Submitted:

28 June 2023

Posted:

29 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Theory and methodology

2.1. Ultrasonic attributes

- Grain Size: The grain size of polycrystalline materials can be estimated via ultrasonic velocity measurements. The interaction between ultrasonic waves and grain boundaries influences the velocity of the waves, allowing the average grain size of the material to be calculated [33].

- Phase Transformations: Under certain temperature or pressure circumstances, some materials undergo phase transformations, such as solid-solid or solid-liquid transitions. Ultrasonic velocity measurements can detect these phase transitions by detecting variations in velocity as the material transforms, making phase diagrams and material behaviour easier to investigate [34].

- Analysis of Stress and Strain: Ultrasonic velocity data can be used to evaluate the effects of stress and strain on the material. Variations in velocity can reflect changes in the mechanical characteristics of a material, providing insight into the presence of residual stresses or deformation mechanisms [35].

- Elastic Anisotropy: Elastic anisotropy refers to the directional dependency of certain materials’ elastic characteristics. Ultrasonic velocity measurements can help characterise and quantify this anisotropy, providing vital information on the mechanical behaviour of the material in different directions [36].

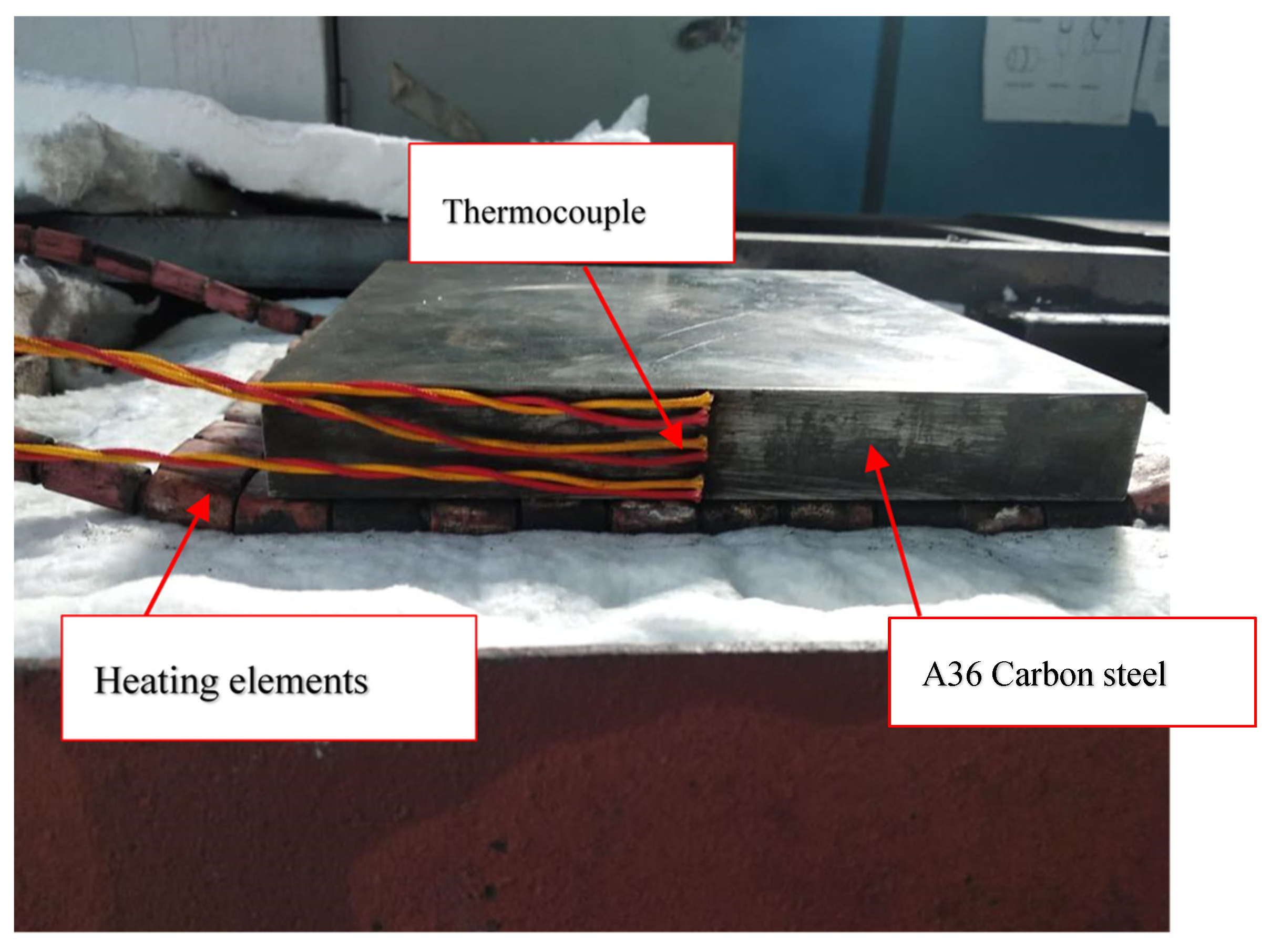

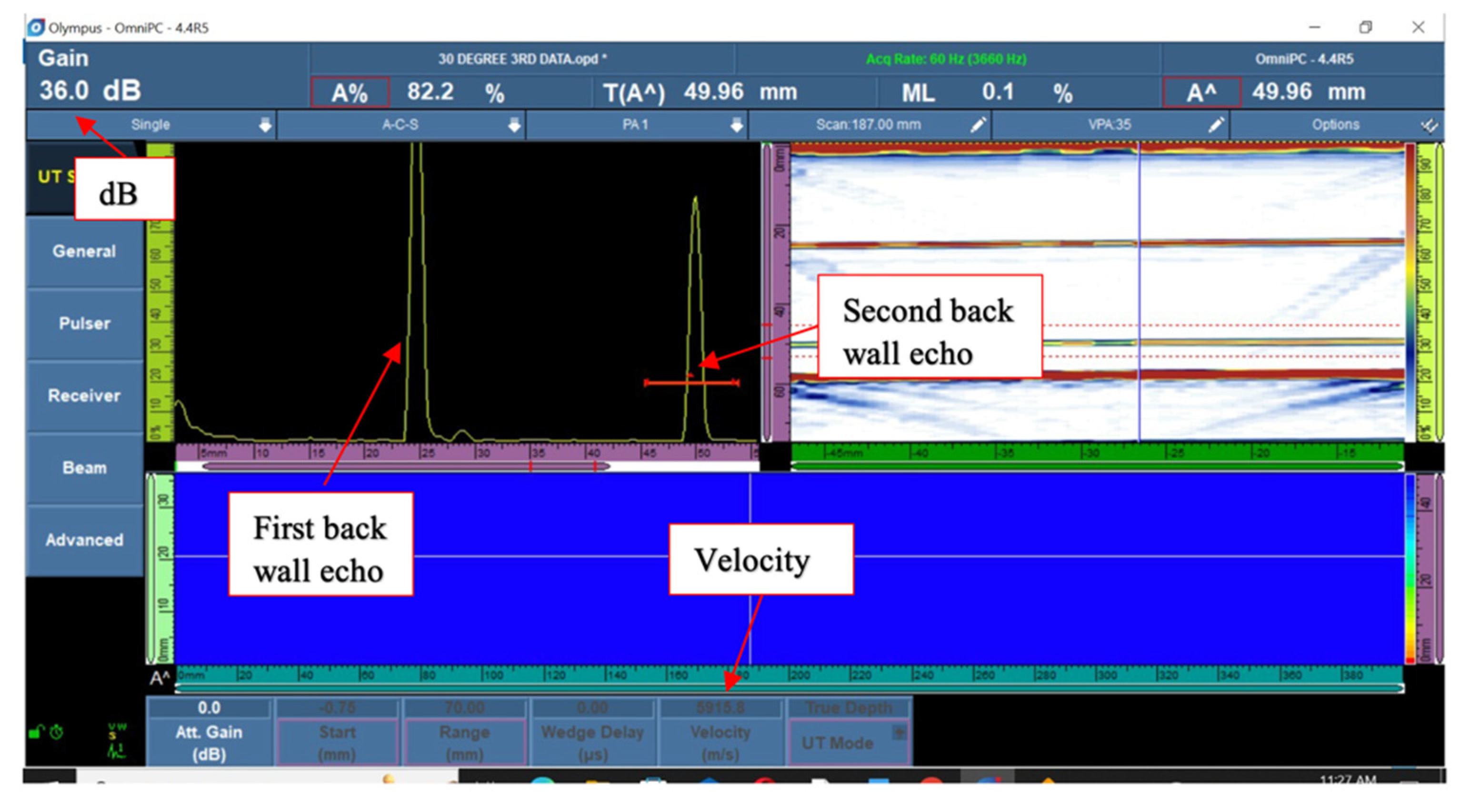

2.2. Experiment test

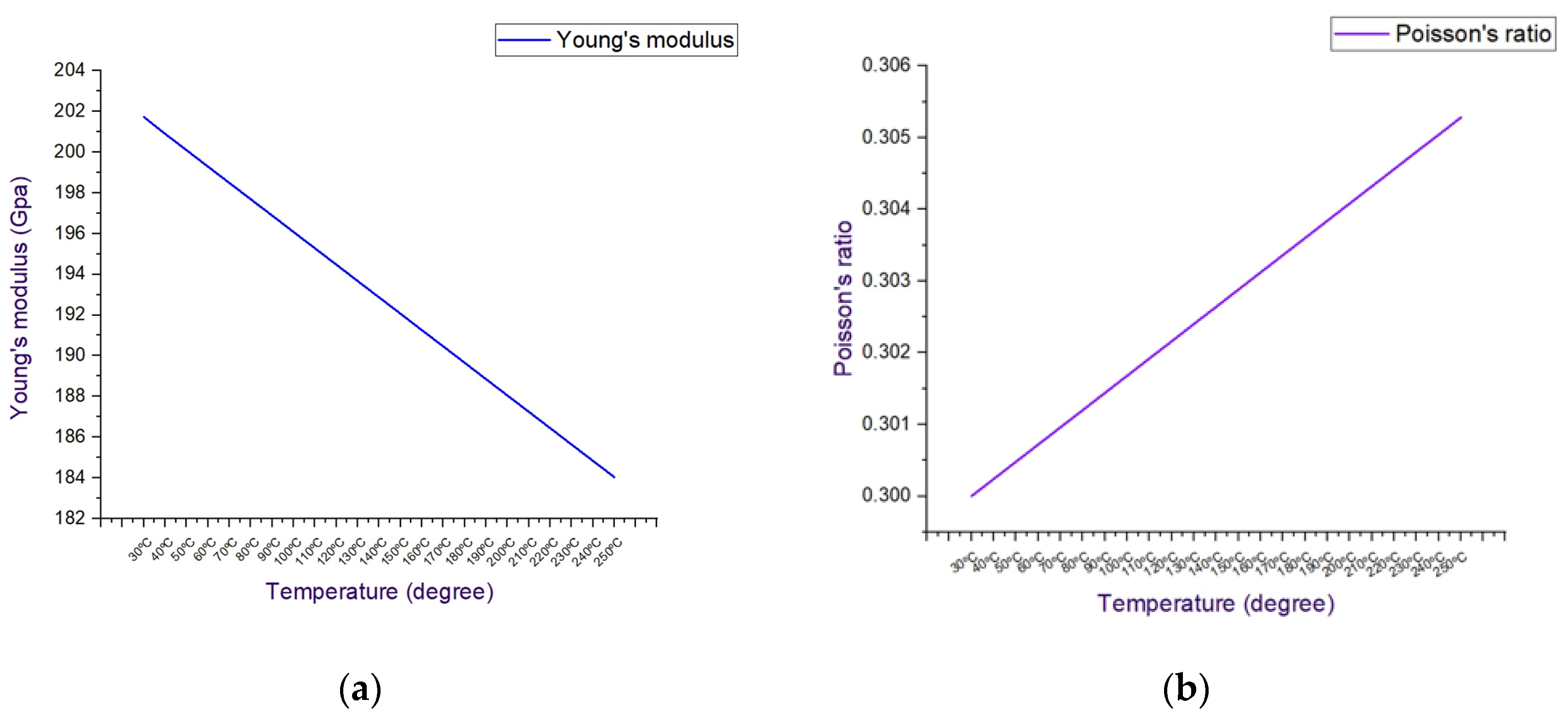

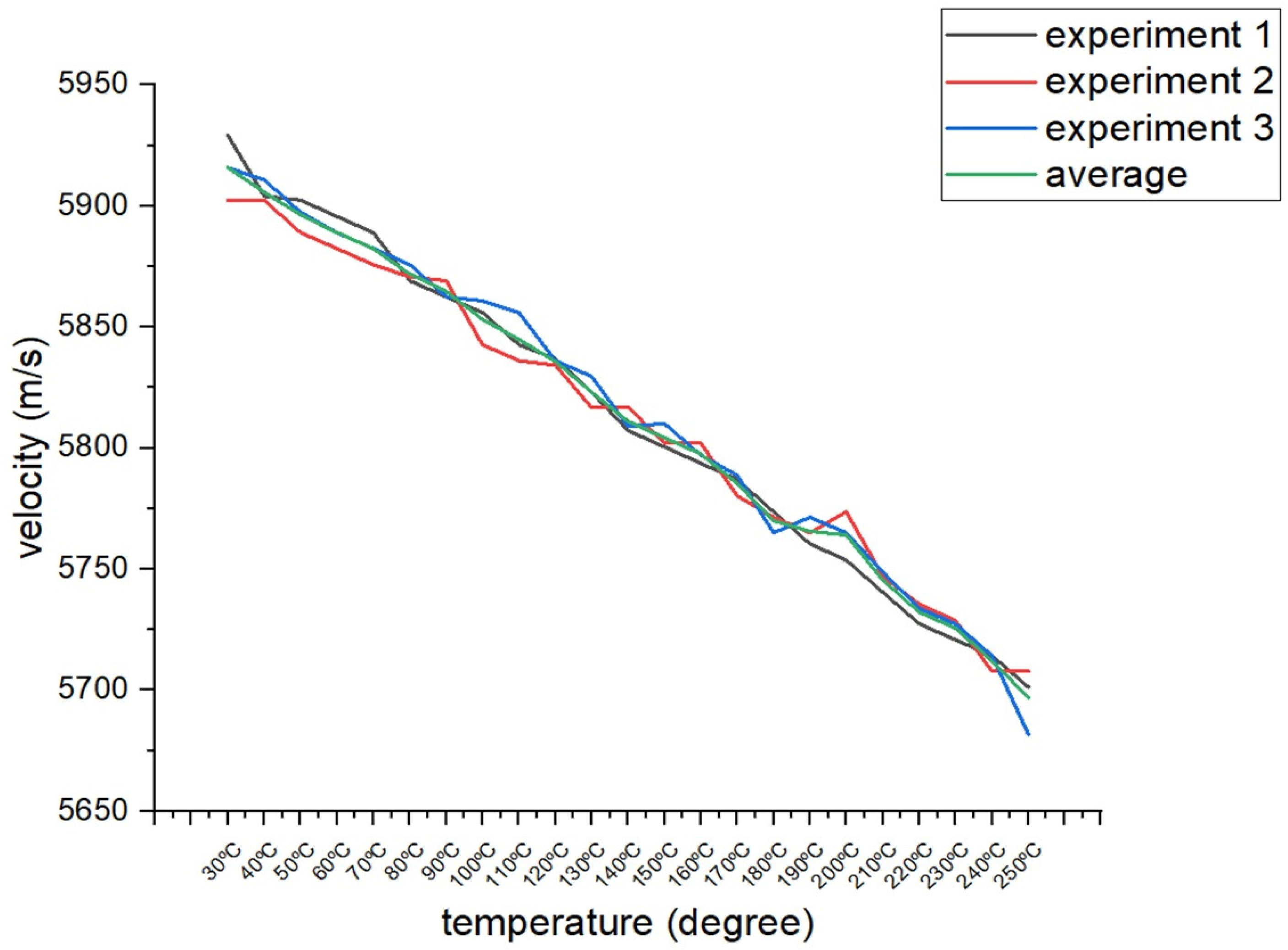

3. Results and discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- Fabić, M.; Pavletić, D.; Šterpin Valić, G. Factors in Turnaround Refinery (TAR) Project Management Process. Tehnicki Vjesnik 2020, 27, 1367–1377. [Google Scholar] [CrossRef]

- Lemecha, M.; Napiórkowski, J.; Ligier, K.; Tarasiuk, W.; Sztukowski, K. Analysis of Wear Properties of Powder Metallurgy Steel in Abrasive Soil Mass. Materials 2022, 15, 6888. [Google Scholar] [CrossRef]

- Guma, T.N.; Olukemi, A.E. Corrosion Management and Control in the Petroleum Industry—A Case Study of Kaduna Refinery. IOSR Journal of Mechanical and Civil Engineering 2018, 15, 6–11. [Google Scholar] [CrossRef]

