1. Introduction

Rice (

Oryza sativa L.) is one of the most important cereal crops all over the world and is the staple food for about half the world’s population. Rice is widely grown in over 100 countries. About 90% of the world’s rice is grown and consumed in Asia [

1]. Global warming is the most serious environmental issue, and high temperature stress during the rice ripening periods causes a deterioration in not only grain yield but also quality by generating chalky grains [

2,

3]. Global warming has serious implications for our future life. Mitsui et al. [

4], Asaoka et al. [

5] and Nakata et al. [

6] reported that high-temperature causes the down-regulation of genes for starch synthases and up-regulation of α-amylase genes.

High-temperature ripening of rice grains causes damage of endosperm starch, which leads to the deterioration in eating properties, such as hardness and stickiness of boiled rice grains and pasting properties of rice flours [

7,

8]. In our previous paper, we reported the different properties between the whole grains and chalky grains using 54

Japonica unpolished rice grains damaged severely or lightly by the high-temperature ripening [

9]. It was shown that the α- amylase activity, proteinase activity and n-6/n-3 ratio of polyunsaturated fatty acid [

10,

11] of chalky grains were significantly higher than those of whole rice grains. Furthermore, the chalky rice grains, after boiling, are different from whole grains, not only in the physical properties, but also in the tasty components such as oligo saccharides and amino acids which affect eating quality of boiled rice [

9]. And we developed a novel estimation formula for the damage degree of rice grains ripened under high temperature based on the pasting properties measured by an RVA [

9,

12]. [

The texture of boiled rice grains is affected markedly by the cell-wall of endosperm [

13]. Boiled rice is softened by the decomposition of cell-wall, which suggests the important role of cell-wall degrading enzymes. The softening of the texture by the addition of cellulase [

14] and xylanase [

15] on boiling were reported [

16]. It was shown that the endogenous xylanase and cellulase play important roles to determine the texture of the cooked rice grains similarly with amylose content [

17]. Furthermore, it seems necessary to measure not only the textural properties of the boiled rice but also low-molecular-weight sugars, free amino acids, because they are related with the taste of the boiled rice [

18,

19]. Therefore, it is necessary to compare the texture and tasty substances of the boiled rice for elucidating the difference in palatability between whole grains and chalky grains [

10,

22,

23]. There were few scientific reports about the relationship between high-temperature damage of rice grains and change in proteinase activity, amino acids, fatty acid compositions [

24,

25].

In these days, rice consumers request not only palatable rice but also “healthy rice”, such as brown rice, pigmented rice and pre-germinated brown rice in order to prevent the life-style related diseases by supplying dietary fibers, vitamins, minerals, gamma-amino butylic acid (GABA), etc.

In this study, we tried to elucidate how high-temperature ripening affects the quality deterioration of chalky grains through the cell-wall degrading enzymes, such as cellulase and xylanase. And another aim is the development of the method to improve the physical properties of boiled rice grains from chalky rice grains.

To achieve the purpose, we collected and analyzed 14 Japonica rice samples (original grains), which were divided to two groups (whole grain group and chalky grain one). A novel method was tried to maintain the good texture by inhibiting glycolytic enzymes and cell-wall degrading enzymes during the boiling. We measured contents of sugars and textural properties of boiled rice grains boiled after soaking in 2 types of hard water. Using rice grains of 100% whole grains or those blended with 30 % of chalky grains, we measured contents of sugars and textural properties of boiled rice after soaking in 2 types of hard water.

2.1. Materials

The unpolished rice samples were purchased in 2021 at a local market and were subjected to the measurement in 2022 (Japonica subspecies) (n = 16). These original rice samples were divided manually based on the apparent chalkiness to two groups (whole grain and chalky grain): The ordinary Japonica rice included Kumasannokagayaki (Kumamoto prefecture), Tsukiakari (Iwate), Sasashigure (Miyagi A), Sasashigure (Miyagi B), Hitomebore (Miyagi), Yosakoibijin (Kochi), Morinokumasan (Kumamoto), Yumeshizuku (Saga), and Tsubusuke (Chiba)(n = 9). The high-quality premium Japonica rice included Koshihikari (Niigata A), Koshihikari (Niigata B) and Koshihikari (Hyogo C) (n = 3). High-amylose Japonica-Indica hybrid rice was Koshinomenjiman (Niigata), and indica rice was Koshinokaori (Niigata)(n=2). Low-amylose Japonica rice were Milky queen (Kyoto), and Yumepirika (Hokkaido) (n=2). Each sample was stored at 10 °C in rice storage chamber.

The Evian (hardness: 304 mg/L, pH: 7.2) and Contrex (hardness: 1468 mg/L, pH: 7.2) for cooking with hard water were purchased at a local market in Niigata city.

2.2. Measurement of the Moisture Content of Rice Flour

The moisture content of the polished and unpolished rice flours was measured using an oven-drying method by drying 2 g flour samples for 1 h at 135 °C.

2.3. Preparation of Two Kinds of Unpolished Rice Flours

The whole or chalky unpolished rice grains of 14 rice samples, Kumasannokagayaki (Kumamoto), Tsukiakari (Iwate), Sasashigure (Miyagi A), Hitomebore (Miyagi), Yosakoibijin (Kochi), Morinokumasan (Kumamoto), Yumeshizuku (Saga), Tsubusuke (Chiba), Koshihikari (Niigata A), Koshihikari (Hyogo C), Koshinomenjiman (Niigata), Koshinokaori (Niigata), Milky queen (kyoto), and Yumepirika (Hokkaido), were used as materials for rice flours. These whole or chalky rice grains were pulverized to rice flours using a cyclone mill (SFC-S1; UDY, Corp., Fort Collins, Co, USA).

2.4. Soaking of Polished or Unpolished Rice Flours in 2 Types of Hard Water

Two kinds of rice cultivars, Koshihikari (Hyogo, C) and Tsubusuke (Chiba), were used for polished rice samples, and Koshihikari (Niigata, A) was used for unpolished rice. The whole or chalky rice grains of polished rice were soaked in Evian, Contrex or purified water (treated tap water with a water purifier) at 8 °C for 3 hrs in refrigerator, respectively and the unpolished rice was soaked similarly for 48 hrs. These polished or unpolished rice flours were prepared by pulverizing rice grains after lyophilization (freeze dryer: FD-1, Eyela, Tokyo, Japan). Pulverization was carried out by using a cyclone mill (SFC-S1; UDY, Corp., Fort Collins, Co, USA).

2.5. α-Amylase Activity

α-amylase activity of the whole or chalky grains of unpolished rice flour (n=14), and those of polished rice flours (n=2) and unpolished rice flour (n=1) soaking in Evian, Contrex or purified water were determined by the enzyme assay kit (Megazyme International Ireland, Ltd). For α-amylase activity measurement, rice flour (0.1 g) was extracted with 1.0 mL of extraction buffer, pH 5.4 at 20 °C for 60 min and thereafter centrifuged for 10 min at 1,000× g. Extraction solution (0.1 mL) and substrate (0.1 mL) were preincubated at 40 °C for 5 min. Thereafter, each sample solution was incubated at 40°C for exactly 20 min, followed by the addition of stopping reagent (pH 11.0, 3.0 mL). The absorbance was measured at 400 nm.

2.6. β-Amylase Activity

β- Amylase activity of the whole or chalky grains of unpolished rice flour (n=14), and those of polished rice flours (n=2) and unpolished rice flour (n=1) soaking in Evian, Contrex or purified water were determined by the enzyme assay kit (Megazyme International Ireland, Ltd). For β- amylase activity measurement, rice flour (0.1 g) was extracted with 0.5 mL of extraction buffer, pH 8.0 at 20 °C for 60 min, and thereafter centrifuged for 10 min at 2000g. Extraction solution (0.6 mL; 6-fold dilution) and substrate (0.1 mL) were preincubated at 40 °C for 5 min. Thereafter, each sample solution was incubated at 40 °C for exactly 10 min, followed by the addition of stopping reagent (3.0 mL). The absorbance was measured at 400 nm.

2.7. Protease Activity

Protease activities of the whole or chalky grains of unpolished rice flour (n=14), and those of polished rice flours (n=2) and unpolished rice flour (n=1) soaking in 2 types of hard water or purified water were measured using casein as substrate. For protease activity measurement, rice flour (0.1 g) was soaked in 1.0 mL of extraction buffer (50 mM K3PO4, pH 7.0) at 8 °C for 60 min and thereafter centrifuged for 10 min at 1,000 × g. After that the supernatant of the extraction solution (0.2 mL) and substrate (0.05 mL: 0.65 % (w/v) casein) were preincubated at 37 °C for 5 min. Thereafter, each sample solution was incubated at 37 °C for exactly 10 min, followed by the addition of stopping reagent (110 mM C2HCl3O2, ; Trichloroacetic acid, pH < 1.0) (1.5 mL) and thereafter centrifuged for 1 min at 1,000 × g. After that supernatant of the extraction solution (1 mL) was mixed with 500 mM Na2CO3 (2.5 mL), immediately mixed with 0.5 M Folin-Ciocalteu reagent (0.5 mL). Thereafter, sample solution was incubated at 37 °C for exactly 30 min. The absorbance was measured at 660 nm. Extraction solution (1.0 mL)

2.8. Xylanase Activity

Xylanase activity of the whole or chalky grains of unpolished rice flour (n=14), and those of polished rice flour (n=2) and unpolished rice flour (n=1) soaking in 2 types of hard water and purified water were determined using a kit (Megazyme International Ireland Ltd, Wicklow, Ireland). For xylanase activity measurement, rice flour (0.1 g) was suspended in 0.1 M C2H3NaO2 (pH 4.5) buffer containing BSA (0.5 mg/mL) and NaN3 (0.02 % (w/v)) at room temperature for 15 min, then centrifuged for 10 min at 1000 x g. After that supernatant of the extraction solution (0.05 mL; 2-fold dilution) and substrate solution (0.05 mL) were preincubated at 40 °C for 3 min. Thereafter, each sample solution was incubated at 40 °C for exactly 10 min, followed by the addition of stopping reagent (Tris-HCl buffer 2% (w/v)) (pH10.0) (1.5 mL). The absorbance was measured at 400 nm.

