1. Introduction

For the upcoming generation, electricity demand will be at an all-time high. At the moment, we derive roughly 70% of our electricity from burning fossil fuels. The remaining demand is met by renewable energy sources, which must be accelerated if global emissions are to be reduced. Companies are focusing all of their efforts on electric vehicles in order to reduce carbon footprints in any manner feasible. For that, generating electricity to meet futuristic innovation and technologies comes under government Initiative of ‘green energy’. 196 countries jointly signed

Paris agreement mentioning serious concerns for an increase in global average temperature estimation by 2

0 Celsius. Requirement for reduction of energy related emissions demand innovation and research related organization and institution to derive new ways to improve existing renewable technologies. Utilizing solar energy with better model development can resolve plenty of such issues. The amount of sunlight and its quality plays an important role in calculating efficiency of power generated via solar panels. One of the approach can be to increase the size of panels in areas with good quality- quantity availability of sun light, that can be compromised with regions with shadow areas. The more will be the efficiency of solar panels, the higher will be prize range. To deal with it, government is providing subsidies which cut nearly half of its cost range with installation. The other can be to work on structural and design techniques and replace the conventional solar panel materials which earlier used or require hard surface to convert sun light into usable form of energy that is electricity [

1,

2]. Advancement of technology leads to more efficient solar thermal collectors which would be able to convert full range of sun light which was earlier not possible. Example of such are previously used single junction photovoltaic cells which were facing drawbacks for not proper energy conversion for the input range of light falling on them. Previously recorded electrical efficiency was 43.5% [

3]. The differentials on types of solar collectors depending on type and nature of collectors are: - (i) flat plate solar thermal collector or non-concentrating collectors (ii) concentrating collectors.

Collector collection or experimental variation that can add up effective panel design, are the types of channel arrangement [

2,

3], glazing techniques [

2], heat transfer fluids specifically their flow rates can provide value addition on the output efficiency of solar panels [

4]. Initially, collector temperature are provided for different temperature range for both non-concentrating and concentrating collectors and variation parameters are then changed [

4,

5]. As it has been observed due to unmet demand of threshold energy of a photon leads to inadequacy of electron hole pairs in a solar cell causing valid decrease in output [

6,

7].

1.1. Flat plate solar thermal collector or non-concentrating collectors

The basic idea of what flat plate solar thermal collector consist of; a flat dark black material, which is a large plate and its orientation lies in such a manner that, light rays when fall on the large black plate, it ends up heating the plate [

8,

9]. The thermal energy then generated is used as working fluid, via tubes. Or ducting can be further used for various purposes [

10].

1.1.1. Structural designs

The basic structural design used in a flat plate thermal collector are

Absorber

Coversheets

An isolating box

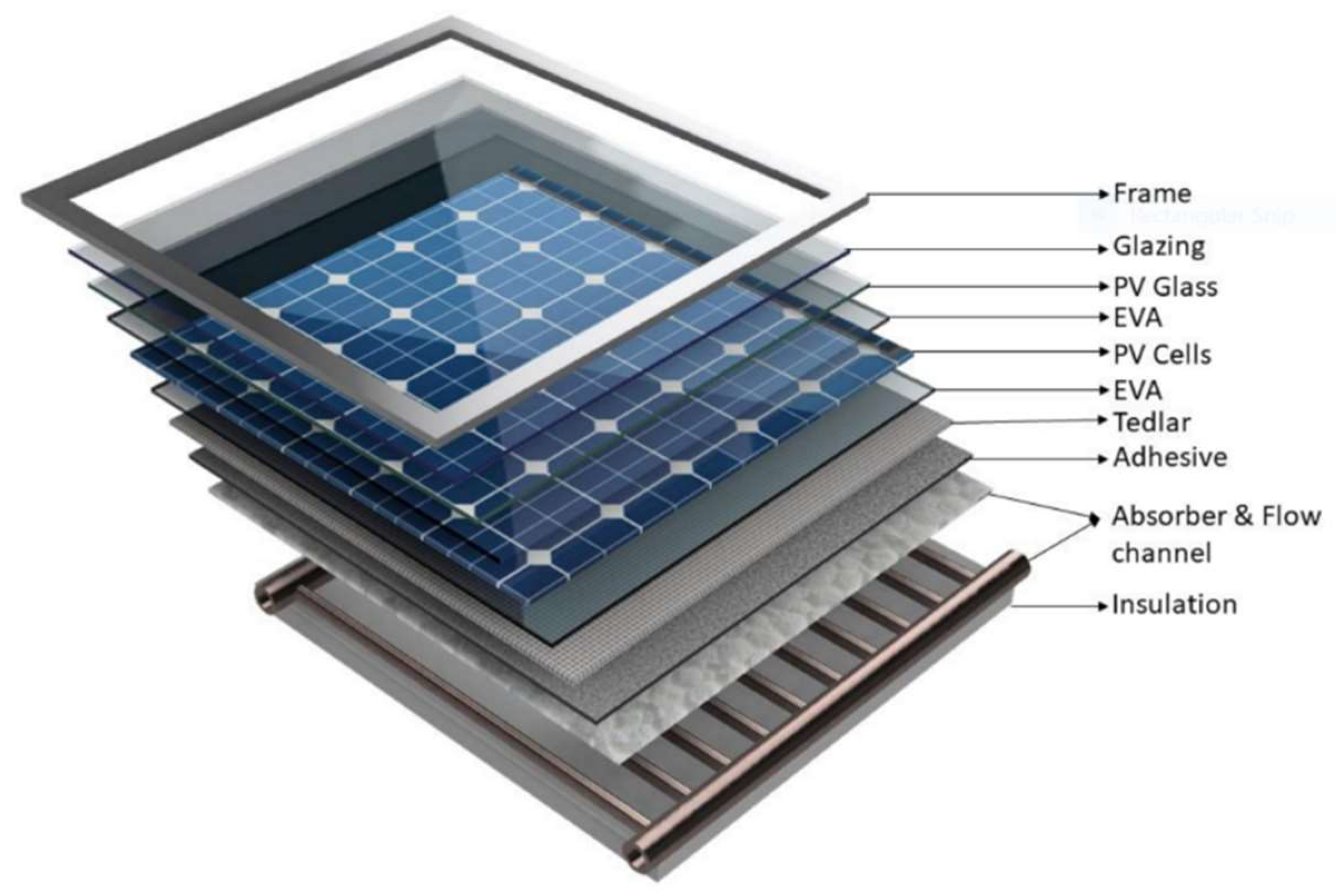

The flat plate collector with different layers is shown in

Figure 1. Light rays falling on glazing cover helps with needed radiation requirement for the absorber. Followed by PV glass to stop the radiations from emitting out, and decreasing overall energy conversion, and to build up connection for electricity conversion with the help of photovoltaic effect including the base insulating box [

11,

12].

EVA layer (Ethyl vinyl acetate) work as a protective layer to deal with adverse climate condition.

Tedlar, a film with versatile properties, being inert and non-sticky helps in providing finishing touch to PV cells [

13,

14,

15]. The absorption variation accounts for surface absorption parameters also known as Conventional Surface Collectors [

16]. The material used to manufacture absorption metal plate used at the bottom of the flat plate collector, be nitrides, carbides or oxides of metal example, Cu, Ag. TiNO

x based metal oxide coating is used to gain maximum efficiency for non-concentrating collectors [

2,

4].

1.1.2. Reasons affecting efficiency of Flat plate solar collector

The properties may then vary on the type of collector needed to manufacture. For first, absorber plate is meant to absorb as much as possible solar irradiance (that is the amount of sun light falling on a surface per unit area) also expressed as irradiance flux [

18,

19,

20]. Following that, heat absorbed into electricity is converted using heat transfer fluid contained in ducts and tubes. One of the reasons which typically adds up to low efficiency of solar collectors is its cooling medium [

21,

22]. As observed, PV cells shows low output with rise in temperature because of the external damage varying from fluctuating environment condition or damage done during installation and internal damages such as cell cracking, short circuits [

4]. As a result, generating an acceptable quantity of heat in the surrounding environment has become rather crucial.

1.1.3. Options to deal with heat loss

To help FPSC’s with less heat loss an insulated thermal screen is put into place. As water being an easily accessible liquid, earlier fluid options were limited to water. In addition to accessibility, it shows good thermal properties high mass density and high volumetric heat capacity. Due to certain disadvantages like a regular need of change, formation of bubbles with varying weather conditions or freezing reasons made researchers to replace water existing technologies [

23,

24]. Phase change material is one of another solution, example refrigerants which changes its phase properties like a change in phase from liquid to gas when there’s an increase in temperature [

15]. On other hand we have antifreeze liquids, or to use nano fluids which is basically liquid used to transfer thermal energy which earlier was of no use and was lowering down its overall efficiency. It not only cuts additional equipment cost used earlier to check for the contamination or less output results, less regular attention for replacement of water is no longer needed. Coversheets, multiple cover sheets can be used to curb convective heat loss. Numbers may vary on the range of temperature we are dealing with. At ambient temperature cover sheets are not required as there is least or no heat loss. But above ambient temperature two and for extreme climate conditions up to three can be made in use. As the thermal efficiency varies directly with coolant temperature, the heat released can be channelized back to thermal generation [

25,

26].

1.2. Channel Geometry

The most common factors resulting in downgrading efficiency were low fluid flow rate, low convection rate, heat loss, thermal insulation. To find a balance between all and increasing active area for heat transfer fluid accessibility, investments in different channel patterns were made. Some of which are

, fins, consisting of number of metallic strips used to enhance convection rate coefficient. And channel patterns involving V-grooved, Honeycomb, rectangular, square with different outlet supply system(double and single pass channels) [

27,

28,

29]. Though number of parameters while creating such geometries may vary depending on fin number, their height, thickens and the specific material with which they are designed.

Figure 2 shows the fins channel pattern in PV module.

Other such channel geometry are; wick type geometry, which are further segmented under Basin wick type, floating wick type, multiple wick type solar still [

4]. While manufacturing such geometries some factors need to considered for maximum result outputs such as

Material involved should have high thermal conductivity

It should be thick, so that there will be least temperature difference required to transfer heat to its base

Tubes and sheets with same materials are more preferred to avoid galvanic corrosion between them.

