Submitted:

12 February 2023

Posted:

20 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

- Local sources of fine aggregates are surveyed, and samples are obtained for ASR detection

- Accelerated mortar bar test for ASR detection of fine aggregates are conducted. Expansion of mortar bars is measured and compared with permissible limits

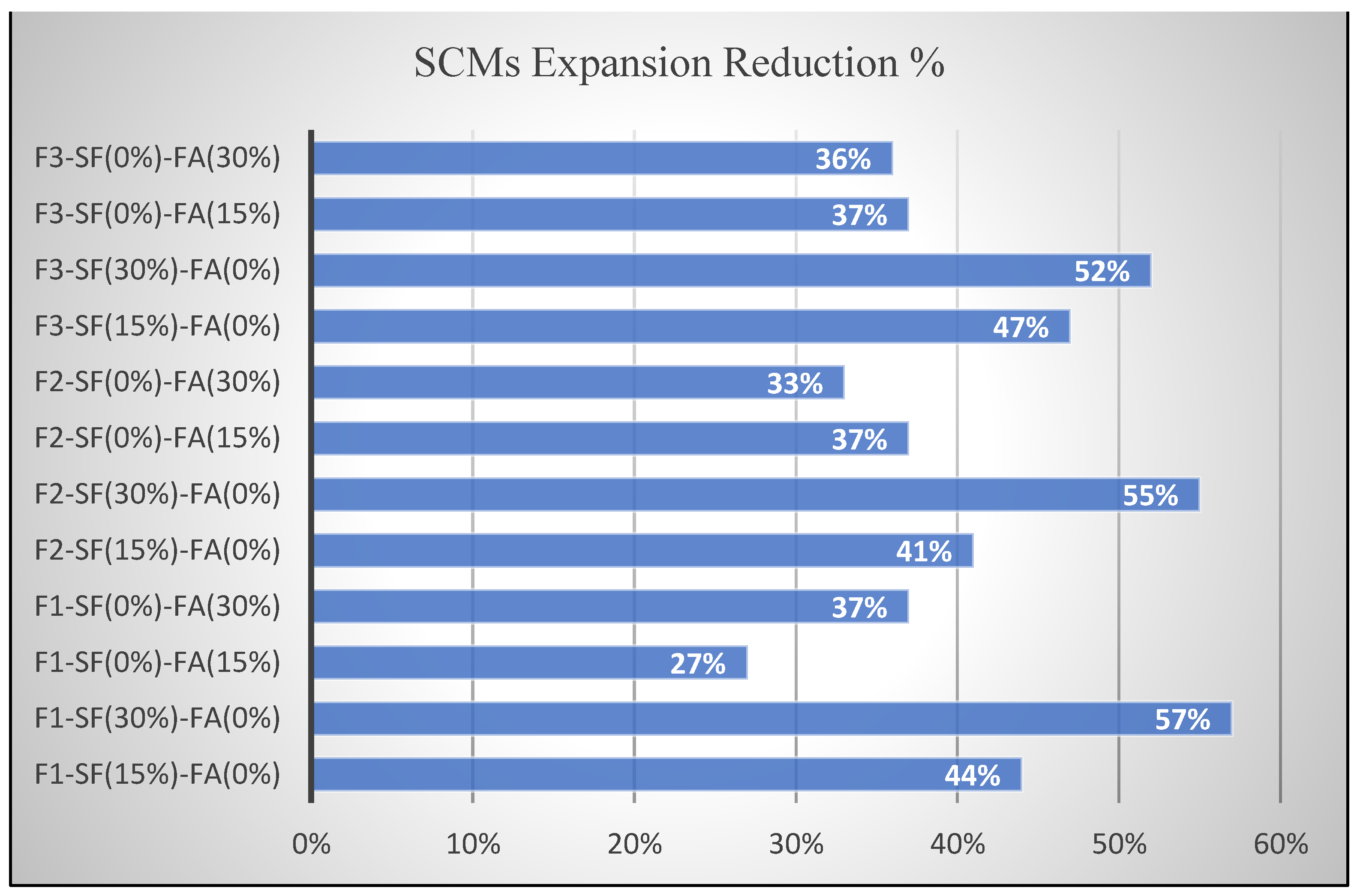

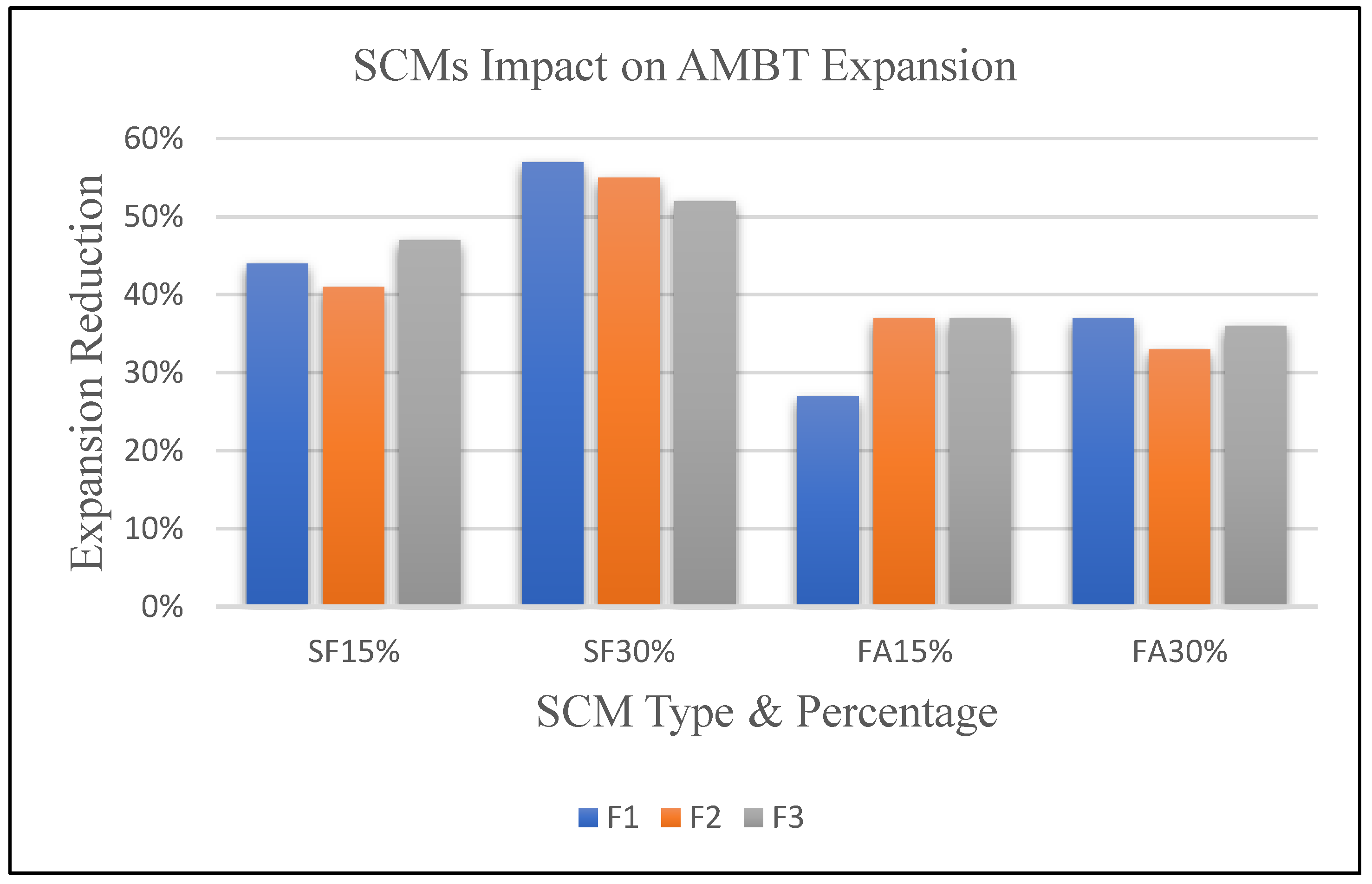

- Different percentages of SCMs, including micro-silica and class c fly ash are used to pour additional mortar bars for expansion measurements

- Efficiency of SCMs in ASR mitigation is quantified through the decrease in bars expansion

3. Experimental Investigation

- Phase 1: Accelerated Mortar Bar Test (AMBT) for ASR of Fine Aggregates

