1. Introduction

Coal, as a precious resource on Earth, has played a significant role in the economic development of many countries, leading to increased surface and underground mining activities in countries with abundant coal reserves [

1]. However, most coal mines are prone to safety hazards due to the unpredictable nature of coal seams and the inherent risks associated with underground mining [

2]. Various types of mining disasters have occurred, such as roof accidents, gas explosions, fires, flooding, and gas poisoning [

3]. These disasters not only pose a serious threat to the safety of miners but also result in substantial property damage for coal mining enterprises. The essence of safety accidents is closely related to the mining environment. For example, methane

is the primary component of gas, and timely monitoring of methane concentration in the mining environment, coupled with appropriate protective measures, can greatly reduce the risk of gas explosions. In the event of a fire, the temperature rises rapidly, but real-time monitoring of the mine’s temperature changes and prompt firefighting measures can help reduce casualties. Toxic gases in underground mines, including

,

,

and

, can cause harm to the workers’ health. Timely monitoring of toxic gas concentrations in the current area serves as a guarantee for the miners’ well-being. Therefore, strengthening coal mine environmental monitoring and early warning systems is an effective means to reduce accidents and holds great significance for ensuring coal mine safety and production.

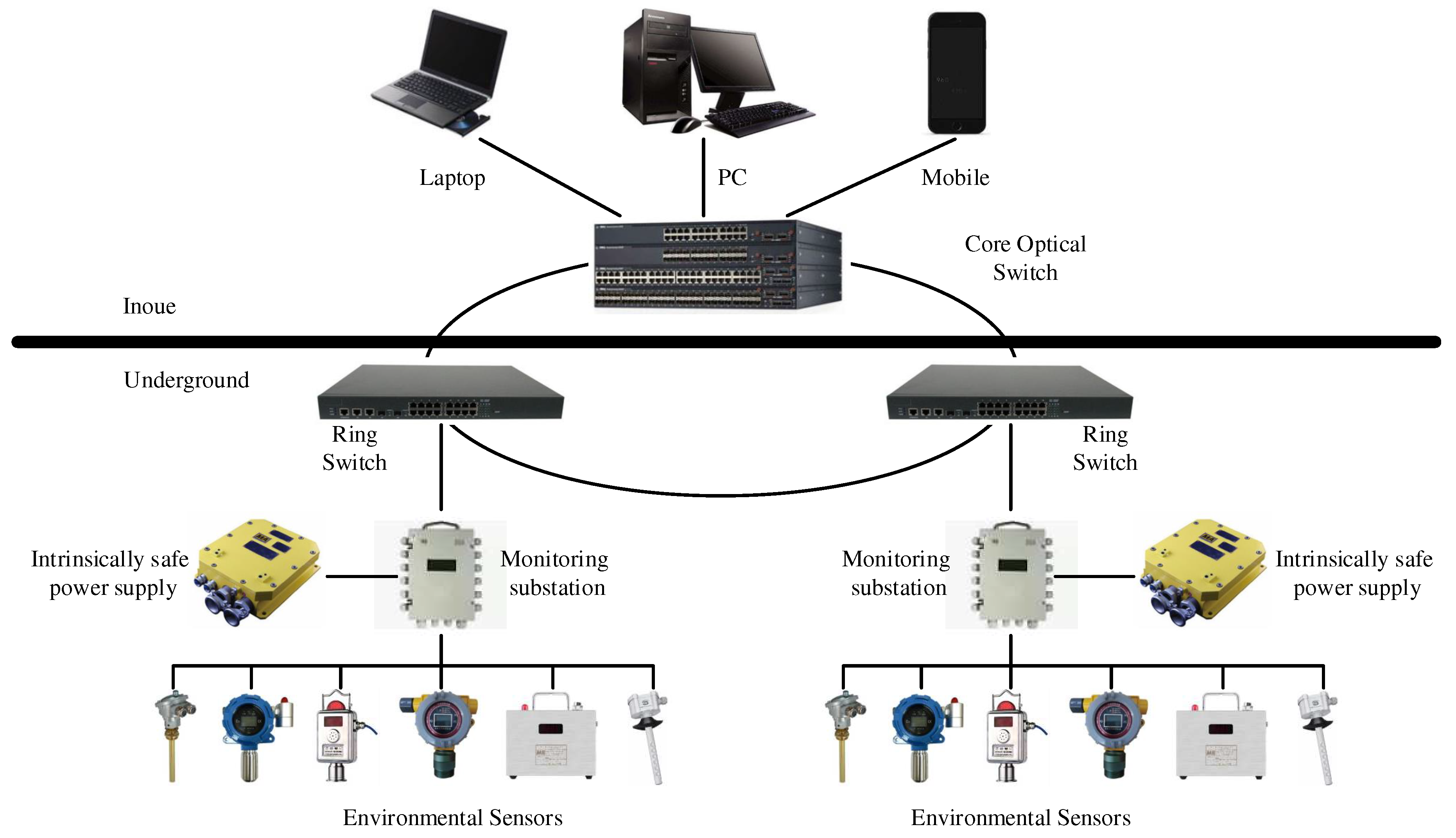

Figure 1 illustrates a commonly used framework for underground environmental monitoring systems, consisting of two main parts: the surface (above ground) and the underground components. The surface part primarily comprises a switch and user terminals, while the underground part consists of monitoring substations, ring network switches, power supplies, and sensors. Various sensors are employed to monitor the actual underground environment, and the data is transmitted in real-time to the surface, enabling users to observe the underground conditions at any given time. With the continuous advancement of Internet of Things (IoT) technology, wireless sensor networks (WSNs) have become vital tools for underground environmental monitoring. Many experts utilize WSNs to collect underground environmental data for further research [

4,

5,

6,

7]. The data used in this study was also collected in real-time through WSNs.