2.9. Cellulase Activity

Cellulase activity of the whole or chalky grains of unpolished rice flour (n=14), and those of polished rice flour (n=2) and unpolished rice flour (n=1) soaking in 2 types of hard water and purified water were determined by a kit (Megazyme International Ireland. Ltd). For cellulase activity measurement, rice flour (0.1 g) was suspended in 0.1 M C2H3NaO2 (pH 4.5) buffer containing BSA (0.5 mg/mL) and NaN3 (0.02 % (w/v)) at room temperature for 15 min, then centrifuged for 10 min at 1000 x g. After that, supernatant of the extraction solution (0.2 mL; 2-fold dilution) and substrate (0.05 mL) were preincubated at 40 °C for 3 min. Thereafter, each sample solution was incubated at 40 °C for exactly 10 min, followed by the addition of stopping reagent (Tris-HCl buffer 2% (w/v)) (pH10.0) (3.0 mL). The absorbance was measured at 400 nm.

2.10. Polishing and Boiling of Rice Samples

We prepared polished rice (milling yield of 90-91%) using an experimental friction-type rice milling machine (Yamamotoseisakusyo Co., Yamagata, Japan). The 10 g of the polished rice grains of blended rice (blending tatio: whole rice grains: chalky rice grains = 7:3) were added to 16 g (1.6 times, w/w) of purified water in an aluminum cup as control samples, and another set of rice grains samples (10 g) were added to 16 g (1.6 times, w/w) of Evian or Contrex [

13]. After soaking for 1 h, the samples were boiled in an electric rice cooker (SR-SW 182 National, Japan). The cooked rice samples were kept in the vessel for 2 h at 25 °C and then used for the measurements [

13]. Used rice samples were used

Kumasannokagayaki (Kumamoto),

Tsukiakari (Iwate),

Sasashigure (Miyagi A),

Sasashigure (Miyagi B),

Hitomebore (Miyagi),

Yosakoibijin (Kochi),

Morinokumasan (Kumamoto),

Yumeshizuku (Saga),

Koshihikari (Niigata A), and

Koshihikari (Niigata B) (n=10).

In contrast, the polished rice grains of 100 % whole or chalky rice grains were boiled similarly [

13]. Used rice samples were used

Koshihikari (Hyogo C) and

Tsubusuke (Chiba).

2.11. Measurements of Textural Properties of Boiled Rice Grains

The physical properties of boiled rice grains were measured based on bulk measurements (10 g) and single-grain measurements (the high-compression/ low-compression method), which included a low compression (compression ratio = 23 %: twice), an intermediate compression (compression ratio = 46 %: twice), and a high compression (compression ratio = 92 %: twice) according to the 2 X 3 bite method for blend rice and a low compression test (compression ratio = 25 %) and a high compression test (compression ratio = 90 %) for 100 % whole and chalky rice using a Tensipresser (My Boy System, Taketomo Electric Co., Tokyo, Japan) according to the method described by Okadome et al [

26]. The bulk measurements were repeated five times, and single-grain measurements were calculated by measuring 20 individual grains. We used the following parameters for the physical properties of the boiled rice grains for bulk measurement: Hardness, Toughness, Adhesion, Stickiness and Cohesiveness [

27]. Cohesiveness: A2/A1 for the ratio of hardness in the low compression, A4/A3 for the ratio of hardness in the intermediate compression, A6/A5 for the ratio of hardness in the high compression, and those of parameters for single-grain measurement: H1 for surface hardness, H2 for overall hardness, S1 for surface stickiness, S2 for overall stickiness, L3 for surface adhesion, S1/H1(balance H1) for the ratio of stickiness to hardness of the surface layer, S2/H2(balance H2) for the ratio of stickiness to hardness of the overall layer, A3/A1(balance A1) for the ratio of adhesiveness to hardness of the surface layer, A6/A4 (balance A2) for the ratio of adhesiveness to hardness of the overall layer.

2.12. Measurement of D-Glucose, Maltose and Saccharose Contents

The cooked rice flour sample was prepared by pulverization after lyophilization.

D-glucose, maltose and saccharose of each sample (0.1 g) were extracted by shaking with 1 mL of 60 % ethanol at room temperature for 1 h, and measured by the Sucrose/ D-Glucose/ D-Fructose contents assay method (F-kit, Roche/ R-Biopharm AG., Darmstadt, Germany).

2.13. Measurement of Color Difference of Boiled Rice after Soaking in 2 Types of Hard Water

The color differences of boiled blended rice (blend rice: whole rice grains: chalky rice grains = 7:3) by soaking in Evian, Contrex or purified water were measured using a Color difference meter (Color Meter NW-11, Nippon Denshoku Co., Tokyo, Japan).

2.14. Analysis of Calcium and Magnesium Contents

The calcium and magnesium of the whole or chalky rice grains of polished or unpolished ones and boiled rice after soaked in 2 types of hard water or purified water of whole grains of polished rice of Koshihikari (Hyogo C) were analyzed by an ICP (Inductively Coupled Plasma) emission spectrometry. The absorbance was measured at 423 nm for calcium, and that of magnesium for 285 nm. Moreover, those of boiled rice of whole or chalky rice of polished rice of Tsubusuke (Chiba) were analyzed similarly. Measurement of the microminerals of rice samples were carried out by the Japan Food Research Laboratories.

2.15. Statistical Analyses

We used Excel Statics (ver. 2006; Microsoft Corp., Tokyo, Japan) for the statistical analysis of the significance of regression coefficients using Student’s t-test, one-way analysis of variance, and Tukey’s test. And the method of Tukey’s multiple comparison was statistically analyzed using Excel NAG Statistics add in 2.0 (The Numerical Algorithms Group Ltd., Tokyo, Japan).

3. Results and Discussion

3.1. Activities of Various Hydrolytic Enzymes in Whole or Chalky Unpolished Rice Grains

In addition to amylose content, the cell wall of rice endosperm also affects the texture of the boiled rice grains. When cellulose of the cell wall is hydrolyzed by cellulase (endo-1,4-beta-D-glucanase), boiled rice grains become softer and stickier. [ 28].

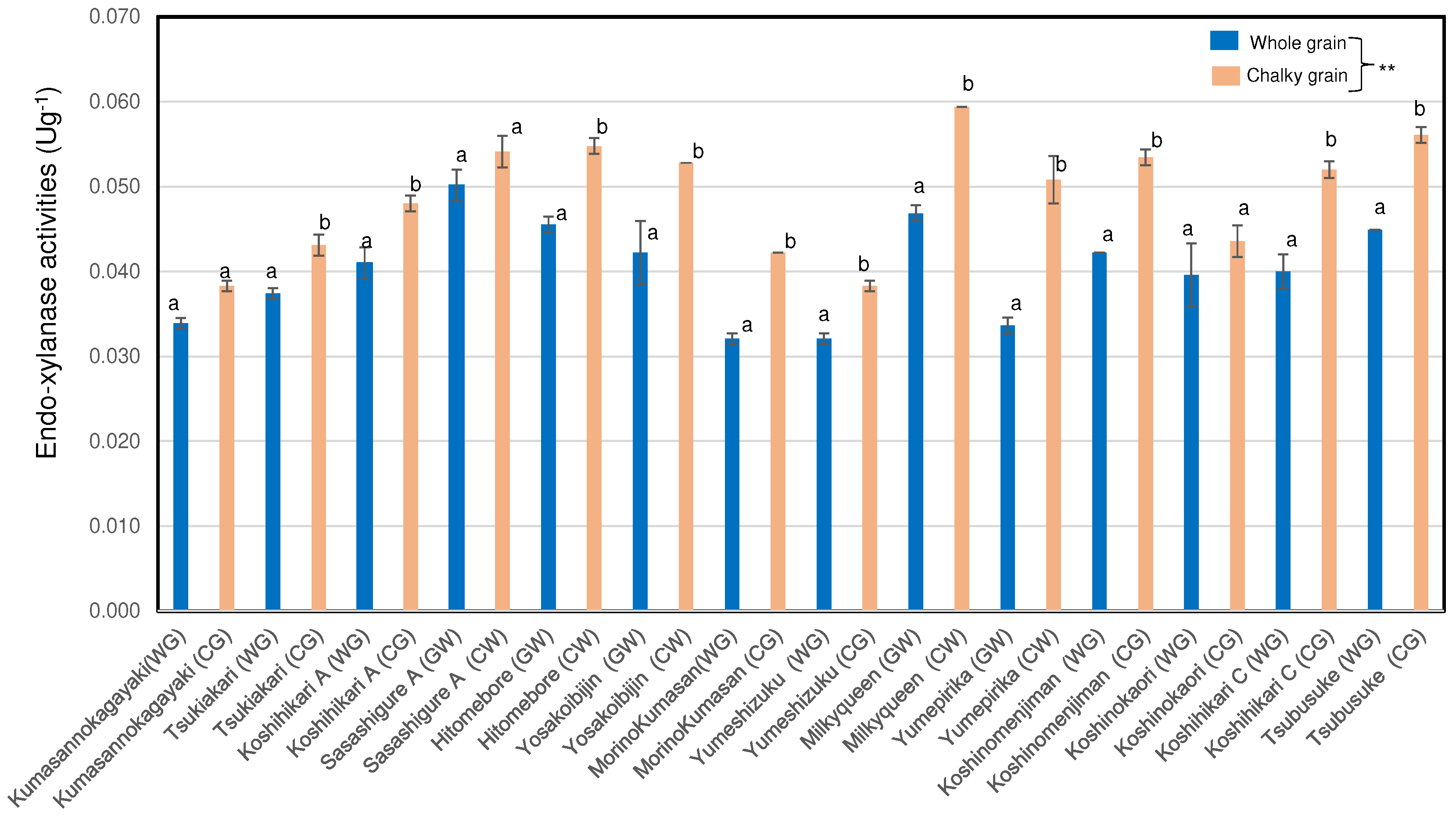

As shown in

Figure 1, the endo-xylanase activities of chalky unpolished rice grains of premium

