1. Introduction

Recently, the low-temperature combustion (LTC) method is applied a lot to reduce exhaust emissions in compression ignition (CI) engines. The high combustion temperature is formed by the rich air-fuel mixture in the CI engine, so to implement the LTC method, there are the premixed charge compression ignition (PCCI), the homogeneous charge compression ignition (HCCI), and the reactivity controlled compression ignition (RCCI) to suppress the rich air-fuel mixture region. Rohani et al. [

1] have conducted the effect of the EGR ratio and the different start of injection timing under the PCCI method. They said the PCCI method emits a small of exhaust emissions due to various auto-ignition points in the air-fuel mixture at a whole cylinder. Pandey et al. [

2] have announced that the PCCI method can secure greater time for air and fuel mixing than the general CI method however, it still does not meet various exhaust emission regulations. So, Cha et al. [

3] and Min et al. [

4] have progressed the studies to simultaneously reduce exhaust emissions by using simulated-EGR under the PCCI method. They found that when the specific start of energizing timing can reduce the exhaust emissions simultaneously. However, the IMEP value was also decreased because a part of the injected fuel that was not burned flowed into the crevice volume. Another method for the low-temperature reaction is the homogeneous charge compression ignition (HCCI) method because it induced a low-temperature reaction by a homogeneous mixture in the cylinder [

5]. Although the HCCI method reduces exhaust emissions, it is difficult to control the exact ignition timing under high load operation [

6,

7].

To solve the difficulty of the control of exact ignition timing in the HCCI method, the RCCI method has been studied by many researchers. Generally, the RCCI method uses two fuels for the homogeneous air-fuel mixture and the control of ignition timing. First, to form the homogeneous air-fuel mixture, high-octane fuel is used and injected into the intake port and mixed homogeneously with air. The homogeneous air-fuel mixture enters the cylinder when the intake valve opens, so the air in the cylinder is charged as the homogeneous air-fuel mixture. And then, to ignite the homogeneously distributed high-octane fuel, a high-cetane fuel is used by injecting directly into the cylinder [

8,

9,

10]. Thus, the start of combustion in the cylinder is easily controlled rather than the HCCI method by the auto-ignition characteristics of the injected high-cetane fuel. However, Singh et al. [

11] announced that substances by incomplete combustion such as carbon monoxide (CO) and hydrocarbon (HC) are discharged a lot by the auto-ignition of the directly injected high-cetane fuel into the cylinder. Jo et al. [

12] progressed the experimental research to reduce the exhaust emissions by incomplete combustion under the different premixed ethanol ratios and energizing timing. The total heating value by ethanol and diesel was constant by 595J, and the premixed ethanol ratio was varied from 0% to 40%. As a result, even though the peak cylinder pressure was decreased with increasing the premixed ethanol ratio, the IMEP (Indicated mean effective pressure) had almost similar values because the ignition delay was longer due to the decrease of cylinder temperature by the increased ethanol ratio. In addition, the NO

X emissions were reduced due to the low combustion temperature and the low intake air temperature. In their study, the injected amount of diesel fuel for ignition of the homogeneously distributed ethanol in the cylinder was changed according to the ethanol ratio. So, to determine the exact ignition timing for reducing the exhaust emissions, the analysis of the injected diesel fuel droplet is important because the intake air temperature would be decreased by the evaporation latent heat of the injected ethanol into the premixing chamber. However, in an experimental study, it is difficult to analyze and compare the injected fuel droplet behavior because the evaporated amount according to the injected diesel fuel amount is difficult to confirm in the visualization experiment of the fuel droplets, so the exact evaporation rate is difficult to measure.

Therefore, this study was conducted to investigate the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distributions and the injected fuel droplet behavior in the cylinder. At the same time, the results according to the premixed ethanol ratio were compared and analyzed in terms of spray tip penetrations, spray evolutions, and the equivalence ratio distributions in the cylinder. This work was a previous study for the investigation of the simultaneous reduction of exhaust emissions and the improvement of combustion performance according to the premixed ethanol ratio based on the same total heating value in-cylinder in the RCCI engine. The fuel droplet behavior injected into the cylinder is changed because the density and pressure in the cylinder are changed by the premixed ethanol ratio rather than by general air in the cylinder, so this study is considered essential. Besides, this work would provide the database for the optimization conditions to improve the combustion performance and reduce the exhaust emissions in the RCCI engine.

2. Experimental and numerical descriptions

2.1. Experimental descriptions

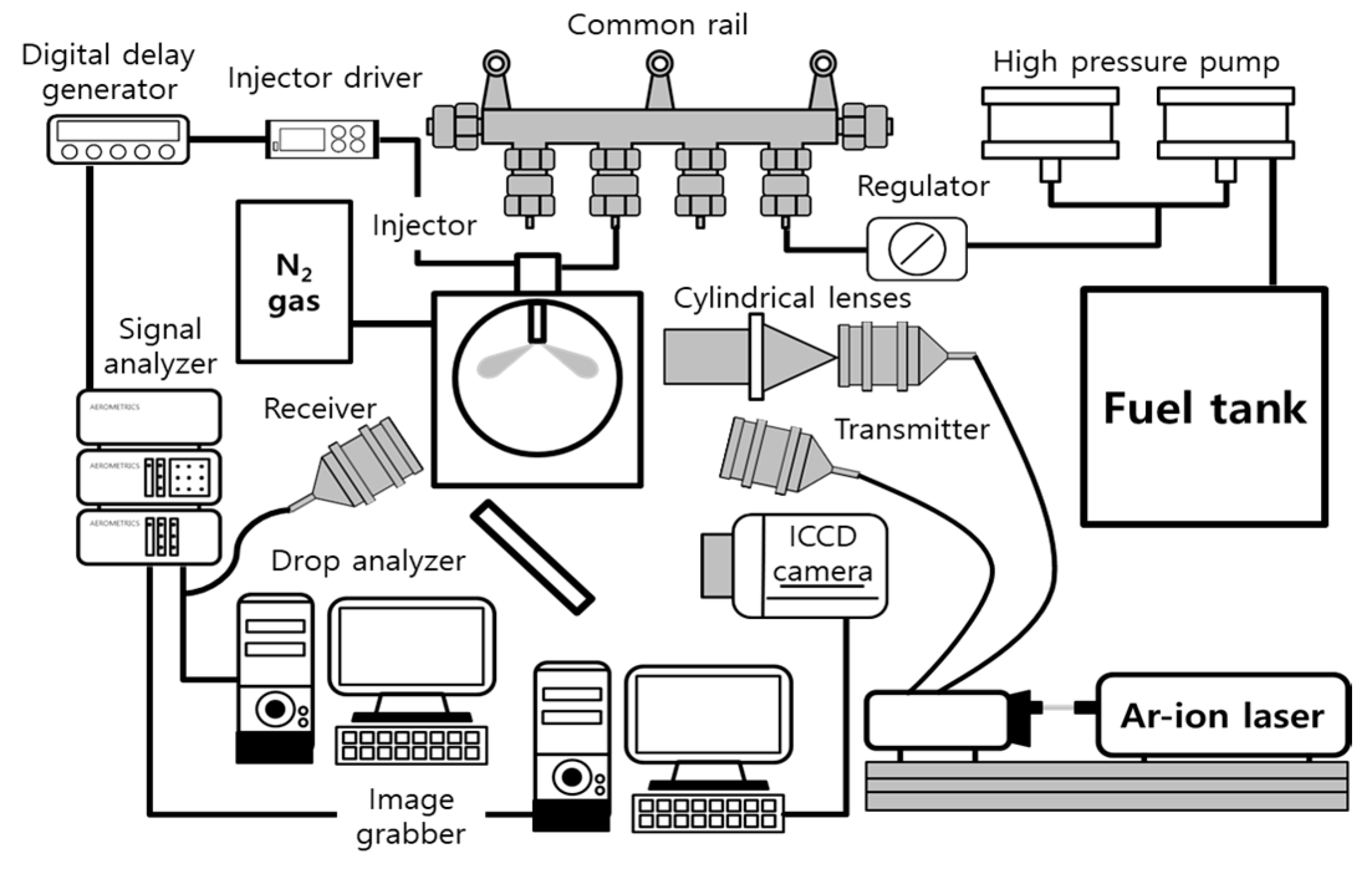

The schematic of the experimental setup for securing reliability in the validation of the numerical analysis is shown in

Figure 1. The experiment setup consisted of a test chamber, an Ar-ion laser, a common-rail injection system, a high-pressure chamber, and an intensified charge-coupled device (ICCD) camera. In the common-rail injection system, the mini sac type test injector has a 0.168mm hole diameter with 5 holes and 154deg of inclined spray angle. The injection pressure and the injection mass were constant by 100MPa and 14mg. The ambient pressure in the chamber was changed from 2.5MPa to 3.5MPa to simulate the pressure change in the cylinder because it was changed according to the crank angle. The experiment was conducted to take images of the spray evolutions. The intervals of spray evolutions were set to 0.4ms from 0ms to 1.2ms and then it was compared with the spray simulation results such as the spray cone angle and the spray tip penetration according to each time of spray evolution. The spray tip penetration was measured by image post-processing. The obtained images by the experiment were changed to black and white and the changed images were controlled by the threshold to obtain clear images. The threshold values were adjusted to left the liquid fuel.