With the development of computer technology, machine learning has gradually become integrated into our daily lives [

8], and its applications in coal mine safety are extensive. Kumari et al. proposed a deep learning model combining Uniform Manifold Approximation and Projection (UMAP) with Long Short-Term Memory (LSTM) in their paper [

9]. They used this model to predict the fire status in sealed areas of coal mines, aiding in the early implementation of fire control strategies to prevent further losses caused by mine fires. Slezak et al., in their publication [

10], combined machine learning techniques with sensor technology to develop a decision support system, which they applied to predicting the risk level of coal mine methane. The system demonstrated good predictive accuracy. In another study by Jo et al. [

11], they proposed an underground mine air quality prediction system based on Azure machine learning. This system allows for the rapid assessment and prediction of air quality in coal mines, providing a safety guarantee for the underground environment. These examples demonstrate the necessity of applying machine learning to analyze various coal mine safety data for risk assessment, ensuring efficiency and accuracy.

Intelligent optimization algorithms are an important research area within machine learning. These algorithms, based on heuristic principles, can overcome the uncertainty and complexity of problems during the optimization process, making them suitable for various types of optimization problems [

12]. Some well-known algorithms in this field include Particle Swarm Optimization (PSO) [

13], Grey Wolf Optimizer (GWO) [

14], Whale Optimization Algorithm (WOA) [

15], and others. In recent years, researchers worldwide have conducted in-depth studies on these algorithms and applied them to complex optimization problems.The Artificial Hummingbird Algorithm (AHA) is an intelligent optimization algorithm proposed by Zhao et al. in 2022 [

16]. It simulates the unique flight skills and intelligent foraging strategies of hummingbirds in nature for optimization purposes. Compared to other intelligent optimization algorithms, AHA has the advantages of having fewer parameters, stable convergence speed, strong optimization capabilities, and high implementation efficiency. However, when solving complex problems, AHA may encounter issues such as getting trapped in local optima, insufficient global exploration capability, and slow convergence speed. To address these limitations, experts have proposed various methods to improve the algorithm, making it more suitable for a wide range of optimization problems.

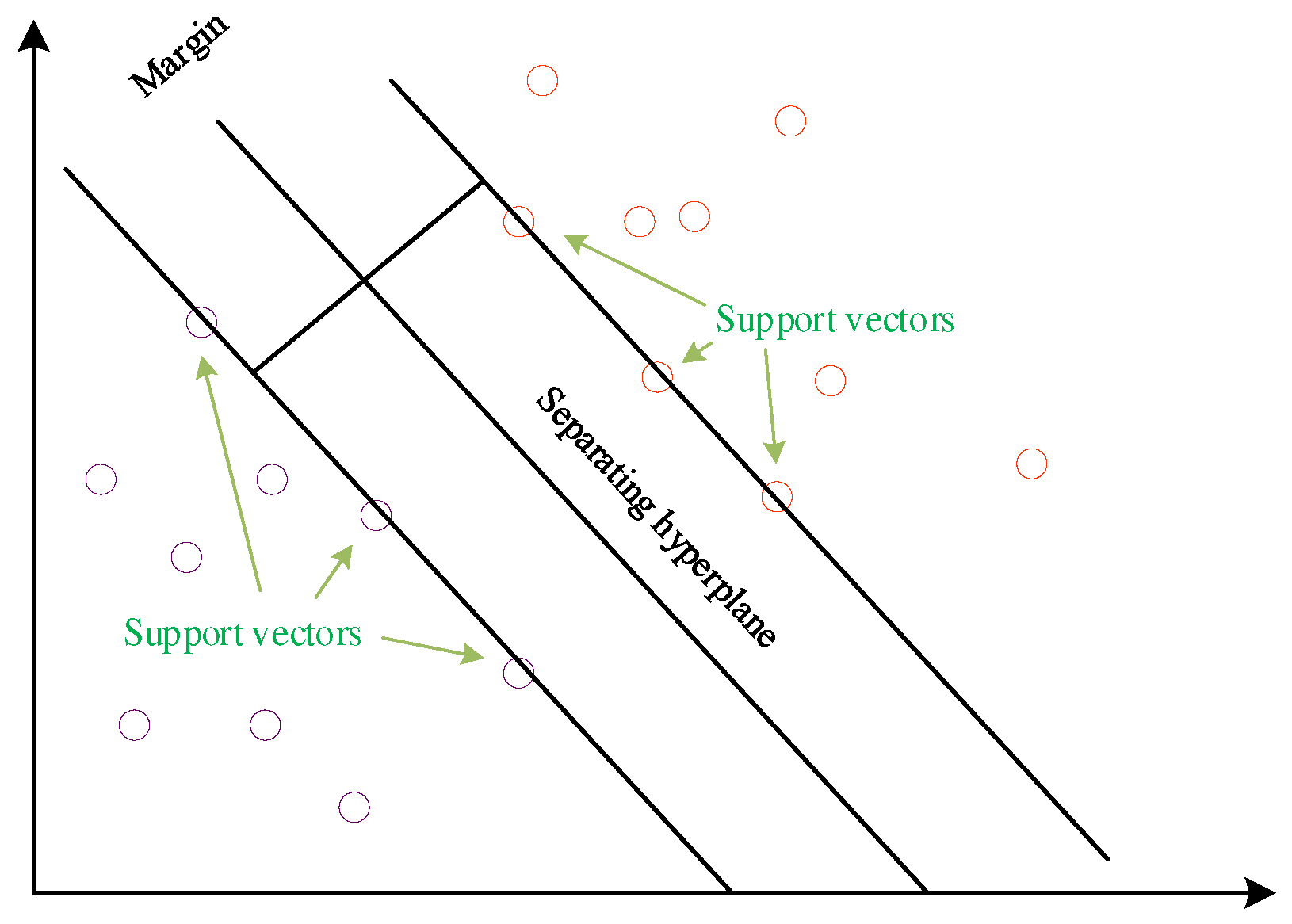

Support Vector Machine (SVM) is a type of generalized linear classifier used for binary classification in supervised learning [