Japonica rice Koshihikari (n=2), ordinary

Japonica rice (n=6), low-amylose

Japonica rice (n=2) and high-amylose

Japonica-Indica hybrid rice (n=1) were significantly higher than those of whole rice grains. Two samples of ordinary Japonica rice and

Indica rice showed a similar tendency. As a result, whole unpolished rice grains was shown to have significantly lower endo-xylanase activities than chalky unpolished rice grains.

The ratios of endo-xylanase activities of chalky unpolished rice grains to whole unpolished rice grains in low-amylose rice (1.38 ± 0.2) was extraordinary higher than those of premium rice Koshihikari (1.24 ± 0.1) and ordinary Japonica rice cultivars (1.20 ± 0.1). Chalky unpolished rice grains showed markedly higher endo-xylanase activities 1.1-1.5 times than whole unpolished rice grains in 12 Japonica rice in 2021 (data not shown).

Our results showed that endo-xylanase activity of chalky unpolished rice grains are higher than those of whole unpolished rice grains, and it was found that the tendancy is stronger in the low-amylose rice group.

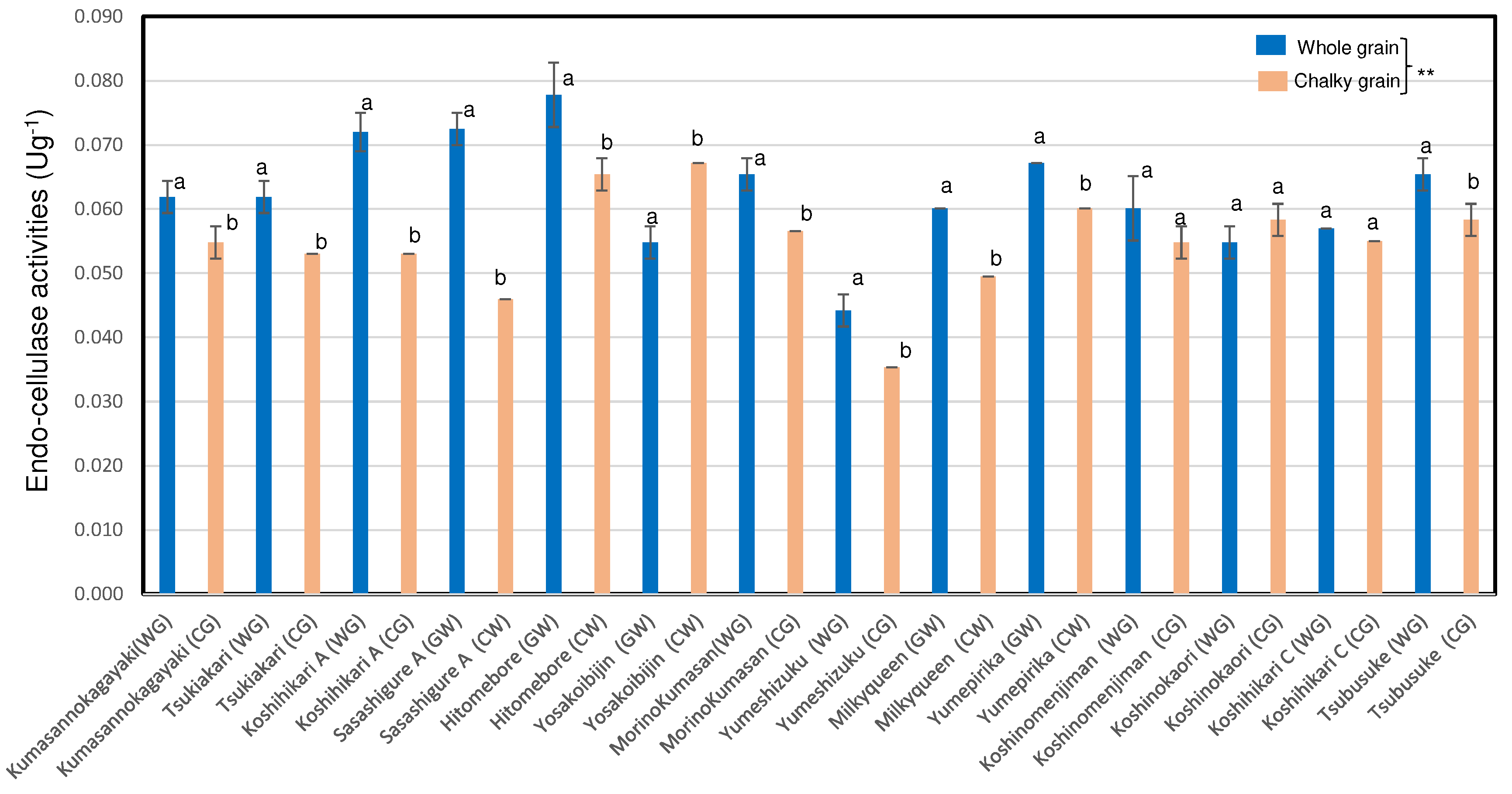

As shown in

Figure 2, the endo-cellulase activities of chalky unpolished rice grains of premium Japonica rice Koshihikari (n=1), ordinary Japonica rice (n=7) and low-amylose Japonica rice (n=2) were significantly lower than those of whole rice grains. The premium Japonica rice Koshihikari (n=1) and Indica rice (n=1) showed a similarly tendency. As a result, whole unpolished rice grains was shown to have significantly higher endo-cellulase activities than chalky unpolished rice grains, which showed an opposite trend with endo-xylanase activities.

Whole unpolished rice grains showed markedly higher endo-cellulase activities 0.8-1.6 time than chalky unpolished rice grains in 12 Japonica rice in 2021 (data not shown).

It seems very interesting that the activities of not only starch-related enzymes but also cell-wall degrading enzymes are changed under the high-temperature ripening of rice grains.

It is well known that rice palatability is affected by varieties or cultivars and variety characteristics are mainly determined by DNA. Tsujii et al. reported that endogenous poly-galacturonase activities showed a positive correlation with pectin contents and negative correlation with hardness of cooked rice [

13]. In our previous paper, xylanase activity showed a positive correlation with amylose content and cellulase activity respectively and negative correlation with adhesion of cooked rice [

17]. Our results shown in

Figure 1 and

Figure 2 are well harmonized with the report about the discriminative DNA markers encoding 1,4-beta-xylanase and endo-1,4-beta-glucanase 13 among the Indica rice, Indica-Japonica hybrid rice, and Javanica rice (tropical Japonica rice) [

17].

Alpha-glucosidase hydrolyzes maltose and soluble starch to glucose, which reported to affect the eating qualities of rice grains [

29]. Iwata et al. reported that alpha-glucosidase activity showed a positive correlation with GBSS activity and amylose content [

30].

As shown in

Table 1, the α-amylase activities of chalky unpolished rice grains of premium Japonica rice Koshihikari (n=1), ordinary Japonica rice (n=7), low-amylose Japonica rice (n=2) and high-amylose Japonica-Indica hybrid rice (n=1) were significantly higher than those of whole rice grains. The premium Japonica rice Koshihikari (n=1) and Indica rice (n=1) showed a similarly tendency. As a result, whole unpolished rice grains was shown to have significantly lower α-amylase activities than chalky unpolished rice grains. Chalky unpolished rice grains showed markedly higher α-amylase activities (1.0-4.3 times) than whole unpolished rice grains in 12 Japonica rice in 2021 (data not shown).

This result is in accordance with that reported by Mitsui et al [

4].

As shown in

Table 1, the β-amylase activities of chalky unpolished rice grains of premium Japonica rice Koshihikari (n=1), ordinary Japonica rice (n=3), low-amylose Japonica rice (n=1), high-amylose Japonica-Indica hybrid rice (n=1) were significantly higher than those of whole rice grains. The premium Japonica rice Koshihikari (n=1), ordinary Japonica rice (n=5), low-amylose Japonica rice (n=1) and Indica rice (n=1) showed a similarly tendency. As a result, whole unpolished rice grains was shown to have lower β-amylase activities than chalky unpolished rice grains.Chalky unpolished rice grains showed markedly higher β-amylase activities 1.0-1.5 times than whole unpolished rice grains in 12 Japonica rice in 2021 (data not shown). This result is in accordance with our previous report [

9,

12].

