Submitted:

29 June 2023

Posted:

30 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Background: Machine Learning and the Manufacturing Industry

3. Material and Methods

3.1. Research Questions

- RQ1

- What are the targeted and achieved industrial benefits machine learning has brought to the manufacturing industry?

- RQ2

- What is the maturity level of the ML solutions presented in the publications?

- RQ3

- Which sectors of the manufacturing industry have used ML solutions?

- RQ4

- In which manufacturing operations have ML solutions been used?

- RQ5

- What is the relative popularity of different ML method families in the publication set?

3.1. Material

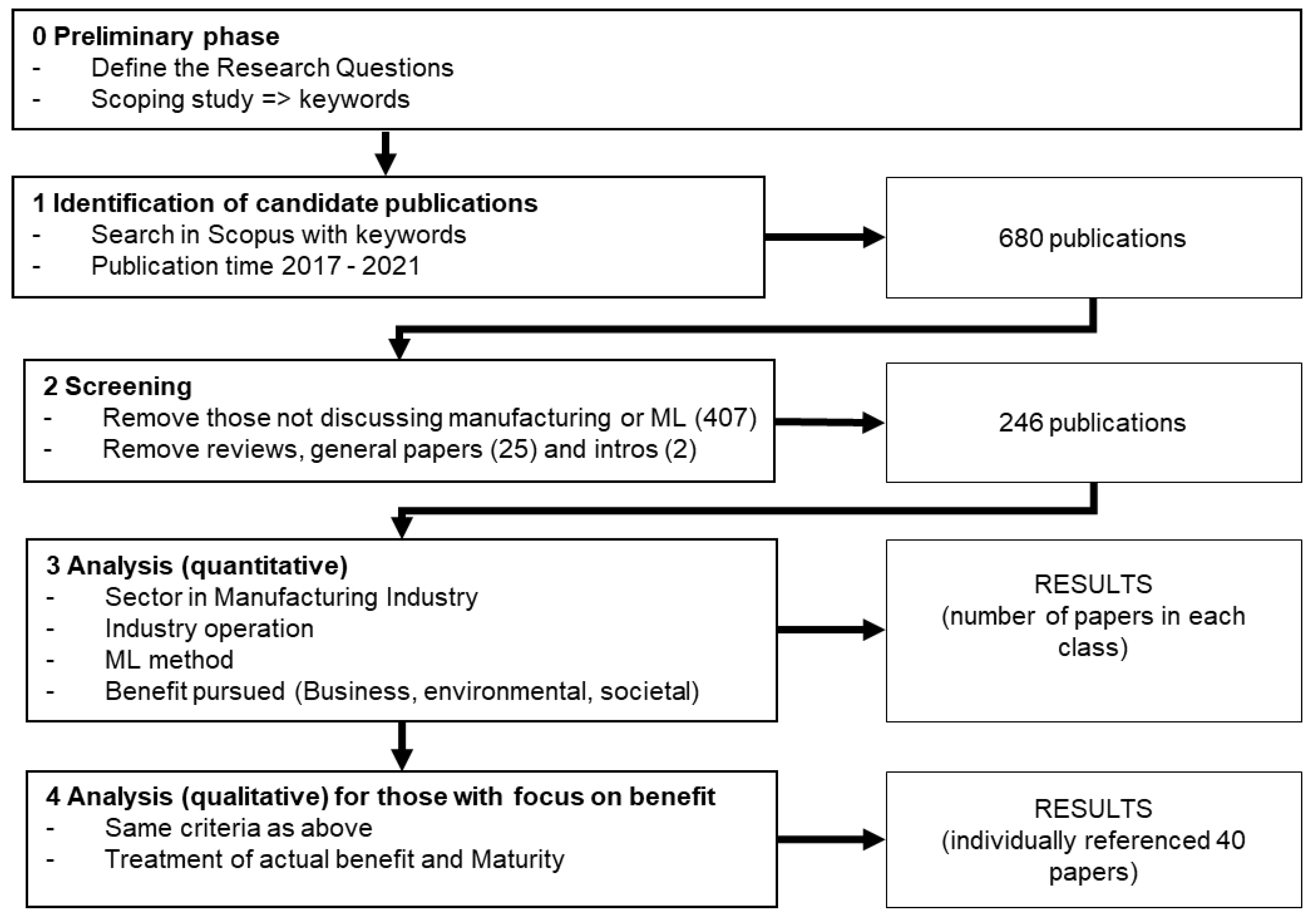

3.3. Methods

3.4. Analysis Framework

4. Results

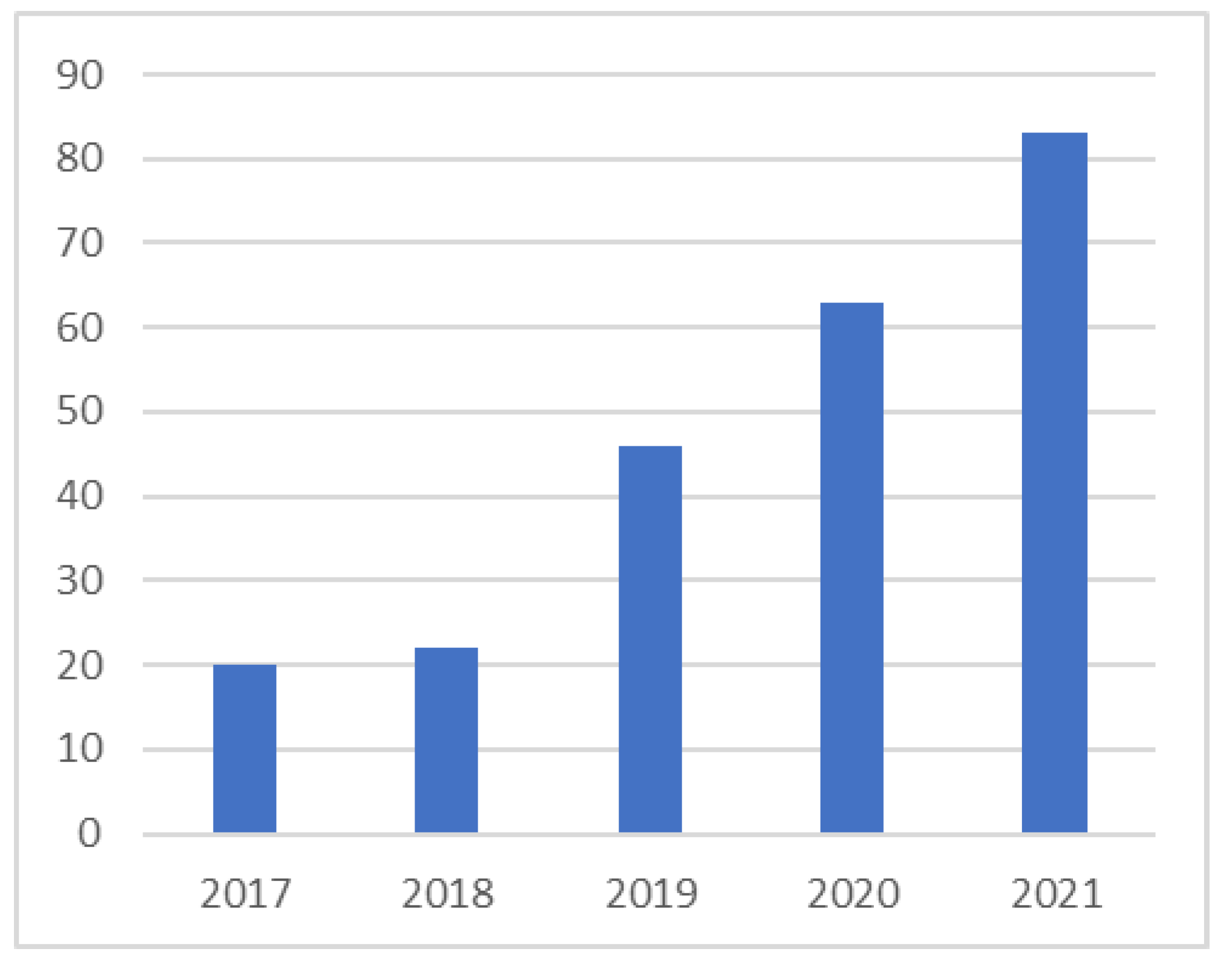

4.1. Bibliometric Analysis

4.2. Quantitative Analysis of All Publications

4.3. Qualitative Analysis of Publications Discussing Direct Benefits

5. Discussion

6. Conclusion

Funding

Data Availability Statement

Conflicts of Interest

References

- Usuga Cadavid, J.P.; Lamouri, S.; Grabot, B.; Pellerin, R.; Fortin, A. Machine learning applied in production planning and control: a state-of-the-art in the era of industry 4.0. Journal of Intelligent Manufacturing 2020, 31. [Google Scholar] [CrossRef]

- Sharp, M.; Ak, R.; Hedberg, T. A survey of the advancing use and development of machine learning in smart manufacturing. J Manuf Syst. 2018, 48. [Google Scholar] [CrossRef]

- Paturi, U.M.R.; Cheruku, S. Application and performance of machine learning techniques in manufacturing sector from the past two decades: A review. In Materials Today: Proceedings; 2020. [Google Scholar] [CrossRef]

- Fornasiero, R.; Nettleton, D.F.; Kiebler, L.; Martinez de Yuso, A.; de Marco, C.E. AI and BD in Process Industry: A Literature Review with an Operational Perspective. In IFIP Advances in Information and Communication Technology; 2021. [Google Scholar] [CrossRef]

- Dogan, A.; Birant, D. Machine learning and data mining in manufacturing. Expert Systems with Applications 2021, 166. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; de Felice, F. Artificial intelligence and machine learning applications in smart production: Progress, trends, and directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.D.P.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput Ind Eng. 2019, 137. [Google Scholar] [CrossRef]

