1. Introduction

Under the high-speed change of market demand, a lot of manufacturing firms present the characteristics of multi-project, multi-variety and batch mixed production. Multi-project refers to the production tasks of multiple projects undertaken by enterprises. Multiple varieties refer to a large number of product items. Variable-batch means that the same item has an unfixed production quantity. Mixed line refers to simultaneous online production of multiple projects. This complex task situation brings greater challenges to the research of scheduling algorithms.

Once manufacturing enterprises have the above production characteristics, they will often encounter problems such as multi-project preemption of resources, overproduction, poor turnover capacity, and delayed planning. These problems will greatly affect the production efficiency and reduce the business ability of enterprises. In addition, in some special industries, the project schedule requirements are very strict. Even in a very complex production environment, it is necessary to achieve the overall schedule goal without delay.

In order to solve such complex problems, we need to pay attention to the development of computer science and management science and combine them effectively. On the hand, we need to solve the issue of job time prediction in complex production environment. On the other hand, we need to provide dynamic control algorithms to realize dynamic control of the total duration of complex projects and optimization of production plans.

The paper designs a dynamic optimization CPM model in the ERP/MES system with the attention mechanism (EMA-DCPM) based on machine learning and CPM technology, which can accurately predict the operation time of variable batch products and realize dynamic control of the total duration of complex projects. This algorithm provides a feasible solution for production planning control in complex manufacturing environment. The method we proposed consists of two modules. The first is the operation time prediction module, and the second is the dynamic optimization control module based on CPM technology. The precision of this method are 2 to 3 times higher than those of earlier control approach, and the calculation amount is small, which can be applied in engineering.

2. Related work

More and more enterprises realize that intelligent scheduling is the fundamental way for enterprises to organize efficient production. The current intelligent scheduling algorithm is mainly divided into two directions.

One direction is to continue to optimize heuristic algorithms to solve practical production problems or improve the efficiency of solving the optimal solution. This kind of more traditional scheduling problem solution is mainly based on the traditional heuristic algorithm represented by Ant colony optimization algorithms, etc. In recent years, scholars have paid more energy to the complexity of the practical and ever-changing production processes. A non-single objective solution based on genetic algorithm was proposed by Chen et al. [

1]. Their goal is to optimize power consumption and minimize production cycles. A new architecture combining pattern matching with genetic algorithm was proposed by Liu et al. [

2]. This algorithm can minimize latency to the greatest extent possible. Lu et al. [

3] proposed a genetic algorithm based method for modeling three-dimensional problems through one-dimensional solutions to solve non-pulsating and non-unit manufacturing workshop scheduling problems. A locally enhanced particle swarm optimization compound algorithm was used by Marichelvam et al. [

4] to solve the multi-layer mixed transportation scheduling problem. For the no-waiting scheduling problem, Zhao et al. [

5] incorporated the advantages of population mechanism into particle swarm optimization algorithm, effectively integrating the direct advantages of the algorithm. The two-level particle swarm optimization enhancement algorithm was proposed by Zarrouk et al. [

6]. The upper layer is used to process the mapping of operations to equipment, and the lower layer is used to process the sequence of operations on equipment. A new complex Ant colony optimization algorithms solution based on crossover and mutation mechanism was designed by Engin et al. [

7]. For the replacement specify task scheduling issues, an algorithm that combines the techniques of cuckoo search with the techniques of ant colony operation was proposed by Zhang et al. [

8]. Elmi et al. [

9] gave a solution method for ant colony optimization of robot tasks was proposed. There are many research reports on such scheduling algorithms [

10,

11,

12,

13,

14,

15,

16,

17,

18]. But the research focus is mainly on algorithm optimization. Few scholars pay attention to the data input and output of the algorithm. Some of the input data are based on assumptions or random numbers, and some of the output data are not the results that enterprises care about.

The other direction is to use machine learning algorithm and give full play to its advantages in efficiency and accuracy. Sha et al. [

19] proposed a priority-based parallel reinforcement learning task scheduling strategy, which verified the high convergence of Q learning. Zhang et al. [

20] replaces automatic learning PDR with end-to-end deep reinforcement learning. Swarup et al. [

21] proposed a double-depth Q learning algorithm using target network and relay technology. Luo et al. [

22] extracted seven general state features to represent the rescheduled production state, and used deep Q learning for training. Silva et al. [

23] uses the concept of reinforcement learning to enable agents to interact with other agents and environments. Park et al. [

24] proposes a RL strategy based on near-end strategy optimization, which is trained in an end-to-end manner. In recent years, deep learning has been widely used to solve shop scheduling issues [

25,

26].

These algorithms have a precondition that the product operation time has been obtained. However, most traditional manufacturing enterprises only have quota working hours and lack the database of actual working hours of products. The quota working hours are applicable to the internal business system of the enterprise and cannot be used in the production planning system. Therefore, mangy traditional manufacturing enterprises fail to use intelligent scheduling algorithm to solve the actual production scheduling problem.

Under the high-speed of information technology, some enterprises have mastered the actual operation time of some stable products through ERP and MES systems, but it is difficult to obtain the operation time of multi-variety and variable-batch mixed-line products. With full consideration of production efficiency, mixed line status, seasonal changes and other factors, such operation time is like stock index, which cannot be directly collected or simply predicted [

27,

28,

29,

30]. In the actual project plan management process, the most important thing is to determine the future project plan in advance. We not only care about the production time of the previous products, but also want to know the possible production time of the products in the future. It can be said that the prediction of production operation time is more accurate and the prediction of project plan is more instructive.

This paper believes that if the real task time management and project management technology are combined, and the former is used as the input of the latter, the relevant management ability of the enterprise will be greatly improved. CPM technology belongs to the field of operational research and is a method used for project planning and control. It forms the specific scheme of project construction through time parameter calculation, critical route analysis and other means [

31,

32,

33,

34,

35,

36,

37]. The traditional CPM technology focuses on the prediction of the total construction period, but it lacks the dynamic optimization feature and is difficult to be used for complex project control. Therefore, in this paper, we optimize the CPM technology to meet the unshakable requirements of total construction period target control.