As shown in

Table 1, protease activities of chalky unpolished grains of ordinary Japonica rice (n=2), low-amylose Japonica rice (n=1), high-amylose Japonica-Indica hybrid rice (n=1) were significantly higher than those of whole rice grains. The others rice samples showed a similarly tendency. As a result, whole unpolished rice grains was shown to have lower protease activities than chalky unpolished rice grains. Chalky unpolished rice grains showed markedly higher protease activities (1.0-1.2 times) than whole unpolished rice grains in 12 Japonica rice in 2021 (data not shown). It was presumed that the neutral protease activities of chalky unpolished grains is higher than whole ones because we used buffer on neutral pH, although both of whole and chalky unpolished grains did not show protease activities in the acidic buffer (pH = 3.0).

Our results are consistent with our previous report that not only α- amylase but also β- amylase and protease activities were higher for chalky rice grains [

9,

31].

Sun et al. reported that

isoamylase is a factor in grain chalkiness using

QTLs studies [

32].

It was reported that the gene expression of gibberellin is closely related with the activation of α-amylase, protease activities and cell-wall degrading enzymes [

33].

Our results may show that the high-temperature ripening has close relationship with the changes in the various enzyme activities affected by the plant hormon, such as gibberellin[

34].

Degradation of cell walls of cereal grains during germination has been studied from the physiological viewpoint [

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37].

3.2. Activities of Various Hydrolytic Enzymes of Rice Grains Soaking in Hard Water

In our previous paper, we reported the different properties between the whole grains and chalky grains. These chalky rice grains are characterized by high α, and

β- amylase activities, high protease activity, and low apparent amylose contents, low degree of hardness and stickiness of boiled rice grains than those of the whole grains [

9]. In this study, we tried to improve the physical properties of boiled rice grains from chalky rice grains by reducing various enzyme activities.

As shown in

Table 2, the α-amylase activities of whole grains soaking in purified water (0.05 ± 0.0 Ug

-1) were significantly higher than those soaking in Evian (hardness: 304 mg/L, Ca: 8.0 mg, Mg: 2.6 mg, pH: 7.2) (0.03 ± 0.0 Ug

-1) and Contrex (hardness: 1468 mg/L, Ca: 46.8 mg, Mg: 7.45 mg, pH: 7.2) (0.04 ± 0.0 Ug

-1), and those of 2 or 4-fold dilution of Evian and Contrex showed a similar tendency to reduce α-amylase activity.

As shown in

Table 2, the

β-amylase activities of whole grains soaking in purified water (0.967 ± 0.0 Ug

-1) were significantly higher than those soaking in Evian (0.630 ± 0.0 Ug

-1), 2 or 4-fold dilution of Evian (0.830 ± 0.0 Ug

-1), (0.543 ± 0.0 Ug

-1), Contrex (0.555 ± 0.0 Ug

-1) and 2 or 4-fold dilution of Contrex (0.612 ± 0.0 Ug

-1), (0.648 ± 0.0 Ug

-1).

As shown in

Table 2, the proteinase activities of whole grains soaking in purified water (0.072 ± 0.0 Ug

-1) were significantly higher than those soaking in Evian (0.065 ± 0.0 Ug

-1), 4-fold dilution of Evian (0.066 ± 0.0 Ug

-1) and 4-fold dilution of Contrex (0.066 ± 0.0 Ug

-1), and those of 2-fold dilution of Evian (0.072 ± 0.0 Ug

-1), Contrex (0.071 ± 0.0 Ug

-1) and 2-fold dilution of Contrex (0.072 ± 0.0 Ug

-1) showed a similar tendency to reduce proteinase activity.

As shown in

Table 2, endo-xylanase activities of whole grains soaking in purified water (0.063 ± 0.0 Ug

-1) were significantly lower than those soaking in Evian (0.077 ± 0.0 Ug

-1), Contrex (0.071 ± 0.0 Ug

-1) and 2 or 4- fold dilution of Contrex (0.074 ± 0.0 Ug

-1), (0.070 ± 0.0 Ug

-1), and those of 2 or 4- fold dilution of Evian (0.064 ± 0.0 Ug

-1), (0.066 ± 0.0 Ug

-1) showed a similar tendency to activate endo-xylanase activity.

As shown in

Table 2, endo-cellulase activities of whole grains soaked in purified water (0.081 ± 0.0 Ug

-1) were significantly lower than those soaking in 2 or 4-fold dilution of Evian (0.138 ± 0.0 Ug

-1), (0.095 ± 0.0 Ug

-1), and 4-fold dilution of Contrex (0.110 ± 0.0 Ug

-1), and those soaked in Evian (0.069 ± 0.0 Ug

-1) were lower than purified water, and those soaked in Contrex (0.083 ± 0.0 Ug

-1) and 2-fold dilution of Contrex (0.078 ± 0.0 Ug

-1) showed a similar tendency with purified water.

As a result, various enzyme activities were inhibited by soaking in hard water with optimal concentration. Activities of various hydrolytic enzymes in polished rice soaked in hard water showed a similar tendency with unpolished rice grains (data not shown).

3.3. Textural Properties of Boiled Rice Grains

In our previous report, boiled rice grains from the chalky grains showed lower hardness, stickiness and higher retrogradation degree after boiling compared with the whole grains [

12].

In the recent Japonica commercial rice market, rice grains contain about 30% of chalky rice are graded as low class of which price is lower than whole rice grains.

In this study, we measured the physical properties of the boiled rice of whole and chalky grains after soaking in Evian, Contrex and purified water of 2 Japonica polished rice by the individual grain method in low compression (25 %) and high compression (90 %) tests using a Tensipresser.

Ogawa et al. [

38] reported that water absorption and swelling of boiled rice adding calcium were inhibited by comparison those in soaking water.

As shown in

Table 3, H1(hardness of surface layer of the boiled rice grains) and H2 (hardness of overall layer) of chalky boiled rice grains were significantly lower than those of whole boiled rice grains, which showed a similarly tendency in our previous report [

9,

12].

As shown in

Table 3, textural properties of chalky grains boiled after soaking in the purified water changes compared with whole grains, such as increasing of hardness and stickiness.

In polished Koshihikari, H2 (hardness of overall layer) and S1(stickiness of surface layer) of chalky boiled rice grains after soaking in Contrex were significantly higher than those of whole rice grains soaking in purified water, and those of S2 (stickiness of overall layer) and L3 (the adhered of surface layer) of chalky boiled rice grains showed a similar tendency.

On the other hand, S1 of chalky boiled rice grains after soaking in Evian were significantly higher than those of whole rice grains soaking in purified water, while those of H2, S2 and L3 of chalky boiled rice grains showed a little lower than those of whole rice grains soaked in purified water.

In polished Tsubusuke, H2 and S1 of chalky boiled rice grains after soaking in Contrex were significantly higher than those of whole rice grains soaking in purified water, and those of S2 of chalky boiled rice grains showed a similar tendency. On the other hand, S1 and S2 of chalky boiled rice grains after soaking in Evian were significantly higher than those of whole rice grains soaking in purified water, and those of L3 of chalky boiled rice grains showed a similar tendency.

