1. Introduction

The air quality inside buildings where people spend much time is an essential determinant of healthy life and performance. Acceptable indoor air quality can be achieved by providing outdoor air ventilation to dilute internally generated contaminants to levels that are not harmful to human health and do not negatively impact occupant perceptions of the indoor environment. Various contaminants can be generated inside buildings depending on the building uses, materials, and conditions. Contaminants from the occupants (bio effluents) can deteriorate people’s health and well-being. Hazardous substances emitted from building materials or due to the operation of indoor appliances can lead to a broad range of health problems and may even be fatal. Furthermore, buildings need enough ventilation to avoid damaging condensation on surfaces or in the structure.

Excessive carbon dioxide (CO

2) in the air inside a room due to lack of ventilation may cause significant reductions in the decision-making performance of occupants, which may result in poor work performance [

1]. More importantly, the indoor CO

2 concentration is an approximate surrogate for indoor pollutants from occupants and buildings [

2]. Human generates pollutants such as carbon dioxide, airborne viruses, germs, and odor. Building materials and appliances can emit hazardous substances that may cause sick house syndrome (SHS) and multiple chemical sensitivity (MCS) with various allergic irritations and diseases [

3,

30]. Kim-Jakyung and Korean Ministry of Environment identified harmful substances emitted from building materials commonly used in Korea. Formaldehyde, volatile organic compounds (VOCs), toluene, and xylene styrene are emitted from finishing materials, insulation materials, and furniture. Radon and chromium are emitted from concrete and cement. Also, hazardous substances are emitted from human activities, such as poisonous gases from heating and cooking. In addition, dust, mold, germs, bacteria, and odors can occur in aged buildings. Besides, excessive water vapor from indoor activities should be exhausted to avoid condensation.

However, the deterioration of indoor air is indiscernible and tends to be overlooked. On the other hand, we are strongly obliged to reduce energy consumption and heat loss against the climate crisis. Building technologies and regulations related to building envelopes in South Korea have been developed aiming to reduce heat loss by maximizing the airtightness of the envelope along with the global trends [

4]. As the envelope of buildings becomes more airtight, the indoor air is barely exchanged with the outside air unless occupants actively ventilate the indoor air. With such trends, the requirements for good indoor air quality and energy efficiency have often been considered in conflict with each other because ventilation could need more operation of HVAC equipment in cooled or heated buildings. Seppanen researched various strategies to reduce energy consumption while simultaneously improving indoor air quality in buildings. One of the strategies is to balance airflow, which is to ventilate the minimum airflow required for a room to prevent energy wasting caused by excessive ventilation [

5].

In Korean regulations and guidelines, the required ventilation rates for existing or smaller buildings are not described nor enforced [

6]. European and American standards recommend several methods for calculating required ventilation rates to achieve desired air quality in a building based on the number of occupants, building sizes, building uses, and building materials [

7,

8]. However, even if a required ventilation rate is defined, designing or ventilating the building with natural ventilation system accordingly to comply with the requirement is not easy. It is intricate to figure out how much air is exchanged indoors and outdoors with natural ventilation. Moreover, the ventilation rates in a building vary depending on the condition of the building and the climate.

Two traditional techniques of measuring the infiltration and ventilation rate are fan pressurization tests and tracer gas methods. Fan pressurization tests are performed to measure the infiltration rate across the building envelope and is intended to be independent of climate variations [

9,

10]. The tests are performed at artificially-induced pressure differences (commonly at 50 Pa and 75 Pa in a test zone) to overwhelm the natural pressure differentials induced by wind and stack effects [

11]. Fan pressurization test results are idealized infiltration rates under the defined test conditions, which may differ from actual in-service conditions. On the other hand, tracer-gas methods are carried out for both infiltration and ventilation rate measurements. These methods inject gas into the test zone and measure its concentration-response. [

12,

13]. The tracer gas methods are conducted in actual environmental conditions and may better reflect seasonal variations in results [

14]. Tracer gas methods can reflect the fluctuating infiltration and ventilation rates influenced by natural pressure difference fluctuations, which is suitable for real-time evaluation in an actual room in service.

The occupant-generated CO

2 tracer gas method has received attention in that it is possible to estimate infiltration and ventilation rates reflecting the actual environmental conditions without injecting a tracking gas [

15,

16]. The method uses CO

2 generated by the occupants as a tracer gas unlike the conventional tracer gas methods that need injecting tracer gas. It tracks the decay of CO

2 concentration indoors after occupants leave the test zone [

17]. The estimations can be done every hour in buildings during the unoccupied periods. However, the low concentration level of occupant-generated CO

2 and short-term estimation periods can lead to much uncertainty in calculations. Some studies reviewed the associated principles, assumptions, and uncertainties [

18,

19,

20,

21,

22].

This method, which can be performed by anyone without many instruments, can help people to maintain desired IAQ while preventing excessive energy use. Occupants can make more accurate plans for natural ventilation by comparing the required ventilation rates and the estimated ones by measurements in their buildings. This paper aims to provide an example of indoor air quality and estimated ventilation rates in an office room with small circular openings in South Korea. Moreover, This paper compared infiltration and ventilation rates from summer to winter and evaluated the estimated ventilation rates compared with recommended ones by standards. The test room has eighteen small circular openings installed on the fixed insulated glasses for natural ventilation. The infiltration rates of the room were estimated while closing all the windows, and the ventilation rates, including infiltration, were estimated while opening four small circular openings on one side of the room.

2. Materials and Methods

2.1. Climate, site, building, and the test room description

Airflow into a room through a window opening and envelop leakage can vary depending on climate. The building of the test office room is located in the middle of Seoul, the largest city of South Korea. Seoul is classified as a temperate climate with four distinct seasons, with extreme temperature differences between summer and winter. Summer is hot and humid with temperatures soaring as high as 35°C on occasion. Winter is cold and dry with temperatures dropping almost as low as -20°C in severe cold waves [

23]. The wind speed in Seoul experiences mild seasonal variation over the course of the year. The windier part of the year is from October to May, with average hourly wind speeds of more than 3.6m/s. The windiest month of the year is February, with an average hourly wind speed of 4.2m/s. The calmest month of the year is June, with an average hourly wind speed of 3.1m/s [

24].

Together with the climate, indoor air quality is affected by outdoor air quality under natural ventilating conditions. The average air quality in South Korea in 2021 was evaluated as "moderate" as reported by IQAir, but the annual level of particulate material, or PM 2.5, which is a main pollutant in the air of South Korea, exceeded WHO PM2.5 guideline value by 3.8 times in 2021 [

25].

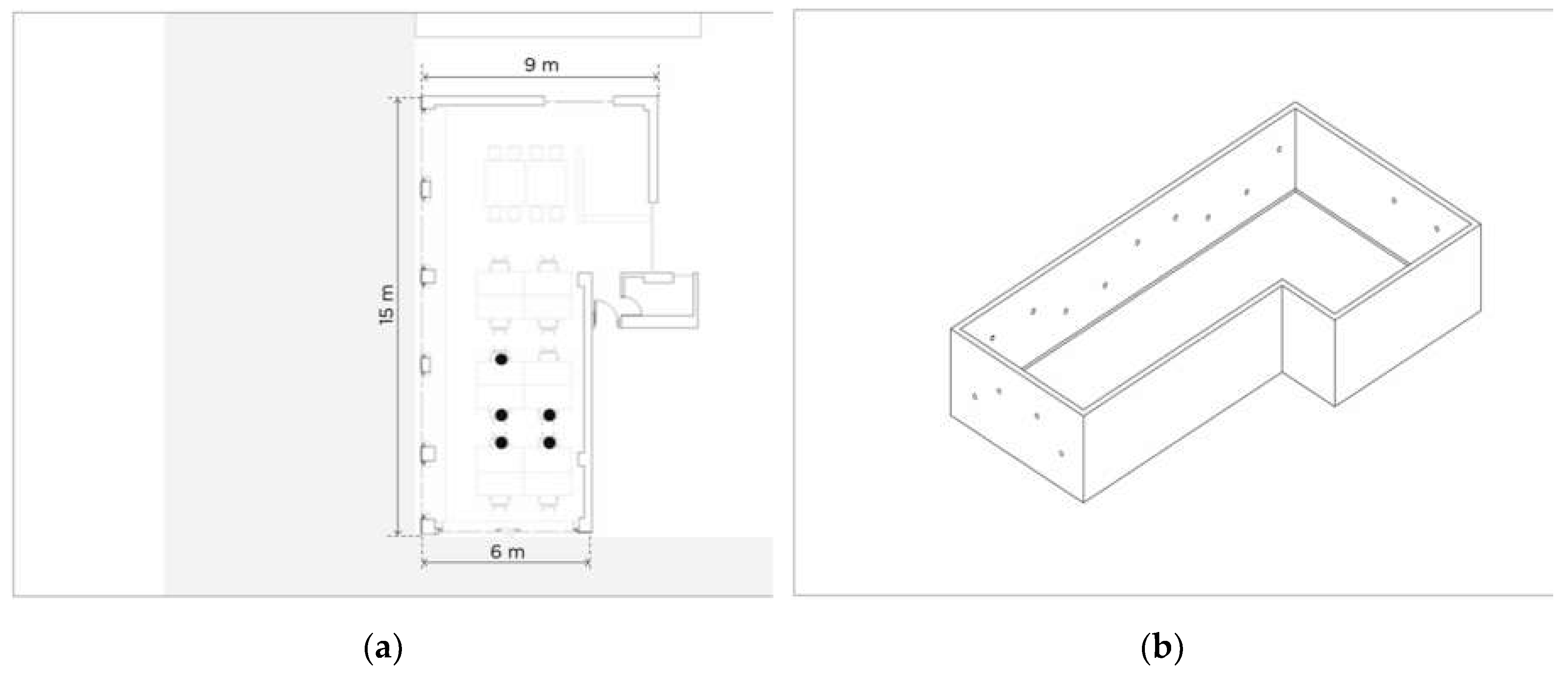

The building of the test room was built in 1982 as a reinforced concrete structure. The four-story building is 15m long along the north-south side, 9m wide, and 13m tall, with a total floor area of 505m2. The building has 150mm of concrete wall clad with stone panels without insulation. The west and south facades of the building face a 20m two-lane road and a 5m road, respectively. East and north facades are adjacent to other buildings.

As seen in

Figure 1(a), the test room is on the 2nd floor of the building. The room’s floor area is 84m

2 with a 2.8m height, and the volume is 235m

3. The room is partly insulated internally with 50mm of insulation. Columns and beams are not insulated, being expected to cause significant heat loss through them. The thermal imaging camera showed that the inner surface temperature of the beam at the corner in the heated room on a winter day was close to 0°C. The north, west, and south walls of the room face directly outdoors, and on the other side of the east wall is a staircase of the building without air conditioning. The room has nine windows with fixed insulated glasses. Seven large, fixed windows (2~2.5m in width, 2m in height) are on the west and south walls. Two long windows (2.3m in width, 0.5m in height) are on the north and east walls. Two small circular openings are on each fixed glass for natural ventilation. The glasses on the west and south walls have the openings with different heights, and the glasses on the north wall have the openings horizontally side by side. In other words, the room has ten small circular openings on the west wall, four small circular openings on the south wall, and two small circular openings on the north wall, as seen in

Figure 1(b).

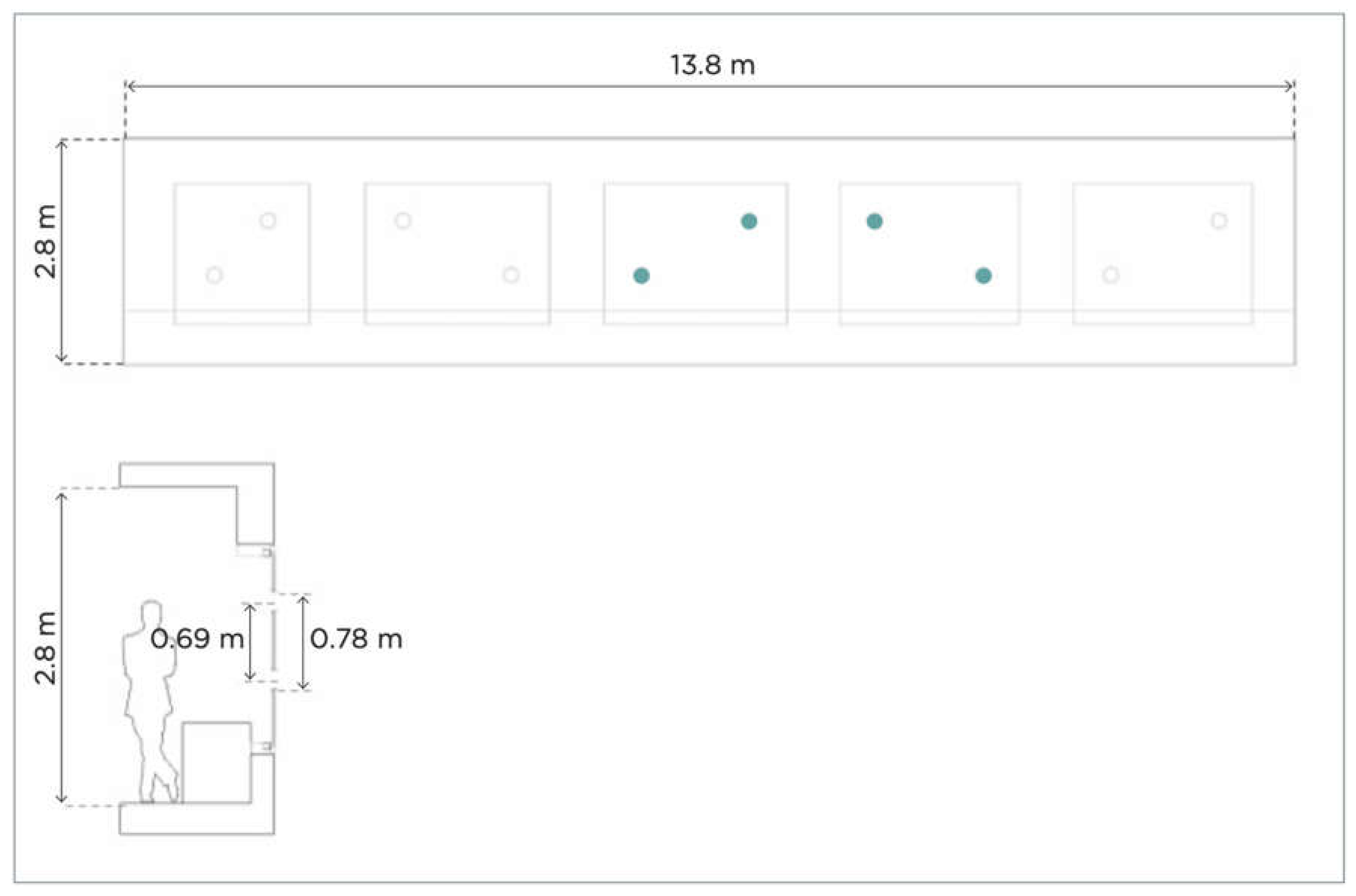

Figure 2 shows the elevation and section plans of the west wall. The diameter of the circular opening is 145mm with an area of 0.017m

2. The useful height for the stack effect between the upper opening and the lower one is 0.98m.

The test room is being used as an office. The room has an open working area, an unseparated kitchen, and a restroom. The room is furnished with desks, chairs, drawers, computers, a refrigerator, a sink, a TV, plants, and more. The concrete wall and furniture were painted. The floor is wood flooring. Five adult workers usually occupied the room during the measurement period. The regular workers usually sat in front of their desks, as shown in

Figure 1(a) with circle symbols. Occupants occasionally moved around in the room and went out for a while during work hours. Sometimes fewer people or more people were in the room. In November and December, we invited several people regularly to the office room on measurement days. The room was heated or cooled with two air conditioners, one against the north wall and one on the ceiling. Occupants used three fans in summer and four movable radiators in winter at their elbows. Occupants used the heating or cooling devices of their own accords over different seasons. The room does not have any mechanical ventilation system.

