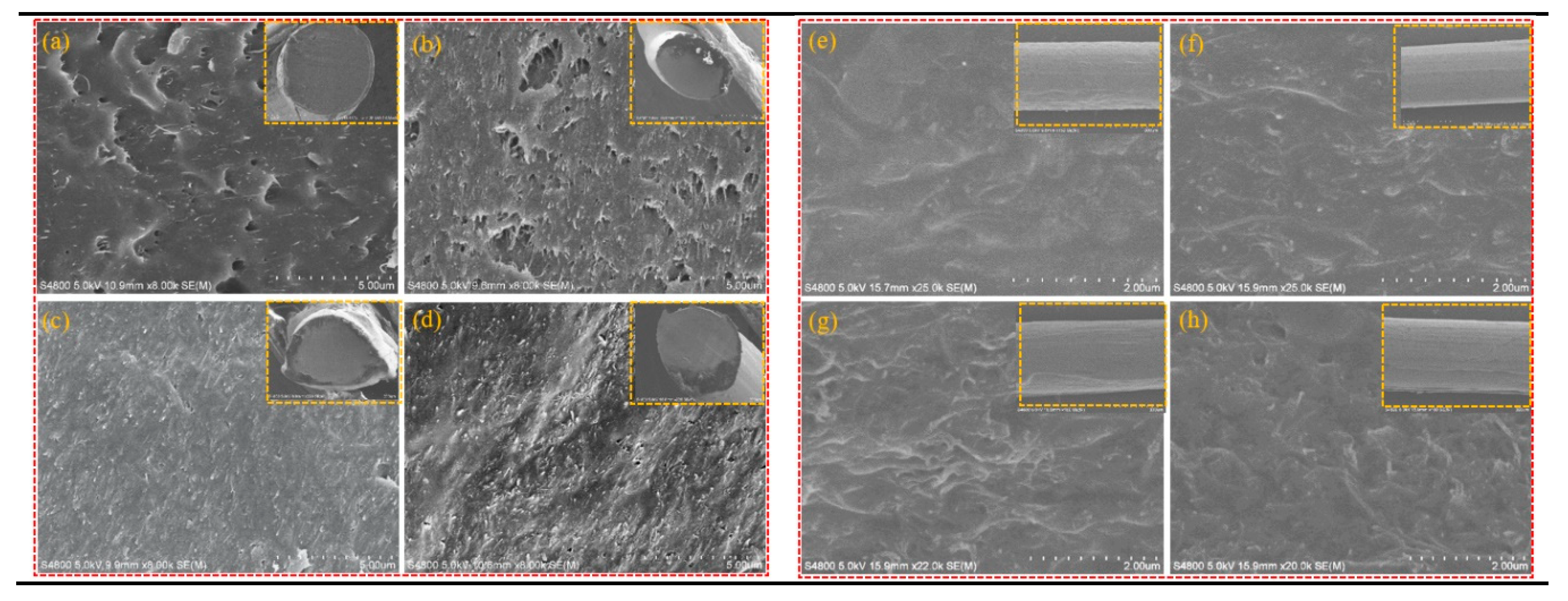

Figure 3 gives the cross section and longitudinal morphologies of CNTs/PLA samples with different contents of CNTs characterized by SEM. In

Figure 3a–d, it could be observed that there are many white strips, which were the electric conductive particles of CNTs, and they were firmly wrapped by PLA. With the increase of CNTs content, the distribution density of CNTs in the composite increased obviously, and most of them followed a certain direction and had a good orientation. At the same time, they were uniformly dispersed and there was no obvious agglomeration phenomenon. In

Figure 3e–h, the longitudinal images showed that the surface of CNTs/PLA samples were flat and no bubbles were generated. At the same time, with the increase of CNTs content, the longitudinal distribution density of CNTs was also increasing, which is conducive to the formation of conductive network.

