1. Introduction

The peculiarities of nutrition and health of modern man oblige to develop research to meet his needs in food of a special composition, contribute to the expansion of the range of food products, cause the need to search for new types of biologically active raw materials [

1,

2].

Sumac (Rhus coriaria L.) - this shrub is found in the mountain forests of the North Caucasus and Transcaucasia, as well as in the mountainous part of the Crimea. In the Republic of Azerbaijan, it can be found in the mountain forests of Lenkaran, Geokchay, Zakatala and Guba districts.

This plant from the Anacardiaceae family is a shrub 2-7 m high. Sumac differs in polymorphism within Azerbaijan. The flowers are heterogeneous, small, greenish - white. The fruit (reaching 5-6 mm in diameter) is a small spherical or kidney-shaped single-seeded drupe, red-brown on the outside, densely pubescent with glandular hairs.

It differs from other species of this family in that it is used directly for food [

3]. In recent years, the use of Rhus coriaria L. (sumac) has been improved not only in cooking and human nutrition, but also in the pharmaceutical, food industry and veterinary medicine. This is due to the accumulation of evidence confirming the ethnobotanical use of this plant; in particular, advanced knowledge about the content of food, medical and functional bioactive ingredients [

4,

5].

It is almost never sold in the form of whole fruits - usually it is a ready-made coarse-grained powder of a beautiful purple-red or purple-pink color. It tastes sour, a little astringent. Its main exporters are Iran and Syria [

6]. There is a growing interest in the use of this important seasoning in medicine and the food industry [

7]. Its aqueous extract has a strong antibacterial and antifungal effect [

8]. This plant is traditionally used in the treatment of diabetes mellitus [

9], stroke and cancer [

10,

11], diseases of the gastrointestinal tract [

12], arterial hypertension [

13]. It is recommended to use it at high temperatures [

3]. Consumption of sumac can provide protection against atherosclerosis [

14]. The antioxidant effect of sumac is 50 times stronger than that of vitamins C and E [

15].

Even with the naked eye, it can be seen that sumac fruits are rich in pigments – anthocyanins, which, by the way, are characterized by high antioxidant activity and are effective for the prevention of esophageal and colon cancer. These effects of anthocyanins are determined by their structure, bioavailability and metabolism [

16].

Anthocyanins usually give purple, blue, brown, red, orange color to various plant organs. This coloration often depends on the pH of the cell contents and, therefore, may change with increasing flowering and maturation. They are secondary metabolites. They are approved for use as food additives (E-163i) belonging to the group of water-soluble natural food dyes.

The main disadvantage of anthocyanin dyes is the color change when the pH of the medium changes. Their other disadvantages are low coloring ability and instability, both in pure form and in the products in which they are used. The raw materials for them are usually berries or their pulp - seasonal, rapidly spoiling raw materials, which makes the process of obtaining dyes multi-stage and technically complex and expensive financially.

All this prompted us to conduct a study aimed at obtaining a natural dye from sumac fruits with a high content of storage-resistant coloring substances, the production of which can be carried out in any required amount, regardless of the time of year, seasonality and any other factors.

3. Results and discussion

The efficiency of the extraction process depends on such basic technological factors as the extraction temperature and time, the degree of grinding of raw materials, the type of solvent, the hydromodule (the ratio between raw materials and solvent); rational parameters, modes, conditions established experimentally are characteristic for each type of raw material.

To select the optimal solvent, experiments were carried out, which showed that when the sumac pieces were treated with water and aqueous solutions of ethyl alcohol, the extract became yellowish-white and cloudy to such an extent that it resembled a suspension.

An aqueous solution of citric acid with a concentration of 0.3 g/cm3 was chosen as the most suitable solvent devoid of these disadvantages.

The use of an aqueous solution of citric acid with a concentration higher than 0.3 g /100 cm3 as a solvent practically did not affect the concentration of coloring substances and the transparency of extracts.

It was found that the optimal degree of grinding is to obtain pieces of sumac 1-3 mm in size, and extraction is better carried out in two stages with the separation of the extract from the first stage. The double maceration method proved to be effective in the sense that it allows to significantly increase the degree of extraction of soluble components of raw materials, that is, to reduce their losses.

