1. Introduction

In recent years, the mainstream media has brought attention to the global environmental crisis resulting from human activities. As a response, the government has taken various measures, based on academic literature, to involve the general public in mitigating this crisis (Jinru et al., 2022a), (Shi et al., 2022), (Zeng et al., 2017), and (Yu, Khan, & Umar, 2022). The ramifications of this phenomenon provide a basis for stakeholders to make legitimate demands that industries take responsibility for any adverse effects due to their economic activities. Industries around the world respond to these demands by seeking models and methods to internalize environmental concerns in their strategic planning (Seroka-Stolka, 2014). Furthermore, literature related to sustainable development of organizations (SDO) emphasizes organizational performance-oriented towards environmental aspects to achieve competitive advantage by applying the concept of green human resource management (GHRM) (Bombiak & Marciniuk-Kluska, 2018).

On the other hand, the concept of sustainable development goals (SDGs) has determined the important role of green logistics (GL) and GHRM in implementing environmentally friendly performance (Rakhmangulov et al., 2017). From a micro perspective, these tools for environmentally friendly practices can directly influence the realization of SDO. GL significantly affects emissions and energy consumption (Liu et al., 2018), (Vienažindienė et al., 2021), hence, its role cannot be ignored in the reduction of the impacts and creation of environmentally friendly solutions. Furthermore, it raises environmental awareness by mandating the consequences of using the logistics system implemented in industries’ operational activities (Fortes, 2009). The main objective is the management of all operational activities to achieve a balance between economic, environmental, and social performance which is a dimension of the SDO concept known as the triple bottom line. A human factor is a tool that can stimulate the practice of increasing the effectiveness of an organizational environment. Meanwhile, environmentally oriented management should be exclusively carried out by individuals possessing the necessary competence in the field of ecology, coupled with a positive attitude towards the environment. These individuals must assume responsibility for the environmental implications of all their actions. GHRM in the development has played an important role, and several sources of literature emphasize the significant potential of HRM that contributes to the popularization of sustainable balance (Cohen et al., n.d.), (Ehnert, 2012), (Egri, 2002), (Ehnert et al., n.d.), (Jabbour, 2008), (Preuss, 2009), (Ahmad, 2015), (Arulrajah et al., 2015), (Davies & Crane, 2010), (Primorac et al., n.d.). Recent research found that GL and the implementation of GHRM mediated by sustainable production (SP) can influence the circular economy (CE) (Cheng et al., 2023) with the object of research being the garment industry in Bangladesh. The research of (Bombiak & Marciniuk-Kluska, 2018) regarding GHRM practices positively affected the performance of SDO in Poland with an emphasis on environmental aspects. In addition, GL is an original approach to achieving SDO based on the harmonization of economic aspects with the principles of sustainable development achieved through the systematization of logistical methods and instruments (Rakhmangulov et al., 2017). Research that raised the issue of implementing GL and GHRM to realize SDO was carried out, but the number of publications with good practices in implementing SDO was limited. Therefore, the relevance is still minimal for environmentally friendly manufacturing industries. This reality stimulated the conduction of research on the issue of GL and GHRM on SDO accompanied by intermediary variables. The addition of these intermediary variables completes the gaps in previous research, as well as explores other factors that can accelerate the realization of SDO. Furthermore, SP was considered a mediator variable in bridging the influence of GL and GHRM on SDO.

In 2022, a total of 44 manufacturing industries that apply the green industry concept have succeeded in following up on the low carbon development (LCD) policy for the government to maintain economic and social growth through development activities with low greenhouse gas (GHG) emissions and minimize the exploitation of natural resources. The impact is determined by the validated GHG program results for the reporting year 2021. These results showed energy and water savings amounting to IDR 3.2 trillion and IDR 169 billion, respectively. Additionally, emissions were reduced by up to 2.73 million tons of CO2e, equivalent to 99.3% of the NDC target for the industrial sector in 2020 at 2.75 million tonnes of CO2e (RI Ministry of Industry, 2022). This was only achieved by 28.95% of green manufacturing industries and the achievements had a relatively small impact on sustainable and environmentally friendly business practices. Therefore, environmentally friendly manufacturing industries should be improved to understand GL and GHRM practices in realizing SDO through SP.

2. Theoretical Basis and Research Hypothesis

2.1. Green Logistics (GL)

The concept of GL covers all functional areas of logistics in production activities, and operations, up to product disposal. Therefore, logistics becomes a tool for managing the problems of an organization in ensuring a balance between economic and environmental aspects (S. M. Kurbatova et al., 2020).

GL is the integration of all activities involving product movement in the supply chain. The process starts from the raw materials for certain products to the production and distribution systems to the end consumers, while linking reverse logistics. These activities have the main objective of achieving a balance of economic, environmental, and social sustainability through a structured sequence of activities to meet customer needs with cost efficiency GREEN LOGISTICS ORG, U. K. (2010). GL practices are related to the concept of sustainability, awareness that is not only oriented towards economic problems but also environmental and social issues impacting the wider community, such as the emergence of pollution, accumulation of waste, and relationships with consumers (Regina Da et al., n.d.).

Other GL concepts have also been stated as part of reducing the environmental impact caused by organizations. This is due to an increase in environmental pollution through product transportation and logistics activities. Therefore, organizations, transportation providers, and the government have taken the initiative to reduce pollution through GL practices (Fahimnia B. B., 2015).

The adoption of the GL approach is attributed to multiple factors, such as heightened public awareness, the implementation of increasingly stringent international standards, and proactive government policies aimed at promoting energy conservation, reducing carbon emissions, and minimizing operational expenses. Furthermore, the use of alternative energy sources, either partially or entirely replacing fossil fuels, also contributes to this trend. Opting for environmentally friendly transportation modes and providing adequate education and training to ensure organizational sustainability essentially constitute GL practices (McKinnon, 2010).

2.2. Green Human Resource Management

GHRM focuses on environmental and future aspects of work processes and functions to obtain positive results in the form of increased performance, innovation, motivation, and satisfaction among employees (Ahmad, 2015), (Mousa & Othman, 2020) The practices, policies, and characteristics are aligned with the concept of sustainability including social justice, health and welfare, behavior, and organizational performance (Amrutha & Geetha, 2020).

GHRM has also been shown to have a positive impact on employee behavior, specifically in terms of environmental, financial, social, and innovation performance (Singh et al., 2020), (Kim et al., 2019), (Pham, Thanh, Tuckova, & and Thuy, 2020), (O'Donohue & Torugsa, 2016). It allows employees to develop their knowledge and competence regarding environmentally friendly behavior, to increase the emergence of innovative ideas that contribute to employee performance by referring to research literature, application of principles in the HRM department in the form of policies, and implementation of environmentally caring practices (Shah, 2019), (Chreif & Farmanesh, 2022), (Huang, 2016). GHRM is a strategic topic that combines environmental and human resource management objectives. The scope includes a set of policies and practices aimed at protecting the workforce in the organization to maintain and develop intellectual capital through the implementation of HRM with effective and efficient methods (Mahmood, 2022), (Tang et al., 2018), (Renwick et al., 2013a). The definition is also interpreted as the implementation of human resource policies to increase the use of sustainable resources and at the same time promote a protective environment within the organization. Meanwhile, green employees’ management practices are also recommended in the GHRM concept. This is because organizations are also required to implement a green culture in all strategies while relying on all employee values, trends, and behaviors (Khan & Muktar, 2020).

2.3. Sustainable Production

The concept of SP originated in the 1990s, as noted by (Sezen & Çankaya, 2013). However, in recent decades, the concept has gained significant traction and become a prominent topic of discussion. The definition of SP provided by the US Department of Commerce pertains to activities aimed at producing goods while minimizing adverse environmental impacts, conserving energy and natural resources, and ensuring healthy economic performance for the benefit of consumers and the wider community (Tate et al., 2012).