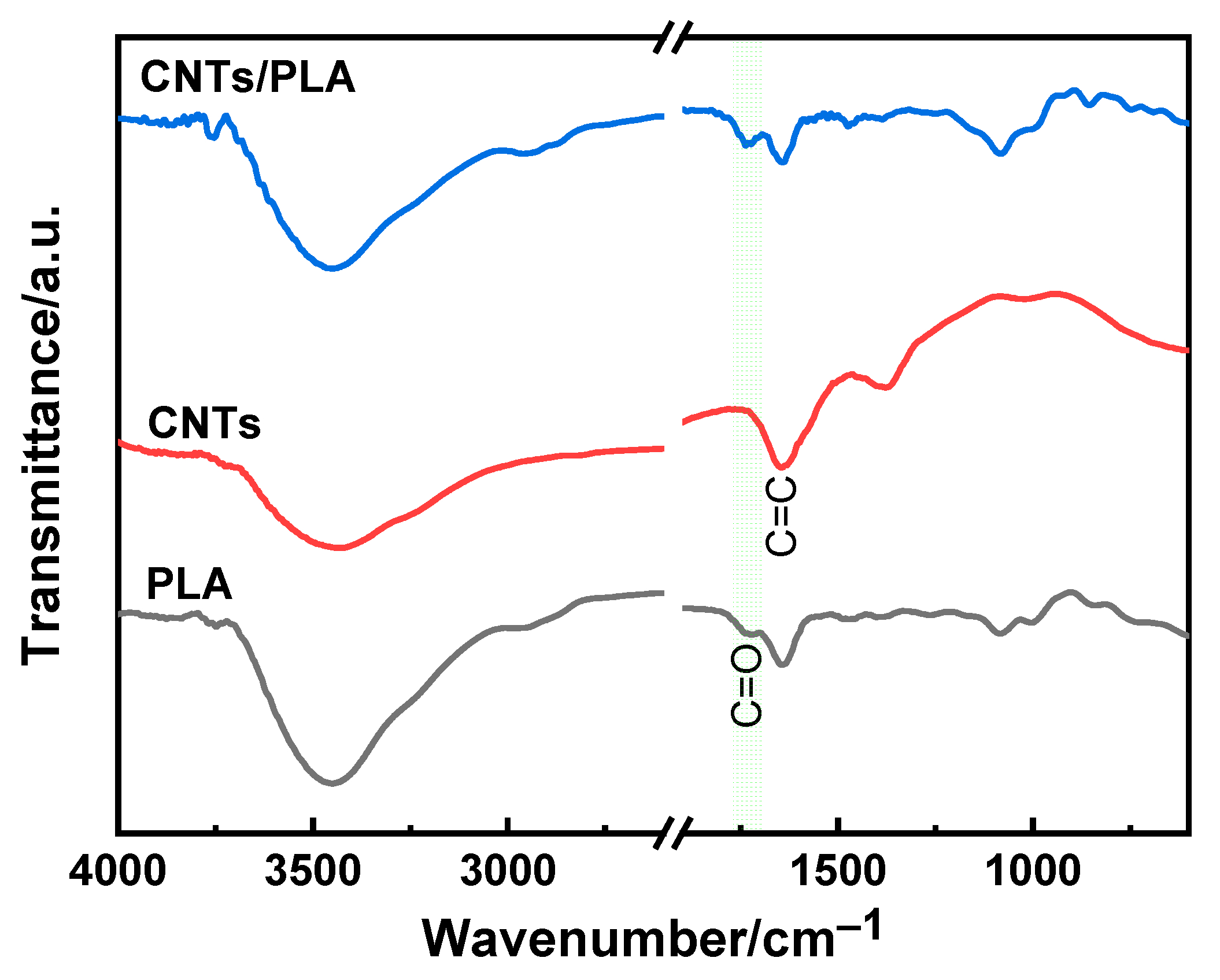

Figure 4 shows the FTIR images of PLA, CNTs and 15 wt% CNTs/PLA composites. In the spectrum of PLA, the characteristic peak at 1720 cm

–1 is related to a C=O stretching vibration [

21]. In the spectrum of CNTs, the characteristic peak at 1645 cm

–1 is attributed to the C=C stretching vibration [

22]. It is obvious that both characteristic peaks of PLA and CNTs were displayed in the CNTs/PLA, which demonstrated PLA and CNTs was well mixed in the composite.