- Bertolini, M.; Mezzogori, D.; Neroni, M.; Zammori, F. Machine Learning for industrial applications: A comprehensive literature review. Expert Systems with Applications 2021, 175. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.D.P.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput Ind Eng. 2019, 137. [Google Scholar] [CrossRef]

- Garnelo, M.; Shanahan, M. Reconciling deep learning with symbolic artificial intelligence: representing objects and relations. Current Opinion in Behavioral Sciences 2019, 29. [Google Scholar] [CrossRef]

- Mitchell, T. Machine Learning; McGraw Hill: New York, 1997. [Google Scholar]

- Kubat, M. An Introduction to Machine Learning; Springer International Publishing: Cham, 2017. [Google Scholar]

- LeCun, Y.; Hinton, G.; Bengio, Y. Deep learning. Nature 2015, 521. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep Learning in neural networks: An overview. Neural Networks 2015, 61. [Google Scholar] [CrossRef]

- Russakovsky, O.; Deng, J.; Su, H.; Krause, J.; Satheesh, S.; Ma, S.; et al. ImageNet Large Scale Visual Recognition Challenge. Int J Comput Vis. 2015, 115. [Google Scholar] [CrossRef]

- Wang, M.; Deng, W. Deep face recognition: A survey. Neurocomputing 2021, 429. [Google Scholar] [CrossRef]

- Pandey, M.; Fernandez, M.; Gentile, F.; Isayev, O.; Tropsha, A.; Stern, A.C.; et al. The transformational role of GPU computing and deep learning in drug discovery. Nature Machine Intelligence 2022, 4. [Google Scholar] [CrossRef]

- Abadi, M.; Barham, P.; Chen, J.; Chen, Z.; Davis, A.; Dean, J.; et al. TensorFlow: A system for large-scale machine learning. In Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementation, OSDI 2016, 2016. [Google Scholar]

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; et al. PyTorch: An imperative style, high-performance deep learning library. In Advances in Neural Information Processing Systems; 2019. [Google Scholar]

- Liu, W.; Wang, Z.; Liu, X.; Zeng, N.; Liu, Y.; Alsaadi, F.E. A survey of deep neural network architectures and their applications. Neurocomputing 2017, 234. [Google Scholar] [CrossRef]

- Young, T.; Hazarika, D.; Poria, S.; Cambria, E. Recent trends in deep learning based natural language processing [Review Article]. IEEE Computational Intelligence Magazine 2018, 13. [Google Scholar] [CrossRef]