2.2. Ventilation rates for the test room in accordance with regulations and standards

2.2.1. In accordance with Korean regulations

According to Standards for Facilities of Buildings [

6], a new office building with a total floor area of over 3000m2 must equip with mechanical ventilation systems to ensure a ventilation rate of 29m

3/person/h. In this case, a natural ventilation system (i.e., openable windows) cannot be substituted for a mechanical ventilation system. The standards also mandate specified ventilation rates for other buildings with more than specific floor areas besides office buildings. The mandate ventilation rates in new buildings in accordance with Korean regulations are summarized in

Table 1. However, Korean regulations do not enforce the test room to satisfy any ventilation requirements due to its use and small size.

2.2.2. In accordance with European standard

European Standard EN 16789-1 [

7] suggests three methods to maintain desired indoor air quality for non-residential buildings. Design ventilation rates can be chosen depending on the desired satisfaction of the indoor air quality. Suppose the test room’s occupants desire to maintain indoor air quality at the level of expected dissatisfaction below 15% (Category I). In that case, the standard recommends that the room’s ventilation system should provide ventilation rates of 134 l/s (= 482.4 m

3/h, 2.05 ACH) or 168 l/s (= 604 m

3/h, 2.58 ACH). Those values were calculated by method 1 and method 3, respectively, provided that the floor area and volume of the room are 84 m

2 and 235 m

2 with five regular occupants. Alternatively, the occupants can keep CO

2 concentrations lower than 990 ppm to maintain the same level of indoor air quality (Category I), provided that the outdoor CO

2 concentration is 430 ppm, which is the mean value during the measurement period. The minimum ventilation rates suggested to ensure the indoor air quality level of expected dissatisfaction below 40% (category IV) are 37.7 l/s (= 135.72 m

3/h, 0.58 ACH) and 46.2 l/s (155 m

3/h, 0.66 ACH), calculated by method 1 and method 3, respectively. Alternatively, the room’s occupants can keep CO

2 concentrations lower than 1790 ppm to maintain the category IV indoor air quality. Design ventilation rates calculated by three methods for different target indoor air quality levels are presented in

Table 2,

Table 3, and

Table 4. Furthermore, the standard recommends ventilating even an unoccupied building room for diluting emissions from building materials. It recommends ventilating the test room at 12.6 l/s (45.36 m

3/h, 0.19 ACH) during unoccupied periods.

2.2.3. In accordance with American standard

The American standard ASHRAE 62 [

8] also suggests three procedures to maintain acceptable indoor air quality for buildings. This standard only presented minimum ventilation rates instead of suggesting several values depending on desired satisfaction levels. If calculated according to the ventilation rate procedure, the minimum design ventilation rate for the test room with five occupants is 37.7 l/s (= 135.72 m

3/h, 0.58 ACH), as summarized in

Table 5. Coincidentally, it is the same value for minimum ventilation rate (category IV) by Standard EN method 1. In the IAQ procedure, ASHRAE listed the maximum concentrations of common air contaminants, such as carbon dioxide, carbon monoxide, formaldehyde, lead, particles, and radon. Those values have been set by various national or international organizations concerned with outdoor and indoor air health and comfort effects. However, the ASHRAE standard is not selecting default limit concentrations of contaminants. The maximum levels of carbon dioxide concentration from various organizations are presented in

Table 6. Lastly, the natural ventilation procedure guides how to design a room to ensure minimum indoor air quality with natural ventilation. It proposes minimum distances from an occupied space to operable openings and minimum openable areas of window openings, which are different by the arrangement of the windows. Accordingly, occupied spaces in the test room should have openable windows closer than 14 m from the spaces, which is five times longer than the room’s height. The openable area of windows must be at least 3.36 m

2, which is 4% of the net occupiable floor area.

2.3. Theory

Carbon dioxide (CO2) is released by human breathing. The CO2 concentrations in an occupied room may become higher than outside when the room is unventilated or not adequately ventilated. Then when occupants leave the room (i.e., when the source of CO2 disappears), the CO2 concentration decreases as the indoor air is exchanged with the outdoor air through leaks of the building envelope and opened windows. Here, the decay rates of the CO2 concentration during unoccupied periods are used to calculate the ventilation rates.

Eq. (1) shows the indoor mass change with entering airflow, including infiltration, and leaving airflow, including exfiltration. The air mass change in a room is the net effect of both:

Here, m is for mass. , and are entering mas flow rates and leaving mas flow rates, respectively. Assuming the air mass in the room to be constant, the entering mass flow rate balances with the leaving one, i.e., .

The change of the tracer-gas concentration in a room can be presented as Eq. (2):

Where m,

,

,

,

, t, and S are the mass, density, room volume, indoor and outdoor tracer-gas concentrations, time, and mass source term, respectively. The tracer gas enters the room at an outdoor concentration through air flow entering the room, and it exists at the indoor concentration through air flow leaving the room. Any mass source or sink in the room should be included in the mass conservation in Eq. (2). When using CO

2 as the tracer gas, the source term S is the human or appliance CO

2 emissions in the room. For the period of non-residency, the source term can be set to zero, which is the case in this study. Combining Eqs. (1) and (2), and taking the limit of the left-hand side at ∆t→0, yields

Where , is the air change rate for the room. Outdoor CO2 concentration can change during the test period as well as indoor CO2 concentration .

To consider time-varying outdoor CO

2 concentration, an alternative form of the equation, Eq. (5) is proposed.

Where

can be decomposed into the mean term

and the time-varying term

. Eq. (5) alters the functional form using logarithmic change. Assuming a high indoor CO

2 concentration and a relatively small shift of outdoor CO

2 concentration,

, the term

is a small number, and Eq. (5) can be approximated as:

Where the 1/(1-x) term can be expressed as (1 + x + x2 + x3 + …) by a Taylor series. If the x is negligibly small, the term after (1+x) can be removed. In Eq. (6), the (1+x) term reflects an error caused when the time-varying outdoor CO

2 concentration is assumed to be an average value. The x term can be considered as the mean value for the time periods of infiltration rate estimates as in Eq. (7), assuming ACH and

are constant:

Here, N is number of the collected data points in the time range. If the mean of the outdoor CO2 concentration in the test range is used for the mean , the x term vanishes. A choice of away from the mean of the test range may result in a measurable value for the x term.

2.4. Measurement set-up and calculations

In this study, the x term in Eq. (6) was not considered because the daily mean of the outdoor CO

2 concentration was used for the mean

, assuming outdoor CO

2 concentration is the same over a day as well as during an estimation period of a day. We measured outdoor CO

2 concentrations near the test room on July 31, 2022. CO

2 concentrations were constant within measurement error ranges throughout the day. It may be because of little planting in the vicinity of the test room or little other factors that could cause changes in the concentration of CO

2 during days and nights. Ultimately, this paper calculated ventilation rates (Air Change rate per Hour) using Eq. (8):

We assumed that the distribution of CO

2 was constant everywhere in the test room. We turned on three fans vigorously before leaving to achieve uniform CO

2 concentrations in the test room. Infiltration and ventilation rates were estimated only using the indoor CO

2 concentrations data above 1000ppm as recommended in Park et al.’s study [

18] to prevent underestimation of estimates due to uncertainty in measurement data under extremely low concentration conditions. Whether the estimate is constant and reliable can be judged by the linearity of the regression equation

during the time range for an estimate. The estimates that satisfy R

2 ≥ 0.99 of

were selected for analysis as recommended in Park et al.’s study [

18].

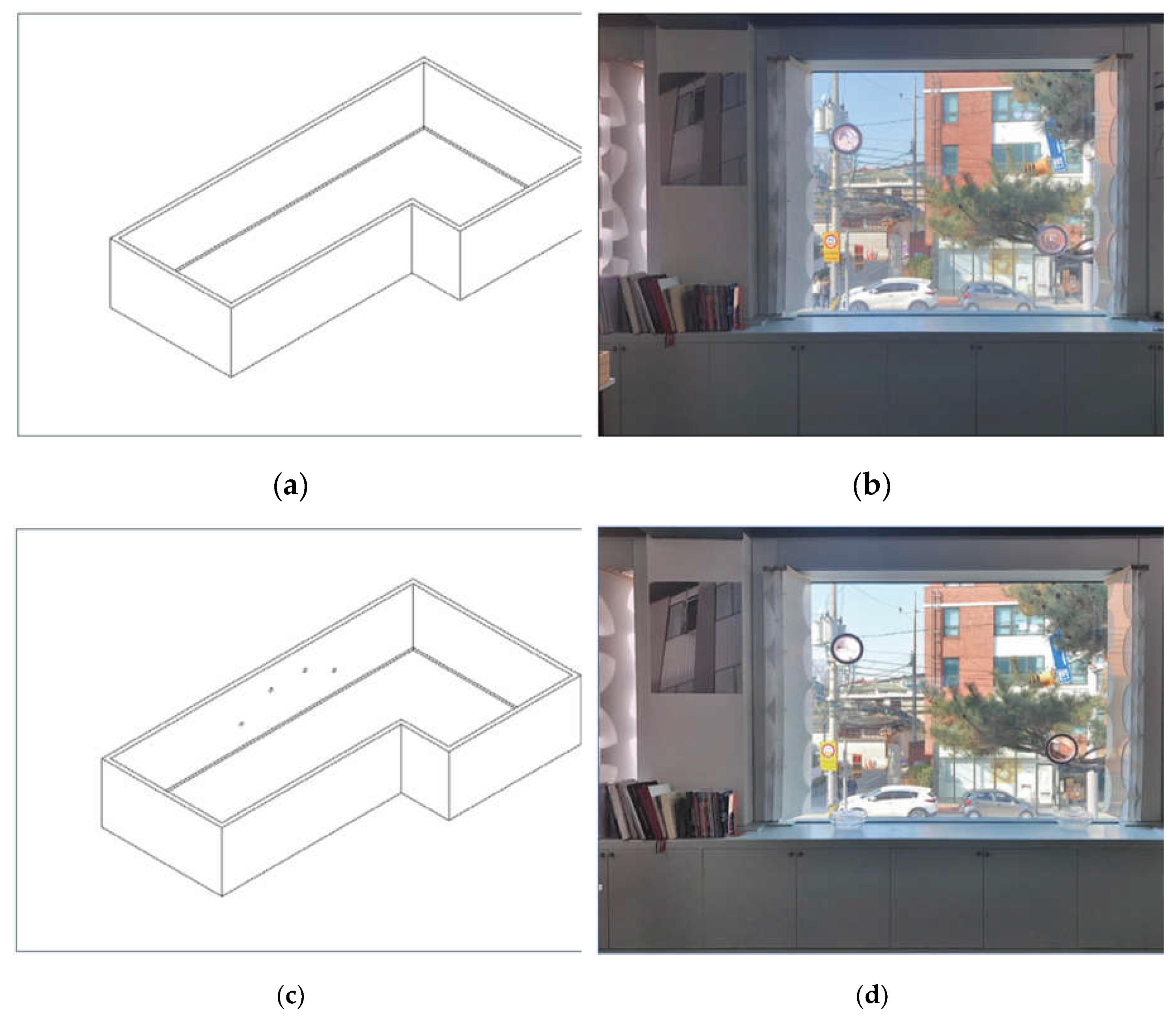

We conducted indoor measurements in the test room for twenty-six days from August to December 2022 and estimated infiltration and ventilation rates. Infiltration rates of the room were estimated for eight days with all the windows closed, which is ventilation case 1, as shown in

Figure 3(a) and (b). Ventilation rates, including infiltration, were estimated for eighteen days, with four circular openings on the west wall open, which is ventilation case 2, as shown in

Figure 3(c) and (d). The openings opened for one-sided natural ventilation are highlighted in blue in

Figure 2.

