Submitted:

24 April 2023

Posted:

24 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

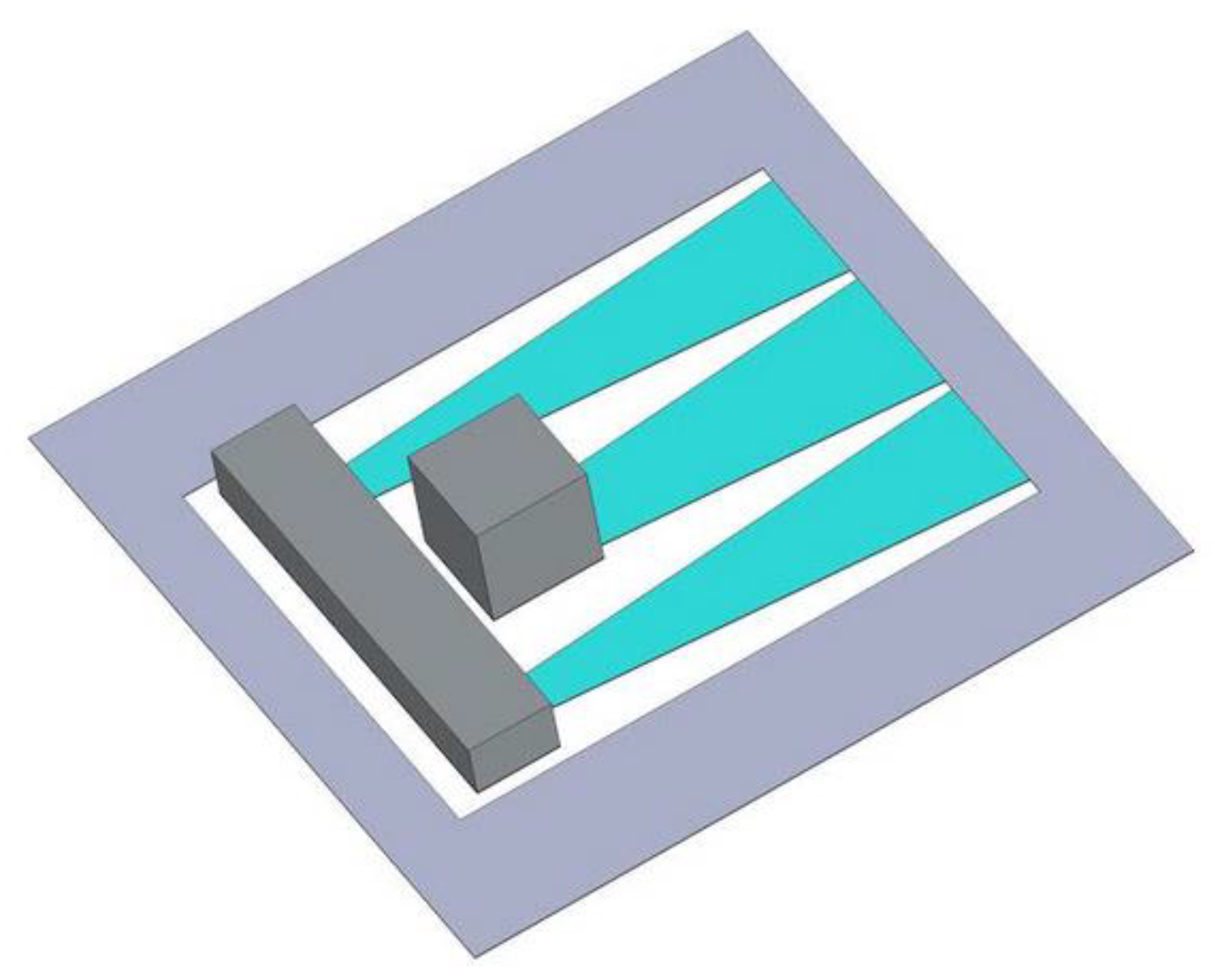

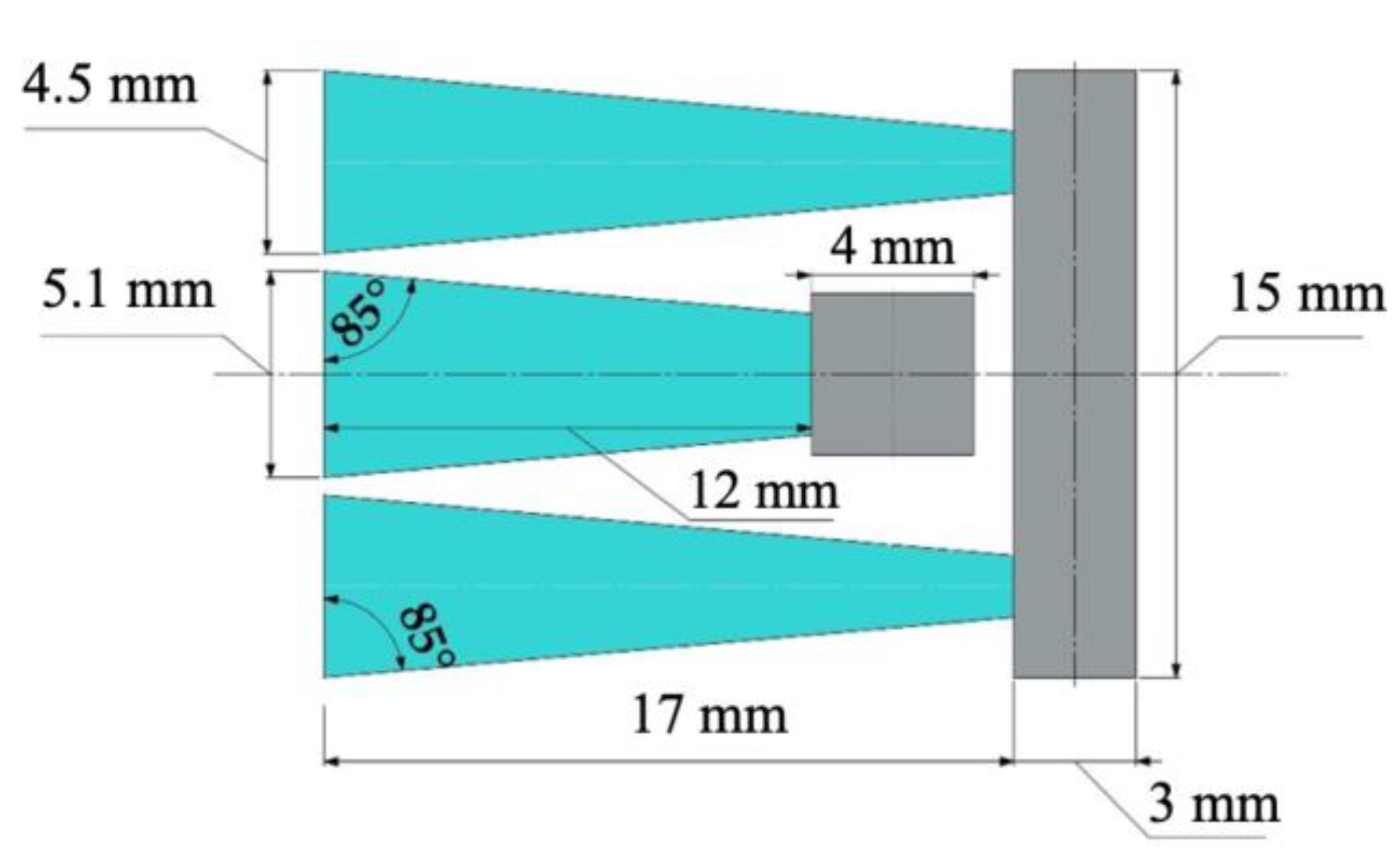

2.1. Device design by CAD software

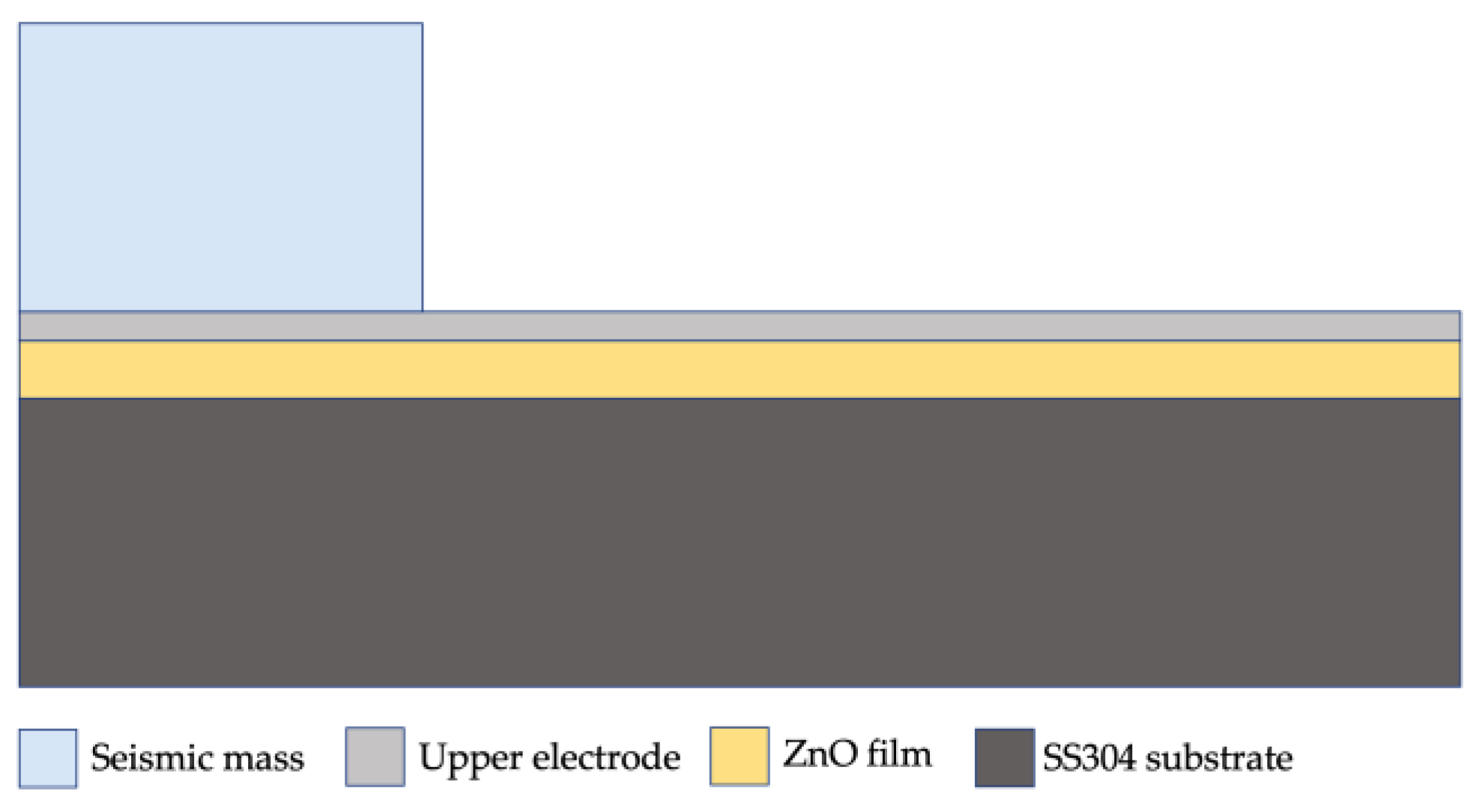

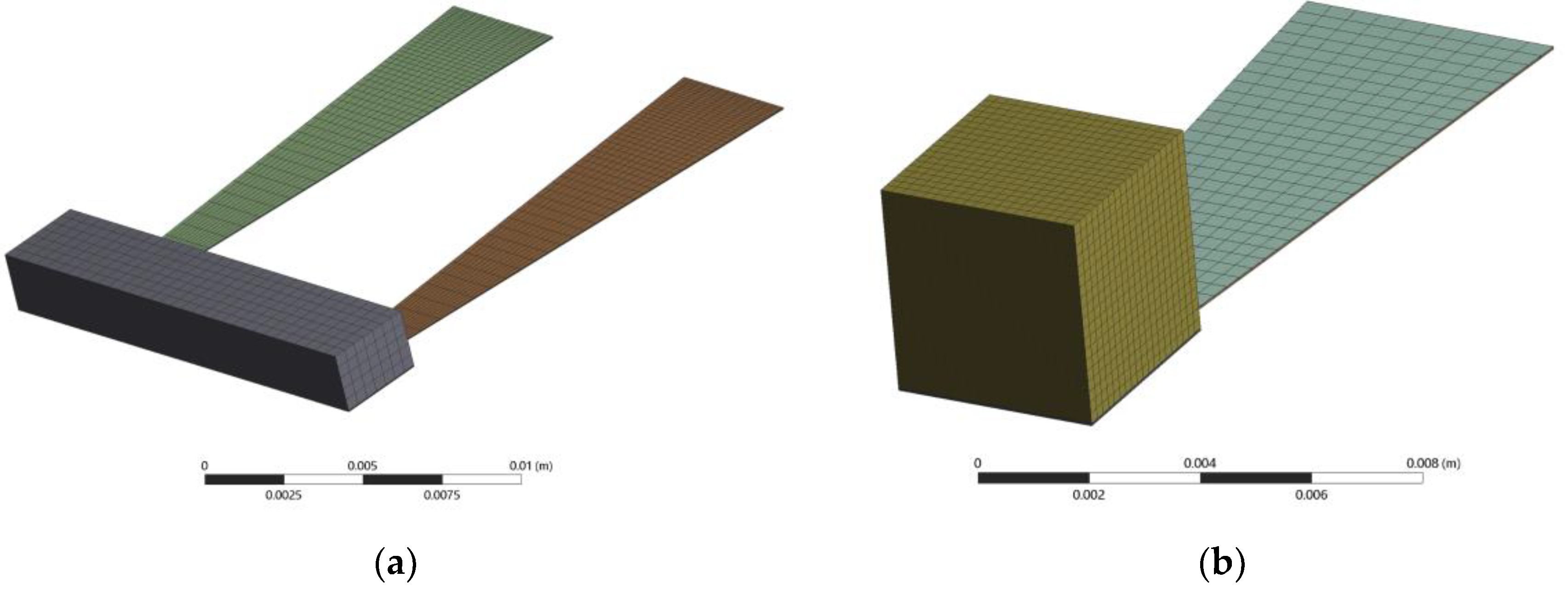

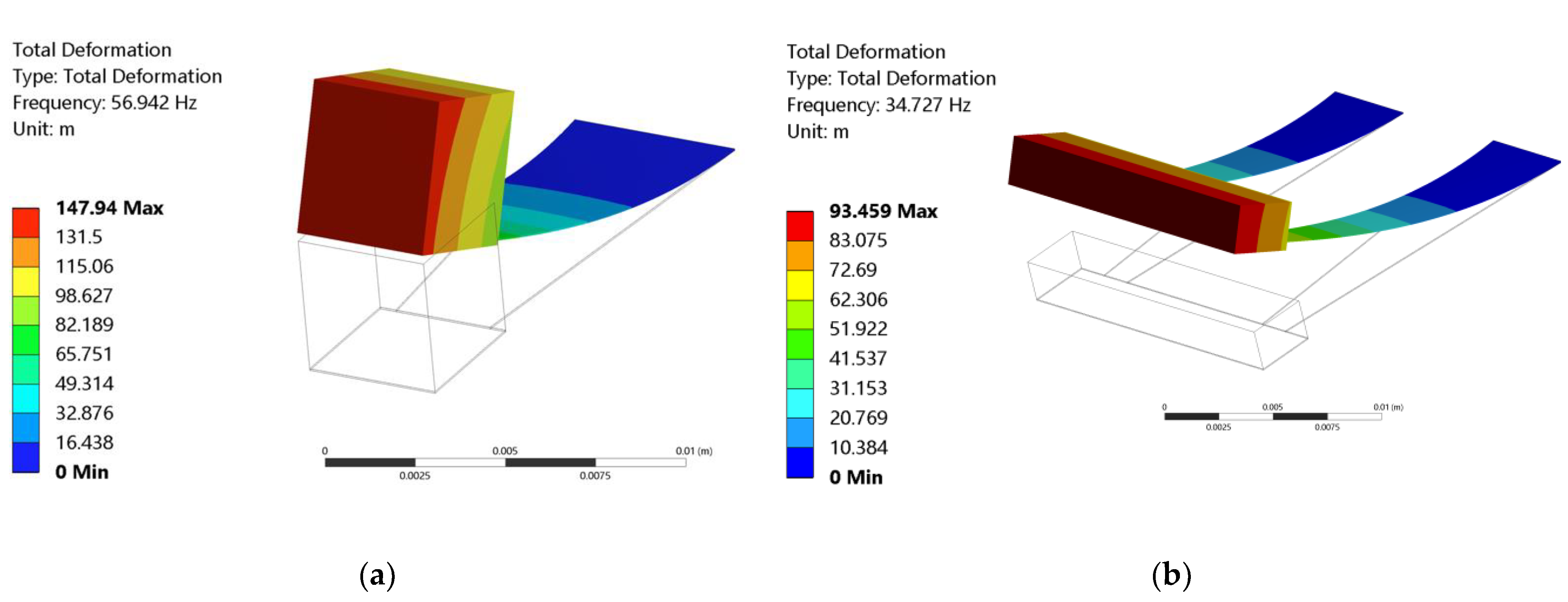

2.2. Finite Element Model

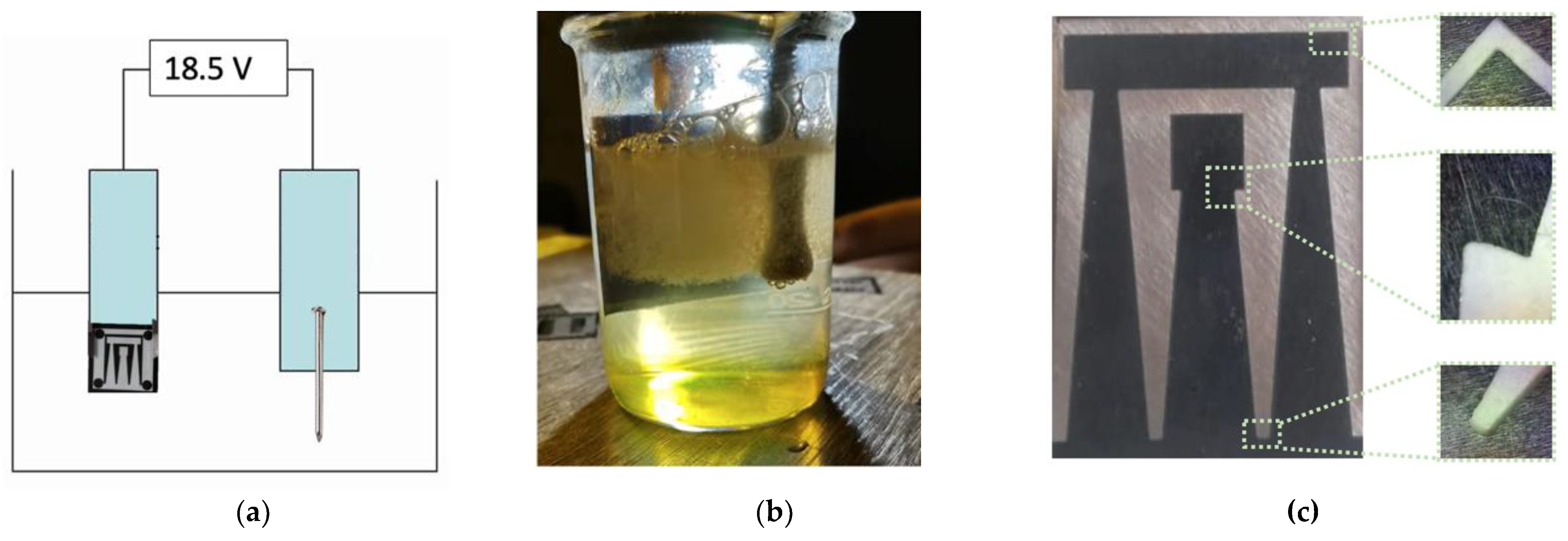

2.3. Micromachining

- Substrate protection with dry film: The substrate was protected with dry film, preventing the incorporation of clusters and bubbles on the surface.

- Lamination: The substrate with dry film is laminated with a commercial laminator. This process is carried out on both sides of the substrate.

- Alignment: The mask is aligned with the substrate previously protected with dry film.

- UV light exposure: The mask is exposed to ultraviolet light for 3 seconds.

- Development: In a solution of 50 ml distilled water and 0.5 grams of sodium carbonate, the substrate is developed, and after 30 seconds, excess dry film is removed.

- Wet etching: a mixture of 100 ml water and 100 grams of sodium chloride was prepared, and a voltage of 18.5 V DC was applied for 5 minutes to remove the steel that does not belong to the PEH device structure.

- Dry film cleaning: The etched substrate is cleaned with acetone.

