1. Introduction

In recent years, we have experienced a tremendous boom in the digitalization of processes that speed up decision-making processes in manufacturing companies. The use of machine learning algorithms and artificial intelligence is gradually becoming a normal part of our lives. At the same time, new designed production and assembly systems need maintenance systems for maintenance management and diagnostics of production equipment. Enterprises [

1] need to identify tools and technologies for maintenance planning and management in line with Industry 4.0 approaches. The focus is on the application of a maintenance prediction program, the implementation of technical diagnostics equipment, the implementation of smart sensors, the interconnection of equipment using the Internet of Things, and the use of mobile applications in maintenance.

The concept of Industry 4.0 [

2,

3,

4,

5] helps industrial enterprises to achieve rapid adaptation of new production and enable timely response against occurring faults caused by new production ramp-up and emerging production equipment failures by using an intelligent maintenance system integrated into a digital twin. The maintenance manager uses standard indicators such as OEE (Overall Equipment Effectiveness), MTTR (Mean Time to Repair), MTBF (Mein Time Between Failure), R(t) (Probability of trouble-free operation), F(t) (Probability of Failure), A (Availability), λ (Intensity of disturbances), availability and reliability of machines and equipment. These indicators take a picture of the state of operation of the production and assembly lines in detail, for decision-making. The above indicators are obtained from data sensed by sensors on the plant floor.

Maintenance departments are still "fighting fires" instead of tackling their problems systematically. Instead of waiting for problems to occur, prevention is a better goal. Although this strategy may be a bit costly initially, but it is much less costly compared to waiting for problems [

6,

7,

8,

9]. Maintenance performance is concerned with four areas: maintaining critical systems, fixing the problem faster than before, determining the causes of frequent failures, and finally identifying the 20% of failures that occupy 80% of the available resources [

10].

The most common troubleshooting process in maintenance includes identifying faults and where machine failures occur, analyzing faults, defining cause relationships, defining goals, and planning resources to eliminate and prevent faults [

11]. The above procedure is defined as a set maintenance management strategy, which needs to be re-evaluated depending on the fulfilment of key production system indicators such as efficiency and quality.

1.1. Subsection

Maintenance is the combination of all practical, managerial, and administrative activities throughout the life cycle of an installation to maintain or restore it to a state in which it can perform its required function. It is also defined as all the necessary and essential activities that are required to maintain a system throughout its life cycle in an operational and functional state or to restore it to a state in which it can perform its intended function [

12]. The importance of the maintenance function has increased over time due to its role and impact on the rest of the working environment in the organization, i.e., by improving product quality and machine availability. Effective maintenance contributes to increased value through more profitable use of resources, improved product quality, and reduced rework and scrap [

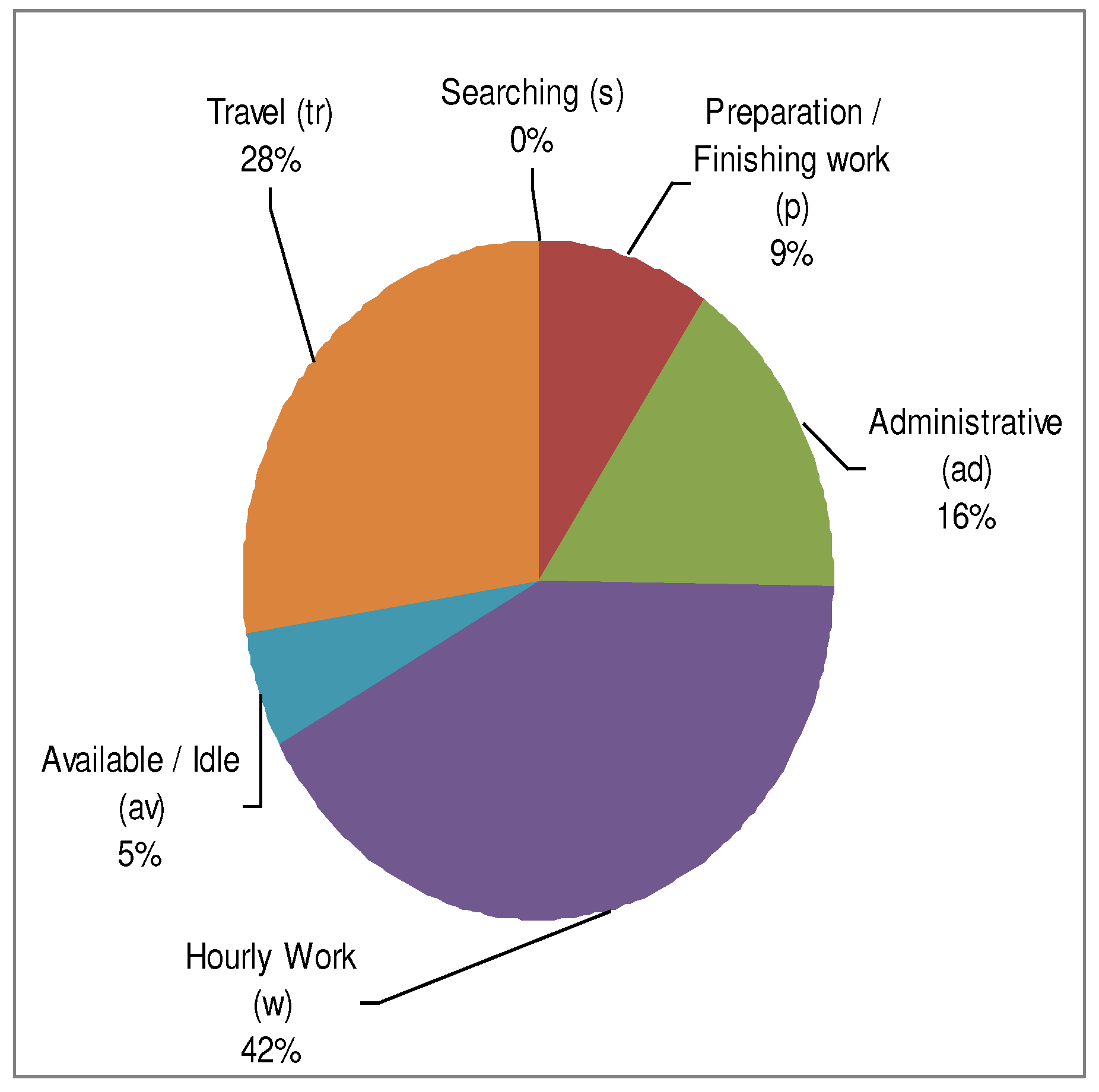

13]. The maintenance is categorized into two main areas, i.e., preventive maintenance, which includes all planned maintenance activities such as condition monitoring and periodic inspection, while corrective maintenance has to do with all unplanned maintenance activities to restore failure (

Figure 1).

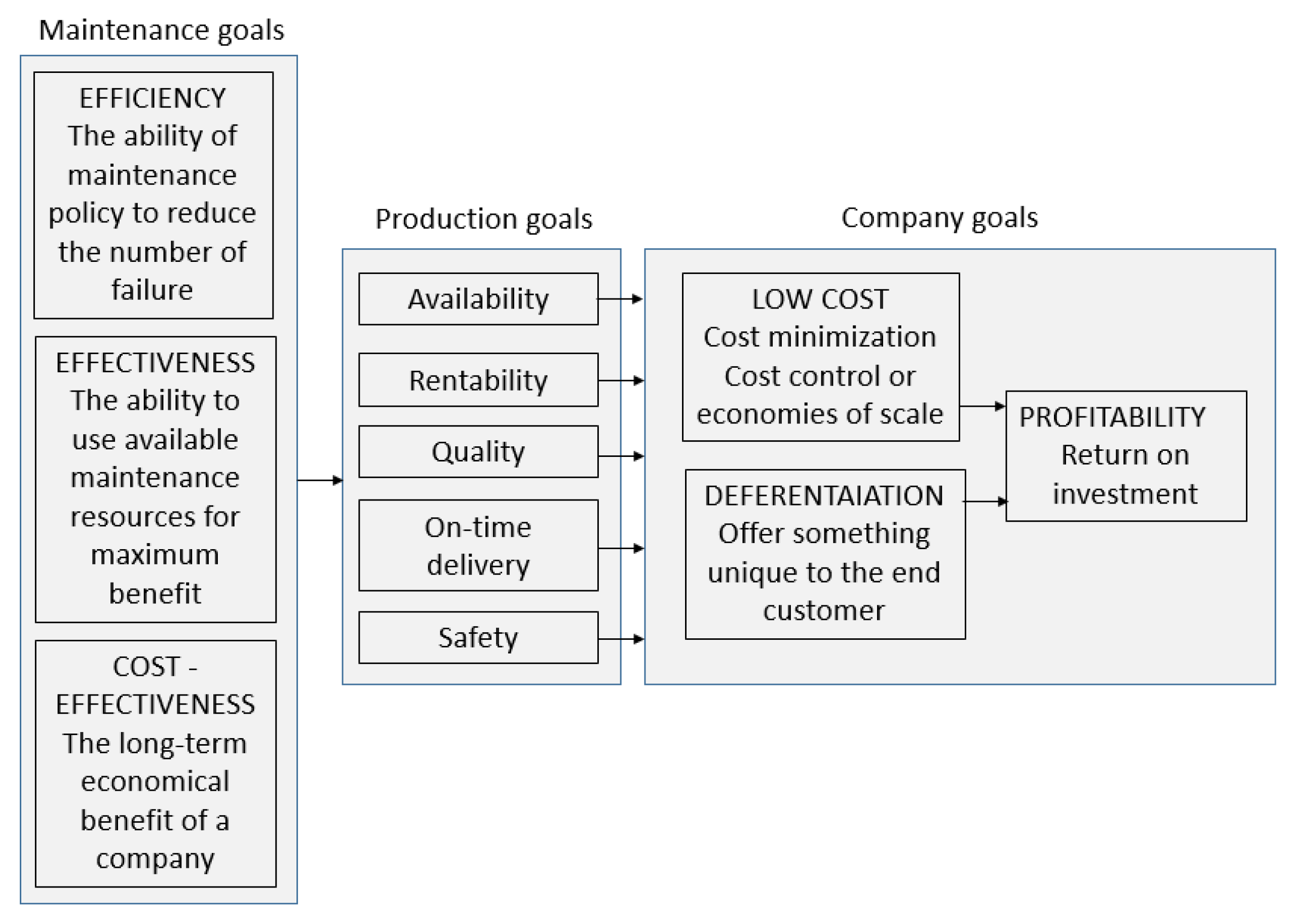

As always, the basic commitment of creation is to deliver the goods, but an effective maintenance strategy affects the production capacity of the machines used to produce these products [

14]. Therefore, maintenance can be considered as an organizational purpose that works in concert with production. When others reiterate that production produces products, others also say that maintenance produces the capacity for production. In this way, it can be stated that maintenance disrupts production by increasing the capacity of production and at the same time controlling the output and quality. Below is a graph that illustrates the impact of maintenance on production.

A company’s profitability and survival may not be sustained without maintaining product quality. High quality can serve as a major edge to a company’s competitive advantage and long-term profitability in the modern global economy. Total Productive Maintenance may be the only adequate model that identifies the relationship between maintenance and quality. Normally, they say that equipment/machines that lack maintenance and break down often lose speed and therefore cause defects (breakdowns). This equipment usually out of control production processes. Obviously, a process that is out of control leads to the production of defective products and increases the cost of production, which minimizes profit [

15].

Profitability is the result of price and productivity recovery. Consequently, productivity determines the efficiency and effectiveness of the production process. According to APQC (American Productivity & Quality Center) cited in [

13], when analyzing the profitability of maintenance, the impact of the work area is also measured, for example, by guaranteeing the role of maintenance within the life cycle of the machine. In general, maintenance improvement aims to reduce operating costs and increase product quality. Certainly, if there is a connection or rather a link between maintenance and profitability. The diagram of

Figure 2 shows how these two objectives are linked together.

1.2. Maintenance Strategy

Maintenance activities are managed in accordance with the established maintenance policy and with the intention of achieving the desired objectives. The maintenance strategy for the production support process (as part of the company’s strategy) can be based on and support the company’s objectives and strategy, perspectives, and background.

For the development of the maintenance strategy, the enterprise strategy provides information on the expected production and product portfolio, expected production expansion and contraction programs, expected changes in production equipment and other tangible assets, logistical aspects of production processes, expected financial resources, the way production equipment is operated and used (it provides information on the expected variability in the use of production equipment and the resulting expected intensity of use of the calendar time pool, the required times of use and operation and the consequent required volumes of maintenance activities, etc.).

For the purposes of the maintenance strategy, these data are expanded into a more detailed and specific form (e.g., the structure and number of production facilities, data on their reliability, in particular the requirements for the volume of preventive and corrective maintenance in standard hours, possibly also in financial terms, the requirements for mechanical, electrical and other maintenance, the expected structure of internal and external maintenance, outsourcing, serviceability, criticality of inclusion in production lines and processes, the effects of downtime, etc.).

A maintenance strategy is defined by HN 13 306 as a management method used to achieve maintenance objectives. The results achieved in the medium and long term depend on the maintenance strategy. It is mainly about efficiency, productivity, economic efficiency, and the fulfilment of basic maintenance requirements, in particular:

keeping assets in a serviceable and adequate condition,

preventing breakdowns,

operational troubleshooting,

reducing the environmental impact of the operation of the equipment,

ensuring operational safety,

incurring optimum maintenance costs.

The objectives should be hierarchical, quantified, realistic and mutually aligned. If a company chooses a strategy, it must implement it consistently if it is to be successful.

Strategies can focus on, for example:

seeking opportunities that make the most of strengths,

overcoming weaknesses to exploit opportunities,

using strengths to eliminate risks,

preventing weaknesses from being attacked, etc.

In general, there are several basic types of maintenance strategies or policies. This is a breakdown of maintenance based on the types that have been formulated in the past [

4] but persist until now (

Table 1).

The required level of maintenance of the long-term asset, the model of excellence is based on:

"world-class" best practice maintenance experience, but for specific organizations it must be tailored to their internal and external conditions,

from a methodological point of view, it is more efficient and practical to determine the levels of excellence directly by individual audit criteria and for individual management audit questions,

this process is extremely difficult, objective information is often lacking, it is necessary to take an expert to intuitive approach to determining the level of excellence,

benchmarking can be a great help if the required data can be obtained.