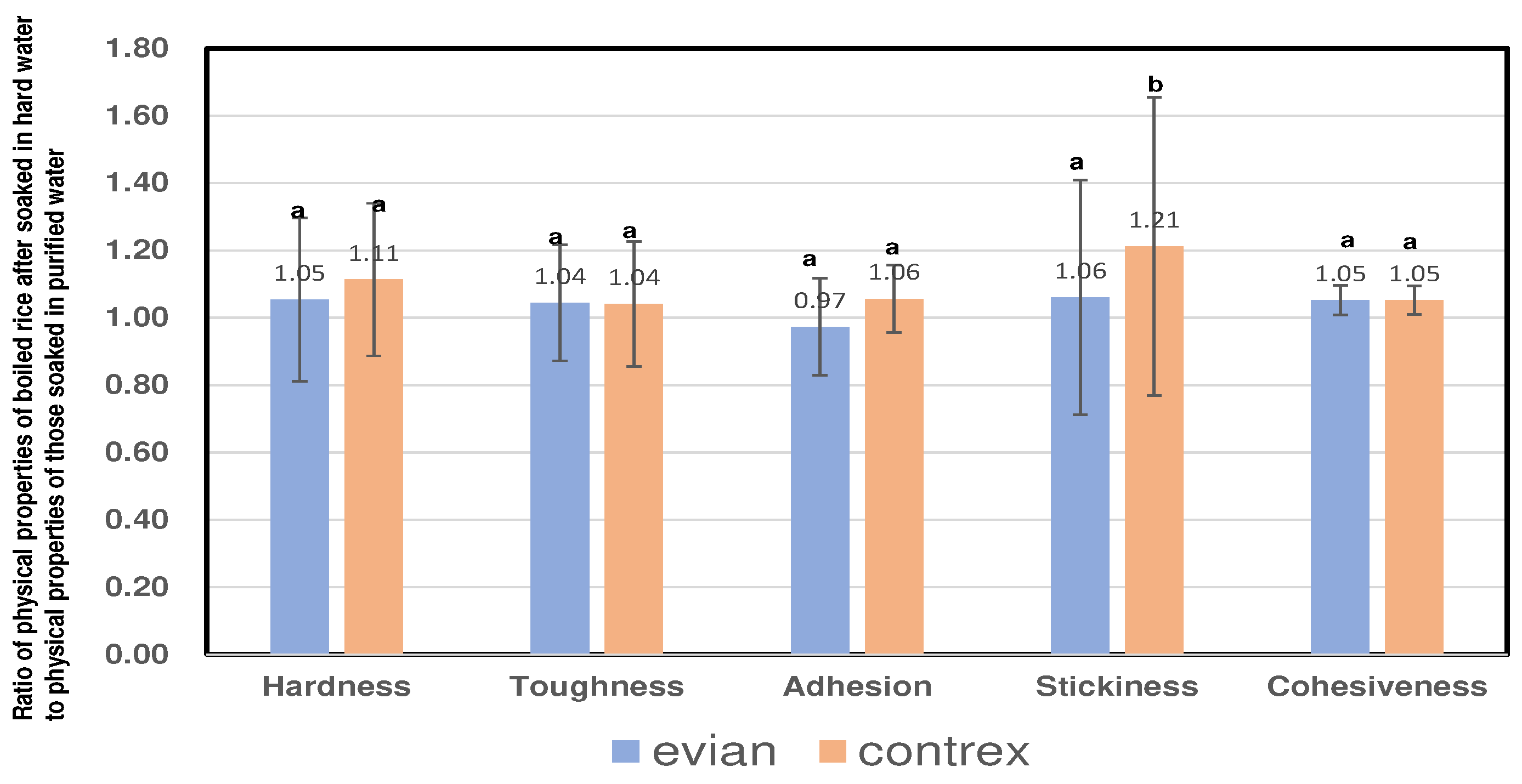

As shown in

Table 4 or

Figure 3, a ratio of hardness of boiled rice of 30 % chalky blended rice after soaking in Evian to hardness of those soaked in purified water was (1.05 ± 0.24) times (n=5). And a ratio of toughness was (1.04 ± 0.17) times (n=6), and a ratio of adhesion was (0.97 ± 0.14) times (n=5), and a ratio of stickiness was (1.06 ± 0.35) times (n=5), and a ratio of cohesiveness was (1.05 ± 0.04) times (n=8), and a ratio of hardness of those soaked in Contrex to hardhess of those soaked in purified water was (1.11 ± 0.23) times (n=5), and a ratio of toughness was (1.04 ± 0.19) times (n=6), and a ratio of adhesion was (1.06 ± 0.10) times (n=7), and a ratio of stickiness was (1.21 ± 0.44) times (n=6) and cohesiveness was (1.05 ± 0.04) times (n=9).

As a result, the various physical properties of boiled rice of 30 % chalky blended rice after soaking in hard water showed a higher values than those of soaking in purified water, and those of physical properties soaking in Contrex were a little higher than those of soaking in Evian.

In the recent commercial market, rice grains containing about 30 % of chalky grains were low grade class and have prices lower than whole rice grains. In our previous report, the hardness and toughness of boiled rice of 30 % chalky blended rice were lower than those of whole boiled rice grains, and those of stickiness and adhesion showed a a similar tendency.

We found that the boiled rice of 30 % chalky grains blended rice after soaking in hard water showed a little higher hardness, toughness, stickiness and cohesiveness than those soaked in pulified water, which means that the physical properties of boiled rice of 30 % chalky blended rice were improved in terms of textural qualities.

3.8. D-Glucose, Maltose and Saccharose Contents in Boiled Rice Grains

Awazuhara et al. [

39] showed that the thermal dependency and stability of enzymes producing reducing sugar were different between outer endosperm and inner endosperm of rice.

As shown in Table 5, D-glucose, maltose and saccharose in chalky boiled rice grains were significantly higher than those in whole boiled rice grains, which was consistent with our previous reports [9, 31].

In Koshihikari, D-glucose and maltose in chalky boiled rice grains after soaking in Evian and Contrex were significantly lower than those in grains soaking in purified water. And those of sugar contents showed a similar with those of whole grains soaking in purified water. And those of saccharose of chalky boiled rice grains after soaking in Evian and Contrex showed a similar tendency.

In Tsubusuke, D-glucose, maltose and saccharose of chalky boiled rice grains after soaking in Evian and Contrex were lower than those of soaking in purified water, and those of sugar contents showed a higher than those of whole grains soaked in purified water.

Shibuya et al. [

28] showed that the isolation of cell walls from different parts of rice grains of a

Japonica variety, their macromolecule composition, and sugar linkages contained in these cell walls. Tsujii et al. [

16] showed that the extent of decomposition of pectin shows negative correlation to the values of hardness of cooked rice.

In two kinds of boiled rice after soaking in Evian, Contrex or purified water, the stickiness of overall layer (S2) of boiled rice showed a positive correlation with D-glucose (r = 0.70,

p <0.05), maltose (r = 0.77,

p <0.01) and saccharose (r = 0.78,

p <0.01), and those of hardness of surface layer (H1) of boiled rice showed a negative correlation with D-glucose (r = - 0.74,

p <0.01), maltose (r = - 0.68,

p <0.05) and saccharose (r = - 0.76,

p <0.01), and the endo-cellulase activities showed a negative correlation with D-glucose (r = - 0.67,

p <0.05), maltose (r = - 0.58,

p <0.05) and saccharose (r = - 0.58,

p <0.05). Furthermore α-amylase activity showed a negative correlation with stickiness of surface layer (S1) (r = - 0.70,

p <0.05) of boiled rice as shown in supplemental

Table 1.

It was shown that rice grains boiled after soaking In Evian and Contrex contained lower amount of glucose due to lower enzyme activity than those of boiled after soaking in purified water.

As shown in

Table 6, D-glucose content of 30 % chalky blended boiled grains after soaking in Evian or Contrex were significantly lower than those of blended rice soaking in purified water (n =10), and those of Maltose or Saccharose showed a similar tendency.

A ratio of D-glucose of the boiled rice of 30 % chalky blended rice after soaking in Evian to D-glucose of those soaking in purified water was (0.82 ± 0.05) times (n=10). And a ratio of Maltose was (0.86 ± 0.08) times (n=8), and a ratio of Saccharose was (0.92 ± 0.04) times (n=10), and those of blended boiled grains after soaked in Contrex showed a similar tendency. As a result, the sugar contents of the boiled rice of 30 % chalky blended rice after soaking in hard water showed a lower than those of the boiled rice of 30 % chalky blended rice soaking in purified water.

In our previous report, the sugar contents of the boiled rice of 30 % chalky blended rice after soaking in pulified water were 1.1 times higher than those of 100 % whole grains rice [

9]. The reason blended boiled rice contain more sugar contents than 100 % whole grains would be due to the higher activities of multiple amylases and lower activities of starch synthesizing enzymes.

In this study, it was shown that the boiled rice of 30 % chalky blended rice after soaking in Evian and Contrex contained lower amount of sugar contents due to lower enzyme activity than those of boiled after soaking in purified water.

3.9. Measurement of Color Difference of Boiled Rice after Soaking in 2 Types of Hard Water

Onishi et al. [

40] showed that cooked rice boiled in hard water is considered to be harder and slightly coloring than boiled in soft water.

As shown in supplemental

Table 2, a ratio of color difference (ΔE*(ab)) of boiled rice of 30 % chalky blended rice after soaked in Evian to color difference of those soaking in purified water was (1.06 ± 0.19) times and those

of a ratio of color difference

of soaked in Contrex w

ere (0.92 ± 0.18) times.

As a result, the color difference of boiled rice of 30 % chalky blended rice after soaking in Evian showed a little higher values than those of soaking in purified water, while those of color differenc soaking in Contrex were a little lower.

In this report, The color difference of boiled rice of 30 % chalky blended rice after soaking in hard water showed a similar tendency with those of boiled rice after soaking in pulified water. Although it is well known that boiled rice of color difference is affected by amino-carbonyl reaction from sugar and amino acids, in our investigation, various enzyme activities were inhibited by soaking in hard water with optimal concentration. The reason why blended rice with 30 % chalky rice boiled after soaking in Evian or and Contrex did not show marked color difference was due to lower sugar contents and amino acids than that of rice boiled after soaking in pulified water. As multiple amylases and proteinase were reduced their activities by the hard water, such as Evian or Contrex, the boiled rice contained less amount of mono-or oligo-sacharides as shown in

Table 4.

3.10. Calcium and Magnesium Contents in Whole and Chalky Polished or Unpolished Rice, and those in Boiled Rice after Soaking In ,

The ash distribution in brown rice is calculated as 51 % in bran, 10 % in germ, 11 % in polish and 28 % in milled rice. And some minerals in calculation has shown that milled rice retains 63 % of the sodium and 74 % of the calcium content of brown rice [

41].

Calcium deficiency is a global problem, especially in the aging population [

42]. A significant relation with bone mineral density and bone fracture was generally found in low calcium intake populations [

43]. To supplement calcium deficiency with boiled rice of staple foods is one of the best ways because many people eat rice almost every day.

As shown in

Table 7, unpolished chalky rice contained about 1.3 times more calcium than unpolished whole rice. Similarly, polished chalky rice contained about 1.3 times more calcium than whole rice in the case of Koshihikari.

As a result, it seems that calcium of chalky unpolished or polished rice grains were significantly higher than those of whole rice grains, and those of magnesium showed a similar tendency. Okuda showed that minerals and protein contents, which in abundance negatively influence sake quality, are distributed more in the outer-layer [

20,

21].

Polished whole rice grains boiled after salking in Evian contained 3.5 times more calcium than those boiled after salking in purified water, and furthermore, those boiled after salking in Contrex contained as much as 16.5 times more than those boiled after salking in purified water in the case of Koshihikari.

In the case of Tsubusuke, chalky polished rice grains boiled after salking in Evian or Contrex contained 2.7 times or 13.5 times more calcium than those boiled after salking in purified water. And whole polished rice grains boiled after salking in Evian or Contrex contained 2.6 times or 13.5 times more calcium than those boiled after salking in purified water.

As shown in

Table 7, in Koshihikari polished rice, magnesium contents of whole or chalky grains showed a similar tendency with Calcium, and Koshihikari polished chalky rice grains showed a little higher magnesium contents than those of whole grains.