- Mortar Bar Preparation

- Type I/II portland cement was used in pouring AMBT specimens. The same cement batch is used in the preparation of all specimens to ensure the consistency of test results

- Fine aggregate specimens (F1, F2, and F3) were used to pour the mortar bars. Three bars were poured using the same aggregate sample

- SCM-free AMBT were poured using high energy paddle mixer using a cement-to-aggregate ratio of 1 : 2.25 by weight

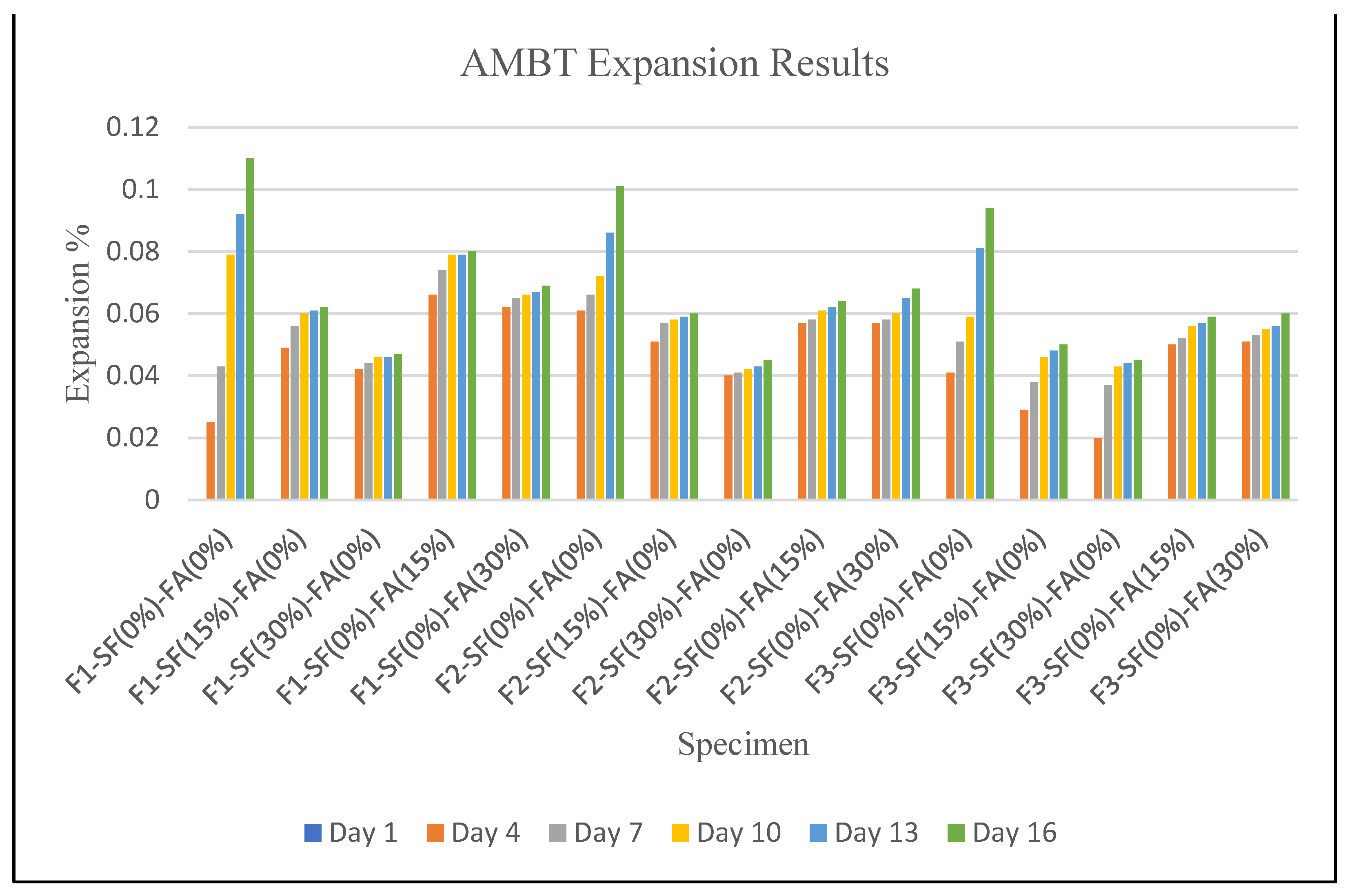

- SCMs including micro-silica, class c fly ash, were used to pour additional mortar bars. SCMs are used in stepwise replacement of portland cement using a 1 : 1 weight ratio. Mortar bars design combinations are shown in Table 2.