1.3. Selecting the Right Maintenance Strategy

Choosing the right maintenance strategy is important for every business. It needs to determine which strategy will be advantageous for it in terms of cost, downtime, and other important factors. It also depends on the type of production or industry. It is common to use several strategies simultaneously, e.g., corrective, and preventive maintenance, depending on the categorization of the machinery [

7].

Maintenance has to do with the development of tasks and activities to prolong or extend the ability of the equipment to function for a long period during its productive life [

8]. Rather, maintenance schedules are performed on a regular (scheduled) daily basis to ensure that equipment is available to meet production specifications and requirements. The basic importance of maintenance is functional and operational checks, servicing, replacement of necessary equipment, plant, machinery, building infrastructure and supporting utilities in industrial areas. It is the work of keeping something in its original condition. This always involves developing a document to ensure that these tasks are carried out in a proper and consistent manner.

In industrial areas, key maintenance tasks have become an essential part of the overall profitability of the organization. Maintenance techniques now can significantly increase an organization’s competitive advantage in the global marketplace. There are many different reasons why maintenance should be performed in a plant or process facility. The importance of maintenance cannot be overlooked because it has such a significant role in the adequacy of lean assembly [

9]. There is a need to adequately reduce wastage and perform an efficient and sustainable assembly activity or administrative task. Regular maintenance is much less costly compared to the cost of serious failures when not in production. The most important purpose of frequent maintenance is to ensure that all equipment required for production is always operating at 100% efficiency. Although checking, lubricating, cleaning, and making small changes daily, small problems can be spotted and handled before they turn into colossal problems that can end up shutting down the entire production line.

A progressive maintenance program needs full support from the bottom management to the top management, from the top executive to the shop floor personnel. Maintenance is carried out in accordance with the legal requirements of the Health and Safety at Work Act.

The aim is to provide a safe working environment for subordinates. Although both the employer and the organization are socially responsible for providing a safe working environment for the company’s subordinates. This can be archived through the appropriate use of maintenance techniques and the implementation of a maintenance program designed to eliminate defects that may have safety implications [

10]. International

Another important reason to perform maintenance is that equipment and facilities that are not properly maintained wear out too soon. This early deterioration has an impact on the costs that are associated with equipment replacement. Implementing a careful maintenance program can lead to increased equipment life, thereby minimizing repair costs. Effective maintenance activities allow equipment to be repaired before it fails, avoiding the cost of uncontrollable breakdowns and the potential loss of revenue. Keeping machinery in very good condition is a sure thing, the most important aspect of today’s industry [

11].

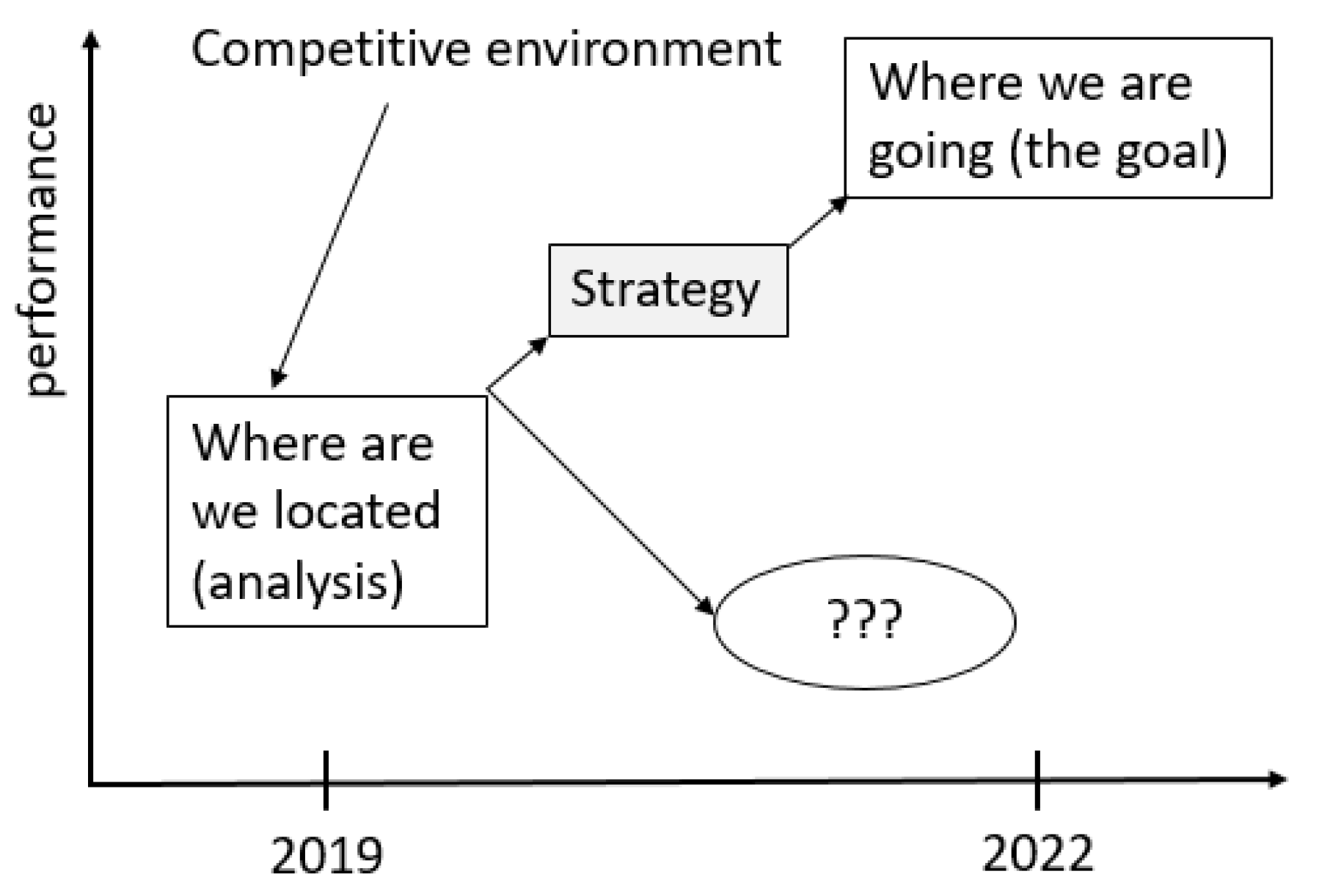

1.4. Strategic Management and Maintenance Management

Strategic management [

5] is most often divided into innovation, marketing, and finance, with options and goals for 3 to 5 years. These are then used as the basis for the company’s operational objectives for the year, which are further developed into individual processes and products. Strategic innovation and financial management primarily influence maintenance. Strategic management usually involves an analysis of the current situation, the formulation of objectives, the choice of strategy and its implementation. The achievement of a company’s strategic objectives must be supported by its individual departments (organizational units), including maintenance. Strategic maintenance management is part of the strategic management of the enterprise and all maintenance requirements. In addition, the collection, analysis, and evaluation of data on the maintenance of the organization’s assets forms an important basis for supporting strategic management.

Maintenance management encompasses all management activities that determine the objectives, strategies, and responsibilities of maintenance and that are applied by management through such means as planning, directing, controlling, and improving the methods of organizing maintenance, including economic aspects.

Strategy is generally defined as the art of directing the activities of a collective towards the achievement of objectives

Figure 3.

2. Materials and Methods

The maintenance objectives and strategies are intended to guide maintenance management to achieve ‘excellence’ in the maintenance of physical assets. The strategy developed requires the development of supporting programs for its implementation. This output should take the form of topics for improvement of maintenance with a time horizon for solutions generally within one year (exceptionally longer), with defined responsibilities of researchers and implementers, resources, and individual milestones for implementation. The same attention as the design of support programs must be given to their implementation.

The maintenance improvement projects implemented, and their results must be measured and evaluated while gathering evidence (data and information for existing, maintenance strategies. To be carried out annually (on a rolling, sliding scale) but always with at least a three-year horizon.

The expected benefit, provided the organization’s strategy is properly integrated into maintenance management, is a significant improvement in its performance, efficiency, and overall economic effectiveness. If the implementation of the strategy is to be successful, it must be known in the organization and supported by maintenance management. It is about creating a sense of belonging amongst the workforce with the company and the workplace. Motivation should be the feeling that their work is meaningful.

In the process of developing a strategy, a long-term programme of improvement and change is created, including a change in working style. In the long term, a flat organizational structure and the use of small, autonomous, and flexible groups are best suited to achieving this in a flexible way.

It is common to see a change in organizational structure with a change in management. Thus, if maintenance is centralized, it is changed to decentralized and vice versa. Similarly, the trend in companies is to focus on the "core business" and to separate other activities - in the case of maintenance, not to outsource them.

There is currently no coherent view of the different organizational structures and their models for businesses, and, in principle, there should be no reason why. Each form of maintenance organization has its pros and cons. Similarly, in-house maintenance is not automatically better or worse than contractor maintenance. It is up to the management of the enterprise to consider the specific conditions, make the most of the strengths, and counteract the weaknesses of each system.

The maintenance strategy should include requirements:

the proportion of outsourced maintenance in the organization as a whole,

shares for individual maintenance processes and production facilities,

expressed as a ratio of the cost of outsourced maintenance to the total cost of the ratio of outsourced maintenance to the total maintenance costs.