- Slongo, J.S.; Gund, J.; Passarin, T.A.R.; Pipa, D.R.; Ramos, J.E.; Arruda, L.V.; Junior, F.N. Effects of Thermal Gradients in High-Temperature Ultrasonic Non-Destructive Tests. Sensors 2022, 22, 2799. [Google Scholar] [CrossRef] [PubMed]

- Honarvar, F.; Salehi, F.; Safavi, V.; Mokhtari, A.; Sinclair, A.N. Ultrasonic Monitoring of Erosion/Corrosion Thinning Rates in Industrial Piping Systems. Ultrasonics 2013, 53, 1251–1258. [Google Scholar] [CrossRef] [PubMed]

- Łukaszewicz, A. Temperature Field in the Contact Zone in the Course of Rotary Friction Welding of Metals. Materials Science 2019, 55, 39–45. [Google Scholar] [CrossRef]

- Mircheski, I.; Łukaszewicz, A.; Szczebiot, R. Injection Process Design for Manufacturing of Bicycle Plastic Bottle Holder Using CAx Tools. Procedia Manuf 2019, 32, 68–73. [Google Scholar] [CrossRef]

- Mircheski, I.; Lukaszewicz, A.; Trochimczuk, R.; Szczebiot, R. Application of CAX System for Design and Analysis of Plastic Parts Manufactured by Injection Moulding. Engineering for Rural Development 2019, 18, 1755–1760. [Google Scholar] [CrossRef]

- Alobaidi, W.M.; Alkuam, E.A.; Al-Rizzo, H.M.; Sandgren, E. Applications of Ultrasonic Techniques in Oil and Gas Pipeline Industries: A Review. American Journal of Operations Research 2015, 05, 274–287. [Google Scholar] [CrossRef]

- Rioux, P. Comparison Corrosion Mapping Solutions Using Phased Array and Conventional UT Techniques. ASNT Ultrasonics for Nondestructive Testing Topical Paper Summaries 2015, 37–47. [Google Scholar]

- Cheong, Y.M.; Kim, K.M.; Kim, D.J. High-Temperature Ultrasonic Thickness Monitoring for Pipe Thinning in a Flow-Accelerated Corrosion Proof Test Facility. Nuclear Engineering and Technology 2017, 49, 1463–1471. [Google Scholar] [CrossRef]

- Mattar, R.A.; Kalai, R. Development of a Wall-Sticking Drone for Non-Destructive Ultrasonic and Corrosion Testing. Drones 2018, 2, 1–11. [Google Scholar] [CrossRef]

- Lukaszewicz, A.; Szafran, K.; Jozwik, J. CAx Techniques Used in UAV Design Process. In Proceedings of the 2020 IEEE International Workshop on Metrology for AeroSpace, MetroAeroSpace 2020—Proceedings; 2020; pp. 95–98. [Google Scholar] [CrossRef]

- Laza, K. The Piping Integrity Management Challenge. Inspectioneering Journal 2017, 23. [Google Scholar]

- Sidun, P.; Łukaszewicz, A. Verification of Ram-Press Pipe Bending Process Using Elasto-Plastic FEM Model. Acta Mechanica et Automatica 2017, 11, 47–52. [Google Scholar] [CrossRef]

- Grzejda, R.; Warzecha, M.; Urbanowicz, K. Determination of pretension in bolts for structural health monitoring of multi-bolted connection: FEM approach. Lubricants 2022, 10, 75. [Google Scholar] [CrossRef]

- Jaszak, P.; Skrzypacz, J.; Borawski, A.; Grzejda, R. Methodology of leakage prediction in gasketed flange joints at pipeline deformations. Materials 2022, 15, 4354. [Google Scholar] [CrossRef]

- Turcu, F.; Jedamski, T.; Treppmann, D.R.D. Service Corrosion Mapping—Challenges for the Chemical Industry. In Proceedings of the 12th ECNDT; 2018; pp. 1–8. [Google Scholar]

- Turcotte, J.; Rioux, P.; Lavoie, J. Comparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D Scanners. In Proceedings of the 19th World Conference on Non-Destructive Testing; 2016; pp. 1–10. [Google Scholar]

- To, T.T.; Dang, T.N. A New Approach to Corrosion Mapping of Fuel Tank from Collected Images Using Phased Array Technology. In Proceedings of the 2019 International Conference on System Science and Engineering, ICSSE 2019; pp. 643–647. [CrossRef]

- Alain, S. Use of Flexible Phased Array Technology for Corrosion Inspection on Pipe Elbows. In Proceedings of the ASNT Annual Conference 2018.

