Submitted:

12 June 2023

Posted:

12 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

| Year of Publication | DT in FM | Publications |

|---|---|---|

| 2022 | 17 | [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31] |

| 2021 | 30 | [32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61] |

| 2020 | 6 | [62,63,64,65,66,67] |

| 2019 | 4 | [68,69,70,71] |

| 2018 | 2 | [72,73] |

| Total | 59 |

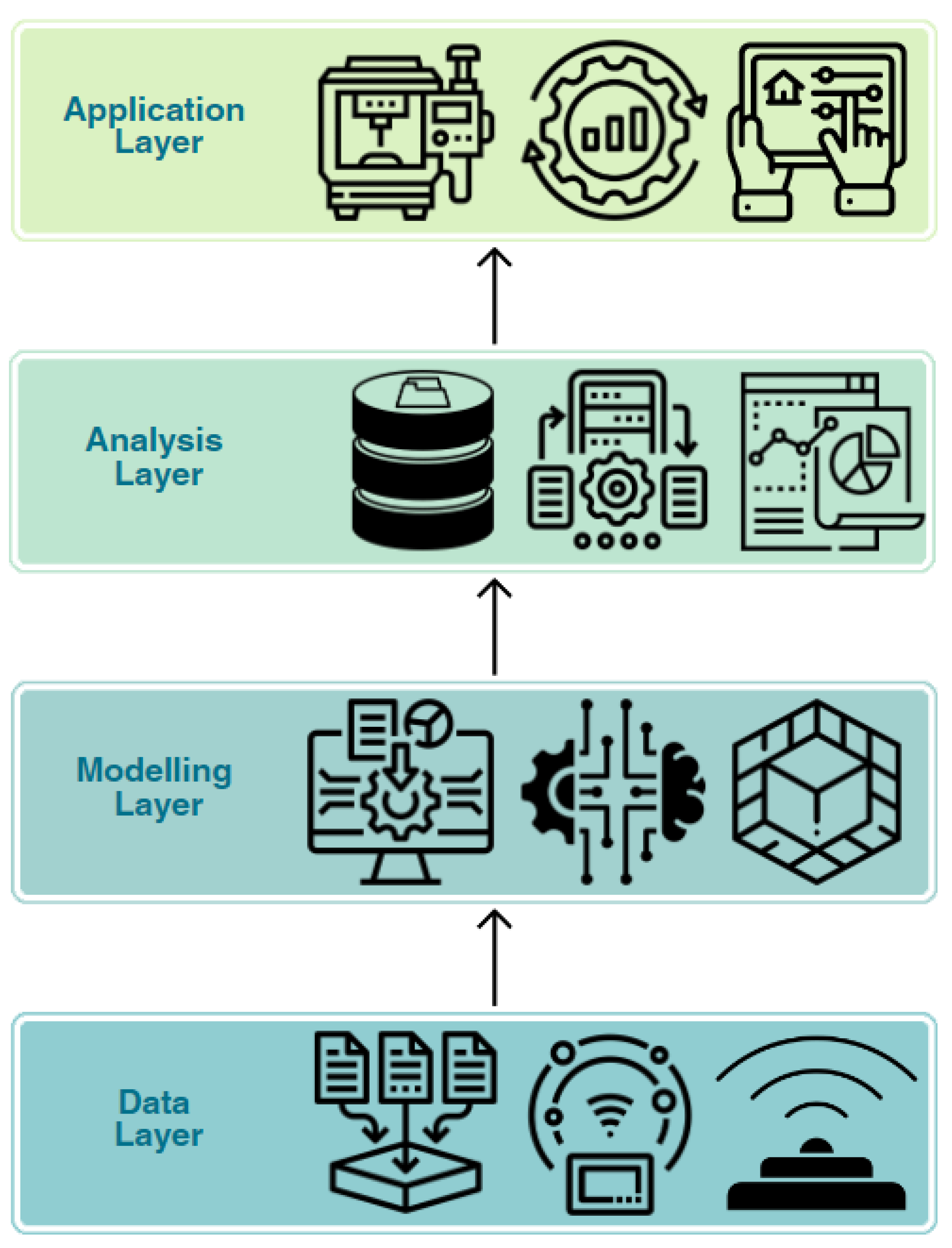

3. Digital Twin Architecture

3.1. Layers of Digital Twin Architecture

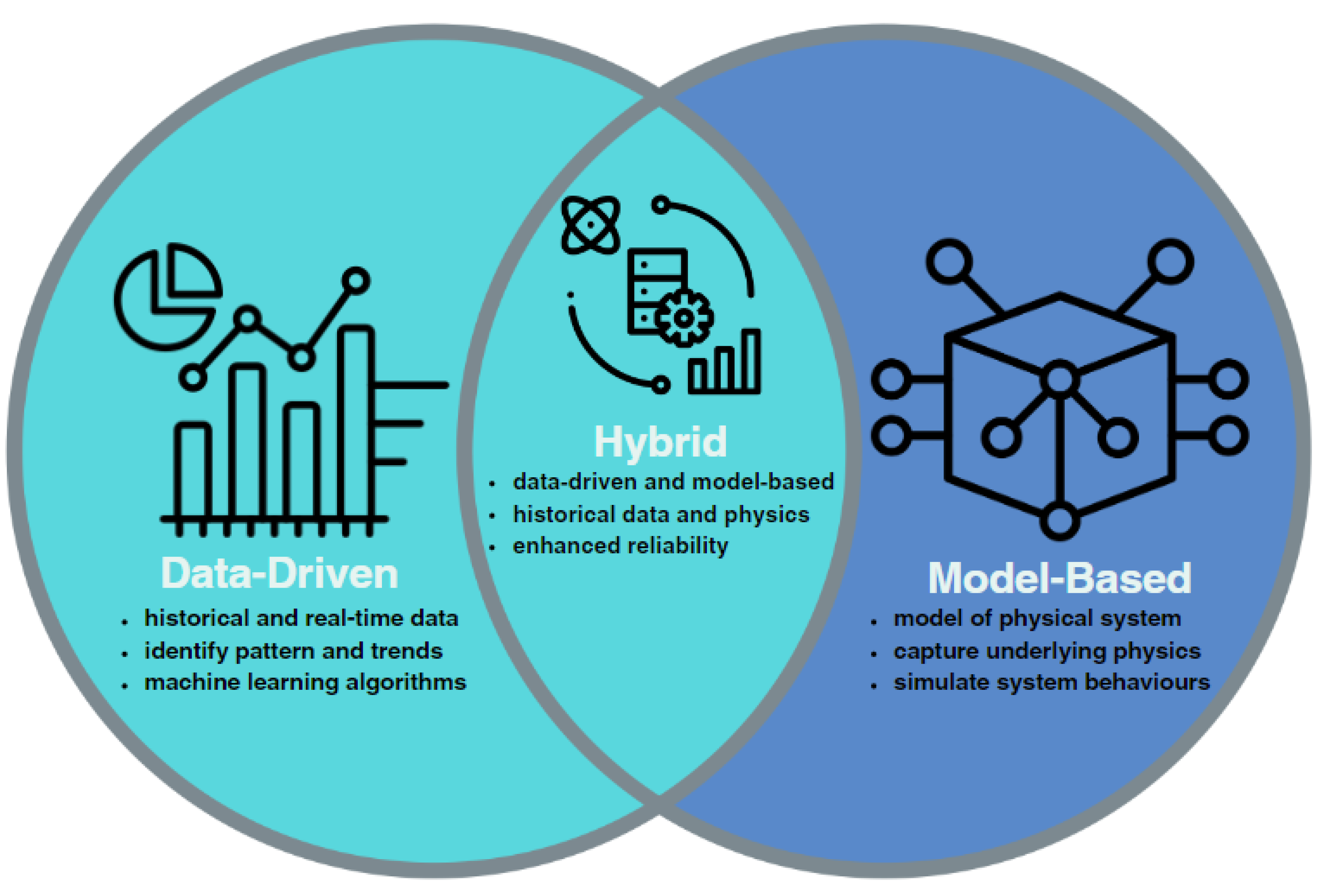

3.2. Digital Twin Prediction Methods

4. Digital Twin in Fault Monitoring

4.1. Equipment-Level Application

| PY | Ref | Industry | Application | Prediction Method |

Proposed Algorithm |

Performance |

|---|---|---|---|---|---|---|

| 2021 | [49] | Manufacturing | Deep Groove Ball Bearing |

Data-Driven | Detail Parameter | r = 0.79, p <0.05 |

| 2021 | [22] | Industrial | Cylindrical Rolling Bearing |

Hybrid | Strict Feedback DT and ML |

Acc: 97.13% |

| 2021 | [18] | Aviation | Turbofan Engine | Hybrid | FOS-based ARMA | %VAF = 99.9% |

| 2022 | [17] | Maritime | Diesel Engine | Data-Driven | Unified Digital System |