- Choi, J.A.; Lim, K. Identifying machine learning techniques for classification of target advertising. ICT Express 2020, 6. [Google Scholar] [CrossRef]

- Weber, F.D.; Schütte, R. State-of-the-art and adoption of artificial intelligence in retailing. Digital Policy, Regulation and Governance 2019, 21. [Google Scholar] [CrossRef]

- Bauer, J.; Jannach, D. Optimal pricing in e-commerce based on sparse and noisy data. Decis Support Syst. 2018, 106. [Google Scholar] [CrossRef]

- Milana, C.; Ashta, A. Artificial intelligence techniques in finance and financial markets: A survey of the literature. Strategic Change 2021, 30. [Google Scholar] [CrossRef]

- Ravi, K.; Ravi, V. A survey on opinion mining and sentiment analysis: Tasks, approaches and applications. Knowl Based Syst. 2015, 89. [Google Scholar] [CrossRef]

- Dalvi, P.K.; Khandge, S.K.; Deomore, A.; Bankar, A.; Kanade, V.A. Analysis of customer churn prediction in telecom industry using decision trees and logistic regression. In Proceedings of the 2016 Symposium on Colossal Data Analysis and Networking, CDAN 2016, 2016. [Google Scholar]

- Hessler, G.; Baringhaus, K.H. Artificial intelligence in drug design. Molecules 2018, 23, 2520. [Google Scholar] [CrossRef] [PubMed]

- Coley, C.W.; Thomas, D.A.; Lummiss, J.A.M.; Jaworski, J.N.; Breen, C.P.; Schultz, V.; et al. A robotic platform for flow synthesis of organic compounds informed by AI planning. Science 2019, 365. [Google Scholar] [CrossRef] [PubMed]

- Editors of Encyclopaedia. Encyclopedia Britannica. 2020. Manufacturing.

- United Nations. International Standard Industrial Classification (ISIC), Rev.4. International Yearbook of Industrial Statistics 2013. 2008. [Google Scholar]

- The World Bank. World Development Indicators (DataBank). 2021. Manufacturing, Value Added (% of GDP).

- Brynjolfsson, E.; McAfee, A. The Second Machine Age: Work, Progress, and Prosperity in a Time of Brilliant Technologies; W.W. Norton & Company: New York, 2014. [Google Scholar]

- Purdy, M.; Daugherty, P. Why Artificial Intelligence is the Future of Growth. Accenture 2016. [Google Scholar]

- Ford, M. Rise of the Robots: Technology and the Threat of a Jobless Future. Basic Books 2015. [Google Scholar]

- Manyika, J.; Lund, S.; Chui, M.; Bughin, J.; Woetzel, J.; Batra, P.; et al. Jobs lost, jobs gained: Workforce transitions in a time of automation, McKinsey Global Institute, December 2017.

- OECD. Artificial Intelligence in Society [Internet]. 2019. Available online: https://www.oecd-ilibrary.org/science-and-technology/artificial-intelligence-in-society_eedfee77-en (accessed on 1 August 2022).

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plann. 2019, 52. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. Journal of Intelligent Manufacturing 2020, 31. [Google Scholar] [CrossRef]

- Udell, M.; Stehel, V.; Kliestik, T.; Kliestikova, J.; Durana, P. Towards a smart automated society: Cognitive technologies, knowledge production, and economic growth. Economics, Management, and Financial Markets 2019, 14. [Google Scholar]

- Rao, A.; Verweij, G.; Cameron, E. Sizing the prize: What’s the real value of AI for your business and how can you capitalise? PwC 2020. [Google Scholar]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; et al. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Frontiers of Mechanical Engineering 2018, 13. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing must embrace big data. Nature 2017, 544. [Google Scholar] [CrossRef]

- Yuan, C.; Li, G.; Kamarthi, S.; Jin, X.; Moghaddam, M. Trends in intelligent manufacturing research: a keyword co-occurrence network based review. Journal of Intelligent Manufacturing 2022, 33. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. British Journal of Management 2003, 14. [Google Scholar] [CrossRef]

- Robles-Velasco, A.; Muñuzuri, J.; Onieva, L.; Rodríguez-Palero, M. Trends and applications of machine learning in water supply networks management. Journal of Industrial Engineering and Management 2021, 14. [Google Scholar] [CrossRef]

- Boguslawski, B.; Boujonnier, M.; Bissuel-Beauvais, L.; Saghir, F.; Sharma, R.D. IIoT edge analytics: Deploying machine learning at the wellhead to identify rod pump failure. In Proceedings of the Society of Petroleum Engineers—SPE Middle East Artificial Lift Conference and Exhibition 2018, MEAL 2018; 2018. [Google Scholar]

- Kumar, P.; Bhamu, J.; Sangwan, K.S. Analysis of Barriers to Industry 4.0 adoption in Manufacturing Organizations: An ISM Approach. In Proceedings of the Procedia CIRP, 2021. 2021. [Google Scholar]

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 applications. International Journal of Production Research 2021, 59. [Google Scholar] [CrossRef]

- Héder, M. From NASA to EU: The evolution of the TRL scale in Public Sector Innovation. Innovation Journal 2017, 22. [Google Scholar]

- EU Comission. Technology readiness levels (TRL); Commission Decision C(2014)4995; Extract from Part 19; EU Comission, 2014. [Google Scholar]

- Farooq, B.; Bao, J.; Li, J.; Liu, T.; Yin, S. Data-Driven Predictive Maintenance Approach for Spinning Cyber-Physical Production System. J Shanghai Jiaotong Univ Sci. 2020, 25. [Google Scholar] [CrossRef]

- Camps, M.; Etxegarai, M.; Bonada, F.; Lacheny, W.; Ballat-Durand, D.; Pauleau, S.; et al. Data-Driven Analysis of Friction Stir Welding for Aerospace Applications. 2021. [Google Scholar]

- de Lima, M.J.; Paredes Crovato, C.D.; Goytia Mejia, R.I.; da Rosa Righi, R.; de Oliveira Ramos, G.; André da Costa, C.; et al. HealthMon: An approach for monitoring machines degradation using time-series decomposition, clustering, and metaheuristics. Comput Ind Eng. 2021, 162. [Google Scholar] [CrossRef]