SP is the most effective strategy in supply chain management, enabling producers to increase operational efficiency, community welfare, and environmental sustainability, while reaping economic benefits sustainably (Maruthi, et al., 2015; Roy, 2016). SP also refers to the production of goods whose processes are environmentally friendly to limit negative ecological impacts, in addition to considering worker safety, and welfare, as well as paying attention to social and environmental factors. The varied SP strategies include businesses based on the nature of operations adopted. The operations determine the long-term survival of industries by knowing the flow of materials and energy in the production system which opens insights into costs, system effectiveness, and the consequences for the environment (Yadav, et al., 2020), (Soundarrajan & Vivek, 2016), (Turner et al., 2019), and (Jinru et al., 2022b)

Green operating resources and GL initiatives are important factors for implementing SP (Bressanelli, et al., 2018). In addition, production activities that focus on saving energy and reducing emissions can result in increased SP performance (Zhang, et al., 2020). The practice is a form of effective and efficient use of natural resources in the production process, and this is a guarantee of fulfilling economic, social, and environmental aspects. These results in a sustainable concept that can protect the environment and improve the quality of life (Garetti and Taisch, 2012).

2.4. Sustainable Development

The concept of sustainable development has evolved but remains a subject of controversy. Some argue that certain approaches are too narrow when considering environmental protection, while others hold negative perspectives on the microeconomic level within organizations (Borys, 2015). The concept of sustainable development is based on the Triple Bottom Line (Dyllick & Hockerts, n.d.), (Elkington, 1997). As for sustainable development, there are three basic dimensions including (Graap, 2001):

- 1)

Ecological (protection of the environment and its natural resources),

- 2)

Economy (unhindered economic development, but driven by technological advances and increased effectiveness in the use of resources, materials, and labor),

- 3)

Social (improvement of living conditions and safety of all people).

Sustainable development can answer global challenges related to human activities in developing and developed countries. These practices and concepts can contribute to civilization-building focused on reducing and preventing the adverse effects of economic development. In addition, the concept is a form of modernization of economic development that emphasizes new management method approaches in organizations that are capable of producing various economic entities as well as replacement of environmentally friendly technologies (Poskrobko, 1997).

The World Commission on Environment and Development believes that sustainable development can meet the needs of the present generation without compromising the capabilities of future generations. In addition, sustainability development is considered smart, environmentally friendly, and in the use of resources carried out effectively using knowledge and producing innovation (Kromer, 2014).

2.5. Hypothesized Model

2.5.1. Green Logistics and Sustainable Development Practice

Scientists (Abdul Rehman Khan, 2019), (Ibrahim et al., 2018), (Evangelista et al., 2018) suggested that sustainable development can be realized by actively implementing GL practices in business processes, transportation, storage, and packaging. Research regarding these practices were also conducted in Germany, Italy, England, Sweden, Slovakia, China, Morocco, and Thailand (Centobelli, et al., 2020), (Pålsson & Kovács, 2014), (Richnák & Gubová, 2021), (Zhang et al., 2014), (Baz and Laguir, 2017) and (Sureeyatanapas, et al., 2018). The results showed a variety of GL practices, with notable differences observed across different countries. These variations can be attributed to various factors, such as the specifics of the cases studied, the duration of industries’ operations, logistics service processes, and cultural differences. However, the main thread was that GL practice had focus on the manufacturing sector and relatively little attention was paid to transportation and logistics services. There were still a lot of variabilities related to the implementation of green practices by manufacturing industries and the factors that encourage their application.

GL plays an important role in achieving SDO in industries, and in discussion forums (Centobelli, et al., 2017), (Karaman, et al., 2020), (Seroka-Stolka & Ociepa-Kubicka, 2019), (Evangelista et al., 2018), (Richnák & Gubová, 2021), (Rakhmangulov et al., 2018), (Kumar, n.d.), (Jum’a et al., 2021), (Baah, et al., 2019), the concept had a foundation of three main aspects interrelated and complementary, including economic, environmental, and environmental, and social aspects. Therefore, the following hypothesis is proposed:

Hypothesis 1 (H1): GL has a positive effect on the SDO.

2.5.2. Green Human Resource Management and Sustainable Development

GHRM practice is focused on making contributions in economic, social, and environmental aspects, which are further related to sustainability known as the tree bottom line (Xu et al., 2022), (Colbert, 2007). There are two main components in GHRM, including environmentally friendly HRM practices and the preservation of knowledge assets. Therefore, it is imperative to construct an organizational culture that is conscientious, proactive, optimistic, and enduring, and instilled in all personnel to enhance their awareness, competence, and pro-environmental behavior (Mukherji & Bhatnagar, 2022) GHRM has a contribution to reducing the energy consumption of natural resources, streamlining transportation, building a sustainable work environment, and reducing carbon emissions (Opatha and Arulrajah, 2014), (Mehta & Chugan, 2015), (Jabbour & De Sousa Jabbour, 2016) and (Milliman, 2013). In addition, it also contributes to the development, welfare, health, and satisfaction of employees through increased creativity and capacity to change, attract and retain competent employees to create a sustainable organization (Ari et al., 2020), (Shipton et al., 2012), and (Renwick, et al., 2016). Therefore, the following hypothesis is proposed:

Hypothesis 2 (H2): GHRM has a positive effect on the SDO.

2.5.3. Green Logistics and Sustainable Production

The first proposal for the concept of sustainable manufacturing emerged as a result of research conducted in 1987 (Repeto, 1987). The results described an action taken to maintain the efficiency of natural resource assets using a sustainable strategy. Furthermore, suggestions were provided for improving the relation to policies that can promote resource conservation, minimize environmental degradation, boost the economy, and alleviate poverty in underdeveloped areas. SP is known as an effective strategy in supply chain management (Ghosh, 2017) The practice of manufacturers developing hazardous compounds to fulfill consumer demand results in industries being obliged to reduce and even eradicate pollution (Roy and Khastagir, 2016). Implementation of SP practices is considered to enable producers to increase operational efficiency, prosper the community, preserve the environment, and increase economic profits (Karaman, et al., 2020).

Based on some of the findings, GL is an important component in SP of manufacturing industries. The practice has included various green initiatives aimed at reducing global ecological consequences as well as promoting pollution prevention activities (Bressanelli et al., 2018). Therefore, the following hypothesis is proposed:

Hypothesis 3 (H3): GL has a positive effect on SDO.

2.5.4. Green Human Resource Management and Sustainable Production

GHRM practices can function as an organizational tool in integrating humans into aspects of environmental sustainability through a series of activities based on human resources and are comprehensive across various lines of the organization (Martínez-del-Río, et al., 2012) and (Renwick et al., 2013b). According to reliable sources, it is widely recognized that supporting the environmental management system through recruitment and selection, training, performance appraisal, and employee rewards is of utmost importance. GHRM practices are also relevant by supporting environmental management systems and the development of products and innovations with lower impacts (Govindarajulu and Daily, 2004). Currently, industries cannot ignore environmental aspects, and this has resulted in major manufacturing industries around the world adopting GHRM which is meant for corporate preference. Therefore, large industries can practice SP by producing environmentally friendly products (Masri, et al., 2017). Based on this, the hypothesis is formulated as follows:

Hypothesis 4 (H4): GHRM has a positive effect on SDO.

2.5.5. Sustainable Production and Sustainable Development

The required parameter is the production of goods using environmentally friendly processes intended to minimize negative ecological impacts (Bag and Pretorius, 2022). Several initiatives on SP practices have been implemented to reduce the impact of production on the environment. This goal is a major effort in reducing unwanted waste, excessive energy consumption, ineffective use of materials, and resource recovery (Pajunen, et al., 2012). These are all processes of integrating the systems of industries with the ability to create quality products through more efficient and environmentally friendly utilization of resources. Furthermore, sustainable production can align economic, environmental, and social impacts in all production processes to realize sustainable development (Machado et al., 2020). Therefore, the following hypothesis is proposed:

Hypothesis 5 (H5): SP has a positive effect on SDO.