1.3. Concentrating Collectors

One intriguing idea was to focus light rays falling on the solar collector at a single focal point. The goal is to provide a smaller surface absorption area in relation to a larger surface capturing area. That was not only applied on structural features of concentrator but to receivers as well [

30,

31]. Increase output was observed as the multiple system act as the provider for direct concentrated solar rays.

Concentrating collectors have wide variety, but the narrow classification can be considered under single and two- axis tracking ways [

32,

33]. Each way has its own advantage of what temperature need to be attained depending on environmental and location variation.

1.3.1. Parabolic troughs Collectors

Such collectors follow reflection to a point of line. Parallel rays of line coming direct from the sun concentrated on the receiver for absorption [

34,

35,

36]. The absorbed light rays are then directly converted into electricity. The fact being sun rays are not every time parallel, the angle these incident rays follow are thoroughly maintained by rotating trough orientation [

37,

38]. More useful versions of parabolic trough collectors need less heat transportation [

39,

40]. Thus it can be best used on roof tops. Thin film interference filters are most widely used for application purpose [

10,

17].

Receiver role is to absorb as much as irradiance flux its surface absorbs and convert it into usable energy form. The glass surrounding steel tube and the black color coating helps parabolic trough collector preventing convection heat loss. TiO

2 and ZnO materials are considered non-appropriate absorbers and thus are not used more often [

2]. Thermal energy converted is then transferred to nanofluid taken in tubes or ducts. Depending on the rays that fall on receiver, its types are further divided into omnidirectional receiver(for rays driving from any random directions) and point cavity receiver(light rays must travel through cavity receiver).

1.4. Heat Transfer Fluids

In optimization for the thermal energy loss, multiple nanofluid in different concentration were tested some leads to a significant increase in efficiency output leading to a new version of collector technology called Hybrid solar cells. As per theory Hybrid solar collectors can range almost double of the present efficiency observed nearly to be at 43.5% [

8]. The basic idea lies on intermixing of two previously used cell properties (optical and thermal). For PV collectors where some limited amount of solar spectrum (visible light rays) was utilized and second on thermal collectors, using UV and IR radiation of solar spectrum [

41,

42,

43]. To carry out high temperature needs, different optical filters are copped with PV cell materials InGaP, InGaAs, CdTe, Si, Ge [

2,

8,

44,

45]. The type of application is co-related to the choice of heat transfer fluid(nano-fluids) which is done by intermixing of nanofluids having particles with different optical resonance in solar spectrum range. Priority is given to fluids with high operating temperatures in addition to affordability.

Fluids with lowest operating temperature is

oil. Both synthesized and hydro-carbon based oil are used but with their combined proportion operational temperature still approach up to 425°

C. Certain drawbacks including safety issue as oil being flammable and its requirement of extra heat energy [

46]. Some of the other examples are,

steam,

water (having limited absorption properties for higher wavelength rays),

Nitrate Salt,

Liquid sodium (operating temperature, 600°

C) and

Air and Helium (operating temperature up to 850°

C) [

47,

48,

49].

1.4.1. Preparation of fluid

PV most efficiently operated at low temperature. Hybrid solar panel are going to operate at high temperature. Therefore, it becomes foremost important to look into account the type of fluid use [

51,

52,

53]. Biofluids for example exhibits vide range of properties essentially required to absorb high wavelength bands, which previously were wasted thermally in a PV panel [

50,

51,

52]. Base fluids needs to be stable under condition where temperature varies rapidly and is not uniform throughout the time period. Large conductive coefficient in addition to the fluid being non-toxic and eco-friendly, provides a room for better functioning and replacement if required [

8,

44,

45,

53].

1.4.2. Issues faced using Heat transfer fluid

Even if hybrid heat transfer fluids provided a new area of development, some of the issue curb and prevent Hybrid PV cells to reach their maximum energy output, because of agglomeration of nanoparticles, low stability, and the effect generated on the walls of tubes which not only diversify purity of fluids used, but also drops fluid flow rates and results in lowering their bars for potential results [

3,

5,

54].

1.5. Single Cell vs. Module

Module efficiency varies with upto 40% when a single cell output is considered in a panel. Considering some intrinsic issues like that of node that provides gap and extensive wiring, it takes a huge lot of time for electron hole pair to travel causing resistive loss [

55,

56,

57]. Wiring let tons of thermal energy being dissipated [

58,

59]. CTM (Cell to module ratio) calculations are used to measure such gaps in efficiency stats [

60]. Efficiency of a modules is an important factor that creates a direct impact on optimizing its cost [

61,

62]. Hotspots are another failure causing factor. Hard to locate power degradation in a panel, due to unequal emission over a surface, cause its valid explanation and correction [

60,

63,

64,

65].

2. Results

Over few years, heat transfer has grabbed all the attention of researcher. In thermal engineering, the exchange of heat energy between heat exchangers by heat transfer fluid is the main area of concern. The number of applications, we encounter, require heat transfer fluid. Water, Oil, vapours are the commonly used Heat transfer fluids. The typical heat transfer fluid work under the condition of ceaseless cycle of the system. Due to low viscosity (higher tendency to flow) and high specific heat capacity, water is one of the widely used HTV (heat transfer fluid). But, there are some limitations of water that it has low conductivity and the freezing point of water is 0 °C (considered lower temperature). However, this problem of freezing can be extent to higher temperature range by adding some antifreeze heat transfer fluid (based Propane-1,3-diol), as this antifreeze additive provide some unique properties [

66].

HTV with high boiling point and high heat capacity is suggested because at low boiling point the vaporization of fluid takes place for a very low temperature. The vapor produces move through the channels and exert high pressure which may damage the heat exchangers [

67]. Nanofluid is a new step towards the heat transfer. It has replaced all the commonly used HTV. Nanofluids have certain merits over other HTV. Nanoparticles (usually metals, oxides etc.) in a base fluid (water, ethyl alcohol etc.) makes a nanofluid. This mixture is called as the colloidal suspension. Since, there are solid particle in a base liquid, this is also called as a two – phase fluid [

68]. Nanofluid has evolved out as an excellent fluid which can be used for heat exchange system. It has been found that nanofluid has enormous application in fire extinguisher, home refrigerator, Air conditioner etc. but still there is one drawback which was found when nanofluids was under testing and it was seen that there is agglomeration of particle which blocks the flow channel of fluid which may further decreases the thermal conductivity and affects the stability of the nanofluid [

69,

70,

71].Every problem comes with solution. There are several methods with which we can enhance the stability of nanofluids [

68,

72].

2.1. Sonication

It is one of the most successful methods used for the deagglomeration of the nanoparticle. Very high force is applied by the ultrasonic waves through the nanofluid. The agglomerated particles get break down and produces a uniform suspension [

73].

2.2. Magnetic Stirring

Magnetic stirrer can be easily found in the laboratories. In this method, the magnetic stirrer keeps rotating the fluid by using uniform magnetic field which doesn’t let impurity to mix and also deagglomerates the particles. Two knobs are present left and right know. The rate of stirring can be control by left knob [

73].

Figure 3 is the image of magnetic stirrer while preparing TiO

2.

2.3. Surfactants

Adding a limited amount of surfactants to the nanofluid help to increase the stability. Surfactants work by minimizing the surface tension of the base fluid which resist the agglomeration of the nanoparticle [

71,

74]. The physio-thermal quantity of nanofluid may get disturbed by use of over surfactant, it may reduce the thermal conductivity [

75]. The chemical structure of surfactants is consists of two part – head and the tail [

76,

77]. The head is hydrophilic polar group and other is hydrophilic tail called long chain hydrocarbons [

68]. Examples of some commonly used surfactants are – Aerosol TR-70HG, Aerosol TR-70, Hypermer LG [

73]. {Citation}

2.4. Stability mechanism of nanofluids

The heat transfer property of fluid can be increase by the use of nanofluid. Somehow if thermal property of nanoparticle could be intensify, the fluid efficiency could also be upgrade. During the formation of the naonofluid, particle may get clump together which dilated particle size [

78,

79,

80]. Increase in particle size could let them to get settle down in solution due to gravity. But there is no agglomeration due to steadiness of the fluids. The reason behind, there exists some forces (attractive Vanderwaal’s and electrical repulsive forces) among the particle. When the particle moves, they performs the Brownian Motion, gives rise to these forces. Suspension will only be stable if the repulsive forces will be higher than attractive forces. The effect of different parameter on the nanofluid stability is given in

Table 1.

3. Discussion

Characterization of nanofluid

Many researchers performed an experiment to improve properties of nanofluid. They ended up with varying conclusion out of which some were contradictory and were not consistent. Some properties discussed below are result of experiment performed by researchers, in the literature [

81].