Polished whole rice grains boiled after salking in Evian contained 1.3 times more magnesium than those boiled after salking in purified water, and furthermore, those boiled after salking in Contrex contained about 1.8 times more than those boiled after salking in purified water in the case of Koshihikari.

In Tsubusuke polished whole or chalky boiled rice grains, a ratio of magnesium contents in chalky rice boiled after soaking in Evian or Contrex to those boiled after salking in purified water was 1.1 or 1.3. And a ratio of magnesium contents in whole rice boiled after soaking in Evian or Contrex to those in rice boiled after soaking in purified water was 1.1 or 1.6

As a result, it became possible to improve the quality of the chalky rice grains not only at the point of textural properties but also at the point of bio-functionality, in terms of mineral absorption, by boiling in the hard water, such as Evian or Contrex. According to the Dietary Reference Intakes for Japanese (2020) , it is recommended to absorb 650mg of calcium and 370mg of magnesium per day. If people eat 300g of boiled rice soaked in Contrex every day, he or she can take 342mg of calcium and 110mg of magnesium and these figures mean about 53% of calcium and 30% of magnesium necessary per day from only boiled rice.

Figure 1.

End-xylanase activities of whole or chalky rice grains in 14 Japonica unpolished rice samples in 2021. Different letters (a, b) mean that whole and chalky grains in each same rice samples are significantly different. **Correlation is significant at 1 % by the method of Tukey’s multiple comparison.

Figure 1.

End-xylanase activities of whole or chalky rice grains in 14 Japonica unpolished rice samples in 2021. Different letters (a, b) mean that whole and chalky grains in each same rice samples are significantly different. **Correlation is significant at 1 % by the method of Tukey’s multiple comparison.

Figure 2.

Cellulase activities of whole or chalky rice grains in 14 Japonica unpolished rice samples in 2021. Different letters (a, b) mean that whole and chalky grains in each same rice samples are significantly different. **Correlation is significant at 1 % by the method of Tukey’s multiple comparison.

Figure 2.

Cellulase activities of whole or chalky rice grains in 14 Japonica unpolished rice samples in 2021. Different letters (a, b) mean that whole and chalky grains in each same rice samples are significantly different. **Correlation is significant at 1 % by the method of Tukey’s multiple comparison.

Figure 3.

Comparison between the ratio of physical properties of boiled rice after soaking in hard water to physical properties of those soaking in purified water in 10 kinds of boiled rice of 30 % chalky grains blended rice in 2021. Different letters (a, b) mean that ratio of physical properties (Hardhess, Toughness, Adhesion, Stickiness, Cohesiveness) of soaking in hard water (Evian or Contrex) to physical properties of those soaked in purifified water are significantly different.

Figure 3.

Comparison between the ratio of physical properties of boiled rice after soaking in hard water to physical properties of those soaking in purified water in 10 kinds of boiled rice of 30 % chalky grains blended rice in 2021. Different letters (a, b) mean that ratio of physical properties (Hardhess, Toughness, Adhesion, Stickiness, Cohesiveness) of soaking in hard water (Evian or Contrex) to physical properties of those soaked in purifified water are significantly different.

Table 1.

Comparison betweenα,β- amylase activities and proteinase activities of whole and chalky unpolished rice grains in 14 Japonica rice in 2021.

Table 1.

Comparison betweenα,β- amylase activities and proteinase activities of whole and chalky unpolished rice grains in 14 Japonica rice in 2021.

| |

α-Amylase |

β-Amylase |

Proteinase |

| |

(Ug-1) |

(Ug-1) |

(Ug-1) |

| Kumasannokagayaki (Kumamoto)(WG) |

0.036 ± 0.002 a |

0.633 ± 0.017 a |

0.052 ± 0.001 a |

| Kumasannokagayaki (Kumamoto)(CG) |

0.036 ± 0.001 a |

0.681 ± 0.025 a |

0.056 ± 0.002 a |

| Tsukiakari (Iwate) (WG) |

0.021 ± 0.000 a |

0.457 ± 0.030 a |

0.047 ± 0.001 a |

| Tsukiakari (Iwate) (CG) |

0.091 ± 0.003 b |

0.591 ± 0.051 b |

0.055 ± 0.000 b |

| Koshihikari A (Niigata) (WG) |

0.059 ± 0.003 a |

0.519 ± 0.000 a |

0.054 ± 0.000 a |

| Koshihikari A(Niigata) (CG) |

0.070 ± 0.003 b |

0.591 ± 0.034 a |

0.056 ± 0.000 a |

| Sasashigure A (Miyagi) (GW) |

0.068 ± 0.003 a |

0.663 ± 0.017 a |

0.050 ± 0.001 a |

| Sasashigure A (Miyagi) (CW) |

0.116 ± 0.005 b |

0.642 ± 0.004 a |

0.055 ± 0.002 a |

| Hitomebore (Miyagi) (GW) |

0.048 ± 0.007 a |

0.758 ± 0.008 a |

0.048 ± 0.000 a |

| Hitomebore (Miyagi) (CW) |

0.161 ± 0.003 b |

0.982 ± 0.030 b |

0.050 ± 0.001 a |

| Yosakoibijin (Kochi) (GW) |

0.035 ± 0.000 a |

0.696 ± 0.046 a |

0.044 ± 0.002 a |

| Yosakoibijin (Kochi) (CW) |

0.047 ± 0.003 b |

0.707 ± 0.038 a |

0.049 ± 0.000 a |

| MorinoKumasan (Kumamoto)(WG) |

0.035 ± 0.001 a |

0.534 ± 0.013 a |

0.053 ± 0.000 a |

| MorinoKumasan (Kumamoto)(CG) |

0.063 ± 0.003 b |

0.537 ± 0.008 a |

0.056 ± 0.000 a |

| Yumeshizuku (Saga) (WG) |

0.026 ± 0.003 a |

0.555 ± 0.017 a |

0.049 ± 0.000 a |

| Yumeshizuku (Saga) (CG) |

0.078 ± 0,002 b |

0.752 ± 0.008 b |

0.056 ± 0.001 b |

| Milkyqueen (Kyoto) (GW) |

0.048 ± 0.008 a |

0.898 ± 0.013 a |

0.044 ± 0.000 a |

| Milkyqueen (Kyoto) (CW) |

0.062 ± 0.002 b |

0.985 ± 0.008 b |

0.053 ± 0.001 b |

| Yumepirika (Hokkaido) (GW) |

0.050 ± 0.001 a |

0.791 ± 0.021 a |

0.045 ± 0.001 a |

| Yumepirika (Hokkaido) (CW) |

0.093 ± 0.006 b |

0.854 ± 0.093 a |

0.052 ± 0.003 a |

| Koshinomenjiman (Niigata) (WG) |

0.050 ± 0.001 a |

0.385 ± 0.030 a |

0.043 ± 0.000 a |

| Koshinomenjiman (Niigata) (CG) |

0.084 ± 0.002 b |

0.561 ± 0.076 b |

0.051 ± 0.000 b |

| Koshinokaori (Niigata) (WG) |

0.032 ± 0.005 a |

0.439 ± 0.038 a |

0.044 ± 0.001 a |

| Koshinokaori (Niigata) (CG) |

0.041 ± 0.001 a |

0.466 ± 0.034 a |

0.048 ± 0.002 a |

| Koshihikari C (Hyogo) (WG) |

0.046 ± 0.000 a |

0.687 ± 0.076 a |

0.041 ± 0.000 a |

| Koshihikari C (Hyogo) (CG) |

0.052 ± 0.003 a |

0.839 ± 0.055 b |

0.043 ± 0.000 a |

| Tsubusuke (Chiba) (WG) |

0.058 ± 0.003 a |

0.618 ± 0.013 a |

0.049 ± 0.001 a |

| Tsubusuke (Chiba) (CG) |

0.081 ± 0.002 b |

0.678 ± 0.021 a |

0.054 ± 0.000 a |

Table 2.

α,and -βAmylase activities, proteinase activities and cell-wall degrading enzymes activities of unpolished rice soaking in Evian, Contrex or purified water.

Table 2.

α,and -βAmylase activities, proteinase activities and cell-wall degrading enzymes activities of unpolished rice soaking in Evian, Contrex or purified water.

| Unpolished rice |

α-Amylase |

β-Amylase |

Proteinase |

endo-Xylanase |

endo-Cellulase |

| (Ug-1) |

(Ug-1) |

(Ug-1) |

(Ug-1) |

(Ug-1) |

| Koshihikari B (purified water) |

0.050 ± 0.000 a |

0.967 ± 0.034 a |

0.072 ± 0.001 a |

0.063 ± 0.000 a |

0.081 ± 0.000 a |

| Koshihikari B (evian) |

0.029 ± 0.003 b |

0.630 ± 0.004 b |

0.065 ± 0.000 b |

0.077 ± 0.002 b |

0.069 ± 0.008 b |

|

Koshihikari B (1/2 dilution evian)

|

0.059 ± 0.005 a |

0.830 ± 0.008 c |

0.072 ± 0.000 a |

0.064 ± 0.002 a |

0.138 ± 0.000 c |

|

Koshihikari B (1/4 dilution evian)

|

0.052 ± 0.003 a |

0.543 ± 0.008 d |

0.066 ± 0.001 b |

0.066 ± 0.000 a |

0.095 ± 0.010 d |

| Koshihikari B (purified water) |

0.050 ± 0.000 a |

0.967 ± 0.034 a |

0.072 ± 0.001 a |

0.063 ± 0.000 a |

0.081 ± 0.000 a |

| Koshihikari B (contrex) |

0.039 ± 0.003 b |

0.555 ± 0.025 b |

0.071 ± 0.001 a |

0.071 ± 0.004 b |

0.083 ± 0.003 a |

|

Koshihikari B (1/2 dilution contrex)

|

0.050 ± 0.000 a |

0.612 ± 0.004 c |

0.072 ± 0.000 a |

0.074 ± 0.000 b |

0.078 ± 0.005 a |

|

Koshihikari B (1/4 dilution contrex)

|

0.055 ± 0.000 a |

0.648 ± 0.004 c |

0.066 ± 0.001 b |

0.070 ± 0.002 b |

0.110 ± 0.005 b |

Table 3.