3. Method

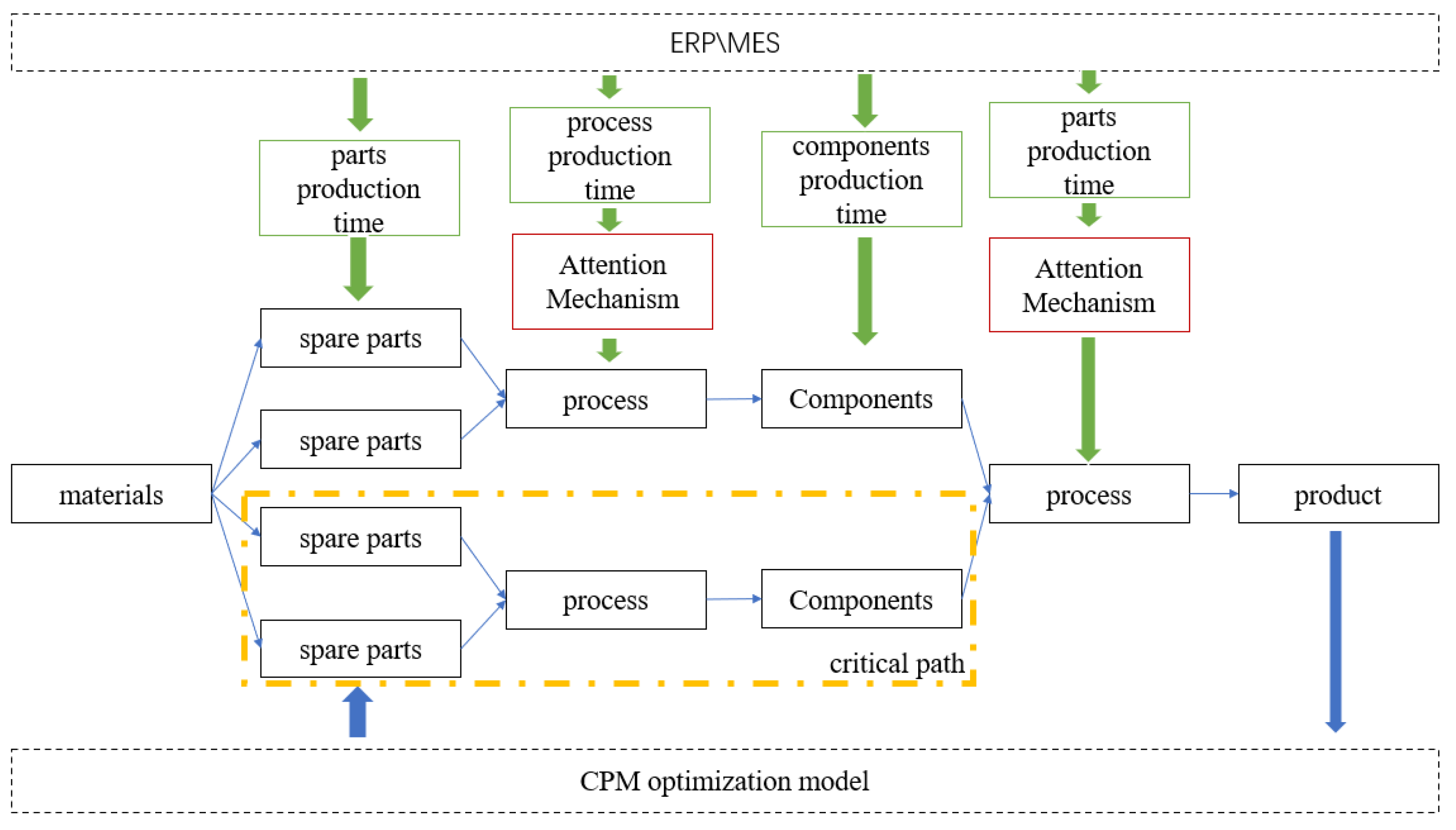

EMA-DCPM algorithm includes data acquisition, preprocessing, operation time prediction and dynamic path optimization.

3.1. Data acquisition

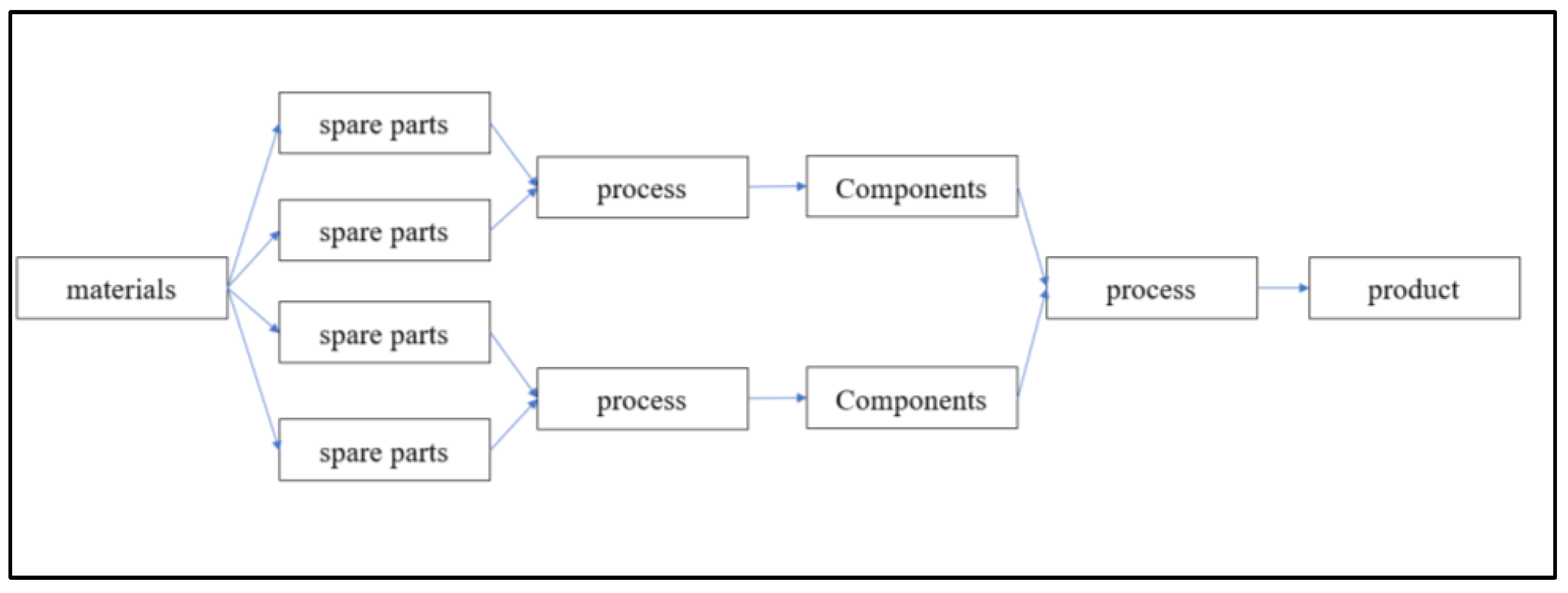

The product production project of an enterprise has the characteristics of tree structure. This type of product is composed of multiple parts or components. Components in the product are also composed of parts. This composition process can be called process, as shown in

Figure 1.

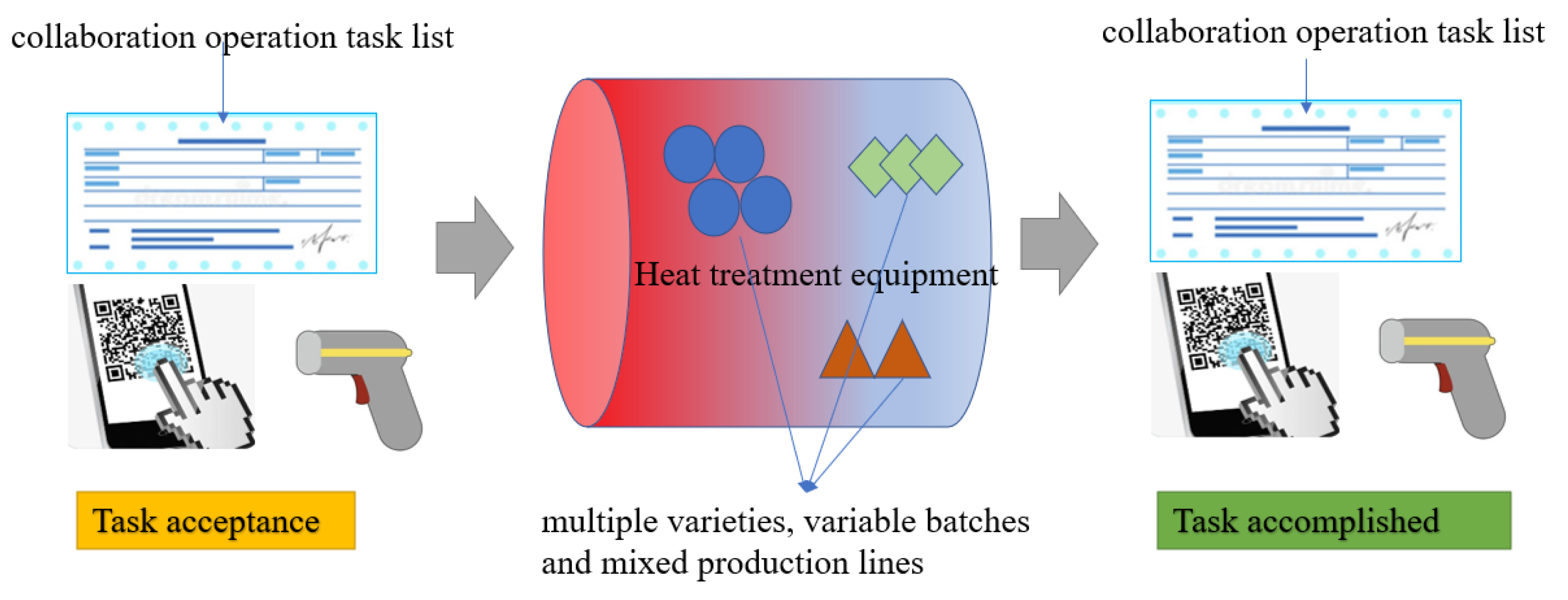

Therefore, we need distinguish between the collection of operation time of finished parts and the collection of operation time of process processing. Generally speaking, the production of a part requires 10 to 20 processes. In the true production process, the order of magnitude of the actual process operation time generated is far greater than that of the parts. Most enterprises can only obtain the actual operation time of parts, but cannot obtain the process operation time. In order to obtain the operation time of a specific process, we decompose the part task list into a part collaboration operation task list. Because of the collaborative process task list, we can conduct the product handover of the collaborative process like the product handover through the infrared radio frequency scanning technology. Through this handover process, we obtained the actual operation time of heat treatment process of all products of an enterprise in the past two years. This process is shown in

Figure 3. Due to the wide variety of heat treatment products and different batches of each product, more than 40000 items of heat treatment data are actually collected.