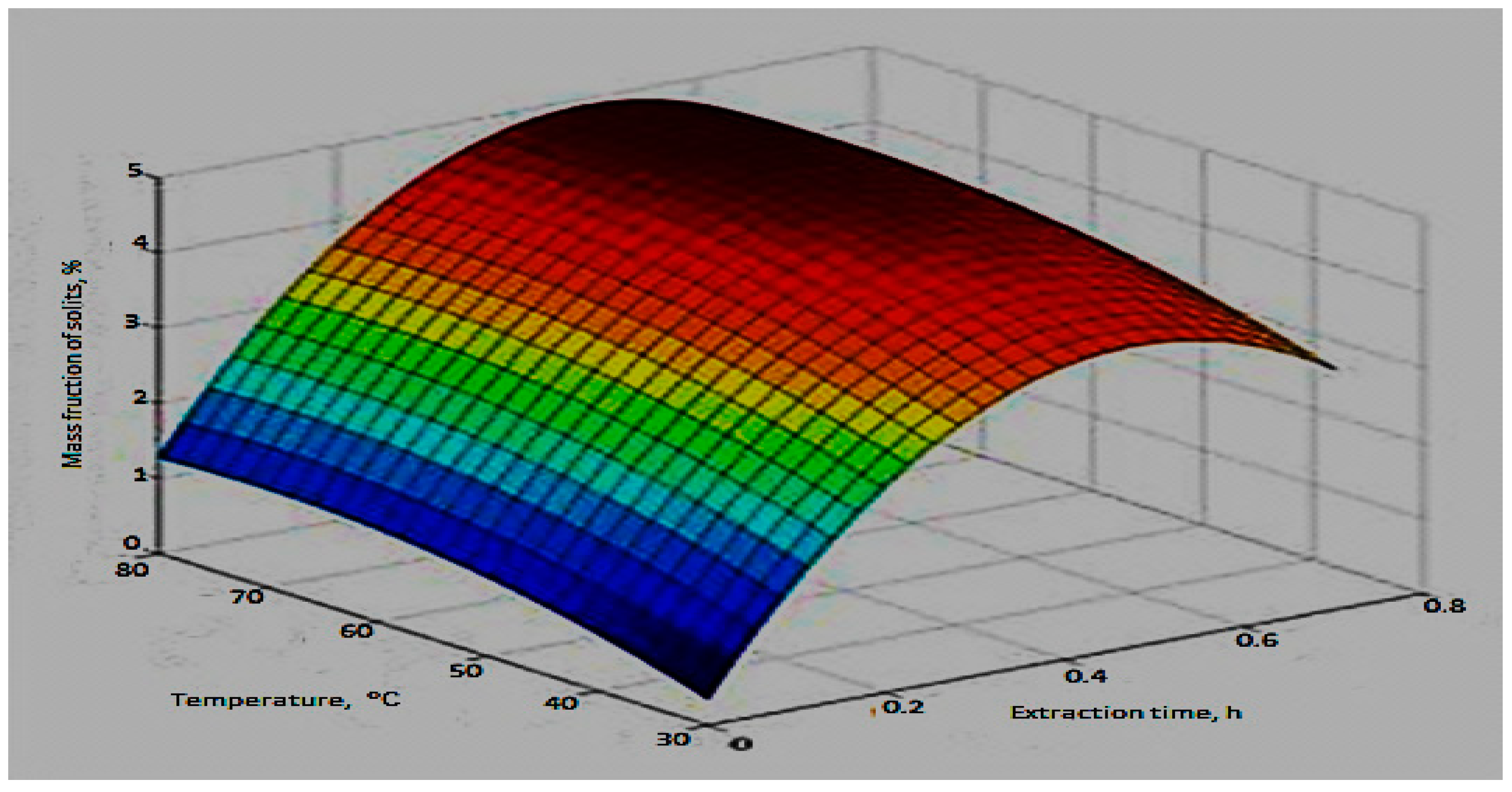

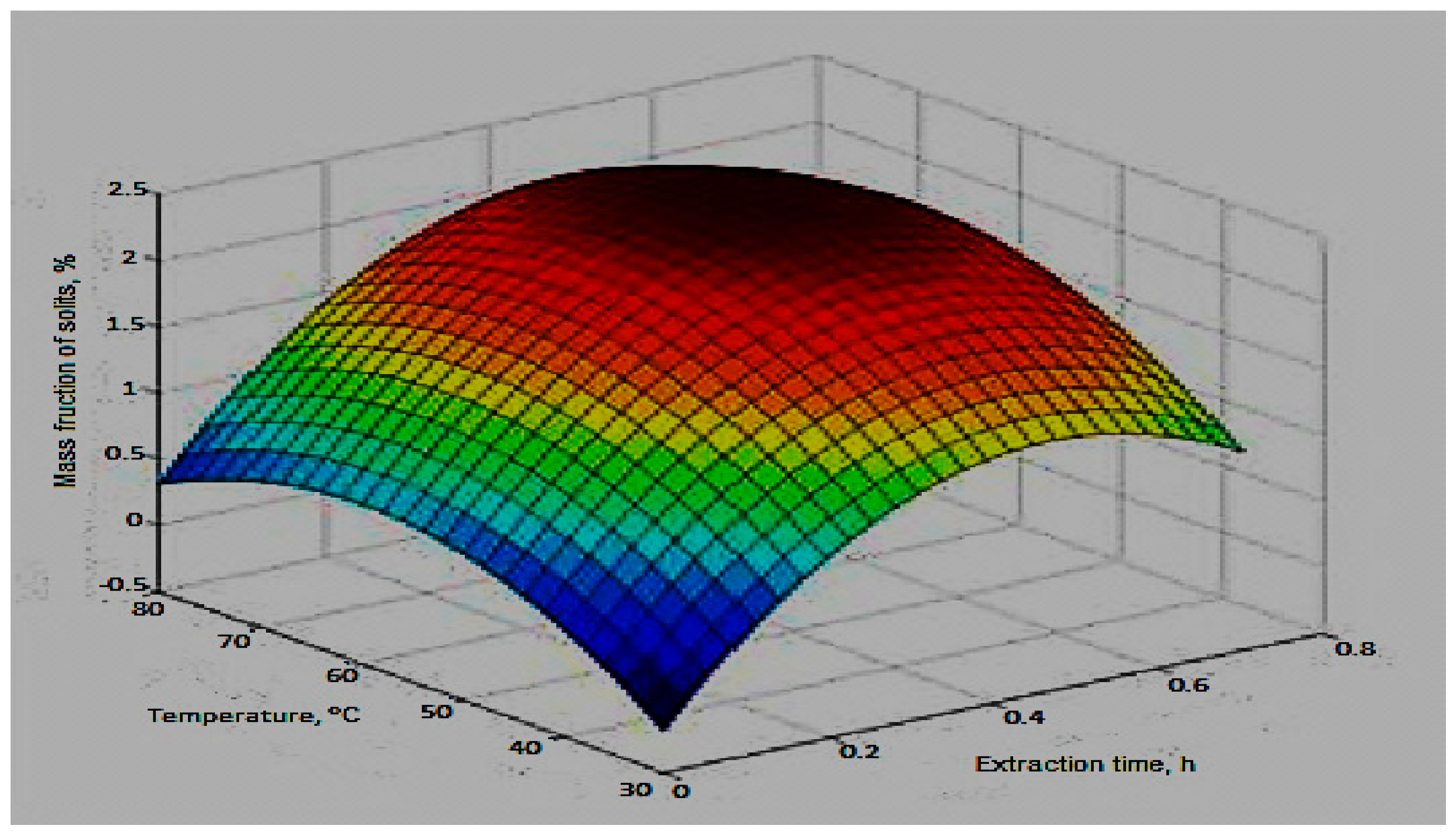

Mathematical models of sumac fruit extraction are expressed in the form of polynomial equations of the second degree 1 and 2, where

F (x, y) is a function of the content of soluble solids, %;

x is the duration of extraction, hour;

y is the solvent temperature, ºC.

The absolute error for mathematical models ranged from 2.2 to 4.2%.

Based on a series of experiments, a graphical interpretation of the dependence of the mass fraction of solids (%) in extracts on two variables was obtained: temperature and extraction time was obtained (

Figure 1 and

Figure 2).