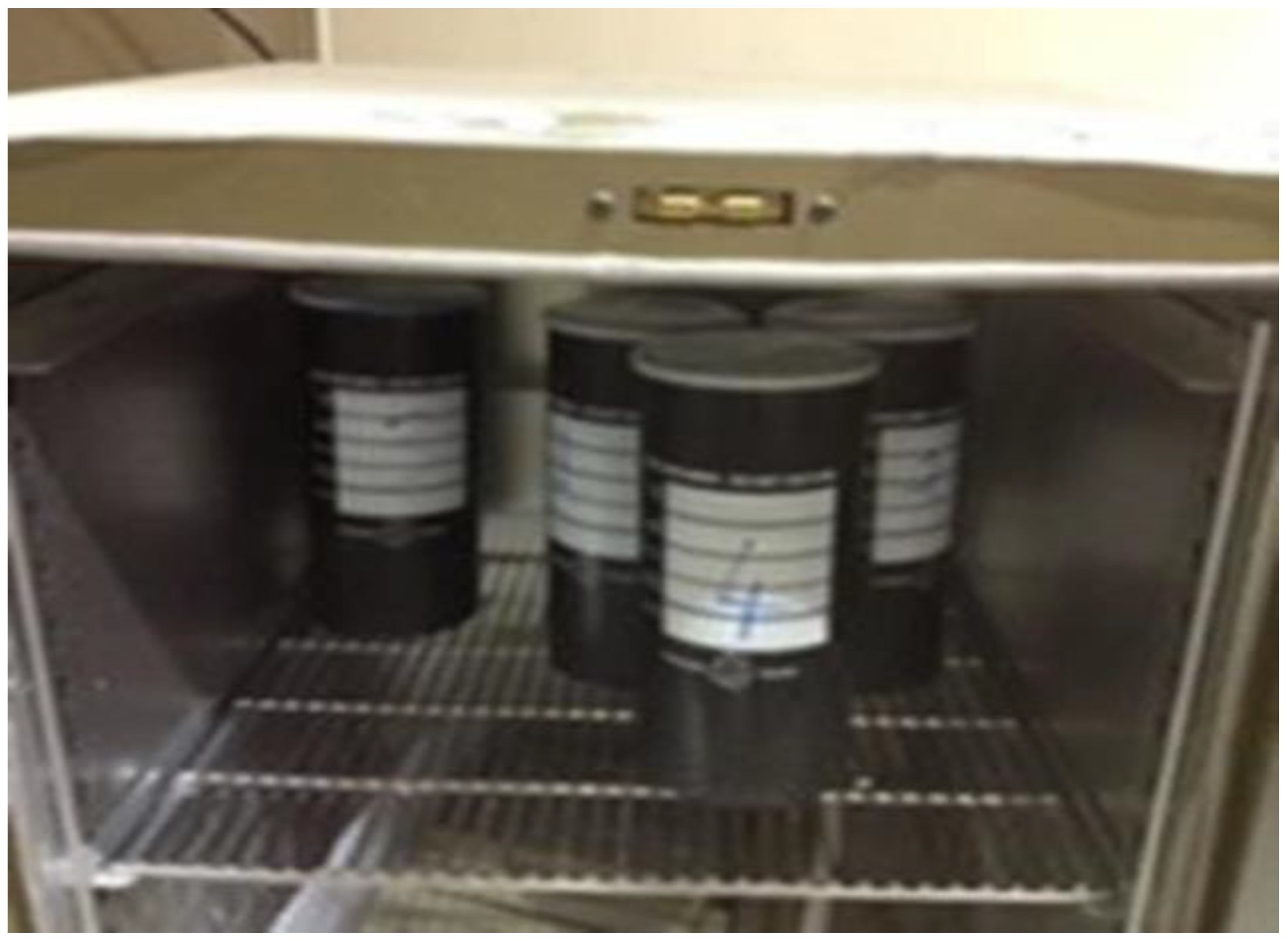

- Mortar Bar Fabrication, Storage, and Expansion Measurements

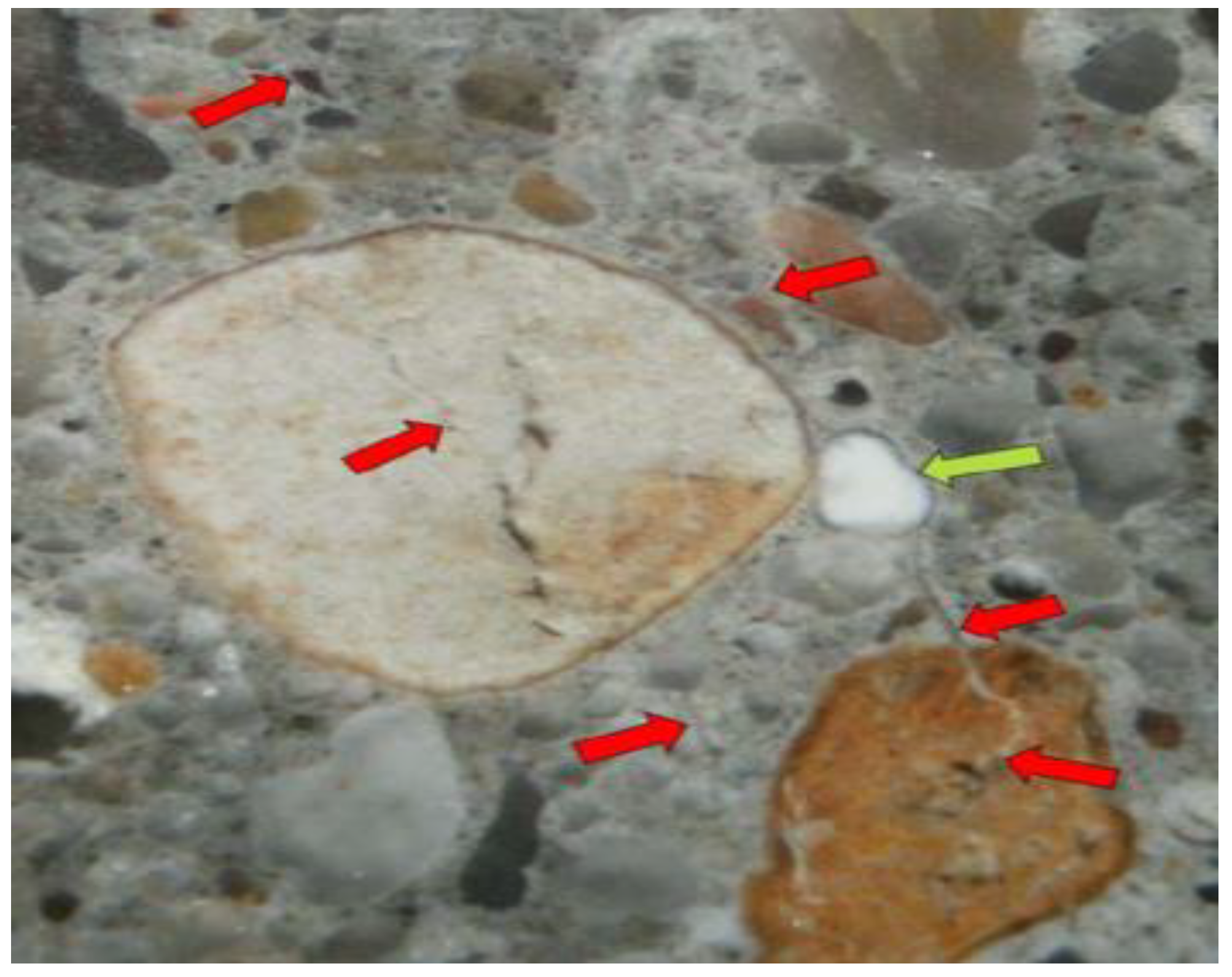

- Fine Aggregates Reactivity

- Phase II: Impact of Supplementary Cementitious Materials on ASR Expansion

- SCMs have a fine particle size as compared to all granular mix constituents. The fine particle size results in an improved packing order of the mix constituents and a decreased void’s ratio. This lowers the rate of moisture ingress and reduces the rate of reactivity

- SCMs result in a lower cement content, which reduce the alkaline content of the mix, and significantly reduce the alkali-silica reactivity within the mix

- The incorporation of SCMs in concrete mix binds the alkaline content during the cement hydration process which reduces the pH value of the mix and slow down the deleterious ASR