Figure 2.

Design of heat treatment process acquisition process.

Figure 2.

Design of heat treatment process acquisition process.

The collaboration task in the collaboration task list is expressed by

, formula (1).

is the product name.

is a special naming number that can distinguish products.

is the collaboration task number.

is the product category.

is the task start time.

is the task end time.

is the product quantity.

the type of heat treatment (such as quenching, tempering, etc.).

In this paper, and are used to extract the data of the same heat treatment process of the same products. Through this method, we obtained real-time processing data of the same heat treatment process of the same products. During the process, we cleaned up null data and incomplete data, and retained thousands of data. These data will be used for subsequent data prediction and analysis.

3.2. Data preprocessing

In this paper, these collaborative task data are transformed into the time vector of single product processing. This time vector is

.

is the time sequence.

is the single product operation time of the current time. We use the formula (2) and formula (3).

The advantage of this is to improve the convergence of the calculation. At the same time, it is convenient to predict the operation time of different batches of products in the same heat treatment process of unknown similar products in the future.

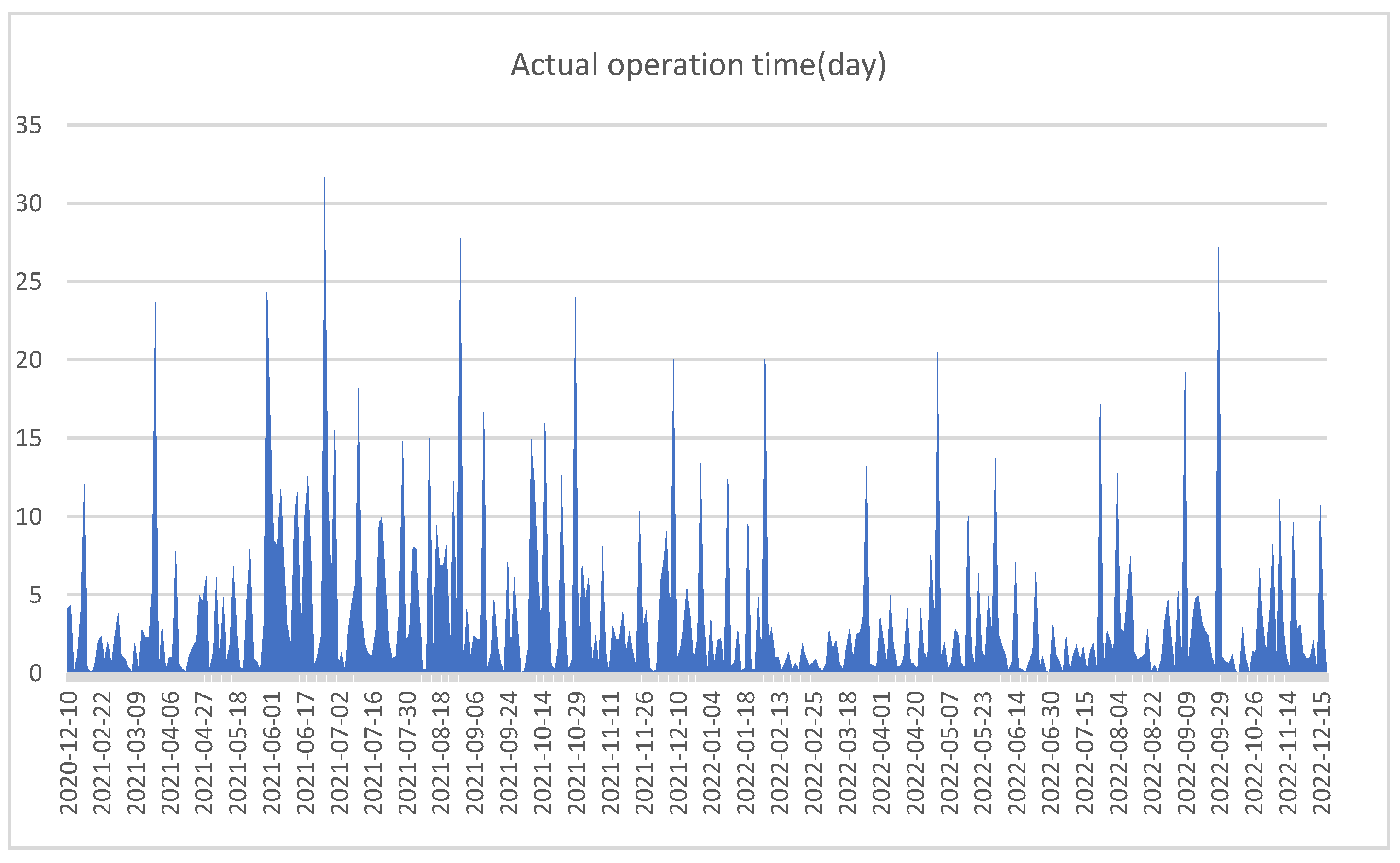

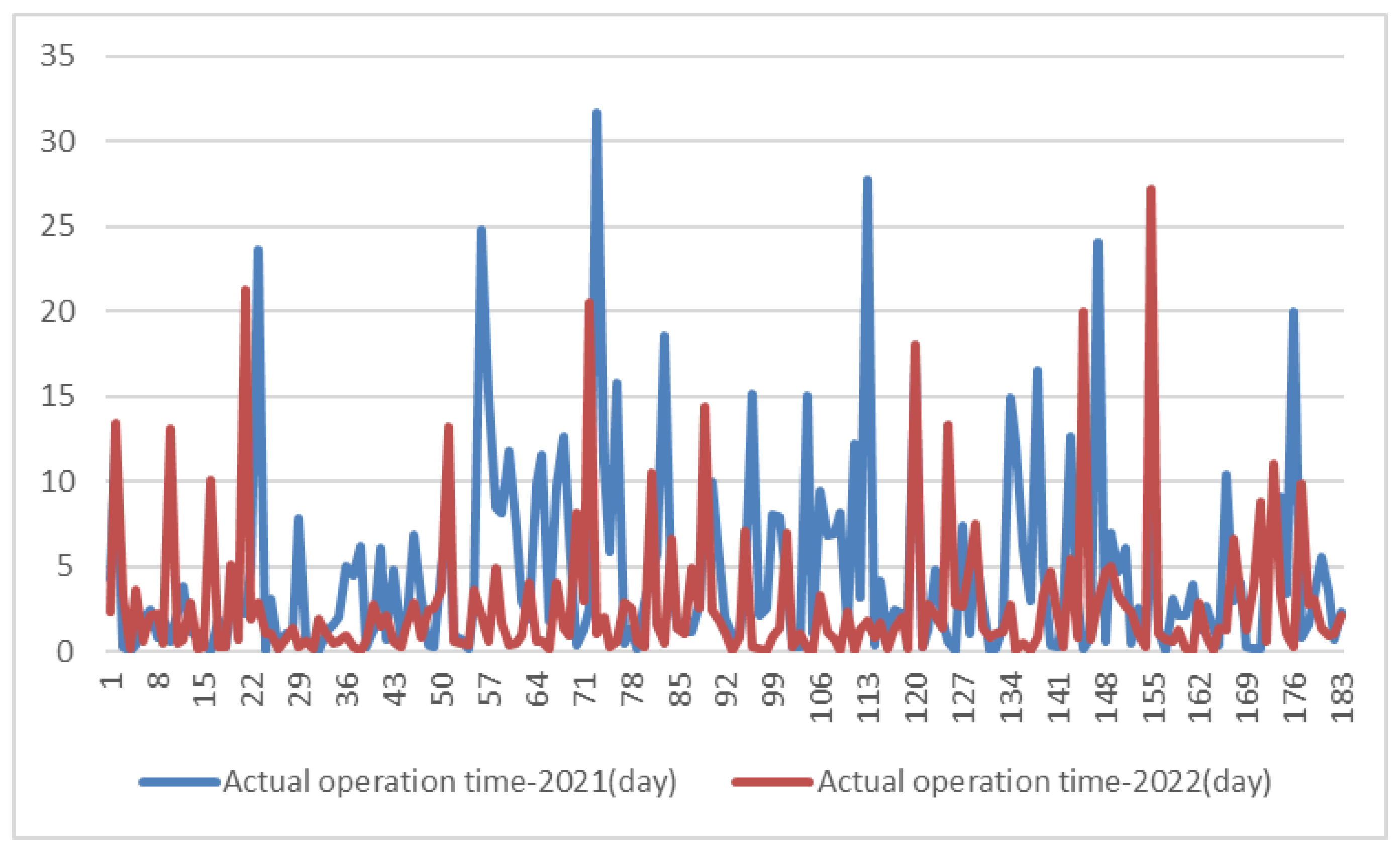

Through the data acquisition and pretreatment methods in 3.1 and 3.2, the actual operation time data of quenching process is obtained in this paper. There are 374 pieces of data in this dataset, and the data distribution is shown in

Figure 3. Other types of heat treatment operation time data can also be processed in this way. This article describes only one type in detail.