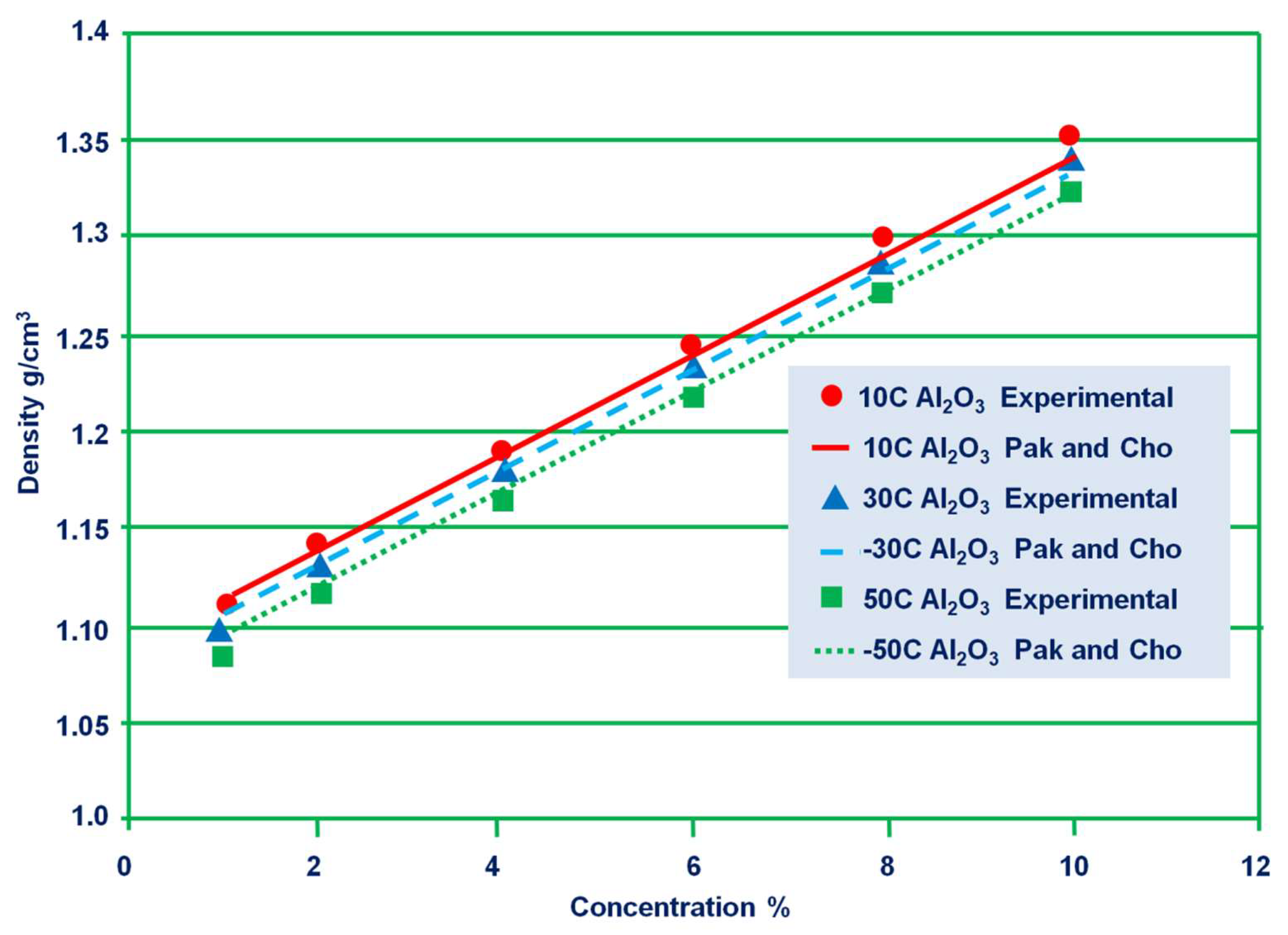

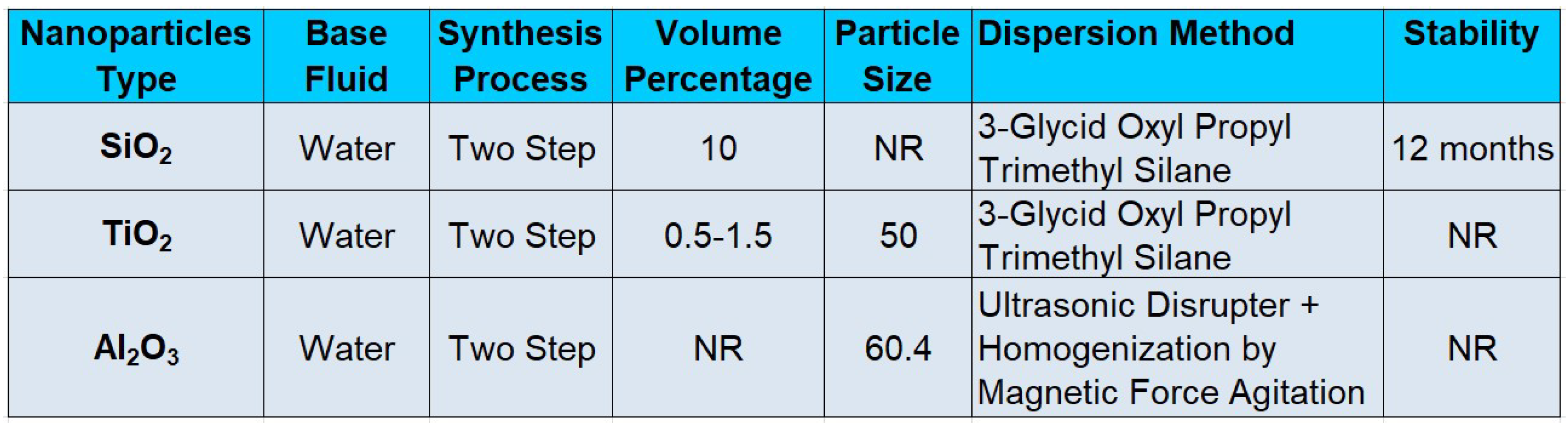

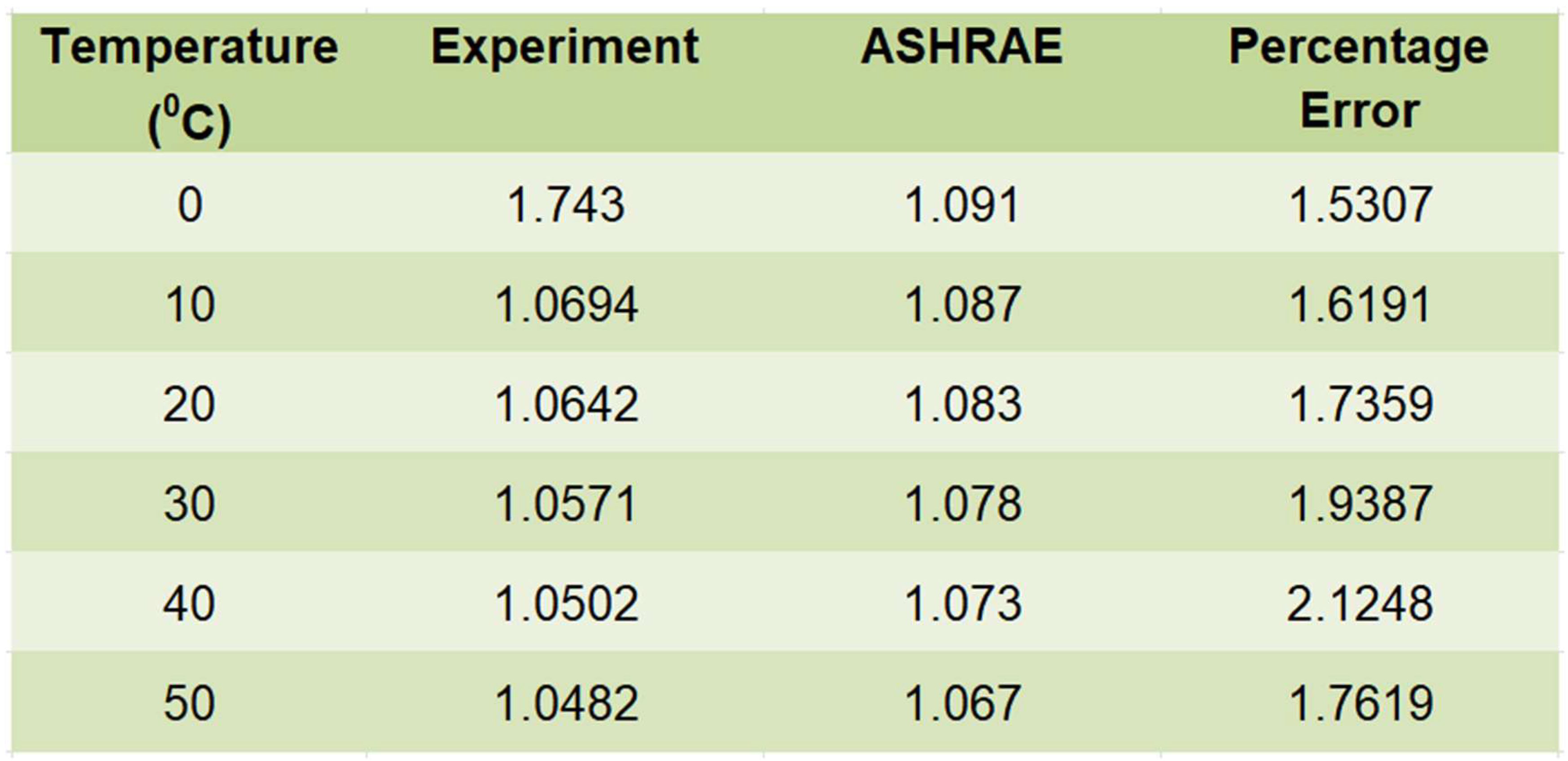

3.1. Density

Density is defined as mass per unit volume. It is important to account density in a heat exchanger system, because density affect the pumping capacity. It is considered that by increasing volume concentration of nanoparticle would increase density of nanofluid [

82]. It is considered that by increasing volume concentration of nanoparticle would increase density of nanofluid [

68,

81]. Density equation given by Pax and Cho [

81] is

where

"

and

"

is the density of nanofluid and base fluid respectively,

"

is the volume concentration.