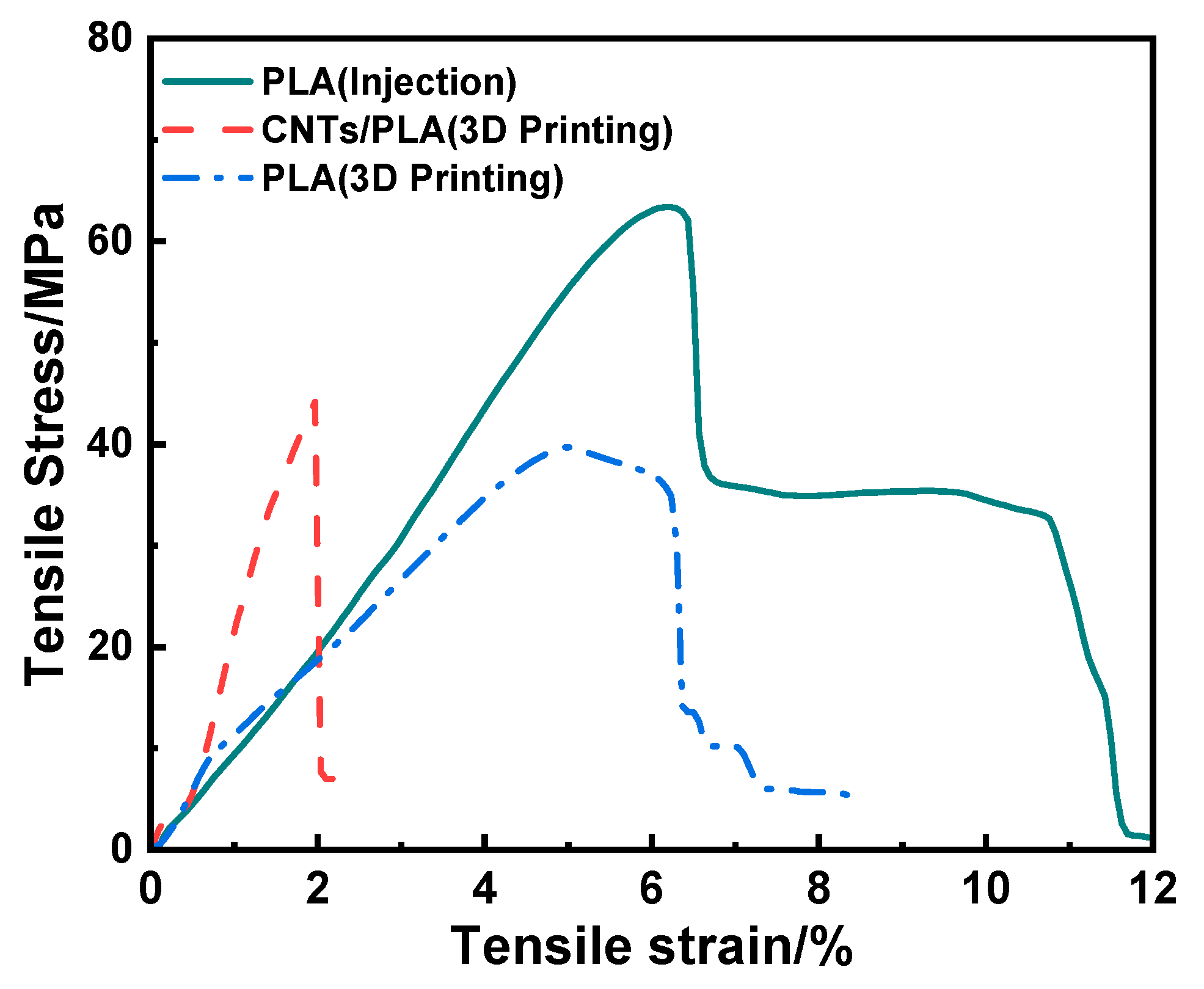

The tensile properties of injected PLA sample, 3D printed PLA and CNTs/PLA samples are respectively provided in

Figure 5. It could be seen that the stress of injected PLA sample reached 63.39 MPa, while that of 3D printed PLA sample was only 39.70 MPa. The reason might be that under the action of external force, the molecule chains in injected PLA sample were more closely connected and oriented, while for 3D printed PLA sample, it was stacked layer by layer, which lacked lateral external force. As a result, its tensile stress was low than that of injected PLA sample. Moreover, the figure showed that the stress of 3D printed CNTs/PLA composite was higher compared with that of 3D printed PLA, which was 44.18 MPa, and improved by 11.3%. At the same time, it could be found that the modulus of the CNTs/PLA composite was also improved significantly. Meanwhile, the strain-stress curve showed brittle feature compared to pure PLA composite made by injection and 3D printing methods. It was because that CNTs possessed excellent mechanical properties, and they are regularly orientated in the PLA matrix, thus CNTs could improve the strength and modulus of the printed composites. Above all, CNTs could reinforced PLA by 3D printing technology and improve its mechanical properties.