2.2. Numerical descriptions

The spray simulation was conducted by dividing two-part. First, the spray validation simulations were performed to find the spray-influenced factor of the test injector. Next, the engine simulations were performed with the spray-influenced factor obtained from spray validation simulations to investigate the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the injected fuel atomization and the equivalence ratio distributions.

Through the spray validation simulation, the spray-influenced factors were able to obtain, and it was applied in the engine simulation. In spray-influenced factors, there are break-up time, inclined spray angle, and so on. So, to validate the spray models, a cylindrical geometry mesh was generated and applied in the spray validation simulation, which is the same shape as the test chamber used in the experiment and it has 140mm in diameter and 50mm in height and the size of mesh is a hexahedron of 1mm × 1mm × 1mm (width × length × height). The size of each mesh was generated by referring to the previous study [

4] and the program manual [

13]. In addition, to express the physical phenomena such as turbulence, break-up, evaporation, and wall interaction in the numerical analysis, the sub-models were employed by the k-zeta-f model, KH-RT model, Dukowicz model, and Mundo-Tropea-Sommerfeld model, respectively. Among the sub-models, KH-RT model was employed for the break-up model. The KH mechanism is used in high relative velocity and high ambient density and the RT mechanism is applied in rapid deceleration of the droplets causing the growth of surface waves at the droplet stagnation point [13 ~ 14]. Furthermore, the KH mechanism is based on the WAVE model equation as follows (1) ~ (4).

Here, Oh and We denote Ohnesorge number and Weber number, respectively.

The RT model is described by Ω (the fastest-growing frequency) and the K (wave number). Its equations are as follows (5) ~ (6).

Where τ

t and Λ

t are defined as the break-up time constant and the wave length and it has equations as follows (7) ~ (8), respectively.

To investigate the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distributions and the injected fuel droplet behavior, the engine simulation was conducted by using engine mesh as shown in

Figure 2. The size of the engine mesh is also a hexahedron of 1mm × 1mm × 1mm (width × length × height) as the test chamber. The specifications of the test engine and test injector were listed in

Table 1. The introduced total heating value was fixed at 595J based on the lower heating value of diesel 14mg. The heating value of the premixed ethanol ratio varied from 0% to 40% based on the same total heating value in-cylinder in steps of 10%. It was assumed that all the ethanol fuel flowing into the cylinder through the premixing chamber was evaporated and introduced in a vaporized state.

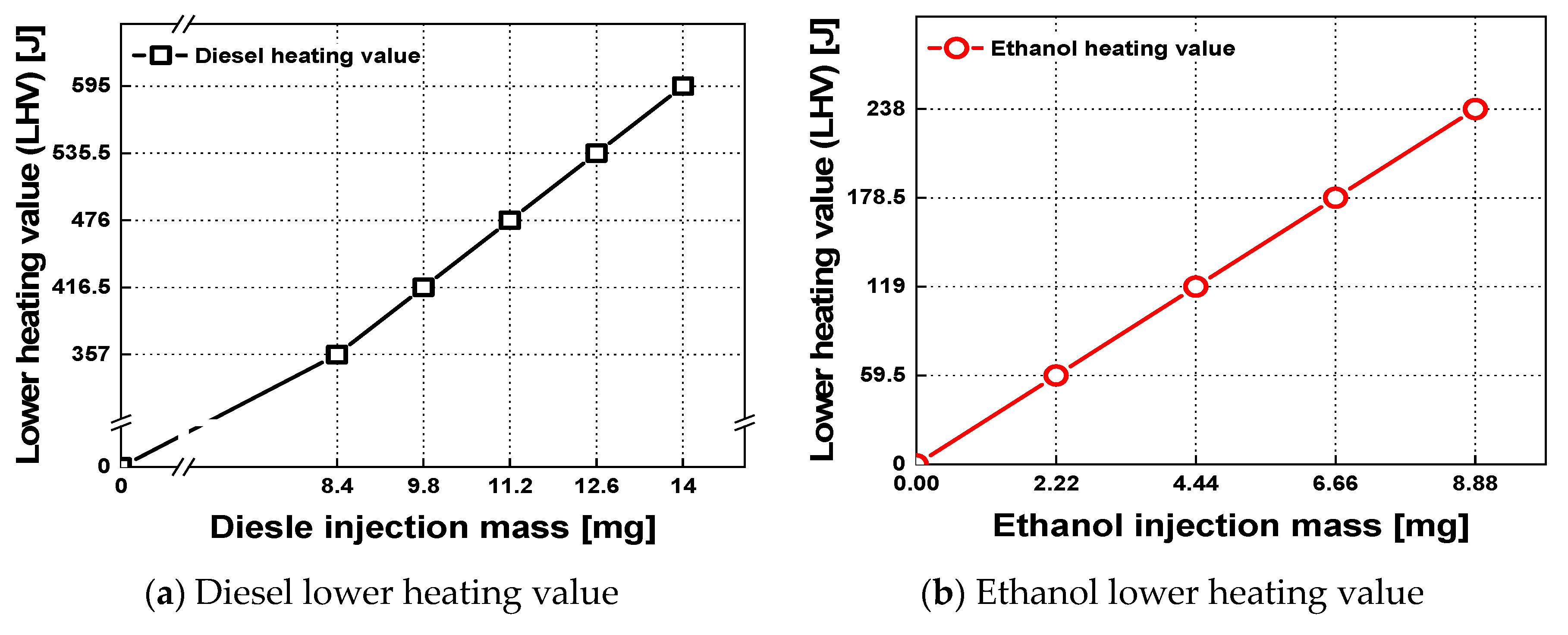

As shown in

Figure 3, since the lower heating value of ethanol is 26.8MJ/kg, when the introduced total heating value into the cylinder was increased by 10%, 2.22mg (59.5J) of ethanol mass was increased. Since the lower heating value of diesel is 42.5MJ/kg, the introduced total heating value into the cylinder excluding the occupied heating value by ethanol was adjusted to decrease the diesel injection mass by 1.4mg (59.5J), and the detailed properties of the test fuels were listed in

Table 2 [

15].

To express the ethanol by flowing from the pre-mixing chamber, the initial air composition in the cylinder was adjusted by a change of mass fraction as listed in

Table 3. In the simulation, the Diesel-D

1 (C

13H

23) fuel was applied by referring the library to a commercial program [

13]. Furthermore, ethanol fuel was used for the homogeneous air-fuel mixture in the cylinder. Since it is an oxygen-containing fuel, it helps combustion and at the same time has a higher heating value than methanol compared to the same mass. The premixed ethanol mass is determined according to the lower heating value of ethanol, the mass fractions of ethanol in the cylinder were adjusted according to the premixed ethanol mass. From these results, the mass fractions of O