%Error = 1.1% |

| 2022 | [57] | Automotive | Battery Packs | Hybrid | OBD Data to Cloud-based DT |

CI = 50% |

4.2. System-Level Application

| PY | Ref | Industry | Application | Prediction Method |

Proposed Algorithm |

Performance |

|---|---|---|---|---|---|---|

| 2021 | [26] | Manufacturing | Assembly Line Robots |

Data-Driven | Structural Intervention |

SHD Score = 9 |

| 2021 | [20] | Energy | Microgrid | Data-Driven | Connected Neural Networks |

Acc: 95% |

| 2021 | [16] | Nuclear | High-Pressure Feedwater System |

Model-Based | Mass Balanced Virtual Sensors |

N/A |

| 2022 | [42] | Energy | Power-Grid Equipment |

Hybrid | N/A | N/A |

| 2022 | [65] | Energy | Smart Building | Model-Based | Prototype Validation |

Small FI Window = 2ms |

5. Conclusions

Conflicts of Interest

Abbreviations

| FM | Fault Monitoring |

| AFMS | Advanced Fault Monitoring Systems |

| DT | Digital Twin |

| IoT | Internet of Things |

| ML | Machine Learning |

| RUL | Remaining Useful Life |

| SPHM | Smart Prognostics and Health Management |

| PHM | Prognostics and Health Management |

| FD | Fault Diagnosis |

| PV | Photovoltaic |

| MEMS | Micro-Electro-Mechanical Systems |

| UDS | Unified Digital System |

| SOC | State of Charge |

| SOH | State of Health |

| OBD | On Board Diagnosis |

| DES | Discrete Event Simulation |

| BN | Bayesian Network |

| SIA | Structural Hamming Distance (SHD) metric |

| ReLU | Rectified Linear Unit |

| PVECU | PV Energy Conversion Unit |

| FI | Fault Identification |

References

- Yang, F.; Cui, Y.; Wu, F.; Zhang, R. Fault monitoring of chemical process based on sliding window wavelet DenoisingGLPP. Processes 2021, 9, 86. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Liu, X.; Ma, T.; Tang, Z. MWRSPCA: Online fault monitoring based on moving window recursive sparse principal component analysis. Journal of Intelligent Manufacturing 2022, pp. 1–17.

- Rodríguez Ramos, A.; Bernal de Lázaro, J.M.; Prieto-Moreno, A.; da Silva Neto, A.J.; Llanes-Santiago, O. An approach to robust fault diagnosis in mechanical systems using computational intelligence. J. Intell. Manuf. 2019, 30, 1601–1615. [Google Scholar] [CrossRef]

- Yang, W.; Zimroz, R.; Papaelias, M. Advances in Machine Condition Monitoring and Fault Diagnosis, 2022.

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Berghout, T.; Benbouzid, M.; Muyeen, S.; Bentrcia, T.; Mouss, L.H. Auto-NAHL: A neural network approach for condition-based maintenance of complex industrial systems. IEEE Access 2021, 9, 152829–152840. [Google Scholar] [CrossRef]

- Sezer, E.; Romero, D.; Guedea, F.; Macchi, M.; Emmanouilidis, C. An industry 4.0-enabled low cost predictive maintenance approach for smes. 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC). IEEE, 2018, pp. 1–8.

- Peng, J.; Xia, G.; Li, Y.; Song, Y.; Hao, M. Knowledge-based prognostics and health management of a pumping system under the linguistic decision-making context. Expert Syst. Appl. 2022, 209, 118379. [Google Scholar] [CrossRef]

- YAMAN, O.; BİÇEN, Y. An Internet of Things (IoT) based monitoring system for oil-immersed transformers. Balk. J. Electr. Comput. Eng. 2019, 7, 226–234. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent manufacturing. Int. J. Prod. Res. 2020, 58, 1034–1051. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. Transdisciplinary perspectives on complex systems: New findings and approaches 2017, pp. 85–113.