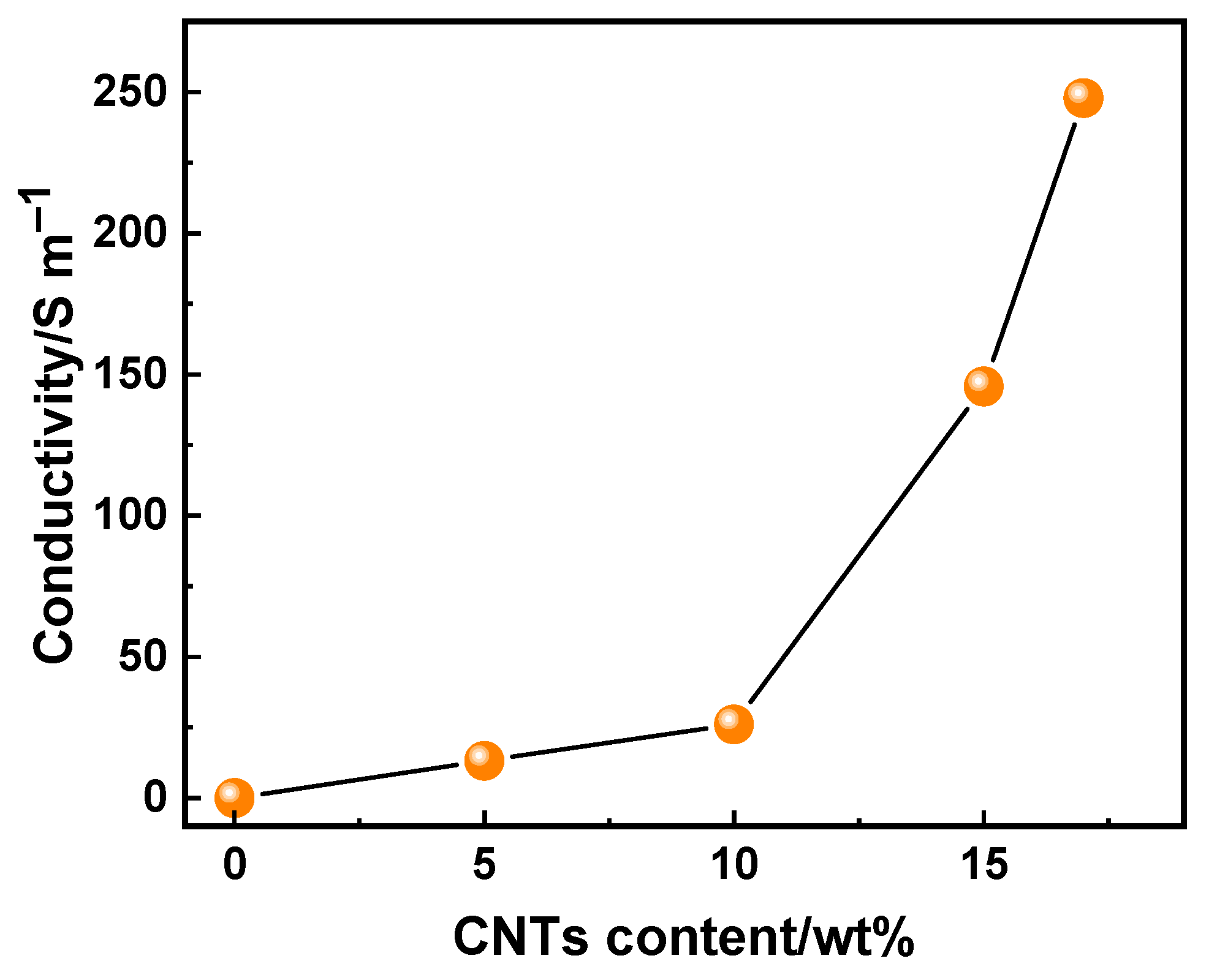

The electrical conductivity of the composite has an important impact on its shielding performance [

23].

Figure 6 gives the relationship between the contents of CNTs and electrical conductivity of CNTs/PLA samples. The variation of the content of CNTs directly affected the electrical conductivity, which resulted from the structure change of internal conductive network of the composite. For pure polylactic acid sample, when CNTs was not added, there was no conductivity. With the increase of CNTs content, the conductivity gradually increased. When the content was 10 wt%, the conductivity could reach 26.02 S/m; when it got to 15 wt%, the conductivity increased quickly and the value of 145.74 S/m was got. It could be contributed to that with more content of CNTs, the more internal conductive network could be efficiently constructed, which could further improve the conductivity of the sample. However, when the CNTs content was up to 17 wt%, although its conductivity is improved, it got more difficult to print the CNTs/PLA samples due to the nozzle clogging. Thus, the further higher CNTs were not added anymore to print relevant samples.