2 and N

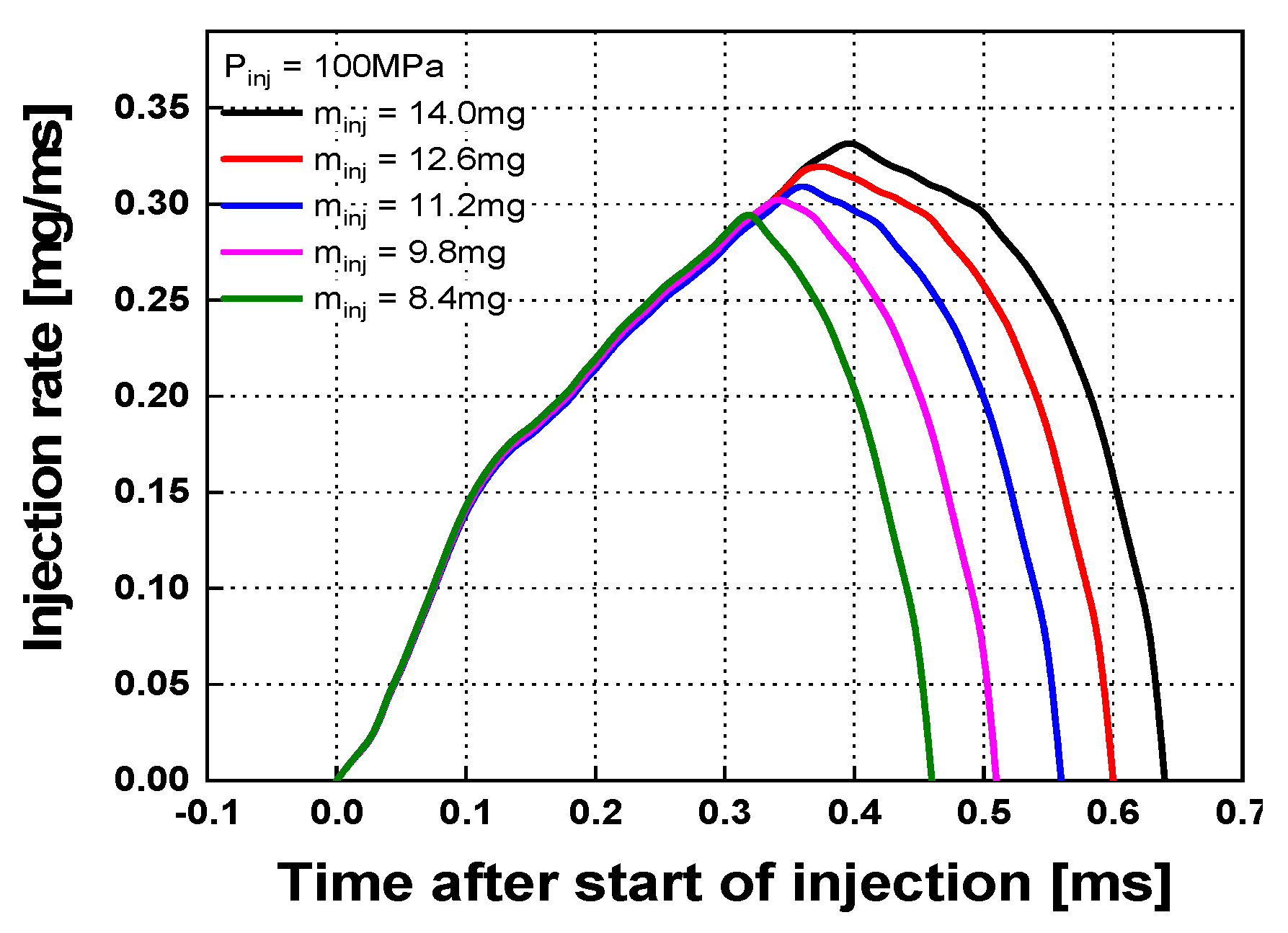

2 were determined by the ratio of 1:3.31, which are atmospheric conditions. As described above, the diesel mass was changed from 8.4mg to 14mg, and the ethanol mass was also varied from 0mg to 8.88mg according to the premixed ethanol ratio based on the same total heating value in-cylinder. So, the injection data according to the various diesel injection mass was measured by Bosch’s suggestion [

16] as shown in

Figure 4. The start of energizing timing and the injection pressure of diesel fuel were fixed to BTDC 12deg and 100MPa, respectively. The detailed numerical analysis conditions for engine simulation were listed in

Table 4.

3. Results

3.1. Validation of numerical models

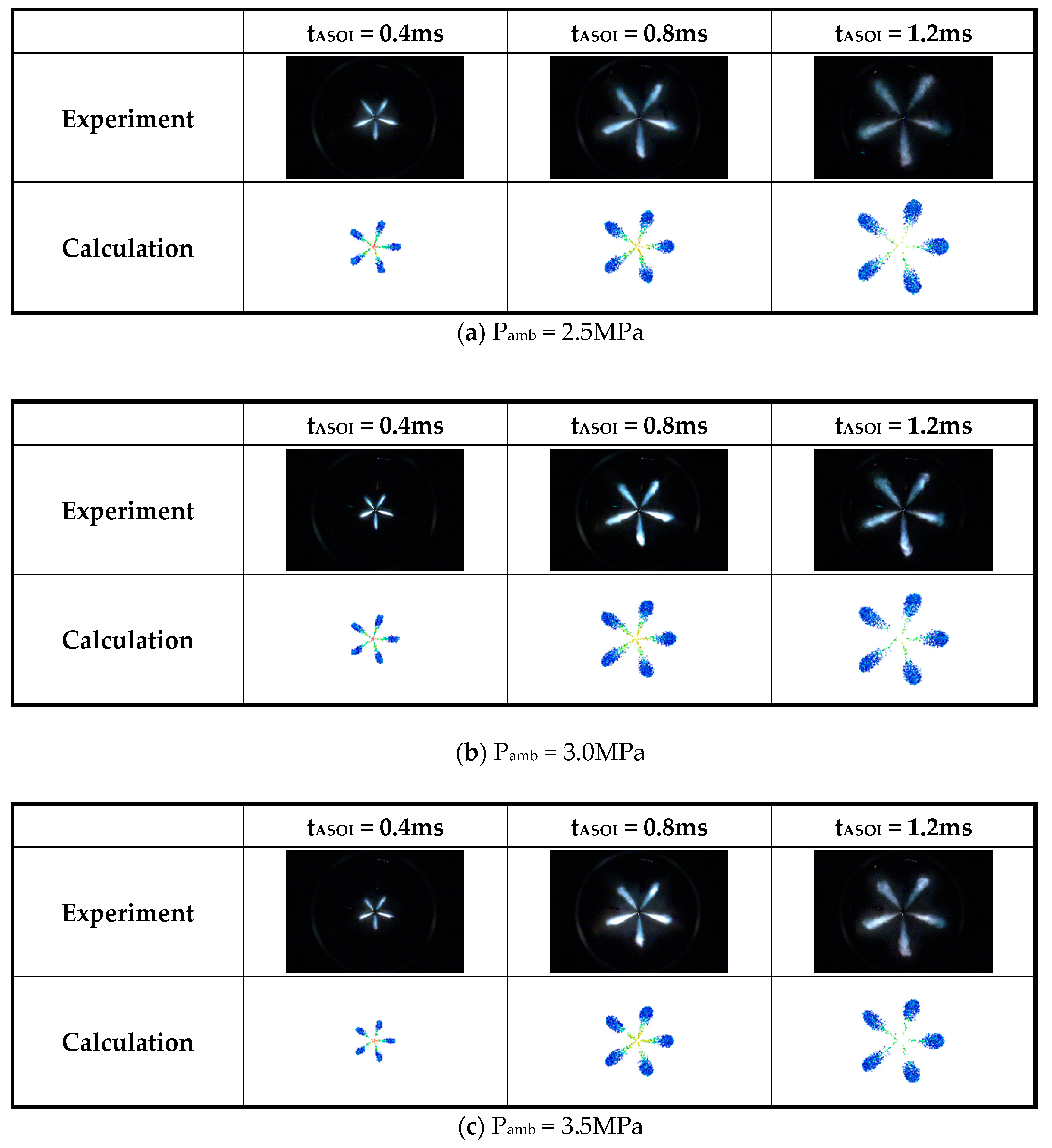

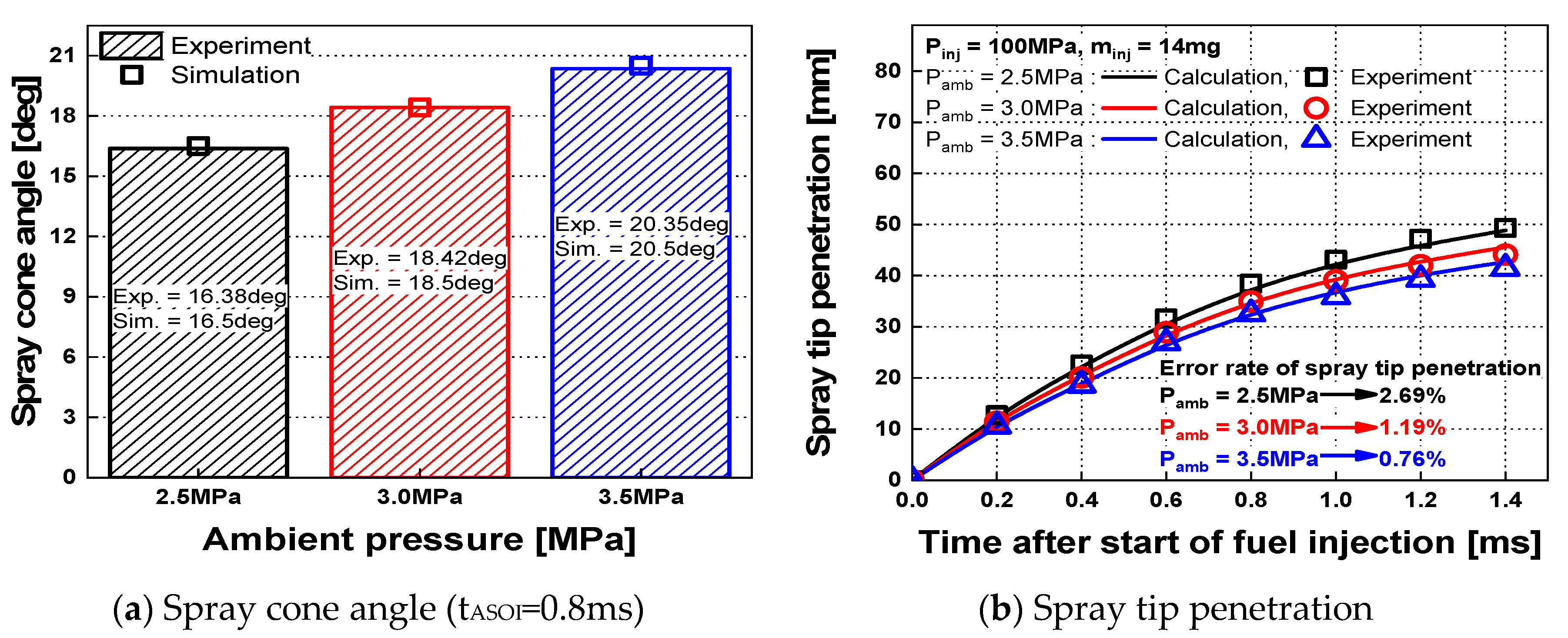

In this work, the reliability of the applied sub-model in the numerical analysis was secured by comparing the results of spray simulation with experiment results. To secure the exact reliability, the results of spray characteristics were compared according to the change of ambient pressure because it was changed according to the crank angle. The ambient pressure in the chamber was changed from 2.5MPa to 3.5MPa.