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.Y.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- LaGrange, E. Developing a digital twin: The roadmap for oil and gas optimization. SPE Offshore Europe Conference and Exhibition. OnePetro, 2019.

- Sukhorukov, A.; Eroshkin, S.; Vanyurikhin, P.; Karabahciev, S.; Bogdanova, E. Robotization of business processes of enterprises of housing and communal services. E3S Web of Conferences. EDP Sciences, 2019, Vol. 110, p. 02082.

- Jiang, J.; Li, H.; Mao, Z.; Liu, F.; Zhang, J.; Jiang, Z.; Li, H. A digital twin auxiliary approach based on adaptive sparse attention network for diesel engine fault diagnosis. Sci. Rep. 2022, 12. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.N.; Ponciroli, R.; Bruck, P.; Esselman, T.C.; Rigatti, J.A.; Vilim, R.B. A digital twin approach to system-level fault detection and diagnosis for improved equipment health monitoring. Ann. Nucl. Energy 2022, 170. [Google Scholar] [CrossRef]

- Stoumpos, S.; Theotokatos, G. A novel methodology for marine dual fuel engines sensors diagnostics and health management. Int. J. Engine Res. 2022, 23. [Google Scholar] [CrossRef]

- Peng, C.C.; Chen, Y.H. Digital Twins-Based Online Monitoring of TFE-731 Turbofan Engine Using Fast Orthogonal Search. IEEE Syst. J. 2022, 16. [Google Scholar] [CrossRef]

- Lin, L.; Athe, P.; Rouxelin, P.; Avramova, M.; Gupta, A.; Youngblood, R.; Lane, J.; Dinh, N. Digital-twin-based improvements to diagnosis, prognosis, strategy assessment, and discrepancy checking in a nearly autonomous management and control system. Ann. Nucl. Energy 2022, 166. [Google Scholar] [CrossRef]

- Chen, W.; Feng, B.; Tan, Z.; Wu, N.; Song, F. Intelligent fault diagnosis framework of microgrid based on cloud–edge integration. Energy Rep. 2022, 8. [Google Scholar] [CrossRef]

- Lv, Z.; Guo, J.; Lv, H. Safety Poka Yoke in Zero-Defect Manufacturing Based on Digital Twins. IEEE Transactions on Industrial Informatics 2022. [Google Scholar] [CrossRef]

- Piltan, F.; Toma, R.N.; Shon, D.; Im, K.; Choi, H.K.; Yoo, D.S.; Kim, J.M. Strict-Feedback Backstepping Digital Twin and Machine Learning Solution in AE Signals for Bearing Crack Identification. Sensors 2022, 22. [Google Scholar] [CrossRef]

- Giannaros, E.; Kotzakolios, A.; Kostopoulos, V.; Sotiriadis, G.; Vignjevic, R.; Djordjevic, N.; Boccaccio, M.; Meo, M. Low- and high-fidelity modeling of sandwich-structured composite response to bird strike, as tools for a digital-twin-assisted damage diagnosis. Int. J. Impact Eng. 2022, 160. [Google Scholar] [CrossRef]

- Garg, H.; Sharma, B.; Shekhar, S.; Agarwal, R. Spoofing detection system for e-health digital twin using EfficientNet Convolution Neural Network. Multimed. Tools Appl. 2022, 81. [Google Scholar] [CrossRef]

- Sisson, W.; Karve, P.; Mahadevan, S. Digital Twin Approach for Component Health-Informed Rotorcraft Flight Parameter Optimization. AIAA J. 2022, 60. [Google Scholar] [CrossRef]

- Ademujimi, T.; Prabhu, V. Digital Twin for Training Bayesian Networks for Fault Diagnostics of Manufacturing Systems. Sensors 2022, 22. [Google Scholar] [CrossRef]

- Hu, W.; Fang, J.; Liu, F.; Chen, W.; Liu, Z.; Liao, J.; Tan, J. Real-time State Mirror-mapping for Driving and Bolting Integration Equipment Based on Digital Twin. Hunan Daxue Xuebao/Journal Hunan Univ. Nat. Sci. 2022, 49. [Google Scholar] [CrossRef]

- Haas, R.; Pichler, K. Fault diagnosis in a hydraulic circuit using a support vector machine trained by a digital twin. Dynamics and Control of Advanced Structures and Machines: Contributions from the 4th International Workshop, Linz, Austria. Springer, 2022, pp. 47–60.