- Olympus Corrosion Mapping on Carbon Steel Using the RollerFORM Scanner. Available online: https://www.olympus-ims.com/en/corrosion-mapping-on-carbon-steel-using-the-rollerform-scanner/ (accessed on 2 March 2023).

- EddyfiTechnologies RMS—Automated NDT Scanner for Corrosion Mapping and Weld Inspection. Available online: https://www.eddyfi.com/en/product/rms-pa-phased-array-corrosion-mapping (accessed on 2 March 2023).

- NDTE SyncScan 2. Available online: https://www.ndte.com.my/index.php?ws=showproducts&products_id=2559104 (accessed on 2 March 2023).

- Mahaut, S.; Godefroit, J.L.; Roy, O.; Cattiaux, G. Application of Phased Array Techniques to Coarse Grain Components Inspection. Ultrasonics 2004, 42, 791–796. [Google Scholar] [CrossRef] [PubMed]

- Nosko, O.; Tarasiuk, W.; Tsybrii, Y.; Nosko, A.; Senatore, A.; D’Urso, V. Performance of acicular grindable thermocouples for temperature measurements at sliding contacts. Measurement 2021, 181, 109641. [Google Scholar] [CrossRef]

- Latête, T.; Gauthier, B.; Belanger, P. Towards Using Convolutional Neural Network to Locate, Identify and Size Defects in Phased Array Ultrasonic Testing. Ultrasonics 2021, 115, 106436. [Google Scholar] [CrossRef]

- Grzejda, R.; Parus, A. Experimental studies of the process of tightening an asymmetric multi-bolted connection. IEEE Access 2021, 9, 47372–47379. [Google Scholar] [CrossRef]

- Bao, Y.; Zhang, H.; Ahmadi, M.; Karim, M.A.; Felix Wu, H. Measurements of Young’s and Shear Moduli of Rail Steel at Elevated Temperatures. Ultrasonics 2014, 54, 867–873. [Google Scholar] [CrossRef]

- Kumar, A.; Jayakumar, T.; Raj, B.; Ray, K.K. Correlation between Ultrasonic Shear Wave Velocity and Poisson’s Ratio for Isotropic Solid Materials. Acta Mater 2003, 51, 2417–2426. [Google Scholar] [CrossRef]

- Bond, L.J. Fundamentals of Ultrasonic Inspection. In Nondestructive Evaluation of Materials; 2018; pp. 155–168. [Google Scholar]

- Lei, X.; Wirdelius, H.; Rosell, A. Experimental Validation of a Phased Array Probe Model in Ultrasonic Inspection. Ultrasonics 2020, 108. [Google Scholar] [CrossRef]

- Palanichamy, P.; Joseph, A.; Jayakumar, T.; Raj, B. Ultrasonic Velocity Measurements for Estimation of Grain Size in Austenitic Stainless Steel. NDT and E International 1995, 28, 179–185. [Google Scholar] [CrossRef]

- Dubois, M.; Moreau, A.; Bussière, J.F. Ultrasonic Velocity Measurements during Phase Transformations in Steels Using Laser Ultrasonics. J Appl Phys 2001, 89, 6487–6495. [Google Scholar] [CrossRef]

- Shao, Z.; Zhang, C.; Li, Y.; Shen, H.; Zhang, D.; Yu, X.; Zhang, Y. A Review of Non-Destructive Evaluation (NDE) Techniques for Residual Stress Profiling of Metallic Components in Aircraft Engines. Aerospace 2022, 9, 534. [Google Scholar] [CrossRef]

- Saha, S.; Majumdar, A. Use of Ultrasonic Phased Arrays for Examination of Austenitic Steel Welds—An Experience. 2015. [Google Scholar]

- Kien, D.T.; Van Thanh, P. Influence of Temperature on Mechanical Characteristics of 1018 Low Carbon Steel Estimated by Ultrasonic Non-Destructive Testing Method. Indian Journal of Pure and Applied Physics 2017, 55, 431–435. [Google Scholar]

- Van Thanh, P.; Thi Tuyet Nhung, P.; Thi Minh Thuy, L.; Hoa Nhai, N. Effect of Temperature on Ultrasonic Velocities, Attenuations, Reflection and Transmission Coefficients between Motor Oil and Carbon Steel Estimated by Pulse-Echo Technique of Ultrasonic Testing Method. VNU Journal of Science: Mathematics-Physics 2015, 31, 39–48. [Google Scholar]