Figure 5 shows the comparison results of spray evolution according to the ambient pressure. The spray evolution results in the simulation were traced well from the experiment results. As mentioned above, if the value of the break-up time constant is small, the injected fuel droplet splits rapidly, and then the spray tip penetration is shortened. In addition, when the ambient pressure is high, the spray cone angle is wider as shown in

Figure 6 because the fuel droplet was broken up well by the high ambient pressure, which increases the drag force.

In the comparison between the results of the numerical analysis and the experiment, the error rates of the spray cone angle according to the ambient pressure were within 0.73%, 0.43% and 0.74% respectively. The error rates according to the ambient pressure were less than a maximum of 2.69%. From these results, it can be said that the cylinder pressure change due to the crank angle variation can be sufficiently described for the spray cone angle and the spray tip penetration.

3.2. The effect of ethanol ratio on the characteristics of spray evolution

The analysis of spray tip penetration is very important because, as reported by Lee et al [

17], the amount of exhaust emissions formation was different according to the collided position of the injected fuel on the piston wall. The injected fuel should be targeted to the point in a cylinder exactly at the desired timing to form a homogeneous air-fuel mixture and ignite.

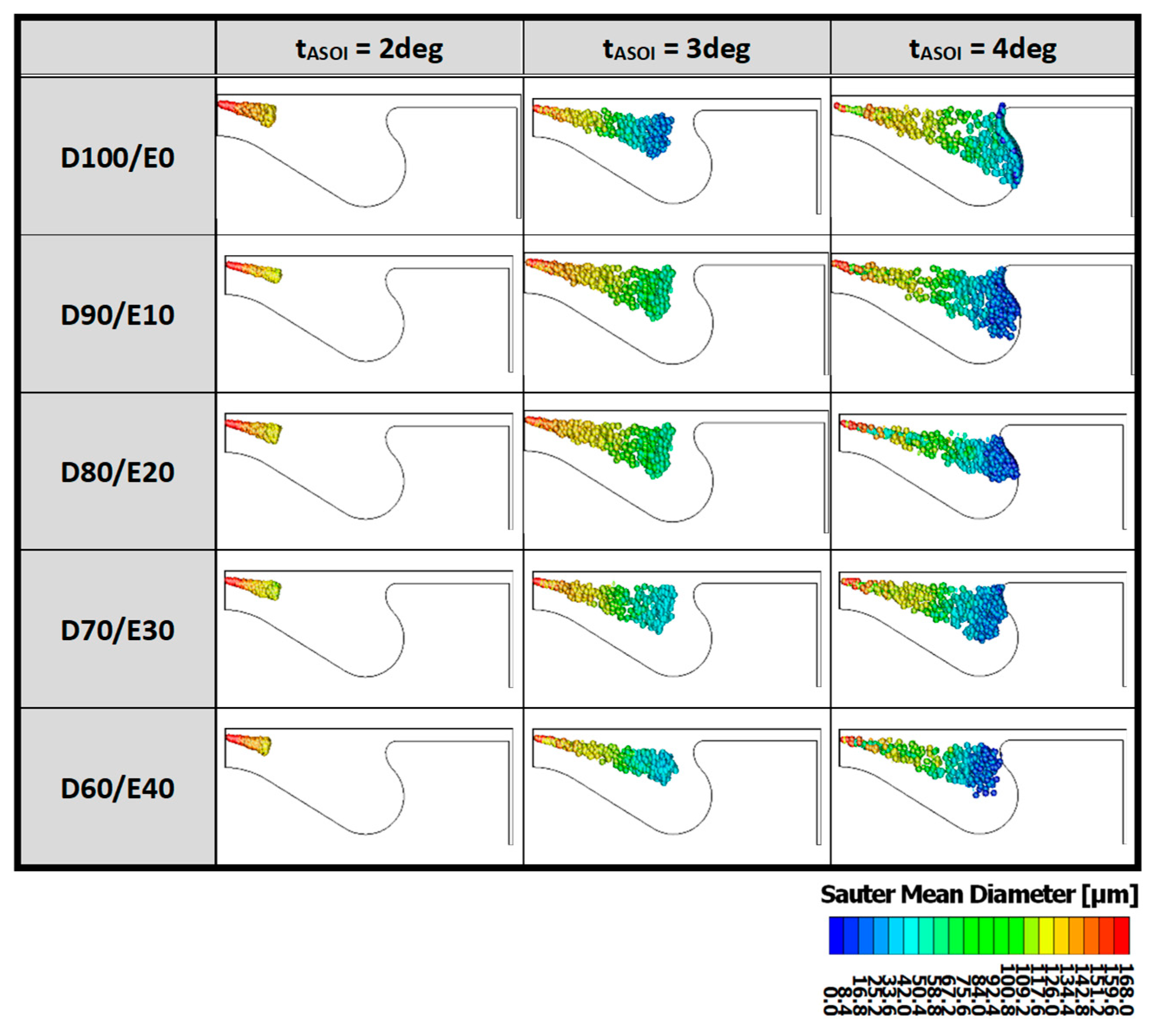

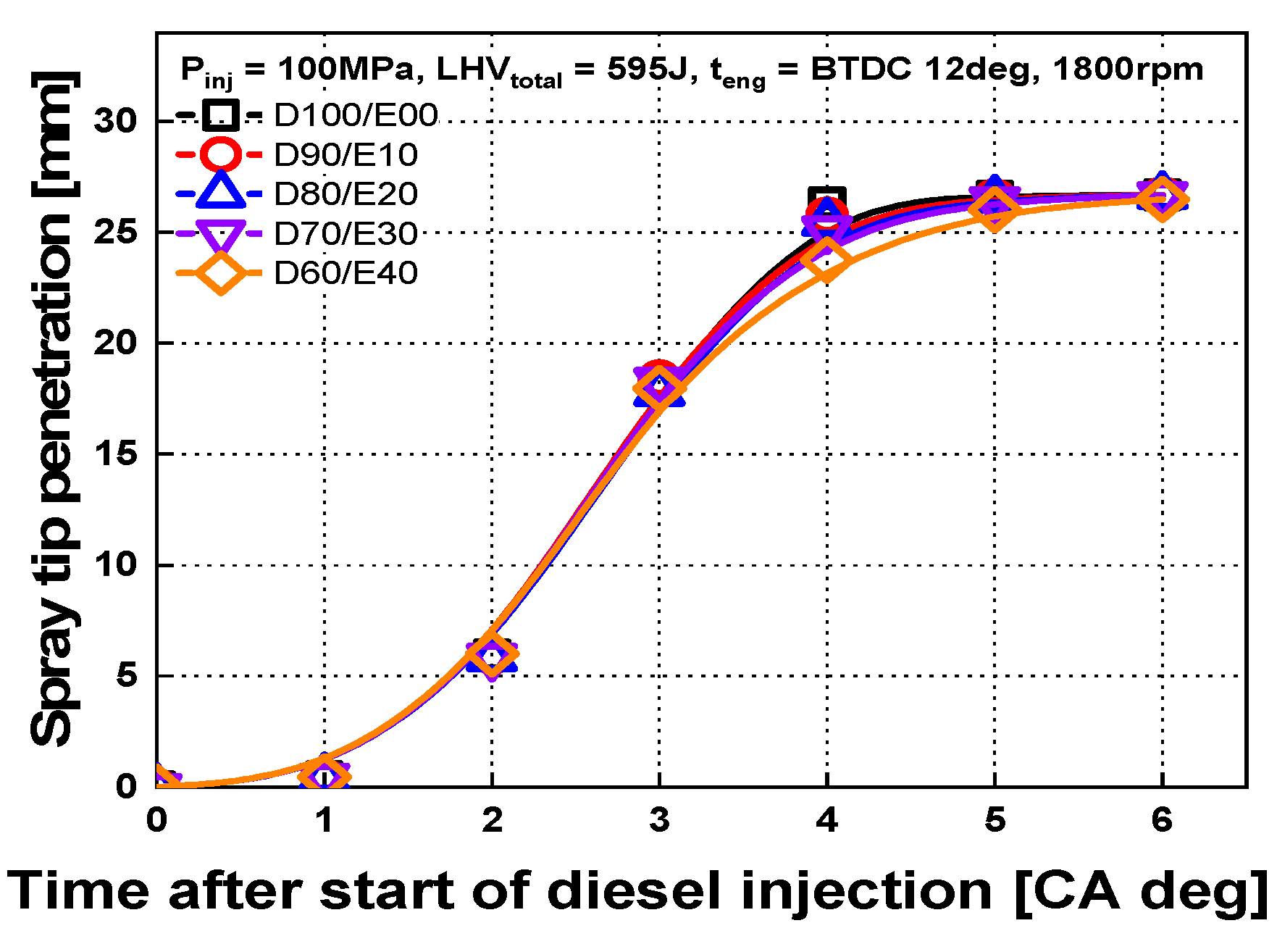

Figure 7 shows the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the visualization of spray evolution characteristics. It was found that when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the collided amount of diesel fuel to the cylinder wall was decreased because the amount of diesel fuel was decreased as shown in

