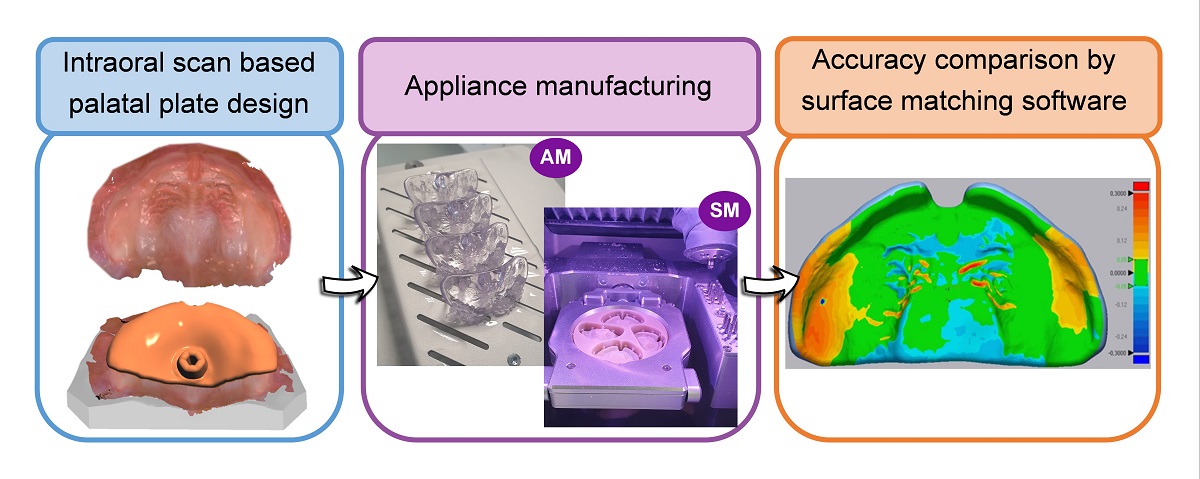

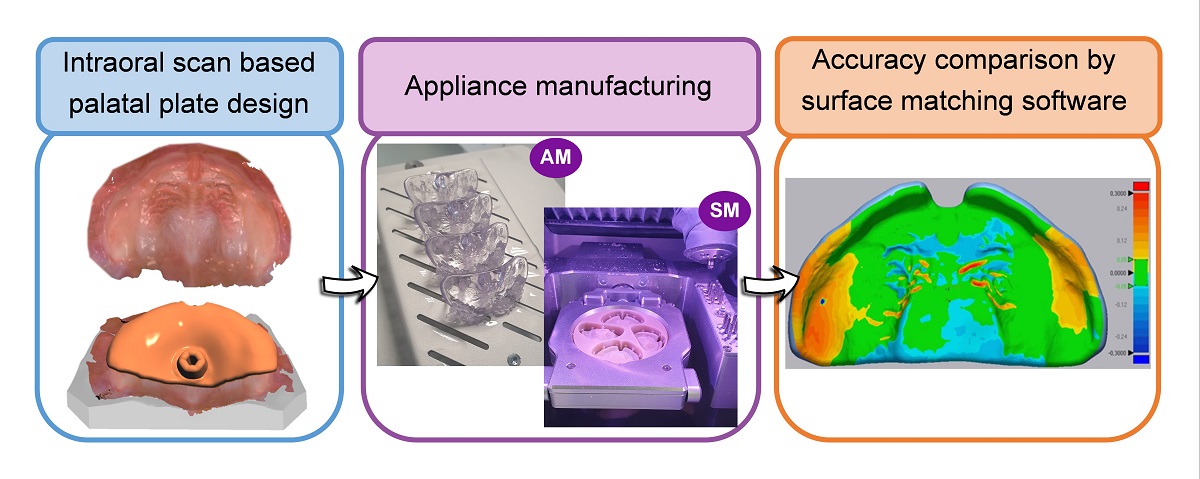

Different approaches for digital workflows have already been presented for their use in palatal plates for newborns and infants. However, there is no evidence on the accuracy of CAD/CAM manufactured orthodontic appliances for this kind of application. This study evaluates trueness and precision provided by different CAM technologies and materials for these appliances. Samples of a standard palatal stimulation plate were manufactured using stereolithography (SLA), direct light processing (DLP) and subtractive manufacturing (SM). The effect of material (for SM) and layer thickness (for DLP) were also investigated. Specimens were digitized with a laboratory scanner (D2000, 3Shape) and analyzed with a 3D inspection software (Geomagic Control X, 3D systems). For quantitative analysis, differences between 3D datasets were measured using root mean square (RMS) error values for trueness and precision. For qualitative analysis, color maps were generated to detect locations of deviations within each sample. SM showed higher trueness and precision than AM technologies. Reducing layer thickness in DLP did not significantly increase accuracy, but prolonged manufacturing time. All materials and technologies met the clinically acceptable range and are appropriate for their use. DLP with 100µm layer thickness showed the highest efficiency, obtaining high trueness and precision within the lowest manufacturing time.