According to the results of the experiments, the optimal modes of obtaining red food dye from sumac fruits were obtained: extraction time of 1 hour (30 minutes in each stage); temperature of 75-80o C; the degree of grinding of raw materials 3.0-4.0 mm; In the first stage of extraction, the mass ratio between the raw material and the solvent is 1:8, in the second -1:4.

The specified ratio between the raw material and the solvent is chosen so that, on the one hand, it is possible to extract from the raw material as many components of a hydrophilic nature as possible, and on the other - there would be no strong dilution of the extracts, which after separation are evaporated under vacuum. This is also due to the need to create an environment with a pH of 3.2-3.5. In a less acidic or neutral environment, diffusion processes occur at a much lower rate.

The absolute error for mathematical models varied from 2.2 to 4.2%.

Based on a series of experiments, a graphical interpretation of the dependence of the percentage of dry matter in the total mass of the formed extract on the temperature and duration of the process was obtained (

Figure 1 and

Figure 2).

According to the results of the experiments, optimal extraction modes were obtained: total time 1 hour (30 minutes each stage); temperature 75-80 ° C; degree of grinding of sumac 1--3 mm; pH 3.2-3.5; ratio between raw materials and solvent 1:8 (first stage) and 1:4 (second stage).

Under these conditions, it is possible to extract 90-92% of hydrophilic substances from their total quantitative content in the initial object (38 wt. %). Deviation from the optimal regime led to undesirable consequences, such as a decrease in the utilization rate of raw materials or dilution of extracts, which was unacceptable given the direction we chose for further processing of extracts.

For drying sumac fruits, a temperature of 60-55 ° C is selected, at which the raw material is quickly dehydrated. Experiments have shown that drying this raw material at higher temperatures activates the process of decomposition of anthocyanins. Drying sumac fruits at temperatures below 55 ° C increases the drying time, and this has a bad effect on its time.

Also, the extraction efficiency depended on the degree of destruction of the cellular structure of the object under study. For this purpose, grinding of the product was used.

The range of grinding of raw materials (with a residual humidity of 10-8 wt. %) was determined experimentally. Experiments have shown that the degree of grinding should be 1-3 mm; with a lower or higher degree of grinding, the passage of diffusion processes becomes difficult or their speed decreases.

In extracts from the first and second stages of maceration, the concentrations of dry substances were 4= 0.1 and 2= 0.2 wt. %, respectively.

Upon completion of extraction, the extracts were filtered under pressure; then they were evaporated.

Evaporation to the desired consistency should be carried out under vacuum at a temperature of 50-60 ° C and a vacuum of 80-87 kPa (600-650 mm Hg). Too long evaporation led to an increase in the amount of degraded anthocyanins, so the process was carried out until a concentration of dry soluble substances of 30-31% was reached.

With such a degree of concentration, the product is stored for a short time; therefore, it was packed in glass bottles with a capacity of 50 ml, pasteurized for 5 minutes at 65 ° C and quickly cooled under a tap to room temperature.

In factory conditions, sumac extraction can be carried out in conventional vertical-type extractors with heating and a filter bottom to which a drain tap is attached. It is important that the separation of the formed extracts occurs quickly. To accelerate filtration, vacuum filtration (suction by a water jet pump) can be used - a method of filtering liquids, in which the difference between atmospheric pressure outside the filtrate receiver and artificially reduced pressure inside it promotes the movement of liquid through the filter element.

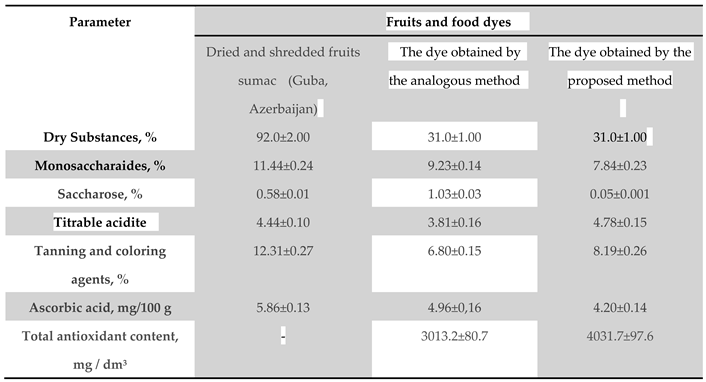

Table 1.