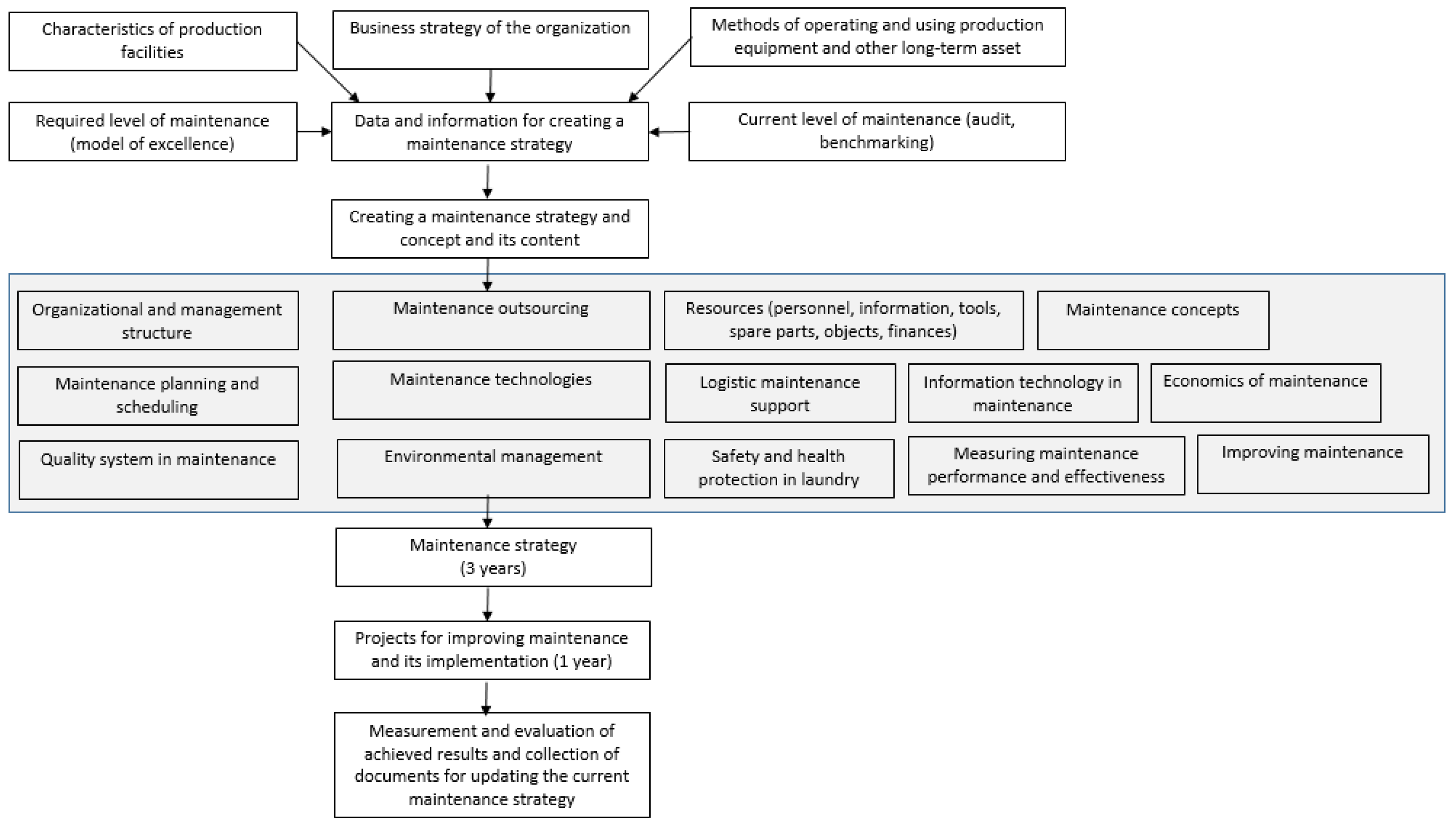

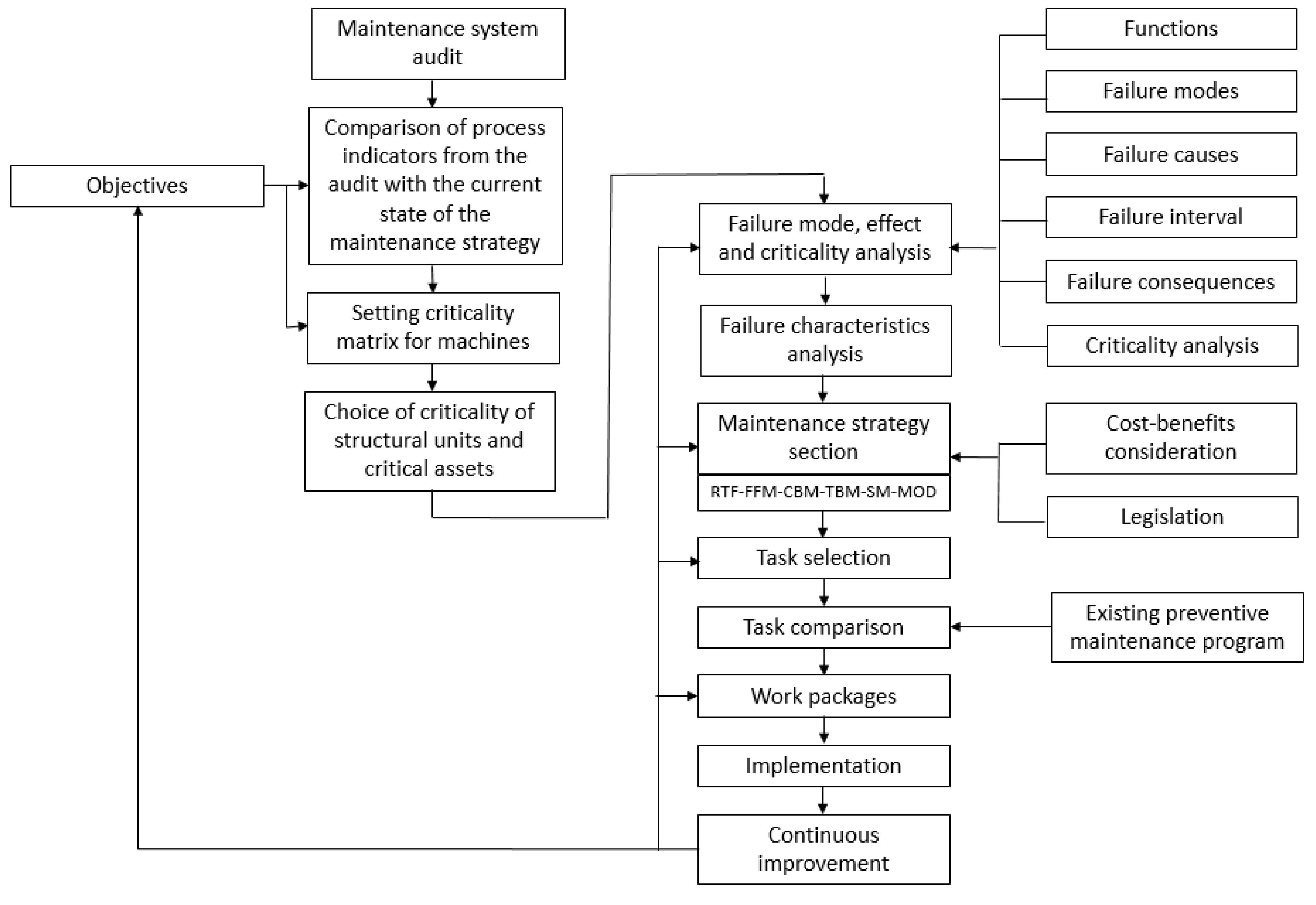

The development of the company’s strategy but also the maintenance (

Figure 4) is a team effort by the cooperation of departments that are directly or indirectly affected by the processes. Prior to release, the documents must be reviewed and approved by the senior management of the enterprise, especially regarding feasibility and security of the required resources.

Based on the analysis, the hypothesis was defined: a managed change in the maintenance strategy will lead to an increase in quality, production efficiency and a better use of maintenance capacity and a reduction in SP costs.

Figure 4.

Algorithm for creating a maintenance strategy and concept.

Figure 4.

Algorithm for creating a maintenance strategy and concept.

2.1. Maintenance Strategy for Long-Term Asset (LTA)

The marketing strategy is based on the organization’s municipal business strategy, which describes the organization and the services provided, the key customers and their degree of satisfaction. It describes an analysis of financial performance and a survey of the competitive and market environment plus strengths, weaknesses, and key business competitive factors. The organization’s strategy provides the business vision of the organization, the specifics of the mission, the major objectives, and the business plan to achieve them.

Characteristics of manufacturing facilities and other fixed assets emerge from the business strategy:

the structure and numbers of production facilities,

data on their reliability, durability, sustainability, maintenance, and availability, in particular the requirements for preventive maintenance and maintenance volume in standard hours, post-failure maintenance, in standard hours and, where appropriate, in financial terms,

mechanical, electrical, and other maintenance requirements,

the expected structure of internal and external maintenance, service provision,

criticality of equipment to production lines and machines,

the impact of downtime on production.

Long-term asset maintenance steps:

Maintenance management encompasses all management activities that determine the objectives, strategies and responsibilities of maintenance and that management applies by such means as planning, directing, and controlling maintenance and improving methods in the organization, including economic EN 13306 considerations.

Maintenance objectives represent the goals assigned and adopted for maintenance activities; these objectives may include, for example, availability, cost reduction, product quality, environmental protection, safety, etc. EN 13306.

The maintenance plan is a structured set of tasks that includes the activities, procedures, resources, and scheduling required carrying out EN 13306 maintenance.

The development of a specific LTA maintenance strategy should be subordinated to the proposed generic strategy development model.

The basis for the design of the maintenance strategy is the acquisition of correct and objective input data and information and its transformation into the required maintenance strategy and subsequent maintenance improvement projects based on it.

2.2. Design of an Algorithm for the Development of a Maintenance Strategy and Concept

The methodology for the development of the maintenance strategy and concept defined the input data, information and starting points. The development of the ‘Maintenance Strategy’ document can be based on teamwork and in cooperation with the various departments that are either directly or indirectly affected by the processes. Prior to release, the document should be reviewed by the organization’s senior management, regarding the feasibility and security of the required resources. It should be borne in mind that this document is intended to set the guidelines for maintenance management to achieve excellence in long-term asset maintenance. The final output must be the identification of key tasks to bridge the gap between the current state and the target state of maintenance management excellence in the organization. This output should take the form of maintenance improvement in project themes with a time horizon for resolution of generally up to one year and exceptionally longer, and with defined responsibilities of the developers and implementers of these projects, resources, and individual milestones for implementation.

The output of the

Figure 5 algorithm is a "Maintenance Strategy "document with a time horizon of up to three years and a "Maintenance Concept Development "document with a horizon of about 1 to 1.5 years and a "Maintenance Strategy "for 10 years.

2.3 Maintenance Management Audit

An audit is a systematic, independent, and documented process of obtaining objective evidence and evaluating it objectively to determine the extent to which audit criteria are being met. Audit criteria is a set of policies, procedures or requirements that are used as evidence against which objective evidence is compared [

5]. Records, reports, statements of fact, or other information that relate to the audit criteria and are verifiable may be considered as audit evidence. Audit findings are then the results of the evaluation of the collected audit evidence against the audit criteria.

An audit finding may be:

compliance or non-compliance (with the audit criteria),

compliance or non-compliance (with regulatory requirements or with regulatory requirements),

an opportunity for improvement,

a record of good practice.

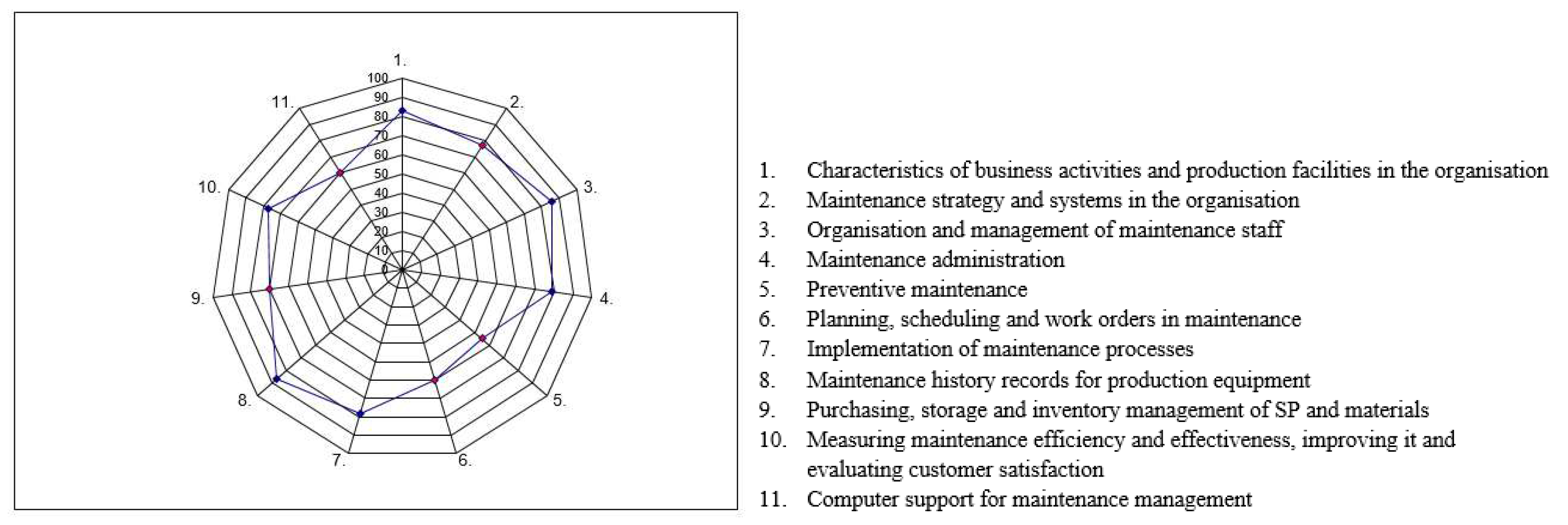

Based on the above criteria for maintenance audits, a system of questions (indicators) and their assessment should be designed to enable practical auditing of possession management in organizations of different types and focuses.

The biggest challenge is evaluating the answers to these questions and quantifying the level of fulfilment of the criteria and requirements contained therein. The evaluation should consider the rating (1 - low importance, 2 - medium importance, 3 - high importance). The questions containing the criteria and the actual answer must be formulated not only in qualitative terms, but also evaluated in terms of percentage points (0% is absolute non-fulfilment of the criterion and 100% is absolute perfect fulfilment of the required criterion).

An even more challenging problem is the determination of the ideal value of the ideal quality criterion of maintenance management. This involves knowing such ideal values as the optimal proportion of preventive maintenance, the optimal proportion of external (outsourced) maintenance, the optimal size of maintenance resources, the optimal ratio of the number of managers and technicians to the number of manual maintainers, etc. An important aid in this area is the benchmarking of maintenance management, carried out at the level of plants in one organization, then between organizations of the same production focus at national level and, where appropriate, at international level. Work of this type is currently in its infancy.

A team-based way of handling responses is preferable to a single worker’s solution. Each question represents one quality indicator of maintenance management, and in addition to the qualitative answer, the quality level Q in percentage is to be assigned based on expert judgement of the level achieved for that indicator (question). The average quality level of the indicator for each area of maintenance management shall be determined by a weighted average (1):

Where: (Q - the average quality level of indicator i - that area of maintenance management,

W (i - the value of the j-th indicator (question) in the i-th maintenance management area.

Q

ij - the quality level of the j-th indicator (answer to the question) in the i-th maintenance management area and not the number of indicators (questions) set in the i-th maintenance management area. Example:

The calculation is done by averaging the quality level of the indicators of the first maintenance management area.

The basis for the evaluation of the maintenance audit is the qualitative and quantitative written responses (

Figure 6) and external benchmarking

Table 2.

These quantitative results give an immediate insight into the weaknesses of maintenance management. The necessary and most important part of the audit is the qualitative answers to the individual questions and their thorough evaluation. The set of questions (indicators) presented is certainly not definitive and exhaustive. It should be considered as an open system that can be further expanded and refined based on experience. The result of this maintenance audit must be a proposal for corrective action to eliminate the causes of the identified deficiencies and to prevent their recurrence.

To ensure competent and reliable production facilities while eliminating material and human factors, to maintain absolute quality (100% excellent product condition), it is necessary to implement quality maintenance [

6] for which it is necessary to determine:

conditions for lining up and setting up for the first time,

conditions for preventive maintenance to achieve a state of zero defects,

determine the causes and consequences that affect the magnitude of deviation from the nominal value,

determine the control and measurement of defined operating and technical conditions of the equipment at time intervals,

based on the magnitude of the deviations, a maintenance plan for the machinery and equipment.

2.4 Quality Maintenance Implementations

The method to maintain machinery and equipment and process of preventive and corrective action to be effective in terms of customer requirements is called maintenance quality. Maintenance quality is a method on how to take preventive measures, the extent and intervals of preventive maintenance and adjustment that will find conditions for reliable equipment condition at optimum maintenance cost and cost of non-conforming production:

Describing the features of quality.

Performing PM analysis (Physical - Mechanism analysis) and discovering the links between quality features and machine design elements.

Determine standard machine accuracy values for maintenance checkpoints.

Concentration of inspection points and reduction of the inspection time.

Develop a maintenance QM (Quality Matrix).

Preparation of QM matrix:

How each inspected item affects the quality attributes.

The number of control nodes that interact with each other affects the quality attributes.

Specification of the conditions of the inspection points so that the inspection worker follows the inspection cycle and the standard range of values that must be maintained.

Research methods were used to investigate this topic:

Analysis and evaluation of the results obtained based on specific successfully solved scientific projects from 2000 - until now, e.g., projects APVV - Slovak Research and Development Agency, VEGA - Ministry of Education, Science, Research and Sport of the Slovak Republic, Operational Research, etc., with a focus on reducing maintenance costs.

Questionnaire - used to find out the status of maintenance strategy for companies in Slovakia.

Interview - interviews conducted with maintenance managers.

Mathematical and statistical methods

Methods for determining labor and time consumption standards.

Seven old and new statistical quality tools.

RCM (Reliability Centered Maintenance), TPM (Total Productive Maintenance), RMI (Repair and Maintenance Information), VDA (The German Association of the Automotive Industry).

Material ordering policies.

Analysis - literature, the current state of maintenance strategy.

Synthesis - results of the analysis of the external and internal environment in the form of a SWOT analysis.

Induction, deduction.

Value stream mapping method was implemented, based on which variants of the new maintenance strategy were created.

3. Results

The research in maintenance strategy and the procedure of improving maintenance processes to increase the efficiency and quality of the production system is based on the audits carried out in Slovak companies, where the projects of maintenance strategy development were implemented. At the same time, knowledge from APVV and VEGA grant projects was applied.

Potential areas of improvement and maintenance problems were identified:

Lack of planning of maintenance activities, weaker planning (lack of planning).

Informal communication of the work to be done with maintenance (flow of requirements).

Lack of leadership of maintenance staff on afternoon and night shifts. Most work done ad-hoc, without work orders.

Working independently, without collaboration.

Lack of a plan for work to be performed outside of breakdowns.

Insufficient, weak reporting.

Lack of autonomous maintenance.

Duplicated work, many things are controlled by the supervisor and by the maintenance person.

No defined standards for specific work.

Lack of motivation of shift maintenance for doing the work. They could perform it faster.

Lack of criteria for evaluating the productivity of the maintenance worker. (What he wrote down did not correspond with what he did).

Work by individuals or small groups without collaboration.

