Submitted:

30 April 2023

Posted:

30 April 2023

You are already at the latest version

Abstract

Keywords:

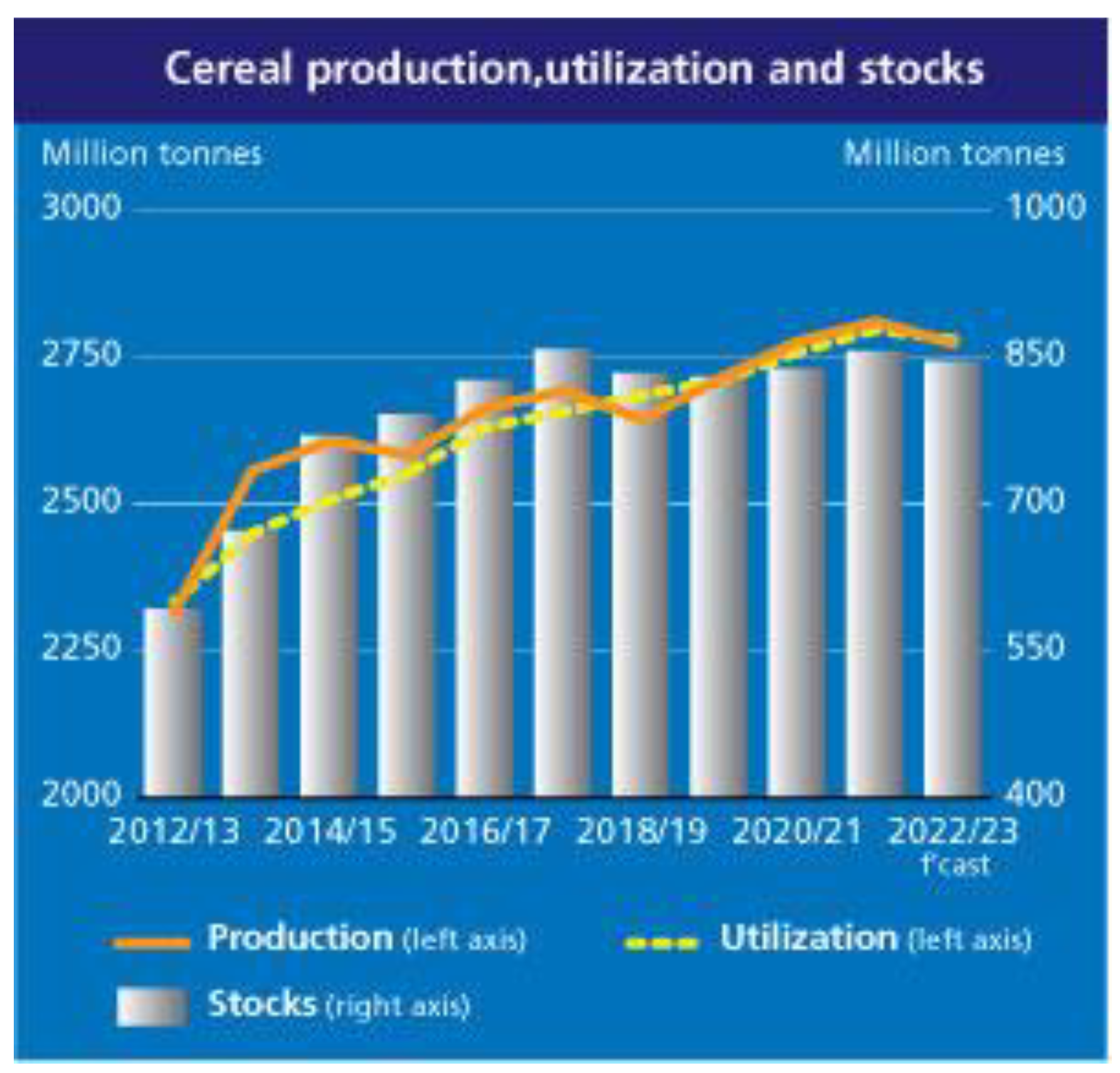

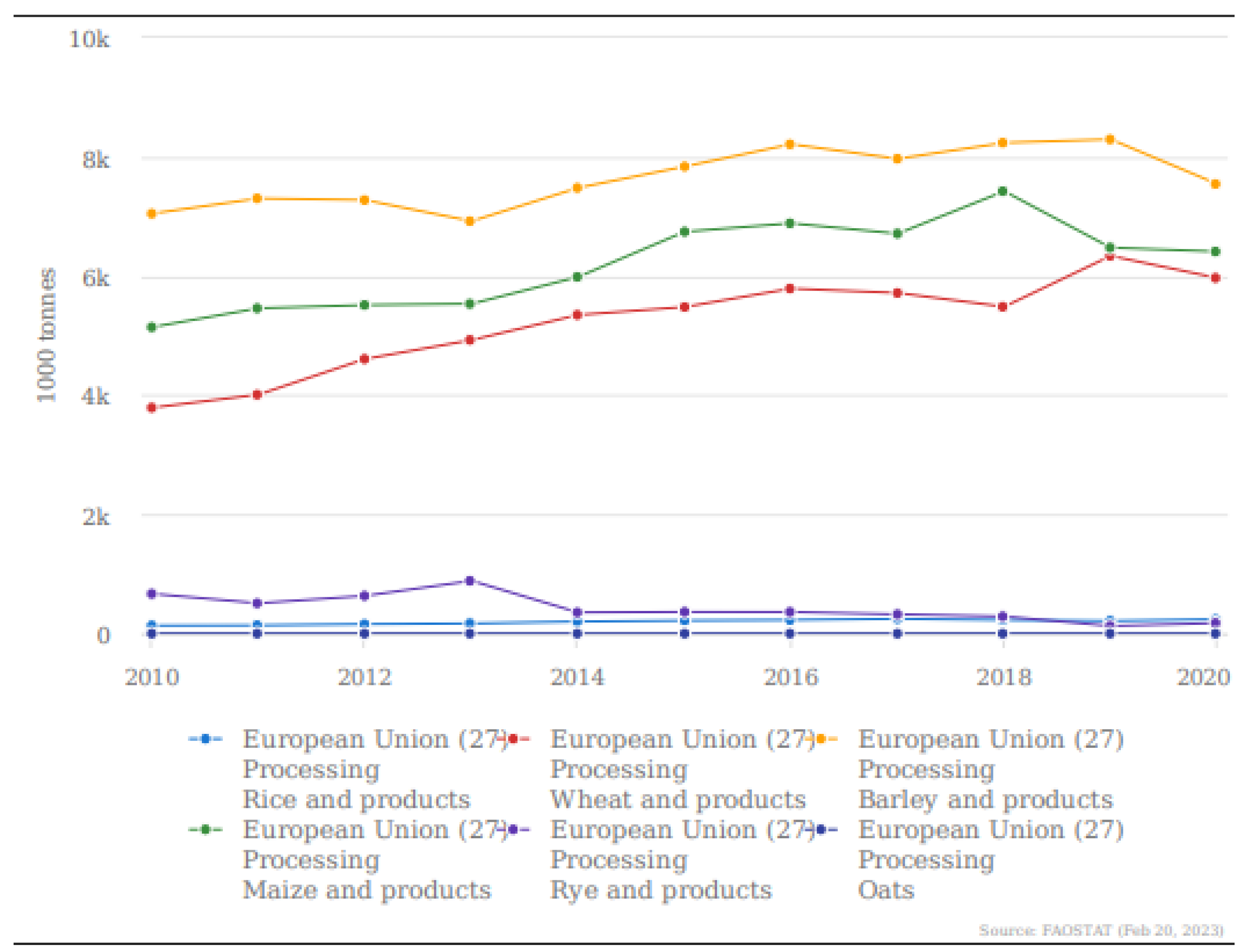

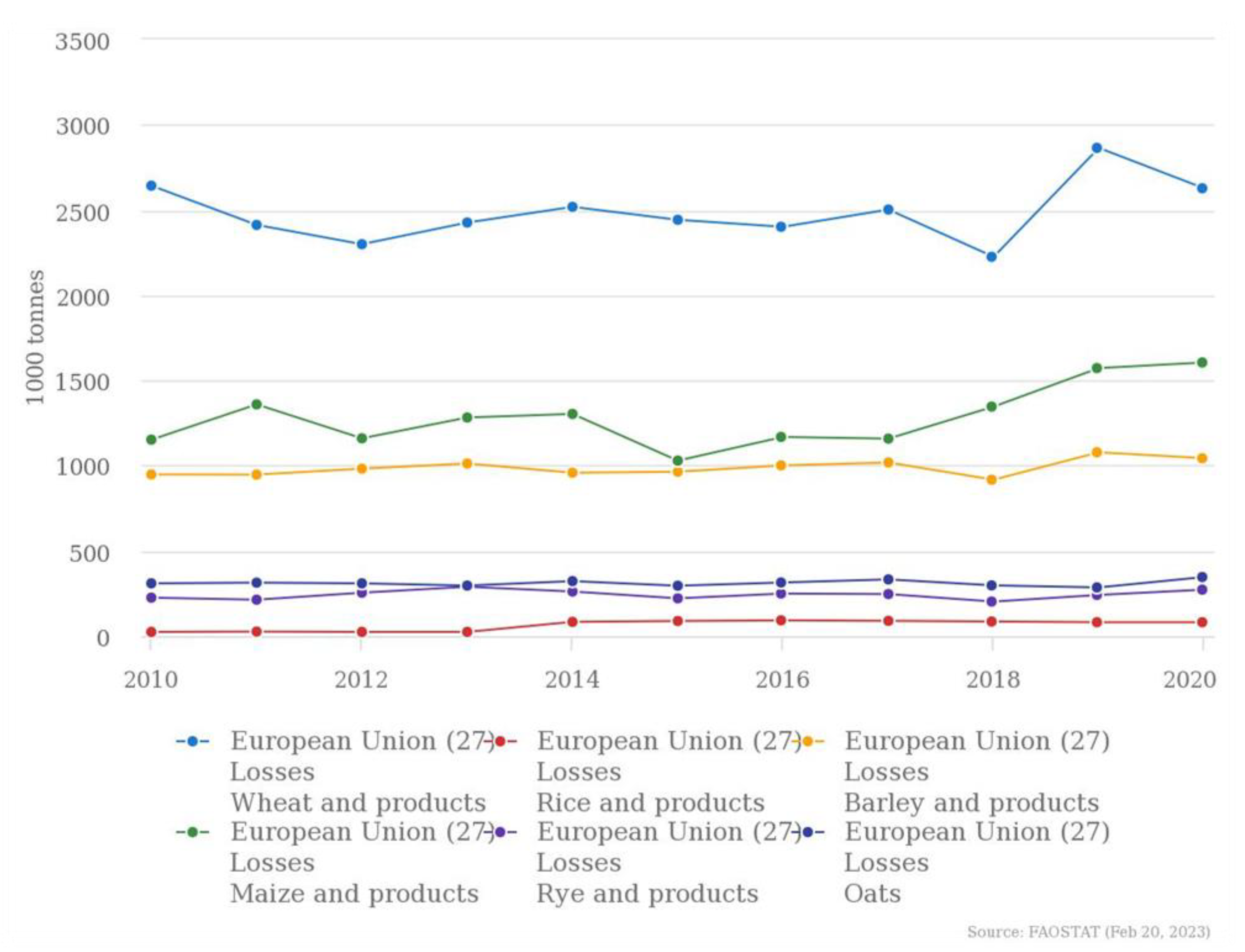

1. Introduction

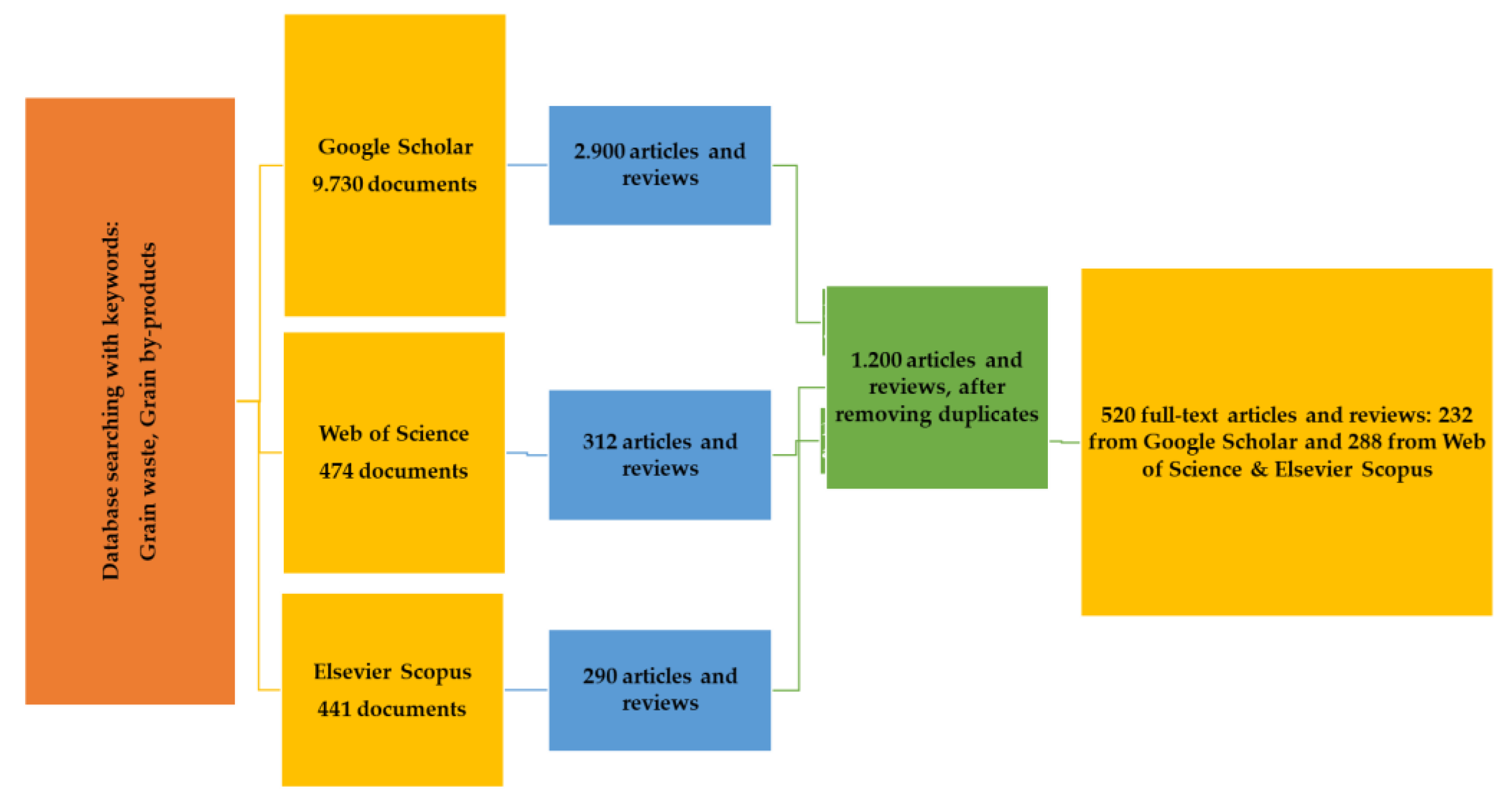

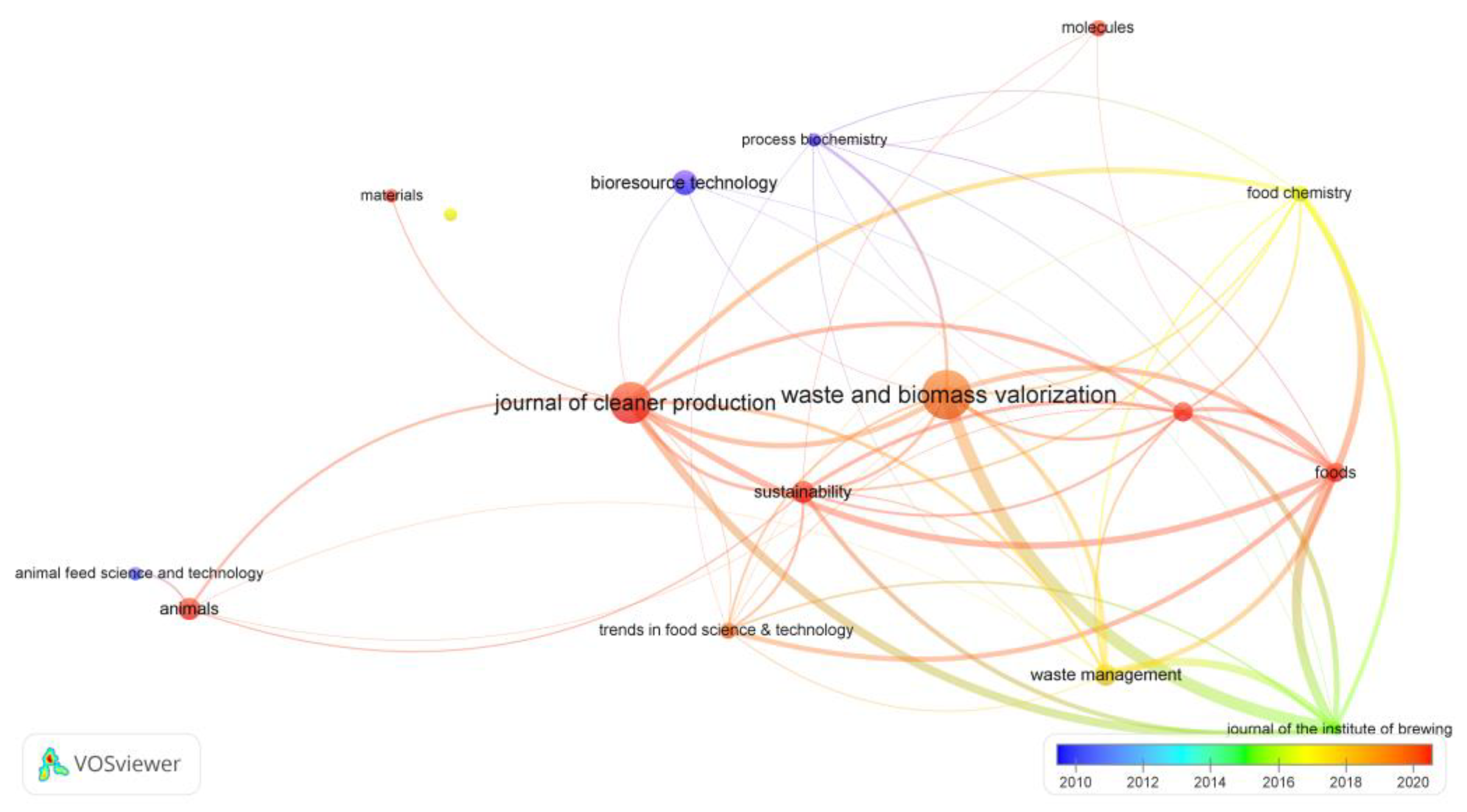

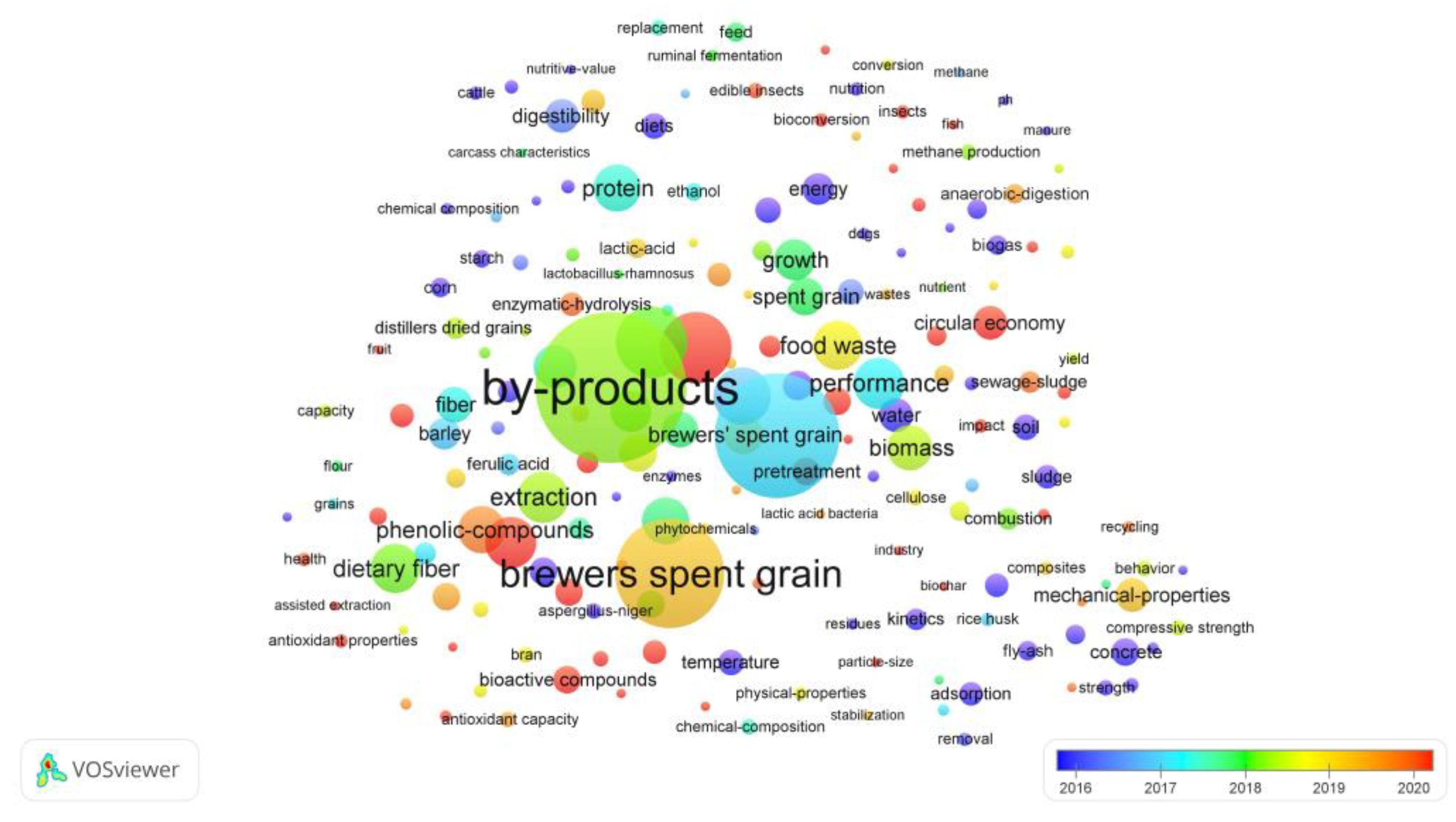

2. Bibliometric Analysis

3. It is waste, only if we waste it!

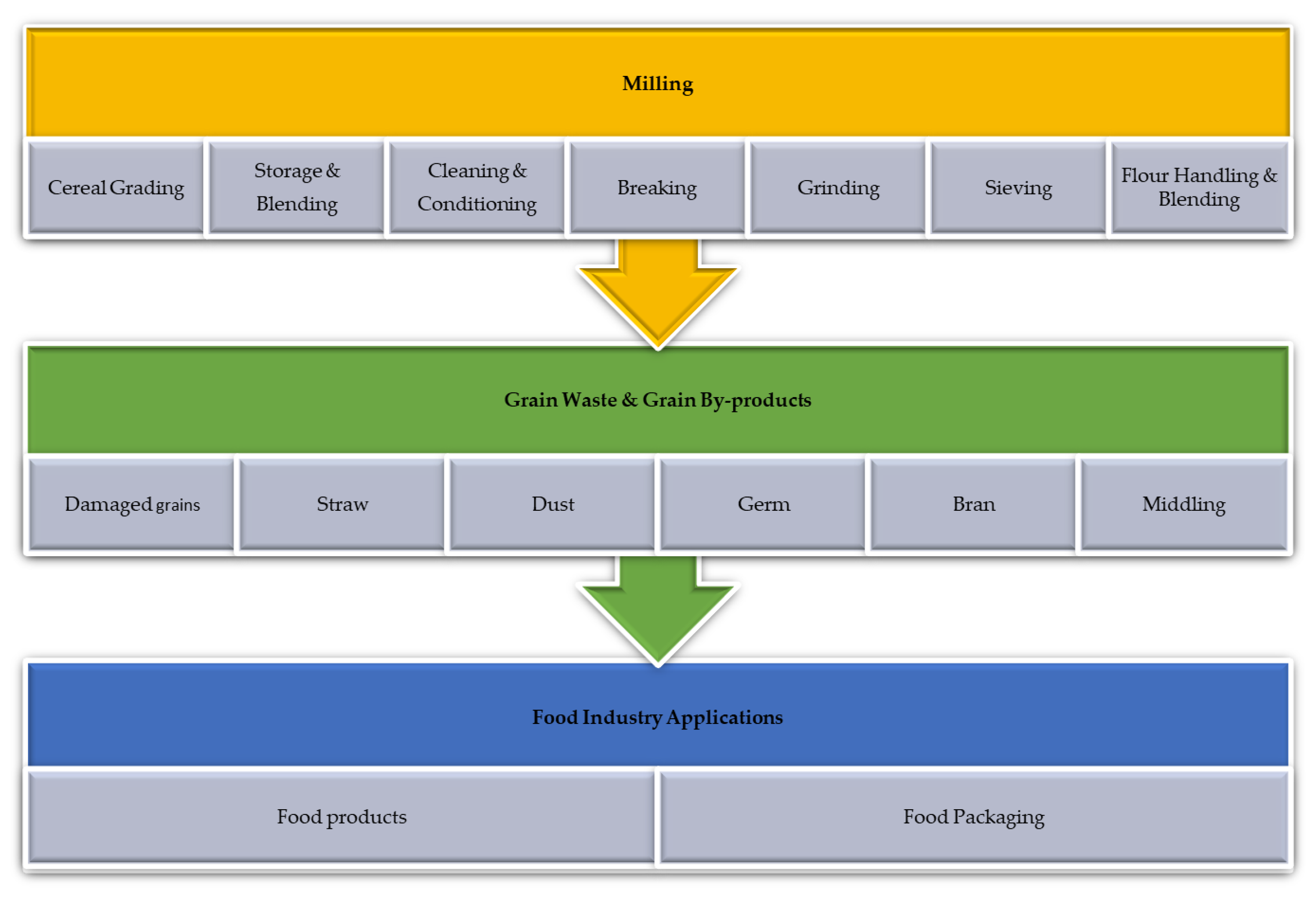

3.1. Conventional milling, the major supplier of grain losses, reused in Food Industry

3.1.1. Dust

3.1.2. Grain bran and germ

3.2. Brewing process and its wastes

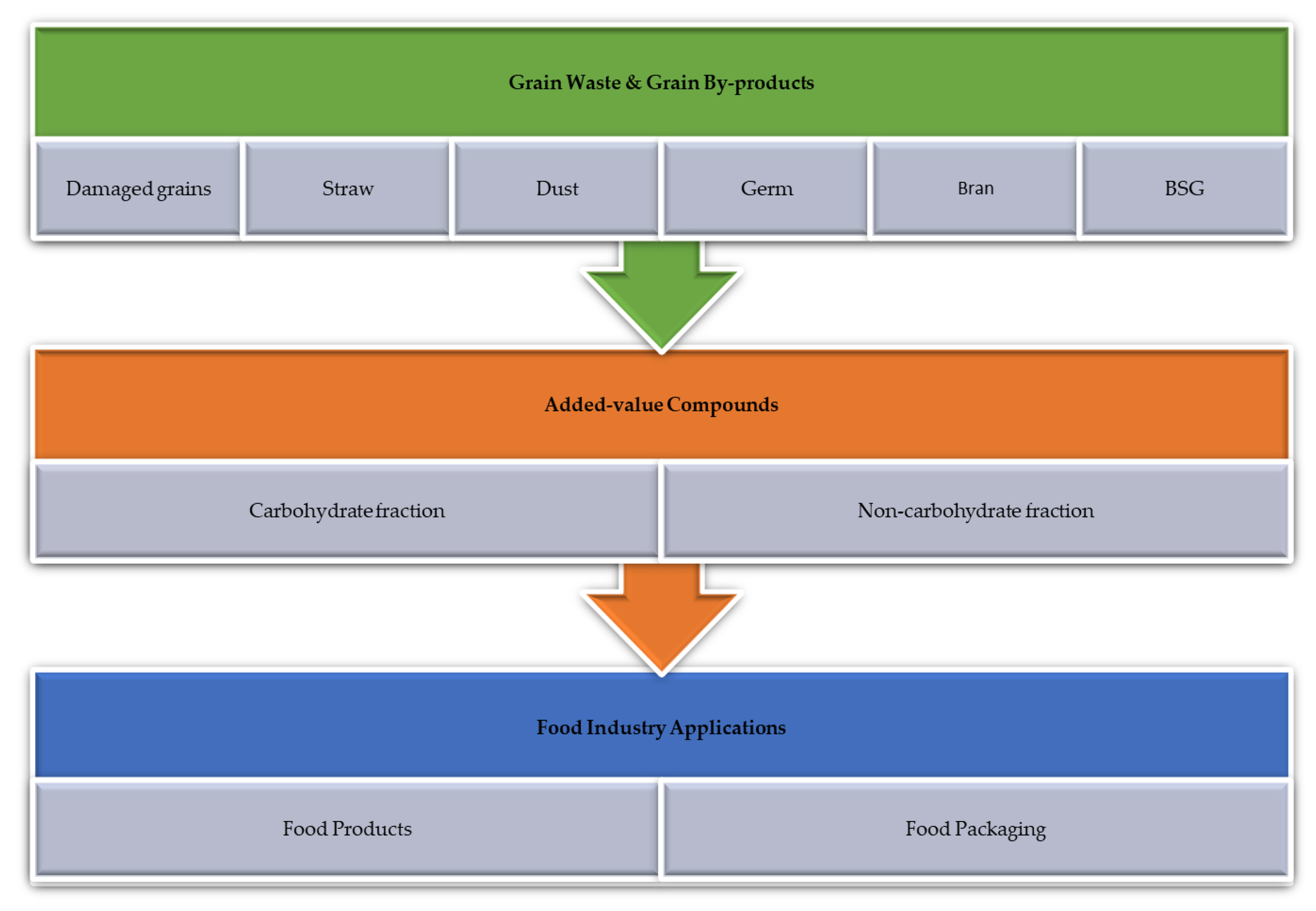

4. Added-value Compounds for Food Industry

4.1. Carbohydrate fraction

4.2. Non-carbohydrate fraction