2.5.6. The Role of Mediation in Sustainable Production

SDO model is complex and inseparable which balances the three components of sustainable development, namely economic, social, and environmental aspects (Rakhmangulov et al., 2017). Many countries around the world, both adopting emerging market economies and those that are advanced in the economic and social fields, are currently striving to realize sustainable development. This is due to the need to create economic growth that can improve the quality of life without having to result in environmental destruction and exploitation of natural resources (S. Kurbatova et al., 2020).

The available literature identified several factors driving the realization of SDO, such as GL and GHRM. However, research assumed that the effect of the green factor on SDO was not direct. The realization of SDO through GL and the implementation of GHRM still feels the need to incorporate sustainability initiatives to complement sustainable development. These variables can minimize the consequences of negative ecological impacts (Lopes de Sousa Jabbour et al., 2019) and the relevance of the research is in line with (Cheng et al., 2023) and (Rakhmangulov et al., 2017), resulting in the effect of GL on SDO. Meanwhile, when facing challenges in the external environment, the industry can take advantage of GHRM practices as an important factor in the development of human resources (Zaid et al., 2018) and (Khan & Muktar, 2020).

Several research showed the results of integrating GHRM into SP as a business process. (Khan & Muktar, 2020) argued that GHRM recommends green employees’ management practices because this is part of a sustainable business management strategy. Therefore, industries must develop a green culture internalized in aspects of the production process as well as the values of employees and behavior. (Jinru et al., 2022a) and Cheng, et al. (2023) found that SP is an important intermediary variable in corporate green practices such as GL and GHRM, affecting SDO. Therefore, the following hypotheses were formulated:

Hypothesis 6 (H6): GL has a positive effect on SDO through SP.

Hypothesis 7 (H7): GHRM has a positive effect on SDO through SPuction.

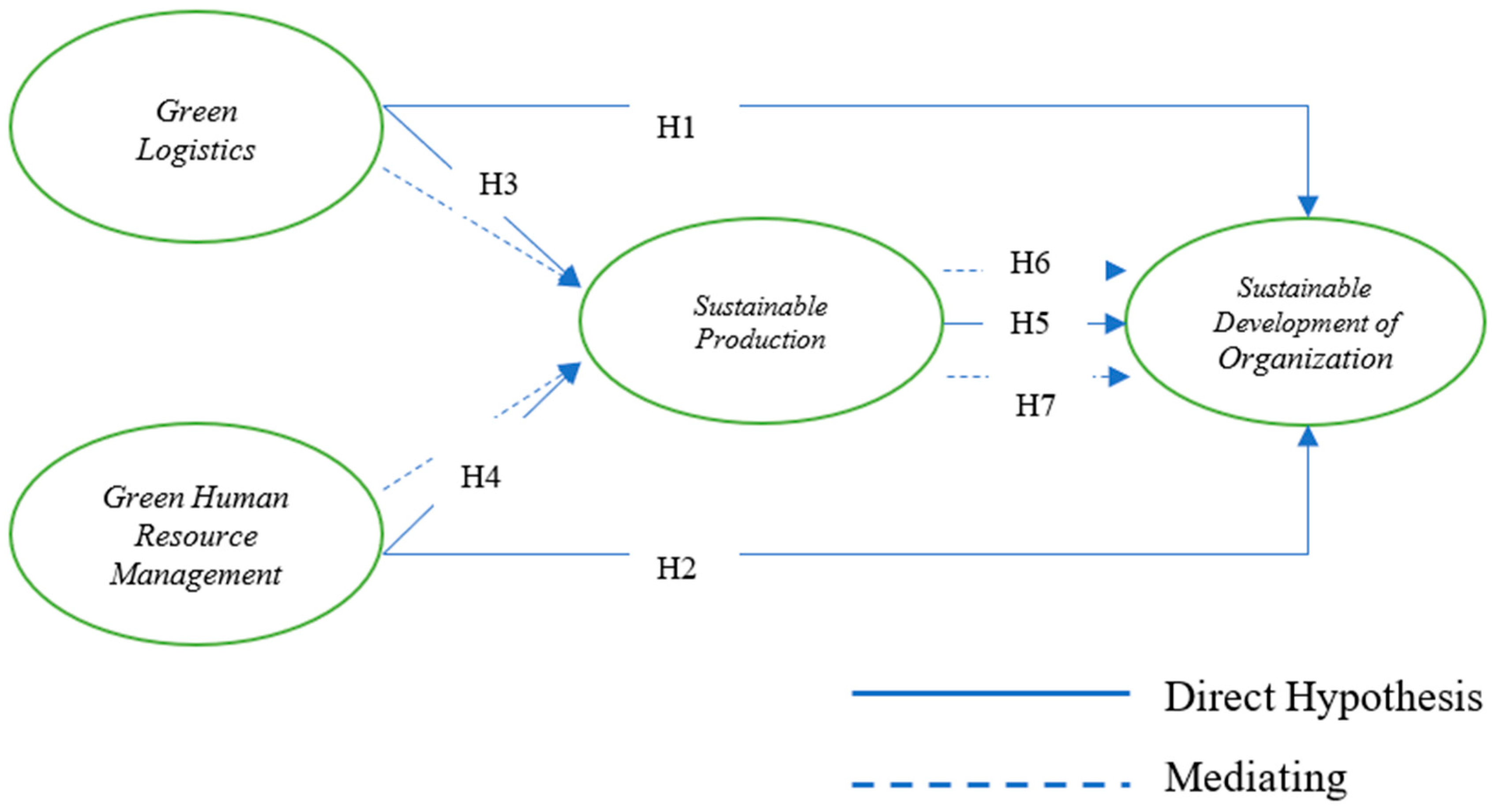

The model framework is shown in

Figure 1 below:

3. Research Methods

3.1. Samples

The population is industries engaged in green-based manufacturing businesses with a total of 152. These industries have been recorded in the database of the Ministry of Industry with the concept of GL, GHRM, SP, and SDO practices. The research distributed questionnaires to 152 industries, accompanied by a letter of introduction. The letter underscored the voluntary nature of the questionnaire and emphasized that respondents were under no obligation to participate. A total of 110 industries, which accounts for 72.36% of the total population, completed the questionnaire data in its entirety and were deemed suitable for research purposes, thereby serving as the research sample. Furthermore, the data were collected between December 2022 and February 2023.

3.2. Profile of Respondents

The most recent data collected and received, which will serve as a research sample, originates from a group of 110 general managers of green-based manufacturing industries in Indonesia, and the profiles of these respondents are presented in

Table 1.

3.3. Measurement

All items in each construct were measured with five Likert scales starting from 1=strongly disagree, 2=disagree, 3=undecided, 4=agree, and 5 = strongly agree. About six indicators were obtained from several relevant literatures to assess GL (Rakhmangulov et al., 2017), (Baah, et al., 2019), (Cheng, et al., 2023) and GHRM (Renwick et al., 2013b) Jabbour, 2011, (Jabbour, 2011), (Bowen, 2009), (Pagell, 2009), (Srinivasan & Kurey, n.d.). Meanwhile, SP (Bag, 2014) (Unob et al., 2007), (Lee et al., 2007), (Zeng et al., 2017) and SDO were measured using four and eight indicators (Glonti et al., 2020) and Blagov, 2006). Each of these indicators was described in the form of variable operational definitions presented in

Table 2.

3.4. Method

Methods of data analysis and hypothesis testing were conducted using Partial Least Square Structural Equation Modeling (PLS-SEM). The measurement tool used SmartPLS version 4 to perform PLS-SEM analysis (Ringle et al., 2015).