- Chen, S.H.; Liou, Y.C.; Chen, Y.H.; Wang, K.C. Order acceptance and scheduling problem with carbon emission reduction and electricity tariffs on a single machine. Sustainability 2019, 11, 5432. [Google Scholar] [CrossRef]

- Zotov, E.; Kadirkamanathan, V. CycleStyleGAN-Based Knowledge Transfer for a Machining Digital Twin. Front Artif Intell. 2021, 4. [Google Scholar] [CrossRef] [PubMed]

- Gaikwad, A.; Giera, B.; Guss, G.M.; Forien, J.B.; Matthews, M.J.; Rao, P. Heterogeneous sensing and scientific machine learning for quality assurance in laser powder bed fusion—A single-track study. Addit Manuf. 2020, 36. [Google Scholar] [CrossRef]

- Song, S.; Jing, J.; Huang, Y.; Shi, M. EfficientDet for fabric defect detection based on edge computing. J Eng Fiber Fabr. 2021, 16. [Google Scholar] [CrossRef]

- Lai, X.; Shui, H.; Ni, J. A two-layer long short-Term memory network for bottleneck prediction in multi-job manufacturing systems. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, MSEC 2018; 2018. [Google Scholar]

- Ning, C.; You, F. Data-driven adaptive nested robust optimization: General modeling framework and efficient computational algorithm for decision making under uncertainty. AIChE Journal 2017, 63, 3790–3817. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, C.; Gao, Z.; Yao, Y. Ensemble deep kernel learning with application to quality prediction in industrial polymerization processes. Chemometrics and Intelligent Laboratory Systems 2018, 174, 15–21. [Google Scholar] [CrossRef]

- Abid, S. Texture defect detection by using polynomial interpolation and multilayer perceptron. J Eng Fiber Fabr. 2019, 14. [Google Scholar] [CrossRef]

- Kim, E.; Cho, S.; Lee, B.; Cho, M. Fault Detection and Diagnosis Using Self-Attentive Convolutional Neural Networks for Variable-Length Sensor Data in Semiconductor Manufacturing. IEEE Transactions on Semiconductor Manufacturing 2019, 32, 302–309. [Google Scholar] [CrossRef]

- Caihong, Z.; Zengyuan, W.; Chang, L. A Study on Quality Prediction for Smart Manufacturing Based on the Optimized BP-AdaBoost Model. In Proceedings of the 2019 IEEE International Conference on Smart Manufacturing, Industrial and Logistics Engineering, SMILE 2019; 2019; pp. 1–3. [Google Scholar]

- Ma, F.; Lin, D.; Zhong, J.; Han, X.; Wang, J.; Sun, W. CNN based process monitoring of spatially distributed system. In Proceedings of the 2019 11th CAA Symposium on Fault Detection, Supervision, and Safety for Technical Processes, SAFEPROCESS 2019; 2019; pp. 695–700. [Google Scholar]

- Wu, X.; Chen, J. The temperature process analysis and control on laser-assisted milling of nickel-based superalloy. International Journal of Advanced Manufacturing Technology 2018, 98, 223–235. [Google Scholar] [CrossRef]

- Biebl, F.; Glawar, R.; Jalali, A.; Ansari, F.; Haslhofer, B.; de Boer, P.; et al. A conceptual model to enable prescriptive maintenance for etching equipment in semiconductor manufacturing. In Proceedings of the Procedia CIRP; 2020; pp. 64–69. [Google Scholar]

- Zhang, W.; Lu, X.; Shi, H.; Zhou, L. Optimization control of coal methanol chemical process based on neural network algorithm. Chem Eng Trans. 2017, 62, 883–888. [Google Scholar] [CrossRef]

- Bhosekar, A.; Ierapetritou, M. A framework for supply chain optimization for modular manufacturing with production feasibility analysis. Comput Chem Eng. 2021, 145. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, K.; Sun, J. Sound singularity analysis for milling tool condition monitoring towards sustainable manufacturing. Mech Syst Signal Process. 2021, 157. [Google Scholar] [CrossRef]

- Frigerio, N.; Marzano, L.; Matta, A. An Online Policy for Energy-Efficient State Control of Manufacturing Equipment. IEEE Transactions on Automation Science and Engineering 2021, 18, 705–716. [Google Scholar] [CrossRef]

- Mendia, I.; Gil-López, S.; Landa-Torres, I.; Orbe, L.; Maqueda, E. Machine learning based adaptive soft sensor for flash point inference in a refinery realtime process. Results in Engineering 2022, 13. [Google Scholar] [CrossRef]

- Apiletti, D.; Barberis, C.; Cerquitelli, T.; Macii, A.; Macii, E.; Poncino, M.; et al. ISTEP, an integrated self-tuning engine for predictive maintenance in industry 4.0. In Proceedings of the 16th IEEE International Symposium on Parallel and Distributed Processing with Applications, 17th IEEE International Conference on Ubiquitous Computing and Communications, 8th IEEE International Conference on Big Data and Cloud Computing; 11t. 2019; pp. 924–931. [Google Scholar]

- Bhosekar, A.; Badejo, O.; Ierapetritou, M. Modular supply chain optimization considering demand uncertainty to manage risk. AIChE Journal 2021, 67. [Google Scholar] [CrossRef]

- Arena, S.; Florian, E.; Zennaro, I.; Orrù, P.F.; Sgarbossa, F. A novel decision support system for managing predictive maintenance strategies based on machine learning approaches. Saf Sci. 2022, 146. [Google Scholar] [CrossRef]

- Schmidt, B.; Wang, L. Predictive Maintenance of Machine Tool Linear Axes: A Case from Manufacturing Industry. In Procedia Manufacturing; 2018; pp. 118–125. [Google Scholar] [CrossRef]

- Wang, C.N.; Nhieu, N.L.; Tran, T.T.T. Stochastic chebyshev goal programming mixed integer linear model for sustainable global production planning. Mathematics 2021, 9, 1. [Google Scholar] [CrossRef]

- Chen, Y.C.; He, B.H.; Lin, S.S.; Soeseno, J.H.; Tan, D.S.; Chen, T.P.C.; et al. Demystifying data and AI for manufacturing: Case studies from a major computer maker. APSIPA Trans Signal Inf Process 2021. [Google Scholar] [CrossRef]