Figure 3.

The single operation time for a certain type of product to complete a specific heat treatment.

Figure 3.

The single operation time for a certain type of product to complete a specific heat treatment.

These data are the operation time of a single piece of a certain product to complete quenching from 2020 to 2022. It can be seen from the figure that although the product type is the same and the heat treatment process is the same, but due to different product batches, different mixed batch tasks and different time intervals, the actual operation time changes irregularly. It can be seen that the distribution values of high latitude change data on the left side of the figure are mostly higher than the data distribution values on the right side, as shown in

Figure 4.

The operation time data group covers 2021 and 2022. This paper compares the two annual data in the data, as shown in

Figure 4. Through this comparison, it is easier to see that after the production capacity of the enterprise is improved in 2022, most of the working time data have declined. By analysis, the main reason for this phenomenon is the development of heat treatment technology and the improvement of production efficiency. This is why it is necessary to predict the future operation time through the previous operation time data. Such factors should be taken into account in the operation time data used for project plan management.

At the same time, this paper finds that there is a certain rule between the operation time and the quarter. The operating hours of enterprises increased significantly in the 2st-4st quarters of 2021 and 2022. This is because in the 2st-4st quarters, the enterprise is operating at full capacity. Under the influence of comprehensive production environment, products cannot be produced according to the standard operation time. Next, we will use machine learning technology to predict the subsequent product operation time.

3.3. EMA-DCPM algorithm

Figure 5 shows the EMA-DCPM algorithm structure. EM represents ERP/MES system, A represents attention mechanism, and DCPM represents dynamic optimization CPM model.

The input of this algorithm model is the product processing data recorded in the ERP/MES system. Production time data is divided into part processing time and operation processing time. The parts production time can be directly used as the input of the CPM model. However, considering the complexity of multi-variety and mixed-line production, process processing time needs to process data in the way of the above two sections, and add attention mechanism for training and learning.

The output of RNN and the input of several previous moments are related to the state. Therefore, RNN can retain the correlation between features. However, the recording of each step will lead to error accumulation, which may cause gradient explosion and gradient disappearance. Because the attention mechanism can extract key information while ignoring irrelevant information to prevent gradient explosion. This article cleverly combines the architecture of the RNN model with attention mechanism, utilizing the advantages of attention mechanism in solving gradient problems to predict and analyze production data with high fluctuations.

One of the advantages of the time prediction model used by artificial intelligence algorithm is that it can obtain real-time and more accurate production time data according to the passage of time. We can use this data to predict and control the whole project plan.

More and more enterprises adopt CPM technology to plan and manage complex projects. CPM technology uses the logical relationship between tasks and the known operation time to calculate the time parameters, thus predicting the total duration of the project. CPM model is a network graph path planning model in operational research. In order to better integrate the predicted job time with the CPM model, The paper define the task in the CPM model as

, such as formula (4).

is the front node of the task,

is the rear node of the task,

is the total float, t is the operation time of the task,

is the node immediately before the task,

is the node immediately after the task, and

is the completion status of the task.

is the difference between the latest completion time and the earliest completion time, seeing equation (5) for details.

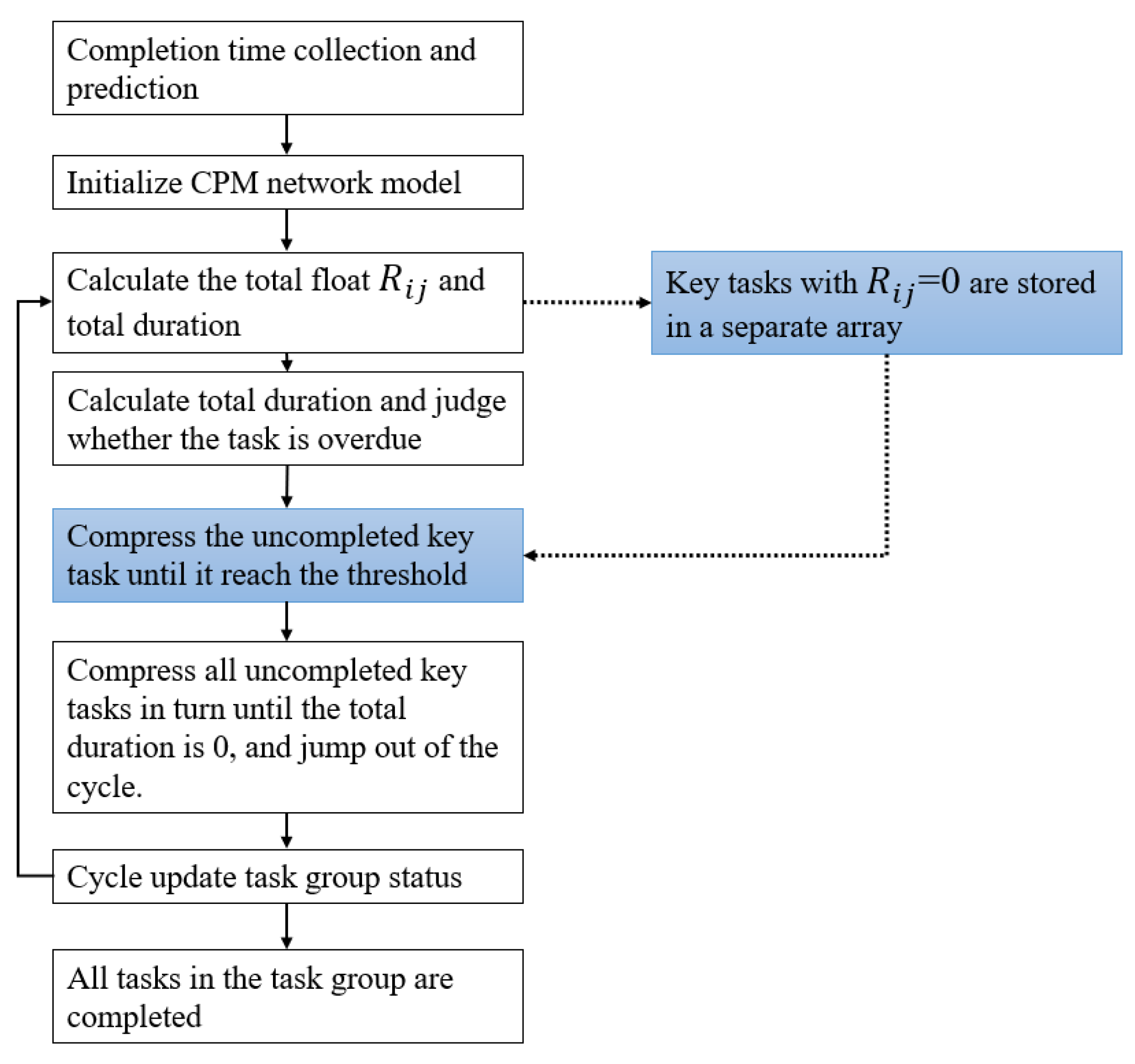

The paper has innovatively adopted an algorithm that can dynamically optimize the CPM model. During the actual project operation, we need to track the total duration according to the actual completion of various tasks in the project. By comparing the current total construction period with the target total construction period, company can get the conclusion whether the project is delayed. Therefore, paper consider the work completion status in . In addition, according to CPM theory, the task of =0 is the key work. Reducing the working time of key work can affect the total construction period. =0 is also an important tag in .

The core of CPM optimization model is to compress the operation time of tasks with =0. When compressing the job time, the paper suggests to compress according to the relative value and set the compression threshold. In addition, we store the key work found each time in an array. When compressing key work, priority shall be given to key work with small sequence number and uncompleted work. The optimization logic is shown in the figure below.

Figure 6.