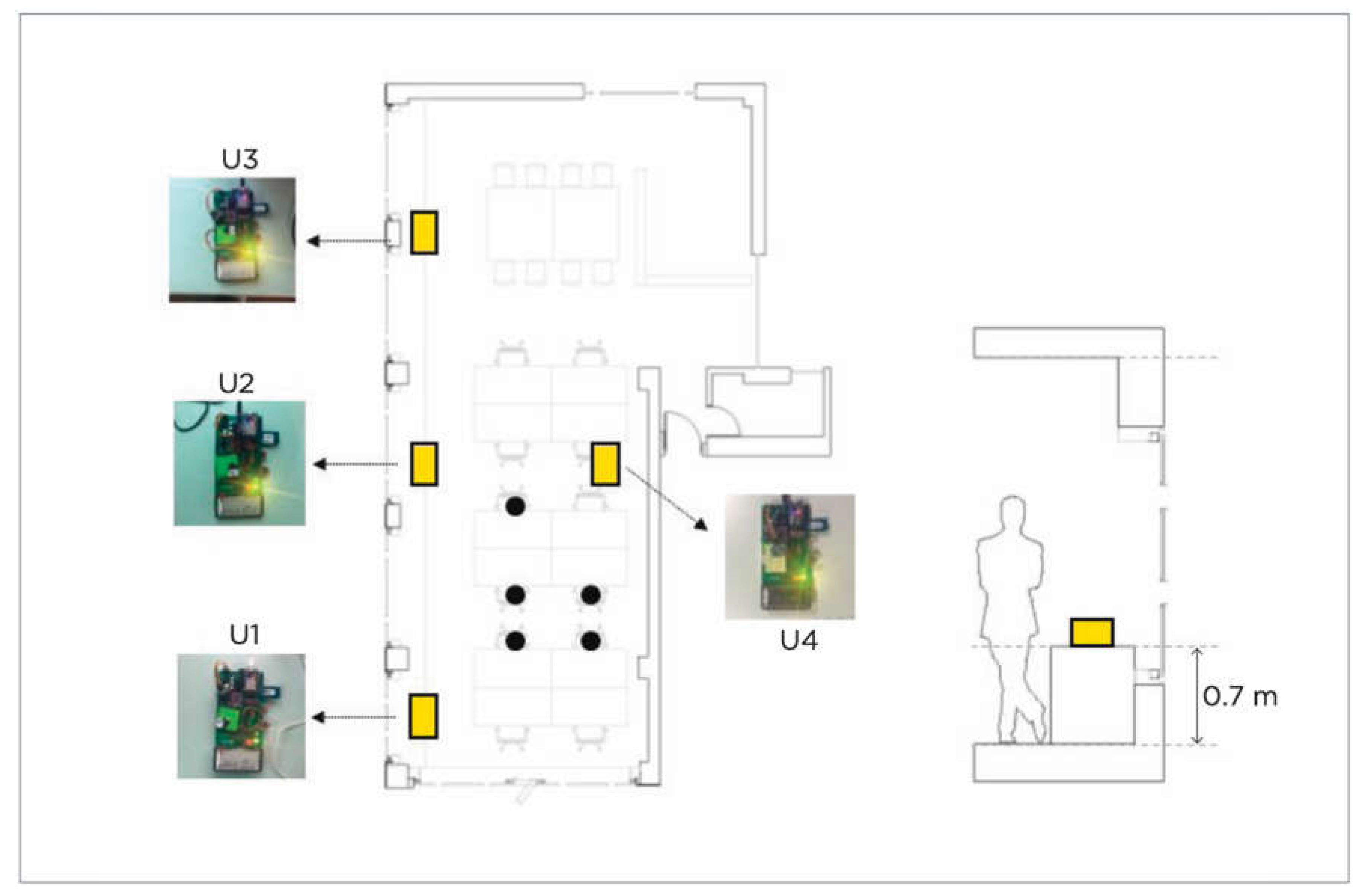

We installed four air-quality monitors (U1~U4) onboard multiple sensors to measure indoor temperature, humidity, CO

2 concentration, and PM concentration. The four monitors were installed in different locations in the test room with the same height of 0.7 m, as seen in

Figure 4. Firstly, the onboard sensor for measuring temperature and humidity is BME 280 from Bosch with a -40~85°C, 0~100% measuring range and a ±1°C, ±3% measurement accuracy, respectively. We calibrated the BME 280 sensors in Korean Laboratory Accreditation Scheme, which signed the ILAC-MRA. Another onboard sensor for measuring CO

2 concentration is SCD30 from Sensirion with a 400 ~ 10000 ppm measuring range and ±30ppm measurement accuracy. We calibrated the SCD30 sensors with the values measured at Namsan Tower, which is 3.3km away from the test building. We measured CO

2 concentrations in the well-ventilated test room on July 31, 2022 and calibrated the sensors to have the same daily mean CO

2 concentration as the one measured at the Namsan Tower on the same day. We assumed the indoor CO

2 concentrations were the same as the outdoor ones because the test room was unoccupied, and all the windows had been open since two days ago. Lastly, the onboard sensor for measuring PM concentration is SPS30 from Sensirion with a 0 ~ 1000 μg/m³ measuring range and ±10% measurement accuracy.

Outdoor temperature, wind speed, and PM concentration were measured at every minute at the meteorological station, 2 km away from the test building. Korean meteorological administration uploads the measurement data on their website [

26]. The outdoor CO

2 concentration was measured at the Namsan Tower, 3.3km away and 380 m higher than the test room. The Climate Lab of Seoul University posts the daily mean of measured CO

2 concentrations on its website [

27].

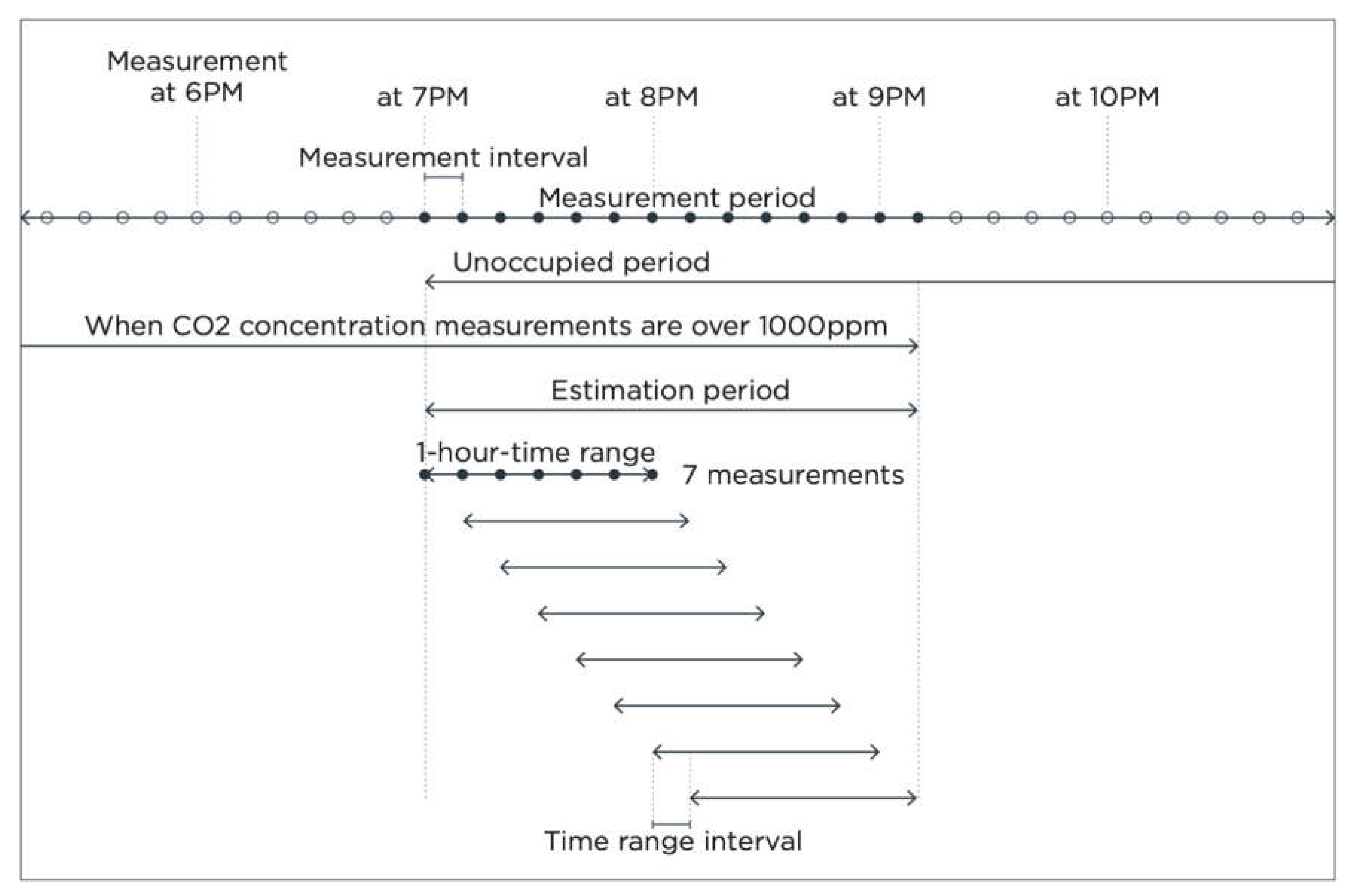

Among measurements during the measurement periods, we used measurements during unoccupied periods and when CO

2 concentrations were more than 1000 ppm to estimate infiltration and ventilation rate. We will call the period as an estimation period in this study. Since occupants usually left the test room between 6 to 8 pm, the estimation period was in the early evening on most measurement days. An estimate was calculated with measurements every 10 minutes for an hour of time range. In other words, seven measurements with 10-minute intervals were used for calculating an estimate. Park et al. quantitatively analyzed that estimates calculated with an hour of time ranges have lower than 20% uncertainty [

28]. The 1-hour time ranges overlapped with 10-minute intervals within the estimation period.

Figure 5 illustrates the terms about periods and intervals of measurement and estimation with a diagram.

The timed datasets (i.e., seven measurements for a 1-hour-time range) were 340 sets, and it was for 77 hours and 40 minutes, except for overlapped time. In this study, R2 ≥ 0.99 of the regression equation was set as the condition to satisfy the linearity. The value of R2 was rounded to two decimal places. Among 340 estimates from the timed datasets of the time ranges, 103 estimates did not satisfy the linearity and were eliminated for the analysis.

3. Results

The measurements and estimations were conducted for twenty-six days from August to December 2022, with seven days in August, six days in October, nine days in November, and four days in December. The dates, ventilation cases, decreases in CO

2 concentrations during unoccupied periods, and mean outdoor CO

2 concentrations on each day are listed in

Appendix A. The highest indoor CO

2 concentration measured in the test room was 2673 ppm during an occupied period and 2592 ppm during an unoccupied period. The mean outdoor CO

2 concentration from august to December measured at Namsan Tower was 430 ppm, with 428 ppm in August and 442 ppm in December.

The date, indoor and outdoor environmental conditions, estimation periods, and the summary of estimates are listed in

Appendix B. During the measurement days, the mean outdoor temperature of measurement days was 13.3°C, with 28.4°C on the hottest day and -4.6°C on the coldest day. The highest indoor temperature was 33.4°C in the afternoon of August, and the lowest one was 7.7°C in the morning of December. The mean outdoor windspeed of measurement days was 2.1m/s, with 3.5m/s on the windiest day, and 1.3m/s on the calmest day.

The highest daily mean of estimated infiltration rates was 0.21 ACH on December 15 and the lowest one was 0.07 ACH on August 4. The highest daily mean of estimated ventilation rates, including infiltration, was 0.61 ACH on December 13 and the lowest one was 0.22 ACH August 14.

3.1. Indoor air quality during an occupied period in the test room

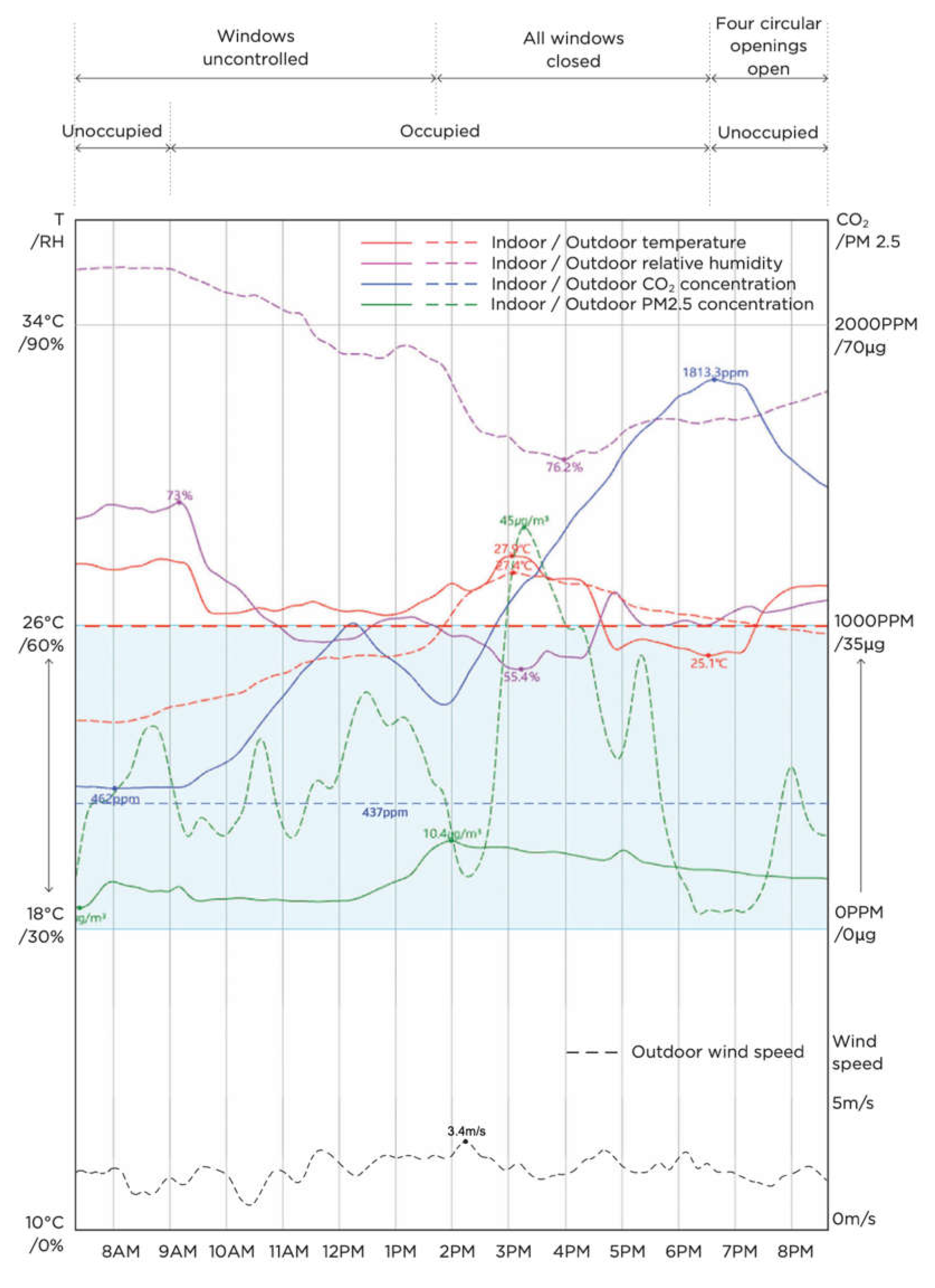

Figure 6 shows indoor air quality in the test room and outdoor weather condition from the morning to evening on August 11, 2022. It was one of the hot and humid summer days in South Korea. Five workers occupied the room from 9 am to 7 pm. Workers turned on cooling devices as they were comfortable during their work hours. The indoor air quality indicators in the chart were measured by sensor U2 located in the middle of the room. We controlled ventilating conditions from 2 pm.