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Poole, N.; Donovan, J.; Erenstein, O. Viewpoint: Agri-nutrition research: Revisiting the contribution of maize and wheat to human nutrition and health. Food Policy 2021, 100, 101976. [Google Scholar] [CrossRef] [PubMed]

- 3. Global and regional food consumption patterns and trends. Available online: https://www.fao.org/3/ac911e/ac911e05.htm (accessed on 6 March 2023).

- Guerrini, A.; Burlini, I.; Lorenzo, B.H.; Grandini, A.; Vertuani, S.; Tacchini, M.; Sacchetti, G. Antioxidant and antimicrobial extracts obtained from agricultural by-products: Strategies for a sustainable recovery and future perspectives. Food Bioprod. Process. 2020, 124, 397–407. [Google Scholar] [CrossRef]

- Poole, N.; Donovan, J.; Erenstein, O. Viewpoint: Agri-nutrition research: Revisiting the contribution of maize and wheat to human nutrition and health. Food Policy 2021, 100, 101976. [Google Scholar] [CrossRef] [PubMed]

- Shiferaw, B.; Smale, M.; Braun, H.-J.; Duveiller, E.; Reynolds, M.; Muricho, G. Crops that feed the world 10. Past successes and future challenges to the role played by wheat in global food security. Food Secur. 2013, 5, 291–317. [Google Scholar] [CrossRef]

- Fukagawa, N.K.; Ziska, L.H. Rice: Importance for Global Nutrition. J. Nutr. Sci. Vitaminol. 2019, 65, S2–S3. Available online: http://www.riceassociation.org.uk/content/1/18/types- (accessed on 8 April 2023). [CrossRef] [PubMed]

- Zhang, R.; Ma, S.; Li, L.; Zhang, M.; Tian, S.; Wang, D.; Liu, K.; Liu, H.; Zhu, W.; Wang, X. Comprehensive utilization of corn starch processing by-products: A review. Grain Oil Sci. Technol. 2021, 4, 89–107. [Google Scholar] [CrossRef]

- FAO Cereal Supply and Demand Brief | World Food Situation | Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 6 March 2023).

