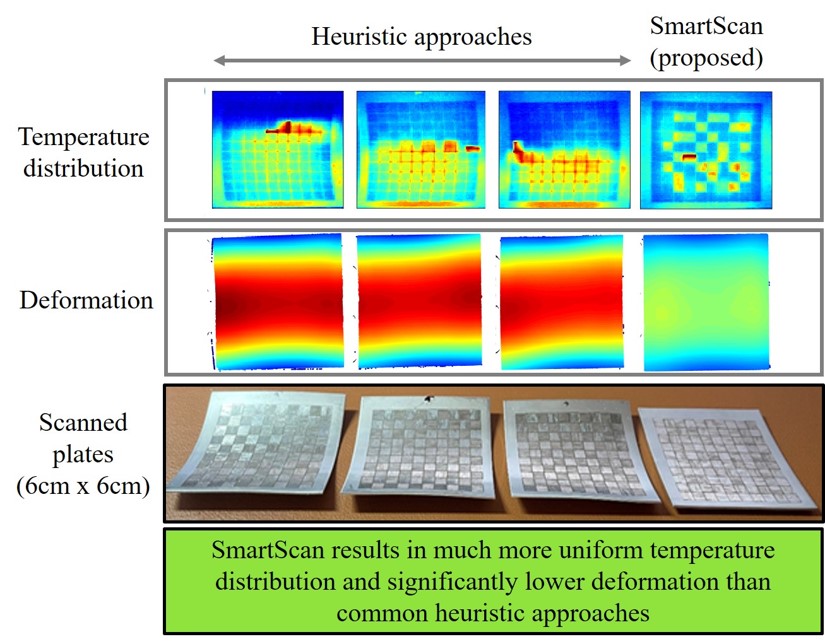

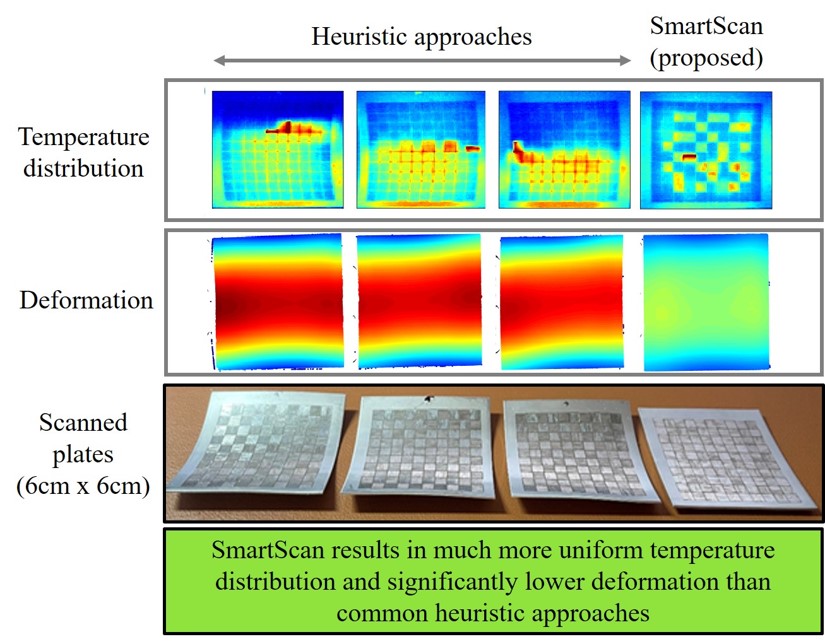

Parts produced by laser or electron-beam powder bed fusion (PBF) additive manufacturing are prone to residual stresses, deformations, and other defects linked to non-uniform temperature distribution during the manufacturing process. Several researchers have highlighted the important role scan sequence plays in achieving uniform temperature distribution in PBF. However, scan sequence continues to be determined offline based on trial-and-error or heuristics, which are neither optimal nor generalizable. To address these weaknesses, we have articulated a vision for an intelligent online scan sequence optimization approach to achieve uniform temperature distribution, hence reduced residual stresses and deformations, in PBF using physics-based and data-driven thermal models. This paper proposes SmartScan, our first attempt towards achieving our vision using a simplified physics-based thermal model. The conduction and convection dynamics of a single layer of the PBF process are modeled using the finite difference method and radial basis functions. Using the model, the next best feature (e.g., stripe or island) that minimizes a thermal uniformity metric is found using control theory. Simulations and experiments involving laser marking of a stainless steel plate are used to demonstrate the effectiveness of SmartScan in comparison to existing heuristic scan sequences for stripe and island scan patterns. In experiments, SmartScan yields up to 43% improvement in average thermal uniformity and 47% reduction in deformations (i.e., warpage) compared to existing heuristic approaches. It is also shown to be robust, and computationally efficient enough for online implementation.