In an experimental paper of Vajjha et. al [

83], they performed an experiment for density measurement of three different nanofluid – Al

2O

3 (Aluminium Oxide), Sb

2O

5:SnO

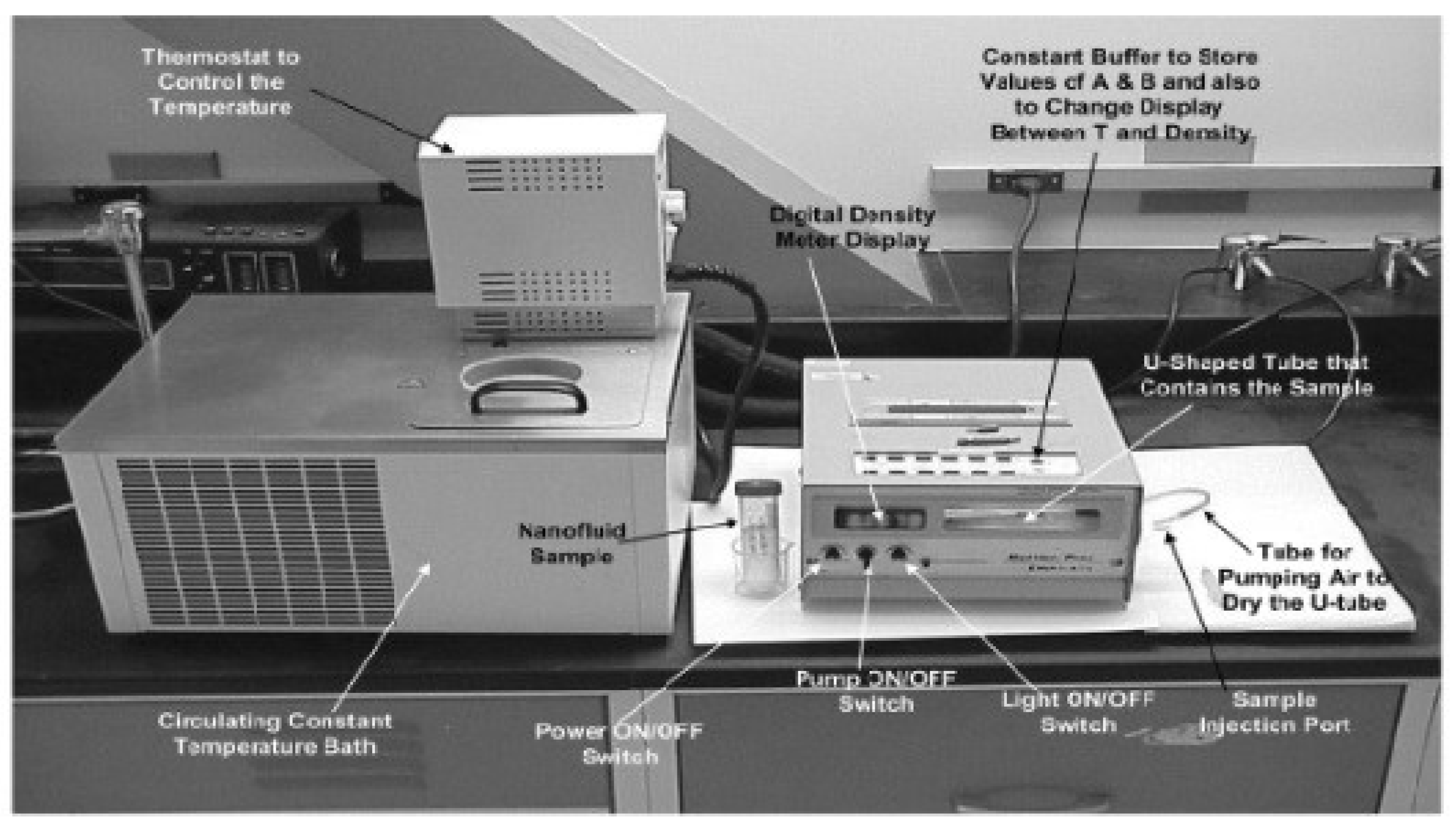

2 (antimony tin-oxide), and zinc oxide (ZnO) nanoparticles in the base fluid of 60:40 of ethylene glycol/water by mass. The experimental value for density was calculated by using Anton-Paar density metre as shown in

Figure 4.

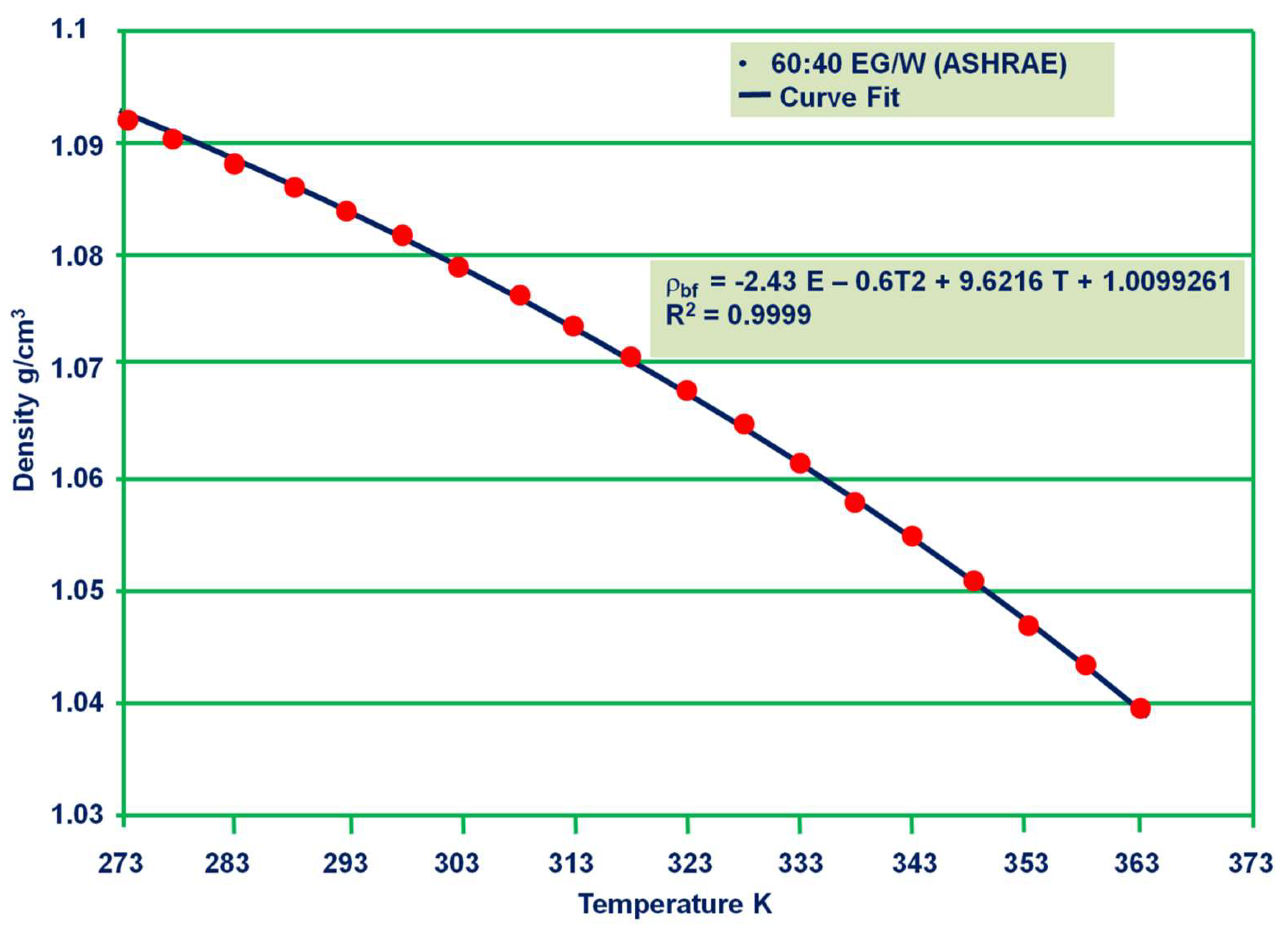

The experimental values which were calculated from above experiment were in excellent agreement with ASHRAE [

84]. The data of measurement(over the temperature range (0 °C-50 °C) and ASHRAE [

84] value is given in the

Table 2. The error and the average value between the measurement [

83] and ASHRAE [

84] were also observed. A polynomial density equation as a temperature function was developed by ASHRAE [

84] data gives curve as shown in

Figure 4.

The equation obtained is

with R2=0.9999, where 273K < T < 363K.

The curve fit equation for density as function of temperature is shown in

Figure 5. The experimental result also found an excellent agreement with Equation 1 given by Pak and Cho [

81]. Given below are the results of the measurement for different concentration (1% ans 2%) of Al

2O

3 over the temperature 0 °C to 50 °C in comparison with the results obtained from Pak and Cho equation.

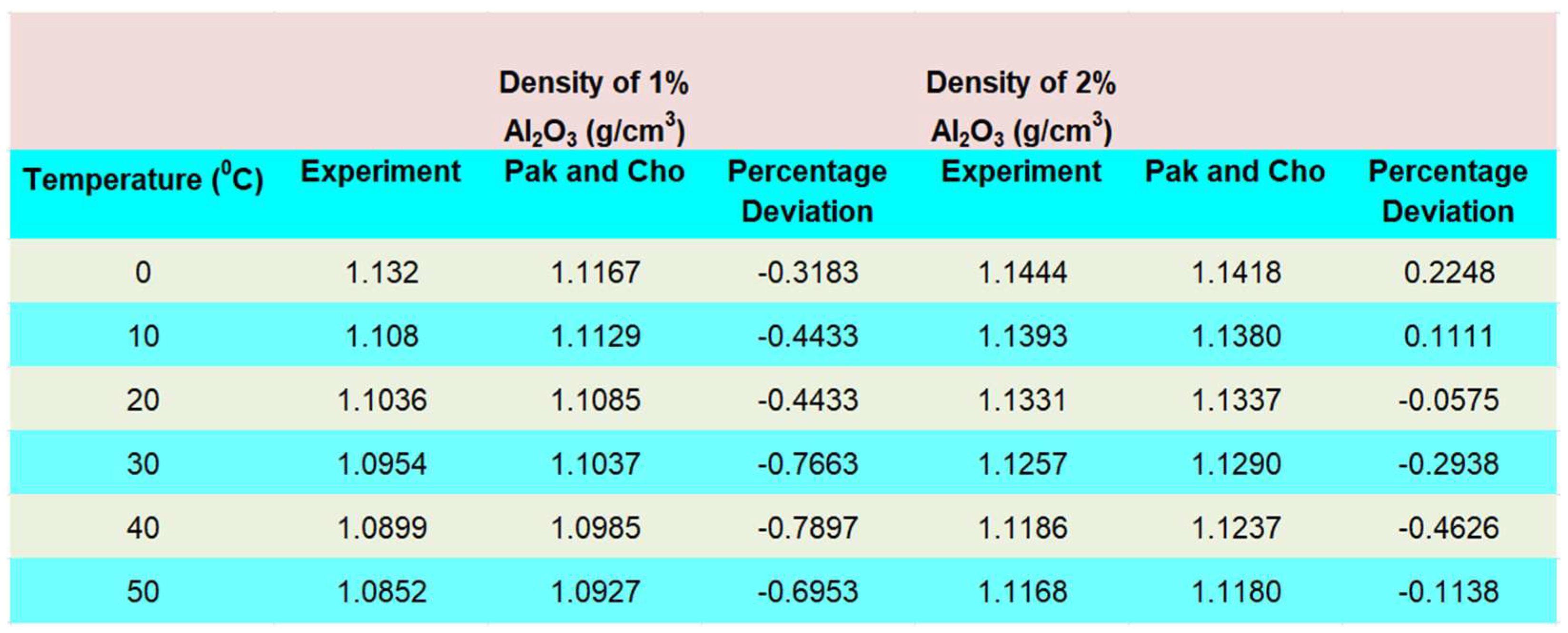

Table 3.