- Teigiserova, D.A.; Bourgine, J.; Thomsen, M. Closing the loop of cereal waste and residues with sustainable technologies: An overview of enzyme production via fungal solid-state fermentation. Sustain. Prod. Consum. 2021, 27, 845–857. [Google Scholar] [CrossRef]

- Thürer, M.; Tomašević, I.; Stevenson, M.; Qu, T.; Huisingh, D. A systematic review of the literature on integrating sustainability into engineering curricula. J. Clean. Prod. 2018, 181, 608–617. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Kamaterou, P. Food waste valorization advocating Circular Bioeconomy - A critical review of potentialities and perspectives of spent coffee grounds biorefinery. J. Clean. Prod. 2019, 211, 1553–1566. [Google Scholar] [CrossRef]

- Gutiérrez-Salcedo, M.; Martínez, M.A.; Moral-Munoz, J.A.; Herrera-Viedma, E.; Cobo, M.J. Some bibliometric procedures for analyzing and evaluating research fields. Appl. Intell. 2018, 48, 1275–1287. [Google Scholar] [CrossRef]

- Jan van Eck, N.; Waltman, L. VOSviewer Manual. 2023. [Google Scholar]

- Skendi, A.; Zinoviadou, K.G.; Papageorgiou, M.; Rocha, J.M. Advances on the Valorisation and Functionalization of By-Products and Wastes from Cereal-Based Processing Industry. Foods 2020, 9, 1243. [Google Scholar] [CrossRef] [PubMed]

- Belc, N.; Mustatea, G.; Apostol, L.; Iorga, S.; Vlăduţ, V.-N.; Mosoiu, C. Cereal supply chain waste in the context of circular economy. [CrossRef]

- MOVING FORWARD ON FOOD LOSS AND WASTE REDUCTION FOOD AND AGRICULTURE. 2019. Available online: www.fao.org/publications (accessed on 8 March 2023).

- Processing of Cereals and Derived-By-Products | Encyclopedia MDPI. Available online: https://encyclopedia.pub/entry/2020 (accessed on 4 April 2023).