- Chidhananda, R.S.; Kulkarni, A. Application of automation strategies to prevent failure in mechatronic water plant system. In Materials Today: Proceedings; 2020; pp. 1480–1485. [Google Scholar] [CrossRef]

- Xu, Q.; Lu, S.; Jia, W.; Jiang, C. Imbalanced fault diagnosis of rotating machinery via multi-domain feature extraction and cost-sensitive learning. J Intell Manuf. 2020, 31, 1467–1481. [Google Scholar] [CrossRef]

- Kiangala, K.S.; Wang, Z. An Effective Predictive Maintenance Framework for Conveyor Motors Using Dual Time-Series Imaging and Convolutional Neural Network in an Industry 4.0 Environment. IEEE Access 2020, 8, 121033–121049. [Google Scholar] [CrossRef]

- Patel, D.; Zhou, N.; Shrivastava, S.; Kalagnanam, J. Doctor for Machines: A Failure Pattern Analysis Solution for Industry 4.0. In Proceedings of the 2020 IEEE International Conference on Big Data, Big Data 2020, 2020; pp. 1614–1623. [Google Scholar]

- Tufano, A.; Accorsi, R.; Manzini, R. Machine learning methods to improve the operations of 3PL logistics. In Procedia Manufacturing; 2020; pp. 62–69. [Google Scholar] [CrossRef]

- Buratti, Y.; Eijkens, C.; Hameiri, Z. Optimization of solar cell production lines using neural networks and genetic algorithms. ACS Appl Energy Mater. 2020, 3, 10317–10322. [Google Scholar] [CrossRef]

- Zhang, C.; Gupta, C.; Joichi, S.; Farahat, A.; Shao, H. Risk-based dynamic pricing via failure prediction. In Proceedings of the 18th IEEE International Conference on Machine Learning and Applications, ICMLA 2019; 2019; pp. 140–147. [Google Scholar]

- Beuth, F.; Schlosser, T.; Friedrich, M.; Kowerko, D. Improving Automated Visual Fault Detection by Combining a Biologically Plausible Model of Visual Attention with Deep Learning. In Proceedings of the IECON Proceedings (Industrial Electronics Conference); 2020; pp. 5323–5330. [Google Scholar]

- Ma, S.; Zhang, Y.; Lv, J.; Ge, Y.; Yang, H.; Li, L. Big data driven predictive production planning for energy-intensive manufacturing industries. Energy 2020, 211. [Google Scholar] [CrossRef]

- Mawson, V.J.; Hughes, B.R. Deep learning techniques for energy forecasting and condition monitoring in the manufacturing sector. Energy Build. 2020, 217. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Sun, Z.; Xiong, H.; Qin, R.; Li, C. Cost-imbalanced hyper parameter learning framework for quality classification. J Clean Prod. 2020, 242. [Google Scholar] [CrossRef]

- Ahmed, S.U.; Arora, R. Quality characteristics optimization in CNC end milling of A36 K02600 using Taguchi’s approach coupled with artificial neural network and genetic algorithm. International Journal of System Assurance Engineering and Management 2019, 10, 676–695. [Google Scholar] [CrossRef]

- Orihara, R. Applications of AI Technologies in Flash Memory Business. In Proceedings of the 2021 5th IEEE Electron Devices Technology and Manufacturing Conference, EDTM 2021; 2021. [Google Scholar]

- Kumar, R.; Patil, O.; Nath, S.K.; Sangwan, K.S.; Kumar, R. A Machine Vision-based Cyber-Physical Production System for Energy Efficiency and Enhanced Teaching-Learning Using a Learning Factory. In Proceedings of the Procedia CIRP; 2021; pp. 424–429. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Lin, K.Y. Preventive maintenance scheduling optimization based on opportunistic production-maintenance synchronization. J Intell Manuf. 2021, 32, 545–58. [Google Scholar] [CrossRef]

- Svoboda, J.; Minner, S. Tailoring inventory classification to industry applications: the benefits of understandable machine learning. Int J Prod Res. 2022, 60, 388–401. [Google Scholar] [CrossRef]

- Martello, R.H.; Ranzan, L.; Farenzena, M.; Trierweiler, J.O. Improving autoencoder training with novel goal functions based on multivariable control concepts. In IFAC-PapersOnLine; 2021; pp. 73–78. [Google Scholar] [CrossRef]

- Danishvar, M.; Danishvar, S.; Katsou, E.; Mansouri, S.A.; Mousavi, A. Energy-Aware Flowshop Scheduling: A Case for AI-Driven Sustainable Manufacturing. IEEE Access 2021, 9, 141678–141692. [Google Scholar] [CrossRef]

- Huseynov, N.T. Application of Modern Technologies for Planning Improvement and Saving on Costs in the Enterprise of the Industry 4.0. AISC, Advances in Intelligent Systems and Computing 2021, 1323, 272–279. [Google Scholar] [CrossRef]

- Frigerio, N.; Cornaggia, C.F.A.; Matta, A. An adaptive policy for on-line Energy-Efficient Control of machine tools under throughput constraint. J Clean Prod. 2021, 287. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Rock, D.; Syverson, C. The Productivity J-Curve: How Intangibles Complement General Purpose Technologies. American Economic Journal: Macroeconomics 2021, 13. [Google Scholar] [CrossRef]

| Field of Business | Manufacturing OR Industry AND |

|---|---|

| AI technology | "machine learning" OR "deep learning" OR "neural network" OR "support vector machine" OR svm OR "random forest" OR "decision tree" OR "Deep Transfer Learning" AND |

| Benefit | benefit OR advantages OR "productivity increase" OR "efficiency increase" OR "quality increase" OR "operational improvement" OR "efficiency improvement" OR "quality improvement" OR "cost saving" OR "cost reduction" OR "cost decrease" OR "emission reduction" OR "emission decrease" OR "energy reduction" OR "energy decrease" OR "resource reduction" OR "resource decrease" OR "material reduction" OR "material decrease" OR "waste reduction" OR "waste decrease" OR "key performance indicator" OR kpi OR "decrease downtime" OR "reduce downtime" OR "decrease inefficiency" OR "reduce inefficiency" OR "downtime reduction" OR "inefficiency reduction" OR "improve response time" OR "response time improvement" OR "improve resource management" OR "resource management improvement" |