4. Data Analysis

4.1. Measurement and Structural Model

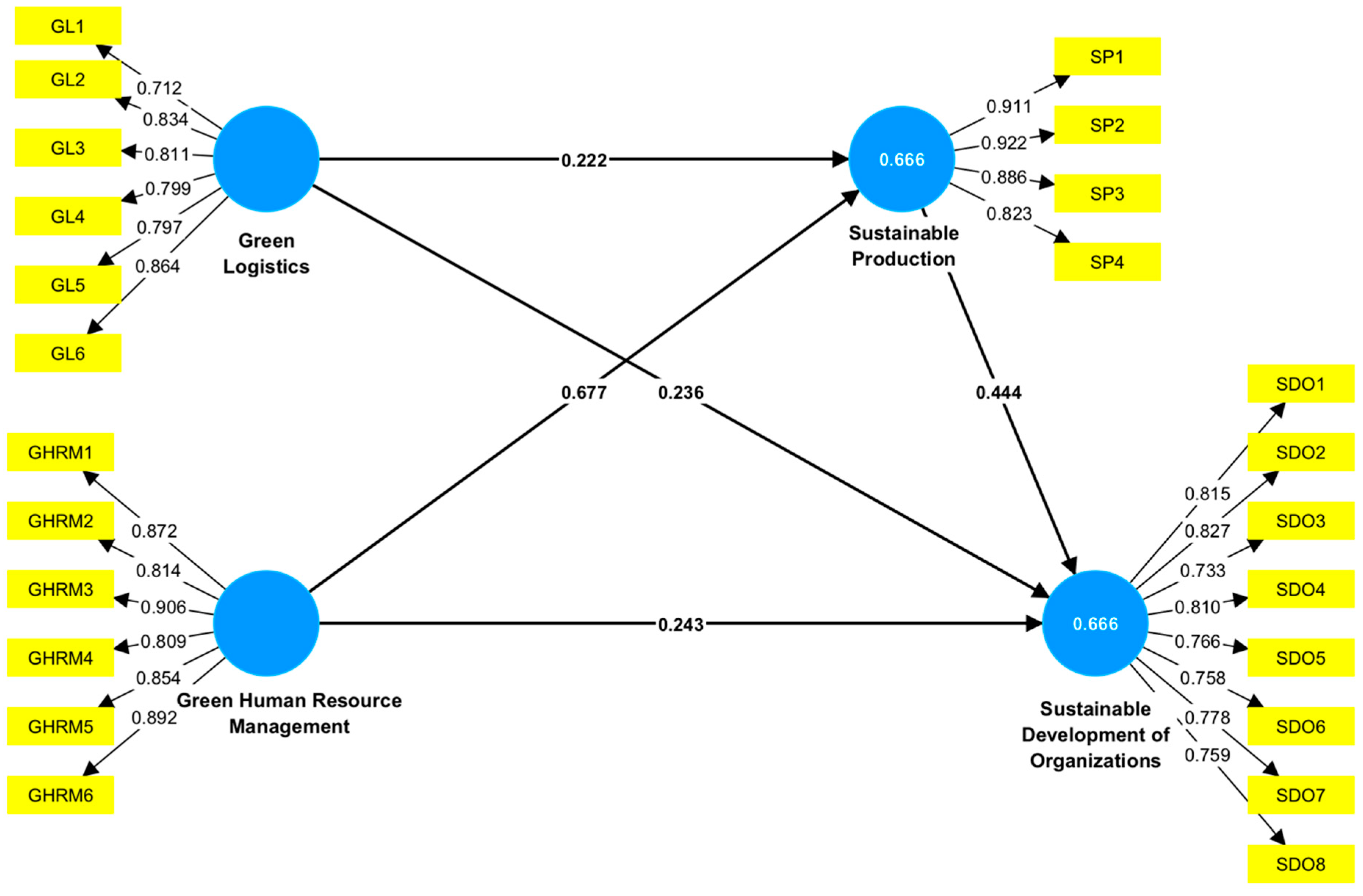

The outer model was a measurement result to evaluate the relationship between constructs and their indicators. Furthermore, there were two measurement methods, namely validity and reliability tests. The validity test assessment used the loading factor value, then the construct reliability is measured through Cronbach's Alpha (CA) and Composite Reliability (CR) values. A valid statement from an indicator was when the loading factor value was > 0.70, while the reliability was considered to meet the requirements for CR and CA values > 0.70 (Hair et al., 2014). The Average Variance Extracted (AVE) value can be stated to be satisfactory when the value was > 0.5 used to determine Convergent Validity (CV) (Palupi, 2021). Therefore, one latent variable can explain more than half of the indicators in the average value (Ghozali, 2016).

The validity and reliability measurements met the required criteria since the loading factor values were > 0.70 as well as the CA and CR values were > 0.70. Therefore, the research model can be stated to be valid and reliable. The AVE value also met the specified requirements of > 0.50 where the results showed values in the range of 0.610 to 0.785, as presented in

Table 3.

Determining the value of R2 has sequential requirements when a value of 0.25, 0.50, and 0.75 is declared weak, moderate, and strong (Henseler, et al., 2016). The results of data processing show that the R2 value for the direct and indirect effect is 0.666 as presented in Table 4. Therefore, this research model is included in the moderate category with direct and indirect effects of GL and GHRM on through SP of 66.6%.

Table 4.

R-square Value (R2).

Table 4.

R-square Value (R2).

| Construct |

R Square |

| Sustainable Production |

0.666 |

| Sustainable Development of Organizations |

0.666 |

The subsequent step entails calculating the Q2 value, which serves to determine the predictive relevance of the research model with the observational value. The relevance of the model is deemed satisfactory or commendable when Q2> 0 (Islam, et al., 2019). The following is the calculation of the Q2 value that meets the requirements, hence, the research model is declared relevant:

Calculation of the Goodness of Fit Index (GoF) value is conducted to find out the fitness level of the model with the requirement of a large GoF value = 0.36 (Ghozali and Latan, 2015). The results of calculating the GoF value amounted to 0.680, meaning the model has a large feasibility level.