Figure 3 and

Figure 4. To exactly compare the spray tip penetration according to the premixed ethanol ratio based on the same total heating value in-cylinder,

Figure 8 shows the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the spray tip penetration characteristics. As resulted in

Figure 7, the difference in spray tip penetration value according to the premixed ethanol ratio was difficult to observe until the time after 3deg of diesel injection started. However, in the case of D60/E40, it was observed that the spray tip penetration value was slightly decreased at the time after 4deg of diesel injection start because the diesel injection was completed due to the shorter diesel injection duration than the other diesel injection duration. From these results, it was found that, as shown in

Figure 9, although the injected fuel kinetic energy was decreased by 20.7% with increasing the ethanol ratio based on the same total heating value in-cylinder, the spray tip penetration was not affected the kinetic energy, and it was affected by the injection duration.

3.3. The effect of ethanol ratio on the fuel behavior characteristics

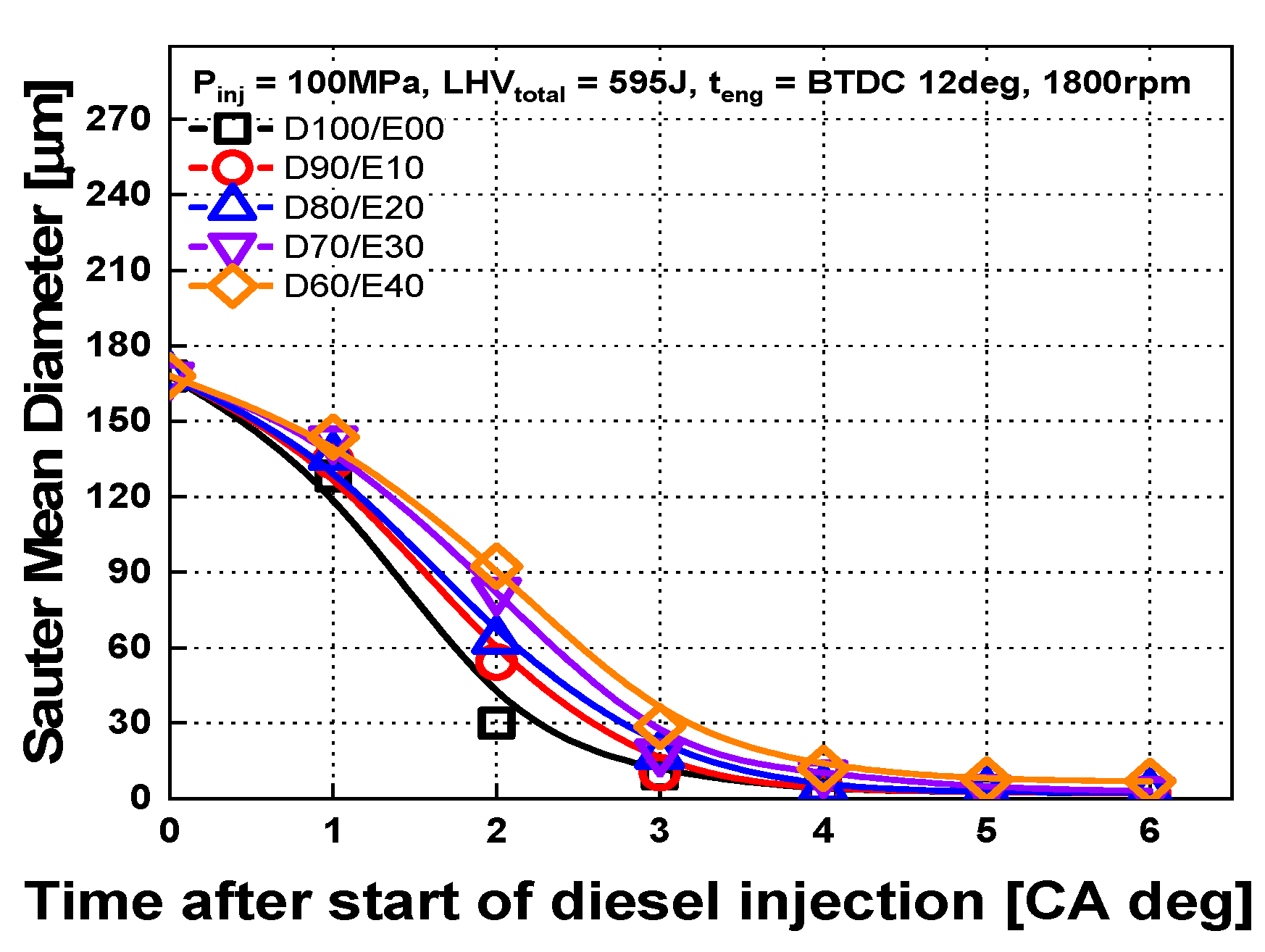

The injected diesel fuel for igniting the homogeneously distributed ethanol fuel in the cylinder may form particulate matter due to incomplete combustion by auto-ignition characteristics. The injected fuel droplet that break-up into smaller sizes can quickly evaporate and mix well with the air in the cylinder, and it induces good combustion performance and reduces the particulate matter.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the SMD characteristics was shown in

Figure 10. It was observed that when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the SMD value also became larger up to about 32.58%. Generally, it is known that the injected fuel is greatly affected by viscosity (μ) in the injected fuel and Weber number (We) [

18]. So, in this study, the density influences Weber number in the cylinder was analyzed as shown in

Figure 11.