4. SUMMARY AND CONCLUSIONS

5. Recommendations for Future Research

References

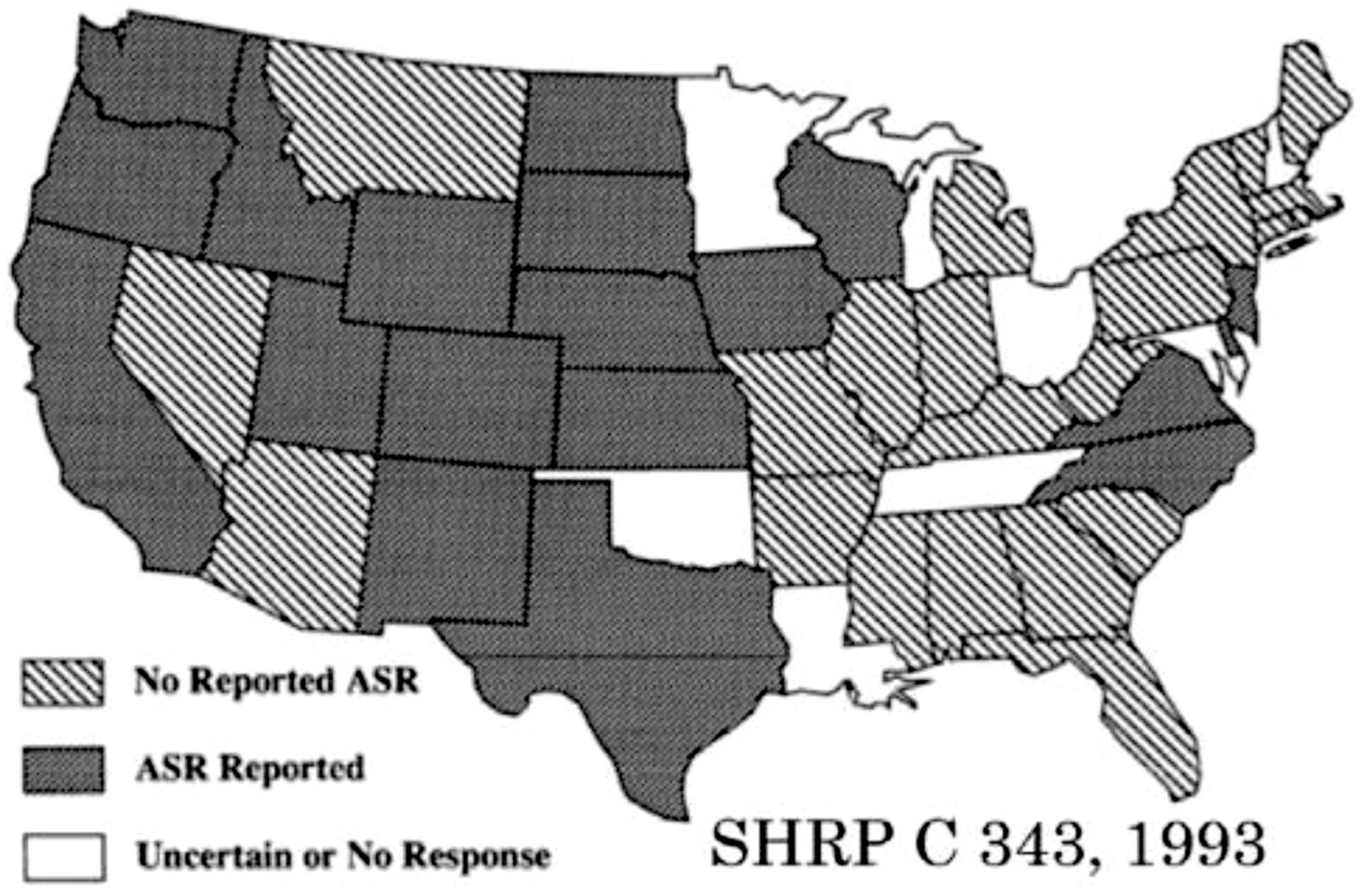

- Stark, D. Handbook for the identification of alkali-silica reactivity in highway structures. SHRP-C/FR-91-101, TRB National Research Council, 1993, 49p.

- FHWA, Guidelines for the use of lithium to mitigate or prevent alkali-silica reaction (ASR). Federal Highway Administration Report No.: FHWA-RD-03-047.

- Stanton, T. E. Expansion of concrete through reaction between cement and aggregate. Proceedings American Society of Civil Engineers, 1940, 66(10), 1781-1811.

- Xu, H. On the alkali content of cement in AAR. Proceedings of the 7th International Conference in Concrete Alkali-Aggregate Reactions, New Jersey, 1987, pp. 451-455.