- Kien, D.T.; Nhung, P.T.T.; Thanh, P. Van Non-Destructive Characteristics of Ultrasonic Waves in 1018 Low Carbon Steel. Communications in Physics 2014, 24, 1–6. [Google Scholar] [CrossRef]

- Gunasekar, S.; Sastikumar, D. Comparison of Side Drilled Holes and Surface Notch Response for Phased Array Sectorial Beams Calibration Process. In Proceedings of the NDE 2020—Conference & Exhibition; 2020; pp. 1–11. [Google Scholar]

- Miatliuk, K.; Lukaszewicz, A.; Siemieniako, F. Coordination Method in Design of Forming Operations of Hierarchical Solid Objects. In Proceedings of the 2008 International Conference on Control, Automation and Systems, ICCAS 2008; 2008; pp. 2724–2727. [Google Scholar] [CrossRef]

- Lhuillier, P.E.; Chassignole, B.; Oudaa, M.; Kerhervé, S.O.; Rupin, F.; Fouquet, T. Investigation of the Ultrasonic Attenuation in Anisotropic Weld Materials with Finite Element Modeling and Grain-Scale Material Description. Ultrasonics 2017, 78, 40–50. [Google Scholar] [CrossRef] [PubMed]

- Kube, C.M. Attenuation of Laser Generated Ultrasound in Steel at High Temperatures; Comparison of Theory and Experimental Measurements. Ultrasonics 2016, 70, 238–240. [Google Scholar] [CrossRef]

- Łukaszewicz, A.; Miatliuk, K. Reverse Engineering Approach for Object with Free-Form Surfaces Using Standard Surface-Solid Parametric CAD System. Solid State Phenomena 2009, 147–149, 706–711. [Google Scholar] [CrossRef]

- Lukaszewicz, A.; Panas, K.; Szczebiot, R. Design Process of Technological Line for Vegetables Packaging Using Cax Tools. Engineering for Rural Development 2018, 17, 871–876. [Google Scholar] [CrossRef]

- Grzejda, R.; Kobielarz, M. Testing the mechanical properties of high-strength zinc-coated bolts: FEM approach. Coatings 2023, 13, 27. [Google Scholar] [CrossRef]

- Sidun, P.; Łukaszewicz, A. Verification of ram-press pipe bending process using elasto-plastic FEM model. Acta Mechanica et Automatica 2017, 11, 47–52. [Google Scholar] [CrossRef]

- Tomczyk, A.; Seweryn, A.; Doroszko, M. Monotonic behaviour of typical Al-Cu-Mg alloy pre-strained at elevated temperature. Journal of Theoretical and Applied Mechanics (Poland) 2018, 56, 1055–1068. [Google Scholar] [CrossRef]

- Tomczyk, A.; Seweryn, A. Experimental Investigation and Modeling of Damage Accumulation of EN-AW 2024 Aluminum Alloy under Creep Condition at Elevated Temperature. Materials 2021, 14, 404. [Google Scholar] [CrossRef]

| Company | Temperature range | Reference |

|---|---|---|

| RollerFORM scanner | 25–80°C | [22] [23] |

| RMS SCUT/Dual element | 25–200°C | |

| SyncScan 2 | −10 °C–45 °C | [24] |

| Element | Carbon (C) | Silicon (Si) | Iron (Fe) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|