Comparison between experimentally calculated density and Pak and Cho equation in 60:40 Ethylene glycol/water by mass (Reproduced with permission from [

83,

85].

Table 3.

Comparison between experimentally calculated density and Pak and Cho equation in 60:40 Ethylene glycol/water by mass (Reproduced with permission from [

83,

85].

After the experiment, it was observed that density decreases with temperature [

68,

84,

86,

87]. It was also observed, if the volume concentration of nanoparticle in a base fluid (ethylene glycol or water) increases, density also increases. The variation in density with different concentration of Al

2O

3 (1%, 2%, And so on) is shown in

Figure 5.

The solid lines in the

Figure 6 are the experimental values measured from Anton-Paar density metre and dotted lines are the density value obtained from Pak and Cho equation. Linear curve is obtained and 1.2% of deviation was obtained. Furthermore, in some literatures, Teng et al. [

88] has also proved the effect of volume concentration on density. They showed the effect of different concentration of carbon nanotubes with 0.02% and 0.04%, the value of density increases from 0.01% to 0.39%.

3.2. Viscosity

Viscosity means resistant to the flow. But sometimes, due to insufficient knowledge of viscosity mechanism and some important mathematical model this property of nanofluid has become infuriating. Simultaneously, this property is prime parameter to determine the convective coefficient of heat transfer.

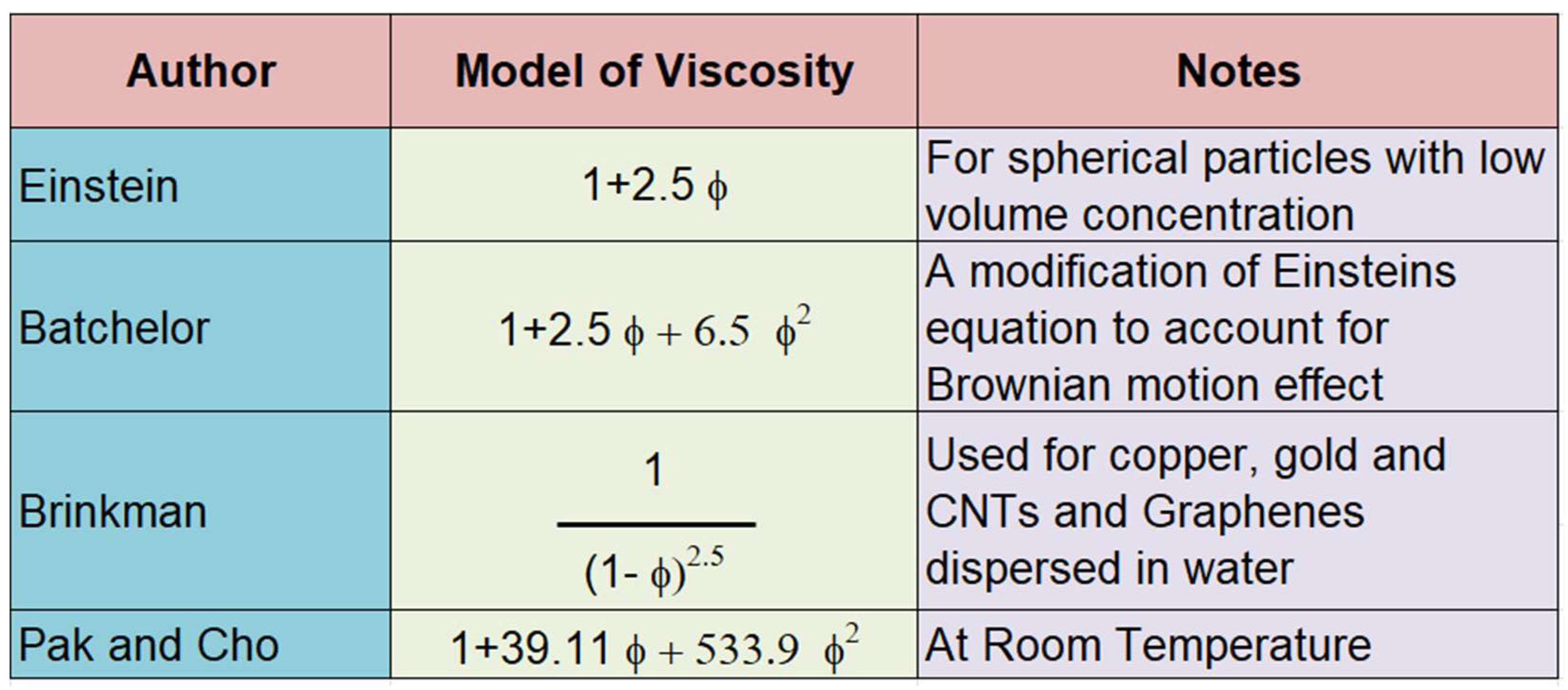

According to Einstein [

89]-

The above equation relates the viscosity of suspension of solid sphere

and the viscosity of dispersion medium (

), and

is the volume occupied by dispersed solid.This was the first model of the viscosity which was put forward by the Einstein. However there was certain limit to this model. It was only valid for the particles having low concentration of 1 volume percentage and for only spherical rigid particles. Many researchers had come up with their modifications in the Einstein model. A model was developed for the particles of higher concentration with Brownian Motion taken account by Brinkman [

90] and Batchelor [

91].

Table 4 shows different theoretical models for predicting viscosity.

In an experiment it was found that there is significant increase of viscosity if we vary the Al

2O

3 concentration [

92] in water with some significant values which further increases friction factor. This proves that there is concentration effect on viscosity. Research confirms that coefficient of heat transfer increases with the concentration of fluid [

11,

12,

93]. It was also observed that along with concentration, shape and size of nanoparticle also affect the viscosity. The effect of temperature on viscosity is such as with increase in temperature there is exponentially decrease in viscosity [

94,

95].

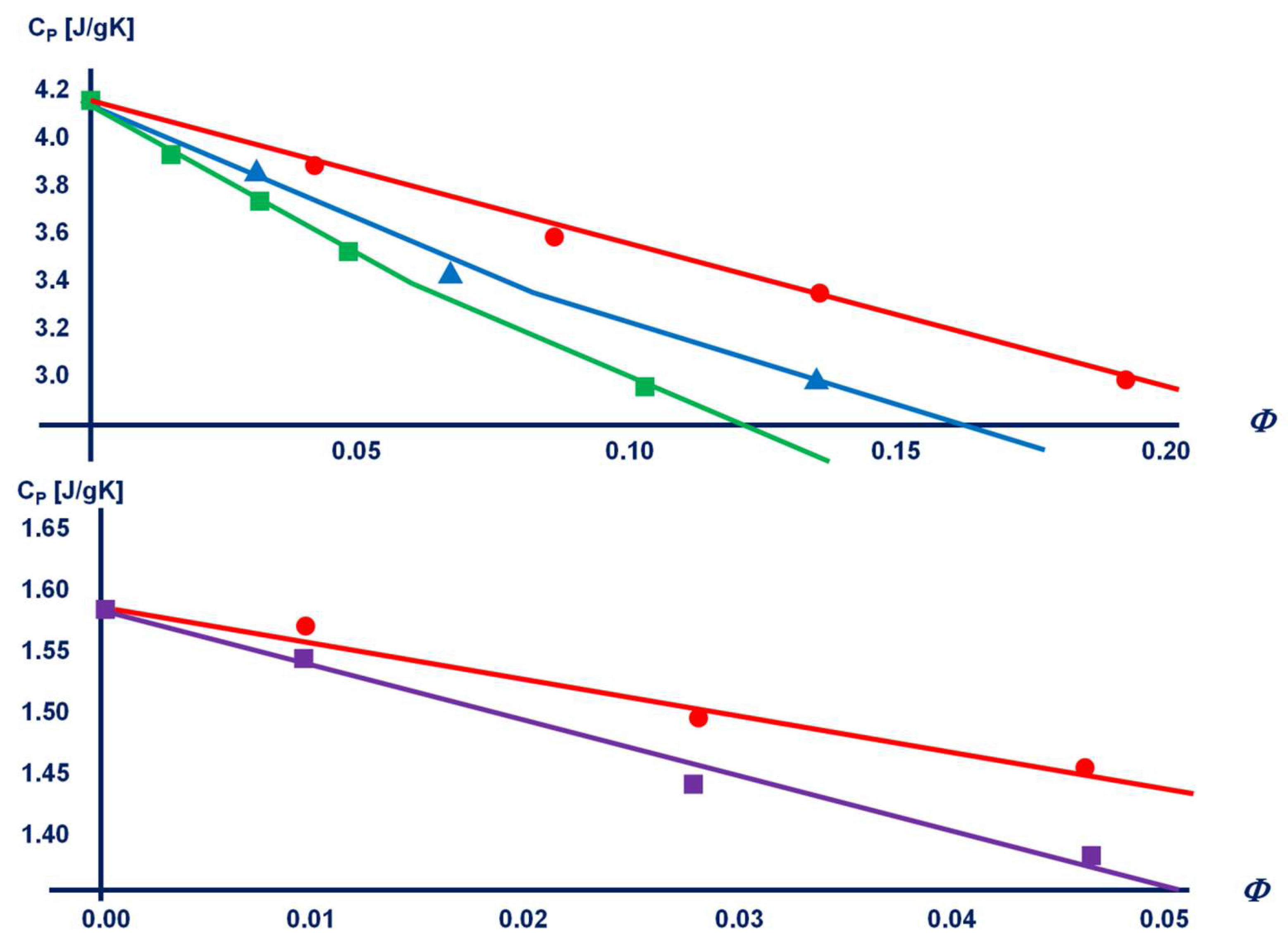

3.3. Specific heat capacity

It is defined as heat energy needed to raise the temperature of 1kg mass of substance by 1 kelvin. It is found in some cases that specific heat capacity [

96] for nanofluid is given as

Here

is the mass of the base liquid, whereas

is the total mass of the nanoparticle

and

are the respective specific heat capacities of the two components. The comparison of this equation 3. [

96] with experimental data is shown in the

Figure 7.