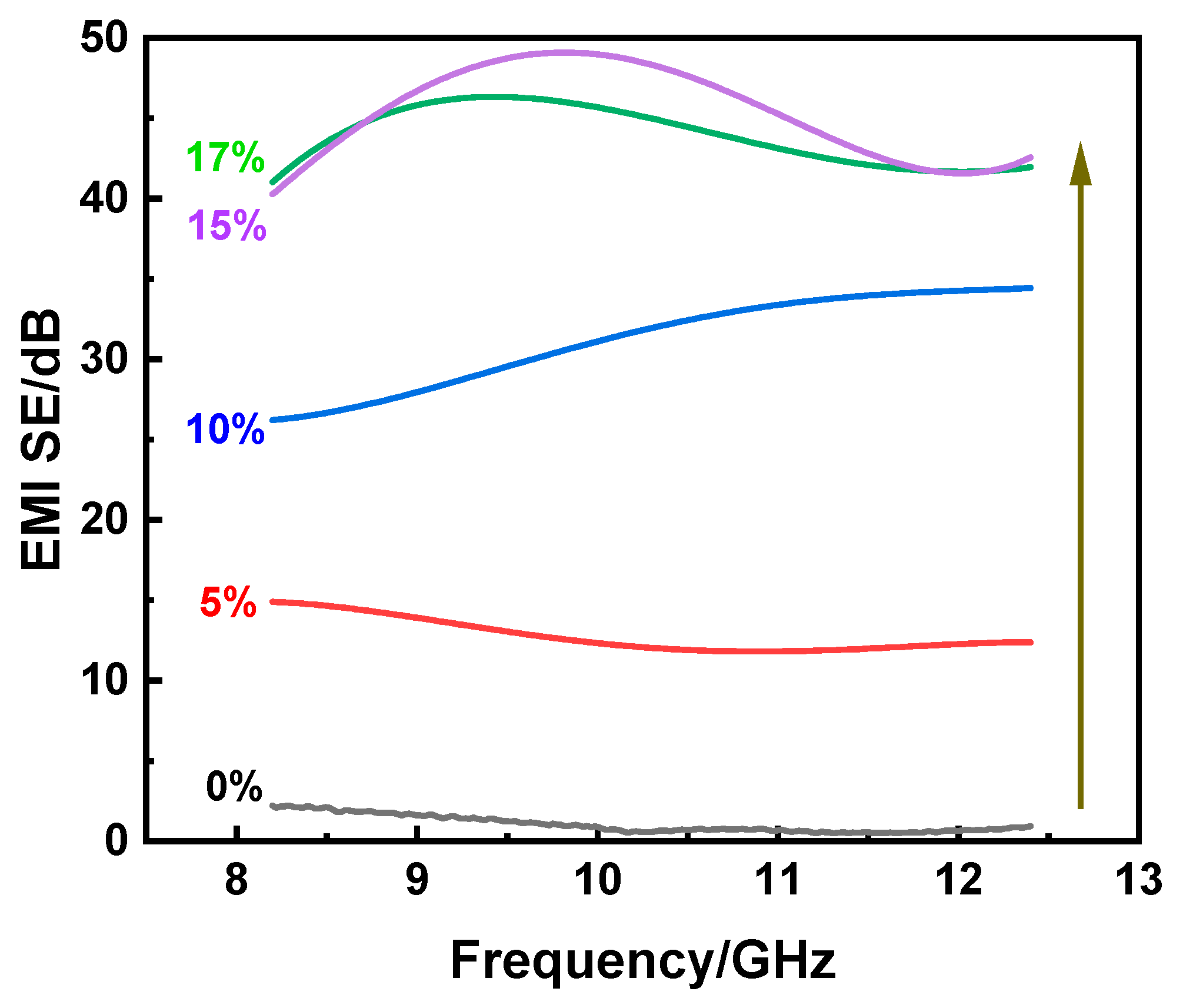

In order to investigate the effect of CNTs content on the EMI shielding performance of CNTs/PLA composite, the shielding effectiveness-frequency diagram was drawn. As shown in

Figure 7, the EMI SE of 3D printed CNTs/PLA sample increased with the increase of CNTs content. Specifically, when no CNTs were added, the average EMI SE of pure PLA was only 1.05 dB, which was consistent with the study results [

18]. This mainly because pure PLA is an insulating material, there are not enough carriers to form a connected conductive network, thus it could not effectively shield electromagnetic waves, and it is an electromagnetic wave transparent material. When the dosage of CNTs was 5 wt%, the shielding efficiency reached up to 14.9 dB, and 96.76% of electromagnetic energy could be shielded. In addition, when the CNTs content further got 10 wt%, the EMI SE was up to 34.42 dB, which could shield 99.96% of electromagnetic energy. When the content of CNTs was 15 wt%, the electromagnetic shielding efficiency was up to 47.1 dB, shielding 99.998% of incident electromagnetic wave and this was absolutely suitable for commercial applications, which only needed 20 dB [

17,

24]. In the whole frequency range, the shielding efficiency of the prepared 3D printed samples with the addition of CNTs had exceeded that published in the literature [

18], where the EMI SE of 3D printed MWCNTs/GNPs (12 wt%) composite was only 13.4 dB. Meanwhile, the density of 3D printed CNTs/PLA composite was only 0.51 g/cm

3 and could steadily stay on a leaf (

Figure 1), which is not only conducive to lightweight, but also could be used as highly efficient EMI shielding composites.