The chemical composition of the feedstock and the target products obtained in two ways.

Table 1.

The chemical composition of the feedstock and the target products obtained in two ways.

Anthocyanins are preserved better in glass vials than in lacquered aluminum vials. This is due to the fact that during prolonged storage of the concentrate in the lacquered coating of aluminum vials, micro-cracks form through which anthocyanins come into contact with metal. This opens the way to the formation of chelate complexes of dark blue color.

The table shows the chemical composition of dried and crushed sumac fruits and food dyes, one of which was obtained by our proposed method (using an aqueous solution of citric acid with a concentration of 0.3 g/100 cm3 as a solvent), and the other using an aqueous solution of ethyl alcohol with a concentration of 20 g/100 cm3 as a solvent (according to the analog method). It shows that in the dye obtained by the analog method, the content of tannins and coloring substances is 6.80 ± 0.15% of its total crude mass and this is significantly lower than that of the dye obtained by the proposed method (8.1 ± 0.26 g / 100 g).

It is also seen that the dye according to the analog method contains a little more vitamin C than the dye obtained by our method. This is due to the fact that alcohol, which was in the composition of the solvent used in the analog method, is removed from the extracts faster than water, which somewhat reduces the time required for their concentration. As the heat treatment time increases, the amount of degraded vitamin C also increases. But this did not affect the biological value of the dye manufactured according to the proposed method, the main advantage of which is a higher quantitative content of antioxidants of phenolic nature. As can be seen, the dye obtained by the technology developed by us has such a high content of coloring and tannins (8.19 ± 0.26% of its raw weight) and such a high antioxidant activity (4031.7 ± 107.6 mg/dm3) that it can be used as a means of botanical therapy.

In the total mass of the dry matter of the dye obtained using the solvent chosen by us, phenolic compounds accounted for 27.33 wt. %, monosaccharides – 26.13 wt. %, organic acids – 15.93 wt. %.

The dye is a transparent thick liquid of dark red color, completely soluble in water and aqueous solutions of ethyl alcohol, with the smell of fresh sumac, a slightly tart sour taste. It can be used for coloring slightly sweet (with a pH of 5-6) and sweet-sour (with a pH of 4 or lower) drinks in red-pink tones of varying intensity at a concentration of 700 - 1000 parts per million (0.7-1 g /l).

The special biological value of water extracts of sumac fruits can be associated with a high content of

It can be seen from the published literature that aqueous extracts of sumac fruits contain delphinidin (delphinidin 3 –glucoside) and some cyanidin glycosides (cyanidin 3-glucoside, cyanidin 3 (2 galloyl) galactoside, 7-methylcyanidin 3 galactoside and 7-methylcyanidin 3 (2 galloyl) galactoside). galactoside), organic substances and mineral salts [

18]. They contain gallic acid derivatives in large quantities and, according to their characteristics, are suitable raw materials for the manufacture of medical microcapsules using spray drying [

19].

The optical density of solutions from dilution of food coloring is highest at a wavelength of 505-515 nm. Cyanidin glycosides are known to have a blue color in an alkaline medium and red in an acidic one. Delphinidine always has a slightly blue and blue color, and turns red only when methylated. The combination of these anthocyanins allows the dye to be used in the production of drinks with a rich range of red shades, provided that their pH does not exceed 6 (at pH 7 and above, the red color disappears).

The developed dye is an acidified natural sumac extract. The presence of a large number of hydrophilic biologically active compounds allows it to be used in the technology of functional beverages.

In Azerbaijan, the market price of 1 kg of dry ground sumac is 7-8 dollars; the yield of the dye developed by us (specific gravity 1.3-1.14) is 116 kg / 100 kg of air-dried sumac fruits.

This suggests that the proposed technology is very promising in terms of the available opportunities for its commercialization. It should also be borne in mind that the modern stage is characterized by an ever-growing demand for natural products, which is associated with the deterioration of the environmental situation.

Thus, this study showed that sumac fruit extracts containing natural bioactive substances with numerous beneficial effects are a very suitable alternative to synthetic food dyes.