- Poole, A.B. Introduction to alkali-aggregate reaction in concrete. The Alkali-Silica Reaction in Concrete, edited by Swamy, R.N., Van Nostrand, R, New York. 1992. [Google Scholar]

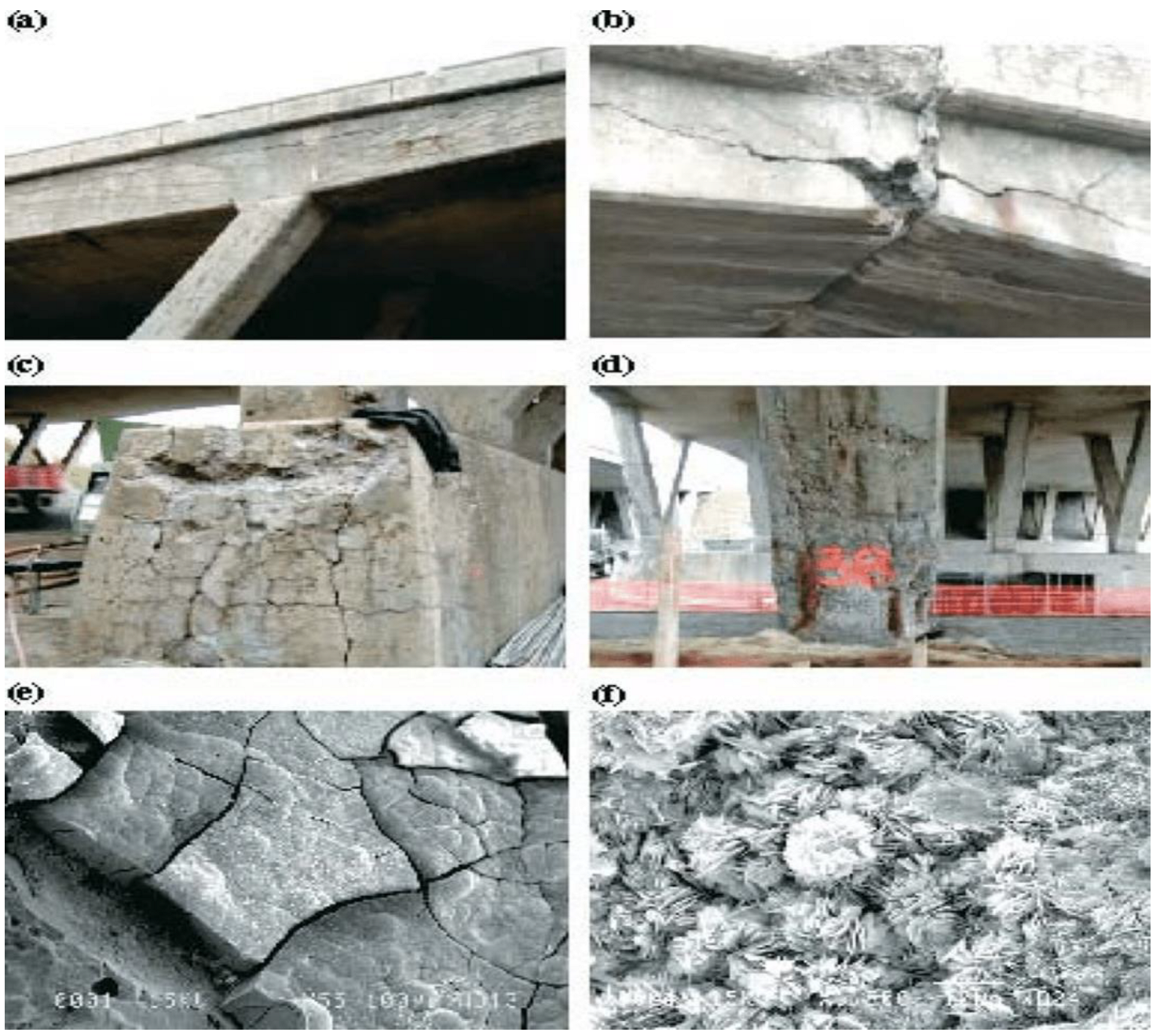

- Moreira, K.M.d.V., Oliveira, P.V.G., de Deus, E.P., and Cabral, A.E.B. Alkali-silica reaction: understanding the phenomenon. Journal of Building Pathology and Rehabilitation, 2021, Vol. 6, No. 5.

- Abbas, S., Ahmed, A., Nehdi, M., Saeed, D., Abbas, W., and Amin, F. Eco-friendly mitigation of alkali-silica reaction in concrete using waste marble powder. ASCE Journal of Material in Civil Engineering, 2020, Vol. 31.

- Deschenes, Jr., R., and Hale, W. Alkali-silica reaction (ASR) in concrete with previously inert aggregates. ASCE Journal of Performance of Constructed Facilities, 2017.

- Deschenes, Jr., R., and Hale, W. Alkali-silica reaction mitigation and prevention measures-phase I. Arkansas Department of Transportation and Mack Blackwell Rural Transportation Center, 2017, 86 pp.

- Folliard, K.J., Thomas, M.D.A., Fournier, B., Resendez, Y., Drimalas, T., & Bentivegna, A. Evaluation of mitigation measures applied to ASR-affected concrete elements: preliminary findings from Austin, TX Exposure Site. Proceeding of the 14th International Conference on Alkali Aggregate Reaction (ICAAR), Austin, Texas, 2012.