There are many properties which are linked with specific heat capacity. Some of them are thermal diffusivity, thermal conductivity etc [

68]. According to the figure it is clear that specific heat capacity of the base liquid is higher than specific heat capacity of nanoparticle. Larger value of specific heat capacity of nanoparticles than their bulk material [

97] is found by many researchers in their theoretical calculations [

98]. At varying conditions, different values of specific heat capacity is observed by the different models. Pak and Cho [

81] had introduced the model. According to this model the specific heat of the nanofluid is given as:

Where C𝑝𝑛𝑓 is the specific heat of the nanofluid, 𝜙 is the volume fraction and C𝑝𝑓𝑏 and C𝑝𝑝 is the specific heat of the base fluid and the specific heat of the nanoparticles, respectively.

This model is based on the liquid and particle mixture. Later some modifications were carried out on the model given by Pak and Cho. A correlation was carried out based on the thermal equillibrium of nanofluid and the base fluid [

99]:

where

is the density of the nanofluid.

It was found that there was deviation [

100] from equation (3) when heat capacities of water and ethylene glycol based Al,Si etc. was compared but equation (4)was in the great agreement. Equation (4) was further modified [

101] and had put forward a correlation for nanoparticles having higher volume concentration

where

is the specific heat of nanofluid,

and

is the density of nanofluid and nanoparticle respectively, and ɸ is the volume fraction from nanofluid [

102,

103].

3.4. Effect of Nano particle’s size and concentration on the specific heat of the nanofluids

Nanoparticles have lower specific heath as compare to the base fluid due to which it was found that nanofluid’s specific heat decreases when volume fraction increases. In a recent study five different nanofluids (Al

2O

3, ZnO, TiO

2, CuO, and SiO

2) were taken with propylene glycol and water with 60:40 by mass. No change in specific heat of nanoparticle could be seen when the concentration of nanoparticles and particle size were varied. But some studies confirm that this result contradicts with CNT nanofluids [

104].

3.5. Effect of temperature on specific heat of nanofluids

Study says specific heat increase with increase in temperature. This result found contradictory [

105] with some research according to which specific heat decreases with increasing temperature.

4. Conclusions

A study shows an increase in range of absorption spectra from wavelength ranging from UV to IR, which in return resulted in increasing PV cell efficiency. The conclusion made out from the study of nanofluids depends on different factors varying from fluid volume fraction of nanoparticles present in nanofluids. Less will be volume fraction more efficient output can be seen. Apart from type of nanofluid used, channel properties and its affordability and complexity in relation to output can be clearly witnessed. Hexagonal honeycomb channel shows high variations on efficiency parameter in comparison to helical or v-grove channel also not only the symmetry of channel leads down to better results, material from which they made plays a crucial role for overall output. For heat transfer fluids, Air PVTs, for example, requires less input as when compared to water based PVTs due to high installation charge and its flow channel requirements, extra use of tubes and in-out flow patterns when were compared to the percentage increase in its efficiency. Thus, Air PVTs are preferred which is followed down to flow materials. On observing open or adding extra layers of sheets, emission of some of thermal emissions accounts for better quality of PVTs. Shifting focus on nanofluid based PV cells, area of focus digs deep down to stability of nanofluids used and morphological features such as shape, size provides contribution to optical absorption parameters in hybrid PV cells. For most carbon based nanofluids not only showed promising result on stability parameter, efficiency too increased outs the best from the rest. In addition to functional properties of nanofluids in hybrid PV panels, environmental factors rises issues leveraging pathways for affordable technology which can also be reduced to minimum level with adding additional energy storage units for transferring excessive heat loads. Such experiments are still left upto futuristic innovations.

Acknowledgments

JRA gratefully acknowledge Dronacharya College of Engineering, Gurgaon, Delhi-NCR for their supports. Richika and Samidha gratefully acknowledge PDM University for the support and co-operation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Al-Waeli, A.H.A.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Photovoltaic/Thermal (PV/T) Systems: Status and Future Prospects. Renewable and Sustainable Energy Reviews 2017, 77, 109–130. [Google Scholar] [CrossRef]

- Goel, N.; Taylor, R.A.; Otanicar, T. A Review of Nanofluid-Based Direct Absorption Solar Collectors: Design Considerations and Experiments with Hybrid PV/Thermal and Direct Steam Generation Collectors. Renewable Energy 2020, 145, 903–913. [Google Scholar] [CrossRef]

- Liang, H.; Wang, F.; Yang, L.; Cheng, Z.; Shuai, Y.; Tan, H. Progress in Full Spectrum Solar Energy Utilization by Spectral Beam Splitting Hybrid PV/T System. Renewable and Sustainable Energy Reviews 2021, 141, 110785. [Google Scholar] [CrossRef]

- Vaka, M.; Walvekar, R.; Rasheed, A.K.; Khalid, M.; Panchal, H. A Review: Emphasizing the Nanofluids Use in PV/T Systems. IEEE Access 2020, 8, 58227–58249. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. A Review on Recent Developments in Thermal Performance Enhancement Methods of Flat Plate Solar Air Collector. Renewable and Sustainable Energy Reviews 2020, 134, 110315. [Google Scholar] [CrossRef]

- Chow, T.T. A Review on Photovoltaic/Thermal Hybrid Solar Technology. Applied Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Weinstein, L.A.; McEnaney, K.; Strobach, E.; Yang, S.; Bhatia, B.; Zhao, L.; Huang, Y.; Loomis, J.; Cao, F.; Boriskina, S.V.; et al. A Hybrid Electric and Thermal Solar Receiver. Joule 2018, 2, 962–975. [Google Scholar] [CrossRef]

- Taylor, R.A.; Otanicar, T.; Rosengarten, G. Nanofluid-Based Optical Filter Optimization for PV/T Systems. Light Sci Appl 2012, 1, e34–e34. [Google Scholar] [CrossRef]

- Sandnes, B.; Rekstad, J. A Photovoltaic/Thermal (PV/T) Collector with a Polymer Absorber Plate. Experimental Study and Analytical Model. Solar Energy 2002, 72, 63–73. [Google Scholar] [CrossRef]

- Dubey, S.; Tiwari, G.N. Analysis of PV/T Flat Plate Water Collectors Connected in Series. Solar Energy 2009, 83, 1485–1498. [Google Scholar] [CrossRef]

- Pang, W.; Cui, Y.; Zhang, Q.; Wilson, Gregory. J.; Yan, H. A Comparative Analysis on Performances of Flat Plate Photovoltaic/Thermal Collectors in View of Operating Media, Structural Designs, and Climate Conditions. Renewable and Sustainable Energy Reviews 2020, 119, 109599. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M.; Ebrahimnia-Bajestan, E. Performance of Nanofluid-Based Photovoltaic/Thermal Systems: A Review. Renewable and Sustainable Energy Reviews 2017, 76, 323–352. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M. A Heat Pump Coupled with Photovoltaic Thermal Hybrid Solar Collectors: A Case Study of a Multi-Source Energy System. Energy Conversion and Management 2017, 151, 386–399. [Google Scholar] [CrossRef]

- Jeong, Y.-D.; Yu, M.G.; Nam, Y. Feasibility Study of a Heating, Cooling and Domestic Hot Water System Combining a Photovoltaic-Thermal System and a Ground Source Heat Pump. Energies 2017, 10, 1243. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A. Feasibility Study of a Smart Building Energy System Comprising Solar PV/T Panels and a Heat Storage Unit. Energy 2020, 210, 118528. [Google Scholar] [CrossRef]

- George, M.; Pandey, A.K.; Abd Rahim, N.; Tyagi, V.V.; Shahabuddin, S.; Saidur, R. Concentrated Photovoltaic Thermal Systems: A Component-by-Component View on the Developments in the Design, Heat Transfer Medium and Applications. Energy Conversion and Management 2019, 186, 15–41. [Google Scholar] [CrossRef]

- Bandaru, S.H.; Becerra, V.; Khanna, S.; Radulovic, J.; Hutchinson, D.; Khusainov, R. A Review of Photovoltaic Thermal (PVT) Technology for Residential Applications: Performance Indicators, Progress, and Opportunities. Energies 2021, 14, 3853. [Google Scholar] [CrossRef]

- Assoa, Y.B.; Menezo, C.; Fraisse, G.; Yezou, R.; Brau, J. Study of a New Concept of Photovoltaic–Thermal Hybrid Collector. Solar Energy 2007, 81, 1132–1143. [Google Scholar] [CrossRef]

- Al-Alili, A.; Hwang, Y.; Radermacher, R.; Kubo, I. A High Efficiency Solar Air Conditioner Using Concentrating Photovoltaic/Thermal Collectors. Applied Energy 2012, 93, 138–147. [Google Scholar] [CrossRef]

- Axaopoulos, P.J.; Fylladitakis, E.D. Performance and Economic Evaluation of a Hybrid Photovoltaic/Thermal Solar System for Residential Applications. Energy and Buildings 2013, 65, 488–496. [Google Scholar] [CrossRef]

-

United Nations The Sustainable Development Goals Report 2019; United Nations: New York, 2019; ISBN 978-92-1-101403-7.