| Time range | 2017–2022 (2022: 08.03.2022) |

| Dimension | Explanation | Related Research question |

|---|---|---|

| Benefit pursued | Business benefit (with sub-categories: productivity, cost saving or efficiency; quality management; other or not specified); environmental sustainability; societal sustainability | Benefit pursued (RQ1) |

| Treatment of benefit | Not discussed or vague, qualitative statements; indirect, e.g. accuracy of ML methods in specific case; direct, measured | Discussion on the benefit (RQ1) |

| Maturity (only in step 4) | Simulation; laboratory experiment; pilot or PoC; operational use (TRL) | Maturity of the solution (RQ2) |

| Data used (only in step 4) | Simulated; laboratory; database; off-line from industry; real-time on-line from industry | n/a |

| Sector of manufacturing industry | International Standard Industrial Classification, 24 classes | Sector of manufacturing industry (RQ3) |

| Industry function | Design and engineering; production and process control, including optimization; quality management; supply chain management; maintenance management; several functions equally | Industry function (RQ4) |

| ML method | ANN incl. DL, CNN; decision tree and variants; SVM; other; several (comparison of methods). | Machine learning method (RQ5) |

| Implementation (Maturity of) | Data (Maturity of) | Corresponding TRL (EU Commission, 2014) |

|---|---|---|

| Simulated | Simulated data or data base | TRL 3 Experimental proof of concept |

| Simulated | Real industry data off-line | TRL 4 Technology validated in lab |

| Laboratory | Lab. data | TRL 4 Technology validated in lab |

| Proof-of-concept | Real on-line | TRL 5–6 Technology validated in relevant environment |

| Operational use | Real on-line | TRL 7 System prototype demonstration in operational environment - TRL 9 Actual system proven in an operational environment |

| Citations per Publication | Field-Weighted Citation Impact | International Collaboration: Publicationc co-Authored with Institutions in Other Countries [%] | Publications in 10% Most Cited Worldwide [%] | Publications in Top 10% Journals (Source Normalized Impact per Paper) [%] |

|---|---|---|---|---|

| 11.8 | 2.24 | 21.2% | 25 | 28.5 |

| Country | Scholarly output |

|---|---|

| China | 50 |

| Germany | 28 |

| USA | 20 |

| Italy | 18 |

| India | 13 |

| UK | 11 |

| Author Affiliation | Number of Publications |

|---|---|

| Academic authors only | 200 |

| Co-authored (academy and industry) | 32 |

| Industry affiliated authors only | 14 |

| Publication Type | Number of Publications |

|---|---|

| Conference proceedings | 106 |

| Article | 136 |

| Chapter in book, other | 4 |

| Section C Manufacturing | Sector of Industry (NB. Sectors with no publications are omitted) | Number of publications |

|---|---|---|

| Division 10 | Manufacture of food products and beverages | 10 |

| Division 13 | Manufacture of textiles | 11 |

| Division 16 | Manufacture of wood and of products of wood and cork, except furniture | 1 |

| Division 17 | Manufacture of paper and paper products | 2 |

| Division 18 | Publishing, printing, and reproduction of recorded media | 1 |

| Division 19 | Manufacture of coke, refined petroleum products, and nuclear fuel | 9 |

| Division 20 | Manufacture of chemicals and chemical products | 19 |

| Division 21 | Manufacture of pharmaceuticals, medicinal chemical, and botanical products | 2 |

| Division 22 | Manufacture of rubber and plastics products | 5 |

| Division 24 | Manufacture of basic metals | 6 |

| Division 25 | Manufacture of fabricated metal products, except machinery and equipment | 1 |

| Division 26 | Manufacture of computer, electronic, and optical products | 33 |

| Division 27 | Manufacture of electrical equipment | 6 |

| Division 28 | Manufacture of machinery and equipment n.e.c. | 56 |

| Division 29 | Manufacture of motor vehicles, trailers and semi-trailers | 14 |

| Division 30 | Manufacture of other transport equipment | 5 |

| Division 31 | Manufacture of furniture | 2 |

| Division 33 | Repair and installation of machinery and equipment | 32 |

| Other | Sector not specified and papers addressing manufacturing in general | 31 |

| Operation | Number of publications |

|---|---|

| Several functions equally | 18 |

| Design and engineering | 6 |

| Production and process control, including optimization | 62 |

| Quality management | 56 |

| Supply chain management | 12 |

| Maintenance management | 92 |

| ML method | Number of publications |

|---|---|

| ANN incl. deep learning and CNN | 147 |

| DT, including random forest | 20 |

| SVM | 15 |

| Other or not specified | 38 |

| Several (method comparison) | 26 |

| Benefit | Subclasses of Business Benefit | Number of Publications |

|---|---|---|

| Business benefit | Subclasses together | 228 |

| Productivity | 26 | |

| Cost saving or efficiency | 90 | |

| Quality management | 73 | |

| Other or not specified | 39 | |

| Environmental sustainability | - | 15 |

| Societal sustainability | - | 3 |

| Treatment | Number of publications |

|---|---|

| Not discussed | 12 |

| Vague, qualitative statement | 83 |

| Indirect, such as accuracy of ML methods in specific case | 111 |

| Direct, measured | 40 |

|

Abbreviations used in the table: Operation: D = design and engineering; P = process and production control, optimization; Q = quality management; M = maintenance management; S = supply chain. Benefit pursued: B = business benefit, E = environmental sustainability, S = social sustainability. Business benefit: P = productivity, E = efficiency, C = cost saving, Q = quality. Maturity: S = simulation; L = laboratory; PoC = proof-of-concept; O = operational in industry | ||||||||

| Author, year | Industry sector | Operation | ML method | Benefit pursued | Business benfit | Maturity | Source of data | Short description of the case |

| [59] | Motor vehicles … (D29) | P | ANN | B | P | S | Off-line | Predicting and then avoiding production bottlenecks and improving system throughput with a two-layer long short-term memory (LSTM). Simulations with industrial data from automotive underbody assembly lines show potential benefits. |