- Roth, M.; Jekle, M.; Becker, T. Opportunities for upcycling cereal byproducts with special focus on Distiller's grains. Trends Food Sci. Technol. 2019, 91, 282–293. [Google Scholar] [CrossRef]

- Fărcaș, A.C.; Socaci, S.A.; Nemeș, S.A.; Pop, O.L.; Coldea, T.E.; Fogarasi, M.; Biriș-Dorhoi, E.S. An Update Regarding the Bioactive Compound of Cereal By-Products: Health Benefits and Potential Applications. Nutrients 2022, 14, 3470. [Google Scholar] [CrossRef] [PubMed]

- Tufail, T.; Ain, H.B.U.; Saeed, F.; Nasir, M.; Basharat, S.; Mahwish; Rusu, A.V.; Hussain, M.; Rocha, J.M.; Trif, M.; et al. A Retrospective on the Innovative Sustainable Valorization of Cereal Bran in the Context of Circular Bioeconomy Innovations. Sustainability 2022, 14, 14597. [Google Scholar] [CrossRef]

- Papageorgiou, M.; Skendi, A. Introduction to cereal processing and by-products. Sustainable Recovery and Reutilization of Cereal Processing By-Products 2018, 1–25. [Google Scholar]

- Serna-Saldivar, S. O. Wet-Milling Processes and Starch Properties and Characteristics. Cereal Grains 2020, 185–204. [Google Scholar] [CrossRef]

- Comino, E.; Dominici, L.; Perozzi, D. Do-it-yourself approach applied to the valorisation of a wheat milling industry's by-product for producing bio-based material. J. Clean. Prod. 2021, 318, 128267. [Google Scholar] [CrossRef]

- Ahmadzadeh, S.; Khaneghah, A. M. Role of Green Polymers in Food Packaging. Encyclopedia of Renewable and Sustainable Materials 2020, 305–319. [Google Scholar] [CrossRef]

- Sánchez-Safont, E.L.; Aldureid, A.; Lagarón, J.M.; Gámez-Pérez, J.; Cabedo, L. Biocomposites of different lignocellulosic wastes for sustainable food packaging applications. Compos. Part B: Eng. 2018, 145, 215–225. [Google Scholar] [CrossRef]

- Torres, M.D.; Fradinho, P.; Rodríguez-Seoane, P.; Falqué, E.; Santos, V.; Domínguez, H. Biorefinery concept for discarded potatoes: Recovery of starch and bioactive compounds. J. Food Eng. 2020, 275, 109886. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Barud, H.; Farinas, C.S.; Vasconcellos, V.M.; Claro, A.M. Bacterial Cellulose as a Raw Material for Food and Food Packaging Applications. Front. Sustain. Food Syst. 2019, 3. [Google Scholar] [CrossRef]

- Duţă, D. E.; Culeţu, A.; Mohan, G. Reutilization of cereal processing by-products in bread making. Sustainable Recovery and Reutilization of Cereal Processing By-Products 2018, 279–317. [Google Scholar] [CrossRef]

- Salazar-López, N. J.; Ovando-Martínez, M.; Domínguez-Avila, J. A. Cereal/Grain By-products. Food Wastes and By-products 2020, 1–34. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F.; Luziatelli, F.; Ruzzi, M. Functional Ingredients from Agri-Food Waste: Effect of Inclusion Thereof on Phenolic Compound Content and Bioaccessibility in Bakery Products. Antioxidants 2020, 9, 1216. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Qamar, A.; Saeed, F.; Rasheed, R.; Niaz, B.; Afzaal, M.; Mushtaq, Z.; Anjum, F. BIOCHEMICAL PROPERTIES OF MAIZE BRAN WITH SPECIAL REFERENCE TO DIFFERENT PHENOLIC ACIDS. Int. J. Food Prop. 2021, 24, 1468–1478. [Google Scholar] [CrossRef]

- Pontonio, E.; Dingeo, C.; Gobbetti, M.; Rizzello, C.G. Maize Milling By-Products: From Food Wastes to Functional Ingredients Through Lactic Acid Bacteria Fermentation. Front. Microbiol. 2019, 10, 561. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.; Gavlighi, H.A.; Sarteshnizi, R.A.; Udenigwe, C.C. Effect of maize germ protein hydrolysate addition on digestion, in vitro antioxidant activity and quality characteristics of bread. J. Cereal Sci. 2021, 97, 103148. [Google Scholar] [CrossRef]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci.Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- Pathera, A.K.; Riar, C.S.; Yadav, S.; Singh, P.K. Effect of Egg Albumen, Vegetable Oil, Corn Bran, and Cooking Methods on Quality Characteristics of Chicken Nuggets Using Response Surface Methodology. Korean J. Food Sci. Anim. Resour. 2018, 38, 901–911. [Google Scholar] [CrossRef]

- Yadav, S.; Malik, A.; Pathera, A.; Islam, R.U.; Sharma, D. Development of dietary fibre enriched chicken sausages by incorporating corn bran, dried apple pomace and dried tomato pomace. Nutr. Food Sci. 2016, 46, 16–29. [Google Scholar] [CrossRef]

- Yan, J.; Lv, Y.; Ma, S. Wheat bran enrichment for flour products: Challenges and solutions. J. Food Process. Preserv. 2022, 46, e16977. [Google Scholar] [CrossRef]

- Packkia-Doss, P.P.; Chevallier, S.; Pare, A.; Le-Bail, A. Effect of supplementation of wheat bran on dough aeration and final bread volume. J. Food Eng. 2019, 252, 28–35. [Google Scholar] [CrossRef]

- Pasqualone, A.; Delvecchio, L.N.; Gambacorta, G.; Laddomada, B.; Urso, V.; Mazzaglia, A.; Ruisi, P.; Di Miceli, G. Effect of Supplementation with Wheat Bran Aqueous Extracts Obtained by Ultrasound-Assisted Technologies on the Sensory Properties and the Antioxidant Activity of Dry Pasta. Nat. Prod. Commun. 2015, 10, 1739–42. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Pathera, A.K.; Islam, R.U.; Malik, A.K.; Sharma, D.P. Effect of wheat bran and dried carrot pomace addition on quality characteristics of chicken sausage. Asian-Australasian J. Anim. Sci. 2018, 31, 729–737. [Google Scholar] [CrossRef] [PubMed]

- Abu-Ghannam, N.; Balboa, E. 9 - Biotechnological, food, and health care applications A2 - Galanakis, Charis M. BT - Sustainable Recovery and Reutilization of Cereal Processing By-Products. 9780. Available online: https://www.sciencedirect.com/science/article/pii/B9780081021620000095 (accessed on 9 April 2023).

- Pontonio, E.; Lorusso, A.; Gobbetti, M.; Rizzello, C.G. Use of fermented milling by-products as functional ingredient to develop a low-glycaemic index bread. J. Cereal Sci. 2017, 77, 235–242. [Google Scholar] [CrossRef]

- Spaggiari, M.; Dall’asta, C.; Galaverna, G.; Bilbao, M.D.d.C. Rice Bran By-Product: From Valorization Strategies to Nutritional Perspectives. Foods 2021, 10, 85. [Google Scholar] [CrossRef]

- (11) (PDF) Gamma-Oryzanol from rice bran oil-A review. Available online: https://www.researchgate.net/publication/ 239785419_Gamma-Oryzanol_from_rice_bran_oil-A_review (accessed on 9 April 2023).