The red, purple, blue, green, and black lines show the every-minute measurements of temperature, relative humidity, CO

2 concentration, PM 2.5 concentration, and wind speed, respectively. Dotted lines in each color represent outdoor measurements, and solid lines represent indoor measurements. The highest and lowest values of the day are written above and below the dots on the lines. The area highlighted in light blue represents the comfort zone, a range of comfortable indoor environments based on Korean regulations and guidelines [

29,

30], where the temperature is between 18°C and 26°C, relative humidity is between 30% and 60%, CO

2 and PM 2.5 concentration are less than 1000 ppm and 35 μg/m³, respectively.

During the occupied period on August 11, 2022, the indoor temperature was slightly higher than the comfort zone most of the time, even though air conditioners were being operated to cool the room. The indoor relative humidity remained high because of the humid weather. The indoor and outdoor temperature and the wind speed fluctuate throughout the measurement period.

Indoor CO2 concentrations were significantly affected by occupancy and ventilating conditions. Before 9 am, when no one was in the room, the CO2 concentration was close to the outdoor one. Then, as workers started to enter the room from 9 am, it started to increase. Later, it decreased again during lunchtime as workers went out severally and opened the door frequently between 12 pm and 2 pm. As all workers returned to the room after 2 pm, we closed all the windows, and the CO2 concentration continued to increase until workers left the room.

The trend implies that even if only five people were in such a spacious room, indoor air quality could deteriorate significantly when all the windows were closed. At noon, the CO2 concentration already reached 990 ppm, which is the maximum CO2 value for category I indoor air quality based on Standard EN (see section 2.2). The CO2 concentration at 7:30 pm reached 1813 ppm, higher than the maximum CO2 value for the minimum indoor air quality (category IV) based on standard EN. After all, at 7 pm, when all the occupants left the room, CO2 concentrations started to decrease. We left the four circular openings open for natural ventilation when we left the room.

PM 2.5 concentrations were usually lower inside than outside because of the higher PM concentrations outside. During lunchtime, between 1 pm and 2 pm, when outside air entered the room due to people coming in and out, the indoor PM 2.5 concentration rose, then decreased slowly when the windows were closed after 2 pm. Still, the outdoor PM concentration was acceptable on that day. So, it would have been much better to open the windows for natural ventilation to dilute bio-effluents and other possible pollutants from buildings.

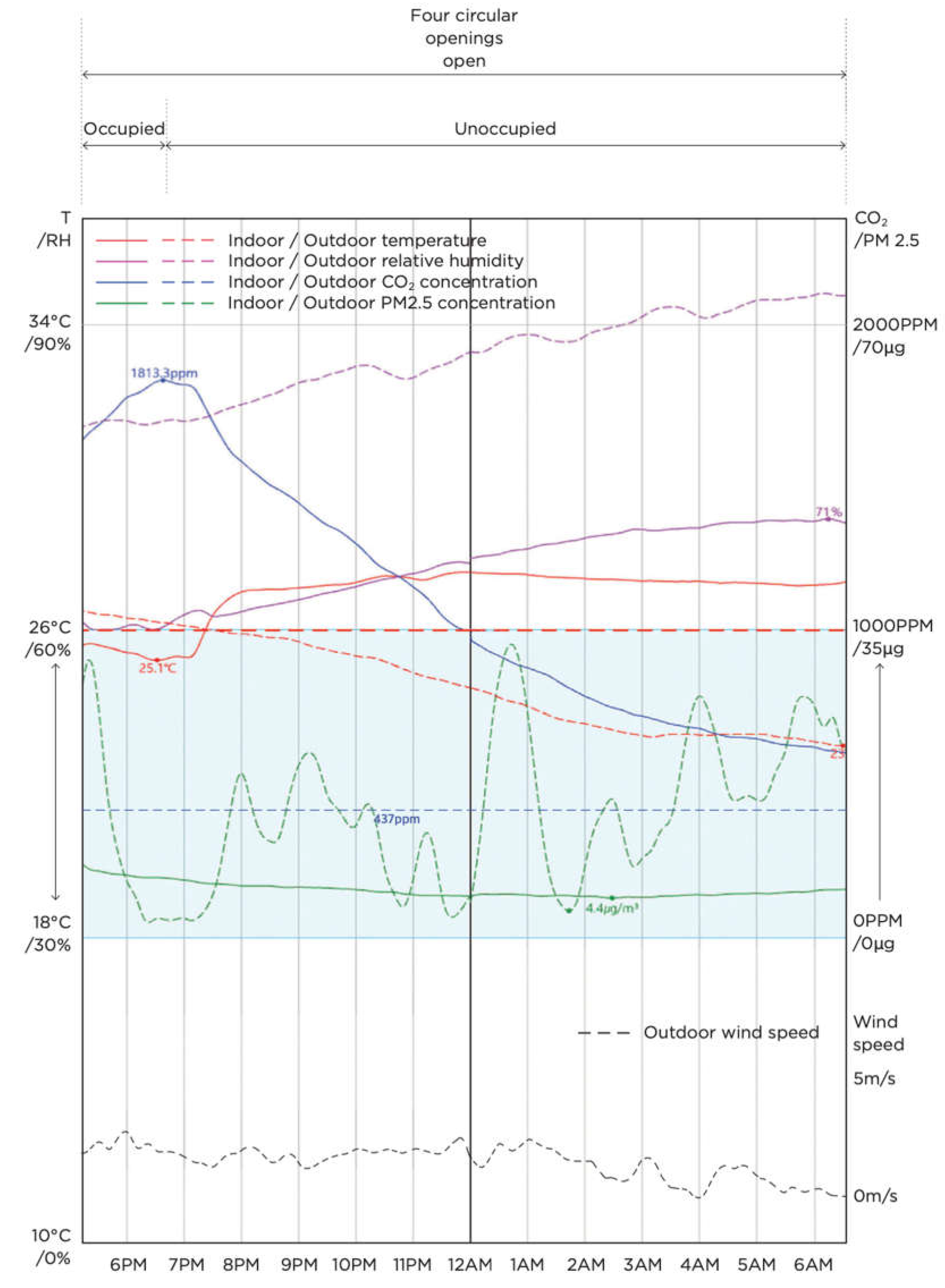

3.2. Decays of indoor carbon dioxide concentration during unoccupied periods

We closed all the windows in the test room during the daytime to increase CO

2 concentration during the measurement period. And then, when all the workers left the room, we left the room with all the windows closed or four circular openings open to measure the CO

2 decays under the two different ventilation cases during unoccupied periods. For example,

Figure 7 shows the indoor air quality during an unoccupied period from the evening on August 11, 2022, to the following morning, when we left the room with four circular openings open. The solid blue line shows the decay of indoor CO

2 concentration. Indoor CO

2 concentration peaked around 7 pm just before the occupants left the room and decreased until it became close to the outdoor CO

2 concentration in the form of a logarithmic graph. The initial CO

2 concentration just after all the occupants left the office was 1811 ppm at 7 pm. And then, it decreased to 1569 ppm after one hour, 1435 ppm after two hours, and 1293 ppm after three hours. This way, we collected the CO

2 concentration decay data every measurement day.

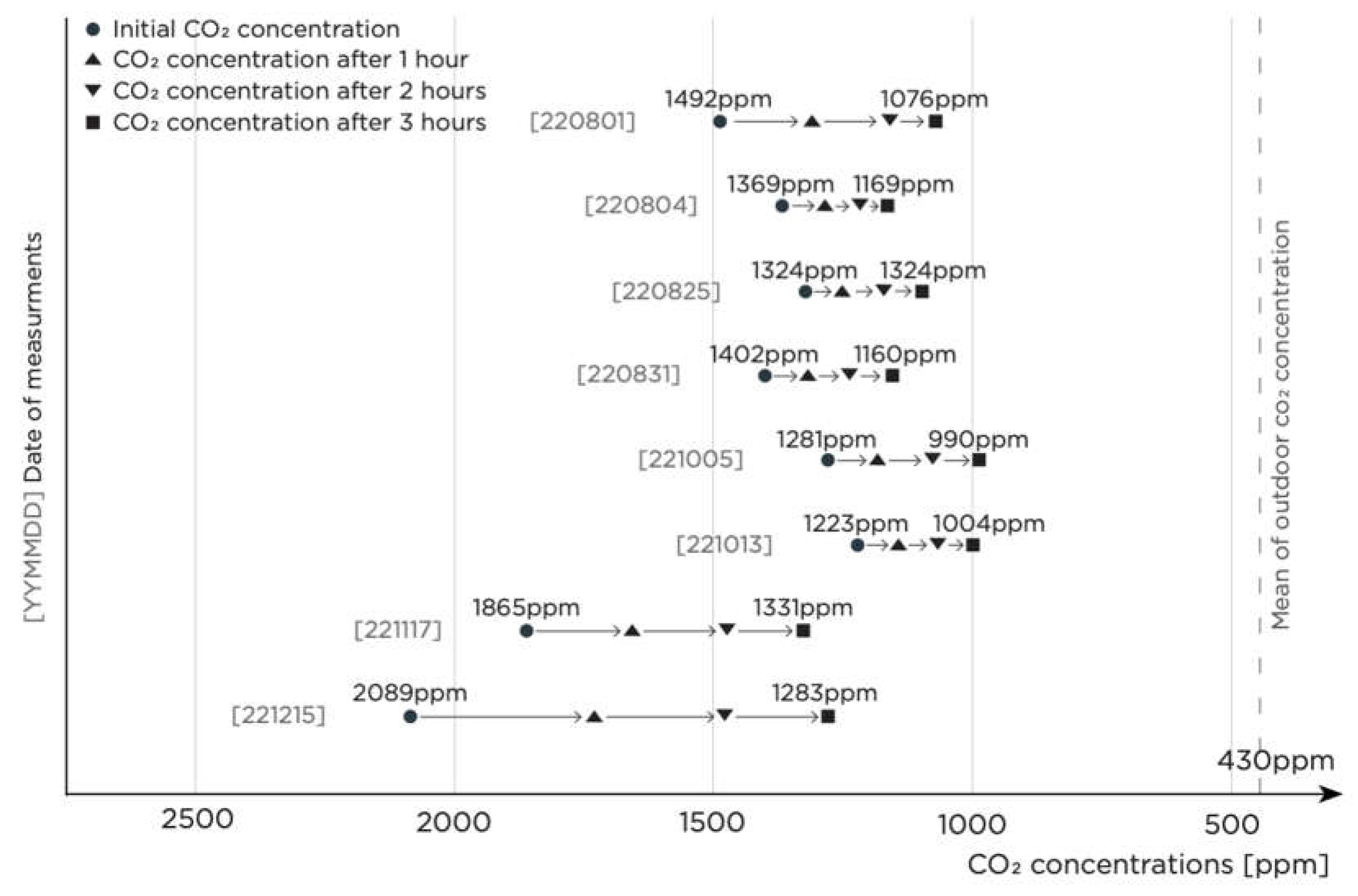

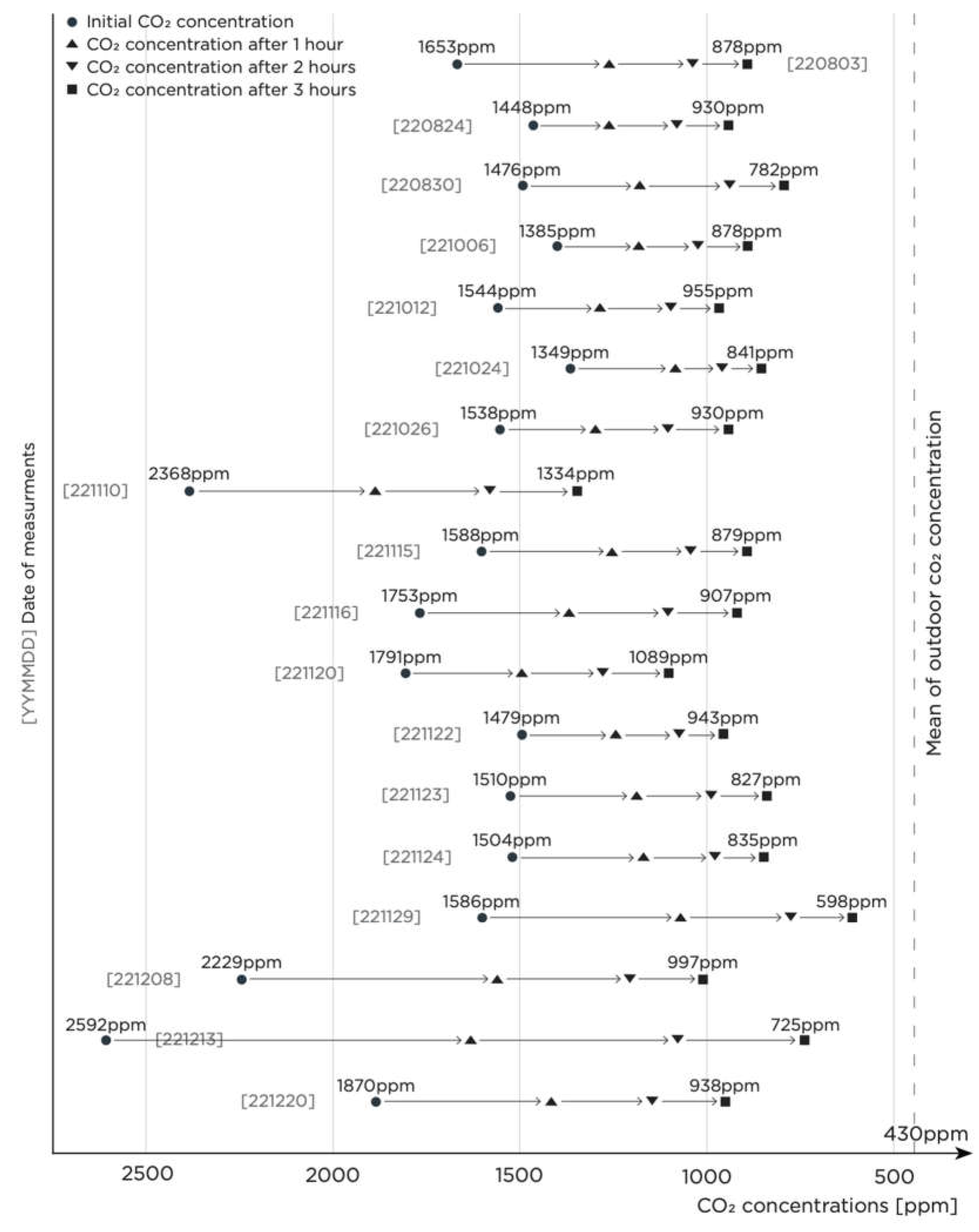

Figure 8 and

Figure 9 show the decays of CO

2 concentration during unoccupied periods of twenty-six measurement days.