4.2. Hypothesis Testing

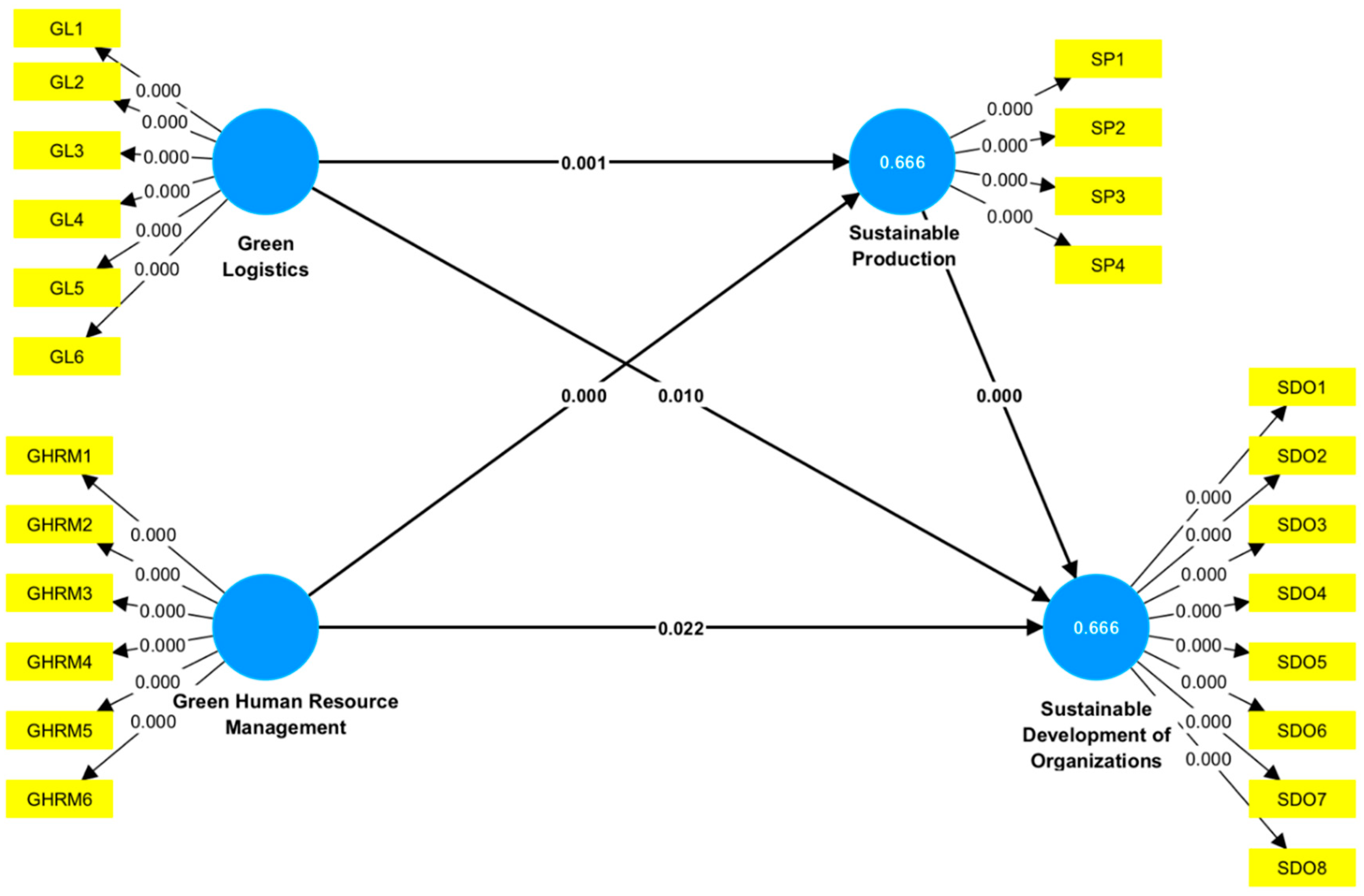

The stages of hypothesis testing were carried out to prove the effect of exogenous variables, namely GL and GHRM on SP and SDO through partial testing of direct and indirect effects where SP becomes the mediating variable, as shown in Table 4.

Table 4.

Hypothesis Test Results.

Table 4.

Hypothesis Test Results.

| Relations Between Constructs |

Original Sample (O) |

t Statistics (|O/STDEV|) |

P Values |

|

H1: GL -> SDO |

0.236 |

2.562 |

0.010 |

|

H2: GHRM -> SDO |

0.243 |

2.284 |

0.022 |

|

H3: GL -> SP |

0.222 |

3.224 |

0.001 |

|

H4: GHRM -> SP |

0.677 |

9.090 |

0.000 |

|

H5: SP -> SDO |

0.444 |

4.106 |

0.000 |

|

H6: GL -> SP -> SDO |

0.099 |

2.464 |

0.014 |

|

H7: GHRM -> SP -> SDO |

0.301 |

3.534 |

0.000 |

Based on Table 4, the results show that each of the seven hypotheses is statistically significant, while the research model for the inner model is shown in

Figure 3. The hypothesis test results are explained in detail as follows:

H1: GL has a positive effect on SDO, meaning H1 is declared true/confirmed. Therefore, H0 is rejected because the t statistic is 2,562 < from the t table = 1,982 with a P-Value <0.000.

H2: GHRM has a positive influence on SDO, meaning H2 is declared true/confirmed. Therefore, H0 is rejected because the t statistic is 2,284 <from the t table = 1,982 with P-Value <0.000.

H3: GL has a positive effect on SP, meaning H3 is also confirmed/correct. Therefore, H0 is rejected because the t statistic is 3,224 <from the t table = 1,982 with a P-Value <0.000.

H4: GHRM has a positive effect on SP, meaning H4 is declared true/confirmed. Therefore, H0 is rejected because the t statistic is 9,090 <from the t table = 1,982 with a P-Value <0.000.

H5: SP has a positive influence on SDO, meaning H5 is true/confirmed. Therefore, H0 is rejected because the t statistic is 4.106 < from the t table = 1.982 with a P-Value < 0.000.

H6: GL has a positive influence on SDO through SP mediation, meaning H6 is also stated to be true/confirmed. Therefore, H0 was rejected since the t statistic was 2,464 <from the t table = 1,982 with a P-Value <0.000.

H7: GHRM has a positive influence on SDO through SP mediation, meaning H7 is declared true/confirmed. Therefore, H0 was rejected since the t statistic was 3,534 <from t table=1,982 with a P-Value <0.000.

5. Discussion and Conclusion

Manufacturing industries are required to improve their performance as a form of commitment to achieving national sustainable development goals. Several industries are oriented towards environmentally friendly and sustainable methods to promote SDO practices (Seroka-Stolka, 2014). For example, various businesses have implemented GL methods, which are efforts to achieve SDO performance (Fortes, 2009). Human resource factors influence the achievement of industries’ SDO performance through GHRM concepts and practices to create an environmentally friendly culture (Bombiak & Marciniuk-Kluska, 2018). Therefore, GHRM practices function to improve SDO performance in environmentally friendly manufacturing industries. Based on the SDGs theory, a model was created that produced a concept by combining four constructions including GL, GHRM, SP, and SDO. The data processing and analysis using PLS-SEM suggested that there was a direct or mediated relationship between the four constructs. These findings can add important insights and knowledge related to relevant literature in the context of green manufacturing industries in developing countries.

First, the implementation of GL practices can affect the performance of SDO, and there are several research with similar findings relevant to these results (Rakhmangulov et al., 2017). The logistics activities implemented in industries can realize all the main aspects of SDO practice, namely economic, environmental, and social aspects (Centobelli, et al., 2017), (Karaman, et al., 2020), (Seroka-Stolka & Ociepa-Kubicka, 2019), (Evangelista et al., 2018), (Richnák & Gubová, 2021), (Rakhmangulov et al., 2018), (Kumar, 2015), (Jum’a et al., 2021), (Baah, et al., 2019). Logistics functional activities covering production and operations are the basis of GL. Therefore, logistics can become a tool for managing problems in organizations to achieve a balance between economic and environmental aspects (S. M. Kurbatova et al., 2020). These findings strengthen the contribution of GL elements in the SDGs theory which is one of the key factors for achieving sustainable development (Rakhmangulov et al., 2017).

Second, GHRM has a significant influence on SDO practices in industries. These findings are also supported by several research which produced a positive relationship between GHRM and SDO (Bombiak & Marciniuk-Kluska, 2018). The findings showed that conscious, proactive, positive, and sustainable internalization of organizational culture can increase competency awareness of employees and green behavior which can certainly promote the achievement of SDO (Mukherji & Bhatnagar, 2022). The SDGs theory also states that the concept of a tree bottom line is the main focus of GHRM practice which directly contributes to sustainable development (Xu, et al., 2021), (Colbert, 2007).

Third, GL also has an impact on SP in industries. The practices can improve the performance of environmentally friendly oriented products. These findings are also relevant to previous research that connected GL with SP (Cheng, et al., 2023).

Fourth, GHRM has a very important influence to create SP in industries. These findings reinforce previous research, where the demand to be aware of the importance of preserving the environment has resulted in large manufacturing industries. Therefore, SP practices can be applied and achieved through the production of innovative products (Masri, et al., 2017).

Fifth, SP has a significant effect on SDO, as supported by previous research (Bag and Pretorius, 2020), (Pajunen, et al., 2012), (Machado et al., 2020), (Bressanelli et al., 2018), (Zhang et al., 2014). The practice is a form of effective and efficient use of natural resources in the production process, which can guarantee the fulfillment of economic, social, and environmental aspects. Therefore, the SDO concept contributes to protecting the environment and improving the quality of life (Garetti and Taisch, 2012).

Finally, the indirect effect analysis showed that there is an influence of SP as a mediator between GL and SDO. There was an indirect influence mediated by SP between GHRM and SDO. Furthermore, SP can be achieved with GHRM practices (Khan & Muktar, 2020) and is a factor in achieving SDO (Jinru et al., 2022b), (Cheng, et al., 2023). In conclusion, industries oriented towards green practices, such as GL and GHRM have succeeded in supporting the performance of environmentally friendly manufacturing industries and SDO. The existence can add to the literature related to GSCM and GHRM. This was due to the lack of research on the indirect effect of GL and GHRM on SDO performance in manufacturing industries.