- Espinales, C.; Cuesta, A.; Tapia, J.; Palacios-Ponce, S.; Peñas, E.; Martínez-Villaluenga, C.; Espinoza, A.; Cáceres, P.J. The Effect of Stabilized Rice Bran Addition on Physicochemical, Sensory, and Techno-Functional Properties of Bread. Foods 2022, 11, 3328. [Google Scholar] [CrossRef]

- de Souza, C. B.; et al. Development of a functional rice bran cookie rich in γ-oryzanol. Journal of Food Measurement and Characterization 2019, 13, 1070–1077. [Google Scholar] [CrossRef]

- Bultum, L. E.; Emire, S. A.; Wolde, Y. T. Influence of full fat rice bran from Ethiopian rice milling industries on nutritional qualities, physicochemical and sensory properties of bread and biscuits. Journal of Food Measurement and Characterization 2020, 14, 2253–2261. [Google Scholar] [CrossRef]

- Kaur, A.; Virdi, A.S.; Singh, N.; Singh, A.; Kaler, R.S.S. Effect of degree of milling and defatting on proximate composition, functional and texture characteristics of gluten-free muffin of bran of long-grain indica rice cultivars. Food Chem. 2020, 345, 128861. [Google Scholar] [CrossRef]

- Demirci, T.; Aktaş, K.; Sözeri, D.; Öztürk, H.I.; Akın, N. Rice bran improve probiotic viability in yoghurt and provide added antioxidative benefits. J. Funct. Foods 2017, 36, 396–403. [Google Scholar] [CrossRef]

- Saka, M.; Özkaya, B.; Saka, I. The effect of bread-making methods on functional and quality characteristics of oat bran blended bread. Int. J. Gastron. Food Sci. 2021, 26, 100439. [Google Scholar] [CrossRef]

- Liu, W.; Brennan, M.; Tu, D.; Brennan, C. Influence of α-amylase, xylanase and cellulase on the rheological properties of bread dough enriched with oat bran. Sci. Rep. 2023, 13, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Brennan, M.; Brennan, C.; You, L.; Tu, D. Effect of Enyzmes on the Quality and Predicting Glycaemic Response of Chinese Steamed Bread. Foods 2023, 12, 273. [Google Scholar] [CrossRef] [PubMed]

- Espinosa-Solis, V.; Zamudio-Flores, P.B.; Tirado-Gallegos, J.M.; Ramírez-Mancinas, S.; Olivas-Orozco, G.I.; Espino-Díaz, M.; Hernández-González, M.; García-Cano, V.G.; Sánchez-Ortíz, O.; Buenrostro-Figueroa, J.J.; et al. Evaluation of Cooking Quality, Nutritional and Texture Characteristics of Pasta Added with Oat Bran and Apple Flour. Foods 2019, 8, 299. [Google Scholar] [CrossRef]

- Verni, M.; Rizzello, C.G.; Coda, R. Fermentation Biotechnology Applied to Cereal Industry By-Products: Nutritional and Functional Insights. Front. Nutr. 2019, 6, 42. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D. Rye Flour and Rye Bran: New Perspectives for Use. Processes 2022, 10, 293. [Google Scholar] [CrossRef]

- Helkar, P.B.; Sahoo, A.; Patil, N. Review: Food Industry By-Products used as a Functional Food Ingredients. Int. J. Waste Resour. 2016, 6, 1–6. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Rachwał, K.; Waśko, A.; Gustaw, K.; Polak-Berecka, M. Utilization of brewery wastes in food industry. PeerJ 2020, 8, e9427. [Google Scholar] [CrossRef]

- Cappa, C.; Alamprese, C. Brewer's spent grain valorization in fiber-enriched fresh egg pasta production: Modelling and optimization study. LWT 2017, 82, 464–470. [Google Scholar] [CrossRef]

- Fărcaş, A.C.; Socaci, S.A.; Mudura, E.; Dulf, F.V.; Vodnar, D.C.; Tofană, M.; Salanță, L.C. Exploitation of Brewing Industry Wastes to Produce Functional Ingredients. Brewing Technology 2017. [Google Scholar] [CrossRef]

- Combest, S.; Warren, C. Perceptions of college students in consuming whole grain foods made with Brewers’ Spent Grain. Food Sci. Nutr. 2019, 7, 225–237. [Google Scholar] [CrossRef] [PubMed]

- Ktenioudaki, A.; Chaurin, V.; Reis, S.F.; Gallagher, E. Brewer’s spent grain as a functional ingredient for breadsticks. Int. J. Food Sci. Technol. 2012, 47, 1765–1771. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; O’shea, N.; Gallagher, E. Rheological properties of wheat dough supplemented with functional by-products of food processing: Brewer’s spent grain and apple pomace. J. Food Eng. 2013, 116, 362–368. [Google Scholar] [CrossRef]

- Nagy, M.; Semeniuc, C.A.; Socaci, S.A.; Pop, C.R.; ROTAR, A.M.; Sălăgean, C.D.; Tofană, M. Utilization of brewer’s spent grain and mushrooms in fortification of smoked sausages. Food Sci. Technol. 2017, 37, 315–320. [Google Scholar] [CrossRef]

- Choi, M.-S.; Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Lee, S.-Y.; Kim, C.-J. Effects of Replacing Pork Back Fat with Brewer's Spent Grain Dietary Fiber on Quality Characteristics of Reduced-fat Chicken Sausages. Korean J. Food Sci. Anim. Resour. 2014, 34, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Saraiva, B.R.; Anjo, F.A.; Vital, A.C.P.; da Silva, L.H.M.; Ogawa, C.Y.L.; Sato, F.; Coimbra, L.B.; Matumoto-Pintro, P.T. Waste from brewing (trub) as a source of protein for the food industry. Int. J. Food Sci. Technol. 2019, 54, 1247–1255. [Google Scholar] [CrossRef]

- dos Santos, M.T.R.; de Aguiar, P.F.; de Almeida e Silva, J.B.; de Mello, P.P.M.; Camporese Servulo, E.F. Brewery Waste Reuse for Protease Production by Lactic Acid Fermentation. Food Technol. Biotechnol. 2017, 55, 218–224. [Google Scholar] [CrossRef]

- Coldea, T. E.; Mudura, E.; Rotar, A. M.; Cuibus, L.; Pop, C. R.; Darab, C. Brewer’s spent yeast exploitation in food industry. Hop and Medicinal Plants 2017, 25, 94–99. [Google Scholar]

- Martins, Z.E.; Erben, M.; Gallardo, A.E.; Silva, R.; Barbosa, I.; Pinho, O.; Ferreira, I.M.P.L.V.O. Effect of spent yeast fortification on physical parameters, volatiles and sensorial characteristics of home-made bread. Int. J. Food Sci. Technol. 2015, 50, 1855–1863. [Google Scholar] [CrossRef]

- Hassan, G.; Shabbir, M.A.; Ahmad, F.; Pasha, I.; Aslam, N.; Ahmad, T.; Rehman, A.; Manzoor, M.F.; Inam-Ur-Raheem, M.; Aadil, R.M. Cereal processing waste, an environmental impact and value addition perspectives: A comprehensive treatise. Food Chem. 2021, 363, 130352. [Google Scholar] [CrossRef]