| [60] | Chemicals … (D20) | P | Other | B | P | S | Off-line | The DDANRO framework is deployed to an industrial multipurpose batch process in Dow Chemical Company for better process control. Bayesian nonparametric models and robust optimization are used. |

| [61] | Chemicals … (D20) | D | ANN | B | P | S | Off-line | Predicting the melt index in industrial polymerization processes for improved process control is proposed. The ensemble deep kernel learning (EDKL) model is compared with, for example, SVM. Data is from process records from an industrial polyethylene process in a Chinese plant. |

| [62] | Textiles (D13) | Q | ANN | B | Q | S | Off-line | Improving fault detection in fabric manufacturing is pursued. A machine vision algorithm using texture analysis and MLP-NN for a company using circular knitting machines was studied. The database consists of 76 images with defects. The detection rate is 98%. |

| [63] | Comp., electr. and optical (D26) | Q | ANN | B | Q, P | S | Off-line | Improved fault detection in the semiconductor industry is pursued. CNN-based method using variable-length status variable identification [SVID) data in semiconductor manufacturing for fault detection. Real-world data from two sets of 778 and 1546 wafers. |

| [64] | General manufacturing (C) | Q | ANN | B | Q | S | Database | Quality prediction method with back-propagation neural network and modified AdaBoost for small manufacturing. Data is from 110560 individual products (96% good, 4% faulty) via Kaggle platform. |

| [65] | Chemicals … (D20) | M | ANN | B | Q | S | Off-line | Goal is to develop a method for the early detection of process deviations. Case study with a pre-reforming reactor of hydrogen production units. Data from 3 months, 1-minute interval. The CNN regression model identified process deviation 4 hours earlier than the process engineer. |

| [66] | Fabricated metal products (D25) | P | ANN | B | Q | L | Laboratory | The goal is to find the most effective method to obtain a good surface quality by changing the laser energy in laser-assisted milling (LAML). A BP neural network is used to train specimens. |

| [67] | Comp., electr. and optical (D26) | M | Other | B | P | S | Off-line | ML algorithms are used to predict time-to-failure intervals for unplanned downtimes to be used for prescriptive maintenance. Data from different sources. In the industrial use case, a potential reduction of downtime of 12–21% and 2 percentage-point increased availability is shown. |

| [68] | Chemicals … (D20) | P | ANN | E, B | n/a | S | Off-line | Control method for reducing CO2 and energy use is proposed for the real-time optimization control of coal-to-methanol production. CNN is used for data from a factory under different conditions. The needed compressor power (kW) is reduced from 530 to 473 with the new method in the simulation. |

| [69] | Chemicals … (D20) | S | SVM | B | C | S | Simulated | The goal is to minimize the total cost of the supply chain. SVM is used. Case studies with reactor and separator systems and an industrial gas supply chain. Simulations provide costs (total, capex, operation, transport, and inventory) for various design options. |

| [70] | Fabricated metal … (D25) | M | SVM | E; B | C | PoC | Real on-line | Tool Condition Monitoring (TCM) system to maximize tool life and reduce CO2 using wavelet and SVM methods. Results with 10 cutters in the Computer numerical control (CNC) manufacturing plant. The average tool wear is improved by about 30%, while CO2 emissions declined by 29.5%. |

| [71] | General manufacturing (C) | P | Other | B; E | C | S | Simulated | The goal is to optimize the energy use of machine tools by switching them off when idle, i.e., waiting for the next job. The maximum likelihood estimation method is used. Data is from a machining center for powertrain applications (simulated or real?). With the on-line policy, the machines save 31% energy with respect to the always-on case. |

| [72] | Coke and Refined petroleum (D19) | P | Several equal | B | C | S | Off-line | The goal is to develop a soft sensor (method) for estimating the flash-point of diesel fuel and thus decrease cost and improve quality. Data from petrochemical plant for 3-year period, 1-min interval. A considerable reduction of the generated losses is estimated, from 29838$ up to 497306$/semester. |

| [73] | General manufacturing (C) | M | Several | B | C | S | Database | Goal is to build a tool for finding the best ML algorithm for predictive maintenance in each situation dynamically. Data is from a public dataset of 90 attributes describing the SMART hard-drive measurements and corresponding device failures for 125627 hard disks. |

| [74] | Chemicals … (D20) | S | Other | B | C, E | S | Simulated | The goal is to optimize the supply chain using mixed-integer linear programming. Two cases: reactor and separator; an industrial gas supply chain problem. The same authors have another publication partly covering the same topic. |

| [75] | Food products (D10) | M | DT | B | C | PoC | Off-line | Goal is to eventually develop a decision support system based on decision trees (DTs) for the decision-making of predictive maintenance implementation. Enable cost comparison between predictive and corrective maintenance approaches. Data from the food industry gearbox for roasting oilseeds. |

| [76] | Fabricated metal products (D25) | M | Several equal (comparison) | B; E | C | S | Off-line | Goal: maintenance decision support system which estimates cost of maintenance and a ratio of unplanned breakdowns for different scenarios. Data from 29 machine tools from 4 years. In the example case, estimated benefit: the direct cost is decreased by around 30-40%, and the value of occurrences of unplanned stops is decreased by a factor from 4 to 8. |

| [77] | Wearing apparel (D14) | P | Other | B, E, S | P, Q, C, E | S | Off-line | Goal: optimize production planning regarding backorder quantity, machine uptime and customer satisfaction as well as profits, emissions, and workforce change rate. The stochastic multi-objective mixed-integer optimization is used. Data from three textile factories. Result: improvements in profitability, emissions, workforce changing, and backorder of 21%, 37%, 30%, and 23%, respectively. |

| [78] | Comp., electr. and optical (D26) | Q | ANN, other | B | C, Q | O | Real-time on-line | Goal is cost reduction and improved quality. Three cases using ML methods are presented in Inventec Inc. company: logistics optimization, quality acceptance, and visual inspection. Results example: reducing the number of verification engineers by over half, which translates to hundreds of people. |

| [79] | General manufacturing (C) | M | Seve-ral | B | C | S | Database | Goal is to predict failure beforehand by producing alert message. Data is from a database of a water pump covering over a year of operation [Kaggle). Result: algorithm detects 6 out of 7 failures in the forehand. |