Multi-level hierarchical structure of maintenance.

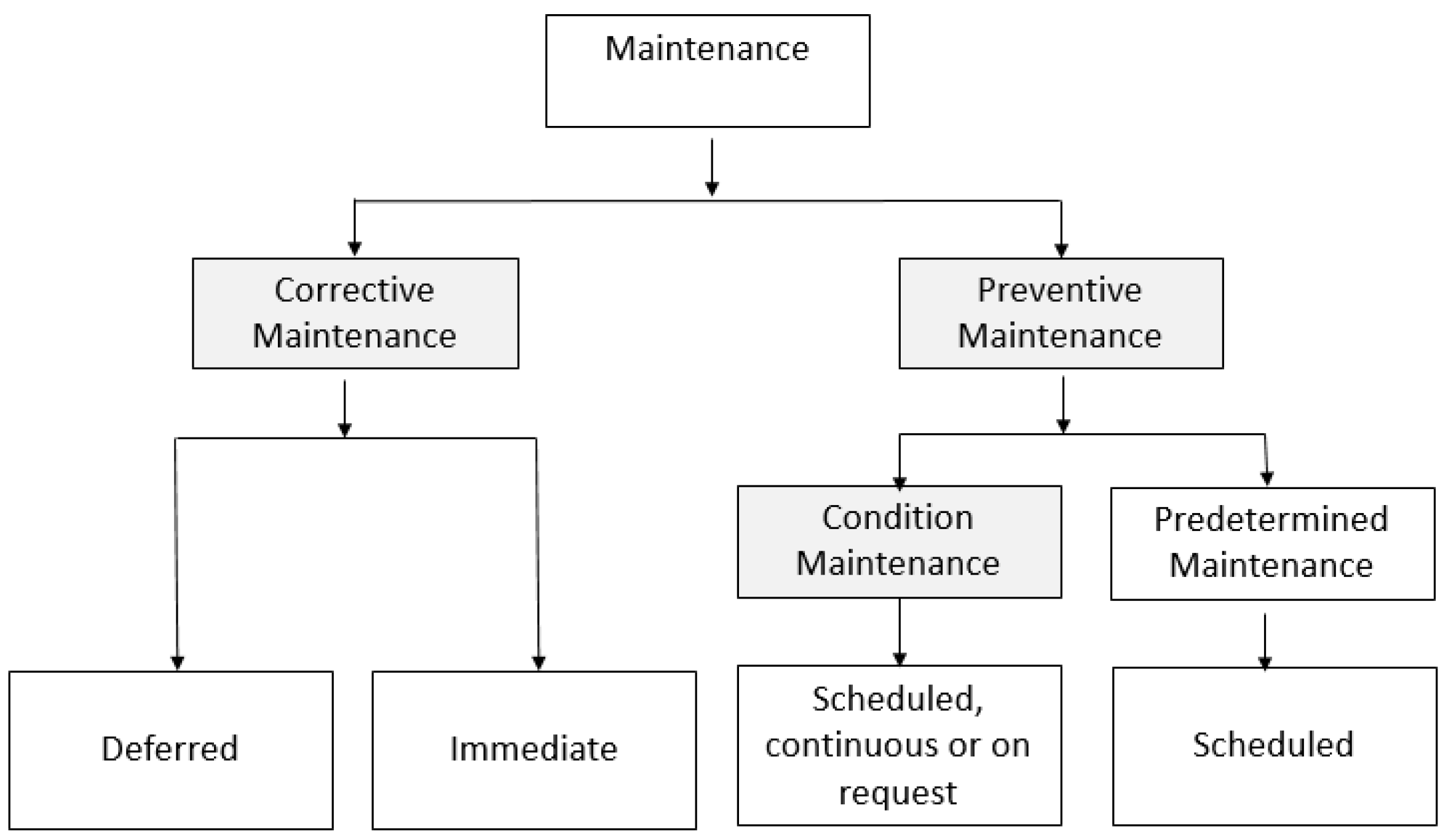

Inappropriate ratio of maintenance worker’s activities, inappropriate organization of work (

Figure 7,

Figure 8).

Figure 7.

Daily snapshot of a Measurement and Regulatory Technology (MART) maintenance worker.

Figure 7.

Daily snapshot of a Measurement and Regulatory Technology (MART) maintenance worker.

Figure 8.

Daily snapshot of a shift maintenance worker.

Figure 8.

Daily snapshot of a shift maintenance worker.

3.1. Proposed Change to the Maintenance Strategy

By analyzing the potential for improvement, by analyzing the processes carried out by which the company organizes its activities and resources to achieve its long-term goals. To ensure the competitiveness and profit of the company, the steps to change the strategy have been proposed

Figure 9. Strategy change steps:

Analysis of the current situation, maintenance audit.

Benchmarking.

Criticality assessment of machinery and equipment.

Evaluation of current maintenance processes.

Selection of a new maintenance strategy

Comparison of the existing maintenance system and the proposed maintenance system.

Implementation of a new maintenance strategy.

Description of maintenance strategies used:

FFM Failure Finding Maintenance i.e., a functional test or inspection of a hidden failure of the equipment. Depending on the results, repairs are carried out.

CBM Condition Based Maintenance i.e., the maintenance activities consist of periodical, inspections, or on-line measurement of the technical condition of the equipment. Depending on the measured condition, repairs are planned or carried out.

TBM Time Based Maintenance i.e. This means regular periodic maintenance.

SM Scheduled Maintenance i.e., the maintenance activities are carried out based on the use of the equipment (i.e., time, hours, operations etc.). They are independent of the condition of the equipment.

MOD Modification i.e., it must be changed. This does not mean it has to be technical -it can be a change of spare parts or instruction.

RTF Run to Failure i.e., the failure will be solved when it occurs. No preventive maintenance.

4. Discussion

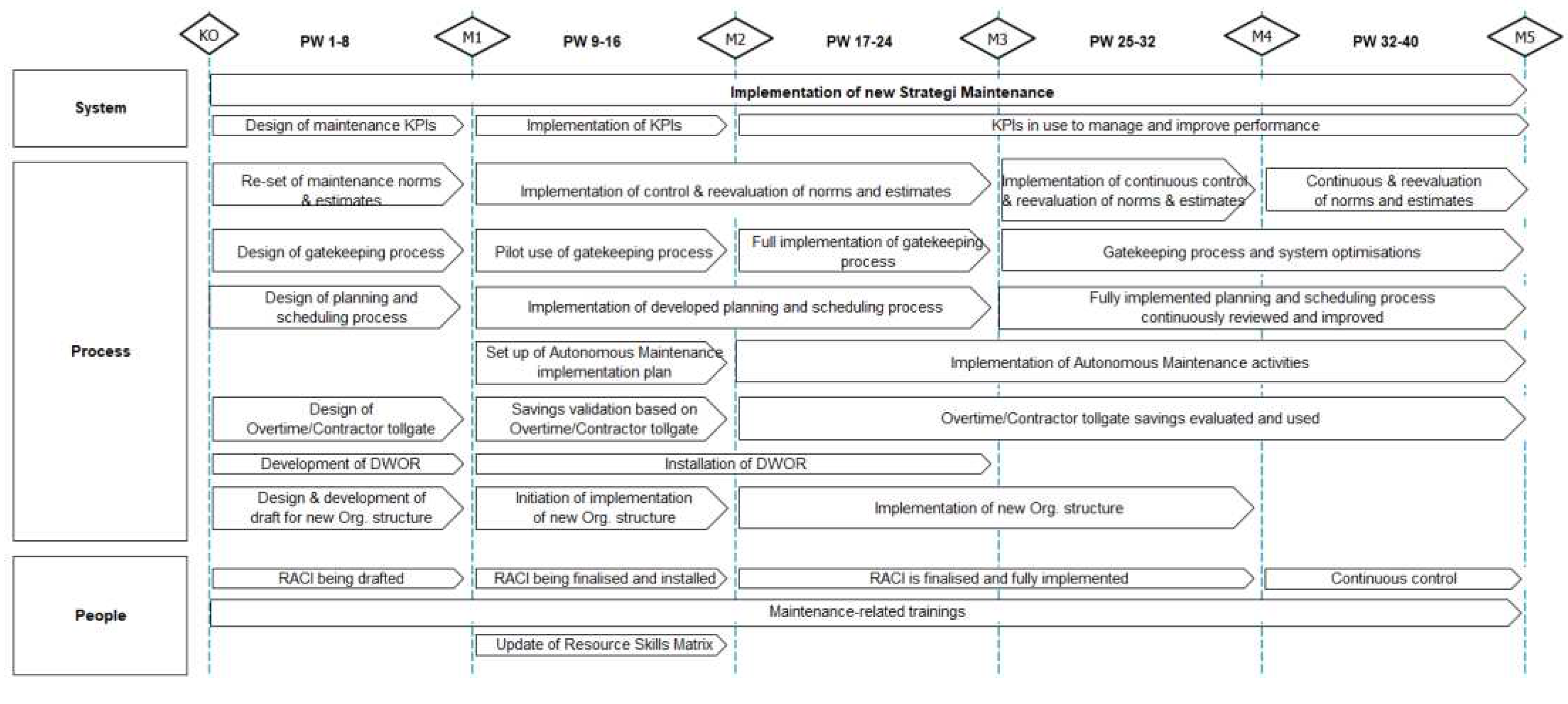

In designing the schedule, we focused on the maintenance system, the maintenance processes, and the maintenance staff, who are scheduled to perform each task on a week-by-week basis. Control milestones are defined to verify the task performance of the strategy development project

Figure 10.

Authors should discuss the results and how they can be interpreted from the perspective of previous studies and of the working hypotheses. The findings and their implications should be discussed in the broadest context possible. Future research directions may also be highlighted.

Figure 10.

Maintenance strategy change plan.

Figure 10.

Maintenance strategy change plan.

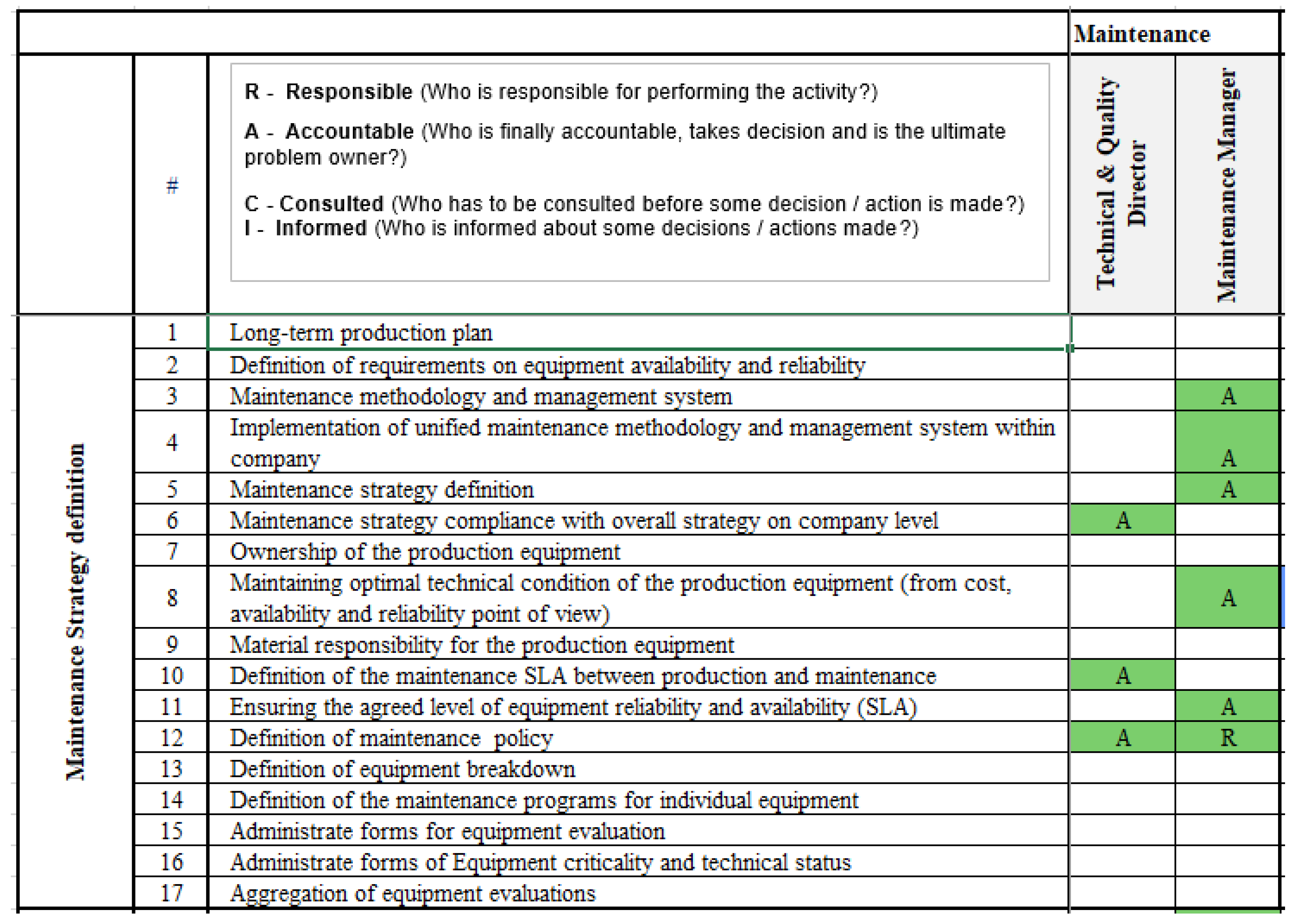

It is necessary to develop a RACI matrix (Responsible, Accountable, Consulted, Informed) for the different maintenance processes and responsibilities for activities within the maintenance management system (

Figure 11).