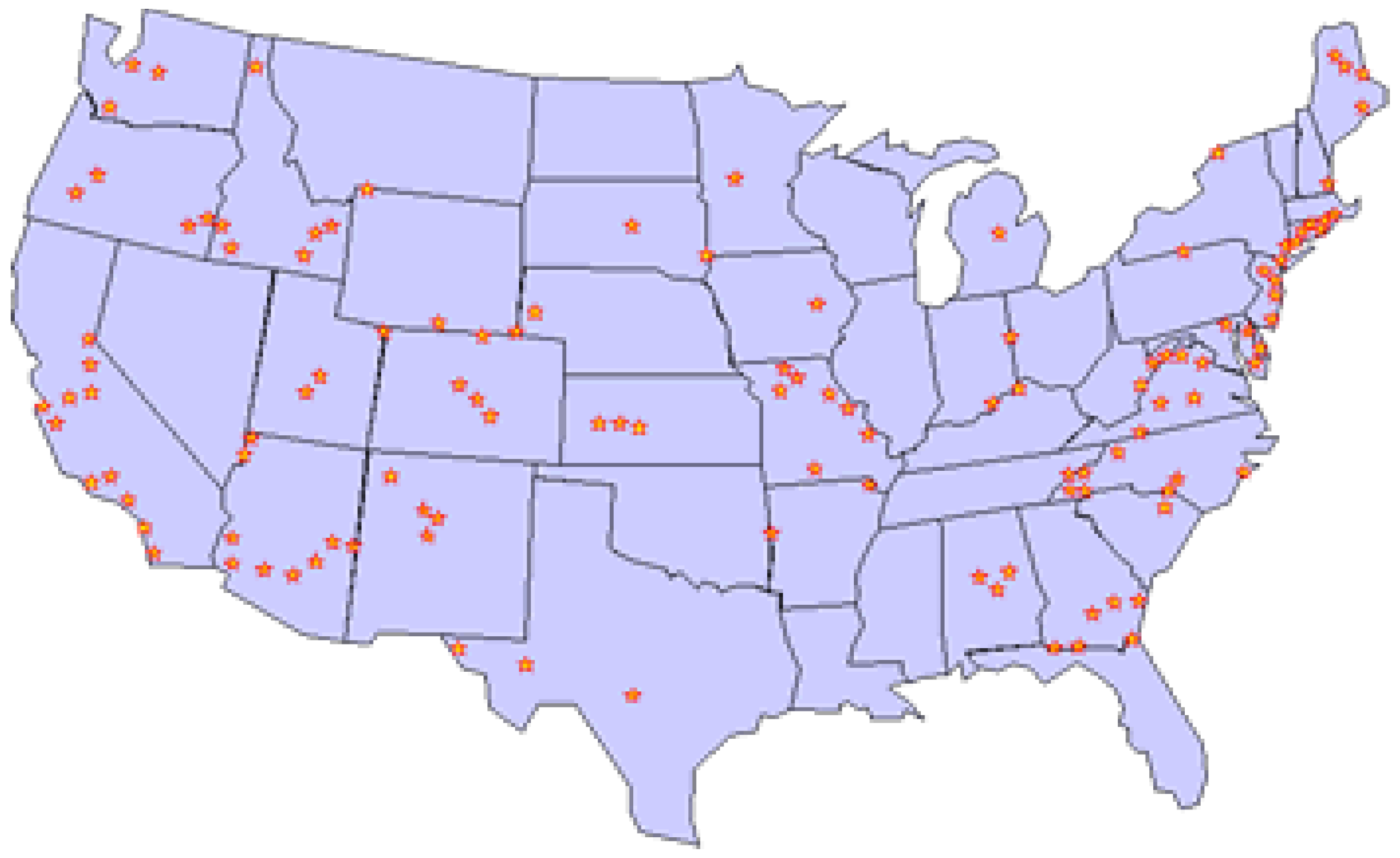

- Akhnoukh, A.K., and Mallu, A.R.. Detection of alkali-silica reactivity using field exposure site investigation. Proceedings of the 58th Annual Associated Schools of Construction International Conference, GA, USA, 2022.

- Akhnoukh, A.K. The use of micro and nano-sized particles in increasing concrete durability. Particulate Science and Technology Journal, 2020, Vol. 38, No. 5, pp. 529-534. [CrossRef]

- Akhnoukh, A.K. , (2013), “Overview of nanotechnology applications in construction industry in the United States,” Journal of Micro and Nano-systems, Vol. 5, No. 2, pp. 147-153.

- Akhnoukh, A.K. , Kamel, L.Z., and Barsoum, M.M., (2016), “Alkali silica reaction mitigation and prevention measures for Arkansas local aggregates,” International Journal of Civil and Environmental Engineering, Vol. 10, No. 2, pp. 95-99. [PubMed]

- Wang, W. , Noguchi, T., and Maruyama, I., (2022), “Mechanism understanding of alkali-silica reaction in alkali-activated materials system,” Cement and Concrete Research, Vol. 156, 2022. [CrossRef]

- Fanijo, E.O. , Kolawole, J.T., and Almakrab, A., (2021), “Alkali-silica reaction (ASR) in concrete structures: mechanism, effects and evaluation test methods adopted in the United States,” Case Studies in Construction Materials, Vol. 15. [CrossRef]

- Abd-Elsammd, A. , Ma, Z.J., Le Pape, Y., (2021), “Influence of mineralogical and chemical composition of AAR carbonate aggregates on the expansion rate of concrete and AAR mitigation,” Construction and Building Materials, Vol. 261. [CrossRef]

- Abd-Elsammd, A. , Ma, Z.J., L Pape, Y., Hayes, N.W., and Guimaraes, M., (2020), “Effect of alkali-silica reaction expansion rate and confinement on concrete degradation,” ACI Material Journal, Vol. 117, No. 1, pp. 265-277. [CrossRef]

- Berube, M. , Smaoui, N., Fournier, B., Bissonnette, B., and Durand, B. (2005), “Evaluation of the expansion attained to date by concrete affected by alkali-silica reaction. Part III: application to existing structures. Canadian Journal of Civil Engineering, Vol. 32, No. 3. [CrossRef]

- Fournier, B. , Berube, M., Folliard, K, and Thomas, M. (2010), “Report on the diagnosis Prognosis and Mitigation of Alkali-Silica Reaction (ASR) in Transportation Structure, FHWA-HIF-09-004, 2010.

- AASHTO-T380, (2019), “Standard method of test for potential alkali reactivity of aggregates and effectiveness of ASR mitigation measures (miniature concrete prism test, MCPT), American Association of State Highway and Transportation Officials (AASHTO).

- ASTM International, (2007), “Standard test method for potential alkali-silica reactivity of aggregates (chemical method),” ASTM International C289-07, (Withdrawn 2016).

- ASTM International, (2018), “Standard test method for determination of length change of concrete due to alkali-silica reaction,” ASTM International C1293-18 (Superseded).

- ASTM International, (2014), “Standard test method for potential alkali-silica reactivity of aggregates (mortar-bar method),” ASTM C1260-14 (Superseded).

- Li, C., Ideker, J.H., and Thomas, M.D.A. (2021), “Evaluation of current ASTM standards for ASR prevention when fine lightweight aggregates are used,” Advances in Civil Engineering Materials, Vol. 10, No. 1. [CrossRef]

- Sanchez, L.F.M. , Fournier, B., Jolin, M., Bastien, J., and Mitchel, D., (2017), “Tools for assessing damage in concrete affected by AAR coming from fine and coarse aggregates,” Rev. IBRACON Estrut. Materials, Vol. 10, No. 10. [CrossRef]

- Johnson, R. , and Shehata, M.H., (2016), “The efficacy of accelerated test methods to evaluate alkali-silica reactivity of recycled concrete aggregates,” Construction and Building Materials, Volume 112, pp. 518-528. [CrossRef]

- Thomas, M.D.A., Fournier, B., Folliard, K., Ideker, J., and Shehata, M., (2006), “Test methods for evaluating preventive measures for controlling expansion due to alkali-silica reaction in concrete,” Cement and Concrete Research, Vol. 36, No. 10, pp. 1842-1856.