6. Theorical Implications

The results can contribute theoretically to the current GL, GHRM, SP, and SDO literature. First, the contribution is to add a little literature related to the relationship between green performance practices and their contribution to SDO in manufacturing industries. Concerning the SDGs concept, this research has significant implications for manufacturing industries that implement environmentally friendly practices to achieve consistent SDO performance in a competitive environment. Second, the results are supported by statistical evidence in supporting the statement that the implementation of GL and GHRM has a major influence on improving SP and SDO practices in industries. These results are also consistent and relevant to research findings in other countries. Therefore, SDGs concept can be applied without being limited by geographical conditions. Third, based on currently available knowledge, this research contributes to establishing a direct link between SP and SDO. The process of SP activities which is increasingly optimal can significantly improve SDO performance in green manufacturing industries. These results have important implications in developing countries because the majority of similar research concepts and models are carried out in developed nations.

Fourth, this research contributes to the literature by adding the effect of SP mediation on the relationship of GL and GHRM to SDO. The majority of the existing literature focuses on the direct influence between GL and SP, GHRM, and SP as an increase in SDO performance of industries (Karaman, et al., 2020; Amrutha and Geetha, 2019). Furthermore, the existence of SP as a mediator positively influences the relationship of GL and GHRM to SDO. This means that the activities of industries can increase the application of technology, information systems, and employees’ competency in implementing green performance to increase corporate value and prioritize social and environmental aspects. There was no previous research that discussed the important role of SP mediation in influencing the relationship between GL and GHRM on SDO.

7. Pactical Implications

The implications for the practical world can cover corporate managers, governments, and legislators. Competitiveness can be increased to achieve SDO performance by combining many initiatives such as GL and GHRM practices to remain consistent in achieving sustainable development. In addition, this research develops a model for the implementation of GL and GHRM in supply chain management to raise employee awareness of environmental care. The ultimate objective is to significantly contribute to achieving Sustainable SDO that are holistic, encompassing economic, social, and environmental aspects. These results can be used by the government to accelerate the implementation of green industry criteria standards with a broad impact on the environment through a low carbon development (LCD) policy to maintain economic and social growth through development activities with low GHG emissions and minimize the exploitation of natural resources.

Author Contributions

Conceptualization, A.S.; data curation, S.P.; formal analysis, A.S. and Y.K.A.; investigation, Y.K.A; methodology, S.A.; project administration, S.P.; resources, S.A.; software, Y.K.A.; supervision, Y.K.A. and S.A.; validation, S.P. and S.A.; visualization, S.A.; writing—original draft, A.S. and Y.K.A.; writing—review & editing, A.S., S.P., S.A., and S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Many thanks to all the contributions and support given by the authors in preparing the writing of this article. The authors also acknowledge the contribution of the participants who answered the survey.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abdul Rehman Khan, S. (2019). The Effect of Green logistics on Economic growth, Social and Environmental sustainability: An Empirical study of Developing countries in Asia. [CrossRef]

- Ahmad, S. (2015). Green Human Resource Management: Policies and practices. In Cogent Business and Management (Vol. 2, Issue 1). Cogent OA. [CrossRef]

- Amrutha, V. N., & Geetha, S. N. (2020). A systematic review on green human resource management: Implications for social sustainability. In Journal of Cleaner Production (Vol. 247). Elsevier Ltd. [CrossRef]

- Ari, E., Karatepe, O. M., Rezapouraghdam, H., & Avci, T. (2020). A conceptual model for green human resource management: Indicators, differential pathways, and multiple pro-environmental outcomes. Sustainability (Switzerland), 12(17). [CrossRef]

- Baah, C., Jin, Z., & Tang, L. (2020). Organizational and regulatory stakeholder pressures friends or foes to green logistics practices and financial performance: investigating corporate reputation as a missing link. Journal of cleaner production, 247, 119125.

- Bag, S., & Pretorius, J. H. C. (2022). Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. International Journal of Organizational Analysis, 30(4), 864-898.

- Baz, J., & Laguir, I. (2017). Third-party logistics providers (TPLs) and environmental sustainability practices in developing countries: the case of Morocco. International Journal of Operations & Production Management.

- Blagov, Y.E., Corporate social responsibility. The concept of CSR includes. (2009). Bulletin Of St. Petersburg University. Classics Of Management Theory. Ser. 8. Issue 3 Diakses pada 5 April 2023 dari. https://td-osz.ru/en/istorii-uspeha/korporativnaya-soc-otvetstvennost-ponyatie-kso-vklyuchaet/.

- Bombiak, E., & Marciniuk-Kluska, A. (2018). Green human resource management as a tool for the sustainable development of enterprises: Polish young company experience. Sustainability (Switzerland), 10(6). [CrossRef]

- Borys, T. (2015). Zrównoważony rozwój organizacji – co chcemy lub powinniśmy równoważyć? Prace Naukowe Uniwersytetu Ekonomicznego We Wrocławiu, 376. [CrossRef]

- Bowen, F. E., Cousins, P. D., Lamming, R. C., & Faruk, A. C. (2001). The role of supply management capabilities in green supply. Production and Operations Management, 10(2), 174–189.

- Bressanelli, G., Adrodegari, F., Perona, M., & Saccani, N. (2018). Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability (Switzerland), 10(3). [CrossRef]

- Centobelli, P., Cerchione, R., & Esposito, E. (2017). Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transportation Research Part D: Transport and Environment, 53, 454-470.

- Centobelli, P., Cerchione, R., & Esposito, E. (2020). Pursuing supply chain sustainable development goals through the adoption of green practices and enabling technologies: A cross-country analysis of LSPs. Technological Forecasting and Social Change, 153, 119920.

- Cheng, Y., Masukujjaman, M., Sobhani, F. A., Hamayun, M., & Alam, S. S. (2023). Green Logistics, Green Human Capital, and Circular Economy: The Mediating Role of Sustainable Production. Sustainability, 15(2), 1045. [CrossRef]

- Chreif, M., & Farmanesh, P. (2022). Applying Green Human Resource Practices toward Sustainable Workplace: A Moderated Mediation Analysis. Sustainability (Switzerland), 14(15). [CrossRef]

- Cohen, E., Taylor, S., & Muller-Camen, M. (n.d.). Use and Management of Downsizing HR’s Role in Corporate Social Responsibility and Sustainability Produced in partnership with the World Federation of People Management Associations (WFPMA) and the North American Human Resource Management Association (NAHRMA).

- Colbert, B. A., & Kurucz, E. C. (2007). Three conceptions of triple bottom line business sustainability and the role for HRM. People and Strategy, 30(1), 21.

- Dyllick, T., & Hockerts, K. (n.d.). Beyond the business case for corporate sustainability.

- Egri, C. P., & Hornal, R. C. (2002). Strategic environmental human resource management and perceived organizational performance: An exploratory study of the Canadian manufacturing sector. Research in corporate sustainability: The evolving theory and practice of organizations in the natural environment, 205236.

- Ehnert, I., Harry, W., & Zink Editors, K. J. (n.d.). Sustainability and Human Resource Management Developing Sustainable Business Organizations. http://www.springer.com/series/11565.

- Ehnert, I., & Harry, W. (2012). Recent Developments and Future Prospects on Sustainable Human Resource Management: Introduction to the Special Issue. Management Revue, 23(3), 221-238. [CrossRef]

- Elkington, J. (1997). Cannibals with forks: the triple bottom line of twenty-first century business. Capstone.