17]. Compared to other classification algorithms, SVM offers several advantages, including simplicity, robustness, and generality. As a result, many researchers have applied SVM to various application domains for classification tasks. SVM relies on two important parameters: the kernel function parameter

C and the penalty factor

g, which determine the performance of SVM. However, these parameters are often selected manually, and choosing inappropriate values can lead to overfitting or underfitting. To ensure the proper selection of the kernel function parameter

C and penalty factor

g, researchers frequently employ intelligent optimization algorithms to optimize these parameters [

18,

19,

20].

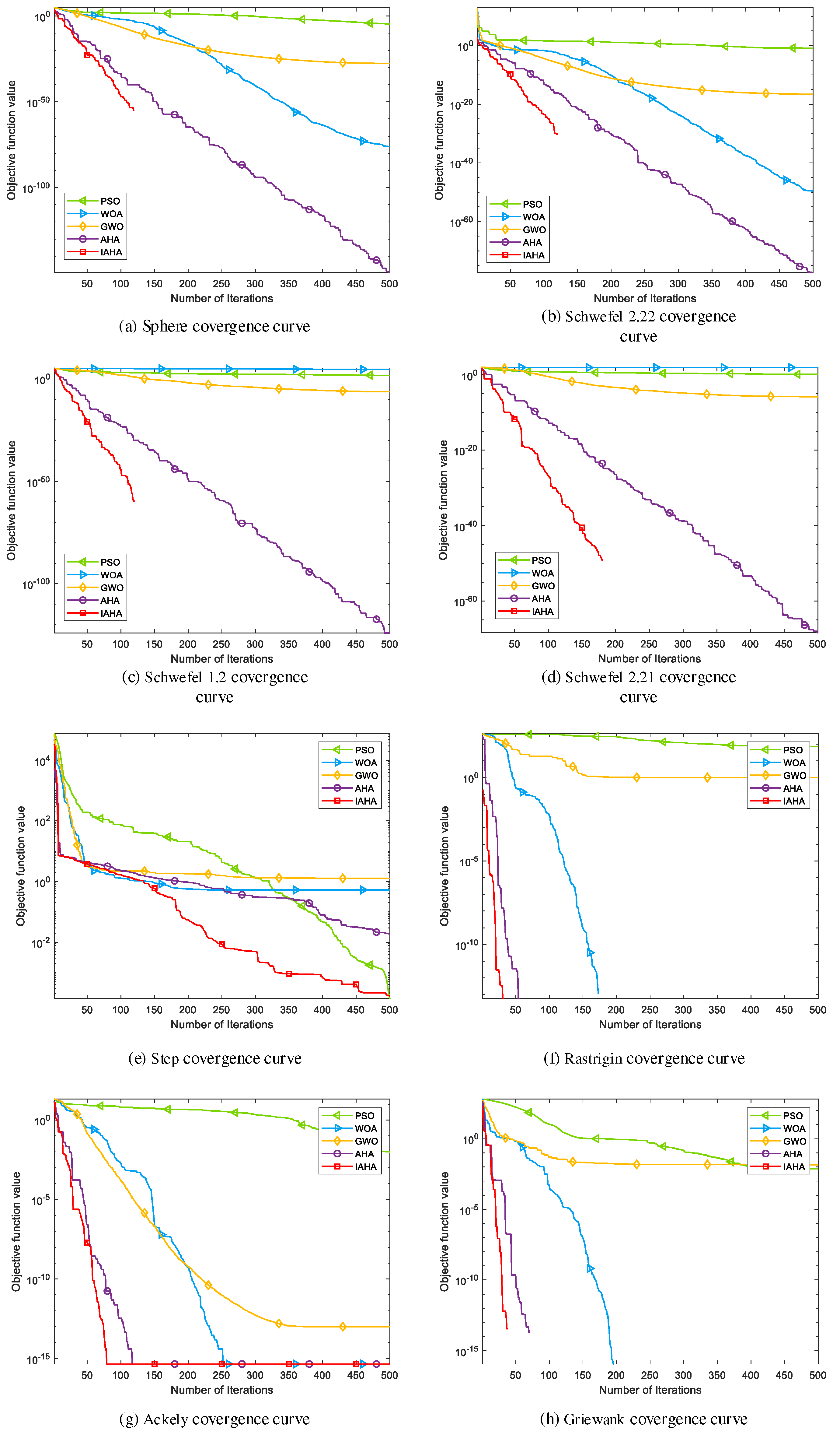

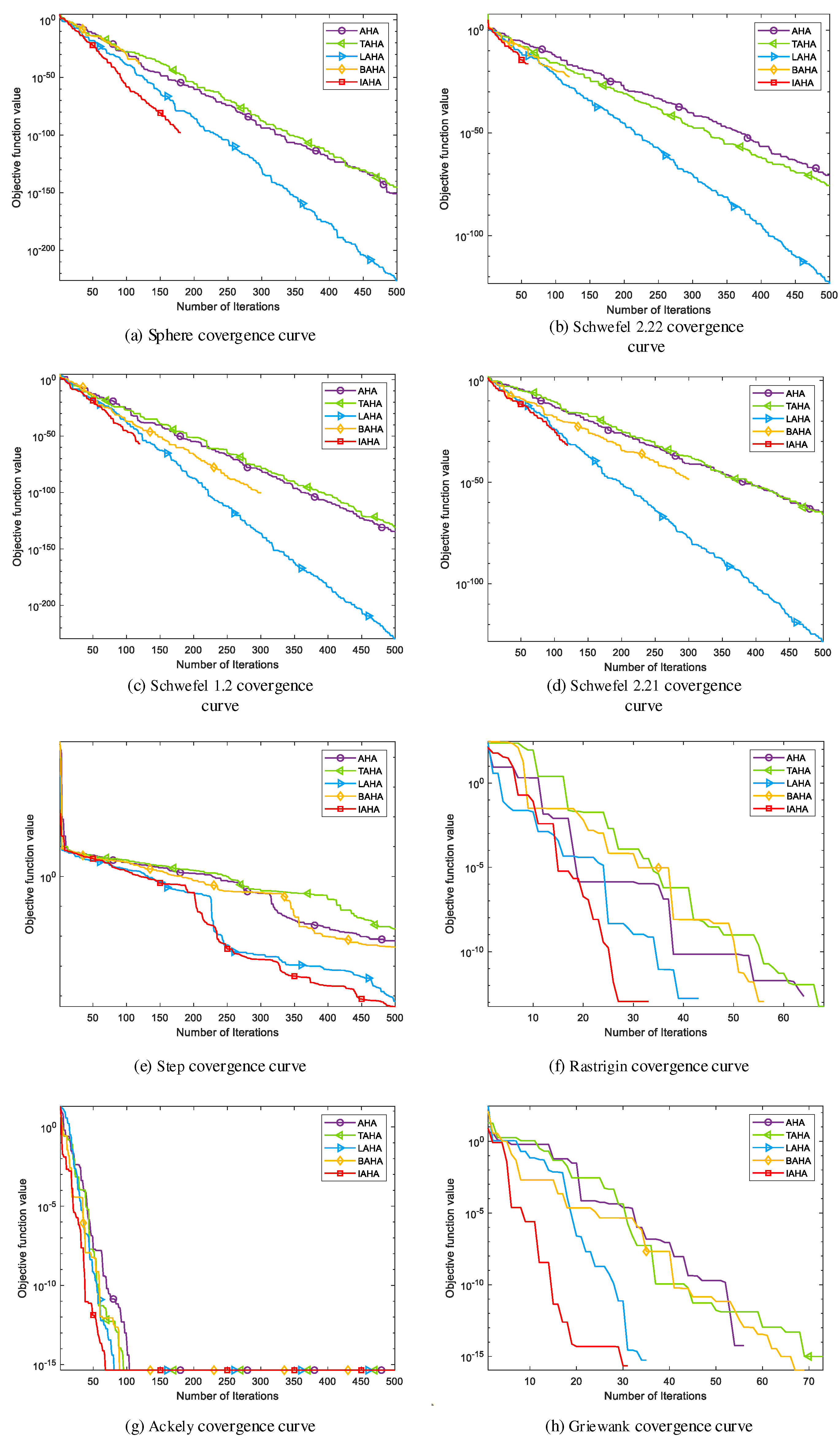

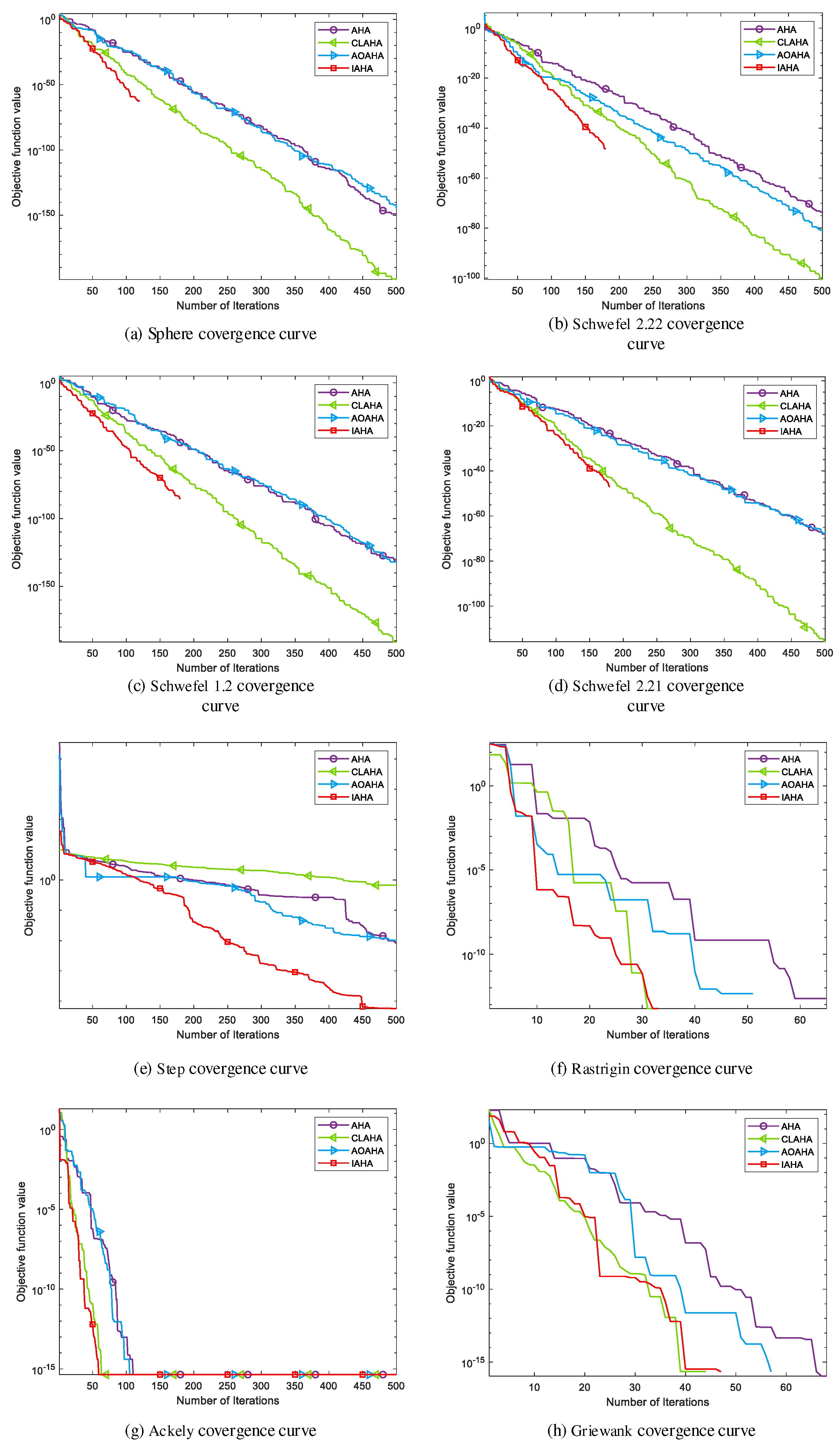

Inspired by the aforementioned research, we propose using an intelligent optimization algorithm combined with SVM to construct a coal mine environmental safety warning model. To improve the model’s performance, we employ an enhanced version of the Artificial Hummingbird Algorithm (AHA) to optimize the kernel function parameter C and penalty factor g. In this study, we introduce an improved version called IAHA, which incorporates the following modifications: 1) Initializing the population using a fusion of the Tent chaotic map and reverse learning strategy, 2) Introducing the Levy flight strategy during the food-guiding phase, and 3) Incorporating the simplex method at the end of each iteration to replace the worst solution. We evaluate the effectiveness and