Logical architecture of CPM optimization model.

Figure 6.

Logical architecture of CPM optimization model.

The algorithm program adopts Python language, uses the NetworkX toolkit, and uses the topological sequence function for programming. In this paper, the project plan data table is imported, and the task time parameter data and directed graph are output. express the Critical path method of the total project duration.

4. Experimental evaluation and Discussion

4.1. Operation time prediction

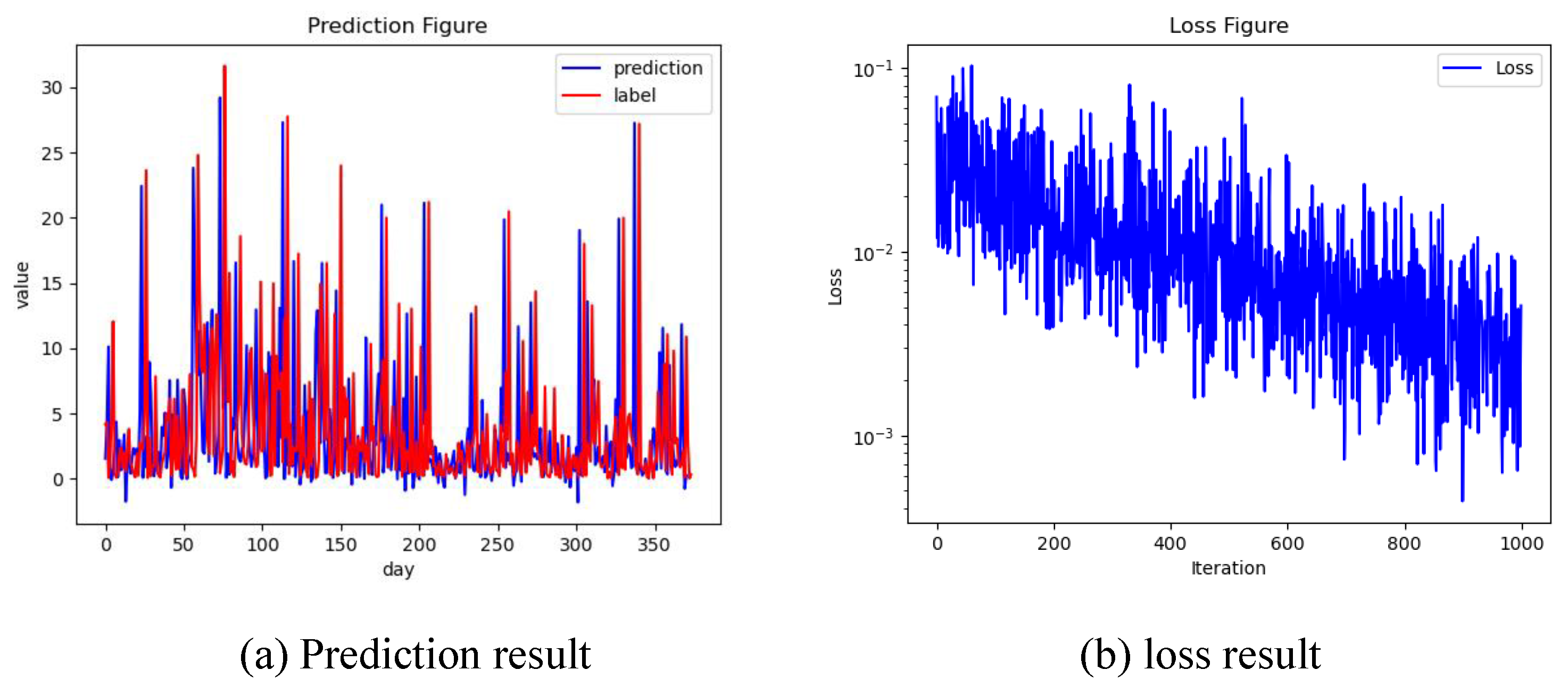

As can be seen from

Figure 3, the data group of operation time shows a large fluctuation. This is one of the significant characteristics of product processing in the process of variable batch mixed production.