- Evangelista, P., Santoro, L., & Thomas, A. (2018). Environmental sustainability in third-party logistics service providers: A systematic literature review from 2000-2016. In Sustainability (Switzerland) (Vol. 10, Issue 5). MDPI. [CrossRef]

- Fahimnia, B., Bell, M. G., Hensher, D. A., & Sarkis, J. (2015). The role of green logistics and transportation in sustainable supply chains. Green Logistics and Transportation: A Sustainable Supply Chain Perspective, 1-12.

- Fortes, J. (2009). Green supply chain management: A literature. Otago Management Graduate Review, 7(1), 51-62.

- Garetti, M., & Taisch, M. (2012). Sustainable manufacturing: trends and research challenges. Production planning & control, 23(2-3), 83-104.

- Govindarajulu, N., & Daily, B. F. (2004). Motivating employees for environmental improvement. Industrial management & data systems, 104(4), 364-372.

- Grapp, T. Nachhaltigkeit und Kooperation; Verlag Peter Lang: Frankfurt/M., Germany; Berlin, Germany; Bern, Switzerland; Bruxelles, Belgium; New York, NY, USA; Oxford, UK; Wien, Austria, 2001; ISBN 978-3-631-37379-8.

- Ghozali, I. (2016). Aplikasi analisis multivariete dengan program IBM SPSS 23.

- Ghosh, S. K. (2017). GREEN SUPPLY CHAIN MANAGEMENT IN PRODUCTION SECTORS AND ITS IMPACT ON FIRM REPUTATION. Number, 53–63. http://www.newtheory.org.

- Glonti, V., Trynchuk, V., Khovrak, I., Mokhonko, G., Shkrobot, M., & Manvelidze, L. (2020). Research podgorica socialization of organization sustainable development based on the principles of corporate social responsibility. Montenegrin Journal of Economics, 16(1), 169–182. [CrossRef]

- Hair, J. F., Sarstedt, M., Hopkins, L., & Kuppelwieser, V. G. (2014). Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. In European Business Review (Vol. 26, Issue 2, pp. 106–121). Emerald Group Publishing Ltd. [CrossRef]

- Huang, X. X., Hu, Z. P., Liu, C. S., Yu, D. J., & Yu, L. F. (2016). The relationships between regulatory and customer pressure, green organizational responses, and green innovation performance. Journal of Cleaner Production, 112, 3423-3433.

- Ibrahim, I., Pandiyan, V., Sundram, K., Normalina Omar, E., Yusoff, N., & Amer, A. (2018). The Determinant Factors of Green Practices Adoption For Logistics Companies in Malaysia. A Case Study of PKT Logistics Group Sdn. Bhd. Islamic Research Journal of Emerging Economies & Islamic Research, 7(1), 14–23. www.jeeir.comwww.jeeir.com.

- Jabbour, C. J. C., & Santos, F. C. A. (2008). The central role of human resource management in the search for sustainable organizations. The International Journal of Human Resource Management, 19(12), 2133-2154.

- Jabbour, C. J. C., & De Sousa Jabbour, A. B. L. (2016). Green Human Resource Management and Green Supply Chain Management: Linking two emerging agendas. Journal of Cleaner Production, 112, 1824–1833. [CrossRef]

- Jinru, L., Changbiao, Z., Ahmad, B., Irfan, M., & Nazir, R. (2022a). How do green financing and green logistics affect the circular economy in the pandemic situation: key mediating role of sustainable production. Economic Research-Ekonomska Istrazivanja , 35(1), 3836–3856. [CrossRef]

- Jinru, L., Changbiao, Z., Ahmad, B., Irfan, M., & Nazir, R. (2022b). How do green financing and green logistics affect the circular economy in the pandemic situation: key mediating role of sustainable production. Economic Research-Ekonomska Istrazivanja , 35(1), 3836–3856. [CrossRef]

- Jum’a, L., Zimon, D., & Ikram, M. (2021). A relationship between supply chain practices, environmental sustainability and financial performance: evidence from manufacturing companies in jordan. Sustainability (Switzerland), 13(4), 1–22. [CrossRef]

- Karaman, A. S., Kilic, M., & Uyar, A. (2020). Green logistics performance and sustainability reporting practices of the logistics sector: The moderating effect of corporate governance. Journal of Cleaner Production, 258, 120718.

- Khan, M. H., & Muktar, S. N. (2020). A bibliometric analysis of green human resource management based on scopus platform. Cogent Business and Management, 7(1). [CrossRef]

- Kim, Y. J., Kim, W. G., Choi, H. M., & Phetvaroon, K. (2019). The effect of green human resource management on hotel employees’ eco-friendly behavior and environmental performance. International Journal of Hospitality Management, 76, 83–93. [CrossRef]

- Kromer, B. Społecznaodpowiedzialnos ́c ́biznesujakoczynnikkonkurencyjnos ́ciprzedsie ̨ biorstw. Studia Ekonomiczne 2014, 180, 131–140. (In Polish).

- Kumar, A. (n.d.). Green Logistics for sustainable development: an analytical review. www.iosrd.orghttp://iosrd.org/journals.

- Kurbatova, S., Aisner, L., Rusakov, A., & Naumkina, V. (2020). Ecological postulates of the national environmental policy (on the example of the Russian Federation). E3S Web of Conferences, 157. [CrossRef]

- Kurbatova, S. M., Aisner, L. Y., & Mazurov, V. Y. (2020). Green logistics as an element of sustainable development. IOP Conference Series: Earth and Environmental Science, 548(5). [CrossRef]

- Lee, J. C., Song, H. T., & Yoo, J. M. (2007). Present status of the recycling of waste electrical and electronic equipment in Korea. Resources, Conservation and Recycling, 50(4), 380-397.

- Liu, J., Feng, Y., Zhu, Q., & Sarkis, J. (2018). Green supply chain management and the circular economy: Reviewing theory for advancement of both fields. In International Journal of Physical Distribution and Logistics Management (Vol. 48, Issue 8, pp. 794–817). Emerald Group Holdings Ltd. [CrossRef]

- Lopes de Sousa Jabbour, A. B., Rojas Luiz, J. V., Rojas Luiz, O., Jabbour, C. J. C., Ndubisi, N. O., Caldeira de Oliveira, J. H., & Junior, F. H. (2019). Circular economy business models and operations management. Journal of Cleaner Production, 235, 1525-1539. [CrossRef]

- Machado, C. G., Winroth, M. P., & Ribeiro da Silva, E. H. D. (2020). Sustainable manufacturing in Industry 4.0: an emerging research agenda. International Journal of Production Research, 58(5), 1462–1484. [CrossRef]

- Mahmood, Q. U. A., Ahmed, R., & Philbin, S. P. (2022). The moderating effect of big data analytics on green human resource management and organizational performance. International Journal of Management Science and Engineering Management, 1-13.

- Maruthi, G. D., & Rashmi, R. (2015). Green Manufacturing: It's Tools and Techniques that can be implemented in Manufacturing Sectors. Materials Today: Proceedings, 2(4-5), 3350-3355.

- Masri, H. A., & Jaaron, A. A. (2017). Assessing green human resources management practices in Palestinian manufacturing context: An empirical study. Journal of cleaner production, 143, 474-489.

- Milliman, J. (2013). Leading-edge green human resource practices: vital components to advancing environmental sustainability. Environmental Quality Management, 23(2), 31-45.

- McKinnon, A. C. (2010). Green logistics : improving the environmental sustainability of logistics. Kogan Page.

- Mehta, K., & Chugan, P. K. (2015). Green HRM in Pursuit of Environmentally Sustainable Business. Universal Journal of Industrial and Business Management, 3(3), 74–81. [CrossRef]

- Mousa, S. K., & Othman, M. (2020). The impact of green human resource management practices on sustainable performance in healthcare organisations: A conceptual framework. Journal of Cleaner Production, 243. [CrossRef]

- Mukherji, A., & Bhatnagar, J. (2022). Conceptualizing and theorizing green human resource management: a narrative review. International Journal of Manpower, 43(3), 862–888. [CrossRef]

- O'Donohue, W., & Torugsa, N. (2016). The moderating effect of ‘Green’HRM on the association between proactive environmental management and financial performance in small firms. The international journal of human resource management, 27(2), 239-261.