| [80] | Coke and refined petroleum (D19) | M | Other | B | C | S | Off-line | Goal is to develop data-driven framework for rotating machinery diagnosis. Data (vibration signal) from a pump in an oil refinery in China. “Our cost-sensitive learning method performs better in imbalanced fault classification.” |

| [81] | General manufacturing (C) | M | ANN | B | C, | S | Off-line | Goal is to develop an experimental predictive maintenance framework for conveyor motors. Data from the conveyor system of a small manufacturing plant was used for testing. ANN classifies conveyor motor status into critical fault, minor fault, and no-fault. |

| [82] | General manufacturing (C) | M | ANN | B | C; | S | Off-line | A framework named DoM (Doctor for Machines) to produce the best predictive model for several oil and gas industry cases. Six data sets, 4 real, 2 synthetic (pumps, turbo fans, hard disc). Result: 1) reduce the labor effort to build predictive models, 2) help to plan maintenance better. |

| [83] | Motor vehicles … (D29) | S | Other | B | P | S | Off-line | Goal is to use clustering methods to address the grouping of products into families for 3rd party logistics in supply chain. Data is from a packaging plant with 58000 different items. Result: capacitated clustering provides the highest balanced scenario with the lowest variance. |

| [84] | Comp., electr. and optical (D26) | P | Other | B | P | S | Simulated | A machine learning (ML) framework for quality improvement and estimation in PV production line is proposed. Simulated data is used. It predicts cell efficiencies with prediction errors of <0.03% absolute efficiency. Optimization method increases the mean cell efficiency of the simulated production line from 18.07% to 19.45%. |

| [85] | General manufacturing (C) | M | Other | B | C, E | S | Databases | A hybrid modeling approach that combines failure prediction with risk-based dynamic pricing (RBDP) for equipment-as-a-service business. Gradient boosting is used. Two public data sets are used: C-MPASS, a jet engine run-to-failure data set, and an Advanced planning and scheduling (APS) failure data set for heavy-duty Scania trucks. Result: improvement of 3.75% in terms of profit gains over a baseline method. |

| [86] | Comp., electr. and optical (D26) | Q | ANN | B | P, Q | S | Off-line | Goal is to develop a biology-inspired visual attention mechanism for automatic visual inspection, using DNN. Data: wafer data set originates from a real-world, laser-based dicing process of semiconductor wafers. Result: classification error rate for the faults drops from 33% to 12%. |

| [87] | Other non-metallic … (D23) | P | Several | B, E | E | S | Off-line | Goal is to establish an architecture for predictive production planning for the energy-intensive industry to achieve cleaner production and decreasing energy use. ML methods: recursive neural networks and long short-term memory. Data: energy consumption of a large ceramic factory. |

| [88] | General manufacturing (C) | P | ANN | B, E | C | S | Off-line | Goal is to forecast manufacturing facility energy consumption and optimize building energy consumption. Energy data is from an industrial building. Results: predicting energy consumption to an accuracy of 96.8%. Accurate forecasting helps optimization with the potential for 30% energy cost reduction by avoiding an oscillatory energy profile. |

| [89] | General manufacturing (C) | Q | DT | B, E | Q, C | S | Databases | Goal is to develop a hyper-learning quality classification system. Data is from published databases, including red vine, used cars, steel plates, and glass. Result: a generalizable framework where economic viability and environmental sustainability can be combined for cost-imbalanced quality classification is demonstrated. |

| [90] | Fabricated metal (D25) | P, Q | ANN | B, E | Q | L | Real data (lab) | Goal: minimizing surface roughness and energy consumption in a CNC end milling. Data from experimental set-up with CNC machine. Improvements in surface quality and reduction in energy consumption were found to be 28% and 30%, respectively. |

| [91] | Comp., electr. and optical (D26) | Q, P | ANN | B | Q P | S | Off-line | Goal is to use data-based methods in the semiconductor industry for defect analysis, design, and other needs. Data from semiconductor production (incl. defect data, images). Results, e.g., automating the potential for defect detection and reducing the human load by about two-thirds. |

| [92] | General manufacturing (C) | Q, P | ANN | E | - | L | Laboratory | Goal: less rework and thus energy use with early machine vision quality control. Data is from a laboratory set-up (“learning factory”). System has enhanced energy efficiency and reduced the total carbon footprint by 18% or more. Reduced labor need. (Note: laboratory set-up). |

| [93] | Comp., electr. and optical (D26) | M | ANN | B | E | S | Off-line | Goal: integrating preventive maintenance (PM) into production planning; to minimize the impact on production and to optimize the number of repairmen to save cost. Data from production line in semiconductor multi-workstation system with 153 workstations and 29 repairmen. Result: reduce personnel numbers while guaranteeing maintenance tasks. |

| [94] | General manuf. (C) | S | DT | B | C | S | Off-line | Goal: cost-based, multi-dimensional inventory classification system. Data from three industry data sets. |

| [95] | Paper and paper products (D17) | P | Other | B | C | S | Database | Goal: predict and classify rare problems in the production process, case leaf breakage. Autoencoder method used on a real-world dataset obtained from a pulp-and-paper manufacturing industry. Potential savings of up to 22 to 38 thousand dollars per month (based on simulation results). |

| [96] | Fabricated metal products (D25) | P | ANN | B, E | C | S | Off-line | Goal: multi-objective batch-based flowshop scheduling optimization (energy, cost, makespan). Shop floor data collection solution was implemented. Result: Scenario simulation decision support models can help decision makers evaluate options and make the best decisions automatically. |

| [97] | Other non-metallic … (D23) | M | ANN | B | C | O | Real data | The goal was to decrease the maintenance costs of production equipment. Data: production data from cement factories and macro-economic data. Result: maintenance costs were reduced to 4% in comparison with initial status. |

| [98] | Fabricated metal products fD25) | P | Other | B, E | C | S | Simulated | The goal is to develop an adaptive policy for on-line energy-efficient control of machine tools under throughput constraint (turning machines off when idle). Data: simulated scenarios partly based on real machines. In the simulated scenarios, the approach reduces the energy consumption up to 25% with respect to the baseline. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).