accuracy of the improved IAHA algorithm by conducting simulation experiments on eight benchmark test functions. We compare IAHA with four basic algorithms, three single-stage improved AHA algorithms, and two existing improved artificial hummingbird algorithms. The results demonstrate the effectiveness and accuracy of the proposed improvements. Furthermore, we combine IAHA with SVM and apply it to predict the safety level of coal mine environments. We conduct simulation experiments to evaluate the performance of the improved model in this context.

The organization of the paper is as follows:

In

Section 2, we provide an introduction to the basic theories of the Artificial Hummingbird Algorithm and Support Vector Machine.

In

Section 3, we propose the improved Artificial Hummingbird Algorithm, namely IAHA, and analyze its performance.

In

Section 4, we utilize the improved algorithm to optimize the parameters of SVM and construct the IAHA-SVM coal mine environmental safety warning model. We compare the performance of this model with the AHA-SVM model optimized by the basic AHA algorithm.

In

Section 5, we summarize the findings of the study and provide an outlook on future work.

By following this organizational structure, we aim to present a comprehensive study on the application of the IAHA algorithm combined with SVM in the prediction of coal mine environmental safety.

4. Our proposed IAHA-SVM coal mine environmental safety warning model

In this section, we utilized the IAHA algorithm to optimize the penalty factor C and kernel function parameter g of the SVM model, resulting in the development of the IAHA-SVM coal mine environmental safety level warning model. Based on the safety regulations of coal mines, the model classified the safety levels into four categories. We then applied the model to classify coal mine safety data that we collected. By comparing the classification accuracy of the IAHA-SVM model with that of the AHA-SVM model, we aimed to demonstrate the advantages of the improved algorithm integrated with the SVM model in this study.

The IAHA-SVM coal mine environmental safety level warning model is designed to provide accurate and reliable safety level predictions for coal mine environments. By optimizing the SVM parameters using the IAHA algorithm, the model can effectively handle the complexities and variations in the coal mine safety data, leading to improved classification performance.The classification accuracy comparison with the AHA-SVM model serves as an evaluation metric for the effectiveness of the IAHA-SVM model. If the IAHA-SVM model achieves higher accuracy in predicting the safety levels compared to the AHA-SVM model, it indicates that the integration of the IAHA algorithm has improved the performance of the SVM model for coal mine safety classification.This analysis provides evidence of the superiority of the IAHA-SVM model in accurately predicting coal mine safety levels. By leveraging the optimization capabilities of the IAHA algorithm, the IAHA-SVM model can better adapt to the characteristics of coal mine safety data, leading to enhanced classification accuracy and more reliable safety level predictions.