Physical properties of boiled rice of chalky rice after soaked in Evian, Contrex and purified water and those whole rice grains soaked in purified water in 2 kinds of Japonica rice in 2021.

Table 3.

Physical properties of boiled rice of chalky rice after soaked in Evian, Contrex and purified water and those whole rice grains soaked in purified water in 2 kinds of Japonica rice in 2021.

| |

Surface |

Overall |

Surface |

Overall |

Surface |

| layer |

|

layer |

|

layer |

| Hardness |

Hardness |

Stickiness |

Stickiness |

Adhered |

| (H 1) |

(H 2) |

(S 1) |

(S 2) |

(L 3) |

| 105(N/cm2) |

105(N/cm2) |

105(N/cm2) |

105(N/cm2) |

[mm] |

| Koshihikari C (WG) (pulified water) |

67.8 ± 16.7 a |

1731.7 ± 190.0 a |

7.9 ± 4.8 a |

307.3 ± 50.0 a |

2.8 ± 0.7 a |

| Koshihikari C (CG) (purified water) |

60.4 ± 16.6 b |

1722.8 ± 144.6 a |

11.2 ± 3.9 b |

351.1 ± 35.8 b |

2.6 ± 0.7 a |

| Koshihikari C(CG) (Evian) |

51.9 ± 11.4 c |

1714.0 ± 167.4 a |

9.7 ± 3.7 c |

305.2 ± 42.5 a |

2.7 ± 0.7 a |

| Koshihikari C (CG) (Contrex) |

53.2 ± 13.5 c |

1784.6 ± 169.5 b |

9.2 ± 3.8 c |

313.2 ± 49.9 a |

2.9 ± 0.5 b |

| Tsubusuke (WG) (pulified water) |

79.8 ± 19.7 a |

1839.5 ± 165.2 a |

5.8 ± 3.3 a |

293.1 ± 62.2 a |

2.6 ± 0.9 a |

| Tsubusuke (CG) (pulified water) |

45.0 ± 14.3 b |

1590.5 ± 193.3 b |

5.9 ± 2.8 a |

303.9 ± 55.6 a |

2.8 ± 0.6 a |

| Tsubusuke (CG) (Evian) |

51.1 ± 16.2 b |

1698.3 ± 183.8 b |

7.1 ± 3.3 b |

318.7 ± 53.9 b |

2.7 ± 0.8 a |

| Tsubusuke (CG) (Contrex) |

73.9 ± 22.3 a |

1716.0 ± 305.2 b |

8.5 ± 5.5 c |

302.5 ± 42.2 a |

2.4 ± 0.9 a |

Table 4.

Physical properties of boiled rice of 30 % chalky grains blended after soaking in Evian, Contrex and purified water in 10 kinds of Japonica rice in 2021.

Table 4.

Physical properties of boiled rice of 30 % chalky grains blended after soaking in Evian, Contrex and purified water in 10 kinds of Japonica rice in 2021.

| |

Hardness |

Toughness |

Adhesion |

Stickiness |

Cohesiveness |

| ×105(N/cm2) |

×105(N/cm2) |

×105(N/cm2) |

×105(N/cm2) |

(A6/A5) |

| Kumasannokagayaki (purified water) |

0.86 ± 0.05 a |

17.12 ± 0.53 a |

12.41 ± 0.49 a |

12.24 ± 1.33 a |

0.38 ± 0.01 a |

| Kumasannokagayaki (Evian) |

1.15 ± 0.17 b |

17.96 ± 0.46 a |

12.67 ± 2.35 a |

17.79 ± 5.89 a |

0.38 ± 0.02 a |

| Kumasannokagayaki (Contrex) |

1.38 ± 0.05 b |

18.33 ± 0.87 a |

14.40 ± 1.16 b |

26.70 ± 079 b |

0.38 ± 0.00 a |

| Tsukiakari (purified water) |

1.63 ± 0.03 a |

18.03 ± 0.71 a |

12.44 ± 2.02 a |

17.94 ± 1.78 a |

0.38 ± 0.02 a |

| Tsukiakari (Evian) |

1.23 ± 0.18 b |

19.96 ± 0.80a |

12.64 ± 1.20 a |

19.13 ± 4.21 a |

0.41 ± 0.01 a |

| Tsukiakari (Contrex) |

1.56 ± 0.37 a |

19.22 ± 2.47 a |

13.48 ± 0.00 b |

17.55 ± 1.00 a |

0.40 ± 0.00 a |

| Koshihikari A (purified water) |

1.14 ± 0.19 a |

16.16 ± 0.41 a |

14.51 ± 0.29 a |

25.66 ± 1.34 a |

0.38 ± 0.00 a |

| Koshihikari A (Evian) |

1.67 ± 0.19 b |

17.22 ± 2.56 a |

12.33 ± 1.12 a |

19.74 ± 4.50 b |

0.41 ± 0.04 a |

| Koshihikari A (Contrex) |

1.29 ± 0.09 a |

16.89 ± 1.06 a |

14.16 ± 1.05 a |

25.95 ± 4.67 a |

0.41 ± 0.05 a |

| Sasashigure A (purified water) |

1.36 ± 0.13 a |

13.32 ± 0.74 a |

12.83 ± 1.49 a |

22.05 ± 5.50 a |

0.41 ± 0.05 a |

| Sasashigure A (Evian) |

1.28 ± 0.46 a |

19.35 ± 1.47 b |

13.52 ± 2.37 a |

24.23 ± 1.52 a |

0.42 ± 0.02 a |

| Sasashigure A (Contrex) |

1.70 ± 0.11 b |

19.72 ± 1.63 b |

15.30 ± 1.66 b |

31.40 ± 3.19 b |

0.42 ± 0.01 a |

| Hitomebore (purified water) |

1.59 ± 0.25 a |

19.92 ± 2.29 a |

15.02 ± 0.28 a |

22.91 ± 0.63 a |

0.37 ± 0.03 a |

| Hitomebore (Evian) |

1.23 ± 0.07 b |

17.55 ± 1.25 b |

12.78 ± 0.19 b |

14.80 ± 0.68 b |

0.38 ± 0.00 a |

| Hitomebore (Contrex) |

1.54 ± 0.06 a |

17.88 ± 1.79 b |

13.35 ± 0.45 b |

24.13 ± 6.77 a |

0.41 ± 0.02 a |

| Yosakoibijin (purified water) |

1.28 ± 0.10 a |

22.07 ± 2.55 a |

10.65 ± 0.14 a |

16.04 ± 5.47 a |

0.39 ± 0.05 a |

| Yosakoibijin (Evian) |

1.40 ± 0.42 a |

20.11 ± 3.03 a |

13.87 ± 1.56 a |

21.20 ± 0.16 a |

0.42 ± 0.04 a |

| Yosakoibijin (Contrex) |

1.27 ± 0.46 a |

18.17 ± 2.55 b |

11.21 ± 0.84 a |

18.97 ± 4.47 a |

0.40 ± 0.04 a |

| Koshihikari B (purified water) |

1.66 ± 0.27 a |

21.43 ± 0.29 a |

12.80 ± 1.10 a |

30.99 ± 0.74 a |

0.39 ± 0.05 a |

| Koshihikari B (Evian) |

1.38 ± 0.11 a |

18.65 ± 0.47 b |

12.33 ± 1.96 a |

23.93 ± 0.15 b |

0.42 ± 0.04 a |

| Koshihikari B (Contrex) |

1.42 ± 0.22 a |

18.69 ± 1.04 b |

15.18 ± 0.96 b |

22.87 ± 6.17 b |

0.40 ± 0.04 a |

| Sasashigure B (purified water) |

1.46 ± 0.40 a |

19.56 ± 1.07 a |

11.09 ± 0.26 a |

17.89 ± 0.84 a |

0.39 ± 0.03 a |

| Sasashigure B (Evian) |

1.45 ± 0.21 a |

22.26 ± 0.92 b |

11.01 ±0.07 a |

17.66 ± 0.24 a |

0.40 ± 0.04 a |

| Sasashigure B (Contrex) |

1.88 ± 0.01 b |

22.76 ± 0.82 b |

11.61 ± 0.31 a |

16.70 ± 4.54 a |

0.41 ± 0.01 a |

| Morinokumasan (purified water) |

0.92 ± 0.00 a |

17.84 ± 0.11 a |

14.68 ± 0.33 a |

28.51 ± 3.76 a |

0.40 ± 0.00 a |

| Morinokumasan (Evian) |

1.16 ± 0.34 a |

18.49 ± 2.41 b |

12.86 ± 0.52 a |

21.81 ± 2.96 b |

0.40 ± 0.02 a |

| Morinokumasan (Contrex) |

1.08 ± 0.16 a |

17.80 ± 1.67 a |

14.38 ± 0.83 a |

25.61 ± 1.72 b |

0.41 ± 0.00 a |

| Yumeshizuku (purified water) |

1.35 ± 0.25 a |

18.90 ± 1.40 a |

15.12 ± 1.85 a |

18.48 ± 5.02 a |

0.37 ± 0.05 a |

| Yumeshizuku (Evian) |

1.47 ± 0.21 a |

17.68 ± 1.14 a |

12.20 ± 1.87 b |

31.78 ± 2.58 b |

0.42 ± 0.01 b |

| Yumeshizuku (Contrex) |

1.23 ± 0.01 b |

18.69 ± 1.85 a |

15.14 ± 0.83 a |

31.86 ± 0.85 b |

0.42 ± 0.04 b |

Table 5.