- International Energy Agency. Renewables 2019: Analysis and Forecasts to 2024; International Energy Agency: Paris, France, 2019; ISBN 978-92-64-36998-6. [Google Scholar]

- Pantic, S.; Candanedo, L.; Athienitis, A.K. Modeling of Energy Performance of a House with Three Configurations of Building-Integrated Photovoltaic/Thermal Systems. Energy and Buildings 2010, 42, 1779–1789. [Google Scholar] [CrossRef]

- Rodrigues Fernandes, M.; Schaefer, L.A. Long-Term Environmental Impacts of a Small-Scale Spectral Filtering Concentrated Photovoltaic-Thermal System. Energy Conversion and Management 2019, 184, 350–361. [Google Scholar] [CrossRef]

- Mittelman, G.; Kribus, A.; Dayan, A. Solar Cooling with Concentrating Photovoltaic/Thermal (CPVT) Systems. Energy Conversion and Management 2007, 48, 2481–2490. [Google Scholar] [CrossRef]

- Diwania, S.; Agrawal, S.; Siddiqui, A.S.; Singh, S. Photovoltaic–Thermal (PV/T) Technology: A Comprehensive Review on Applications and Its Advancement. Int J Energy Environ Eng 2020, 11, 33–54. [Google Scholar] [CrossRef]

- Zafar, S.; Dincer, I. Thermodynamic Analysis of a Combined PV/T–Fuel Cell System for Power, Heat, Fresh Water and Hydrogen Production. International Journal of Hydrogen Energy 2014, 39, 9962–9972. [Google Scholar] [CrossRef]

- Gagliano, A.; Tina, G.M.; Aneli, S.; Nižetić, S. Comparative Assessments of the Performances of PV/T and Conventional Solar Plants. Journal of Cleaner Production 2019, 219, 304–315. [Google Scholar] [CrossRef]

- Pardo García, N.; Zubi, G.; Pasaoglu, G.; Dufo-López, R. Photovoltaic Thermal Hybrid Solar Collector and District Heating Configurations for a Central European Multi-Family House. Energy Conversion and Management 2017, 148, 915–924. [Google Scholar] [CrossRef]

- Chow, T.-T.; Ji, J. Environmental Life-Cycle Analysis of Hybrid Solar Photovoltaic/Thermal Systems for Use in Hong Kong. International Journal of Photoenergy 2012, 2012, 1–9. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F. Design and Modeling of a Concentrating Photovoltaic Thermal (CPV/T) System for a Domestic Application. Energy and Buildings 2013, 62, 392–402. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, X.; Shen, J.; Wu, Y.; Connelly, K.; Yang, T.; Tang, L.; Xiao, M.; Wei, Y.; Jiang, K.; et al. A Review of Thermal Absorbers and Their Integration Methods for the Combined Solar Photovoltaic/Thermal (PV/T) Modules. Renewable and Sustainable Energy Reviews 2017, 75, 839–854. [Google Scholar] [CrossRef]

- Kasaeian, A.; Nouri, G.; Ranjbaran, P.; Wen, D. Solar Collectors and Photovoltaics as Combined Heat and Power Systems: A Critical Review. Energy Conversion and Management 2018, 156, 688–705. [Google Scholar] [CrossRef]

- Pierrick, H.; Christophe, M.; Leon, G.; Patrick, D. Dynamic Numerical Model of a High Efficiency PV–T Collector Integrated into a Domestic Hot Water System. Solar Energy 2015, 111, 68–81. [Google Scholar] [CrossRef]

- Rejeb, O.; Dhaou, H.; Jemni, A. Parameters Effect Analysis of a Photovoltaic Thermal Collector: Case Study for Climatic Conditions of Monastir, Tunisia. Energy Conversion and Management 2015, 89, 409–419. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A.; Vicidomini, M. Transient Analysis, Exergy and Thermo-Economic Modelling of Façade Integrated Photovoltaic/Thermal Solar Collectors. Renewable Energy 2019, 137, 109–126. [Google Scholar] [CrossRef]

- Moaleman, A.; Kasaeian, A.; Aramesh, M.; Mahian, O.; Sahota, L.; Nath Tiwari, G. Simulation of the Performance of a Solar Concentrating Photovoltaic-Thermal Collector, Applied in a Combined Cooling Heating and Power Generation System. Energy Conversion and Management 2018, 160, 191–208. [Google Scholar] [CrossRef]

- Renno, C. Optimization of a Concentrating Photovoltaic Thermal (CPV/T) System Used for a Domestic Application. Applied Thermal Engineering 2014, 67, 396–408. [Google Scholar] [CrossRef]

- Ibrahim, A.; Othman, M.Y.; Ruslan, M.H.; Mat, S.; Sopian, K. Recent Advances in Flat Plate Photovoltaic/Thermal (PV/T) Solar Collectors. Renewable and Sustainable Energy Reviews 2011, 15, 352–365. [Google Scholar] [CrossRef]

- Jiang, K.; Du, X.; Kong, Y.; Xu, C.; Ju, X. A Comprehensive Review on Solid Particle Receivers of Concentrated Solar Power. Renewable and Sustainable Energy Reviews 2019, 116, 109463. [Google Scholar] [CrossRef]

- Calise, F.; Dentice d’Accadia, M.; Figaj, R.D.; Vanoli, L. A Novel Solar-Assisted Heat Pump Driven by Photovoltaic/Thermal Collectors: Dynamic Simulation and Thermoeconomic Optimization. Energy 2016, 95, 346–366. [Google Scholar] [CrossRef]

- Thakare, M.S.; Krishna Priya, G.S.; Ghosh, P.C.; Bandyopadhyay, S. Optimization of Photovoltaic–Thermal (PVT) Based Cogeneration System through Water Replenishment Profile. Solar Energy 2016, 133, 512–523. [Google Scholar] [CrossRef]

- Zondag, H.A.; de Vries, D.W.; van Helden, W.G.J.; van Zolingen, R.J.C.; van Steenhoven, A.A. The Thermal and Electrical Yield of a PV-Thermal Collector. Solar Energy 2002, 72, 113–128. [Google Scholar] [CrossRef]

- Dale, J.; Otanicar, T. Nanoparticle Based Concentrating Photovoltaic/Thermal Hybrid Collector.; Santiago, Chile, 2018; p. 170003.

- Hassani, S.; Taylor, R.A.; Mekhilef, S.; Saidur, R. A Cascade Nanofluid-Based PV/T System with Optimized Optical and Thermal Properties. Energy 2016, 112, 963–975. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Kamyab, M.H.; Valadkhani, M. Application of Nanofluids and Fluids in Photovoltaic Thermal System: An Updated Review. Solar Energy 2020, 199, 796–818. [Google Scholar] [CrossRef]

- Lari, M.O.; Sahin, A.Z. Effect of Retrofitting a Silver/Water Nanofluid-Based Photovoltaic/Thermal (PV/T) System with a PCM-Thermal Battery for Residential Applications. Renewable Energy 2018, 122, 98–107. [Google Scholar] [CrossRef]

- Yang, D.J.; Yuan, Z.F.; Lee, P.H.; Yin, H.M. Simulation and Experimental Validation of Heat Transfer in a Novel Hybrid Solar Panel. International Journal of Heat and Mass Transfer 2012, 55, 1076–1082. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, X.; Smith, S.; Xu, J.; Yu, X. Review of R&D Progress and Practical Application of the Solar Photovoltaic/Thermal (PV/T) Technologies. Renewable and Sustainable Energy Reviews 2012, 16, 599–617. [Google Scholar] [CrossRef]

- Sripadmanabhan Indira, S.; Vaithilingam, C.A.; Chong, K.-K.; Saidur, R.; Faizal, M.; Abubakar, S.; Paiman, S. A Review on Various Configurations of Hybrid Concentrator Photovoltaic and Thermoelectric Generator System. Solar Energy 2020, 201, 122–148. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Akhlaghi, Y.G.; Ma, X.; Zhao, X.; Ayodele, E. Advancements in Thermoelectric Generators for Enhanced Hybrid Photovoltaic System Performance. Renewable and Sustainable Energy Reviews 2019, 109, 24–54. [Google Scholar] [CrossRef]

- Vokas, G.; Christandonis, N.; Skittides, F. Hybrid Photovoltaic–Thermal Systems for Domestic Heating and Cooling—A Theoretical Approach. Solar Energy 2006, 80, 607–615. [Google Scholar] [CrossRef]

- Sachit, F.A.; Rosli, M.A.M.; Tamaldin, N.; Mishra, S.; Abdulla, A.L. Nanofluids Used in Photovoltaic Thermal (PV/T) Systems: A Review. International Journal of Engineering & Technology 2018, 7, 12. [Google Scholar]

- Brownson, J.R.S. Systems Logic of Devices: Patterns. In Solar Energy Conversion Systems; Elsevier, 2014; pp. 307–318. ISBN 978-0-12-397021-3.

- Lamnatou, Chr. ; Chemisana, D. Photovoltaic/Thermal (PVT) Systems: A Review with Emphasis on Environmental Issues. Renewable Energy 2017, 105, 270–287. [Google Scholar] [CrossRef]

- Wysocki, J.J.; Rappaport, P. Effect of Temperature on Photovoltaic Solar Energy Conversion. Journal of Applied Physics 1960, 31, 571–578. [Google Scholar] [CrossRef]

- Babu, C.; Ponnambalam, P. The Role of Thermoelectric Generators in the Hybrid PV/T Systems: A Review. Energy Conversion and Management 2017, 151, 368–385. [Google Scholar] [CrossRef]

- Shah, T.R.; Ali, H.M. Applications of Hybrid Nanofluids in Solar Energy, Practical Limitations and Challenges: A Critical Review. Solar Energy 2019, 183, 173–203. [Google Scholar] [CrossRef]

- Said, Z.; Arora, S.; Bellos, E. A Review on Performance and Environmental Effects of Conventional and Nanofluid-Based Thermal Photovoltaics. Renewable and Sustainable Energy Reviews 2018, 94, 302–316. [Google Scholar] [CrossRef]

- MITEI-The-Future-of-Solar-Energy (1).Pdf.

- Erixno, O.; Rahim, N.A. A Techno-Environmental Assessment of Hybrid Photovoltaic-Thermal Based Combined Heat and Power System on a Residential Home. Renewable Energy 2020, 156, 1186–1202. [Google Scholar] [CrossRef]

- Kazanci, O.B.; Skrupskelis, M.; Sevela, P.; Pavlov, G.K.; Olesen, B.W. Sustainable Heating, Cooling and Ventilation of a plus-Energy House via Photovoltaic/Thermal Panels. Energy and Buildings 2014, 83, 122–129. [Google Scholar] [CrossRef]

- Waqar Akram, M.; Li, G.; Jin, Y.; Zhu, C.; Javaid, A.; Zuhaib Akram, M.; Usman Khan, M. Study of Manufacturing and Hotspot Formation in Cut Cell and Full Cell PV Modules. Solar Energy 2020, 203, 247–259. [Google Scholar] [CrossRef]

- Benda, V.; Černá, L. PV Cells and Modules – State of the Art, Limits and Trends. Heliyon 2020, 6, e05666. [Google Scholar] [CrossRef]

- Ritou, A.; Voarino, P.; Raccurt, O. Does Micro-Scaling of CPV Modules Improve Efficiency? A Cell-to-Module Performance Analysis. Solar Energy 2018, 173, 789–803. [Google Scholar] [CrossRef]

- Mikšík, F.; Skolil, J.; Kotlík, J.; Čáslavský, J.; Miyazaki, T.; Koyama, S.; Půčková, H.; Levek, P. Antifreeze Heat Transfer Fluid Based on Propane-1,3-Diole 2017.