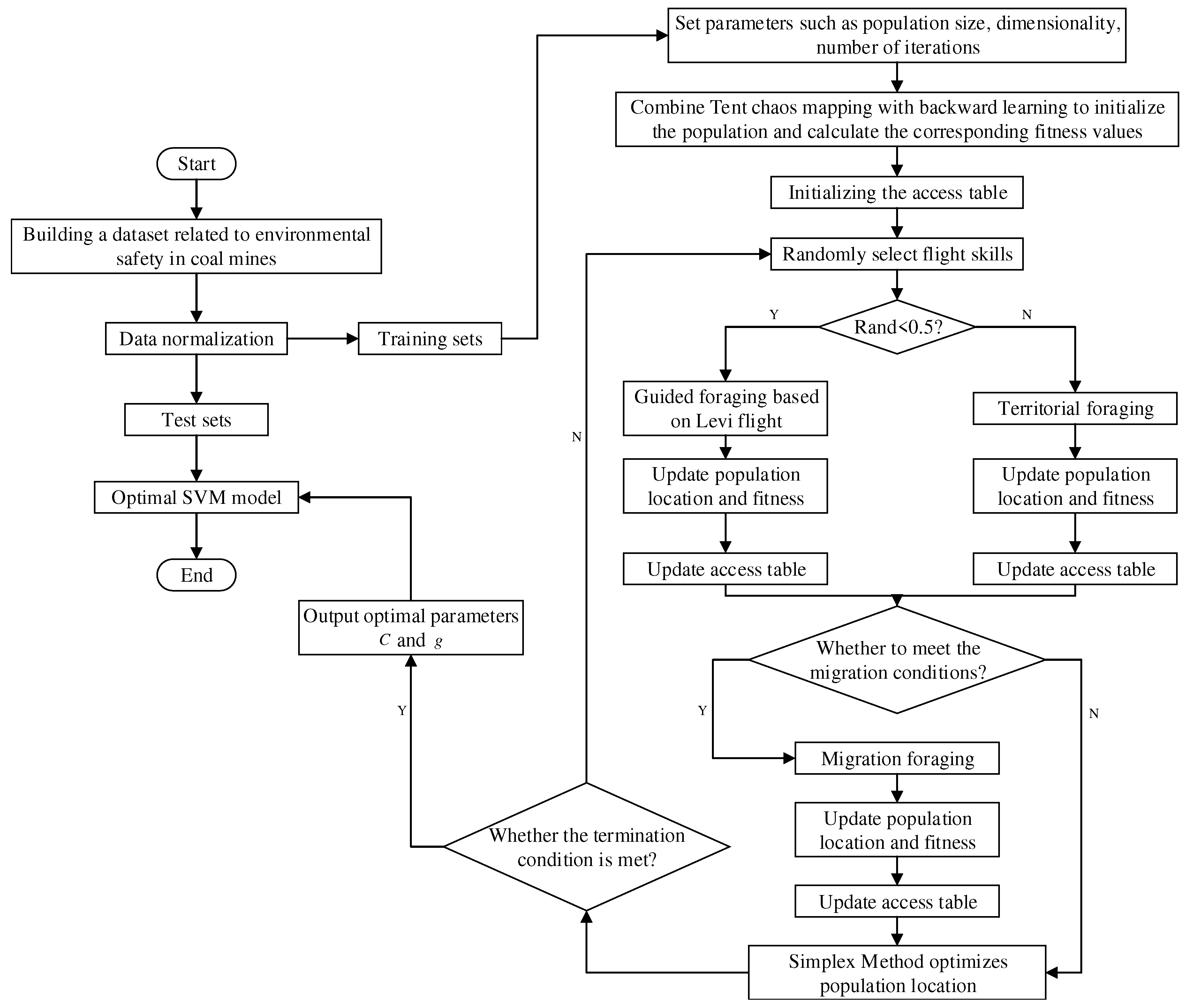

4.1. Our proposed IAHA-SVM model

In the SVM model, the penalty factor

C and the kernel function parameter

g have a significant impact on the prediction accuracy of the model. Usually, these parameters are determined empirically and greatly affect the prediction results. Therefore, in this study, we employed the IAHA algorithm to optimize these parameters and select the values that lead to the best performance of the model. The flowchart of the proposed model is shown in the

Figure 7, and the algorithm steps are as follows:

Step 1: The collected coal mine safety-related data are divided into training and test sets and normalized.

Step 2: Initialize the SVM penalty term coefficients C, kernel function parameters g and IAHA related parameters, including population size, maximum number of iterations, etc.

Step 3: The food source locations are initialized using a fused Tent chaos mapping and direction learning strategy, and and classify the training set samples with the SVM coal mine environmental safety classification accuracy as the individual fitness value.

Step 4: Randomly select flight skills.

Step 5: Enter the phase of guided foraging or area foraging based on the Levi flight strategy with a 50% probability of each of the two foraging behaviors. The visit table was updated after the foraging behavior.

Step 6: When migratory foraging conditions are met, hummingbirds perform migratory foraging, randomly replacing the worst food source location. The access table is updated after the foraging behavior.

Step 7: Optimize the location of poorer food sources using the simplex method.

Step 8: Terminate the algorithm if the IAHA algorithm termination condition is met and output the optimal parameters C and g. Otherwise, skip to step 4.

Step 9: Establish IAHA-SVM coal mine environmental safety warning model.

4.2. Experimental results

In this section of the simulation experiment, the population size is set to 20, and the maximum number of iterations is set to 50. The experimental data is obtained from a coal mine in Ningdong. Due to the scarcity of data in some extreme situations, in order to better meet the requirements of the experiment, part of the data is simulated based on the surface of real environmental data to form the dataset. According to the coal mine safety regulations, this study classifies the coal mine environmental safety conditions into four levels, as shown in

Table 6.