2.4. Piezoelectric Film Synthesis and Deposition

3. Results and discussions

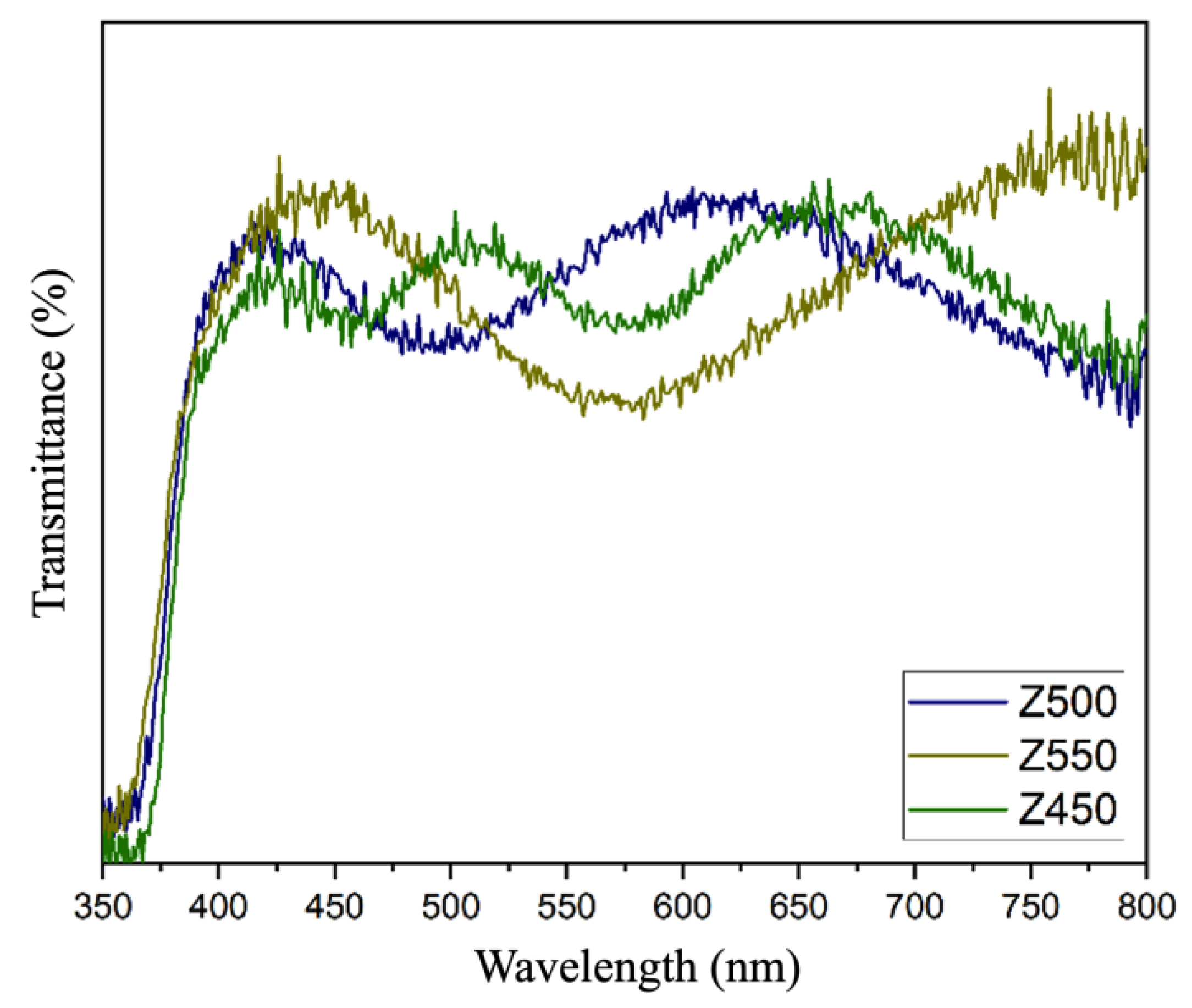

3.1. Optical analysis of ZnO films

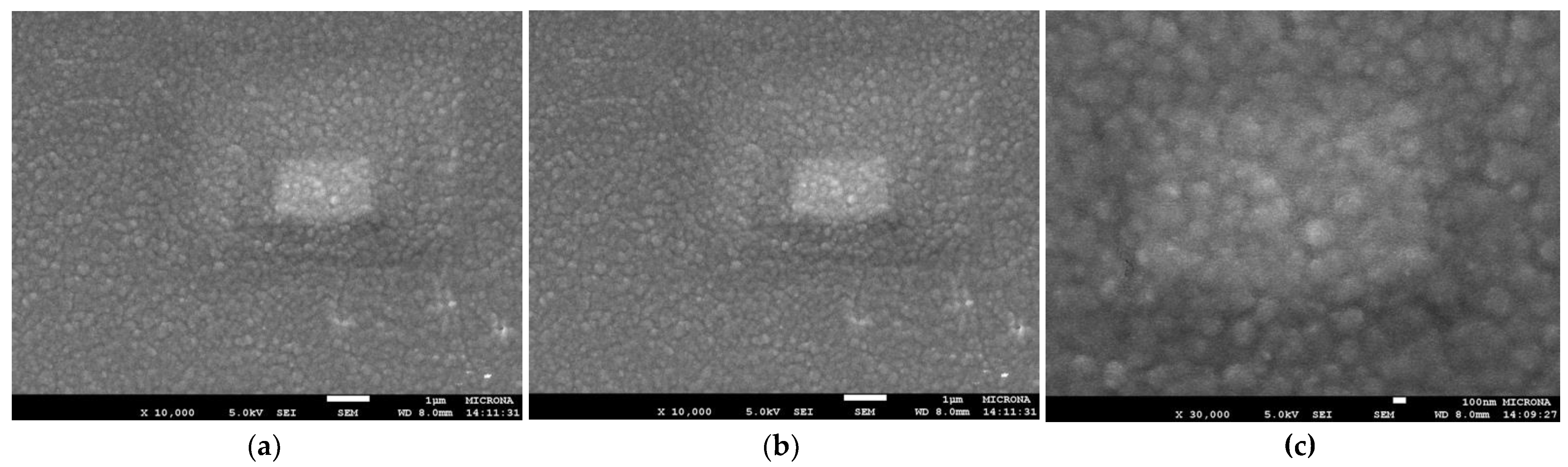

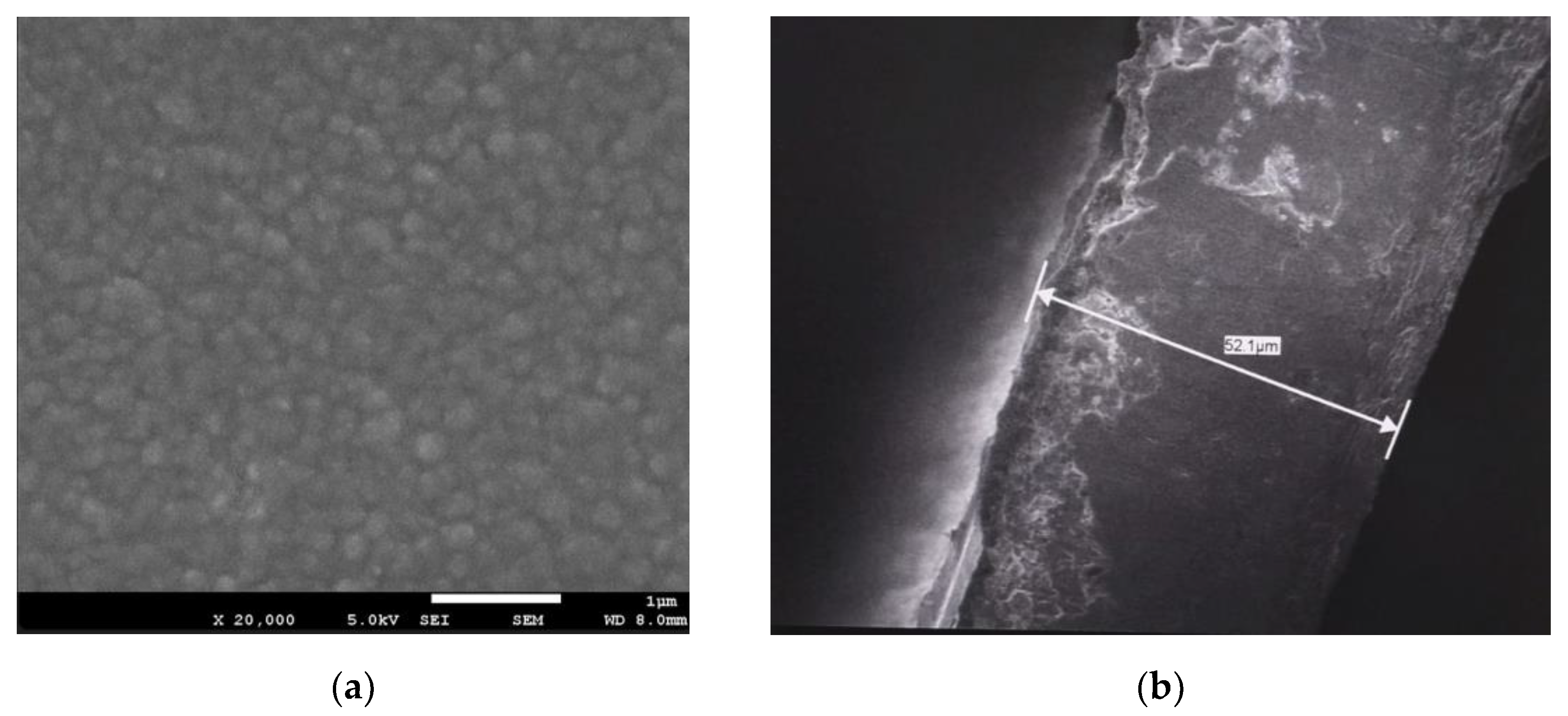

3.2. Scanning electron microscopy

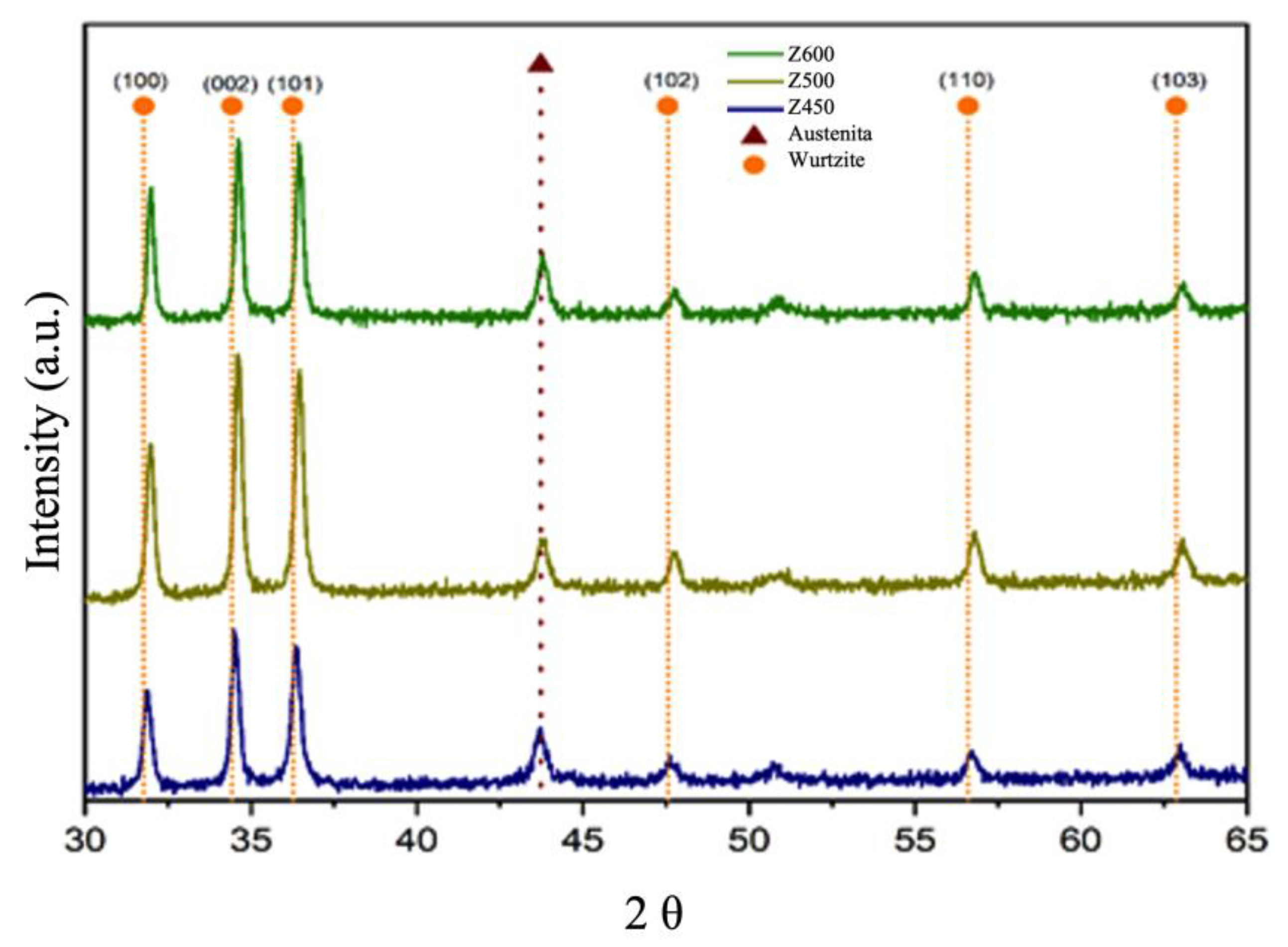

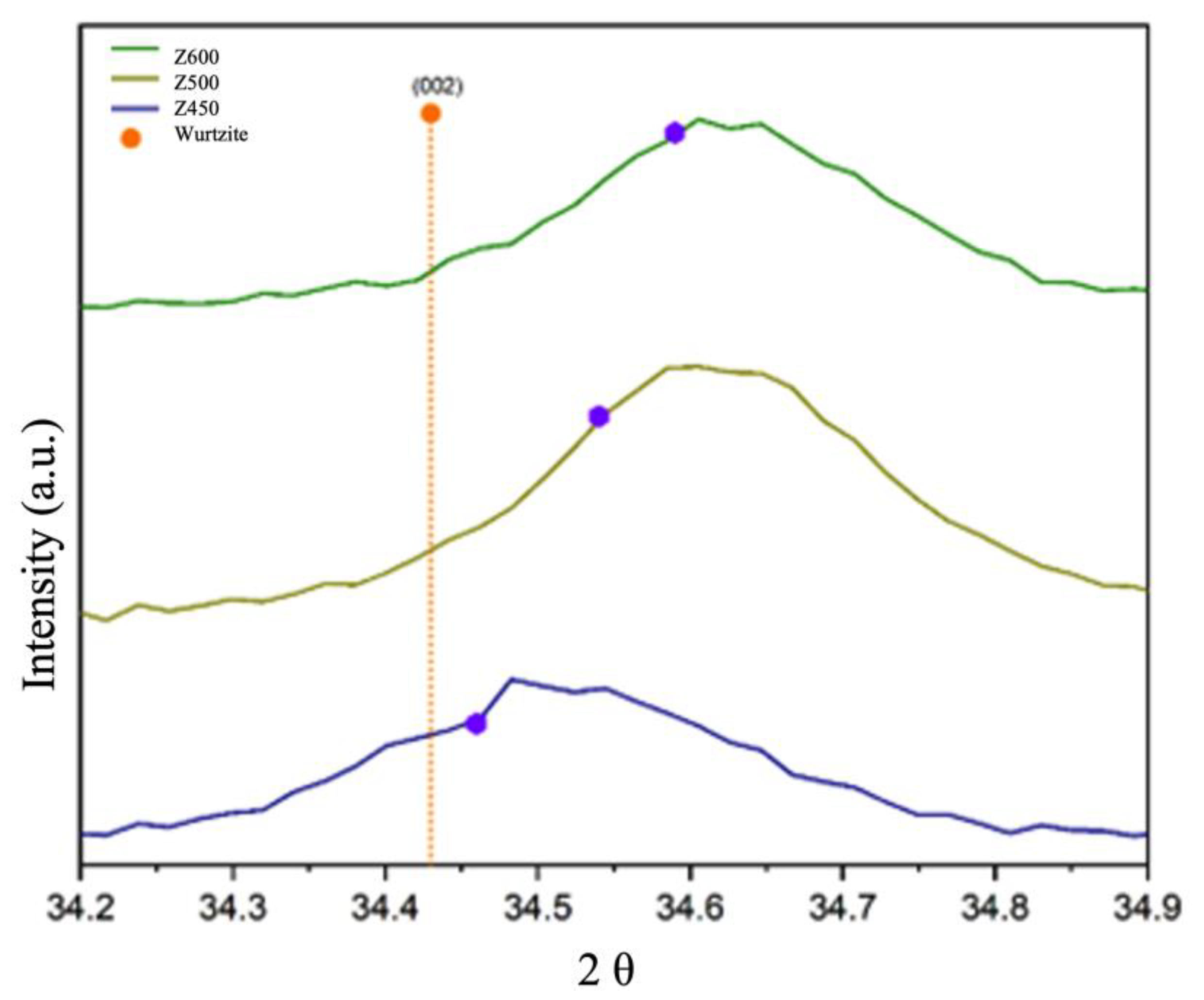