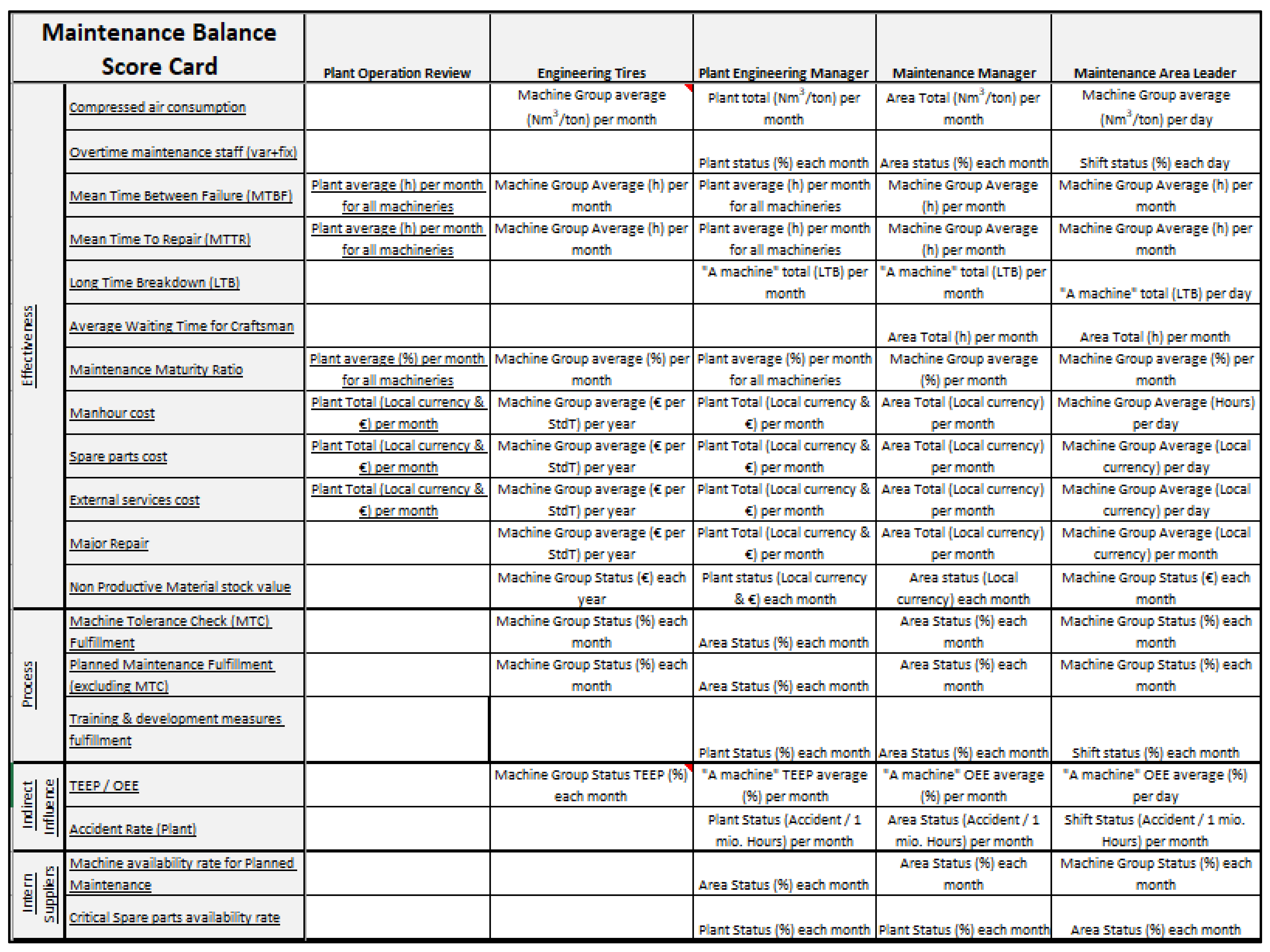

Current maintenance management indicators need to be reviewed.

Table 3 presents a proposal of maintenance indicators to meet the milestones of the new strategy development project. To effectively commission the system and maintain it at optimum life-cycle cost in the long term, maintenance and provisioning activities need to be planned and the necessary resources procured.

These activities start early in the conception and development phase and continue throughout the subsequent stages of the life cycle. The objectives of maintenance activity planning and maintenance assurance are as follows:

develop a maintenance concept and add maintenance and maintenance assurance requirements to the system requirements,

to determine the effect of system maintainability design in the form of maintenance requirements and to optimise the maintenance concept,

define the maintenance provisioning requirements and the maintenance plan,

specify the resources required.

4.1 Evaluation of Maintenance Choice Alternatives and Analysis of the Optimisation Procedure

The objective of the evaluation of alternatives is to select a maintenance assurance system. The analysis of the optimization procedure for operation and maintenance provisioning is part of the inherent development system. Optimal benefits are obtained when these analyses consider all system factors (cost, schedule, operational characteristics, and maintenance provisioning) before system development is completed.

The following steps are to be performed in the evaluation and analysis of the optimization procedure:

identify criteria that are related to maintenance provisioning requirements, cost, and availability,

select or develop models or analytical relationships between the maintenance provisioning design and the operational or any other identified evaluation criteria,

perform an optimisation procedure or evaluation that uses the developed relationships or models, and select the best alternative(s) based on the developed criteria,

perform sensitivity analyses of those variables that have a high degree of risk or a significant impact on the maintenance provision, cost, or availability of the new system,

document the results of the optimisation procedure and evaluation, including any risks and assumptions involved.

5. Conclusions

Research in maintenance strategy and maintenance process improvement procedure to increase the efficiency and quality of the production system through the application of the proposed methodology/algorithm for changing the maintenance strategy, results were achieved, which showed a positive impact on production efficiency and quality.

5.1 Achieved Impact of Maintenance Strategy Change on Production Efficiency

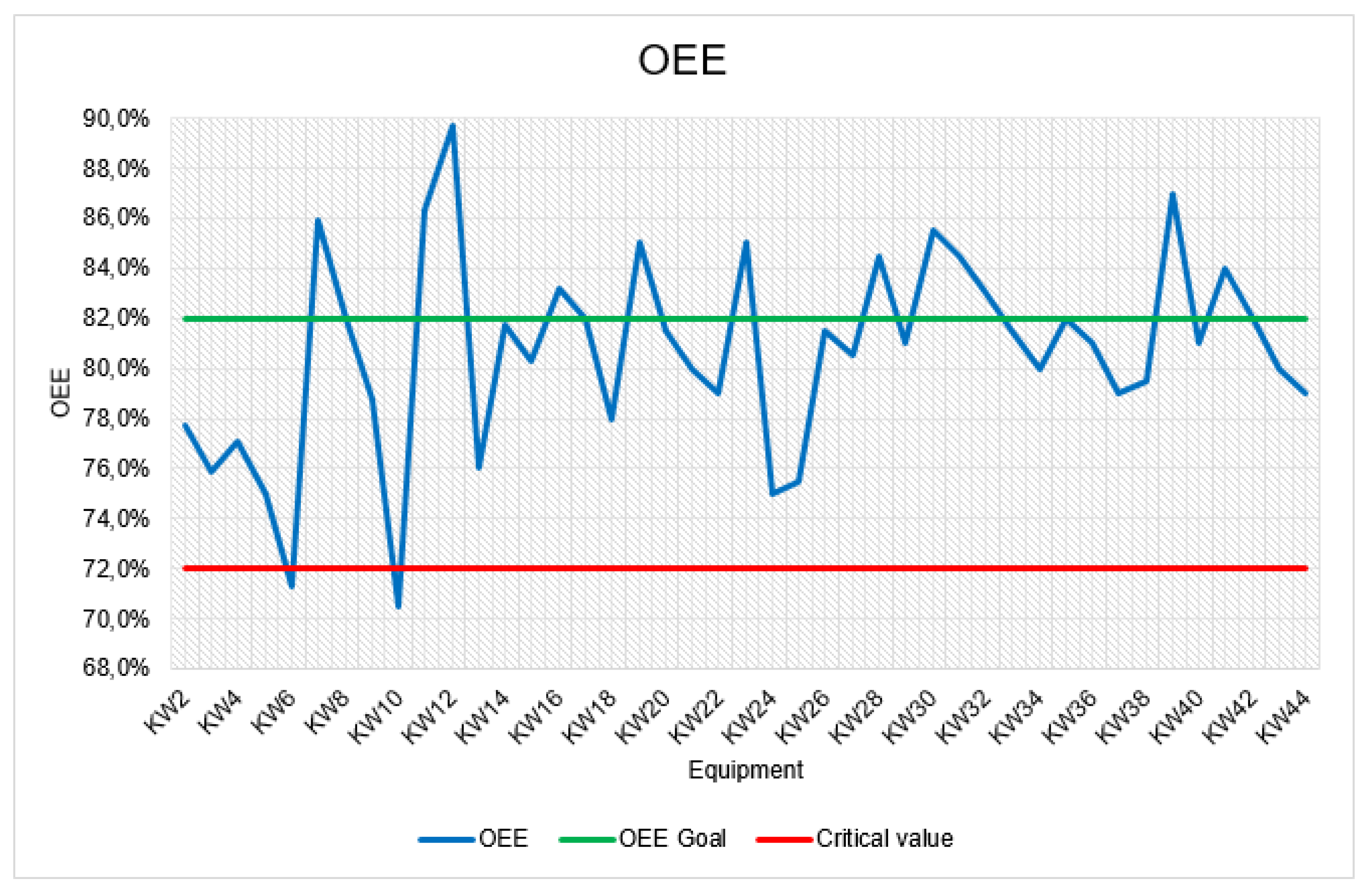

The Overall Equipment Effectiveness (OEE) rating on is a function of losses due to faults (interruptions), power losses due to reduced speeds and queuing times and low quality of the products produced

Figure 11.

Maximizing the efficiency of equipment operations and minimizing costs over its life cycle could be ensured by eliminating the "six major losses" that significantly affect the efficiency of equipment on schedule (

Figure 9):

Failures resulting from equipment defects.

Rearranging and setting up (changing jig, tool, etc.).

Loss of speed

Inactivity, idling and small breaks (abnormal sensor activity, blocking in slips, etc.).

Speed reduction (mismatch between the designed and actual speed of the devices).

Errors

Process errors and repairs (screw-ups and quality defects in need of correction).

Reduction of time between machine start-up and stable operation.

5.2 Impact of a Change in Maintenance Strategy on Production Quality

Through the new designs and the entire methodology of PPM (preventive planned maintenance), as well as all other supporting processes, detailed analysis of line object failures has been enabled. New possibilities have been opened for more efficient and faster problem analysis and corrective action to improve and stabilize the process, especially the production quality process.

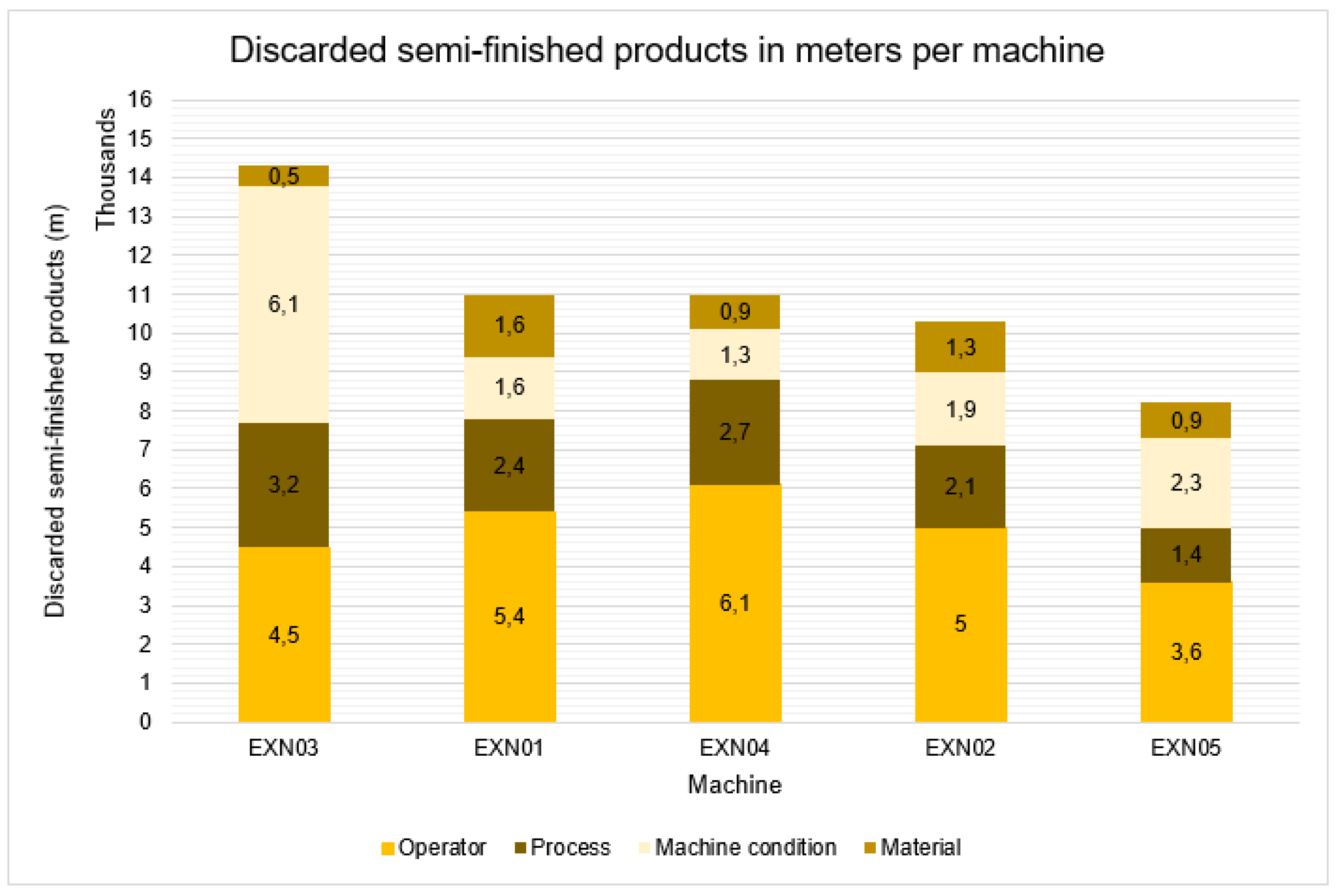

However, due to the implementation of the so-called zero interval, improvements can already be seen in some indicators after a shorter period. Other important indicators can be estimated, or the expected improvement can be determined, but only after a certain period. The indicators that can be realistically assessed now relate to the number of materials discarded in the six-hour interval before the failure occurred. As can be seen in

Table 4, the improvement in this indicator is approximately 24% compared to the initial situation. This means that 23.76% more blanks were discarded in the six-hour interval before the failure than before the introduction of the new preventive planned maintenance. This is also because its introduction has reduced the frequency of failures. The new preventive maintenance has thus had a positive impact on both factors, resulting in the improvement in the indicator.

A follow-up indicator that can also be measured in a shorter period after the introduction of PPM is the number of meters of semi-finished products discarded due to machinery.