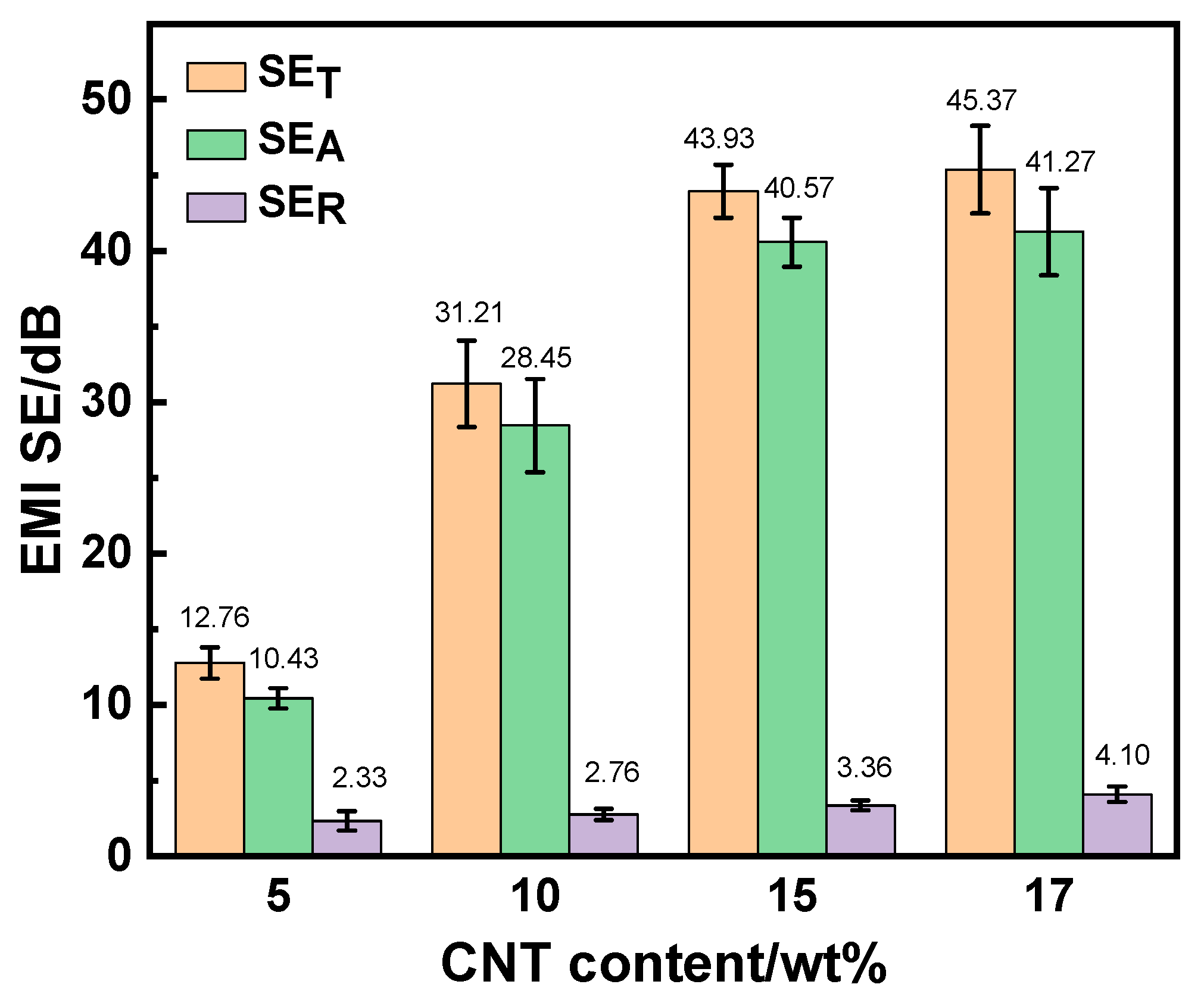

In

Figure 8, SE

T, SE

A and SE

R of CNTs/PLA composites with different CNTs contents are given, where error bars were also provided. It could be seen that as the content of CNTs increased, both the SE

A and SE

R increased. Specifically, the SE

A increased from 10.43 dB to 28.45 dB, 40.57 dB and 41.27 dB, and the SE

R increased from 2.33 dB to 2.76 dB, 3.36 dB and 4.10 dB when the CNTs contents increased from 5 wt% to 10 wt%, 15 wt% and 17 wt%. This meant that the addition of CNTs was much more beneficial to the SE

A than SE

R. In addition, the EMI shielding mechanism of CNTs/PLA was mainly absorption loss, and it generally accounted for more than 80% of the total shielding loss. When the contents of CNTs reached 10 wt%, 15 wt% and 17 wt%, absorption loss even exceeded 90%. The higher the proportion of absorption loss, the stronger the ability of electromagnetic shielding material to absorb electromagnetic waves which incidents into material. On the other hand, the less electromagnetic waves were reflected, the less harmful it was to the environment.