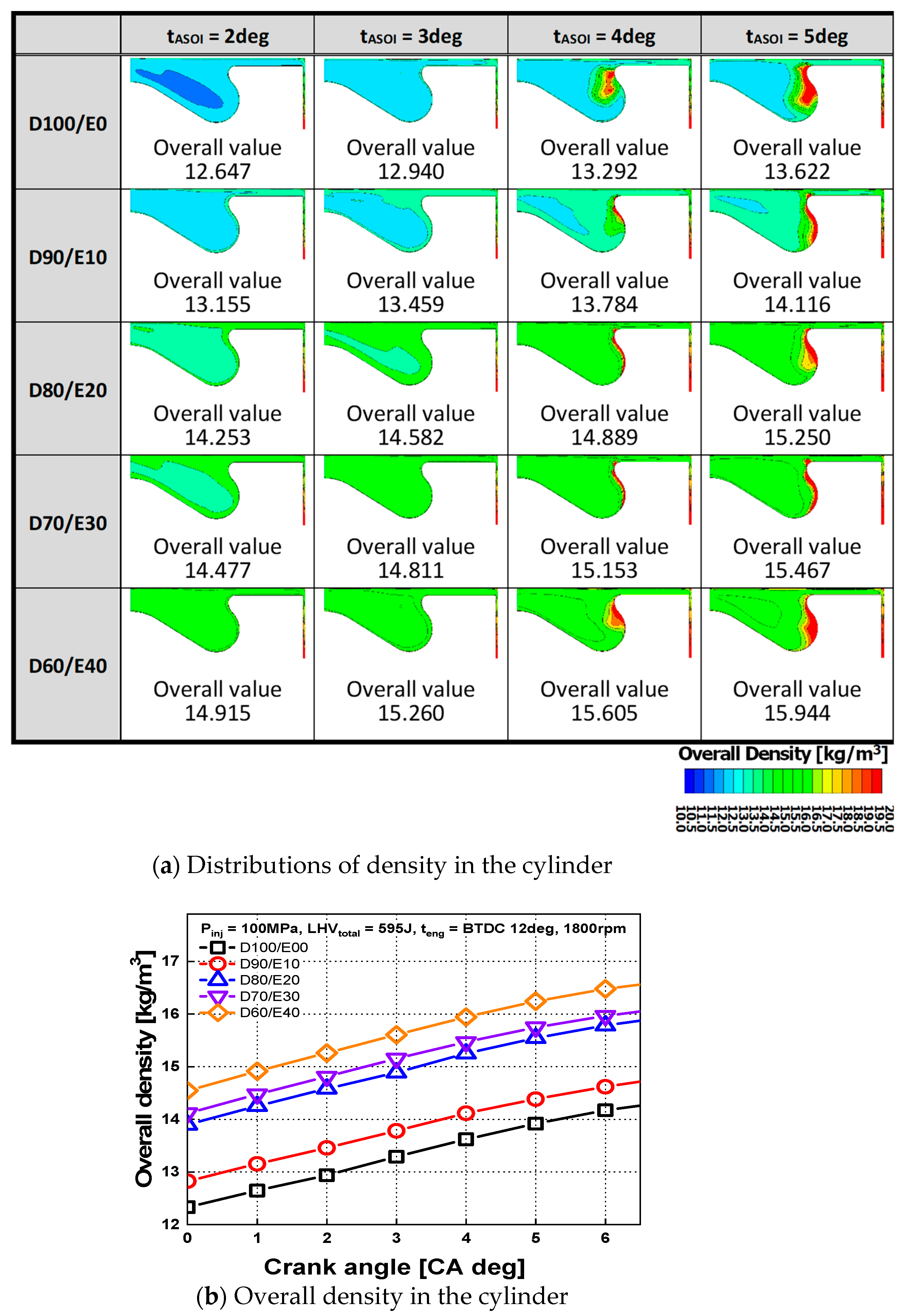

Figure 11 shows the effect of premixed ethanol ratio based on the same total heating value in-cylinder on the density characteristics.

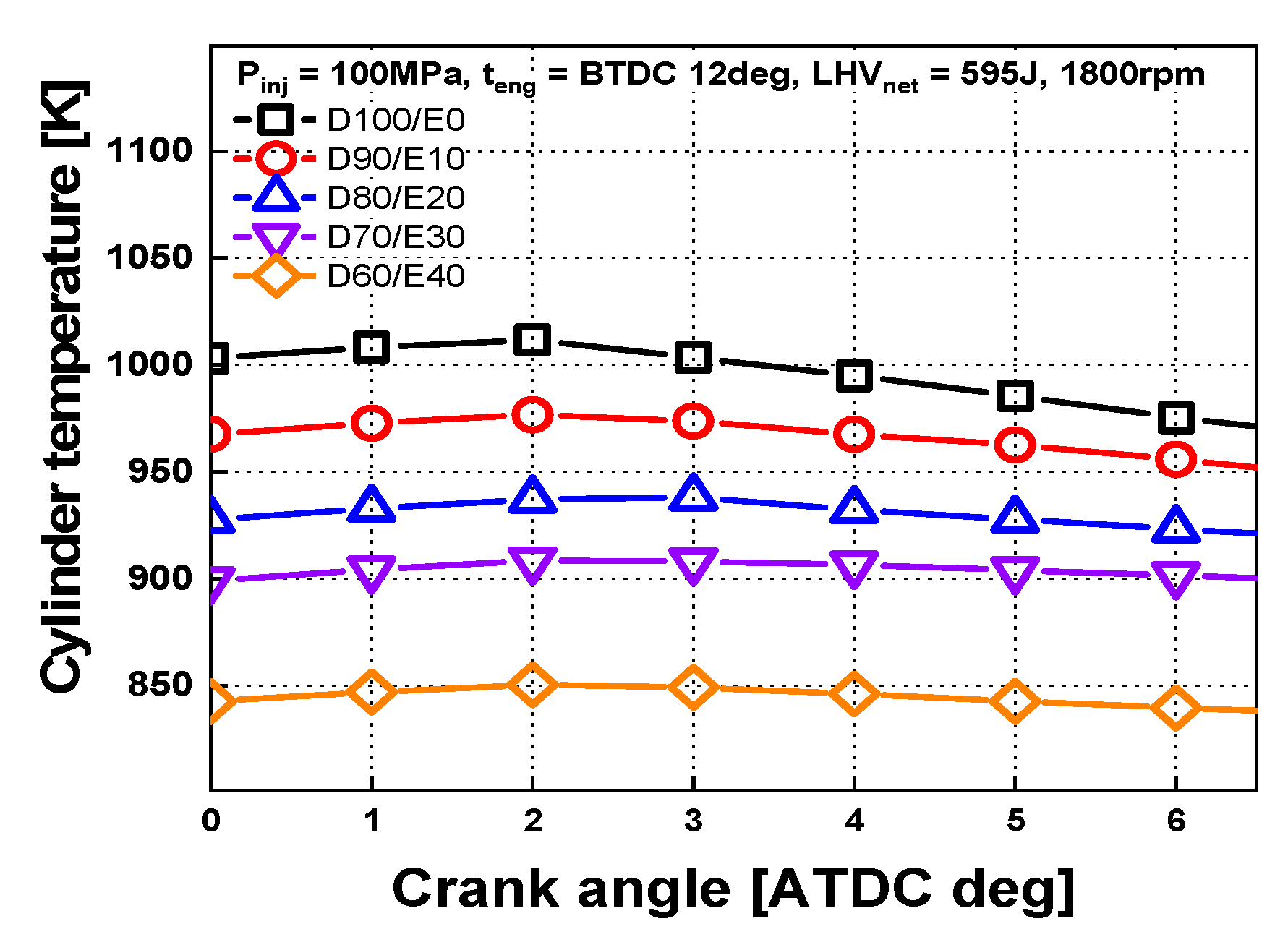

When the premixed ethanol ratio was increased, the density value in the cylinder was also increased by about 3.85% because the intake air temperature was decreased by -4.16% as shown in

Figure 12 due to the latent heat of evaporation by the evaporation of the ethanol injected into the premixing chamber [

12]. Moreover, over time, the high-density distributions were observed at the piston bowl wall and the piston rim region because the injected diesel fuel collided with the piston rim region, and it was broken up well by the collision effect. The well-broken small size of diesel droplets was converted to the gas state by evaporation, and it increased the density. Furthermore, it was found that when the time after the start of diesel injection was 2 deg, although the difference of the injected fuel kinetic energy was observed difficult as shown in

Figure 9, the difference of SMD was large as shown in

Figure 10 because both the injected fuel kinetic energy and the SMD value were obtained overall value in the cylinder. In the case of the injected fuel kinetic energy, although the total injected fuel kinetic energy was the same, the injected fuel droplets were well split. However, in the case of SMD, the difference in values appeared to be relatively large because when the ethanol ratio was increased, the diesel fuel injection duration was shorter.