- Piltan, F.; Kim, J.M. An Adaptive-Backstepping Digital Twin-Based Approach for Bearing Crack Size Identification Using Acoustic Emission Signals. 2022, Vol. 418 LNNS. [CrossRef]

- Zhang, X.; Lv, X.; Wang, Y.; Fan, H. Production process management for intelligent coal mining based on digital twin. In Digital Twin Driven Service; Elsevier, 2022; pp. 251–277.

- Suhail, S.; Hussain, R.; Jurdak, R.; Hong, C.S. Trustworthy Digital Twins in the Industrial Internet of Things With Blockchain. IEEE Internet Comput. 2022, 26. [Google Scholar] [CrossRef]

- Hu, S.; Wang, S.; Su, N.; Li, X.; Zhang, Q. Digital twin based reference architecture for petrochemical monitoring and fault diagnosis. Oil Gas Sci. Technol. 2021, 76. [Google Scholar] [CrossRef]

- Moutis, P.; Alizadeh-Mousavi, O. Digital Twin of Distribution Power Transformer for Real-Time Monitoring of Medium Voltage from Low Voltage Measurements. IEEE Trans. Power Deliv. 2021, 36. [Google Scholar] [CrossRef]

- Seghezzi, E.; Locatelli, M.; Pellegrini, L.; Pattini, G.; Giuda, G.M.D.; Tagliabue, L.C.; Boella, G. Towards an occupancy-oriented digital twin for facility management: Test campaign and sensors assessment. Appl. Sci. (Switzerland) 2021, 11. [Google Scholar] [CrossRef]

- Wei, Y.; Guo, L.; Chen, L.; Zhang, H.; Hu, X.; Zhou, H.; Li, G. Research and implementation of digital twin workshop based on real-time data driven. Jisuanji Jicheng Zhizao Xitong/Computer Integr. Manuf. Syst. CIMS 2021, 27. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, S.; Guo, Z.; Long, X.; Hou, J.; Jin, T. Design of automatic spray monitoring and tele-operation system based on digital twin technology. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2021, 235. [Google Scholar] [CrossRef]

- Sundaram, S.; Zeid, A. Smart prognostics and health management (SPHM) in smart manufacturing: An interoperable framework. Sensors 2021, 21. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Dong, H.; Maschek, U.; Song, H. A digital-twin-assisted fault diagnosis of railway point machine. 2021. [CrossRef]

- Tang, L.; Huang, X.; Zhang, C.; He, X.; Zhu, T.; Gu, L.; Wan, Y. Health assessment and fault diagnosis of substation equipment based on digital twin. 2021, Vol. 2030. [CrossRef]

- Zhao, H.; Hu, W.; Liu, Z.; Tan, J. A capsnet-based fault diagnosis method for a digital twin of a wind turbine gearbox. 2021, Vol. 2021-July. [CrossRef]

- Hu, J.; Hu, N.; Luo, P.; Yang, Y. Fault Diagnosis of Gearbox Based on Digital Twin Concept Model. 2021. [CrossRef]

- Wang, H.; Lin, P.; Hou, Z.; Sun, S. Research on Intelligent Monitoring and Maintenance Technology of Substation Based on Digital Twin. 2021, Vol. 2136. [CrossRef]

- Tan, Y.; Niu, C.; Tian, H.; Zhang, J. A Digital Twin Based Design of the Semi-physical Marine Engine Room Simulator for Remote Maintenance Assistance. 2021. [CrossRef]

- Xing, Y.; Song, X.; Zhang, Z.; Zhang, J.; Song, W.; Liu, B. Intelligent Diagnosis Method of Distribution Network Fault for Construction of Digital Twin Coordination System. 2021. [CrossRef]

- Deebak, B.D.; Al-Turjman, F. Digital-twin assisted: Fault diagnosis using deep transfer learning for machining tool condition. International Journal of Intelligent Systems 2021. [Google Scholar] [CrossRef]