Figure 8 shows the CO

2 concentration decays under ventilation case 1, when all the windows were closed, whereas

Figure 9 shows the decays under ventilation case 2, when four circular openings on one side were open. Circle symbols represent initial CO

2 concentrations when all the occupants just left the room. Triangles, upside-down Triangles, and squares represent the decreased CO

2 concentrations after one hour, two hours, and three hours, respectively. More measurement values are summarized in a table in

Appendix A.

In August and October, when 3-5 regular workers were in the room, the initial CO2 concentration increased to 1200 ~ 1800 ppm. On some days in November and December, when many people visited the room, the initial CO2 concentration exceeded 2000 ppm. The average 3-hour decrease during unoccupied periods when all the windows were closed was 366 ppm, and the decrease when four circular openings were open was 800 ppm. The greatest three-hour decrease was 1876 ppm on December 13, 2022, when the four circular openings were open. It was windy and cold, and the initial CO2 concentration was the highest among the measurement days. Nevertheless, a greater decrease in CO2 concentration does not always mean a greater magnitude of ventilation. Even if the same amount of ventilation occurs, if the indoor CO2 concentration is much higher than the outdoor one, the indoor one decreases more quickly.

3.3. Estimated infiltration rates when all the windows were closed (ventilation case 1)

One hundred twenty-nine valid infiltration rate estimates were calculated using the occupant-generated CO

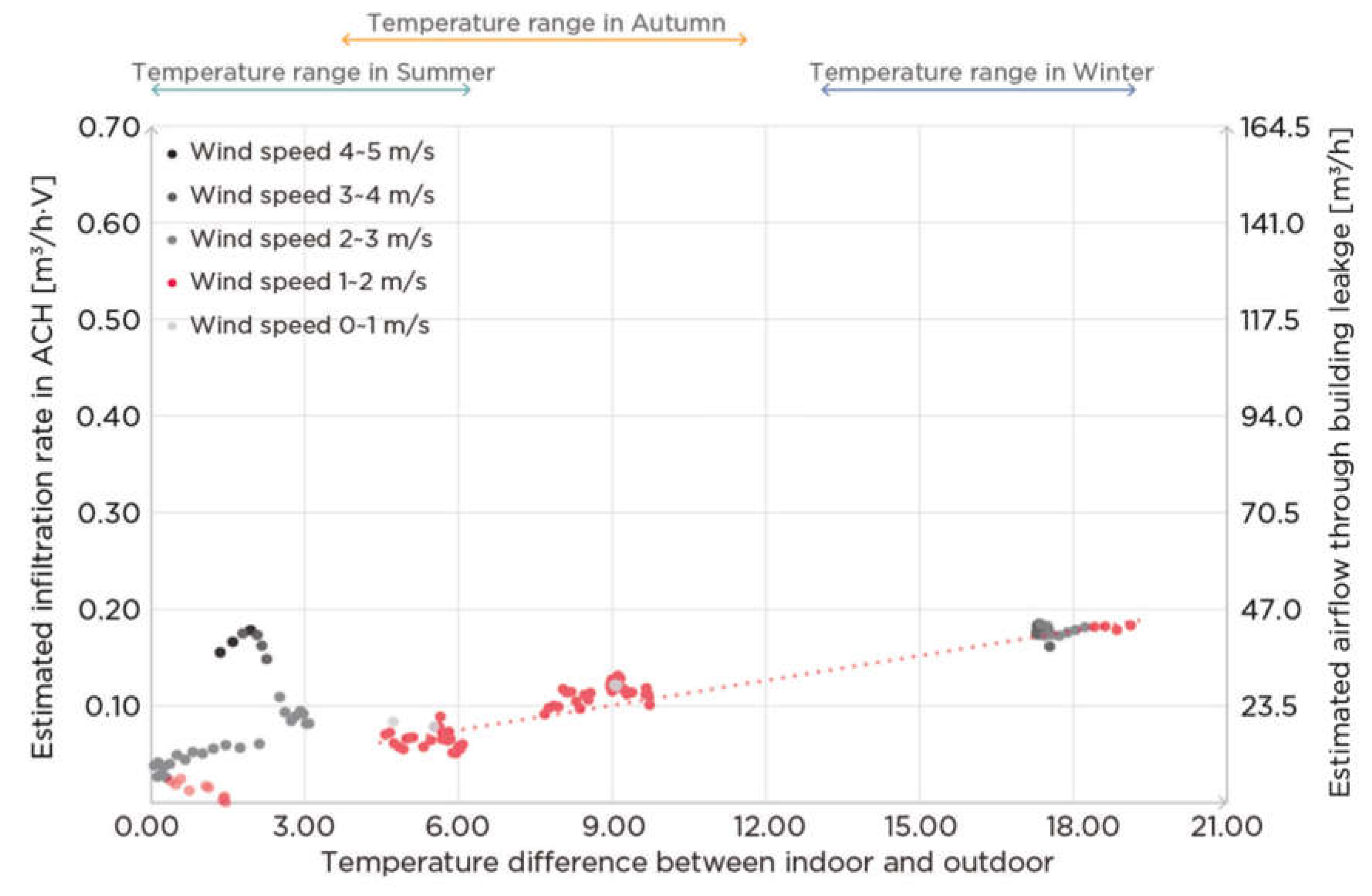

2 tracer gas decay method during the measurement period. The estimates are coordinated as dots in scattered charts, as shown in

Figure 10 and

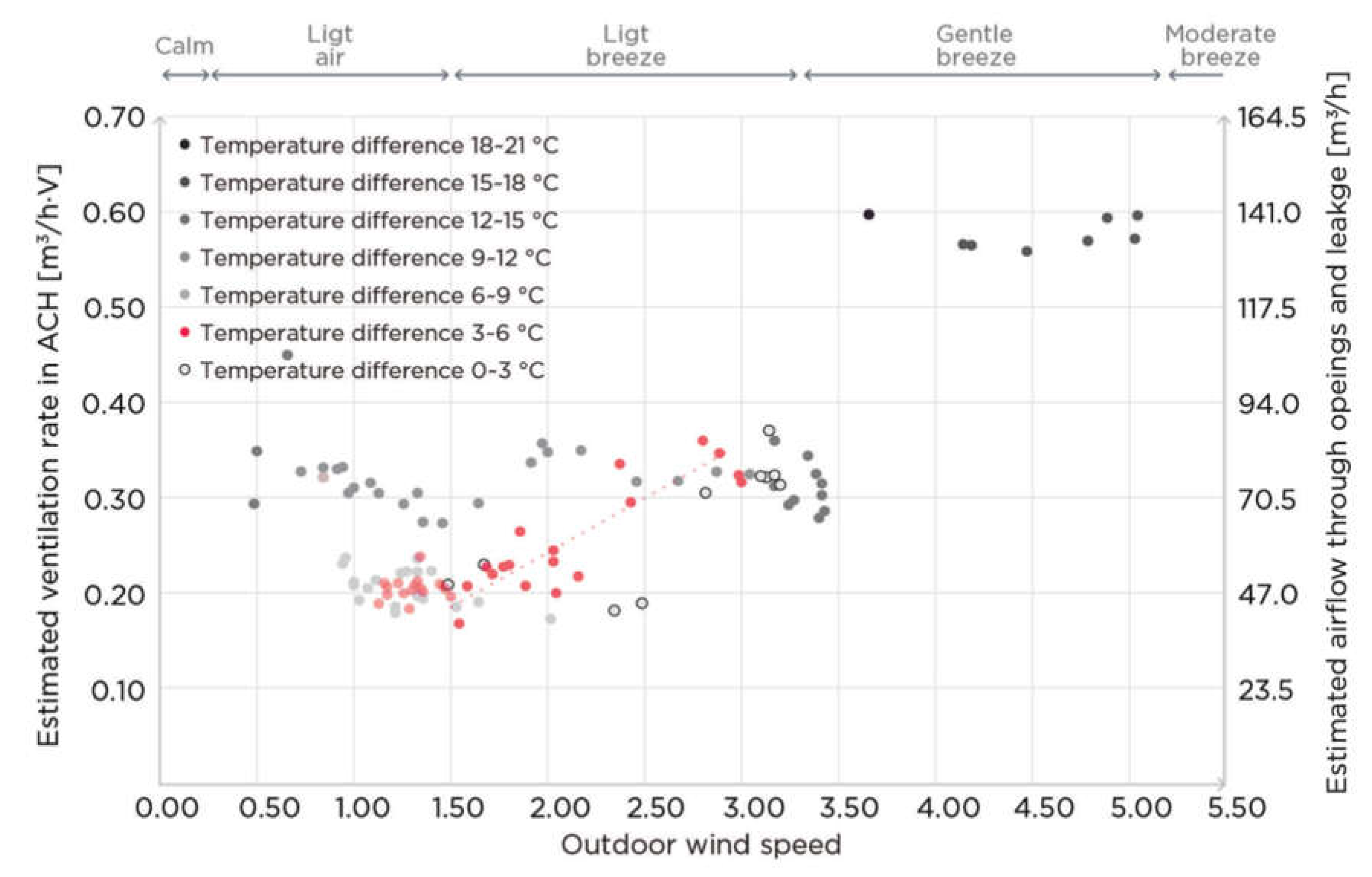

Figure 11. The charts show the correlation between estimated infiltration rates and the environmental conditions (temperature difference between indoor and outdoor, outdoor wind speed). The x-axis of

Figure 10 shows the temperature difference between inside and outside the test room, and the x-axis of

Figure 11 shows the outdoor wind speed. The y-axis shows the estimated infiltration rates in two different units. Additionally, the dots of estimates are expressed in different shades to express the other condition that is also changing simultaneously. The darker dots represent higher wind speeds in

Figure 10 and the greater temperature difference in

Figure 11.

In

Figure 10, when the wind speeds were less than 2m/s (colored dots in red) and the temperature differences were greater than 3°C , the infiltration rate estimates showed an increasing trend as the temperature differences increased. Meanwhile, when the temperature differences were less than 3°C, it was difficult to trace a relationship between the temperature difference and estimates.

In

Figure 11, When the temperature differences were less than 3°C (colored dots in red), and the wind speeds were greater than 1.5m/s, the infiltration rate estimates showed an increasing trend with increasing wind speeds. Meanwhile, when the wind speeds were less than 2m/s, it was difficult to trace a relationship between wind speed and estimates. Rather, dots of different shades were vertically layered, implying that the estimates were more affected by the temperature differences when the outdoor wind speeds were calm.

3.4. Estimated ventilation rates, including infiltration, when four circular openings on one side were open (ventilation case 2)

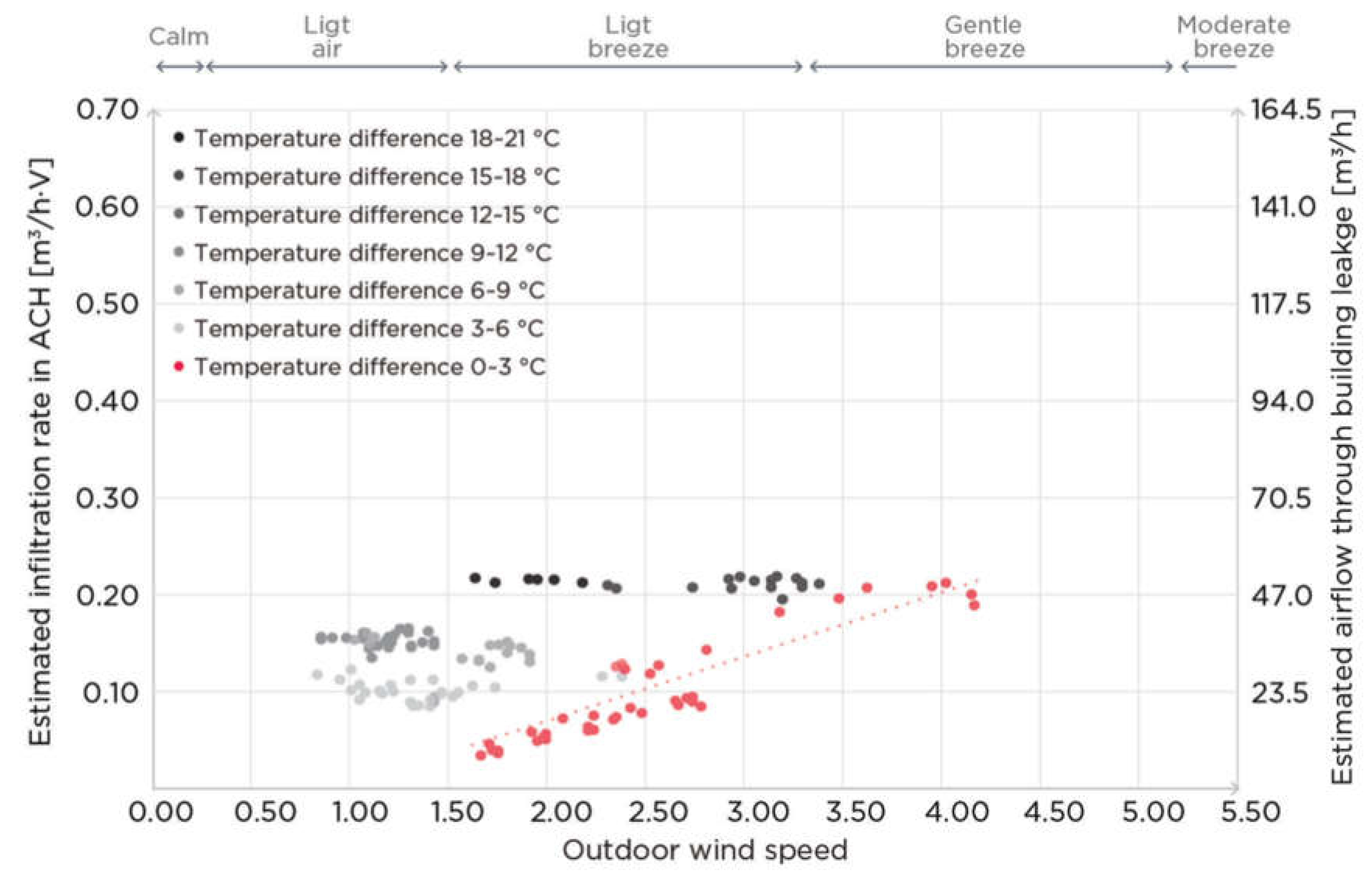

One hundred eight valid ventilation rate estimates, including infiltration, were calculated using the occupant-generated CO