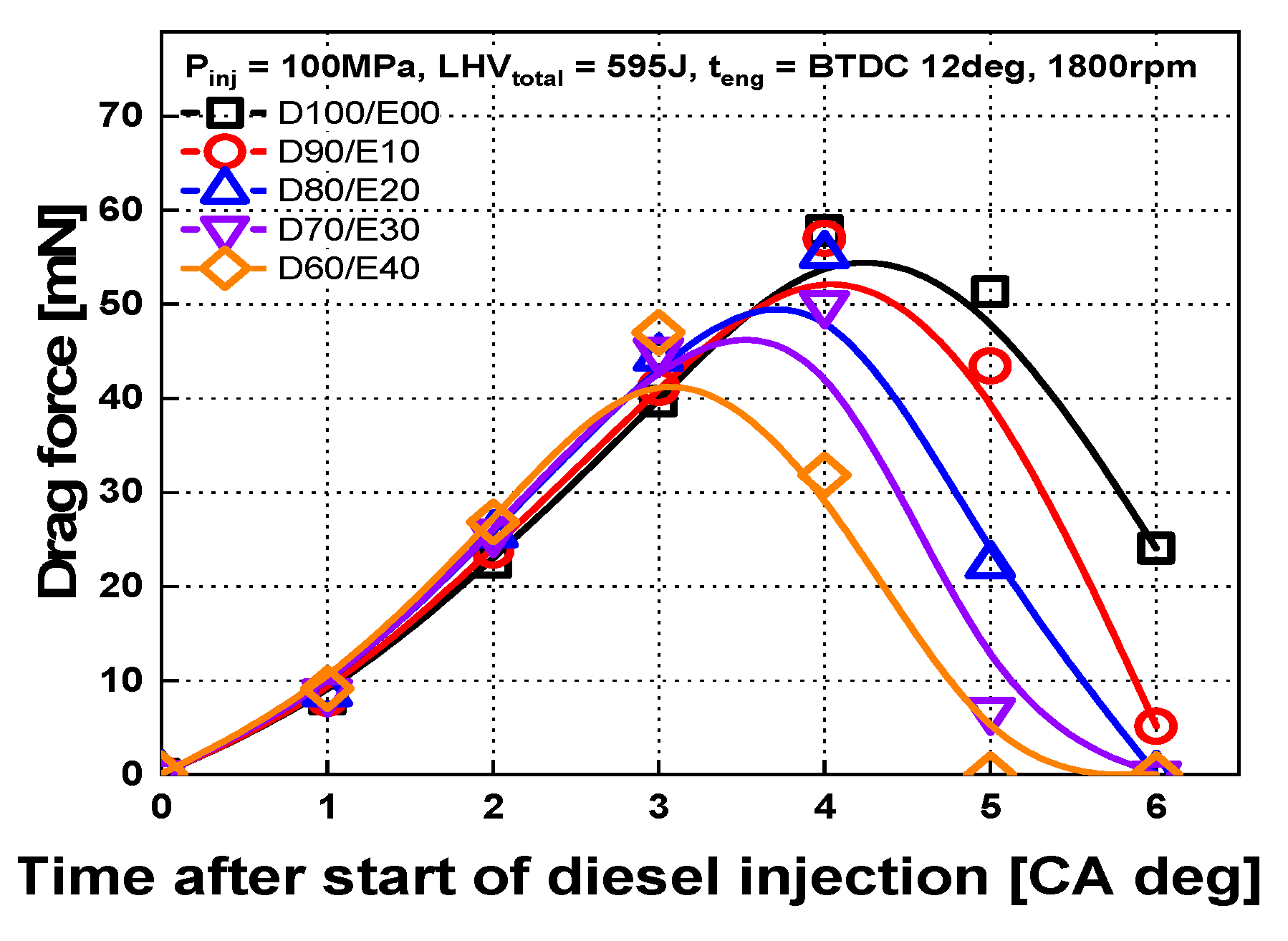

Since the drag force also affects Weber's number, it is compared as shown in

Figure 13.

Figure 13 shows the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the drag force. The original drag force should be calculated using the local density value, however, it is difficult to obtain the value. So, in this study, the overall density value was applied to calculate the drag force because the density distribution in the cylinder was observed almost the same excluding the crevice volume as shown in

Figure 11 (a). Although as shown in

Figure 9, the kinetic energy decreased by 20.7% with increasing the ethanol ratio based on the same total heating value in-cylinder, the drag force had shown a similar value due to the increase in the density in the cylinder. However, when the ethanol ratio based on the same total heating value in-cylinder was increased, although the difference of SMD values was little at the beginning of diesel fuel injection, it was decreased after 3deg, which affects combustion, by 32.58%. Thus, it was judged that the drag force was not the affected factor to the SMD.

Therefore, the evaporation rate which is another factor affecting SMD was compared as shown in

Figure 14. The injected fuel evaporation rate was determined by the evaporated amount per the injected fuel mass at each point in time. It was found that when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the injected fuel was slowly evaporated due to the decrease of intake air temperature by -4.16%. Consequently, it was found that the kinetic energy and the evaporation of the injected fuel were more affected by the droplet atomization of the injected fuel than the drag force of the injected fuel which affects Weber's number.

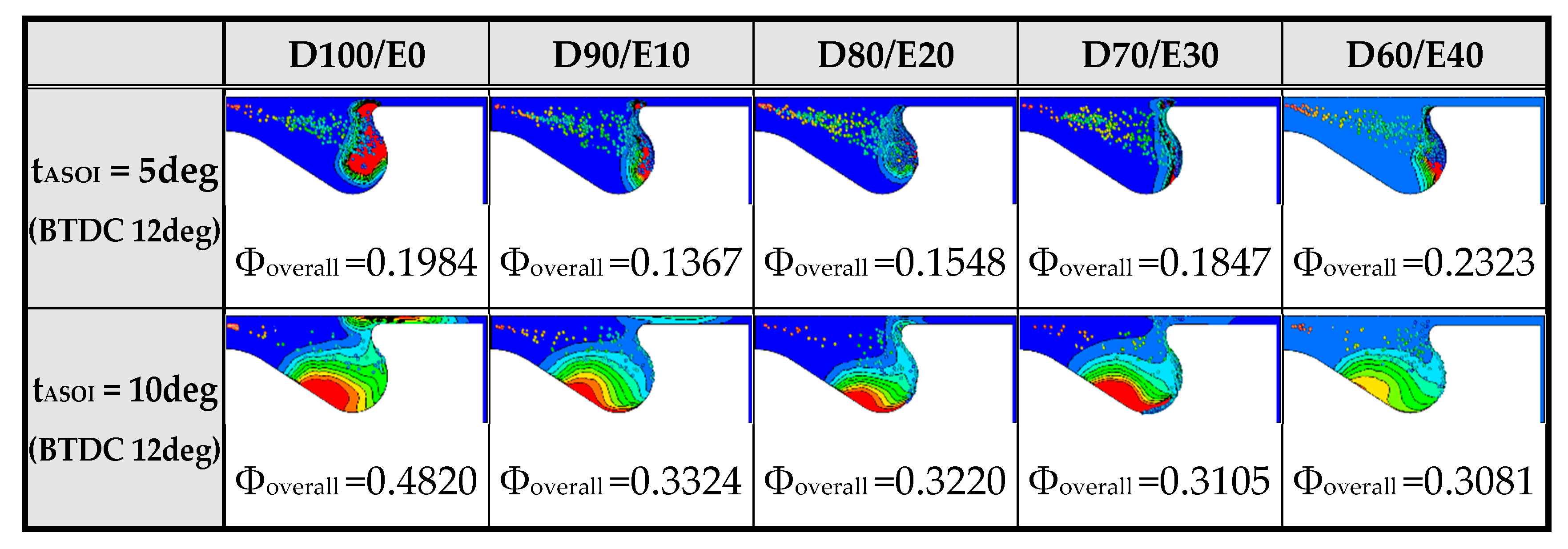

3.4. The effect of ethanol ratio on the equivalence ratio distribution characteristics

Figure 15 shows the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distribution characteristics. At the beginning of the diesel injection (t

ASOI = 5deg), it was observed that when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the overall value of the equivalence ratio was increased. The reason is that although the injected fuel was slowly evaporated due to the low cylinder temperature, the amount of the premixed ethanol was also increased, which increased the equivalence ratio. However, at t

ASOI = 10deg, the overall value of the equivalence ratio was decreased with increasing the premixed ethanol ratio because many unevaporated diesel droplets remained in the cylinder due to the slowly evaporating injected diesel fuel.

At t

ASOI = 5deg, a rich equivalence ratio was distributed in the piston bowl because the injected diesel fuel collided with the piston bowl wall, and the collided diesel fuel droplet was atomized by the collision effect so that the smaller diesel fuel droplets evaporated well. Furthermore, at t

ASOI = 10deg, it was observed that a part of the injected fuel was introduced to the squish volume, and the amount of the introduced fuel into the squish volume was decreased with increasing the premixed ethanol ratio based on the same total heating value in-cylinder. In general, as reported by Lee et al [

17], when a small fuel amount among the total injected fuel is introduced into the piston bowl and a lot of fuel amount is introduced into the squish volume, the combustion performance would deteriorate because the squish volume has a small amount of air. The small amount of air induces incomplete combustion by the rich equivalence ratio and then a lot of exhaust emissions such as soot and CO would be generated because it cannot be oxidized by a lean concentration of O

2. In this study, when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the amount of injected diesel fuel was decreased, and the amount of diesel fuel introduced into the squish volume was also decreased as shown in

Figure 15. From these results, it is expected that the combustion performance will be promoted by increasing the ethanol ratio based on the same total heating value in-cylinder because the amount of diesel fuel having a high heating value introduced into the squish volume was small.

4. Conclusions

This study is to investigate the effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distributions and the injected fuel droplet behavior in the cylinder under the RCCI engine. The conclusions were able to obtain as follows.

In the case of D60/E40, it was observed that the spray tip penetration value was slightly decreased at the time after 4deg of diesel injection start because the diesel injection was completed due to the shorter diesel injection duration than the other diesel injection amount.

When the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the SMD value was also more enormous up to 32.58% because of the low kinetic energy of the injected fuel by the short injection duration and the slow evaporation of the injected fuel by the low cylinder temperature.

At tASOI = 5deg, when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the overall value of the equivalence ratio was increased because the amount of premixed ethanol was increased. However, at tASOI = 10deg, the overall value of the equivalence ratio was decreased because many unevaporated diesel droplets remained in the cylinder due to the slowly evaporating injected diesel fuel.

At tASOI = 10deg, it was observed that when the premixed ethanol ratio based on the same total heating value in-cylinder was increased, the amount of injected diesel fuel was decreased, and the amount of diesel fuel introduced into the squish volume was also decreased

It is expected that the combustion performance will be promoted by increasing the ethanol ratio based on the same total heating value of the introduced fuels into the cylinder because the amount of diesel fuel having a high heating value introduced into the squish volume was small.

Funding

This work was supported by the National Research Foundation of Korea(NRF) grant funded by the Korea government(MSIT) (No. 2020R1A2C1011641).

References

- Rohani, B., Park S. S. and Bae C. S., Effect of injection strategy on smoothness, emissions and soot characteristics of PCCI-conventional diesel mode transition. Journal of Applied Thermal Engineering 2016, 93, 1033–1042. [CrossRef]

- Pandey S., K., Vandana S., Akella S. R. S. and Ravikrishna R. V., Potential of early direct injection (EDI) for simultaneous NOX and soot emission reduction in a heavy duty turbocharged diesel engine. Journal of Applied Thermal Engineering 2019, 158, 1–15.