3.3. X-ray Diffraction (XRD)

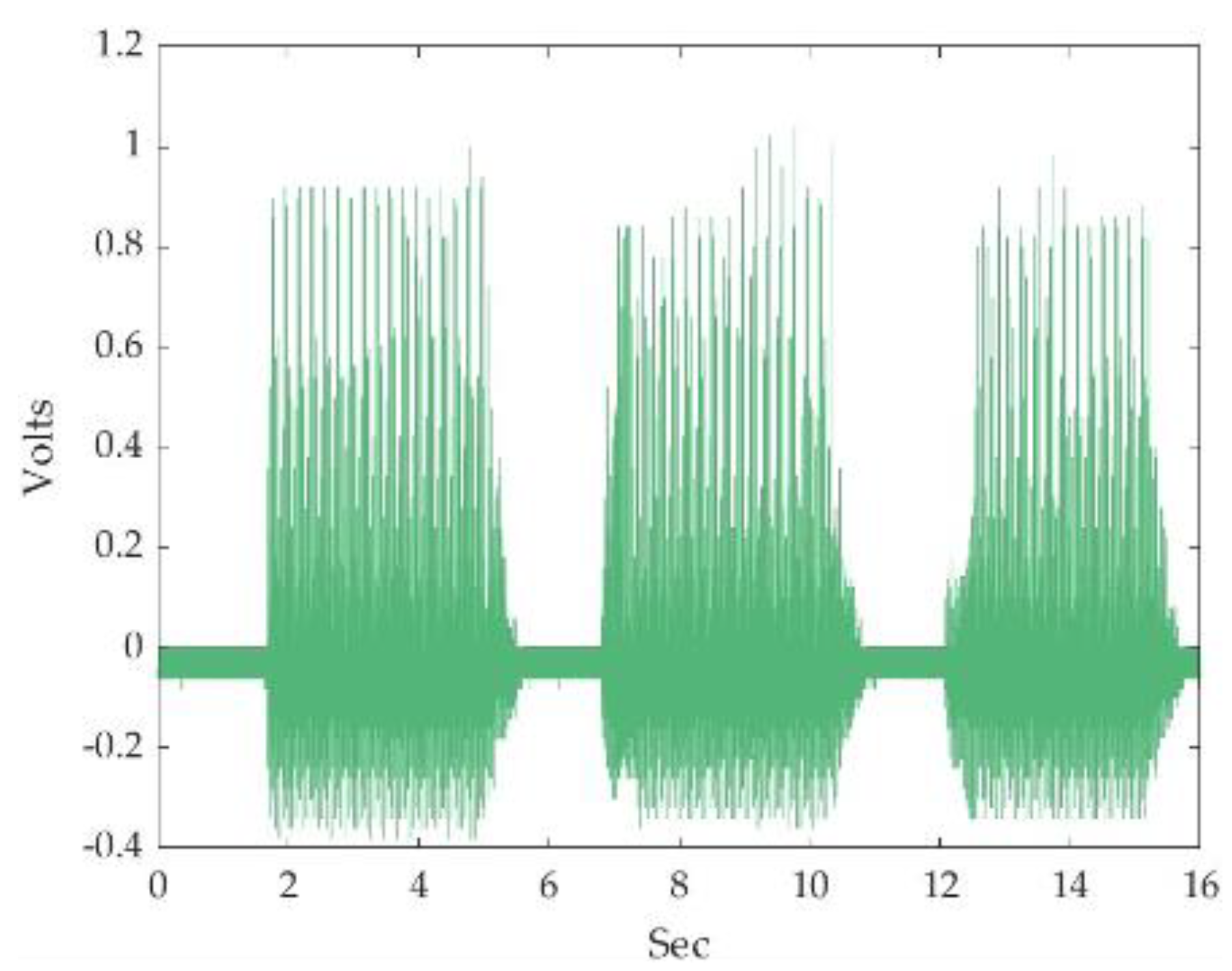

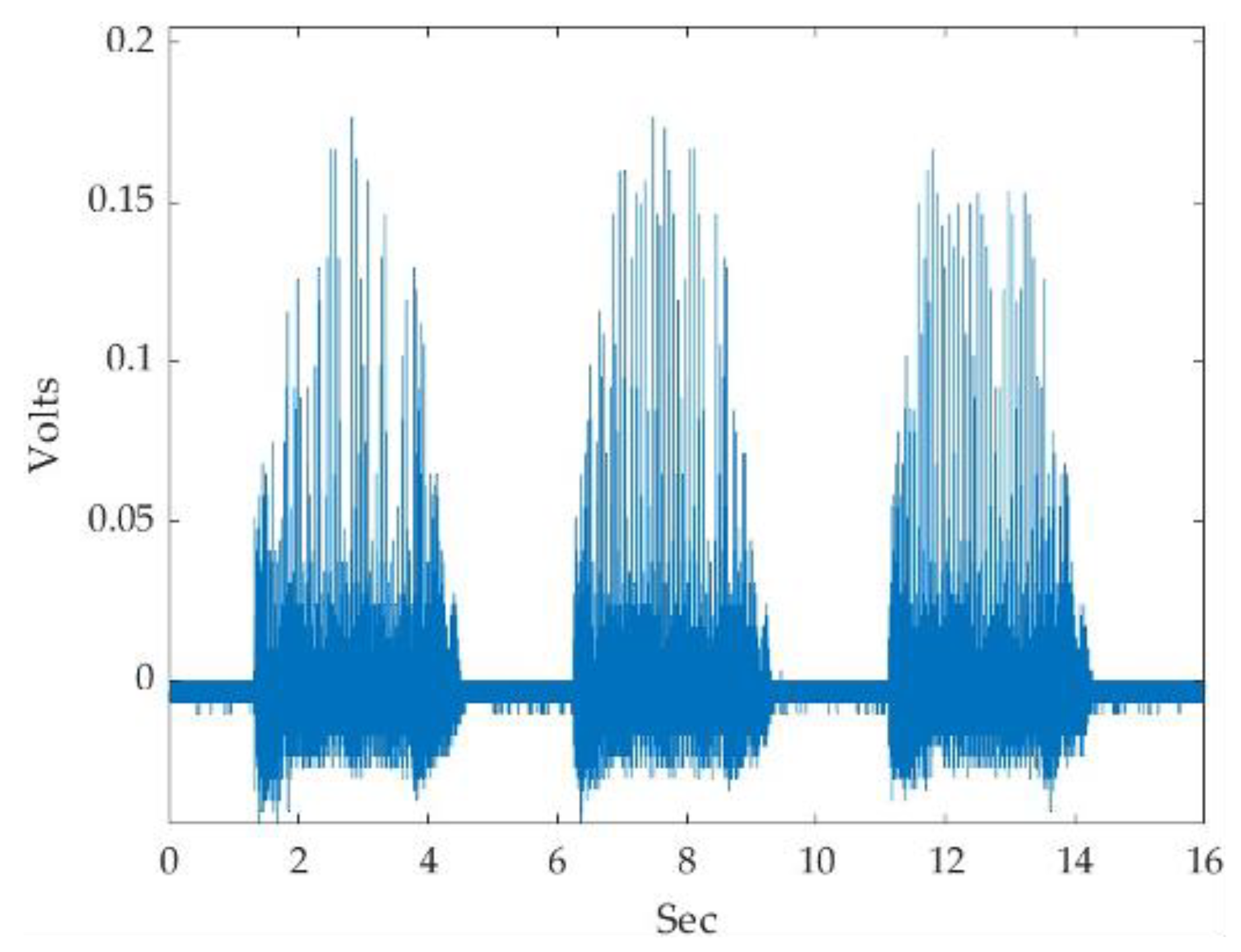

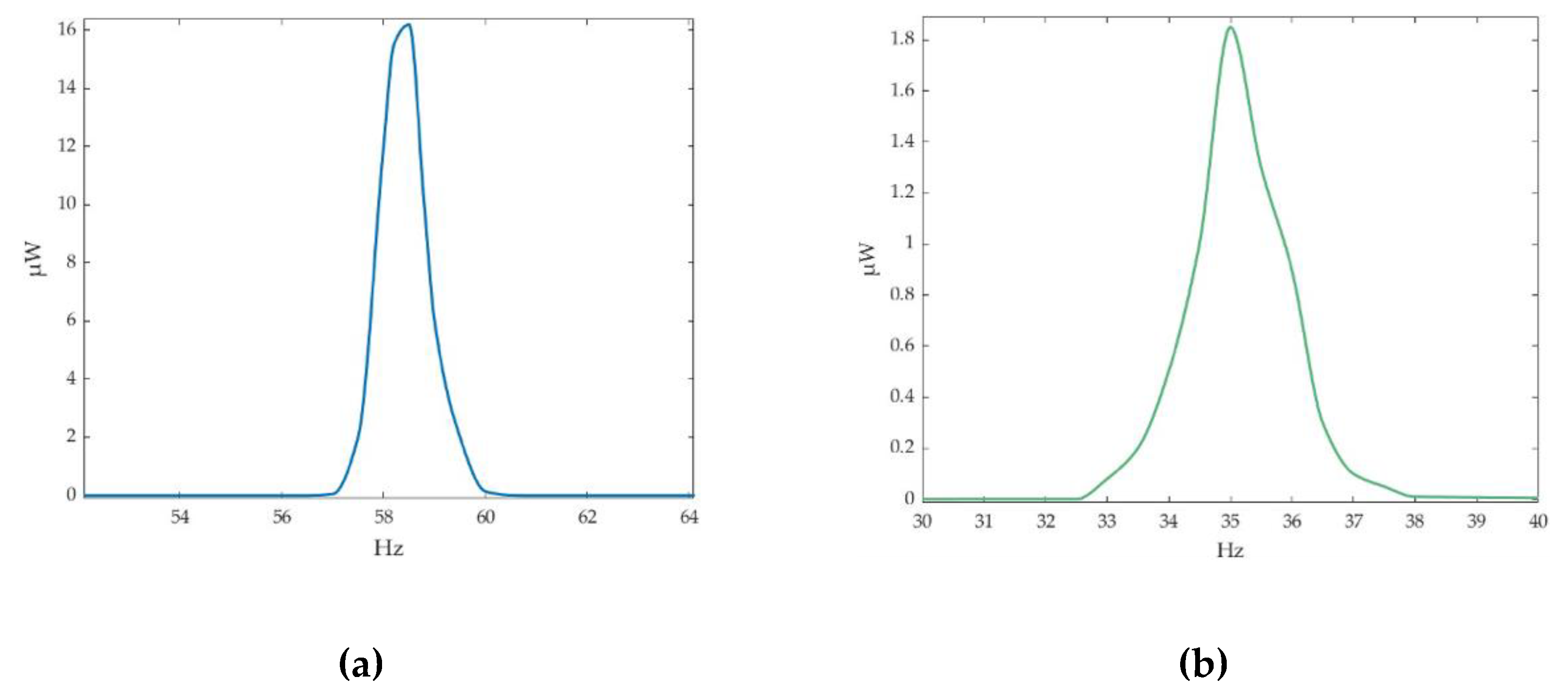

3.4. Electrical characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Noh, C.; Shin, M.; Kwon, Y. A strategy for lowering cross-contamination of aqueous redox flow batteries using metal-ligand complexes as redox couple. J. Power Sources 2022, 520, 230810. [Google Scholar] [CrossRef]

- Mumtaz, S.; Jiang, C.; Tolli, A.; Al-Dulaimi, A.; Butt, M.M.; Asif, H.M.; Ashraf, M.I. Guest Editorial: 6G: The Paradigm for Future Wireless Communications. IEEE Wirel. Commun. 2022, 29, 14–15. [Google Scholar] [CrossRef]

- Attaran, M. The impact of 5G on the evolution of intelligent automation and industry digitization. J. Ambient Intell. Humaniz. Comput. 2021. [Google Scholar] [CrossRef] [PubMed]

- Fazea, Y.; Mohammed, F.; Al-Nahari, A. A Review on 5G Technology in IoT-Application Based on Light Fidelity (Li-Fi) Indoor Communication. In; 2022; pp. 371–384.