- Opatha, HHDNP, & Arulrajah, A. A. (2014). Green human resource management: Simplified general reflections. International Business Research, 7(8), 101-112.

- Pagell, M., & Wu, Z. (2009). Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. Journal of supply chain management, 45(2), 37-56.

- Pajunen, N., Watkins, G., Wierink, M., & Heiskanen, K. (2012). Drivers and barriers of effective industrial material use. Minerals Engineering, 29, 39-46.

- Pålsson, H., & Kovács, G. (2014). Reducing transportation emissions: A reaction to stakeholder pressure or a strategy to increase competitive advantage. International Journal of Physical Distribution and Logistics Management, 44(4), 283–304. [CrossRef]

- Pham, N. T., Thanh, T. V., Tučková, Z., & Thuy, V. T. N. (2020). The role of green human resource management in driving hotel’s environmental performance: Interaction and mediation analysis. International Journal of Hospitality Management, 88, 102392.

- Poskrobko, B. (1997). Teoretyczne aspekty ekorozwoju. Ekonomia i środowisko, (1 (10)), 7-20.

- Preuss, Lutz., Axel Haunschild & Dirk Matten (2009) The rise of CSR: implications for HRM and employee representation, The International Journal of Human Resource Management, 20:4, 953-973. [CrossRef]

- Rakhmangulov, A., Sladkowski, A., Osintsev, N., & Muravev, D. (2017). Zelena logistika: Element koncepta održivog razvoja. Dio 1. Nase More, 64(3), 120–126. [CrossRef]

- Rakhmangulov, A., Sladkowski, A., Osintsev, N., & Muravev, D. (2018). Zelena logistika: Sustav metoda i instrumenata – 2. dio. Nase More, 65(1), 49–55. [CrossRef]

- Regina Da, P., Zaluski, S., Souza, D., Meireles Rocha, G., Rodrigues, L., Merelles, O., & Machado, R. L. (n.d.). 72 DIFERENÇAS ENTRE LEAN MANUFACTURING E GREEN SUPPLY CHAIN-REVISÃO SISTEMÁTICA.

- Renwick, D. W. S., Redman, T., & Maguire, S. (2013a). Green Human Resource Management: A Review and Research Agenda*. International Journal of Management Reviews, 15(1), 1–14. [CrossRef]

- Renwick, D. W. S., Redman, T., & Maguire, S. (2013b). Green Human Resource Management: A Review and Research Agenda*. International Journal of Management Reviews, 15(1), 1–14. [CrossRef]

- Repetto, R. (1987). Economic incentives for sustainable production. The Annals of Regional Science, 21, 44-59.

- Richnák, P., & Gubová, K. (2021). Green and reverse logistics in conditions of sustainable development in enterprises in Slovakia. Sustainability (Switzerland), 13(2), 1–23. [CrossRef]

- Ringle, C. M., Wende, S., & Becker, J. M. (2015). SmartPLS 3.

- Roy, M., & Khastagir, D. (2016). Exploring role of green management in enhancing organizational efficiency in petro-chemical industry in India. Journal of Cleaner Production, 121, 109-115.

- Seroka-Stolka, O. (2014). The Development of Green Logistics for Implementation Sustainable Development Strategy in Companies. Procedia - Social and Behavioral Sciences, 151, 302–309. [CrossRef]

- Seroka-Stolka, O., & Ociepa-Kubicka, A. (2019). Green logistics and circular economy. Transportation Research Procedia, 39, 471–479. [CrossRef]

- Sezen, B., & Çankaya, S. Y. (2013). Effects of Green Manufacturing and Eco-innovation on Sustainability Performance. Procedia - Social and Behavioral Sciences, 99, 154–163. [CrossRef]

- Shah, M. (2019). Green human resource management: Development of a valid measurement scale. Business Strategy and the Environment, 28(5), 771-785.

- Shi, Y., Siddik, A. B., Masukujjaman, M., Zheng, G., Hamayun, M., & Ibrahim, A. M. (2022). The Antecedents of Willingness to Adopt and Pay for the IoT in the Agricultural Industry: An Application of the UTAUT 2 Theory. Sustainability (Switzerland), 14(11). [CrossRef]

- Shipton, H., Budhwar, P. S., & Crawshaw, J. (2012). HRM, Organizational Capacity for Change, and Performance: A Global Perspective. Thunderbird International Business Review, 54(6), 777–790. [CrossRef]

- Singh, S. K., Giudice, M. Del, Chierici, R., & Graziano, D. (2020). Green innovation and environmental performance: The role of green transformational leadership and green human resource management. Technological Forecasting and Social Change, 150. [CrossRef]

- Soundarrajan, P., & Vivek, N. (2016). Green finance for sustainable green economic growth in india. Agricultural Economics (Czech Republic), 62(1), 35–44. [CrossRef]

- Srinivasan, A., & Kurey, B. (n.d.). Creating a Culture of Quality.

- Sureeyatanapas, P., Poophiukhok, P., & Pathumnakul, S. (2018). Green initiatives for logistics service providers: An investigation of antecedent factors and the contributions to corporate goals. Journal of cleaner production, 191, 1-14.

- Tang, G., Chen, Y., Jiang, Y., Paillé, P., & Jia, J. (2018). Green human resource management practices: scale development and validity. Asia Pacific Journal of Human Resources, 56(1), 31–55. [CrossRef]

- Tate, W. L., Ellram, L. M., & Dooley, K. J. (2012). Environmental purchasing and supplier management (EPSM): Theory and practice. Journal of Purchasing and Supply Management, 18(3), 173–188. [CrossRef]

- Turner, C., Moreno, M., Mondini, L., Salonitis, K., Charnley, F., Tiwari, A., & Hutabarat, W. (2019). Sustainable production in a circular economy: A business model for re-distributed manufacturing. Sustainability (Switzerland), 11(16). [CrossRef]

- Unob, F., Wongsiri, B., Phaeon, N., Puanngam, M., & Shiowatana, J. (2007). Reuse of waste silica as adsorbent for metal removal by iron oxide modification. Journal of Hazardous Materials, 142(1–2), 455–462. [CrossRef]

- Vienažindienė, M., Tamulienė, V., & Zaleckienė, J. (2021). Green logistics practices seeking development of sustainability: Evidence from lithuanian transportation and logistics companies. Energies, 14(22). [CrossRef]

- Xu, B.; Gao, X.; Cai, W.; Jiang, L. How Environmental Leadership Boosts Employees’ Green Innovation Behavior? A Moderated Mediation Model. Front. Psychol. 2021, 12, 689671.

- Yadav, G., Luthra, S., Jakhar, S. K., Mangla, S. K., & Rai, D. P. (2020). A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. Journal of Cleaner Production, 254, 120112.

- Yu, Z.; Khan, S.A.R.; Umar, M. Circular Economy Practices, and Industry 4.0 Technologies: A Strategic Move of Automobile Industry. Bus. Strategy Environ. 2022, 31, 796–809.

- Zaid, A. A., Jaaron, A. A. M., & Talib Bon, A. (2018). The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study. Journal of Cleaner Production, 204, 965–979. [CrossRef]

- Zeng, H., Chen, X., Xiao, X., & Zhou, Z. (2017). Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. Journal of Cleaner Production, 155, 54–65. [CrossRef]

- Zhang, Y., Thompson, R. G., Bao, X., & Jiang, Y. (2014). Analyzing the Promoting Factors for Adopting Green Logistics Practices: A Case Study of Road Freight Industry in Nanjing, China. Procedia - Social and Behavioral Sciences, 125, 432–444. [CrossRef]

- Zhang, W., Zhang, M., Zhang, W., Zhou, Q., & Zhang, X. (2020). What influences the effectiveness of green logistics policies? A grounded theory analysis. Science of the Total Environment, 714, 136731.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).