D-level warning indicates a safe state where all parameters of the current environment are within normal range, allowing normal operation. C-level warning indicates the occurrence of abnormal conditions, such as an increase in the concentration of flammable or explosive gases or leakage of toxic gases. The situation should be promptly investigated to eliminate hazards. B-level warning triggers the underground alarm device when there are significant anomalies in the underground gas parameters. Personnel should be evacuated and the situation should be investigated promptly. A-level warning is the highest level of warning, indicating the occurrence of dangerous situations such as fire or massive leakage of toxic gases. Immediate evacuation and power cut-off should be carried out, and the situation should be investigated. Corresponding measures should be taken to resolve the issue when the parameters decrease to the B-level warning. In order to better ensure the safety of workers, this study determines the overall warning level based on the highest level of each parameter. For example, if the value of is 5%, which corresponds to the A-level, but the ranges of other parameters are not in the A-level, we consider this situation as an overall A-level warning

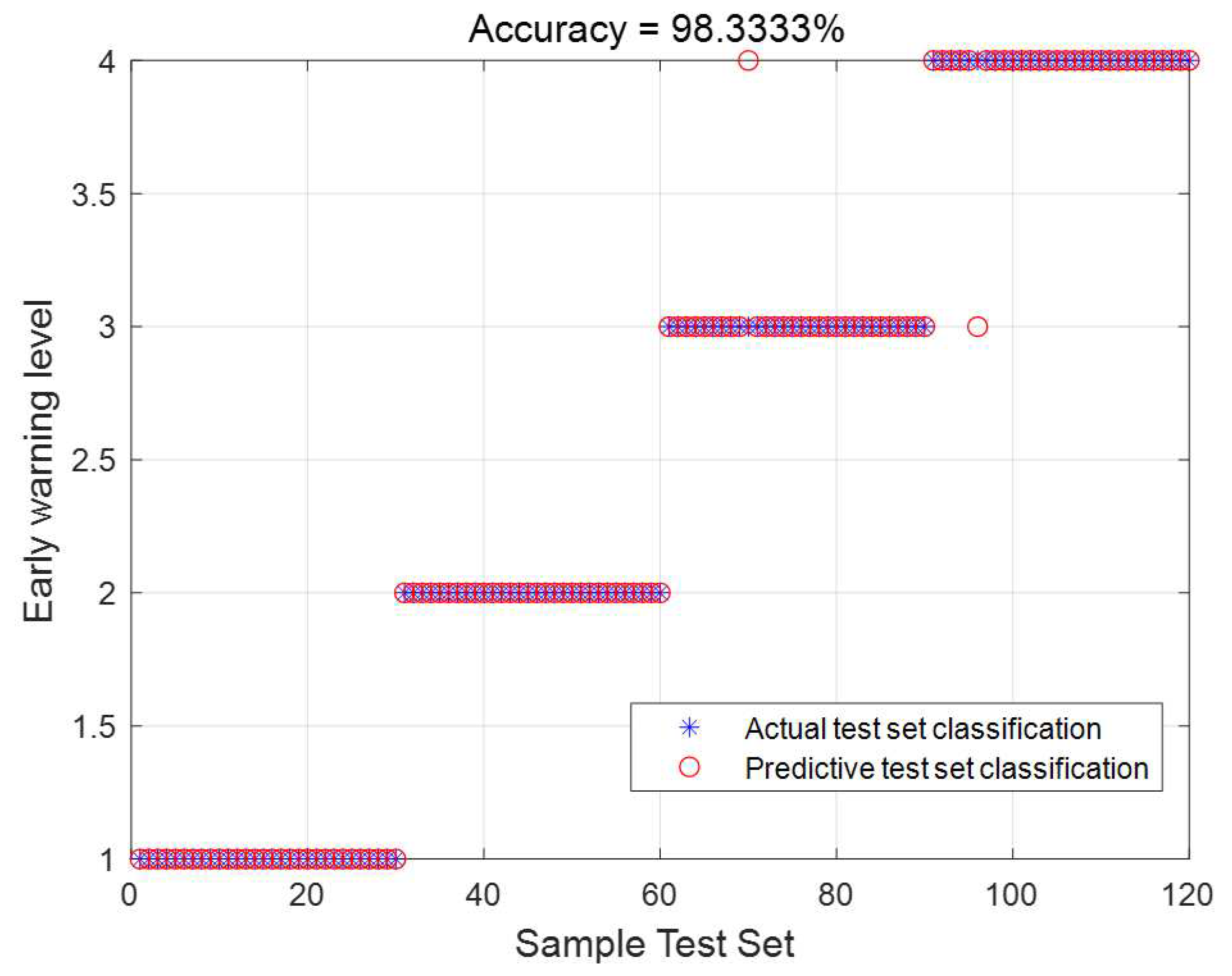

In this section, a total of 4120 data samples were selected for the simulation experiment. Among them, 4000 samples were used for training, with 1000 samples for each warning level. The remaining 120 samples were used for testing, with 30 samples for each warning level. The purpose of the experiment was to find the optimal penalty factor C and kernel function parameter g that would achieve the best classification performance based on the accuracy of the training data levels. The parameter range was set from 0 to 1000. The experimental results are shown in the

Figure 8. From the figure, it can be observed that out of the 120 test data samples, only 2 data samples were misclassified, resulting in a classification accuracy of 98.3333%.

To demonstrate the improved performance of the proposed model, a comparative experiment was conducted by combining the basic AHA algorithm with SVM. The experimental results are presented in

Table 7. From the table, it can be observed that the accuracy of the IAHA-SVM model is significantly higher compared to the AHA-SVM model. This indicates that the use of the IAHA algorithm to optimize the SVM model improves the precision of classification and reduces the impact of boundary values. As a result, the overall performance of the model is further enhanced.