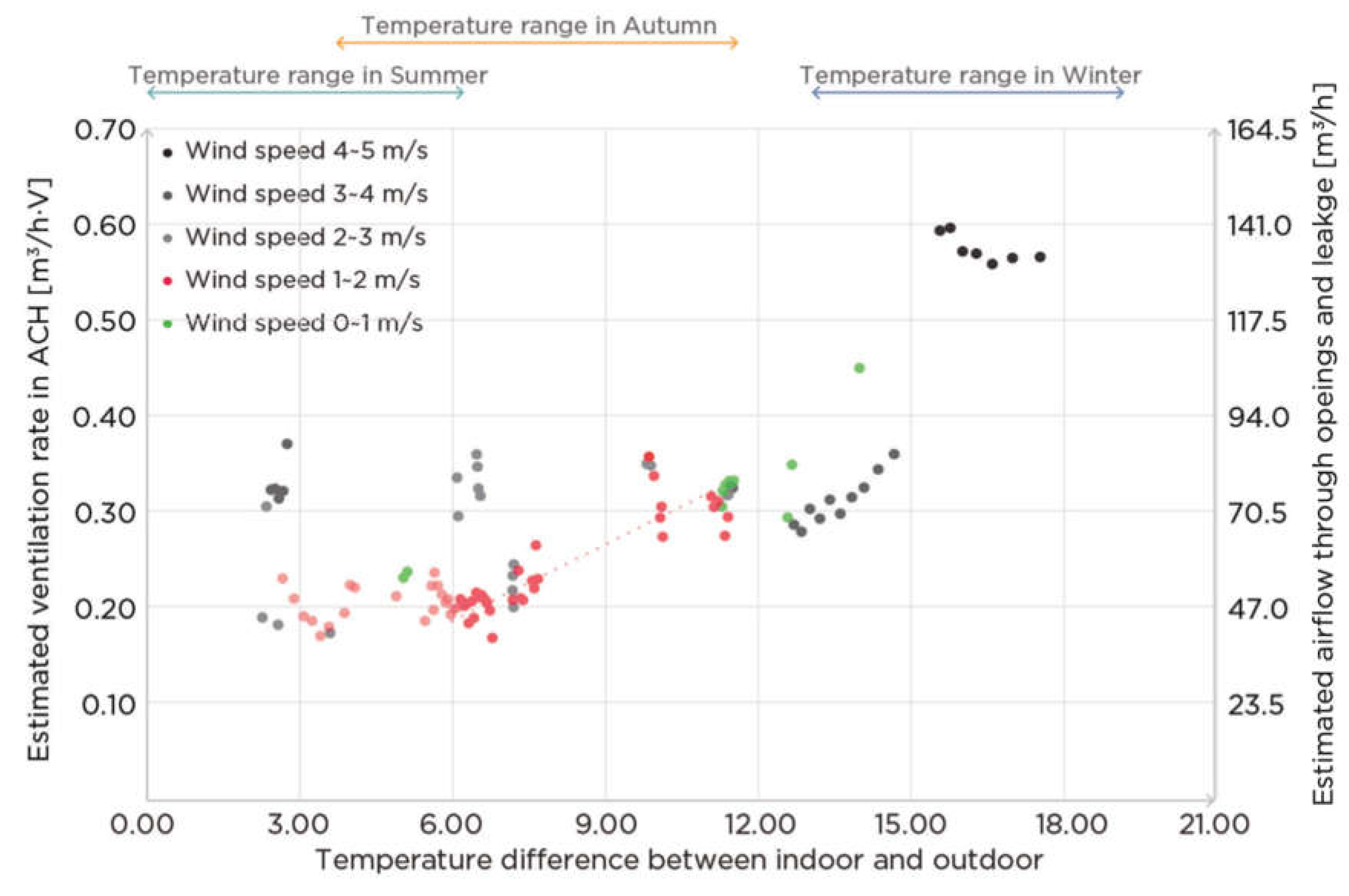

2 tracer gas decay method during the measurement period. The estimates are coordinated as dots in scattered charts, as shown in

Figure 12 and

Figure 13. The charts show the correlation between estimated ventilation rates and the environmental conditions. The x-axis of

Figure 12 shows the temperature difference between inside and outside the test room, and the x-axis of

Figure 13 shows the outdoor wind speed. The y-axis shows the estimated infiltration rates in two different units. Additionally, the dots of estimates are expressed in different shades to express the other condition that is also changing simultaneously. The darker dots represent higher wind speeds in

Figure 12 and the greater temperature difference in

Figure 13.

In

Figure 12, when the wind speeds were less than 2m/s (colored dots in red and green) and the temperature differences were greater than 6°C, the ventilation rate estimates showed an increasing trend as the temperature differences increased. When the wind speeds were more than 2m/s, it was difficult to find a relationship between the temperature difference and the ventilation rates based on the estimates obtained in this study.

In

Figure 13, when the temperature differences were less than 6°C (colored dots in red) and the wind speeds were greater than 1.5m/s, the ventilation rate estimates showed an increasing trend as the wind speeds increased. When the wind speeds were less than 1.5m/s or when the temperature differences were more than 6°C, it was difficult to find a relationship between wind speed and ventilation with the estimates obtained in this study.

Estimated ventilation rates more than doubled on days when wind speeds were higher than 4m/s and the temperature differences were more than 18°C. These estimates were calculated with winter measurements, implying that even with the same openings, ventilation rates could more than double depending on the weather.

Moreover, ventilation rate estimates were more scattered than infiltration rate estimates, and it was difficult to trace a trend. It implies that temperature difference and wind speed were the main factors that significantly affected infiltration rates. However, other factors may have influenced ventilation rates more significantly, such as the direction of the outdoor wind, the airflow inside the room formed by ventilation, and the uneven air and temperature distribution inside the room.

3.5. Various infiltration and ventilation rates in different seasons of South Korea

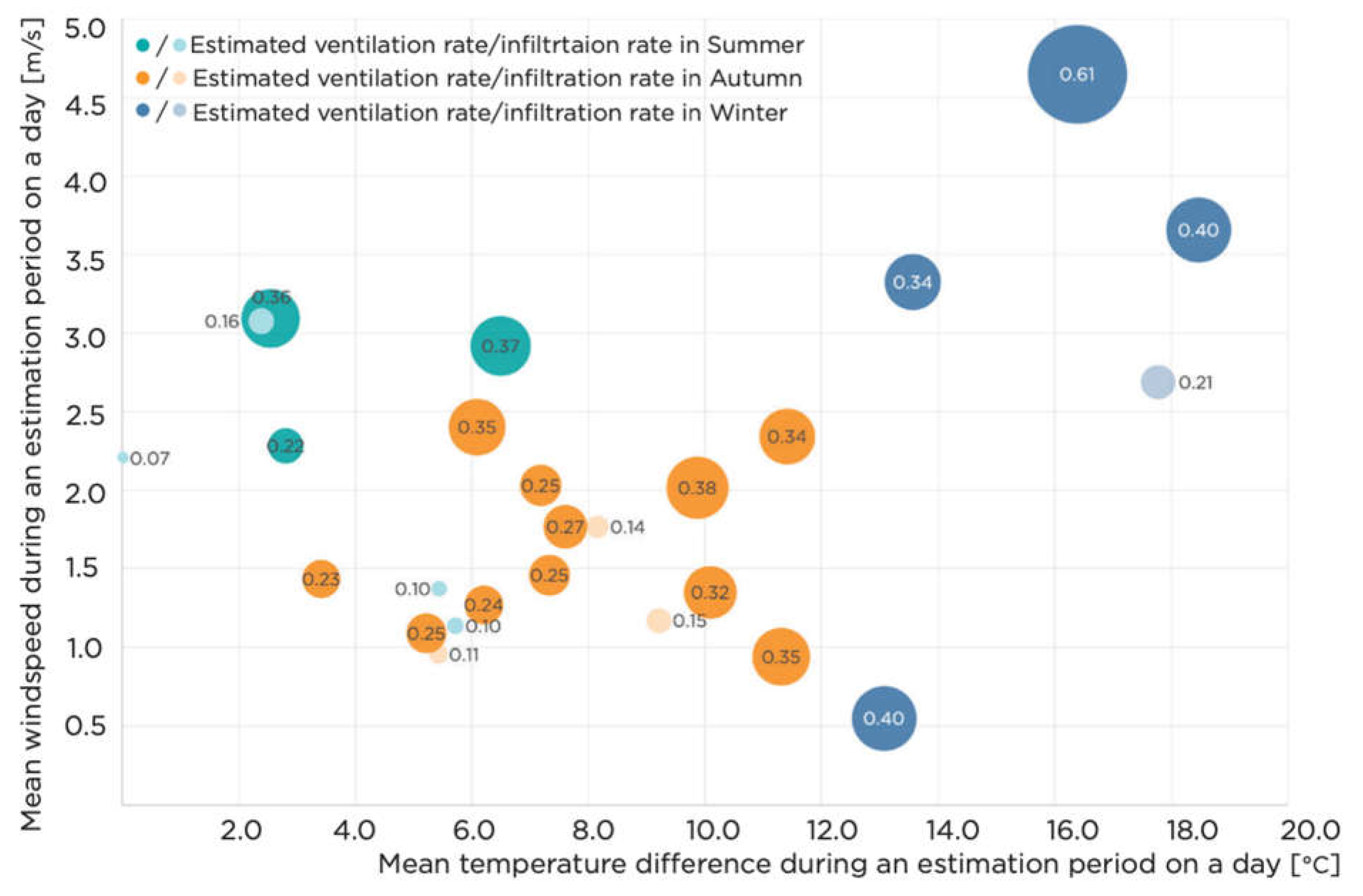

Figure 14 shows various environmental conditions in different seasons of South Korea of the test room and, subsequently, various infiltration and ventilation rates estimated in each season. One bubble represents the magnitude of mean estimated infiltration or ventilation rates during one measurement day, so twenty-six bubbles of each day were coordinated accordingly by their environmental conditions during their corresponding estimation periods. The values beside and inside the bubbles are average of valid infiltration and ventilation estimates during a day, respectively. Green, orange, and blue bubbles represent Summer, Autumn, and Winter estimates, respectively. Pale bubbles represent infiltration rates, and dark bubbles represent ventilation rates.

As shown in

Figure 14, green bubbles are on the left side, orange bubbles are in the middle, and blue bubbles are on the right side of the chart, indicating that the test room’s temperature difference increased from summer to winter. Green and blue bubbles are in the upper part of the chart than orange bubbles, indicating that the summer and winter were windier than the autumn. More importantly, the sizes of the bubbles increase as they go up and to the right, indicating that the infiltration or ventilation rates increased as the temperature difference and wind speed increased. The pale bubbles are generally smaller than darker ones, indicating that the infiltration rates were less than the ventilation rates. For the reference, the estimated ventilation rates include leakage of the room.

The temperature differences in the summer among the measurement days were slight, with an average of 3.6°C (0~6.5 °C), while the wind speed averaged 2.3m/s (1.1~3.1 m/s). The result in

Section 3.4 showed when the temperature differences were less than 6°C and the wind speeds were greater than 1.5m/s, the ventilation rate estimates showed an increasing trend as the wind speeds increased. Based on the result, it can be assumed that the estimated ventilation rates in the summer generally increased with a more significant influence on wind speeds. The bubbles which get bigger as they go up in the chart confirm that assumption. On the other hand, in autumn, the temperature differences increased to an average of 7.8°C (3.4~11.4°C), while the wind speeds were calmer on most days, being averaged 1.6m/s (0~2.4 m/s). It can be assumed that the primary factors that would have significantly affected the ventilation rates would have changed depending on the day’s weather. At any rate, the estimated ventilation rates in summer and autumn were similar because the two factors complemented one another.

The temperature differences in winter increased significantly to an average of 15.9°C (13.1~18.5°C). On top of that, the wind speeds increased to an average of 3m/s (0.6~4.7 m/s) with a wide variance. As a result, the estimated ventilation rates in winter increased significantly compared to summer and autumn. Also, the variance of the magnitude of estimates, or bubble sizes, increased due to the wide variation in wind speeds. Yet, it is hard to assume which factor had a greater effect on winter ventilation rates only with this study’s results.

4. Discussion

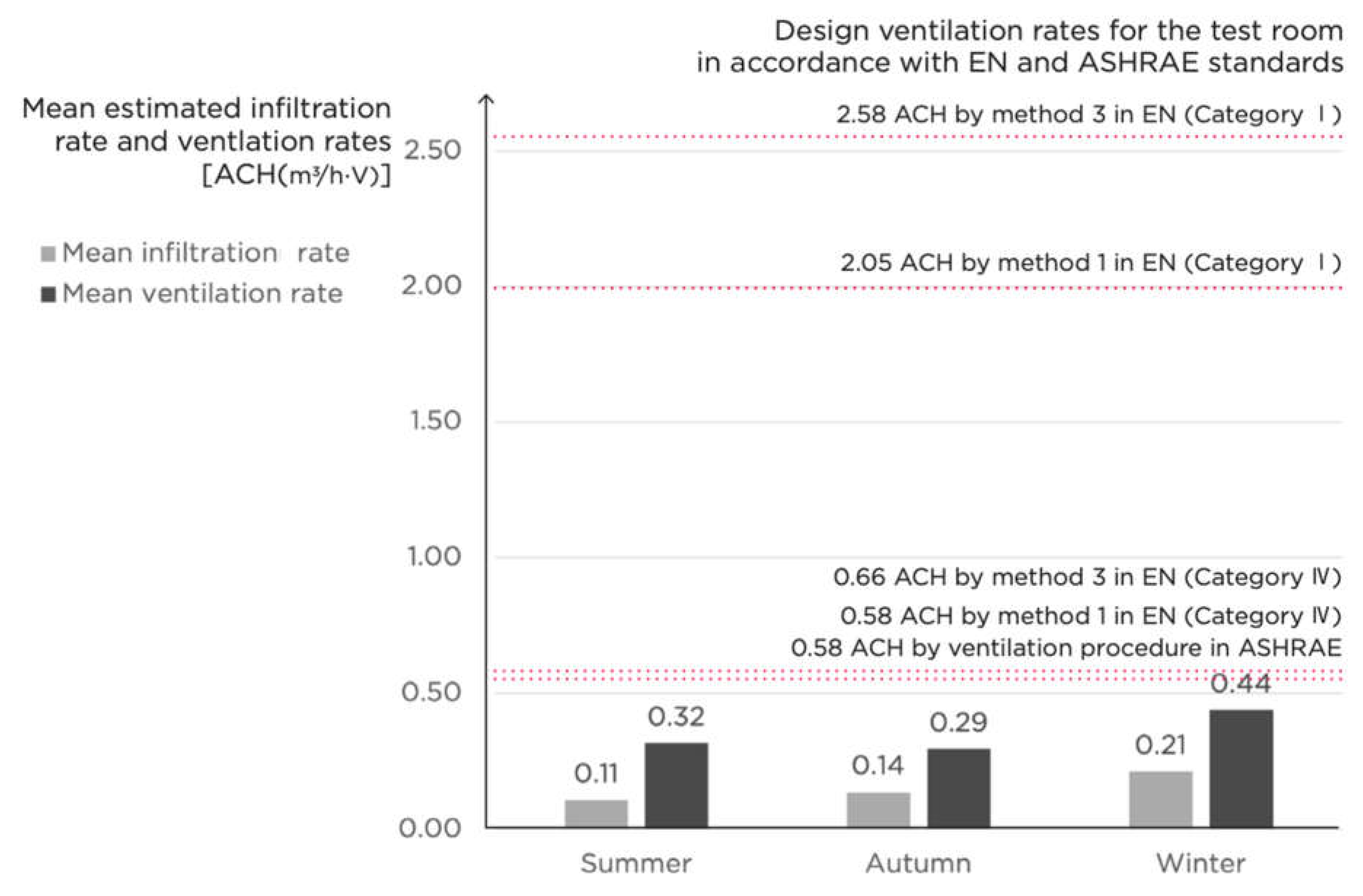

4.1. Evaluation of the estimated ventilation rates in the test room in accordance with standards EN and ASHRAE

The minimum ventilation rate suggested in standard EN and ASHRAE is 0.58 ACH. Among the eighteen days of estimating the ventilation rates, including infiltration, with the four circular openings open, the daily mean ventilation rate on December 13 only exceeded the minimum requirement, with 0.61 ACH.