- Wu, Y.; Li, Y.; Zou, Y.; Rao, W.; Gai, Y.; Xue, J.; Wu, L.; Qu, X.; Liu, Y.; Xu, G.; et al. A multi-mode triboelectric nanogenerator for energy harvesting and biomedical monitoring. Nano Energy 2022, 92, 106715. [Google Scholar] [CrossRef]

- He, T.; Lee, C. Evolving Flexible Sensors, Wearable and Implantable Technologies Towards BodyNET for Advanced Healthcare and Reinforced Life Quality. IEEE Open J. Circuits Syst. 2021, 2, 702–720. [Google Scholar] [CrossRef]

- Miraz, M.H.; Ali, M.; Excell, P.S.; Picking, R. A review on Internet of Things (IoT), Internet of Everything (IoE) and Internet of Nano Things (IoNT). In Proceedings of the 2015 Internet Technologies and Applications (ITA); IEEE, 2015; Vol. 113; pp. 219–224. [Google Scholar]

- Tan, Y.; Dong, Y.; Wang, X. Review of MEMS electromagnetic vibration energy harvester. J. Microelectromechanical Syst. 2017, 26, 1–16. [Google Scholar] [CrossRef]

- Yan, J.; Liao, X.; Yan, D.; Chen, Y. Review of Micro Thermoelectric Generator. J. Microelectromechanical Syst. 2018, 27, 1–18. [Google Scholar] [CrossRef]

- Chen, T.; Shi, Q.; Li, K.; Yang, Z.; Liu, H.; Sun, L.; Dziuban, J.; Lee, C. Investigation of Position Sensing and Energy Harvesting of a Flexible Triboelectric Touch Pad. Nanomaterials 2018, 8, 613. [Google Scholar] [CrossRef]

- Liu, L.; Guo, X.; Liu, W.; Lee, C. Recent Progress in the Energy Harvesting Technology—From Self-Powered Sensors to Self-Sustained IoT, and New Applications. Nanomaterials 2021, 11, 2975. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Z.W. A new type of piezoelectric self-excited vibration energy harvester for micro-actuator’s energy storage. J. Energy Storage 2022, 46, 103519. [Google Scholar] [CrossRef]

- Prajwal, K.T.; Manickavasagam, K.; Suresh, R. A review on vibration energy harvesting technologies: analysis and technologies. Eur. Phys. J. Spec. Top. 2022 2318 2022, 231, 1359–1371. [Google Scholar] [CrossRef]

- Pourashraf, T.; Bonello, P.; Truong, J. Analytical and Experimental Investigation of a Curved Piezoelectric Energy Harvester. Sensors 2022, 22, 2207. [Google Scholar] [CrossRef]

- Abouzarkhanifard, A.; Chimeh, H.E.; Janaideh, M. Al; Zhang, L. FEM-Inclusive Transfer Learning for Bistable Piezoelectric MEMS Energy Harvester Design. IEEE Sens. J. 2023, 23, 3521–3531. [Google Scholar] [CrossRef]

- Zhu, X.; Xiao, J.; Mao, Q.; Zhang, Z.; You, Z.; Tang, L.; Zhong, Q. A promising regeneration of waste carbon residue from spent Lithium-ion batteries via low-temperature fluorination roasting and water leaching. Chem. Eng. J. 2022, 430, 132703. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Salehi, H.; Zhang, H.; Zhou, H.; Jiao, P. Integrated structural health monitoring in bridge engineering. Autom. Constr. 2022, 136, 104168. [Google Scholar] [CrossRef]

- Blokhina, E.; El Aroudi, A.; Alarcon, E.; Galayko, D. Introduction to Vibration Energy Harvesting. In Nonlinearity in Energy Harvesting Systems; Springer International Publishing: Cham, 2016; pp. 1–21. [Google Scholar]

- Kargar, S.M.; Hao, G. An Atlas of Piezoelectric Energy Harvesters in Oceanic Applications. Sensors 2022, 22, 1949. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Xu, M.; Xiao, X.; Ma, Y.; Li, Z.; Wang, Z.L. Recent progress in blue energy harvesting for powering distributed sensors in ocean. Nano Energy 2021, 88, 106199. [Google Scholar] [CrossRef]

- Sun, H.; Yin, M.; Wei, W.; Li, J.; Wang, H.; Jin, X. MEMS based energy harvesting for the Internet of Things: a survey. Microsyst. Technol. 2018, 24, 2853–2869. [Google Scholar] [CrossRef]

- Zheng, X.; He, L.; Wang, S.; Liu, X.; Liu, R.; Cheng, G. A review of piezoelectric energy harvesters for harvesting wind energy. Sensors Actuators A Phys. 2023, 352, 114190. [Google Scholar] [CrossRef]

- Huang, M.; Zhu, M.; Feng, X.; Zhang, Z.; Tang, T.; Guo, X.; Chen, T.; Liu, H.; Sun, L.; Lee, C. Intelligent Cubic-Designed Piezoelectric Node (iCUPE) with Simultaneous Sensing and Energy Harvesting Ability toward Self-Sustained Artificial Intelligence of Things (AIoT). ACS Nano 2023. [Google Scholar] [CrossRef] [PubMed]

- Almurisi, N.; Tadisetty, S. Cloud-based virtualization environment for IoT-based WSN: solutions, approaches and challenges. J. Ambient Intell. Humaniz. Comput. 2022. [Google Scholar] [CrossRef]

- Krishnamoorthy, S.; Dua, A.; Gupta, S. Role of emerging technologies in future IoT-driven Healthcare 4.0 technologies: a survey, current challenges and future directions. J. Ambient Intell. Humaniz. Comput. 2021. [CrossRef]

- Alamin Dow, A.B.; Schneider, M.; Koo, D.; Al-Rubaye, H.A.; Bittner, A.; Schmid, U.; Kherani, N. Modeling the performance of a micromachined piezoelectric energy harvester. Microsyst. Technol. 2012, 18, 1035–1043. [Google Scholar] [CrossRef]

- Megdich, A.; Habibi, M.; Laperrière, L. A review on 3D printed piezoelectric energy harvesters: Materials, 3D printing techniques, and applications. Mater. Today Commun. 2023, 35, 105541. [Google Scholar] [CrossRef]

- Luo, J.; Cao, Z.; Yuan, M.; Liang, Y.; Xu, X.; Li, M. Fabrication and characterization of miniature nonlinear piezoelectric harvester applied for low frequency and weak vibration. Results Phys. 2018, 11, 237–242. [Google Scholar] [CrossRef]

- Elvira-Hernández, E.; Uscanga-González, L.; de León, A.; López-Huerta, F.; Herrera-May, A. Electromechanical Modeling of a Piezoelectric Vibration Energy Harvesting Microdevice Based on Multilayer Resonator for Air Conditioning Vents at Office Buildings. Micromachines 2019, 10, 211. [Google Scholar] [CrossRef]

- Song, H.C.; Kumar, P.; Maurya, D.; Kang, M.G.; Reynolds, W.T.; Jeong, D.Y.; Kang, C.Y.; Priya, S. Ultra-Low Resonant Piezoelectric MEMS Energy Harvester With High Power Density. J. Microelectromechanical Syst. 2017, 1–9. [Google Scholar] [CrossRef]

- Nesser, H.; Yuan, J.; Colin, A.; Poulin, P.; Dufour, I.; Debeda, H.; Ayela, C. Electrostriction as an integrated transduction method for organic MEMS. Symp. Des. Test, Integr. Packag. MEMS/MOEMS, DTIP 2016 2016, 8–12. [CrossRef]

- Yang, Z.; Zhou, S.; Zu, J.; Inman, D. High-Performance Piezoelectric Energy Harvesters and Their Applications. Joule 2018, 2, 642–697. [Google Scholar] [CrossRef]

- Frost & Sullivan Advances in energy harvesting technologies; 2007; ISBN 2103481003.