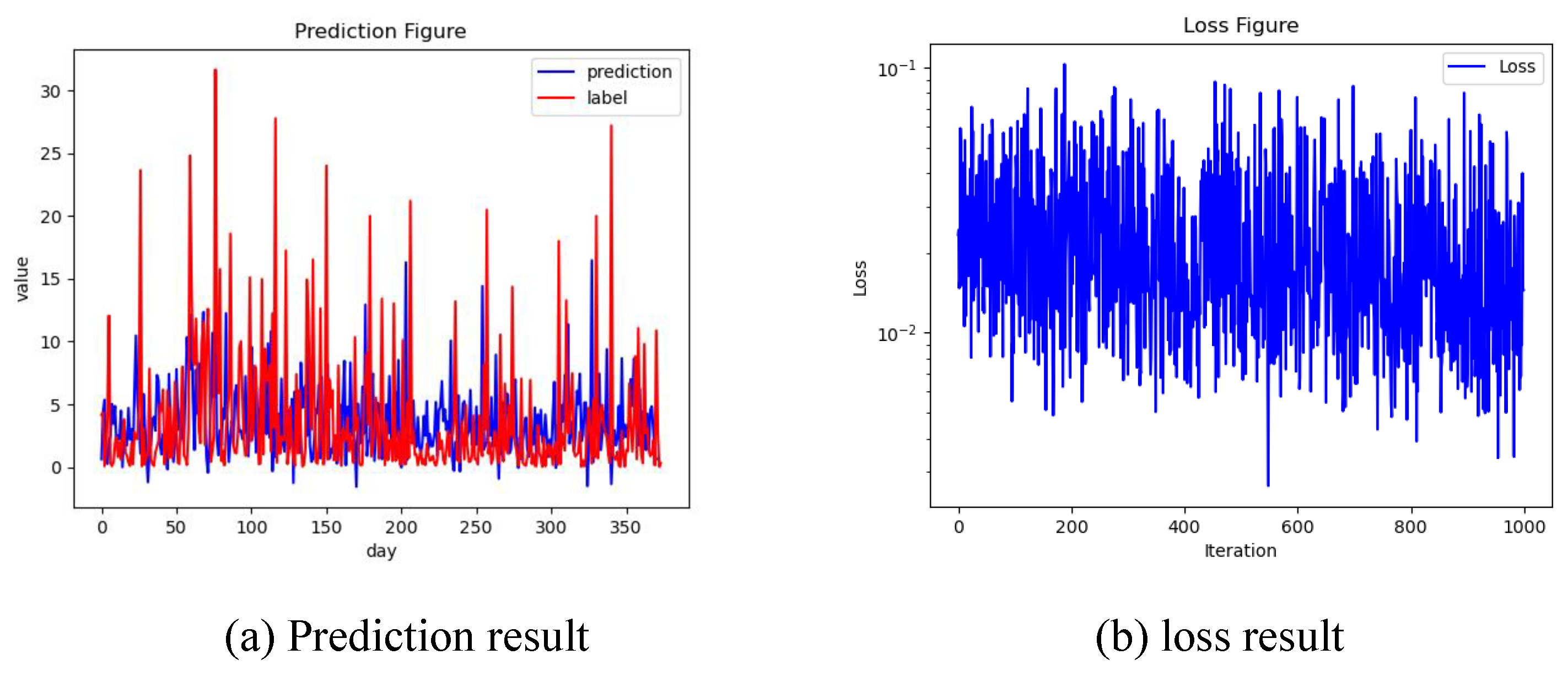

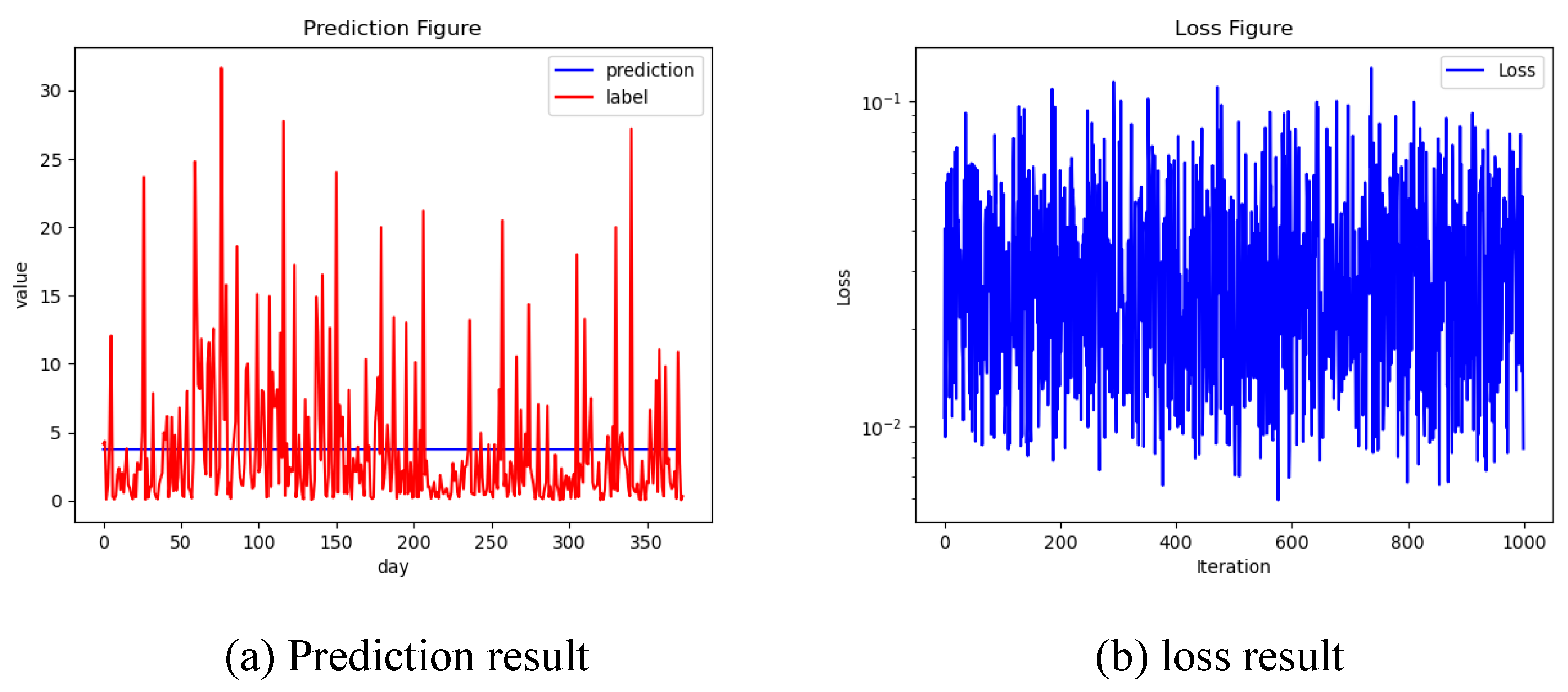

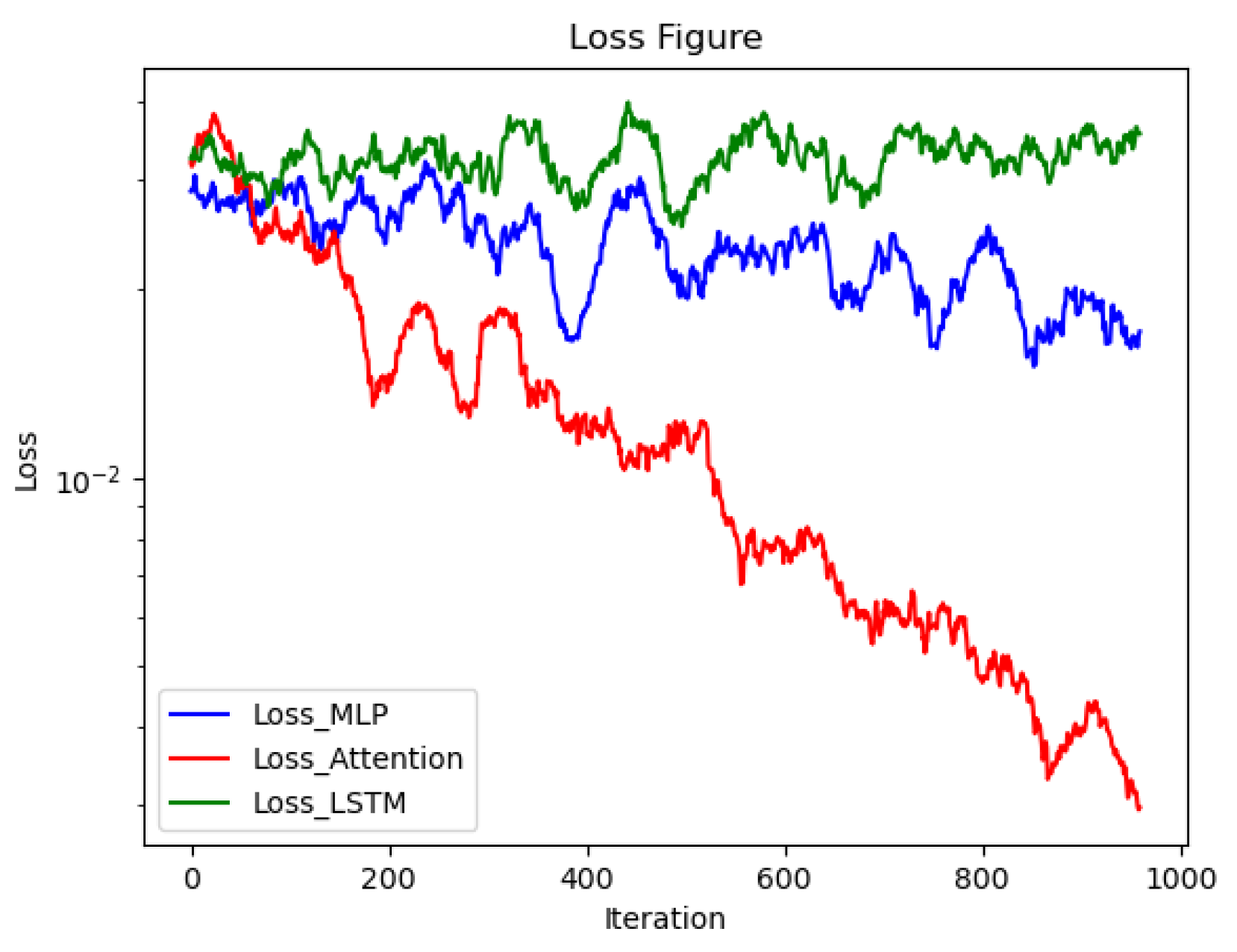

In order to select appropriate algorithms for operation time prediction, this paper adopts three different algorithms, namely MLP (Multilayer Perceptron), LSTM (Long short-term memory) and Attention Mechanism. The above three methods are often used for training and learning of time series data. Through comparative experiments, we will show that the attention mechanism has more advantages than other models in dealing with actual product operation time data.

Through calculation, we get the prediction results of different algorithms and the process of calculation convergence, as shown in

Figure 7,

Figure 8,

Figure 9 and

Figure 10.

It can be seen from

Figure 10 that the attention mechanism has obvious advantages over MLP and LSTM in predicting the operation time of multi-variety and variable batch mixed production. The main reason for this result is that the attention mechanism can focus on relevant information and ignore irrelevant information. The attention mechanism directly establishes the dependency between input and output, enhances the degree of parallelism, and greatly improves the running speed. It overcomes some limitations in MLP and LSTM. It can extract the characteristics of large fluctuation data, capture remote information well, reduce the depth of hierarchy and effectively improve the accuracy.

Then, we compare the data of the first week of operation in 2023 predicted by the three models, the data of the traditional mean method and the actual data collected, as shown in

Table 1.

From the results, the attention mechanism selected in this paper has more advantages and higher accuracy than the other two algorithms in the prediction of operation time. The difference between the traditional method data and the actual data is about 3 days. This difference data will affect the final result of the scheduling algorithm, resulting in inaccurate project schedule forecast. In other words, the traditional calculation method cannot be used for the complex production environment scheduling of mixed line and variable batch production.