Figure 15 compares the mean estimated infiltration and ventilation rate of different seasons. The mean estimated infiltration rates of summer, autumn, and winter, represented with grey bars, were 0.11, 014, and 0.21 ACH, respectively. While the mean estimated ventilation rates of summer, autumn, and winter, represented with black bars, were 0.32, 029, and 0.44 ACH, respectively. Design ventilation rates for the test room by EN and ASHRAE standards were indicated with dotted red lines. Nevertheless, any of the mean estimates of each season did not satisfy the recommended values. We should open more windows to maintain acceptable or desired indoor air quality.

Then, how many circular openings should we open to satisfy the recommended ventilation rates? Suppose that the airflow only through the openings can be calculated by subtracting the mean estimated infiltration rate from the mean estimated ventilation rate. Also, suppose airflow through the openings increases at the same rate whenever we open two more circular openings on one side while the infiltration of the room is constant. In that case, we can calculate the expected ventilation rates in the test room when we open more circular openings: (the mean estimated infiltration rate) + (the mean estimated ventilation rate - the mean estimated infiltration rate) * (the number of open circular openings/4). Accordingly, we calculated the minimum number of circular openings we should open each season. In summer, opening ten circular openings on one side can satisfy the minimum ventilation rate (0.64 ACH = 0.11 + (0.32-0.11)*2.5), and in autumn and winter, opening twelve and six circular openings on one side, respectively, can satisfy the minimum ventilation rate (0.59 ACH = 0.14+(0.29-0.14)*3, 0.57 ACH =0.21+(0.44-0.21)*1.5). In other words, the test room needs two circular openings per 47m3, 39m3, and 78m3 in summer, autumn, and winter, respectively.

However, it was only a rough calculation. The mean estimates of each season cannot represent each season’s average infiltration and ventilation rate because the measurement days were irregular and insufficient. In addition, when we open two more openings, the ventilation rates will not increase at the same rate due to various factors that could influence on ventilation rate. We should repeat the tracer gas decay method with the calculated number of circular openings open, and then we can evaluate more accurately whether the minimum ventilation rate is satisfied.

5. Conclusion and significance

This study shows an example of indoor air quality in an office room in Seoul, South Korea. Korea has four distinct seasons with severe temperature changes over a year. So, most office buildings operate air-conditioning facilities in summer and winter. However, in many office rooms, workers do not ventilate the room adequately to save energy consumption or because they are indifferent to indoor air quality. In this study, measuring indoor air quality indicators while all the windows were closed allowed us to see how much indoor air quality could deteriorate if ventilation was not properly performed in actual living conditions. The degree of deterioration may vary in other office rooms depending on their environmental conditions, such as insulating conditions, ventilating conditions, occupants’ habits, and heating and cooling system types. Therefore, if one wants to know the indoor air quality in another room, measuring the indoor air quality indicators in the room would be necessary.

We looked into how outdoor temperatures, wind speeds, and CO2 concentrations have changed from summer to winter in Seoul, South Korea. We also looked into how much the outdoor and indoor temperatures differ by season in the test room in an old building when using cooling or heating devices as usual. Then, we estimated how much infiltration occurred when we closed all the windows and how much natural ventilation, including infiltration, occurred when we opened the four circular openings on one side. Further, we analyzed how those estimates changed with varying indoor and outdoor conditions. The exchanged air due to leaks and airflow through openings increased significantly in winter than in other seasons in Korea. It is because both the temperature difference and the wind speed increased significantly in winter. Therefore, using the windows the same way over a year would not be an optimal ventilation strategy in Korea with four distinct seasons.

Existing buildings in Korea have various types of windows, but it is not easy to know how much ventilation occurs with the windows they have. Especially many old buildings do not have mechanical ventilating facilities installed, so natural ventilation is often the only available ventilation method. In addition, there is a high possibility that a lot of air leakage has occurred in old buildings through non-airtight envelopes. The air exchange caused by the leaks should not be ignored to reduce excessive energy loss. However, because of its complexity and cost, only a few people conduct ventilation measurements to determine the actual magnitude of ventilation through windows and leaks in their buildings. Also, Korea does not have regulations or guidelines that propose the recommended ventilation rates and practicable suggestions to maintain acceptable indoor air quality for various small buildings. The tracer gas method with occupant-generated CO2 in this study can be done only with CO2 sensors and a few people in any living room. Then, the occupants can evaluate whether they have ventilated the room properly, too little, or too much. If the ventilation has been insufficient, the occupants will be able to pay more attention to improving the indoor air quality by ventilating more. Conversely, they can reduce energy loss by reducing ventilation if it has been excessive. Altogether, the method allows people to easily set up specific ventilation strategies for which windows and for how long should be open in their room to achieve the desired indoor air quality.

Small circular openings in the test room are not typical window types. A full-scale experiment found that they could achieve sufficient ventilation to maintain acceptable air quality by keeping them open all the time in the test room. Generally, it is recommended to ventilate a room once every few hours with large openings to save energy use in cooling and heating seasons. However, many workers often leave windows closed throughout work hours. It may be because occupants can directly feel the discomfort of temperature fluctuation and city noise when they open the windows. Yet, awareness about the impact of poor indoor air quality is low and opening and closing windows often is a hassle. The small circular openings can maintain the indoor condition that does not fluctuate greatly all the time, leaving only the minimum number of openings open adequate for maintaining acceptable air quality by season. It can also prevent excessive heat loss by ventilation. In addition, since there is no risk of a break-in through the small openings, they can be left open even when emptying the room for minimum ventilation during unoccupied periods.

Author Contributions

N.K. conceived the original idea; H.S. performed the measurements; N.K., A.B. and D.A. were involved in planning and supervised the work; H.S. processed the experimental data, performed the analysis, drafted the manuscript, and designed the figures; N.K. and A.B. aided in interpreting the results and worked on the manuscript. All authors discussed the results and commented on the manuscript.

Funding

This research was funded by UBLO Inc.

Acknowledgments

Hugo van Santen for the technical support related to air-quality monitors and sensors, Nari Yoon and Robert van Santen for the review on planning and presenting the work.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

| No. |

Date |

Ventilation case |

Initial

indoor CO2

|

Indoor CO2 after 1hr |

Indoor CO2 after 2hr |

Indoor CO2 after 3hr |

Daily mean outdoor CO2

|

| 1 |

2022/08/01 |

1 |

1492 |

1308 |

1161 |

1076 |

425 |

| 2 |

2022/08/03 |

2 |

1653 |

1247 |

1025 |

878 |

431 |

| 3 |

2022/08/04 |

1 |

1369 |

1284 |

1220 |

1169 |

433 |

| 4 |

2022/08/24 |

2 |

1448 |

1242 |

1069 |

930 |

417 |

| 5 |

2022/08/25 |

1 |

1324 |

1251 |

1174 |

1101 |

418 |

| 6 |

2022/08/30 |

2 |

1476 |

1165 |

928 |

782 |

423 |

| 7 |

2022/08/31 |

1 |

1402 |

1317 |

1241 |

1160 |

425 |

| 8 |

2022/10/05 |

1 |

1281 |

1182 |

1080 |

990 |

439 |

| 9 |

2022/10/06 |

2 |

1385 |

1167 |

1012 |

878 |

438 |

| 10 |

2022/10/12 |

2 |

1544 |

1271 |

1085 |

955 |

442 |

| 11 |

2022/10/13 |

1 |

1223 |

1142 |

1070 |

1004 |

442 |

| 12 |

2022/10/24 |

2 |

1349 |

1068 |

946 |

841 |

439 |

| 13 |

2022/10/26 |

2 |

1538 |

1283 |

1091 |

930 |

448 |

| 14 |

2022/11/10 |

2 |

2368 |

1873 |

1567 |

1334 |

452 |

| 15 |

2022/11/15 |

2 |

1588 |

1239 |

1031 |

879 |

452 |

| 16 |

2022/11/16 |

2 |

1753 |

1355 |

1092 |

907 |

452 |

| 17 |

2022/11/17 |

1 |

1865 |

1657 |

1478 |

1331 |

452 |

| 18 |

2022/11/20 |

2 |

1791 |

1481 |

1266 |

1089 |

452 |

| 19 |

2022/11/22 |

2 |

1479 |

1229 |

1062 |

943 |

452 |

| 20 |

2022/11/23 |

2 |

1510 |

1173 |

976 |

827 |

452 |

| 21 |

2022/11/24 |

2 |

1504 |

1155 |

966 |

835 |

452 |

| 22 |

2022/11/29 |

2 |

1586 |

1055 |

763 |

598 |

452 |

| 23 |

2022/12/08 |

2 |

2229 |

1546 |

1192 |

997 |

448 |

| 24 |

2022/12/13 |

2 |

2592 |

1618 |

1065 |

725 |

432 |

| 25 |

2022/12/15 |

1 |

2089 |

1732 |

1483 |

1283 |

432 |

| 26 |

2022/12/20 |

2 |

1870 |

1402 |

1132 |

938 |

432 |

Appendix B

| No. |

Season |

Date |

Daily mean temperature |

Daily mean wind speed |

Estimation period |

The number of valid estimations |

Average temperature difference during time ranges of estimates |

Average wind speed during time ranges of estimates |

Average infiltration rate or ventilation rates of valid estimates |

| 1 |

Summer |

220801 |

28.4 |

2.4 |

9:00~22:40 |

15 |

2.4 |

3.1 |

0.16 |

| 2 |

220803 |

27.1 |

2.8 |

16:10~18:00 |

6 |

-2.5 |

3.1 |

0.36 |

| 3 |

220804 |

28.9 |

2.5 |

18:30~02:30 |

25 |

0 |

2.2 |

0.07 |

| 4 |

220824 |

24.7 |

2.5 |

18:40~21:00 |

3 |

2.8 |

2.3 |

0.22 |

| 5 |

220825 |

22.3 |

1.8 |

22:00~23:50 |

2 |

5.7 |

1.1 |

0.1 |

| 6 |

220830 |

19.1 |

2.6 |

19:00~20:30 |

4 |

6.5 |

2.9 |

0.37 |

| 7 |

220831 |

21.6 |

1.8 |

20:20~01:50 |

22 |

5.4 |

1.4 |

0.1 |

| 8 |

Autumn |

221005 |

16.6 |

2.1 |

19:50~22:40 |

12 |

8.2 |

1.8 |

0.14 |

| 9 |

221006 |

15.7 |

2.1 |

18:50~20:50 |

5 |

7.6 |

1.8 |

0.27 |

| 10 |

221012 |

13.4 |

1.8 |

18:30~21:00 |

5 |

5.2 |

1.1 |

0.25 |

| 11 |

221013 |

16.2 |

1.5 |

18:40~21:40 |

4 |

5.4 |

1 |

0.11 |

| 12 |

221024 |

10.8 |

2.8 |

19:00~20:20 |

2 |

6.1 |

2.4 |

0.35 |

| 13 |

221026 |

12.6 |

1.9 |

18:40~21:10 |

5 |

7.2 |

2 |

0.25 |

| 14 |

221110 |

13.5 |

1.3 |

19:00~23:50 |

23 |

6.2 |

1.3 |

0.24 |

| 15 |

221115 |

8 |

2 |

19:50~21:50 |

6 |

11.4 |

2.3 |

0.34 |

| 16 |

221116 |

8.6 |

1.7 |

19:10~21:30 |

9 |

11.3 |

0.9 |

0.35 |

| 17 |

221117 |

10.2 |

1.6 |

19:10~01:40 |

28 |

9.2 |

1.2 |

0.15 |

| 18 |

221120 |

13.8 |

1.7 |

17:40~21:20 |

9 |

3.4 |

1.4 |

0.23 |

| 19 |

221122 |

10.7 |

1.9 |

19:50~22:10 |

3 |

7.3 |

1.5 |

0.25 |

| 20 |

221123 |

11.1 |

2.1 |

19:10~20:40 |

4 |

9.9 |

2 |

0.38 |

| 21 |

221124 |

9.3 |

1.5 |

20:30~22:00 |

3 |

10.1 |

1.3 |

0.32 |

| 22 |

Winter |

221129 |

7.9 |

3.5 |

20:20~21:20 |

1 |

18.5 |

3.7 |

0.24 |

| 23 |

221208 |

3.9 |

1.4 |

19:20~22:10 |

3 |

13.1 |

0.5 |

0.4 |

| 24 |

221213 |

0.6 |

3.5 |

18:20~20:20 |

7 |

16.4 |

4.6 |

0.61 |

| 25 |

221215 |

-4.6 |

2.5 |

19:20~23:50 |

21 |

17.8 |

2.7 |

0.21 |

| 26 |

221220 |

-3.7 |

2.2 |

19:40~22:10 |

10 |

13.6 |

3.3 |

0.34 |

References

- Satish, Usha, Mark J. Mendell, Krishnamurthy Shekhar, Toshifumi Hotchi, Douglas Sullivan, Siegfried Streufert, and William J. Fisk. 2012. “Is Co2an Indoor Pollutant? Direct Effects of Low-to-Moderate CO2Concentrations on Human Decision-Making Performance.” Environmental Health Perspectives 120, no. 12: 1671–77. [CrossRef]

- APTE, MICHAEL G., WILLIAM J. FISK, and JOAN M. DAISEY. 2000. “Associations between Indoor Co2 Concentrations and Sick Building Syndrome Symptoms in U.S. Office Buildings: An Analysis of the 1994-1996 Base Study Data.” Indoor Air 10, no. 4: 246–57. [CrossRef]

- Kim, Jakyung and Nam, Kyungsook. 2007. “A study on the Finishing Materials for Reduction of Indoor Pollution.” 한국실내디자인학회논문집 16, no. 2(April): 303-313.