Oligo saccharides in boiled whole rice grains after soaking in purified water and those in boiled chalky rice grains soaking in purified water or 2 kinds of hard water.

Table 5.

Oligo saccharides in boiled whole rice grains after soaking in purified water and those in boiled chalky rice grains soaking in purified water or 2 kinds of hard water.

| |

D-glucose cntent |

Maltose content |

Saccharose content |

| |

(g/100g) |

(g/100g) |

(g/100g) |

| Koshihikari C (WG) (purified water) |

0.068 ± 0.002 a |

0.096 ± 0.003 a |

0.322 ± 0.006 a |

| Koshihikari C (CG) (purified water) |

0.079 ± 0.001 b |

0.119 ± 0.007 b |

0.417 ± 0.009 b |

| Koshihikari C (CG) (Evian) |

0.067 ± 0.002 a |

0.100 ± 0.001 a |

0.387 ± 0.012 c |

| Koshihikari C (CG) (Contrex) |

0.070 ± 0.001 a |

0.108 ± 0.006 a |

0.380 ± 0.006 c |

| Tsubusuke (WG) (purified water) |

0.041 ± 0.000 a |

0.080 ± 0.003 a |

0.266 ± 0.007 a |

| Tsubusuke (CG) (purified water) |

0.077 ± 0.002 b |

0.110 ± 0.006 b |

0.362 ± 0.013 b |

| Tsubusuke (CG) (Evian) |

0.065 ± 0.001 c |

0.095 ± 0.002 c |

0.351 ± 0.012 b |

| Tsubusuke (CG) (Contrex) |

0.067 ± 0.002 c |

0.105 ± 0.003 b |

0.344 ± 0.008 c |

Table 6.

Oligo saccharides of boiled rice of 30 % chalky blended rice after soaking in Evian, Contrex and purified water in 10 kinds of Japonica rice in 2021.

Table 6.

Oligo saccharides of boiled rice of 30 % chalky blended rice after soaking in Evian, Contrex and purified water in 10 kinds of Japonica rice in 2021.

| |

D-glucose content |

Maltose content |

Saccharose content |

| |

(g/100g) |

(g/100g) |

(g/100g) |

| Kumasannokagayaki (purified water) |

0.065 ± 0.004a |

0.095 ± 0.002 a |

0.313 ± 0.008 a |

| Kumasannokagayaki (evian) |

0.058 ± 0.001b |

0.091 ± 0.001 a |

0.299 ± 0.001 a |

| Kumasannokagayaki (contrex) |

0.055 ± 0.002b |

0.087 ± 0.002 a |

0.299 ± 0.000 a |

| Tsukiakari (purified water) |

0.078 ± 0.002a |

0.134 ± 0.001 a |

0.302 ± 0.002 a |

| Tsukiakari (evian) |

0.057 ± 0.002b |

0.090 ± 0.000 b |

0.260 ± 0.006 b |

| Tsukiakari (contrex) |

0.055 ± 0.002b |

0.088 ± 0.007 b |

0.254 ± 0.007 b |

| Koshihikari A (purified water) |

0.074 ± 0.001a |

0.100 ± 0.000 a |

0.345 ± 0.000 a |

| Koshihikari A (evian) |

0.058 ± 0.002b |

0.089 ± 0.000 b |

0.311 ± 0.006 b |

| Koshihikari A (contrex) |

0.057 ± 0.001b |

0.089 ± 0.001 b |

0.306 ± 0.008 b |

| Sasashigure A (purified water) |

0.077 ± 0.002a |

0.097 ± 0.000 a |

0.331 ± 0.009 a |

| Sasashigure A (evian) |

0.063 ± 0.002b |

0.087 ± 0.001 b |

0.313 ± 0.006 a |

| Sasashigure A (contrex) |

0.066 ± 0.002b |

0.091 ± 0.002 a |

0.322 ± 0.009 a |

| Hitomebore (purified water) |

0.062 ± 0.001a |

0.088 ± 0.001 a |

0.281 ± 0.008 a |

| Hitomebore (evian) |

0.050 ± 0.001b |

0.073 ± 0.003 b |

0.259 ± 0.007 a |

| Hitomebore (contrex) |

0.046 ± 0.001b |

0.072 ± 0.002 b |

0.252 ± 0.006 a |

| Yosakoibijin (purified water) |

0.060 ± 0.001a |

0.115 ± 0.003 a |

0.514 ± 0.007 a |

| Yosakoibijin (evian) |

0.051 ± 0.001b |

0.107 ± 0.001 a |

0.492 ± 0.002 a |

| Yosakoibijin (contrex) |

0.055 ± 0.001b |

0.112 ± 0.001 a |

0.500 ± 0.005 a |

| Koshihikari B (purified water) |

0.070 ± 0.001a |

0.092 ± 0.001 a |

0.295 ± 0.001 a |

| Koshihikari B (evian) |

0.061 ± 0.001b |

0.083 ± 0.001 b |

0.280 ± 0.003 a |

| Koshihikari B (contrex) |

0.063 ± 0.001b |

0.082 ± 0.001 b |

0.277 ± 0.001 a |

| Sasashigure B (purified water) |

0.062 ± 0.000a |

0.085 ± 0.000 a |

0.295 ± 0.000 a |

| Sasashigure B (evian) |

0.051 ± 0.000b |

0.073 ± 0.003 b |

0.270 ± 0.001 a |

| Sasashigure B (contrex) |

0.054 ± 0.002b |

0.073 ± 0.001 b |

0.277 ± 0.001 a |

| Morinokumasan (purified water) |

0.075 ± 0.000a |

0.113 ± 0.003 a |

0.411 ± 0.001 a |

| Morinokumasan (evian) |

0.063 ± 0.001b |

0.099 ± 0.003 a |

0.378 ± 0.003 a |

| Morinokumasan (contrex) |

0.066 ± 0.000b |

0.104 ± 0.001 a |

0.385 ± 0.001 a |

| Yumeshizuku (purified water) |

0.074 ± 0.000a |

0.098 ± 0.001 a |

0.318 ± 0.002 a |

| Yumeshizuku (evian) |

0.057 ± 0.001b |

0.079 ± 0.001 b |

0.275 ± 0.001 b |

| Yumeshizuku (contrex) |

0.060 ± 0.000b |

0.084 ± 0.001 b |

0.285 ± 0.001 b |

Table 7.

Calciuum and Magnesium contents of whole and chalky of unpolished rice, and those of polishued rice, and those of polished rice of boiled rice after soaking in Evian, Contrex and purified water in 2 kinds of Japonica rice in 2021.

Table 7.

Calciuum and Magnesium contents of whole and chalky of unpolished rice, and those of polishued rice, and those of polished rice of boiled rice after soaking in Evian, Contrex and purified water in 2 kinds of Japonica rice in 2021.

| |

Calcium |

Magnesium |

| |

(mg/100g) |

(mg/100g) |

| Koshihikari C (WG) (unpolished rice) |

9.6 ± 0.0 a |

103.0 ± 0.0 a |

| Koshihikari C (CG) (unpolished rice) |

12.3 ± 0.0 b |

102.0 ± 0.0 a |

| Koshihikari C (WG) (polished rice) |

5.4 ± 0.0 a |

19.3 ± 0.0 a |

| Koshihikari C (CG) (polished rice) |

6.8 ± 0.0 b |

22.5 ± 0.0 b |

| Koshihikari C (WG) (polished boiled rice) (pulified water) |

5.5 ± 0.0 a |

17.5 ± 0.0 a |

| Koshihikari C (CG) (polished boiled rice) (pulified water) |

6.9 ± 0.0 b |

20.4 ± 0.0 b |

| Koshihikari C (WG) (polished boild rice) (Evian) |

19.0 ± 0.0 a |

22.1 ± 0.0 a |

| Koshihikari C (CG) (polished boild rice) (Evian) |

23.9 ± 0.0 b |

25.8 ± 0.0 b |

| Koshihikari C (WG) (polished boiled rice) (Contrex) |

90.5 ± 0.0 a |

31.3 ± 0.0 a |

| Koshihikari C (CG) (polished boiled rice) (Contrex) |

114.0 ± 0.0 b |

36.5 ± 0.0 b |

| Tsubusuke (WG) (polished boiled rice) (pulified water) |

6.1 ± 0.0 a |

26.6 ± 0.1 a |

| Tsubusuke (CG) (polished boiled rice) (pulified water) |

6.4 ± 0.0 a |

29.4 ± 0.1 b |

| Tsubusuke (WG) (polished boiled rice) (Evian) |

15.8 ± 0.0 a |

30.4 ± 0.1 a |

| Tsubusuke (CG) (polished boiled rice) (Evian) |

17.5 ± 0.0 b |

32.6 ± 0.1 a |

| Tsubusuke (WG) (polished boiled rice) (Contrex) |

82.6 ± 0.2 a |

41.3 ± 0.1 a |

| Tsubusuke (CG) (polished boiled rice) (Contrex) |

86.1 ± 0.2 b |

39.0 ± 0.1 a |