- Xia, M.; Shao, H.; Williams, D.; Lu, S.; Shu, L.; de Silva, C.W. Intelligent fault diagnosis of machinery using digital twin-assisted deep transfer learning. Reliab. Eng. Syst. Saf. 2021, 215. [Google Scholar] [CrossRef]

- Liu, J.; Yu, D.; Hu, Y.; Yu, H.; He, W.; Zhang, L. CNC Machine Tool Fault Diagnosis Integrated Rescheduling Approach Supported by Digital Twin-Driven Interaction and Cooperation Framework. IEEE Access 2021, 9. [Google Scholar] [CrossRef]

- Olatunji, O.O.; Adedeji, P.A.; Madushele, N.; Jen, T.C. Overview of Digital Twin Technology in Wind Turbine Fault Diagnosis and Condition Monitoring. 2021. [CrossRef]

- Zhang, M.; Amaitik, N.; Xu, Y.; Rossini, R.; Bosi, I.; Cedola, A.P. A New Implementation of Digital Twins for Fault Diagnosis of Large Industrial Equipment. J. Robot. Mech. Eng. 2021, 1. [Google Scholar] [CrossRef]

- Lee, J.; Lin, L.; Athe, P.; Dinh, N. Development of the Machine Learning-based Safety Significant Factor Inference Model for Diagnosis in Autonomous Control System. Ann. Nucl. Energy 2021, 162. [Google Scholar] [CrossRef]

- Lopes, T.D.; Raizer, A.; Júnior, W.V. The use of digital twins in finite element for the study of induction motors faults. Sensors 2021, 21. [Google Scholar] [CrossRef]

- Gao, D.; Liu, P.; Jiang, S.; Gao, X.; Wang, K.; Zhao, A.; Xue, Y. Intelligent instrument fault diagnosis and prediction system based on digital twin technology. 2021, Vol. 1983. [CrossRef]

- Classens, K.; Heemels, W.P.; Oomen, T. Digital twins in mechatronics: From model-based control to predictive maintenance. 2021. [CrossRef]

- Zhu, Y.; Qian, Z.; Yuan, S.; Yu, H. Fault Diagnosis of High-Voltage Circuit Breaker Based on Digital Twin. 2021. [CrossRef]

- Zhen, W.; Dunbing, T.; Changchun, L.; Xin, X.; Linqi, Z.; Zhuocheng, Z.; Xuan, L. Augmented-Reality-Assisted Bearing Fault Diagnosis in Intelligent Manufacturing Workshop Using Deep Transfer Learning. 2021. [CrossRef]

- Bhatti, G.; Singh, R.R. Intelligent Fault Diagnosis Mechanism for Industrial Robot Actuators using Digital Twin Technology. 2021. [CrossRef]

- Merkle, L.; Pöthig, M.; Schmid, F. Estimate e-golf battery state using diagnostic data and a digital twin. Batteries 2021, 7. [Google Scholar] [CrossRef]

- Liu, J.; Lu, X.; Zhou, Y.; Cui, J.; Wang, S.; Zhao, Z. Design of Photovoltaic Power Station Intelligent Operation and Maintenance System Based on Digital Twin. 2021. [CrossRef]

- Ren, S.S.; Shen, F.; Zhang, X.Y.; Feng, C.M.; Luo, H.W. Digital Twin of Beam Pumping Unit Control and Analysis. 2021, Vol. 1894. [CrossRef]

- Yu, Q.; Huang, Y.; Liu, Y.; Yu, S.; Wang, S. Research on Application of Information Model in Wind Turbine Fault Diagnosis. 2021. [CrossRef]

- Delong, Z.; Zhijun, Y.; Huipeng, C.; Peng, Z.; Jiliang, L. Research on Digital Twin Model and Visualization of Power Transformer. 2021. [CrossRef]

- Shangguan, D.; Chen, L.; Ding, J. A digital twin-based approach for the fault diagnosis and health monitoring of a complex satellite system. Symmetry 2020, 12. [Google Scholar] [CrossRef]

- Bouzid, S.; Viarouge, P.; Cros, J. Real-time digital twin of a wound rotor induction machine based on finite element method. Energies 2020, 13. [Google Scholar] [CrossRef]

- Panov, V.; Cruz-Manzo, S. Gas turbine performance digital twin for real-time embedded systems. 2020, Vol. 5. 5. [CrossRef]

- Jain, P.; Poon, J.; Singh, J.P.; Spanos, C.; Sanders, S.R.; Panda, S.K. A digital twin approach for fault diagnosis in distributed photovoltaic systems. IEEE Trans. Power Electron. 2020, 35. [Google Scholar] [CrossRef]

- Rossini, R.; Conzon, D.; Prato, G.; Pastrone, C.; Reis, J.; Gonçalves, G. REPLICA: A solution for next generation iot and digital twin based fault diagnosis and predictive maintenance. 2020, Vol. 2739.