- Kim, Jeong Tai, and Chuck Wah Yu. “Sustainable Development and Requirements for Energy Efficiency in Buildings – the Korean Perspectives.” Indoor and Built Environment 27, no. 6 (2018): 734–51. [CrossRef]

- Seppanen, Olli. 2008. Ventilation strategies for good indoor air quality and energy efficiency. International Journal of Ventilation 6. no. 4: 287-306.

- MOLIT. 2021. Regulations on Facilities of Buildings (건축물의 설비기준 등에 관한 규칙). Ministry of Land, Infrastructure and Transport. Seoul, South-Korea.

- EN. 2019. EN 16798-1. Energy performance of buildings - Ventilation for buildings - Part 1: Indoor environmental input parameters for design and assessment of energy performance of buildings addressing indoor air quality, thermal environment, lighting and acoustics - Module M1-6. CEN European Committee for Standardization.

- ASHRAE. 2010. ASHRAE STANDARD 62.1-2010. Ventilation for Acceptable Indoor Air Quality. 0. American Society of Heating, Refrigeration and Air conditioning Engineer.

- ASTM. 2010. E779-10. Standard Test Method for Determining Air Leakage Rage by Fan Pressurization. American Society of Testing and Materials. Philadelphia. Pennsylvania.

- ISO 9972. 2015. Thermal Performance of Building-Determination of Air Permeability of Buildings-Fan Pressurization Method. International Organization for Standardization. Geneva. Switzerland.

- Lozinsky, Cara H., and Marianne F. Touchie. 2018 “Improving Energy Model Calibration of Multi-Unit Residential Buildings through Component Air Infiltration Testing.” Building and Environment 134: 218–29. [CrossRef]

- Etheridge, D., and M. Sandberg. 1996. Building Ventilation: Theory and Measurement. Chichester: Wiley.

- Sandberg, Mats, and Claes Blomqvist. 1985. “A Quantitative Estimate of the Accuracy of Tracer Gas Methods for the Determination of the Ventilation Flow Rate in Buildings.” Building and Environment 20, no. 3: 139–50. [CrossRef]

- Patel, Tapan, Constandinos Mitsingas, James P. Miller, and Ty A. Newell. 2011 “Comparison of Blower Door and Tracer Gas Testing Methods for Determination of Air Infiltration Rates through Building Envelopes at Normal Operating Conditions.” ASME 2011 5th International Conference on Energy Sustainability, Parts A, B, and C. [CrossRef]

- Smith, P.N. 1988. “Determination of Ventilation Rates in Occupied Buildings from Metabolic CO2 Concentrations and Production Rates.” Building and Environment 23, no. 2: 95–102. [CrossRef]

- Lu, Tao, Anssi Knuutila, Martti Viljanen, and Xiaoshu Lu. 2010. “A Novel Methodology for Estimating Space Air Change Rates and Occupant CO2 Generation Rates from Measurements in Mechanically-Ventilated Buildings.” Building and Environment 45, no. 5: 1161–72. [CrossRef]

- Dias Carrilho, João, Mário Mateus, Stuart Batterman, and Manuel Gameiro da Silva. 2015. “Air Exchange Rates from Atmospheric CO2 Daily Cycle.” Energy and Buildings 92: 188–94. [CrossRef]

- Park, Sowoo, Paul Choi, Doosam Song, and Junemo Koo. 2021. “Estimation of the Real-Time Infiltration Rate Using a Low Carbon Dioxide Concentration.” Journal of Building Engineering 42: 102835. [CrossRef]

- Kabirikopaei, Adel, and Josephine Lau. 2020. “Uncertainty Analysis of Various CO2-Based Tracer-Gas Methods for Estimating Seasonal Ventilation Rates in Classrooms with Different Mechanical Systems.” Building and Environment 179: 107003. [CrossRef]

- Remion, Gabriel, Bassam Moujalled, and Mohamed El Mankibi. 2019. “Review of Tracer Gas-Based Methods for the Characterization of Natural Ventilation Performance: Comparative Analysis of Their Accuracy.” Building and Environment 160: 106180. [CrossRef]

- ISO 12569. 2017. Thermal performance of buildings and materials — Determination of specific airflow rate in buildings — Tracer gas dilution method. International Organization for Standardization. Geneva. Switzerland.

- ASTM. E741-11. 2017. Standard Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution. American Society of Testing and Materials. Philadelphia. Pennsylvania.

- “Climate of Seoul.” Wikipedia. Wikimedia Foundation, Accessed December 27, 2022. https://en.wikipedia.org/wiki/Climate_of_Seoul.

- “Weatherspark.com.” Seoul Climate, Weather By Month, Average Temperature (South Korea) - Weather Spark. Accessed January 1, 2023. https://weatherspark.com/y/149312/Average-Weather-at-Seoul-South-Korea-Year-Round#Figures-WindSpeed.

- “South Korea Air Quality Index (AQI) and Air Pollution Information.” IQAir. Accessed January 1, 2023. https://www.iqair.com/south-korea.

- Meteorological Data Open Portal (기상자료개방포털). Korea Meteorological Administration. Accessed January 3, 2023. https://data.kma.go.kr/cmmn/main.do.

- Climate Lab, Seoul National University (서울대 기후연구실). Accessed January 3, 2023. https://climatelab.snu.ac.kr/.

- Park, Sowoo, Doosam Song. 2021. “Effect of indoor concentration level on uncertainty in infiltration rate estimation using tracer gas decay method.” 대한설비공학회 2021 동계학술발표대회 논문집: 12~15.

- MOTIE. 2020. Regulations on rationalization of energy use in public buildings (공공기관 에너지이용 합리화 추진에 관한 규정). Ministry of Trade, Industry and Energy. Seoul, South-Korea.

- MOE. 2020. Master plan for indoor air quality (실내공기질 관리 기본계획). Ministry of Environment. Seoul, South Korea.

Figure 1.

(a) Site plan and floor plan of the test room; (b) Arrangement of small circular openings in the test room.

Figure 1.

(a) Site plan and floor plan of the test room; (b) Arrangement of small circular openings in the test room.

Figure 2.

Elevation plan and section plan of the west wall in the test room.

Figure 2.

Elevation plan and section plan of the west wall in the test room.

Figure 3.

(a) Ventilation case 1: when all the windows are closed to estimate infiltration rate; (b) Closed circular openings; (c) Ventilation case 2: when four circular openings are open to estimate ventilation rate, including infiltration (d) Opened circular openings.

Figure 3.

(a) Ventilation case 1: when all the windows are closed to estimate infiltration rate; (b) Closed circular openings; (c) Ventilation case 2: when four circular openings are open to estimate ventilation rate, including infiltration (d) Opened circular openings.

Figure 4.

Location of air-quality monitors and occupants in the test room.

Figure 4.

Location of air-quality monitors and occupants in the test room.

Figure 5.

Terms about periods and intervals of measurement and estimation.

Figure 5.

Terms about periods and intervals of measurement and estimation.

Figure 6.

Indoor air quality and outdoor weather condition during an occupied period in the test room on August 11, 2022.

Figure 6.

Indoor air quality and outdoor weather condition during an occupied period in the test room on August 11, 2022.

Figure 7.

Decay of indoor CO2 concentration and indoor and outdoor air qualities during an unoccupied period in the test room on August 11, 2022.

Figure 7.

Decay of indoor CO2 concentration and indoor and outdoor air qualities during an unoccupied period in the test room on August 11, 2022.

Figure 8.

Decays of indoor CO2 concentration during unoccupied periods when all the windows were closed (ventilation case 1).

Figure 8.

Decays of indoor CO2 concentration during unoccupied periods when all the windows were closed (ventilation case 1).

Figure 9.

Decays of indoor CO2 concentration during unoccupied periods when four circular openings were open (ventilation case 2).

Figure 9.

Decays of indoor CO2 concentration during unoccupied periods when four circular openings were open (ventilation case 2).

Figure 10.

The effect of temperature differences on estimated infiltration rates.

Figure 10.

The effect of temperature differences on estimated infiltration rates.

Figure 11.

The effect of temperature differences on estimated infiltration rates.

Figure 11.

The effect of temperature differences on estimated infiltration rates.

Figure 12.

The effect of temperature differences on estimated ventilation rates, including infiltration, when four circular openings on one side were open.

Figure 12.

The effect of temperature differences on estimated ventilation rates, including infiltration, when four circular openings on one side were open.

Figure 13.

The effect of wind speeds on estimated ventilation rates, including infiltration, when four circular openings on one side were open.

Figure 13.

The effect of wind speeds on estimated ventilation rates, including infiltration, when four circular openings on one side were open.

Figure 14.

Daily mean of estimated infiltration and ventilation rates in different seasons.

Figure 14.

Daily mean of estimated infiltration and ventilation rates in different seasons.

Figure 15.

Comparison of mean infiltration and ventilation rates of each season and design ventilation rates by various standards.

Figure 15.

Comparison of mean infiltration and ventilation rates of each season and design ventilation rates by various standards.

Table 1.

Mandate ventilation rates in new buildings in accordance with Korean regulations (according to Standards for Facilities of Buildings and School Health Act).

Table 1.

Mandate ventilation rates in new buildings in accordance with Korean regulations (according to Standards for Facilities of Buildings and School Health Act).

| Building use and size |

Mandate ventilation rates |

| l/s per person |

m3/h per person |

ACH (m3/h·V) |

| Office buildings over 3000 m2 of floor area |

8.2 |

29 |

|

| Exhibition halls or wedding halls over 2000m2 of floor area |

8.2 |

29 |

|

| Supermarkets or shopping centers over 3000m2 of floor area |

8.2 |

29 |

|

| Medical facilities over 2000m2 of floor area or with more than 100 sickbeds |

10 |

36 |

|

| Schools |

6 |

21.6 |

|

| Apartments over 50 households |

|

|

0.5 |

Table 2.

Design ventilation rates for a five-person office with a floor area of 84m2 in a low-polluting building (non-adapted person) calculated by Method 1 in EN 16789-1.

Table 2.

Design ventilation rates for a five-person office with a floor area of 84m2 in a low-polluting building (non-adapted person) calculated by Method 1 in EN 16789-1.

| Cate- gory |

Expected

percentage

dissatisfied |

Design ventilation rate for sedentary, adults, non- adapted persons for diluting bio effluents (a) |

Design ventilation rate for diluting emissions from low polluting building, LPB-2 (b) |

Total design ventilation rate for the room

= a × number of occupants + b × floor area |

| % |

l/s per person |

l/s·m2

|

l/s |

m3/h |

ACH (m3/h·V) |

| I |

15 |

10 |

1.0 |

134 |

482.4 |

2.05 |

| II |

20 |

7 |

0.7 |

93.8 |

337.68 |

1.44 |

| III |

30 |

4 |

0.4 |

53.6 |

192.96 |

0.82 |

| IV |

40 |

2 |

0.3 |

37.7 |

135.7 |

0.58 |

Table 3.

Maximum CO2 concentrations calculated by Method 2 in EN 16789-1.

Table 3.

Maximum CO2 concentrations calculated by Method 2 in EN 16789-1.

| Category |

Expected

percentage

dissatisfied |

Maximum CO2 concentrations in a room located in Seoul |

| % |

ppm |

| I |

15 |

990 1

|

| II |

20 |

1240 1

|

| III |

30 |

1790 1

|

| IV |

40 |

1790 1

|

Table 4.

Predefined design ventilation rates for a five-person office with a floor area of 84m2 (non-adapted person) calculated by Method 3 in EN 16789-1.

Table 4.

Predefined design ventilation rates for a five-person office with a floor area of 84m2 (non-adapted person) calculated by Method 3 in EN 16789-1.

| Cate- gory |

Expected

percentage

dissatisfied |

Total design ventilation air flow rate per person for an office (a) |

Total design ventilation air flow rate per floor area for an office (b) |

Total design ventilation rate for the room

= Max (a × number of occupants; b × floor area |

| % |

l/s per person |

l/s m2 |

l/s |

m3/h |

ACH (m3/h·V) |

| I |

15 |

20 |

2 |

168 |

604.8 |

2.58 |

| II |

20 |

14 |

1.4 |

117.6 |

423.36 |

1.80 |

| III |

30 |

8 |

0.8 |

67.72 |

243.79 |

1.04 |

| IV |

40 |

5.5 |

0.55 |

46.2 |

155.52 |

0.66 |

Table 5.

Ventilation rate required in the breathing zone of the occupiable space calculated by Ventilation Rate Procedure in ASHRAE Standard 62.1.

Table 5.

Ventilation rate required in the breathing zone of the occupiable space calculated by Ventilation Rate Procedure in ASHRAE Standard 62.1.

Occupancy

category |

Minimum ventilation rates in breathing zone depending on people |

Minimum ventilation rates in breathing zone depending on floor area |

The outdoor airflow required

in the breathing zone

= a × number of occupants + b × floor area |

| l/s per person |

l/s m2 |

l/s |

m3/h |

ACH (m3/h·V) |

| Office buildings - office space |

2.5 |

0.3 |

37.7 |

135.72 |

0.58 |

Table 6.

Comparison of limit values of CO2 concentration in regulations and guidelines pertinent to indoor environments in Indoor Air Quality Procedure in ASHRAE Standard 62.1.

Table 6.

Comparison of limit values of CO2 concentration in regulations and guidelines pertinent to indoor environments in Indoor Air Quality Procedure in ASHRAE Standard 62.1.

Air

contaminants |

Enforceable and/or regulatory levels |

Non-enforced guidelines and reference levels |

| NAAQS/ EPA |

OSHA |

MAK |

Canadi- an |

WHO/ Europe |

NIOSH |

ACGIH |

| Carbon dioxide |

- |

5000 ppm |

5000 ppm |

3500 ppm |

- |

5000 ppm |

5000 ppm |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).