- Thomas, M.D.A., Fournier, B., Folliard, K., Ideker, J., and Shehata, M., (2006), “Test methods for evaluating preventive measures for controlling expansion due to alkali-silica reaction in concrete Report No. ICAR 302-1,” International Center for Aggregate Research (ICAR), Austin, Texas, 62 pp.

- Davis, D.E., Deschenes Jr., R., and Hale, W., (2018), “Development of a field exposure site for predicting and mitigating ASR,” Final Report: Arkansas Department of Transportation TRC 1401, Little Rock, Arkansas.

- Thomas, M.D.A., Fournier, B., Folliard, K., Ideker, J., and Resendez, Y., (2011), “Alkali-silica reactivity field identification handbook (Report No. FHWA-HIF-12-022),” Federal Highway Administration, U.S. Department of Transportation, Washington, D.C., 80 pp.

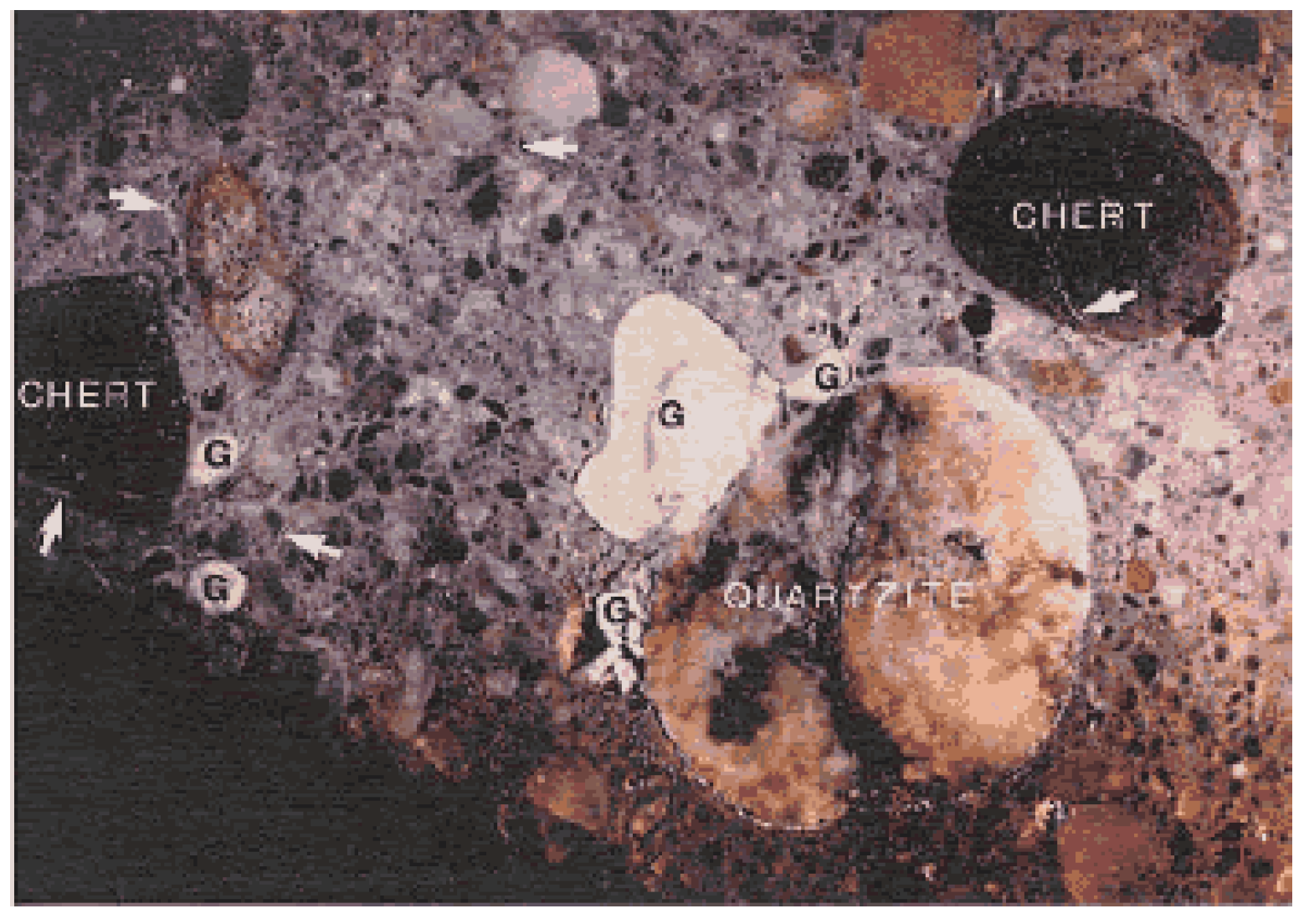

- Locati, F. , Zega, C., Santos, G., Marfil, S., Falcone, D., (2021), “Petrographic method to semi-quantify the content of particles with reactive components and residual mortar in ASR-affected fine recycled concrete aggregates,” Cement and Concrete Research, Vol. 119. [CrossRef]

- Fernandez, I. , Ribeiro, M., Martins, H., Broekmans, M., Sims, I., Nixon, P., and Noronha, F., (2015), “Assessment of concrete aggregates for ASR potential by petrography,” Engineering Geology for Society and Territory,” Vol. 5, pp. 37-40.

- Shi, Z., and Lothenbach, B., (2022), “Role of aluminum and lithium in mitigating alkali-silica reaction – a review,” Frontiers Material Journal. [CrossRef]

- Kim, T. , and Olek, J., (2016), “The effect of lithium ions on chemical sequence of alkali-silica reaction,” Cement and Concrete Research, Volume 79, pp.. 159-168. [CrossRef]

- Leemann, A. , Bernard, L., Alahrache, S., and Winnefeld, F., (2015), “ASR prevention – effect of aluminum and lithium ions on the reaction products,” Vol. 76, pp. 192-201. [CrossRef]

- Thomas, M.D.A. , Fournier, B., Folliard, K., Ideker, J., and Resendez, Y., (2007), “The use of lithium to prevent or mitigate alkali-silica reaction in concrete pavements and structures (Report No. FHWA-HRT-06-133), Federal Highway Administration, U.S. Department of Transportation, 41 pp.

- Tuan, C.Y., Kelly, M.T., Sun, H., and Buss, M.E., (2005), “Evaluation of use of lithium nitrate in controlling alkali-silica reactivity in existing concrete pavement,” Transportation Research Record, Journal of the Transportation Research Board, 1914, 34-44.