- Palchevskyi, B.; Krestyanpol, L. The use of the “digital twin” concept for proactive diagnosis of technological packaging systems. 2020, Vol. 1158. [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient Intell. Humaniz. Comput. 2019, 10. [Google Scholar] [CrossRef]

- Venkatesan, S.; Manickavasagam, K.; Tengenkai, N.; Vijayalakshmi, N. Health monitoring and prognosis of electric vehicle motor using intelligent-digital twin. IET Electr. Power Appl. 2019, 13. [Google Scholar] [CrossRef]

- Brandtstaedter, H.; Ludwig, C.; Hubner, L.; Tsouchnika, E.; Jungiewicz, A.; Wever, U. Digital Twins for Large Electric Drive Trains. 2018, Vol. 2018-June. [CrossRef]

- Zaccaria, V.; Stenfelt, M.; Aslanidou, I.; Kyprianidis, K.G. Fleet monitoring and diagnostics framework based on digital twin of aero-engines. 2018, Vol. 6. 6. [CrossRef]

- Talkhestani, B.A.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An architecture of an intelligent digital twin in a cyber-physical production system. at-Automatisierungstechnik 2019, 67, 762–782. [Google Scholar] [CrossRef]

- Guan, P.; Huang, J.; Anvar, A.; Casey, M.B.; Fisher, C.L.; You, S.; Neumann, U. Multi-view 3D object recognition from a point cloud and change detection, 2017. US Patent 9,619,691. 9,619.

- Răileanu, S.; Borangiu, T.; Ivănescu, N.; Morariu, O.; Anton, F. Integrating the digital twin of a shop floor conveyor in the manufacturing control system. Service Oriented, Holonic and Multi-agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2019 9. Springer, 2020, pp. 134–145.

- Dong, M.; Peng, Y. Equipment PHM using non-stationary segmental hidden semi-Markov model. Robot. Comput.-Integr. Manuf. 2011, 27, 581–590. [Google Scholar] [CrossRef]

- Zhang, H.; Kang, R.; Pecht, M. A hybrid prognostics and health management approach for condition-based maintenance. 2009 IEEE international conference on industrial engineering and engineering management. IEEE, 2009, pp. 1165–1169.

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Adamenko, D.; Kunnen, S.; Pluhnau, R.; Loibl, A.; Nagarajah, A. Review and comparison of the methods of designing the Digital Twin. Procedia CIRP 2020, 91, 27–32. [Google Scholar] [CrossRef]

- Lei, Y.; Jia, F.; Lin, J.; Xing, S.; Ding, S.X. An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data. IEEE Trans. Ind. Electron. 2016, 63, 3137–3147. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S. Analog circuit incipient fault diagnosis method using DBN based features extraction. Ieee Access 2018, 6, 23053–23064. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Zhao, R.; Zhang, L.; Duan, L. Multisensory fusion based virtual tool wear sensing for ubiquitous manufacturing. Robot. Comput.-Integr. Manuf. 2017, 45, 47–58. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Xu, M. Reliability-based maintenance optimization under imperfect predictive maintenance. Chin. J. Mech. Eng. 2012, 25, 160–165. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Gontarz, S.; Lin, J.; Radkowski, S.; Dybala, J. A Model-Based Method for Remaining Useful Life Prediction of Machinery. IEEE Trans. Reliab. 2016, 65, 1314–1326. [Google Scholar] [CrossRef]

- Yu, J.; Liu, P.; Li, Z. Hybrid modelling and digital twin development of a steam turbine control stage for online performance monitoring. Renew. Sustain. Energy Rev. 2020, 133, 110077. [Google Scholar] [CrossRef]

- Biggio, L.; Kastanis, I. Prognostics and health management of industrial assets: Current progress and road ahead. Front. Artif. Intell. 2020, 3, 578613. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).