| Content | 0.146% | 0.275% | 97.79% | 0.018% | 0.021% |

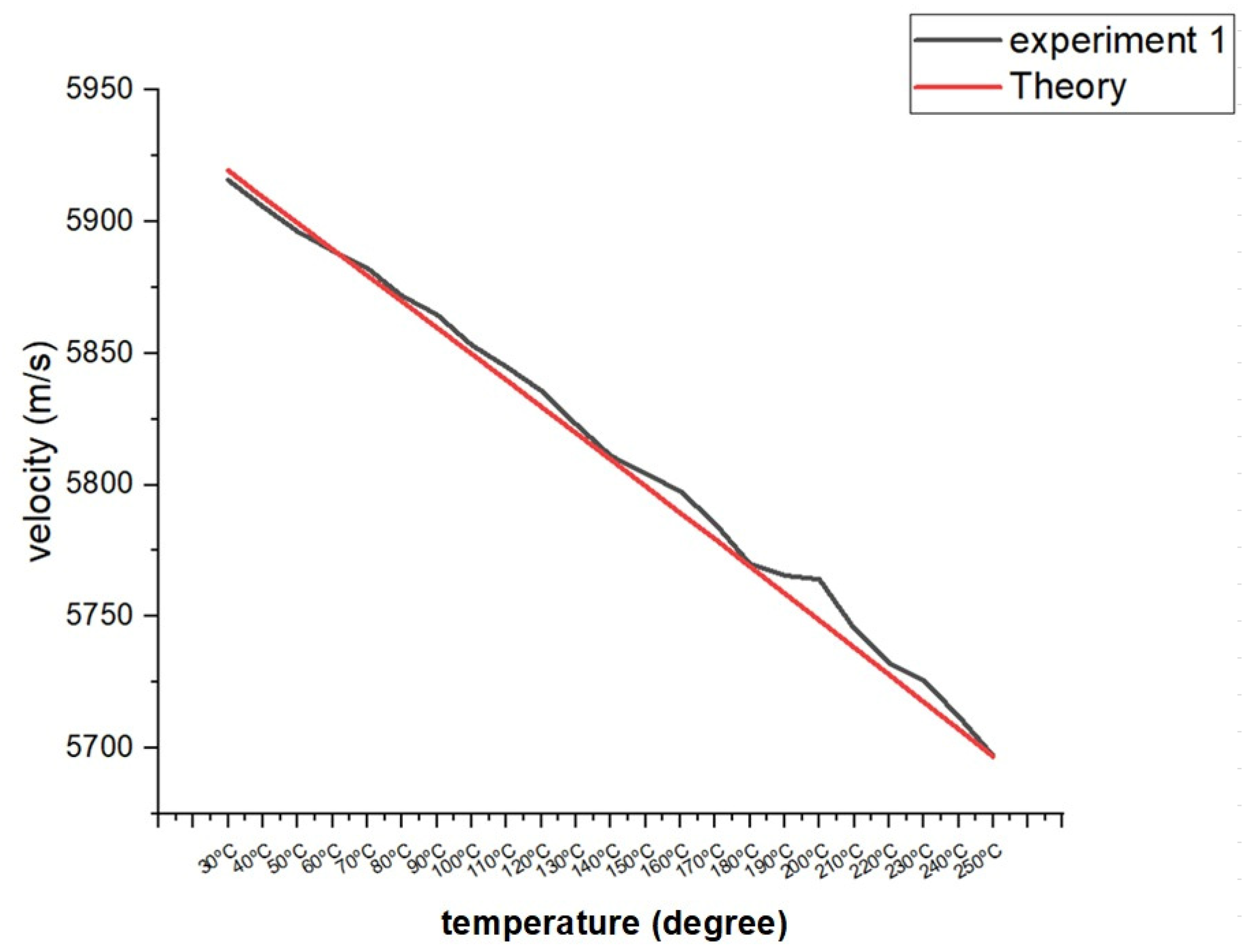

| Temperature | Experiment (m/s) | Calculated (m/s) | Temperature | Experiment (m/s) | Calculated (m/s) |

|---|---|---|---|---|---|

| 30°C | 5915.8 | 5919.5 | 150°C | 5804.2 | 5799.5 |

| 40°C | 5905.7 | 5909.2 | 160°C | 5797.6 | 5789.3 |

| 50°C | 5896.2 | 5899.4 | 170°C | 5785.3 | 5779.5 |

| 60°C | 5889 | 5889.5 | 180°C | 5770 | 5769 |

| 70°C | 5882.3 | 5879.6 | 190°C | 5765.6 | 5758.8 |

| 80°C | 5871.8 | 5869.7 | 200°C | 5764.1 | 5748.5 |

| 90°C | 5864.7 | 5859.7 | 210°C | 5745.4 | 5738.2 |

| 100°C | 5853.1 | 5849.8 | 220°C | 5732.3 | 5727.9 |

| 110°C | 5844.9 | 5839.8 | 230°C | 5725.6 | 5717.5 |

| 120°C | 5835.7 | 5829.7 | 240°C | 5712.1 | 5707.2 |

| 130°C | 5823.1 | 5819.7 | 250°C | 5696.9 | 5696.7 |

| 140°C | 5811 | 5809.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).