- Feng, X., Thomas, M.D.A., Bremmer, T.W., Balcom, B.J., and Folliard, K.J., (2005), “Studies on lithium salts to mitigate ASR-induced expansion in new concrete: a critical review,” Cement and Concrete Research, Vol. 35, pp. 1789-1796.

- Kawamura, M., and Fuwa, H., (2003), “Effects of lithium salts on ASR gel composition and expansion of mortars,” Cement and Concrete Research, Vol. 33, No. 6, pp. 913-919. [CrossRef]

- Lumley, J.S., (1997), “ASR suppression by lithium compounds,” Cement and Concrete Research,” Vol. 27, No. 2, pp. 235-244. [CrossRef]

- Akhnoukh, A.K., and Buckhalter, C.R., (2021), “Ultra-high-performance concrete: constituents, mechanical properties, applications, and current challenges,” Elsevier Journal of Case Studies in Construction Materials, Vol. 15. [CrossRef]

- Akhnoukh, A.K., and Elia, H., (2019), “Developing high performance concrete for precast/prestressed concrete industry,” Elsevier Journal of Case Studies in Construction Materials, Vol. 11. [CrossRef]

- Figueira, R.B., Sousa, R., Coelho, L., Azenha, M., De Almeida, J.M., Jorge, P.A.S., and Silva, C.J.R., (2019), Alkali-silica reaction in concrete: mechanism, mitigation, and test methods,” Construction and Building Materials, Vol. 222, pp. 903-931. [CrossRef]

- Mahyar, M., Erdogan, S.T., and Tokyay, M., (2018), “Extension of the chemical index model for estimating alkali-silica reaction mitigation efficiency to slags and natural pozzolans,” Construction and Building Materials, Vol. 179, No. 10, pp. 587-597. [CrossRef]

- Kawabata, Y. , and Yamada, K., (2017), “The mechanism of limited inhibition by fly ash on expansion due to alkali-silica reaction at the pessimum proportion,” Cement and Concrete Research, Vol. 92, pp. 1-15. [CrossRef]

- Akhnoukh, A.K. , (2020), “The use of micro and nano-sized particles in increasing concrete durability,” Particulate Science and Technology Journal, Vol. 38, No. 5, pp. 529-534. [CrossRef]

- Deschenes, R. , Murray, C.D., and Hale, W., (2017), “Mitigation of alkali-silica reaction and freezing and thawing through surface treatment,” ACI Material Journal, Vol. 114, No. 2. [CrossRef]

- Thomas, M.D.A., Folliard, K.J., Fournier, B., Drimalas, T., and Rivard, P., (2012), “Study of remedial actions on highway structures affected by ASR,” Proceedings of the 14th International Conference on Alkali-Aggregate Reaction (ICAR), Austin Texas.

- Ideker, J.H., Drimalas, T., Bentivegna, A.F., Folliard, K.J., Fournier, B., Thomas, M.D.A., Hooten, R.D., and Rogers, C.A., (2012), “The importance of outdoor exposure site testing,” Proceedings of the 14th International Conference on Alkali Aggregate Reaction (ICAAR), Texas.

| ASR Damage Rating | Nature and Extent of Damage Features |

| Low |

|

| Moderate |

|

| High |

|

| Specimen | Aggregate | Silica Fume | Class c fly ash |

|---|---|---|---|

| F1-SF(0%)-FA(0%) | Fine Aggregate (F1) | 0% | |

| F1-SF(15%)-FA(0%) | 15% | 0% | |

| F1-SF(30%)-FA(0%) | 30% | 0% | |

| F1-SF(0%)-FA(15%) | 0% | 15% | |

| F1-SF(0%)-FA(30%) | 0% | 30% | |

| F2-SF(0%)-FA(0%) | Fine Aggregate (F2) | 0% | |

| F2-SF(15%)-FA(0%) | 15% | 0% | |

| F3-SF(30%)-FA(0%) | 30% | 0% | |

| F4-SF(0%)-FA(15%) | 0% | 15% | |

| F5-SF(0%)-FA(30%) | 0% | 30% | |

| F3-SF(0%)-FA(0%) | Fine Aggregate (F3) | 0% | |

| F3-SF(15%)-FA(0%) | 15% | 0% | |

| F3-SF(30%)-FA(0%) | 30% | 0% | |

| F3-SF(0%)-FA(15%) | 0% | 15% | |

| F3-SF(0%)-FA(30%) | 0% | 30% | |

| Specimen | Day 1 | Day 4 | Day 7 | Day 10 | Day 13 | Day 16 |

|---|---|---|---|---|---|---|

| F1-SF(0%)-FA(0%) | 0.000 | 0.025 | 0.043 | 0.079 | 0.092 | 0.110 |

| F1-SF(15%)-FA(0%) | 0.000 | 0.049 | 0.056 | 0.060 | 0.061 | 0.062 |

| F1-SF(30%)-FA(0%) | 0.000 | 0.042 | 0.044 | 0.046 | 0.046 | 0.047 |

| F1-SF(0%)-FA(15%) | 0.000 | 0.066 | 0.074 | 0.079 | 0.079 | 0.080 |

| F1-SF(0%)-FA(30%) | 0.000 | 0.062 | 0.065 | 0.066 | 0.067 | 0.069 |

| F2-SF(0%)-FA(0%) | 0.000 | 0.061 | 0.066 | 0.072 | 0.086 | 0.101 |

| F2-SF(15%)-FA(0%) | 0.000 | 0.051 | 0.057 | 0.058 | 0.059 | 0.060 |

| F2-SF(30%)-FA(0%) | 0.000 | 0.040 | 0.041 | 0.042 | 0.043 | 0.045 |

| F2-SF(0%)-FA(15%) | 0.000 | 0.057 | 0.058 | 0.061 | 0.062 | 0.064 |

| F2-SF(0%)-FA(30%) | 0.000 | 0.057 | 0.058 | 0.060 | 0.065 | 0.068 |

| F3-SF(0%)-FA(0%) | 0.000 | 0.041 | 0.051 | 0.059 | 0.081 | 0.094 |

| F3-SF(15%)-FA(0%) | 0.000 | 0.029 | 0.038 | 0.046 | 0.048 | 0.050 |

| F3-SF(30%)-FA(0%) | 0.000 | 0.020 | 0.037 | 0.043 | 0.044 | 0.045 |

| F3-SF(0%)-FA(15%) | 0.000 | 0.050 | 0.052 | 0.056 | 0.057 | 0.059 |

| F3-SF(0%)-FA(30%) | 0.000 | 0.051 | 0.053 | 0.055 | 0.056 | 0.060 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).