- Kamel, M.; Lezsovits, F. Boiling Heat Transfer of Nanofluids: A Review of Recent Studies. Therm sci 2019, 23, 109–124. [Google Scholar] [CrossRef]

- Jama, M.; Singh, T.; Gamaleldin, S.M.; Koc, M.; Samara, A.; Isaifan, R.J.; Atieh, M.A. Critical Review on Nanofluids: Preparation, Characterization, and Applications. Journal of Nanomaterials 2016, 2016, 1–22. [Google Scholar] [CrossRef]

- Obalanlege, M.A.; Mahmoudi, Y.; Douglas, R.; Ebrahimnia-Bajestan, E.; Davidson, J.; Bailie, D. Performance Assessment of a Hybrid Photovoltaic-Thermal and Heat Pump System for Solar Heating and Electricity. Renewable Energy 2020, 148, 558–572. [Google Scholar] [CrossRef]

- Thakare, M.S.; Ghosh, P.C.; Bandyopadhyay, S. Utilization of Excess Energy in the Sizing of Photovoltaic-Thermal System (Pvt) Using Design Space Approach. Chemical Engineering Transactions 2015, 45, 1609–1614. [Google Scholar] [CrossRef]

- Fraisse, G.; Ménézo, C.; Johannes, K. Energy Performance of Water Hybrid PV/T Collectors Applied to Combisystems of Direct Solar Floor Type. Solar Energy 2007, 81, 1426–1438. [Google Scholar] [CrossRef]

- Gosens, I.; Post, J.A.; de la Fonteyne, L.J.; Jansen, E.H.; Geus, J.W.; Cassee, F.R.; de Jong, W.H. Impact of Agglomeration State of Nano- and Submicron Sized Gold Particles on Pulmonary Inflammation. Part Fibre Toxicol 2010, 7, 37. [Google Scholar] [CrossRef]

- Ali, A.R.I.; Salam, B. A Review on Nanofluid: Preparation, Stability, Thermophysical Properties, Heat Transfer Characteristics and Application. SN Appl. Sci. 2020, 2, 1636. [Google Scholar] [CrossRef]

- Chow, T.T. Performance Analysis of Photovoltaic-Thermal Collector by Explicit Dynamic Model. Solar Energy 2003, 75, 143–152. [Google Scholar] [CrossRef]

- Akilu, S.; Baheta, A.T.; Sharma, K.V. Characterization and Modelling of Density, Thermal Conductivity, and Viscosity of TiN–W/EG Nanofluids. J Therm Anal Calorim 2020, 140, 1999–2010. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, X.; Ma, X.; Du, Z.; Fan, Y.; Cheng, Y.; Zhang, X. Clear-Days Operational Performance of a Hybrid Experimental Space Heating System Employing the Novel Mini-Channel Solar Thermal & PV/T Panels and a Heat Pump. Solar Energy 2017, 155, 464–477. [Google Scholar] [CrossRef]

- Sotehi, O.; Chaker, A.; Maalouf, C. Hybrid PV/T Water Solar Collector for Net Zero Energy Building and Fresh Water Production: A Theoretical Approach. Desalination 2016, 385, 1–11. [Google Scholar] [CrossRef]

- Lari, M.O.; Sahin, A.Z. Design, Performance and Economic Analysis of a Nanofluid-Based Photovoltaic/Thermal System for Residential Applications. Energy Conversion and Management 2017, 149, 467–484. [Google Scholar] [CrossRef]

- Gang, P.; Huide, F.; Jie, J.; Tin-tai, C.; Tao, Z. Annual Analysis of Heat Pipe PV/T Systems for Domestic Hot Water and Electricity Production. Energy Conversion and Management 2012, 56, 8–21. [Google Scholar] [CrossRef]

- Ji, J.; Lu, J.-P.; Chow, T.-T.; He, W.; Pei, G. A Sensitivity Study of a Hybrid Photovoltaic/Thermal Water-Heating System with Natural Circulation. Applied Energy 2007, 84, 222–237. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. HYDRODYNAMIC AND HEAT TRANSFER STUDY OF DISPERSED FLUIDS WITH SUBMICRON METALLIC OXIDE PARTICLES. Experimental Heat Transfer 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Kumaresan, V.; Velraj, R. Experimental Investigation of the Thermo-Physical Properties of Water–Ethylene Glycol Mixture Based CNT Nanofluids. Thermochimica Acta 2012, 545, 180–186. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Mahagaonkar, B.M. Density Measurement of Different Nanofluids and Their Comparison With Theory. Petroleum Science and Technology 2009, 27, 612–624. [Google Scholar] [CrossRef]

- American Society of Heating, R. and A.-C.E. 2005 ASHRAE Handbook: Fundamentals, Inch-Pound Edition; The Society: Atlanta, Ga, 2005. [Google Scholar]

- Pak, B.C.; Cho, Y.I. HYDRODYNAMIC AND HEAT TRANSFER STUDY OF DISPERSED FLUIDS WITH SUBMICRON METALLIC OXIDE PARTICLES. Experimental Heat Transfer 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Saidur, R.; Amalina, M.A. Thermal Conductivity, Viscosity and Density of R141b Refrigerant Based Nanofluid. Procedia Engineering 2013, 56, 310–315. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Mahagaonkar, B.M. Density Measurement of Different Nanofluids and Their Comparison With Theory. Petroleum Science and Technology 2009, 27, 612–624. [Google Scholar] [CrossRef]

- Teng, T.-P.; Cheng, C.-M.; Pai, F.-Y. Preparation and Characterization of Carbon Nanofluid by a Plasma Arc Nanoparticles Synthesis System. Nanoscale Res Lett 2011, 6, 293. [Google Scholar] [CrossRef] [PubMed]

- Einstein, A. Eine neue Bestimmung der Moleküldimensionen. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Brinkman, H.C. The Viscosity of Concentrated Suspensions and Solutions. The Journal of Chemical Physics 1952, 20, 571–571. [Google Scholar] [CrossRef]

- Batchelor, G.K. The Effect of Brownian Motion on the Bulk Stress in a Suspension of Spherical Particles. J. Fluid Mech. 1977, 83, 97–117. [Google Scholar] [CrossRef]

- Albadr, J.; Tayal, S.; Alasadi, M. Heat Transfer through Heat Exchanger Using Al2O3 Nanofluid at Different Concentrations. Case Studies in Thermal Engineering 2013, 1, 38–44. [Google Scholar] [CrossRef]

- Jaaz, A.H.; Hasan, H.A.; Sopian, K.; Haji Ruslan, M.H.B.; Zaidi, S.H. Design and Development of Compound Parabolic Concentrating for Photovoltaic Solar Collector: Review. Renewable and Sustainable Energy Reviews 2017, 76, 1108–1121. [Google Scholar] [CrossRef]

- Albadr, J.; Tayal, S.; Alasadi, M. Heat Transfer through Heat Exchanger Using Al2O3 Nanofluid at Different Concentrations. Case Studies in Thermal Engineering 2013, 1, 38–44. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Choi, S.U.S. Thermal Conductivity of Nanoparticle - Fluid Mixture. Journal of Thermophysics and Heat Transfer 1999, 13, 474–480. [Google Scholar] [CrossRef]

- Hentschke, R. On the Specific Heat Capacity Enhancement in Nanofluids. Nanoscale Res Lett 2016, 11, 88. [Google Scholar] [CrossRef]

- Wang, B.-X.; Zhou, L.-P.; Peng, X.-F. Surface and Size Effects on the Specific Heat Capacity of Nanoparticles. Int J Thermophys 2006, 27, 139–151. [Google Scholar] [CrossRef]

- Saeedian, M.; Mahjour-Shafiei, M.; Shojaee, E.; Mohammadizadeh, M.R. Specific Heat Capacity of TiO 2 Nanoparticles. j comput theor nanosci 2012, 9, 616–620. [Google Scholar] [CrossRef]

- Xuan, Y.; Roetzel, W. Conceptions for Heat Transfer Correlation of Nanofluids. International Journal of Heat and Mass Transfer 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- O’Hanley, H.; Buongiorno, J.; McKrell, T.; Hu, L. Measurement and Model Validation of Nanofluid Specific Heat Capacity with Differential Scanning Calorimetry. Advances in Mechanical Engineering 2012, 4, 181079. [Google Scholar] [CrossRef]

- Zhou, L.-P.; Wang, B.-X.; Peng, X.-F.; Du, X.-Z.; Yang, Y.-P. On the Specific Heat Capacity of CuO Nanofluid. Advances in Mechanical Engineering 2010, 2, 172085. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Yu, W.; France, D.M.; Singh, D.; Routbort, J.L. Base Fluid and Temperature Effects on the Heat Transfer Characteristics of SiC in Ethylene Glycol/H2O and H2O Nanofluids. Journal of Applied Physics 2011, 109, 014914. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Yu, W.; France, D.M.; Singh, D.; Routbort, J.L. Nanofluids for Heat Transfer: An Engineering Approach. Nanoscale Res Lett 2011, 6, 182. [Google Scholar] [CrossRef] [PubMed]

- Satti, J.R.; Das, D.K.; Ray, D. Specific Heat Measurements of Five Different Propylene Glycol Based Nanofluids and Development of a New Correlation. International Journal of Heat and Mass Transfer 2016, 94, 343–353. [Google Scholar] [CrossRef]

- Saeedinia, M.; Akhavan-Behabadi, M.A.; Nasr, M. Experimental Study on Heat Transfer and Pressure Drop of Nanofluid Flow in a Horizontal Coiled Wire Inserted Tube under Constant Heat Flux. Experimental Thermal and Fluid Science 2012, 36, 158–168. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).