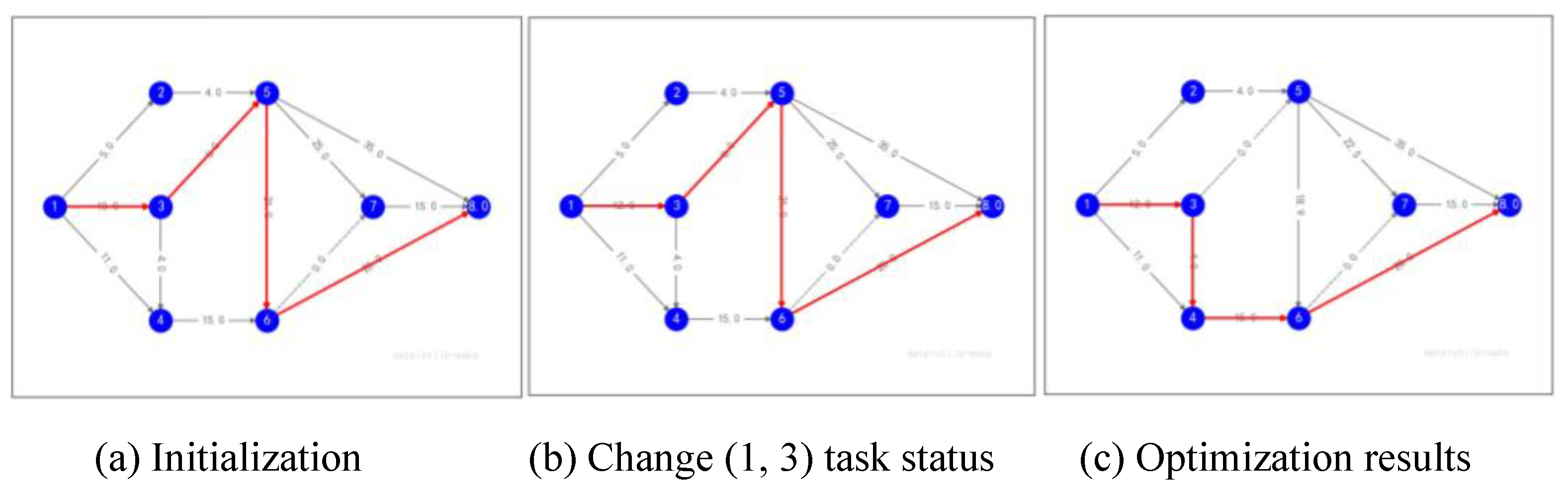

4.2. Dynamic optimization CPM model validation

Through the new calculation model, the paper quickly obtains the digraph before and after the planning. In order to verify the function of the calculation model, we analyze the classic calculation example. The model operation results are shown in the

Figure 11. Red lines represent critical paths.

It can be seen from the above figure that the total construction period is delayed because the duration of (1, 3) key tasks is changed. The initialization duration is 51 days. After the task status changes, the duration changes to 53 days. After the model judges that the total construction period is delayed, the duration of the key work (5, 6) that has not been started will be compressed until the original total construction period target is met. The optimized duration is the same as the expected duration. In addition, we also found that the compressed critical work will affect the results of the critical path and even generate new critical paths.

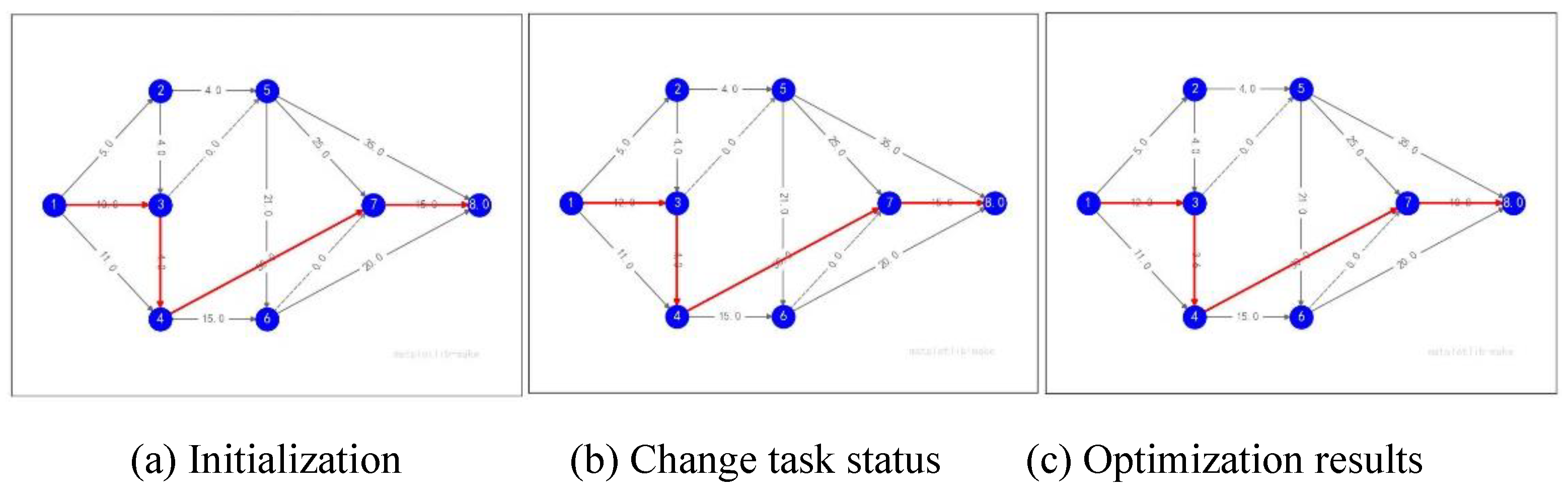

In order to verify the effectiveness of the model, the paper uses random data sets for testing. The test results are shown in

Figure 12.

It can be seen from

Figure 12 that the total construction period target obtained from the random data set is 59 days. By importing random actual task data, the total duration is 61 days. According to the current task, it is predicted that the project will be delayed by 2 days. After the optimization of the model, the total construction period is 56.4 days, and the project is completed 2.6 days ahead of schedule. The optimization model achieves the project control objectives. Because the key operation time is compressed in a certain proportion, it may be completed ahead of schedule.

From the optimized results, it can be seen that the algorithm can achieve dynamic control and adjustment of the duration, and the task operation time on the critical path is compressed within a controllable range. Further, paper find that the original critical path may change and a new critical path will be generated when the critical path is compressed. The new critical path will not affect our dynamic control of the total duration.

The EMA-DCPM model meets the design expectations and achieves the dynamic control of the project schedule objectives. In addition, the EMA-DCPM can be used for projects with high planning rigidity, that is, the plan can only be advanced but not postponed. The EMA-DCPM model has the following advantages compared with the traditional CPM model. See

Table 2. The main reason for the improvement of the accuracy of the plan is that the attention mechanism is used to predict the operation time of the process.

5. Conclusions

(1) The paper focuses on the production operation time is the important basic data of intelligent algorithm, and carries out data collection and prediction research. Through information technology and taking the collaborative task list as the carrier, the process-level operation time collection is realized. Flexible use of time data processing methods, combined with artificial intelligence models, to predict the production time of unknown batches of products in the future.

(2) The paper optimizes the CPM model and proposes a new EMA-DCPM algorithm based on the dynamic prediction characteristics of machine learning. Compared with traditional calculation methods, the accuracy of the prediction results has been significantly improved. It solves the problem that the operation time of multiple varieties, variable batches and mixed line products cannot be determined. Through the end-to-end characteristics of machine learning models, to some extent, the paper considers the complex factors in the actual production environment.

(3) For the prediction of the operation time of the heat treatment process, the project adopts three different artificial intelligence model algorithms. Through comparative study, it is found that the attention mechanism model is more suitable for the prediction of production time.

(4) By optimizing the CPM algorithm, an algorithm that can dynamically track the project progress and dynamically optimize the path is proposed. Combined with the previous work time prediction results, the algorithm can further improve the manufacturing enterprise's control ability of the total duration of complex projects.