4. Conclusions

In this study, the lightweight 3D printed CNTs/PLA composites with different CNTs contents were prepared. CNTs were evenly distributed in CNTs/PLA composites, and were tightly bound to PLA. The mechanical properties of 3D printed CNTs/PLA composite was higher than that of the pure 3D printed PLA composite. Moreover, with the increase of the content of CNTs, the conductive performance was improved, and the conductivity increased. Meanwhile, the electromagnetic shielding effect of CNTs/PLA composite was improved with the increase of CNTs content. When the content of CNTs reached 15 wt%, the electromagnetic shielding efficiency of 3D printed CNTs/PLA composite was up to 47.1 dB, blocking 99.998% electromagnetic energy. However, when the CNTs was added to 17 wt%, the composite was not easily printed any more. The increase of the content of CNTs was conducive to the enhancement of the absorption loss. Additionally, the loss mechanism of 3D printed CNTs/PLA composite was mainly absorption loss, and it generally accounted for more than 80% of the total shielding loss. When the content of CNTs got 10 wt%, 15 wt% and 17 wt%, the proportion of absorption loss even reached more than 90%. In this case, the prepared 3D printed CNTs/PLA composite had great potential in the field of EMI shielding.

Author Contributions

Conceptualization, L.Z.; methodology, T.D. and Y.W.; software, Y.W.; validation, T.D., X.C. and M.Z.; formal analysis, Z.X.; investigation, L.Z., Z.X.; resources, L.Z. and H.Z; data curation, T.D. and Y.W; writing—original draft preparation, Z.X.; writing—review and editing, L.Z. and H.Z.; visualization, Z.X.; supervision, L.Z.; funding acquisition, L.Z. and H.Z.. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by Youth Fund Project of Anhui Natural Science Foundation (No. 2208085QE141); Initiating Research Fund for Talent Introduction of AnHui Polytechnic University (No. S022022038); University level scientific research project of AnHui Polytechnic University (No. KZ42022133); Undergraduate top-notch talent train-ing program of AnHui Polytechnic University (No. KP40000141; No. Y412022069; No. Y412022070); Anhui Polytechnic University Scientific Research Project (No. FFBK202367; FFBK202368); Advanced Fiber Materials Engineering Research Center of Anhui Province Project (No. 2023AFMC19).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tian, K.; Hu, D.; Wei, Q.; Fu, Q.; Deng, H. Recent progress on multifunctional electromagnetic interference shielding polymer composites. J. Mater. Sci. Technol. 2023, 134, 106–131. [Google Scholar] [CrossRef]

- Wu, B.; Zhu, H.; Yang, Y.; Huang, J.; Liu, T.; Kuang, T.; Jiang, S.; Hejna, A.; Liu, K. Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly(lactic acid) nanocomposites. e-Polymers 2023, 23(1), 20230006. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F. A review on recent advancement of electromagnetic interference shielding novel metallic materials and processes. Compos. Part B Eng. 2019, 176, 107207. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, F.; Li, N.; Shi, J.-F.; Jia, L.-C.; Yan, D.-X.; Li, Z.-M. Carbon-based aerogels and foams for electromagnetic interference shielding: A review. Carbon 2023, 205, 10–26. [Google Scholar] [CrossRef]

- Cheng, Z.; Chang, G.; Xue, B.; Xie, L.; Zheng, Q. Hierarchical Ni-plated melamine sponge and MXene film synergistically supported phase change materials towards integrated shape stability, thermal management and electromagnetic interference shielding. J. Mater. Sci. Technol. 2023, 132, 132–143. [Google Scholar] [CrossRef]

- Cheng, H.; Pan, Y.; Wang, T.; Zhou, Y.; Qin, Y.; Liu, C.; Shen, C.; Liu, X. Synergistic effects between carbon nanotube and anisotropy-shaped Ni in polyurethane sponge to improve electromagnetic interference shielding. Sci. China Mater. 2023. [Google Scholar] [CrossRef]

- Han, L.; Li, K.; Liu, H.; Jiao, Y.; Yin, X.; Li, H.; Song, Q.; Qi, L. Heterogeneous stacking strategy towards carbon aerogel for thermal management and electromagnetic interference shielding. Chemical Engineering Journal 2023, 465, 142839. [Google Scholar] [CrossRef]

- Chen, Y.; Potschke, P.; Pionteck, J.; Voit, B.; Qi, H. Multifunctional Cellulose/rGO/Fe3O4 Composite Aerogels for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2020, 12, (19), 22088–22098. [Google Scholar] [CrossRef]

- Yin, H.; Bi, L.; Wu, Z.; Wang, G.; Li, M.; Zhou, X.; Ji, S.; Zhang, W.; Peng, Y.; Pan, J.; Ye, C.; Huang, Q. 2D foaming of ultrathin MXene sheets with highly conductive silver nanowires for wearable electromagnetic interference shielding applications owing to multiple reflections within created free space. Nano Futures 2020, 4 (3). [Google Scholar] [CrossRef]

- Zhao, B.; Hamidinejad, M.; Wang, S.; Bai, P.; Park, C. Advances in electromagnetic shielding properties of composite foams. J. Mater. Chem. A 2021, 9, 8896–8949. [Google Scholar] [CrossRef]