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Srinivasulu Raju, S.; Choi, S.-B.; Umapathy, M.; Uma, G. An effective energy harvesting in low frequency using a piezo-patch cantilever beam with tapered rectangular cavities. Sensors Actuators A Phys. 2019, 297, 111522. [Google Scholar] [CrossRef]

- Dietl, J.M.; Garcia, E. Beam Shape Optimization for Power Harvesting. J. Intell. Mater. Syst. Struct. 2010, 21, 633–646. [Google Scholar] [CrossRef]

- Mallick, D.; Constantinou, P.; Podder, P.; Roy, S. Multi-frequency MEMS electromagnetic energy harvesting. Sensors Actuators A Phys. 2017, 264, 247–259. [Google Scholar] [CrossRef]

- V, S.; M, R.; Kumar, S.S.; Tripathi, V.; Sharma, R.; Puthilibai, G.; Sudhakar, M.; Negash, K. Study on Developments in Protection Coating Techniques for Steel. Adv. Mater. Sci. Eng. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Pérez-Cuapio, R.; Pacio, M.; Juarez, H.; Alvarado, J.A.; Guarneros, C.; Bueno, C.; Pacio, A. Effect of ZnO Film Thickness on its Optical and Structural Properties. J. Nano Res. 2018, 52, 102–114. [Google Scholar] [CrossRef]

- Uscanga-González, L.A.; Elvira-Hernández, E.A.; Pérez-Cuapio, R.; Pacio, A.; López-Huerta, F.; Alvarez-Sanchez, E.J.; Herrera-May, A.L. Deposition of Multilayer Films of ZnO by Sol-gel Process on Stainless Steel Substrates for Energy Harvesting Devices. IOP Conf. Ser. Mater. Sci. Eng. 2020, 908, 012005. [Google Scholar] [CrossRef]

- Velazquez, B.J.M.; Baskaran, S.; Gaikwad, A. V; Ngo-Duc, T.T.; He, X.; Oye, M.M.; Meyyappan, M.; Rout, T.K.; Fu, J.Y.; Banerjee, S. Effective piezoelectric response of substrate-integrated ZnO nanowire array devices on galvanized steel. ACS Appl. Mater. Interfaces 2013, 5, 10650–10657. [Google Scholar] [CrossRef]

- Fan, T. Nano-scale energy harvester of piezoelectric/piezomagnetic structures with torsional mode. Mech. Syst. Signal Process. 2018, 112, 147–153. [Google Scholar] [CrossRef]

- Bestley Joe, S.; Maflin Shaby, S. Performance analysis on the electrical behaviour of Zinc oxide based nanowire for energy harvesting applications. Proc. 5th Int. Conf. Electron. Commun. Aerosp. Technol. ICECA 2021 2021, 230–236. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, G.; Al-Dossary, O.; Umar, A. ZnO nanostructured thin films: Depositions, properties and applications—A review. Mater. Express 2015, 5, 3–23. [Google Scholar] [CrossRef]

- Jabbar, R.H.; Hilal, I.H.; Ali, H.J. Study of Physical Properties and Sensitivity of Mercury Doped ZnO Thin Films. IOP Conf. Ser. Mater. Sci. Eng. 2019, 571, 012109. [Google Scholar] [CrossRef]

- Novak, N.; Keil, P.; Frömling, T.; Schader, F.H.; Martin, A.; Webber, K.G.; Rödel, J. Influence of metal/semiconductor interface on attainable piezoelectric and energy harvesting properties of ZnO. Acta Mater. 2019, 162, 277–283. [Google Scholar] [CrossRef]

- Cao, J.; Gu, Y.; Fan, W.; Chen, L.Q.; Ogletree, D.F.; Chen, K.; Tamura, N.; Kunz, M.; Barrett, C.; Seidel, J.; et al. Extended Mapping and Exploration of the Vanadium Dioxide Stress-Temperature Phase Diagram. Nano Lett. 2010, 10, 2667–2673. [Google Scholar] [CrossRef] [PubMed]

- Priya, S.; Song, H.-C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.-G.; Kanno, I.; Wu, L.; Ha, D.S.; Ryu, J.; et al. A Review on Piezoelectric Energy Harvesting: Materials, Methods, and Circuits. Energy Harvest. Syst. 2019, 4, 3–39. [Google Scholar] [CrossRef]

- Espinoza-Beltrán, F. .; Che-Soberanis, O.; Garcı́a-González, L.; Morales-Hernández, J. Effect of the substrate bias potential on crystalline grain size, intrinsic stress and hardness of vacuum arc evaporated TiN/c-Si coatings. Thin Solid Films 2003, 437, 170–175. [Google Scholar] [CrossRef]

- Young, A. Channeling Fisher: Randomization Tests and the Statistical Insignificance of Seemingly Significant Experimental Results*. Q. J. Econ. 2019, 134, 557–598. [Google Scholar] [CrossRef]

- Tsiang, S.C. The Rationale of the Mean-Standard Deviation Analysis, Skewness Preference, and the Demand for Money. In Finance Constraints and the Theory of Money; Elsevier, 1989; pp. 221–248.

- Stamatellou, A.-M.; Kalfas, A.I. Experimental investigation of energy harvesting from swirling flows using a piezoelectric film transducer. Energy Convers. Manag. 2018, 171, 1405–1415. [Google Scholar] [CrossRef]

- Li, K.; He, Q.; Wang, J.; Zhou, Z.; Li, X. Wearable energy harvesters generating electricity from low-frequency human limb movement. Microsystems Nanoeng. 2018, 4, 24. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Deng, W.; Pan, J.; Zhou, Z.; Du, W.; Zhu, P. Harvesting wind energy with bi-stable snap-through excited by vortex-induced vibration and galloping. Energy 2019, 189, 116237. [Google Scholar] [CrossRef]

- Butram, V.; Naugarhiya, A. Performance Enhancement of Piezoelectric MEMS Energy Harvester Using Split Proof Mass for Powering Ultralow Power Wireless Sensor Nodes. Arab. J. Sci. Eng. 2022, 47, 2755–2762. [Google Scholar] [CrossRef]

- Shi, M.; Holmes, A.S.; Yeatman, E.M. Piezoelectric wind velocity sensor based on the variation of galloping frequency with drag force. Appl. Phys. Lett. 2020, 116, 264101. [Google Scholar] [CrossRef]

- Fareeza, F.; Krishna Veni, S.; Rambabu, C.; Yanore, T.Z.; Rajkumar, P. Future Energy Source for Remote IoT Systems using MEMS-based Piezoelectric Energy Harvesting Devices. J. Phys. Conf. Ser. 2021, 1979. [Google Scholar] [CrossRef]

- Debnath, B.; Kumar, R. A Comparative Simulation Study of The Different Variations of PZT Piezoelectric Material by Using A MEMS Vibration Energy Harvester. IEEE Trans. Ind. Appl. 2022, 1–1. [Google Scholar] [CrossRef]

- Salem, S.; Fraňa, K. Harvesting energy of flow-induced vibrations using cylindrical piezoelectric transducers. Energy Reports 2023, 9, 279–285. [Google Scholar] [CrossRef]

| Resistance (Ohms) | Central beam voltage (mV) |

External beam voltage (mV) |

Central beam power (µW) |

External beams Power (µW) |

|---|---|---|---|---|

| 464000 | 12 | 34 | 0.00015 | 0.0012 |

| 200000 | 80 | 860 | 0.016 | 1.849 |

| 100000 | 57 | 560 | 0.0162 | 1.568 |

| 98000 | 20 | 70 | 0.0020 | 0.025 |

| 93449.7 | 43.11 | 503.7 | 0.0064 | 1.3574 |

| 93000 | 40 | 504 | 0.0086 | 1.3656 |

| 49500 | 40 | 230 | 0.0161 | 0.5343 |

| Year | Piezoelectric material | Piezoelectric Film Thickness (𝜇m) | Power (𝜇W) |

Frequency (Hz) |

Voltage (mV) |

Acceleration(g) | Reference |

|---|---|---|---|---|---|---|---|

| 2018 | PVDF | 200 | 3 | 6 | 3.7 x 10 3 | - | [52] |

| 2018 | PZT | 60 | 3.5 | 5 | 4 x 10 3 | 1 | [53] |

| 2019 | PZT | 150 | 0.50 | 1.53 | 3 x 10 3 | - | [54] |

| 2020 | PVDF | 28 | 4.9 | 6.1 | 9 x 10 3 | 1.5 | [55] |

| 2021 | PVDF | 28 | 0.14 | 25 | 376.92 | 0.24 | [56] |

| 2021 | ZnO | 1.5 | 1.97 | 108.84 | 545 | 2 | [57] |

| 2022 | PZT | 2 | 0.01 | 28.6 | 40 | 0.07 | [58] |

| 2022 | Barium Titanate | - | 1.6 | 57.1 | 3.7 x 10 3 | 1 | [55] |

| 2023 | PZT | 500 | 0.000370 | - | 13 | 1 | [59] |

| This work | ZnO | 1 | 1.849 a | 35 | 1.08 x 10 3 a | 2 | External beams |

| This work | ZnO | 1 | 0.00016 a | 58.5 | 180 a | 2 | Central beam |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).