Author Contributions

Conceptualization, L.W. and H.L.; methodology, validation, L.W. and M.X.; analysis, L.W.; resources, H.L.; writing-original draft preparation, L.W.; writing-review and editing, Y.W.; visualization, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by National Key Research and Development Program of China (2021YFB1716200) and Research Funds for Leading Talents Program (048000514122549).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data are included in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, T.-L.; Cheng, C.-Y.; Chou, Y.-H. Multi-objective genetic algorithm for energy-efficient hybrid flow shop scheduling with lot streaming. Ann. Oper. Res. 2018, 290, 813–836. [Google Scholar] [CrossRef]

- Liu, G.-S.; Zhou, Y.; Yang, H.-D. Minimizing energy consumption and tardiness penalty for fuzzy flow shop scheduling with state-dependent setup time. J. Clean. Prod. 2017, 147, 470–484. [Google Scholar] [CrossRef]

- Lu, P.-H.; Wu, M.-C.; Tan, H.; Peng, Y.-H.; Chen, C.-F. A genetic algorithm embedded with a concise chromosome representation for distributed and flexible job-shop scheduling problems. J. Intell. Manuf. 2015, 29, 19–34. [Google Scholar] [CrossRef]

- Marichelvam, M.; Geetha, M.; Tosun, Ö. An improved particle swarm optimization algorithm to solve hybrid flowshop scheduling problems with the effect of human factors – A case study. Comput. Oper. Res. 2020, 114, 104812. [Google Scholar] [CrossRef]

- Zhao, F.; Qin, S.; Yang, G.; Ma, W.; Zhang, C.; Song, H. A factorial based particle swarm optimization with a population adaptation mechanism for the no-wait flow shop scheduling problem with the makespan objective. Expert Syst. Appl. 2019, 126, 41–53. [Google Scholar] [CrossRef]

- Zarrouk, R.; Bennour, I.E.; Jemai, A. A two-level particle swarm optimization algorithm for the flexible job shop scheduling problem. Swarm Intell. 2019, 13, 145–168. [Google Scholar] [CrossRef]

- Engin, O.; Güçlü, A. A new hybrid ant colony optimization algorithm for solving the no-wait flow shop scheduling problems. Appl. Soft Comput. 2018, 72, 166–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, Y.; Zhang, S.; Luo, Y.; Zhang, L. Ant colony optimization for Cuckoo Search algorithm for permutation flow shop scheduling problem. Syst. Sci. Control. Eng. 2018, 7, 20–27. [Google Scholar] [CrossRef]

- Elmi, A.; Topaloglu, S. Cyclic job shop robotic cell scheduling problem: Ant colony optimization. Comput. Ind. Eng. 2017, 111, 417–432. [Google Scholar] [CrossRef]

- Bożejko, W.; Gnatowski, A.; Pempera, J.; Wodecki, M. Parallel tabu search for the cyclic job shop scheduling problem. Comput. Ind. Eng. 2017, 113, 512–524. [Google Scholar] [CrossRef]

- Li, J.-Q.; Duan, P.; Cao, J.; Lin, X.-P.; Han, Y.-Y. A Hybrid Pareto-Based Tabu Search for the Distributed Flexible Job Shop Scheduling Problem With E/T Criteria. IEEE Access 2018, 6, 58883–58897. [Google Scholar] [CrossRef]

- Shao, Z.; Pi, D.; Shao, W. Estimation of distribution algorithm with path relinking for the blocking flow-shop scheduling problem. Eng. Optim. 2017, 50, 894–916. [Google Scholar] [CrossRef]

- Dabah, A.; Bendjoudi, A.; AitZai, A.; Taboudjemat, N.N. Efficient parallel tabu search for the blocking job shop scheduling problem. Soft Comput. 2019, 23, 13283–13295. [Google Scholar] [CrossRef]

- González-Neira, E.M.; Urrego-Torres, A.M.; Cruz-Riveros, A.M.; Henao-García, C.; Montoya-Torres, J.R.; Molina-Sánchez, L.P.; Jiménez, J.-F. Robust solutions in multi-objective stochastic permutation flow shop problem. Comput. Ind. Eng. 2019, 137, 106026. [Google Scholar] [CrossRef]

- Arık, O.A. Population-based Tabu search with evolutionary strategies for permutation flow shop scheduling problems under effects of position-dependent learning and linear deterioration. Soft Computing. 2021, 25, 1501–1518. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Chu, F.; Yu, J. An energy-efficient two-stage hybrid flow shop scheduling problem in a glass production. Int. J. Prod. Res. 2019, 58, 2283–2314. [Google Scholar] [CrossRef]

- Vela, C.R.; Afsar, S.; Palacios, J.J.; González-Rodríguez, I.; Puente, J. Evolutionary tabu search for flexible due-date satisfaction in fuzzy job shop scheduling. Comput. Oper. Res. 2020, 119, 104931. [Google Scholar] [CrossRef]

- Gmira, M.; Gendreau, M.; Lodi, A.; Potvin, J.-Y. Tabu search for the time-dependent vehicle routing problem with time windows on a road network. Eur. J. Oper. Res. 2020, 288, 129–140. [Google Scholar] [CrossRef]

- Sha, Z.; Xue, F.; Zhu, J. Scheduling strategy of cloud robots based on parallel reinforcement learning. Journal of Computer Applications 2019, 39, 501. [Google Scholar]

- Zhang, C.; Song, W.; Cao, Z.; Zhang, J.; Tan, P.S.; Chi, X. Learning to dispatch for job shop scheduling via deep reinforcement learning. Advances in Neural Information Processing Systems 2020, 33, 1621–1632. [Google Scholar]

- Swarup, S.; Shakshuki, E.M.; Yasar, A. Task Scheduling in Cloud Using Deep Reinforcement Learning. Procedia Comput. Sci. 2021, 184, 42–51. [Google Scholar] [CrossRef]

- Luo, S. Dynamic scheduling for flexible job shop with new job insertions by deep reinforcement learning. Appl. Soft Comput. 2020, 91, 106208. [Google Scholar] [CrossRef]

- Silva, M.A.L.; de Souza, S.R.; Souza, M.J.F.; Bazzan, A.L.C. A reinforcement learning-based multi-agent framework applied for solving routing and scheduling problems. Expert Syst. Appl. 2019, 131, 148–171. [Google Scholar] [CrossRef]

- Park, J.; Chun, J.; Kim, S.H.; Kim, Y.; Park, J. Learning to schedule job-shop problems: representation and policy learning using graph neural network and reinforcement learning. Int. J. Prod. Res. 2021, 59, 3360–3377. [Google Scholar] [CrossRef]

- Fischer, T.; Krauss, C. Deep learning with long short-term memory networks for financial market predictions. European Journal of Operational Research 2018, 270, 654–669. [Google Scholar] [CrossRef]

- Su, Z.; Xie, H.; Han, L. Multi-Factor RFG-LSTM Algorithm for Stock Sequence Predicting. Comput. Econ. 2020, 57, 1041–1058. [Google Scholar] [CrossRef]

- Mnih, V.; Heess, N.; Graves, A. Recurrent models of visual attention. Advances in Neural Information Processing Systems 2014, 27. [Google Scholar]

- Kondo, T.; Ueno, J.; Takao, S. Hybrid multi-layered GMDH-type neural network using principal component-regression analysis and its application to medical image diagnosis of lung cancer. In 2012 ASE/IEEE International Conference on BioMedical Computing 2012, 20-27.

- Liu, J.; Zhao, K.; Kusy, B.; Wen, J.-R.; Zheng, K.; Jurdak, R. Learning abstract snippet detectors with Temporal embedding in convolutional neural Networks. 2016, 895–905. [Google Scholar] [CrossRef]

- Tang, W.; Long, G.; Liu, L.; Zhou, T.; Jiang, J.; Blumenstein, M. Rethinking 1d-cnn for time series classification: A Stronger Baseline. arXiv 2020, arXiv:2002.10061. [Google Scholar]

- Chakrabortty, R.K.; Sarker, R.A.; Essam, D.L. Resource constrained project scheduling with uncertain activity durations. Comput. Ind. Eng. 2017, 112, 537–550. [Google Scholar] [CrossRef]

- Tripathi, K.K.; Jha, K.N. An empirical study on performance measurement factors for construction organizations. KSCE Journal of Civil Engineering 2018, 22, 1052–1066. [Google Scholar] [CrossRef]

- Tripathi, K.K.; Jha, K.N. Determining success factors for a construction organization: A structural equation modeling approach. Journal of Management in Engineering 2018, 34, 04017050. [Google Scholar] [CrossRef]

- Kadri, R.L.; Boctor, F.F. An efficient genetic algorithm to solve the resource-constrained project scheduling problem with transfer times: The single mode case. European Journal of Operational Research 2018, 265, 454–462. [Google Scholar] [CrossRef]

- Olivieri, H.; Seppänen, O.; Granja, A.D. Improving workflow and resource usage in construction schedules through location-based management system (LBMS). Constr. Manag. Econ. 2018, 36, 109–124. [Google Scholar] [CrossRef]

- Habibi, F.; Barzinpour, F.; Sadjadi, S.J. A mathematical model for project scheduling and material ordering problem with sustainability considerations: A case study in Iran. Computers & Industrial Engineering 2019, 128, 690–710. [Google Scholar]

- Bao, W.; Yue, J.; Rao, Y. A deep learning framework for financial time series using stacked autoencoders and long-short term memory. PLOS ONE 2017, 12, e0180944. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).