- Salazar-López, N. J.; Ovando-Martínez, M.; Domínguez-Avila, J. A. Cereal/Grain By-products. Food Wastes and By-products 2020, 1–34. [Google Scholar] [CrossRef]

- Fărcaș, A.C.; Socaci, S.A.; Nemeș, S.A.; Salanță, L.C.; Chiș, M.S.; Pop, C.R.; Borșa, A.; Diaconeasa, Z.; Vodnar, D.C. Cereal Waste Valorization through Conventional and Current Extraction Techniques—An Up-to-Date Overview. Foods 2022, 11, 2454. [Google Scholar] [CrossRef] [PubMed]

- Arzami, A.N.; Ho, T.M.; Mikkonen, K.S. Valorization of cereal by-product hemicelluloses: Fractionation and purity considerations. Food Res. Int. 2021, 151, 110818. [Google Scholar] [CrossRef] [PubMed]

- Qaseem, M.F.; Shaheen, H.; Wu, A.-M. Cell wall hemicellulose for sustainable industrial utilization. Renew. Sustain. Energy Rev. 2021, 144, 110996. [Google Scholar] [CrossRef]

- Luo, Y.; Li, Z.; Li, X.; Liu, X.; Fan, J.; Clark, J.H.; Hu, C. The production of furfural directly from hemicellulose in lignocellulosic biomass: A review. Catal. Today 2018, 319, 14–24. [Google Scholar] [CrossRef]

- Valoppi, F.; Wang, Y.-J.; Alt, G.; Peltonen, L.J.; Mikkonen, K.S. Valorization of Native Soluble and Insoluble Oat Side Streams for Stable Suspensions and Emulsions. Food Bioprocess Technol. 2021, 14, 751–764. [Google Scholar] [CrossRef]

- Herrera-Balandrano, D.D.; Báez-González, J.G.; Carvajal-Millán, E.; Méndez-Zamora, G.; Urías-Orona, V.; Amaya-Guerra, C.A.; Niño-Medina, G. Feruloylated Arabinoxylans from Nixtamalized Maize Bran Byproduct: A Functional Ingredient in Frankfurter Sausages. Molecules 2019, 24, 2056. [Google Scholar] [CrossRef] [PubMed]

- Apprich, S.; Tirpanalan, Ö.; Hell, J.; Reisinger, M.; Böhmdorfer, S.; Siebenhandl-Ehn, S.; Novalin, S.; Kneifel, W. Wheat bran-based biorefinery 2: Valorization of products. LWT 2013, 56, 222–231. [Google Scholar] [CrossRef]

- Jackowski, M.; Niedźwiecki, Ł.; Jagiełło, K.; Uchańska, O.; Trusek, A. Brewer’s Spent Grains—Valuable Beer Industry By-Product. Biomolecules 2020, 10, 1669. [Google Scholar] [CrossRef]

- Lech, M.; Labus, K. The methods of brewers’ spent grain treatment towards the recovery of valuable ingredients contained therein and comprehensive management of its residues. Chem. Eng. Res. Des. 2022, 183, 494–511. [Google Scholar] [CrossRef]

- Bacha, E.G. Response Surface Methodology Modeling, Experimental Validation, and Optimization of Acid Hydrolysis Process Parameters for Nanocellulose Extraction. South Afr. J. Chem. Eng. 2022, 40, 176–185. [Google Scholar] [CrossRef]

- Ideia, P.; Sousa-Ferreira, I.; Castilho, P.C. A Novel and Simpler Alkaline Hydrolysis Methodology for Extraction of Ferulic Acid from Brewer’s Spent Grain and its (Partial) Purification through Adsorption in a Synthetic Resin. Foods 2020, 9, 600. [Google Scholar] [CrossRef] [PubMed]

- Macias-Garbett, R.; Serna-Hernández, S.O.; Sosa-Hernández, J.E.; Parra-Saldívar, R. Phenolic Compounds From Brewer's Spent Grains: Toward Green Recovery Methods and Applications in the Cosmetic Industry. Front. Sustain. Food Syst. 2021, 5. [Google Scholar] [CrossRef]

- Alonso-Riaño, P.; Sanz Diez, M.T.; Blanco, B.; Beltrán, S.; Trigueros, E.; Benito-Román, O. Water Ultrasound-Assisted Extraction of Polyphenol Compounds from Brewer’s Spent Grain: Kinetic Study, Extract Characterization, and Concentration. Antioxidants 2020, 9, 265. [Google Scholar] [CrossRef]

- Guido, L.F.; Moreira, M.M. Techniques for Extraction of Brewer’s Spent Grain Polyphenols: a Review. Food Bioprocess Technol. 2017, 10, 1192–1209. [Google Scholar] [CrossRef]

- Rebolleda, S.; José, M.L.G.-S.; Sanz, M.T.; Beltrán, S.; Solaesa, G. Bioactive Compounds of a Wheat Bran Oily Extract Obtained with Supercritical Carbon Dioxide. Foods 2020, 9, 625. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, R.; Liu, C. Extraction and antioxidant activity of phenolic compounds from wheat bran treated by steam explosion. Trop. J. Pharm. Res. 2015, 14, 1857–1863. [Google Scholar] [CrossRef]

- Radenkovs, V.; Juhnevica-Radenkova, K.; Górnaś, P.; Seglina, D. Non-waste technology through the enzymatic hydrolysis of agro-industrial by-products. Trends Food Sci. Technol. 2018, 77, 64–76. [Google Scholar] [CrossRef]

- Călinoiu, L.F.; Cătoi, A.-F.; Vodnar, D.C. Solid-State Yeast Fermented Wheat and Oat Bran as A Route for Delivery of Antioxidants. Antioxidants 2019, 8, 372. [Google Scholar] [CrossRef]

- View of RYE (SECALE CEREALE L.) PHENOLIC COMPOUNDS AS HEALTH-RELATED FACTORS. Available online: http://ojs.ihar.edu.pl/index.php/pbss/article/view/140/215 (accessed on 14 April 2023).

- Fărcaș, A.C.; Socaci, S.A.; Nemeș, S.A.; Pop, O.L.; Coldea, T.E.; Fogarasi, M.; Biriș-Dorhoi, E.S. An Update Regarding the Bioactive Compound of Cereal By-Products: Health Benefits and Potential Applications. Nutrients 2022, 14, 3470. [Google Scholar] [CrossRef]

| Journal1 | Document/year | Citation |

|---|---|---|

| Waste and Biomass Valorization | 18 | 200 |

| Journal of Cleaner production | 15 | 410 |

| Bioresource Technology | 9 | 1800 |

| Waste Management | 8 | 172 |

| Sustainability | 8 | 59 |

| Animals | 8 | 133 |

| Foods | 7 | 57 |

| Applied Sciences - Basel | 7 | 48 |

| Food Chemistry | 6 | 273 |

| Trends in Food Science & Technology | 6 | 312 |

| Molecules | 6 | 49 |

| Journal of the Institute of Brewing | 5 | 338 |

| Process Biochemistry | 5 | 203 |

| Animal Feed Science and Technology | 5 | 220 |

| Materials | 5 | 30 |

| Resources Conservation and Recycling | 5 | 166 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).