The improvement in the two-week interval can be seen in

Table 5. After the introduction of the proposals, the incidence of semi-finished products scrapped due to machinery decreased by 23.01% and the number of all semi-finished products scrapped, irrespective of the reason for scrapping, decreased by about 16%. These are significant improvements, which may be slightly distorted by the shortness of the monitoring interval, but the improving trend is evident. Talking not only about semi-finished products discarded due to machines is important because machines can still have an impact on other cases as well.

The previous indicators and improvements were expressed only for the production line whose winding station design was the subject of a pilot verification of the proposed methodology.

The financial evaluation of the design solutions and estimates of improvements have already been calculated for all five-extrusion lines. This is because most of the quality indicators are related to the whole process and the new PPM plan will be gradually introduced on the other lines as well.

This financial assessment and the estimate of expected savings can be seen in

Table 6. Three basic indicators (Scrap I, WOT - Work off, Downtime/ Faults) have been selected. For all indicators, improvements were estimated based on the changes made, experience and especially in view of the improving indicators interpreted above. For Scrap I, the expected improvement after a certain period is at the level of 4 to 7 percent. In this case, this is a lower expectation percentage because only tread and sidewall wastes do not enter Scrap I. The price saving is thus at a level of around €20,000 per month on average. For WOT, based on intermediate results, improvements of up to 13 to 17 percent are expected. This amounts to an average of around €16,500 per month for both semi-finished products together with rework costs. A final indicator that directly reflects potential savings is the duration of downtime caused by failures. Here again, according to the assumptions and intermediate results, a reduction of 10 to 15 per cent in the duration of breakdowns is expected. In financial terms, this translates into an average of around €1 150.

The cost of implementing design solutions is minimal. There is no need to purchase new equipment, software, or external help. Everything will be done within the shutdown lines as before, with the same number of internal staff, etc. The only cost has been the salaries of the staff in setting up the PPM plan and training them. This cost was estimated at approximately € 1 100.

As a result, an average monthly saving of € 36 500 is expected after the implementation of the proposed solutions on all lines. This represents an average annual saving of €438 200. It can be argued that this is a significant cost saving, which is mainly due to the improvement in the quality of the production process by using the newly designed PPM plan in the context of quality. It should be noted that everything so far only applies to the single most critical design unit within all five production lines of the production system.

Once the PPM plan is extended to the whole lines, even greater savings, and improvements in the quality of the production process can be expected

Figure 12.

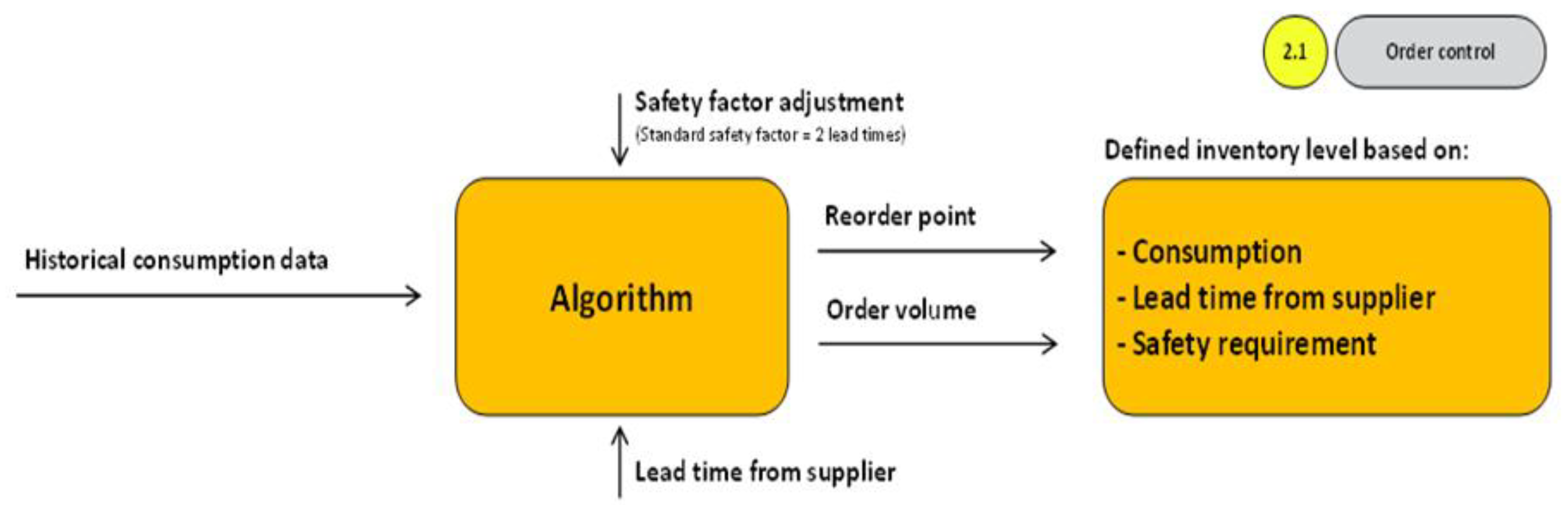

5.2 Impact of the Strategy Change on Spare Parts

As we found from the analysis of the current situation in the enterprises, most of the interviewed enterprises determine the size of the insurance stock and the associated signal level only by estimation, which is not supported either by calculation or by statistical methods.

Therefore, for a more objective and professional determination of the basic data for ND inventory management, we recommend their determination by calculation. However, the value determined by calculation may not be final, but may still be adjusted as necessary by the responsible staff but based on the underlying calculations.

In the enterprise under analysis, they determine signal levels and order sizes by estimation, which is not very accurate, and some values may be incorrect. Therefore, we want to use calculations to determine the safety stock, signal levels, etc. and then compare the two options.

The following algorithm will be used for the calculations, for which data such as historical consumption data, the criticality of the ND SP and the delivery time from the supplier are important. The algorithm can be seen in

Figure 13. In

Table 7 we can see based on which criteria we divide the items into groups A, B, C.

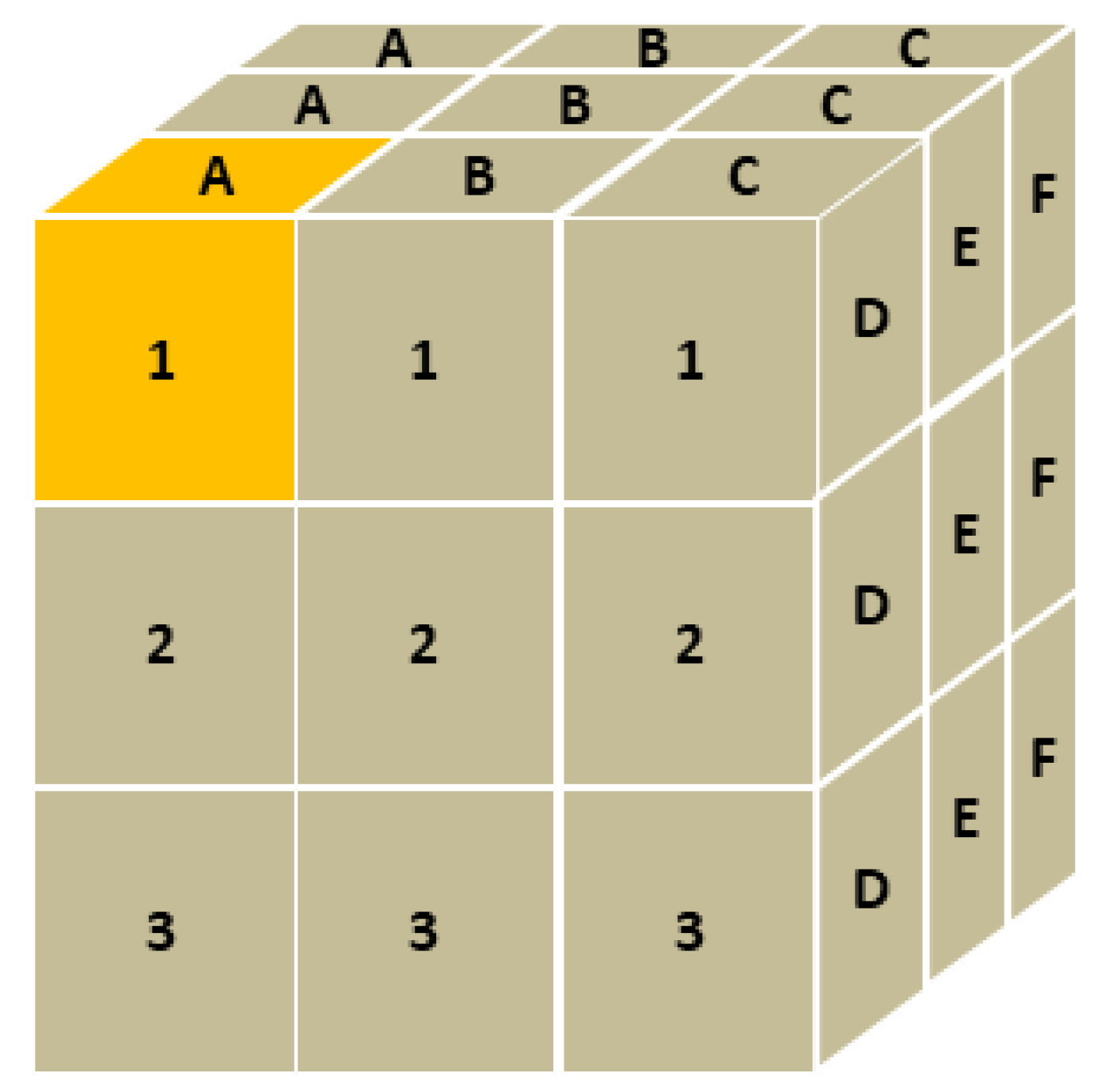

The ABCX spare parts categorization is a comprehensive SP analysis where various data is examined such as how the part affects the functionality of the machine, the lead time of the part, the failure rate of the part, whether there is a replacement for the part, whether it is used in critical machines, whether it can be manufactured or refurbished, whether it is a standard standardized part or a consumable part. The categorization can be seen in

Table 7.

Table 7.

Categories for determining the criticality of SP ABCX.

Table 7.

Categories for determining the criticality of SP ABCX.

| Kategória |

Popis |

| A |

A spare part without which a machine cannot function, with a high failure rate, with a long procurement time, without replacement, used in critical machines. |

| B |

A spare part without which the machine can run (at least suboptimal), which has high reliability, which can be manufactured/ purchased repaired in a short time, and which have a replacement. |

| C |

Consumables, wear parts (filters, bits, belts) |

| X |

Obsolete or never used spare parts. |

In

Table 7, we see that category A are the most critical parts and category X the least.

The overall criticality of spare parts (SP) is based on several criteria which are then input into a matrix to determine the resulting SP criticality value. The criteria are shown in

Table 8.

After evaluating these sub-criteria, we develop a matrix that shows the real criticality of the work. The matrix can be seen in

Figure 14. We also call the criticality of the SP determined in this way the safety factor, which we then use to calculate the safety margins and signal levels.

The part located at position A1D shows the highest criticality and the part located at position C3F shows the lowest criticality. The overall criticality of the parts is more complex and is recommended for implementation in the SP Logistics Procurement and Management System. But it can also be combined with other methods. The individual criteria are also assigned a score, after summing which the most critical part has a score of 4 and conversely the least critical part has a score of -1.

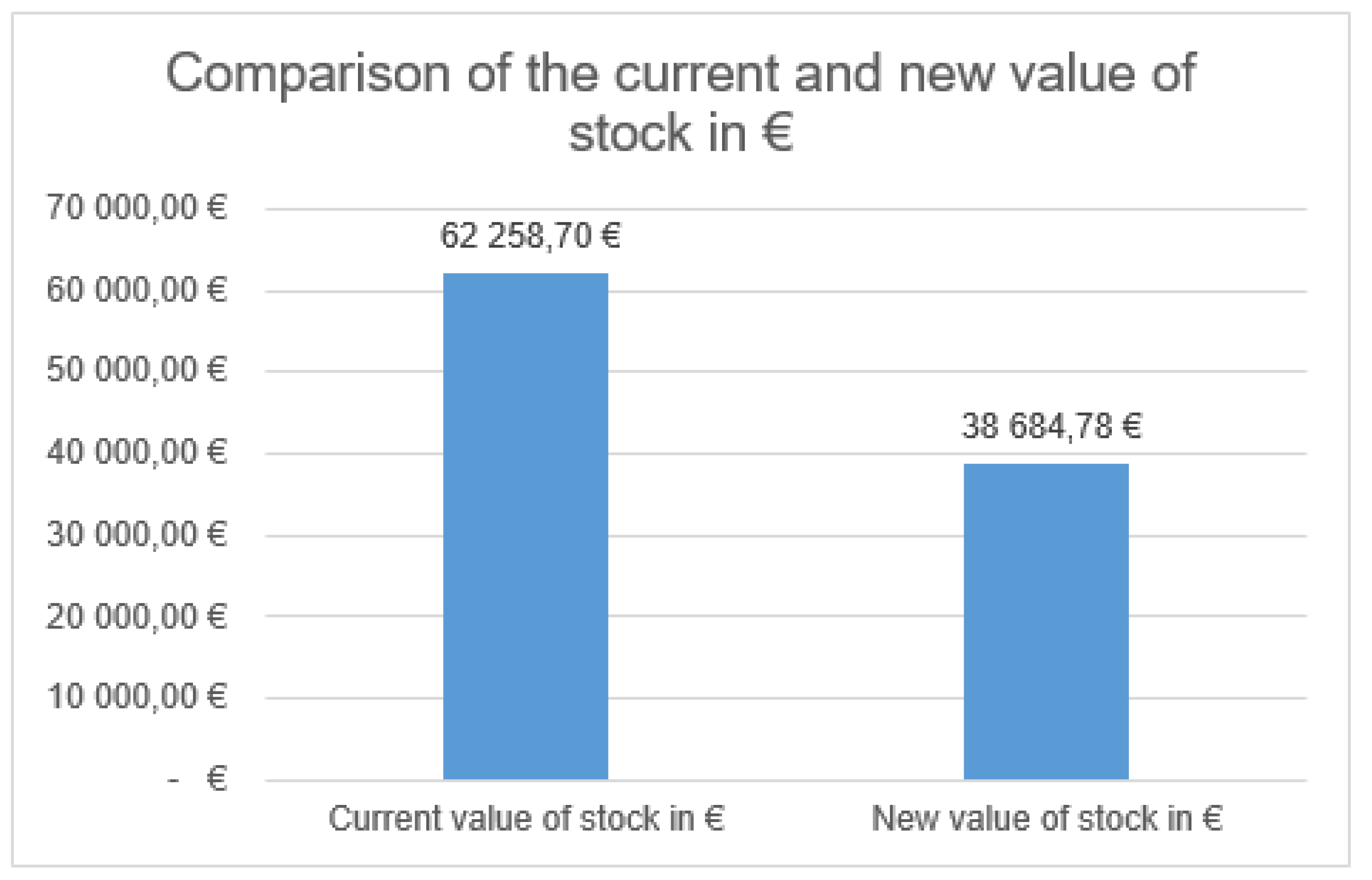

Having made calculations based on the criticality of the SP, past consumption, and lead times to determine the new safety stock, signal levels, batch sizes, minimum and maximum stock, we can say that for several items the values were unreasonably high. The total value of the stock items decreased from € 62 258,70 to € 38 684,78 for the new variant, which is a reduction of € 23 573,92. The comparison can be seen in

Table 9 and

Figure 15.