- Cha J., P., Yoon S. J., Lee S. H. and Park S. W., Effect of intake oxygen mole fraction on the near-stoichiometric combustion and emission characteristics of a CI (compression ignition) engine. Journal of Energy 2015, 80, 677–686. [CrossRef]

- Min S., H., Suh H. K. and Cha J. P., Effect of simulated-EGR (N2) on the distribution characteristics of equivalence ratio and the formation of exhaust emissions in a CI engine under early injection conditions. Journal of Energy 2020, 199, 116850.

- Kook S., H., Kong J. S., Park S. I., Bae C. S. and Kim J. H., The effect of injection angle and nozzle diameter on HCCI combustion. Transaction of KSAE 2007, 15, 1–7.

- Peng, Z., Zhao H. and Ma T., Characteristics of premixed homogeneous charge compression ignition (HCCI) diesel combustion and emissions”. Journal of Combustion Science and Technology 2005, 177, 2113–2150. [CrossRef]

- Kim M., Y. and Lee C. S., Effect of a narrow fuel spray angle and a dual injection configuration on the improvement of exhaust emissions in a HCCI diesel engine. Journal of Fuel 2007, 86, 2871–2880. [CrossRef]

- Kumar K., S. and Raj R. T. K., Effect of fuel injection timing and elevated intake air temperature on the combustion and emission characteristics of dual fuel operated diesel engine. Journal of Procedia Engineering 2013, 64, 1191–1198. [CrossRef]

- Pan, W., Yao C. D., Han G. P., Wei H. Y. and Wang Q. G., The impact of intake air temperature on performance and exhaust emissions of a diesel methanol dual fuel engine”. Journal of Fuel 2015, 162, 101–110. [CrossRef]

- Rocha H. M., Z., Pereira R. D. S., Nogueira M. F. M., Belchior C. R. P. and Tostes M. E. D. L., Experiment investigation of hydrogen addition in the intake air of compressed ignition engines running on biodiesel blend. International Journal of Hydrogen Energy 2017, 42, 4530–4539. [CrossRef]

- Singh A., P., Kumar V. and Agarwal A. K., Evaluation of comparative engine combustion, performance and emission characteristics of low temperature combustion (PCCI and RCCI) modes. Journal of Applied Energy 2020, 278, 115644. [CrossRef]

- Jo S., I., Park S. H., Kim H. J. and Lee J. T., Combustion improvement and emission reduction through control of ethanol ratio and intake air temperature in reactivity controlled compression ignition combustion engine. Journal of Applied Energy 2019, 250, 1418–1431. [CrossRef]

- AVL List GmbH, Fire Version 2013 ESE-Diesel (Engine Simulation Environment) Module Manual, 2013.

- AVL GmbH, Fire Version 2013.2 Spray Module Manual, 2013.

- Suh H., K. and Lee C. S., “A review on atomization and exhaust emissions of a biodiesel-fueled compression ignition engine”. Journal of Renewable and Sustainable Energy Reviews, 1620. [Google Scholar]

- Bosch, W. , The Fuel Rate Indicator : A New Measuring Instrument for Display of the Characteristics of Individual Injection, SAE 660749, 1966.

- Lee. S. and Reitz R. D., Spray targeting to minimize soot and CO formation in premixed charge compression ignition (PCCI) combustion with a HSDI diesel engine, Journal of SAE, No. 2006-01-0918, pp. 1-12, 2006.

- Arthur, H. Lefebvre, Atomization and spray, Taylor & Francis, pp. 41-54, 1989.

Figure 1.

Schematic of an experimental setup.

Figure 1.

Schematic of an experimental setup.

Figure 2.

Geometry of test engine mesh.

Figure 2.

Geometry of test engine mesh.

Figure 3.

The lower heating value of diesel and ethanol according to the injection mass.

Figure 3.

The lower heating value of diesel and ethanol according to the injection mass.

| Item |

Specification |

| Engine |

Engine type |

Single cylinder |

| Bore / Stroke |

83mm / 92mm |

| Displacement |

498cc |

| Compression ratio |

17.7 |

| Injector |

Nozzle |

5 hole mini-sac type |

| Hole diameter |

0.168mm |

| Inclined spray angle |

154deg |

Figure 4.

Injection rate according to the injection mass of diesel fuel.

Figure 4.

Injection rate according to the injection mass of diesel fuel.

Figure 5.

Validation results of spray evolution characteristics (Pinj = 100MPa).

Figure 5.

Validation results of spray evolution characteristics (Pinj = 100MPa).

Figure 6.

Validation results of spray cone angle and spray tip penetration characteristics (Pinj = 100MPa).

Figure 6.

Validation results of spray cone angle and spray tip penetration characteristics (Pinj = 100MPa).

Figure 7.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the visualization of spray evolution characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 7.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the visualization of spray evolution characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 8.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the spray tip penetration characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 8.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the spray tip penetration characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 9.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the injected fuel kinetic energy characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 9.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the injected fuel kinetic energy characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 10.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the Sauter mean diameter characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 10.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the Sauter mean diameter characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 11.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the density in the cylinder characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 11.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the density in the cylinder characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 12.

The effect of the premixed ethanol ratio based on based on the same total heating value in-cylinder on the cylinder temperature characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 12.

The effect of the premixed ethanol ratio based on based on the same total heating value in-cylinder on the cylinder temperature characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 13.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the drag force in the cylinder characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 13.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the drag force in the cylinder characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 14.

The effect of the premixed ethanol based on the same total heating value in-cylinder on the injected fuel evaporation rate characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 14.

The effect of the premixed ethanol based on the same total heating value in-cylinder on the injected fuel evaporation rate characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 15.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distribution characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Figure 15.

The effect of the premixed ethanol ratio based on the same total heating value in-cylinder on the equivalence ratio distribution characteristics (Pinj = 100MPa, LHVtotal = 595J, teng = BTDC 12deg, 1800rpm).

Table 1.

Detailed specifications of test engine and test injector.

Table 1.

Detailed specifications of test engine and test injector.

| Item |

Specification |

| Engine |

Engine type |

Single cylinder |

| Bore / Stroke |

83mm / 92mm |

| Displacement |

498cc |

| Compression ratio |

17.7 |

| Injector |

Nozzle |

5 hole mini-sac type |

| Hole diameter |

0.168mm |

| Inclined spray angle |

154deg |

Table 2.

Properties of test fuels [

15].

Table 2.

Properties of test fuels [

15].

| Item |

Diesel |

Ethanol |

| LHV; Lower Heating Value [MJ/kg] |

42.5 |

26.8 |

| Latent heat of Evaporation [kJ/kg] |

250 |

846 |

| Density @ 20℃ [kg/m3] |

838.2 |

789.4 |

| Carbon Content [% mass] |

86.7 |

52.14 |

| Hydrogen content [% mass] |

12.71 |

13.13 |

| Sulfur content [% mass] |

0.041 |

- |

| Oxygen content [% mass] |

- |

34.73 |

| Flash point [℃] |

67 |

13 |

| Kinematic viscosity @ 40℃ [mm2/s] |

2.8271 |

1.056 |

| Typical formula |

C14.09H24.78

|

C2H6O |

| Cetane number |

42.6 |

8.5 |

| Lubricity, HFRR @60℃m] |

Max. 520 |

Max. 605 |

Table 3.

Initial air composition in the cylinder according to the heating value ratio of diesel and ethanol.

Table 3.

Initial air composition in the cylinder according to the heating value ratio of diesel and ethanol.

| Fuel injection ratio[Main/Premixed] |

Fuel amount [mg] |

Heating value [J] |

O2 mass fraction [-] |

N2 mass fraction [-] |

Ethanol mass fraction [-] |

| D100/E0 |

14/0 |

595/0 |

0.23200 |

0.76800 |

0.00000 |

| D90/E10 |

12.6/2.2 |

535.5/59.5 |

0.23081 |

0.76407 |

0.00512 |

| D80/E20 |

11.2/4.4 |

476/119 |

0.22984 |

0.76084 |

0.00932 |

| D70/E30 |

9.8/6.7 |

416.5/178.5 |

0.22876 |

0.75273 |

0.01396 |

| D60/E40 |

8.4/8.9 |

357/238 |

0.22781 |

0.75413 |

0.01806 |

Table 4.

Numerical analysis conditions for engine simulation.

Table 4.

Numerical analysis conditions for engine simulation.

| Contents |

Numerical analysis |

| RPM |

1,800 |

| Injection pressure [MPa] |

Diesel : 100, Ethanol : 10 |

| Total heating value [J] |

595 |

| Start of energizing timing [ATDC deg] |

-12 |

| Fuel injection ratio[Main fuel/Premixed fuel] |

D100/E0, D90/E10, D80/E20,D70/E30, D60/E40 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).