- Guo, Z.; Ren, P.; Wang, J.; Hou, X.; Tang, J.; Liu, Z.; Chen, Z.; Jin, Y.; Ren, F. Methylene blue adsorption derived thermal insulating N, S-co-doped TiC/carbon hybrid aerogel for high-efficient absorption-dominant electromagnetic interference shielding. Chem. Eng. J. 2023, 451, 138667. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Saghlatoon, H.; Honari, M. M.; Mirzavand, R.; Montemagno, C.; Mousavi, P. Investigation on electrical and mechanical properties of 3D printed nylon 6 for RF/microwave electronics applications. Addit. Manufact. 2018, 21, 69–75. [Google Scholar] [CrossRef]

- Lee, K. P. M.; Baum, T.; Shanks, R.; Daver, F. Electromagnetic interference shielding of 3D-printed graphene–polyamide-6 composites with 3D-printed morphology. Add. Manufact. 2021, 43, 102020. [Google Scholar] [CrossRef]

- Wu, T.; Huan, X.; Zhang, H.; Wu, L.; Sui, G.; Yang, X. The orientation and inhomogeneous distribution of carbon nanofibers and distinctive internal structure in polymer composites induced by 3D-printing enabling electromagnetic shielding regulation. J. Colloid Interface Sci. 2023, 638, 392–402. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, Z.-W.; Zhang, H.; Guo, J.; Yan, D.-X.; Wang, S.; Dai, K.; Li, Z.-M. 3D-printing of segregated carbon nanotube/polylactic acid composite with enhanced electromagnetic interference shielding and mechanical performance. Mater. Des. 2021, 197, 109222. [Google Scholar] [CrossRef]

- Pei, X.; Zhao, M.; Li, R.; Lu, H.; Yu, R.; Xu, Z.; Li, D.; Tang, Y.; Xing, W. Porous network carbon nanotubes/chitosan 3D printed composites based on ball milling for electromagnetic shielding. Compos. Part A Appl. Sci. Manufact. 2021, 145, 106363. [Google Scholar] [CrossRef]

- Shi, S.; Peng, Z.; Jing, J.; Yang, L.; Chen, Y. 3D Printing of Delicately Controllable Cellular Nanocomposites Based on Polylactic Acid Incorporating Graphene/Carbon Nanotube Hybrids for Efficient Electromagnetic Interference Shielding. ACS Sustain. Chem. Eng. 2020, 8, (21), 7962–7972. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Kotsilkova, R.; Ivanov, E.; Menseidov, D.; Naddeo, C.; Romano, V.; Guadagno, L.; Adami, R.; Meisak, D.; Bychanok, D.; Kuzhir, P. Nanocarbon/Poly(Lactic) Acid for 3D Printing: Effect of Fillers Content on Electromagnetic and Thermal Properties. Materials 2019, 12, 2369. [Google Scholar] [CrossRef]

- Paleari, L.; Bragaglia, M.; Fabbrocino, F.; Luciano, R.; Nanni, F. Self-Monitoring Performance of 3D-Printed Poly-Ether-Ether-Ketone Carbon Nanotube Composites. Polymers 2022, 15(1), 8. [Google Scholar] [CrossRef]

- Zou, L.; Lan, C.; Zhang, S.; Zheng, X.; Xu, Z.; Li, C.; Yang, L.; Ruan, F.; Tan, S. C. Near-Instantaneously Self-Healing Coating toward Stable and Durable Electromagnetic Interference Shielding. Nanomicro. Lett. 2021, 13(1), 190. [Google Scholar] [CrossRef]

- Cai, Y.; Lv, J.; Feng, J. Spectral Characterization of Four Kinds of Biodegradable Plastics: Poly (Lactic Acid), Poly (Butylenes Adipate-Co-Terephthalate), Poly (Hydroxybutyrate-Co-Hydroxyvalerate) and Poly (Butylenes Succinate) with FTIR and Raman Spectroscopy. J. Polym. Environ. 2012, 21(1), 108–114. [Google Scholar] [CrossRef]

- Varga, M.; Izak, T.; Vretenar, V.; Kozak, H.; Holovsky, J.; Artemenko, A.; Hulman, M.; Skakalova, V.; Lee, D. S.; Kromka, A. Diamond/carbon nanotube composites: Raman, FTIR and XPS spectroscopic studies. Carbon 2017, 111, 54–61. [Google Scholar] [CrossRef]

- He, J.; Han, M.; Wen, K.; Liu, C.; Zhang, W.; Liu, Y.; Su, X.; Zhang, C.; Liang, C. Absorption-dominated electromagnetic interference shielding assembled composites based on modular design with infrared camouflage and response switching. Compos. Sci. Technol. 2023, 231, 109799. [Google Scholar] [CrossRef]

- Zou, L.; Sun, Y.; Dou, T.; Yao, M.; Xu, Z.; Lan, C. Low-temperature treated polypyrrole coated cotton fabrics for efficient electromagnetic interference shielding. Cellulose 2023, 30(5), 3283–3296. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).