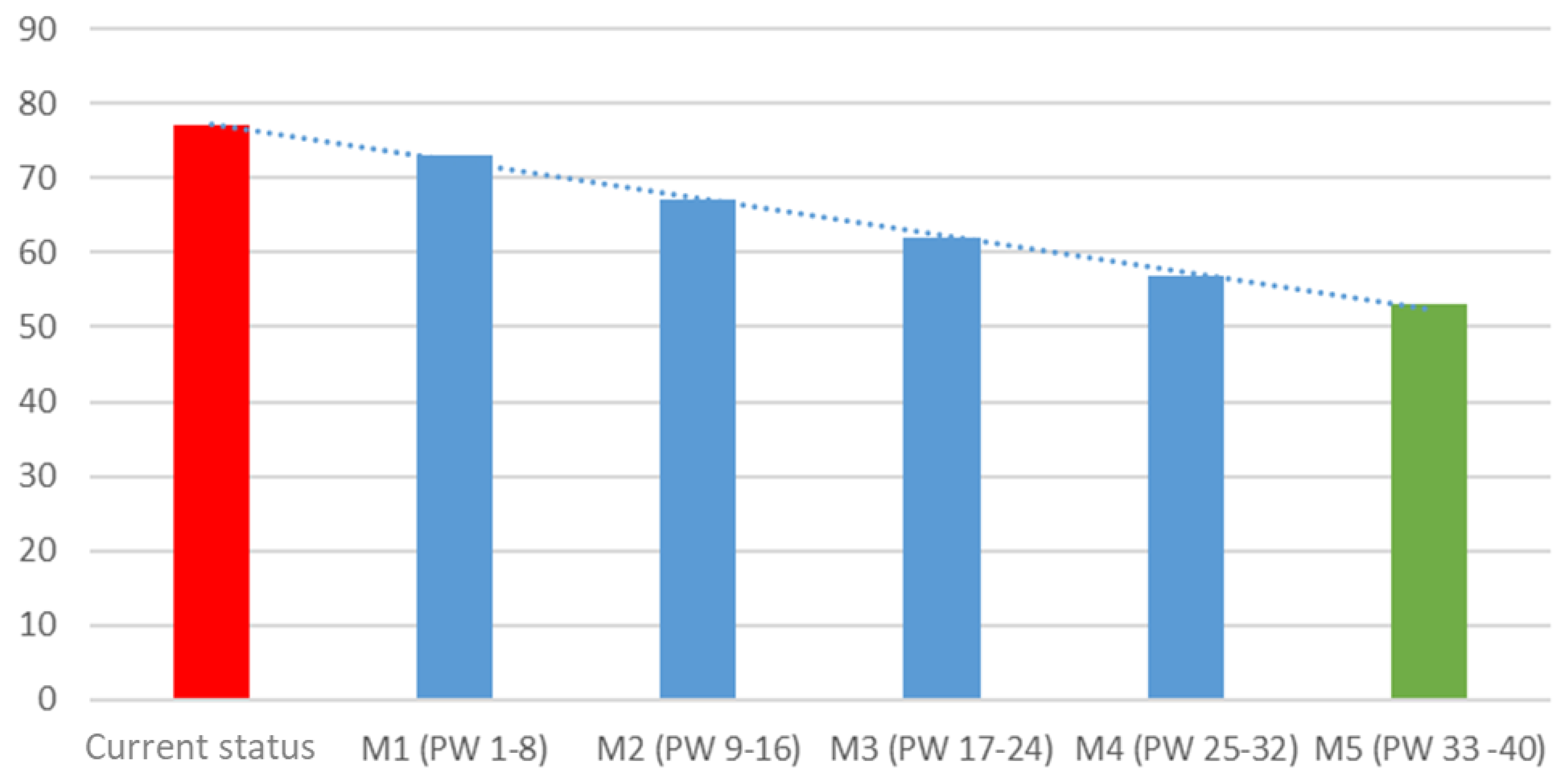

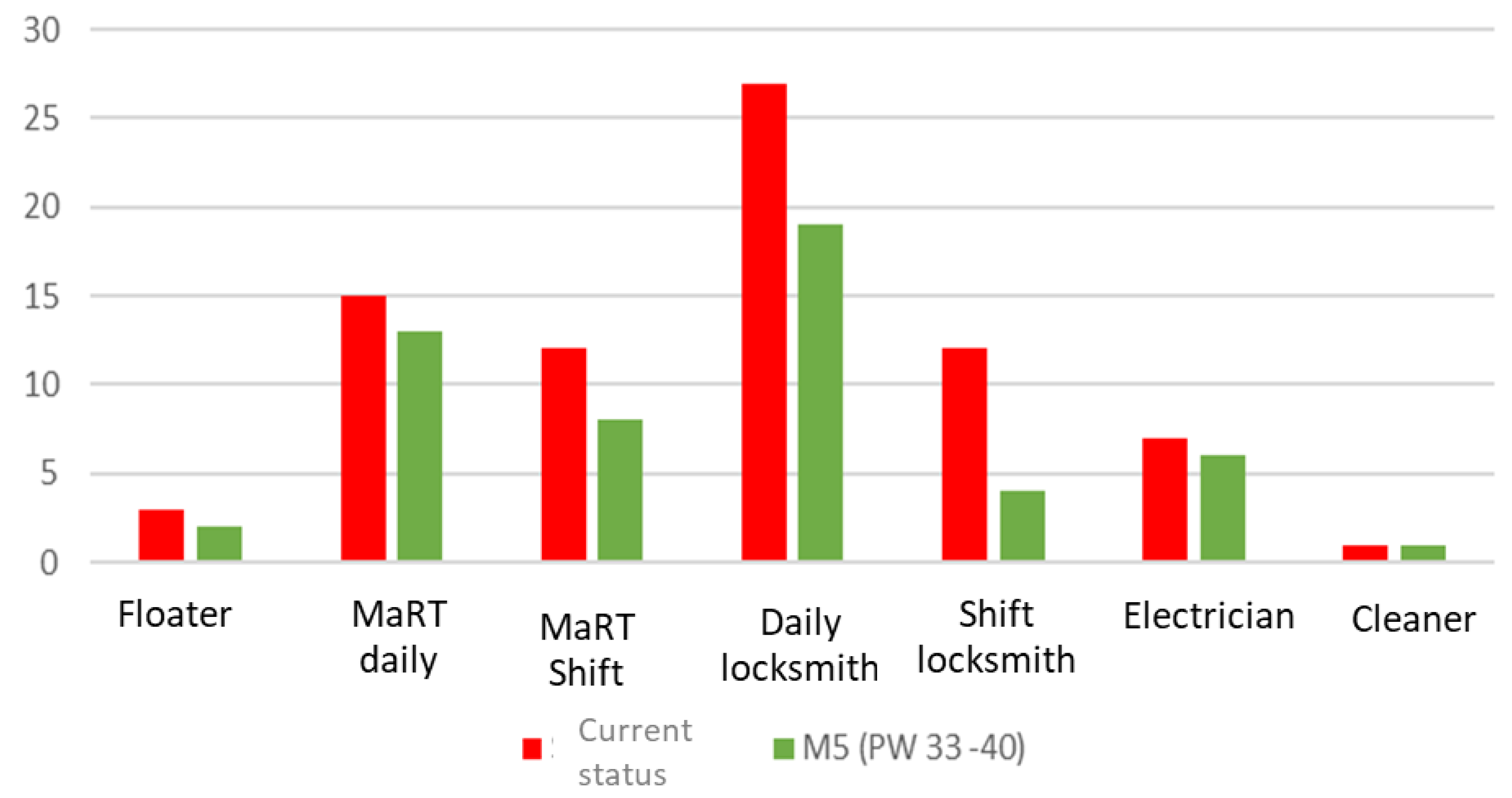

The proposed phased sequence of planned maintenance change steps, the change in staffing levels, is per

Figure 12. This results in a reduction of maintenance staff from 77 to 53. The above change followed the plan to change the maintenance strategy by milestones (

Figure 9). The change was implemented by reducing shift maintenance workers and sending workers to preventive maintenance tasks

Table 14,

Figure 16,

Figure 17. This achieves the same production and quality efficiency (or higher) with fewer workers, reduction in direct maintenance costs, reduction in the need for SP.

This change in strategy determines the comprehensive operation of the emergency strategy

Table 15. The method of implementation, the measures, and the distribution of responsibilities in accordance with the requirements of the current internal and external environment. The aim is to provide the necessary resources for the different facilities to make the production process work and to ensure competitiveness.

Procedure: The above table describes how a company’s emergency strategy works in a crisis environment.

Table 15.

Description of emergency strategy.

Table 15.

Description of emergency strategy.

| Description |

Approves |

Frequency |

Document |

| 1. Risk factors influencing the emergency maintenance strategy are defined for lines, machines and equipment, maintenance processes. |

MC/MM |

1 x a year |

List of risk factors, processes |

| 2. Elaboration of a matrix of responsibility and authority in the event of a maintenance emergency. |

MM |

1 x a year |

Matrix of responsibilities for handling a maintenance emergency |

| 3. Elaboration of the categorization of critical lines of machines and equipment in lines (A, B, C). |

MT/MM |

1 x a year |

List of machines by priority |

| 4. Declaring the maintenance system for individual categories of machines. |

MC/MM |

1 x a year |

Maintenance concept for machines and equipment |

| 5. For critical machines of category A, development of a flow chart of duties and responsibilities for emergency removal. |

MC/MM |

1 x a year |

Continuous process diagram of the realization of the created emergency state |

| 6. On category A machinery and equipment, development of a list of critical structural units. |

MT/MM |

1 x a year |

List of critical structural units |

| 7. Develop a list of risky spare parts for category A machines and critical structural units. |

MT/MM |

1 x a year |

List of critical spare parts |

In the current economic problems with the emergence of COVID, the energy crisis and the war, every company should re-evaluate its maintenance strategy to update its maintenance processes and to determine a so-called emergency maintenance strategy to remain competitive. It is necessary to focus on the data that provide us with the required information. At the same time, we will prepare for the implementation of an intelligent maintenance system.

Author Contributions

Conceptualization, M.R. and P.B.; methodology, M.R.; software, P.B.; validation, M.R. and P.B.; formal analysis, K.S.; investigation, V.B.; resources, M.R.; data curation, M.R.; writing—original draft preparation, V.B.; writing—review and editing, V.B.; visualization, K.S.; supervision, G.G.; project administration, V.B.; funding acquisition, V.B.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

This work was supported by the VEGA 1/0524/22 - Research of proactive approach sustainability of production systems under crisis conditions in the context of the green economy.This work was supported by the VEGA 1/0248/21 - Research of innovative solutions for segmentation and sustainability of product regarding assembly operations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bubeníková, E.; Bubeník, P. Internet vecí (IoT) = Internet of things (IoT). Technológ 2017, 9, 131–134. [Google Scholar]

- Peniak, P.; Bubeníková, E. Validation of IoT secure communication gateway for constrained devices. In Proceedings of the 2019 International Conference on Applied Electronics (AE), Pilsen, Czech Republic; 2019; pp. 1–5. [Google Scholar]

- Fusko, M.R.M. Manažment konfigurácie údržby pre "Priemysel 4.0". In Údržba 2016 = Maintenance 2016: sborník mezinárodní odborné konference: 12. a 13. října 2016, Konferenční centrum AV ČR - zámek Liblice. - Praha: Česká zemědělská univerzita, 2016. - ISBN 978-80-213-2668-2. - S. 25-33.

- Campbell, J.D.; Reyes-Picknell, J.V.; Kim, H.S. Uptime: Strategies for excellence in maintenance management; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Legát, V. Management a inženýrství údržby; Kamil Mařík-Professional Publishing, 2016. [Google Scholar]

- Rakyta, M.; Grznár, P.; Fusko, M. Efektívne procesy údržby a ich digitalizácia v kontexte 4.0. In Manufacturing systems today and tomorrow 2017 [elektronický zdroj]: 10th annual international scientific conference: Liberec 9.11.-10.11. 2017: conference proceedings. - Liberec: Technická univerzita, 2017. - ISBN 978-80-7494-370-6. - CD-ROM.

- Mushavhanamadi, K.; McGloin, K. Investigating the Risk Management Systems in the South African Banking Industry.

- Bubeník, P.; Rakyta, M. Technológia dolovania dát a jej prínos v podnikovej praxi. In Manufacturing systems today and tomorrow 2017 [elektronický zdroj]: 8th annual international conference. - Liberec: Technická univerzita, 2014. - ISBN 978-80-7494-150-4. - CD-ROM, [6] s.