5. Conclusions and Future Work

In this paper, we propose the IAHA-SVM coal mine environmental safety warning model. Firstly, to address the limited global exploration capability and slow convergence speed of the Artificial Bee Hummingbird Algorithm (AHA), we employ a strategy that combines the Tent chaotic map with reverse learning to initialize the population. In the foraging phase, the Levy flight strategy is introduced to enhance the search ability. Additionally, the Simplex method is incorporated at the end of each iteration to replace the worst solution. Comparative experiments are conducted to demonstrate the effectiveness of the IAHA algorithm.Next, we combine the improved IAHA algorithm with Support Vector Machines (SVM) to optimize the SVM model’s penalty factor and kernel function parameters. The IAHA algorithm is used to search for the optimal parameters, and a coal mine environmental safety level warning model is established. The effectiveness of the proposed model is validated using a dataset generated from actual measurements in a coal mine in Ningdong Town, Ningxia. Compared to the SVM model optimized by the basic AHA algorithm, the IAHA-SVM model shows superior performance.

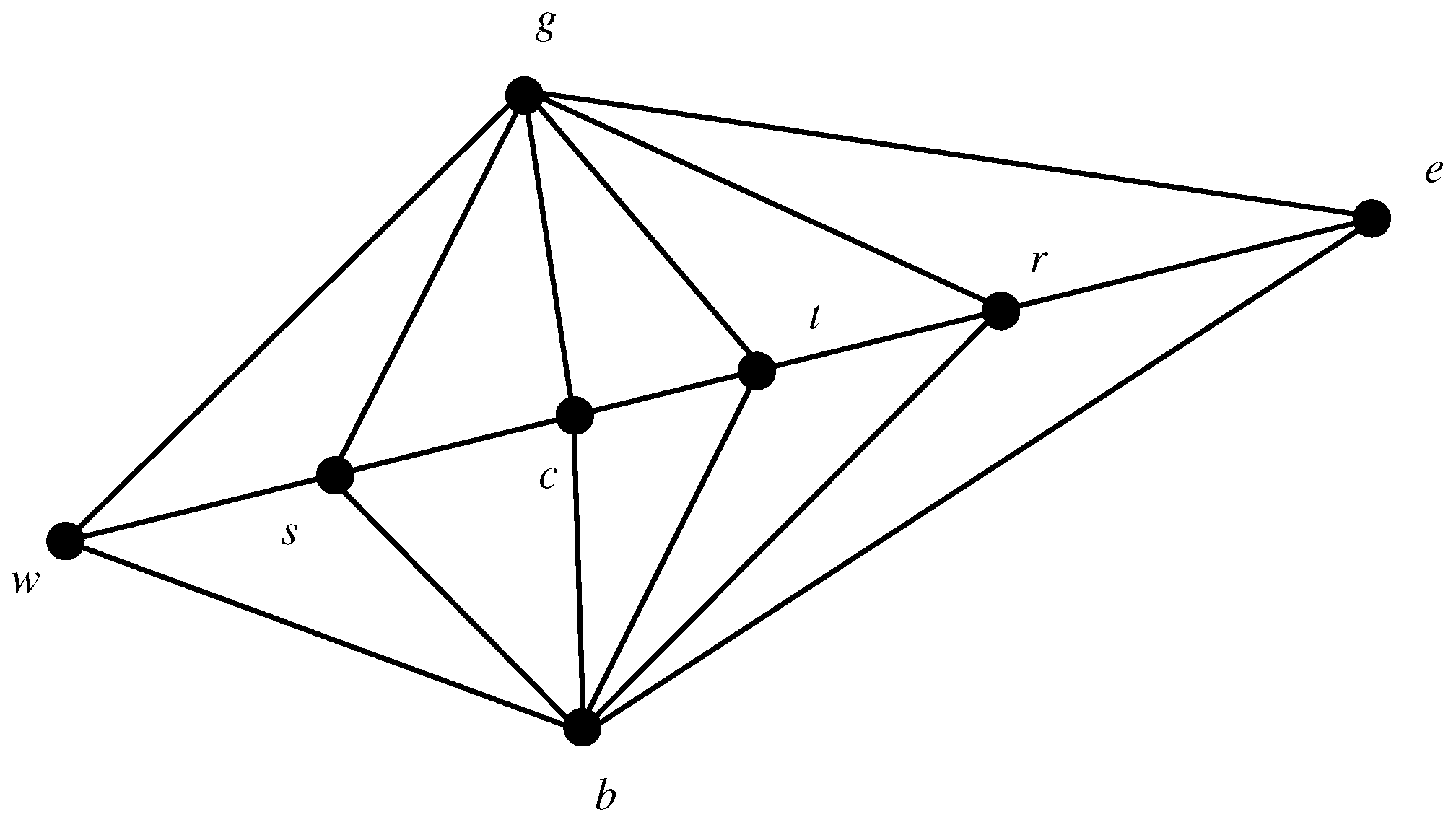

Integrating intelligent optimization algorithms with real-world application problems can enhance work efficiency. The IAHA-SVM model proposed in this paper can also be applied to classification problems in various other domains. In our future work, we will continue to explore the application of intelligent optimization algorithms in different aspects of coal mine safety. Some potential directions include optimizing the deployment of wireless sensors underground, addressing underground positioning problems, and solving three-dimensional path planning for underground drones.