- Krar, S.F.; Gill, A. Machine tool technology basics; Industrial Press Inc., 2003. [Google Scholar]

- Mushavhanamadi, K.; Selowa, T.B. The impact of plant maintenance on quality productivity in Gauteng breweries. In Proceedings of the International Conference on Industrial Engineering and Operations Management; 2018; pp. 1743–1753. [Google Scholar]

- Dowler, P. CAOM-2.0: the inevitable evolution of a data model. Astronomical Data Analysis Software and Systems XXI 2012, 461, 339. [Google Scholar]

- Blanchard, B.S.; Verma, D.C.; Peterson, E.L. Maintainability: a key to effective serviceability and maintenance management; John Wiley & Sons: Hoboken, NJ, USA, 1995; Volume 13. [Google Scholar]

- Alsyouf, I. Cost effective maintenance for competitve advantages. Doctoral dissertation, Växjö university press, 2004. [Google Scholar]

- Al-Najjar, B. The lack of maintenance and not maintenance which costs: A model to describe and quantify the impact of vibration-based maintenance on company’s business. International Journal of Production Economics 2007, 107, 260–273. [Google Scholar] [CrossRef]

- Duffuaa, S.O.; El-Ga’aly, A. Impact of inspection errors on the formulation of a multi-objective optimization process targeting model under inspection sampling plan. Computers & Industrial Engineering 2015, 80, 254–260. [Google Scholar]

- Bezděk, J.; Rakyta, M. Inovatívne využitie umelej inteligencie v údržbe = Innovative application of artificial intelligence in maintenance. In Národné fórum údržby 2017: 17. ročník medzinárodnej konferencie: 30-31 May 2017, Vysoké Tatry, Štrbské Pleso: zborník prednášok. - Žilina: Žilinská univerzita, 2017. - ISBN 978-80-554-1335-8. - S. 74-81.

- Rakyta, M. Zvyšovanie kvality produkcie prognózovaním spoľahlivosti a spôsobilosti strojov = Increasing quality of production forecasting reliability and capability equipment. In Bezpečnosť. Kvalita. Spoľahlivosť [elektronický zdroj]: 6. medzinárodná vedecká konferencia: máj 2015 Košice. - Košice: Technická univerzita, 2015. - ISBN 978-80-553-2044-1. - CD-ROM, s. 223-230.

- Rakyta, M.; Fusko, M.; Haluška, M.; Grznár, P. Maintenance support system for reconfigurable manufacturing systems [Systém podpory údržby pre rekonfigurovateľné výrobné systémy]. In Annals of DAAM [elektronický zdroj]: proceedings of the 26th DAAAM international symposium on intelligent manufacturing and automation. - ISSN 1726-9679. - Vienna: DAAAM International Vienna, 2016. - ISBN 978-3-902734-07-5. - online, s. 1102-1108.

- Christiane Fellbaum WordNet: An Electronic Lexical Database, (1998, ed.) MIT Press: Cambridge, MA, USA.

- Magvaši, V.; Herčko, J. Pokrokové priemyselné inžinierstvo a digitálne a znalostné inžinierstvo. ProIN.-ISSN, 1339-2271. - Roč. 17, č. 2 (2016), s. 28-31.

- Kováčová, L.; Čapek, J.; Bubeník, P. Performance of the company. In InvEnt 2016: industrial engineering - toward the smart industry: proceedings of the international conference: 15.6.-17.6.2016, Rožnov pod Radhoštěm, CZ. - Žilina: University of Žilina, 2016. - ISBN 978-80-554-1223-8. - S. 92-95.

- Gašová, M.; Gašo, M. Advenced industrial tools of ergonomics based on Industry 4.0. In Aktuálne otázky bezpečnosti práce: XXIX. ročník medzinárodnej vedeckej konferencie: 14.-16. novembra 2016, Štrbské Pleso. – Košice: TU v Košiciach, 2016. - ISBN 978-80-553-3006-8. – CD-ROM, [7] s. Process of Everything. Available online: https://www.pega.com/ (2017-02-20).

- Gregor, T.; Krajčovič, M. Smart connected Mobile robotic systems. In InvEnt 2016: industrial engineering - toward the smart industry: proceedings of the international conference: 15.6.-17.6.2016, Rožnov pod Radhoštěm, CZ. - Žilina: University of Žilina, 2016. - ISBN 978-80-554-1223-8. - S. 52-55.

- Čechová, I.; Dulina, Ľ.; Kramárová, M. Ergonomics and occupation safety and health as a part of productive workplace. In Aktuálne otázky bezpečnosti práce, XXIX. Ročník medzinárodnej vedeckej konferencie: 14.-16. novembra 2016, Štrbské Pleso. - Košice: TU v Košiciach, 2016. - ISBN 978-80-553-3006- 8. CD, [8] s.

- Bubeník, P.; Horák, F. Knowledge-based systems to support production planning. Technical gazette 2014, 21, 505–509. [Google Scholar]

- Rakyta, M.; Biňasová, V. Totálne produktívna údržba – TPM, 1. Vydanie, Žilina: EDIS, 2016. ISBN 978-80-554-1210-8.

- Manažérstvo údržby 2: synergia teórie a praxe / Juraj Grenčík... [et al.]. - 1. vyd. –Košice: BEKI Design, 2020. - 697 s. [print]. ISBN 978-80-553-3539-1.

- Rakyta, M. Údržba ako zdroj produktivity, GEORG, Žilina 2002. ISBN 80-968324-3-3.

- Slack, N.; CHambers, S.; Jonston, R. Operations management. Education, 2007. 728 s. ISBN 978-0-273-70847-6.

- Improvement of the production system [electronic] [Zlepšenie výrobného systému] / Ľuboslav Dulina... [et al.]. In: Smart City 360° [electronic]: 2nd EAI international summit: revised selected papers. - 1. vyd. - Ghent: EAI, 2017. ISBN 978-1-63190-149-2.

- Basics of designing maintenance processes in Industry 4.0 [electronic] [Základy projektovania údržbových procesov v Priemysle 4.0] / Miroslav Fusko, Miroslav Rakyta, Martin Krajčovič, Ľuboslav Dulina, Martin Gašo, Patrik Grznár. In: MM Science Journal [print, electronic]. - ISSN 1803-1269. - č. March (2018), s. 2252-2259.

- Data collection for technical services / Miroslav Fusko, Miroslav Rakyta, Vladimíra Biňasová. In: TRANSCOM 2015 [elektronický zdroj]: 11-th European conference of young researchers and scientists: Žilina, June 22-24, 2015, Slovak Republic. Section 2: Economics and management. - Žilina: University of Žilina, 2015. ISBN 978-80-554-1044-9. CD-ROM, s. 98-102.

- Koc, M. Introduction to e-Manufacturing. Mitchigan University: USA, 2004; 97 str. [Google Scholar]

- Lee, J.; Ni, J.; Djurdjanovic, D.; Qiu, H.; Liao, H. Intelligent prognostics tools and e-maintenance. Computers in industry 2006, 57, 476–489. [Google Scholar] [CrossRef]

- Preez, J. Thesis presented in partial ful_lment of the requirements for the degree of master of science in the faculty of industrial engineering at Stellenbosch university. Stellenbosch University: South Africa, 2011; 123s. [Google Scholar]

- Supadulchai, P. Reasoning-based capability configuration management in adaptable service systems. NTNU, Nórsko, Trondheim, 2008, 238 s.

- Vyatkin, V. Function blocks for embedded and distributed control systems design. ISA: New Zealand, 2011; 260 s; ISBN 978-1-936007-93-6. [Google Scholar]

- Shirose, K. TPM Team Guide. Productivity Press, Inc.: Cambridge, USA, 1995; (digital twin). [Google Scholar]

- Peniak, P.; Rástočný, K.; Kanáliková, A.; Bubeníková, E. Simulation of Virtual Redundant Sensor Models for Safety-Related Applications. Sensors 2022, 22, 778, (IoT). [Google Scholar] [CrossRef] [PubMed]

- Peniak, P.; Bubenikova, E.; Kanalikova, A. Extended gateway model for OPC UA/IoT device integration. In Proceedings of the 2021 IEEE 19th World Symposium on Applied Machine Intelligence and Informatics (SAMI); Published 2021. pp. 155–159.

Figure 1.

Overview of maintenance.

Figure 1.

Overview of maintenance.

Figure 2.

Connection between maintenance and profitability.

Figure 2.

Connection between maintenance and profitability.

Figure 3.

Strategic management of the maintenance organization.

Figure 3.

Strategic management of the maintenance organization.

Figure 5.

Algorithm for creating a maintenance strategy and concept.

Figure 5.

Algorithm for creating a maintenance strategy and concept.

Figure 6.

Internal audit.

Figure 6.

Internal audit.

Figure 9.

Maintenance strategy change algorithm.

Figure 9.

Maintenance strategy change algorithm.

Figure 12.

The impact of a change in maintenance strategy on the production quality of a production system.

Figure 12.

The impact of a change in maintenance strategy on the production quality of a production system.

Figure 13.

Parameter determination algorithm for SP inventory management.

Figure 13.

Parameter determination algorithm for SP inventory management.

Figure 14.

Proposed spare parts criticality matrix.

Figure 14.

Proposed spare parts criticality matrix.

Figure 15.

Comparison of inventory values.

Figure 15.

Comparison of inventory values.

Figure 16.

Procedure for reducing maintenance capacity.

Figure 16.

Procedure for reducing maintenance capacity.

Figure 17.

Reduction of maintenance capacities by profession.

Figure 17.

Reduction of maintenance capacities by profession.

Table 1.

Characteristics of maintenance excellence [

4].

Table 1.

Characteristics of maintenance excellence [

4].

| Strategy |

The organization has developed a perfect marketing strategy for the management of production facilities and other long-term asset (LTA) and their maintenance. |

| Personnel management |

The organization has widely qualified and loyal maintenance workers and operators, handling independently assigned maintenance processes. |

| Production planning and scheduling |

The organization has maintenance improvement projects, fully implements them, and has a perfect maintenance planning and scheduling system. |

| Concept (maintenance systems) |

All maintenance concepts in the organization are based on thorough analyzes of the reliability and operation of production equipment and other LTA. |

| Measuring maintenance performance |

In the organization, the measurement of the efficiency of production equipment is fully implemented, there is a detailed monitoring and evaluation of maintenance costs and benchmarking based on the care of selected indicators. |

| Information technologies |

An integrated and functional maintenance management of computer support system with all required databases is applied in the organization. |

| Employee involvement |

Fully functional autonomous maintenance improvement teams are established in the organization. |

| Failure-free analysis, maintainability, and maintenance assurance |

Failure analysis, maintainability and maintenance assurance programs are applied in the organization and their results are fully used for the creation of the LTA maintenance concept. |

| Process analyses |

In the organization, a regular review of the costs of individual maintenance processes, their time characteristics (labor, running time) and the fulfillment of the required quality features is applied. |

Table 2.

External benchmarking.

Table 2.

External benchmarking.

| Indicator |

Nordic benchmarking analysis |

World Class |

| Overall equipment efficiency (OEE) |

76,4 |

> 90 % |

| Actual running time as % of planned running time (Emergency) |

88,1 |

> 90 - 95 % |

| Maintenance costs as % of company turnover |

4,1 |

< 3 |

| Maintenance costs as % of the replacement value of fixed assets |

3,0 |

< 1,8 % |

| Inventory of spare parts and materials as % of man-hours for maintenance |

0,8 |

< 0,25 % |

| Man-hours for preventive maintenance as % of man-hours for maintenance |

38,4 |

40 % |

| Maintenance man-hours after failure as % of maintenance man-hours |

29,8 |

5 % |

| Man-hours planned and scheduled as % of man-hours for maintenance |

63,0 |

> 90 - 95 % |

Table 3.

KPI’s indicators for management (BSC maintenance).

Table 3.

KPI’s indicators for management (BSC maintenance).

Table 4.

Comparison of discarded materials after the introduction of the new PPM.

Table 4.

Comparison of discarded materials after the introduction of the new PPM.

| Discarded material before failure |

|---|

| Original state (%) |

Status (%) |

Improvement (%) |

| 29,84 |

22,75 |

23,76 |

Table 5.

Comparison of the number of rejected semi-finished products.

Table 5.

Comparison of the number of rejected semi-finished products.

| The number of rejected semi-finished products |

|---|

| A type of elimination |

Original state (%) |

Status (%) |

Improvement (%) |

| As a results of machinery and equipment |

804 |

619 |

23,01% |

| All the reasons |

5821 |

4887 |

16,05% |

Table 6.

Table of economic evaluation of proposals.

Table 6.

Table of economic evaluation of proposals.

| Economic evaluation of design solutions |

|---|

| Indicator |

Expected improvement (%) |

Expected savings (€) |

Average (€) |

| Min. |

Max. |

| Scrap I |

4%-7% |

14 566,39 € |

25 491,19 € |

20 028,79 € |

| WOT |

13%-17% |

14 244,82 € |

18 627,84 € |

16 436,33 € |

| Downtime/Disruptions |

10%-15% |

921,32 € |

1 381,99 € |

1 151,66 € |

| Cost |

|

1 100,00 € |

1 100,00 € |

1 100,00 € |

| Monthly saving |

28 632,53 € |

44 401,01 € |

36 516,77 € |

| Annual saving |

343 590,40 € |

532 812,14 € |

438 201,27 € |

Table 8.

Criteria for determining the overall criticality of SP.

Table 8.

Criteria for determining the overall criticality of SP.

| Description |

A |

B |

C |

| Importance of part |

Machine stop |

Machine can run (sub optimally) |

Consumables, Wear parts |

| Adjustment |

+1 |

+0,5 |

0 |

| Description |

1 |

2 |

3 |

| Importance of part |

Customer stop (Continuous run) |

63 % TEEP (Regular production) |

Ramp down, low volume |

| Adjustment |

+2 |

0 |

-1 |

| Description |

D |

E |

F |

| No. of parts in machine |

>10 |

3-10 |

1-2 |

| Adjustment |

+1 |

+0,5 |

0 |

Table 9.

Comparison of the current situation with the new situation.

Table 9.

Comparison of the current situation with the new situation.

| |

Original values |

New values |

| Total value of stock items in € |

62 258,70 € |

38 684,78 € |

| Total number of stock items |

31 401 |

6 998 |

Table 14.

Reduction of maintenance capacities based on the strategy change plan.

Table 14.

Reduction of maintenance capacities based on the strategy change plan.

| Profession |

Current status |

M1 (PW 1-8) |

M2 (PW 9-16) |

M3 (PW 17-24) |

M4 (PW 25-32) |

M5 (PW 33-40) |

pre-post period |

| Floater |

3 |

3 |

3 |

2 |

2 |

2 |

1 |

| MaRT daily |

15 |

18 |

14 |

14 |

14 |

13 |

2 |

| MaRT shift |

12 |

8 |

8 |

8 |

8 |

8 |

4 |

| Daily locksmith |

27 |

24 |

23 |

23 |

18 |

19 |

8 |

| Shift locksmith |

12 |

12 |

12 |

8 |

8 |

4 |

8 |

| Electrician |

7 |

7 |

6 |

6 |

6 |

6 |

1 |

| Cleaner |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

| Total |

77 |

73 |

67 |

62 |

57 |

53 |

24 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).