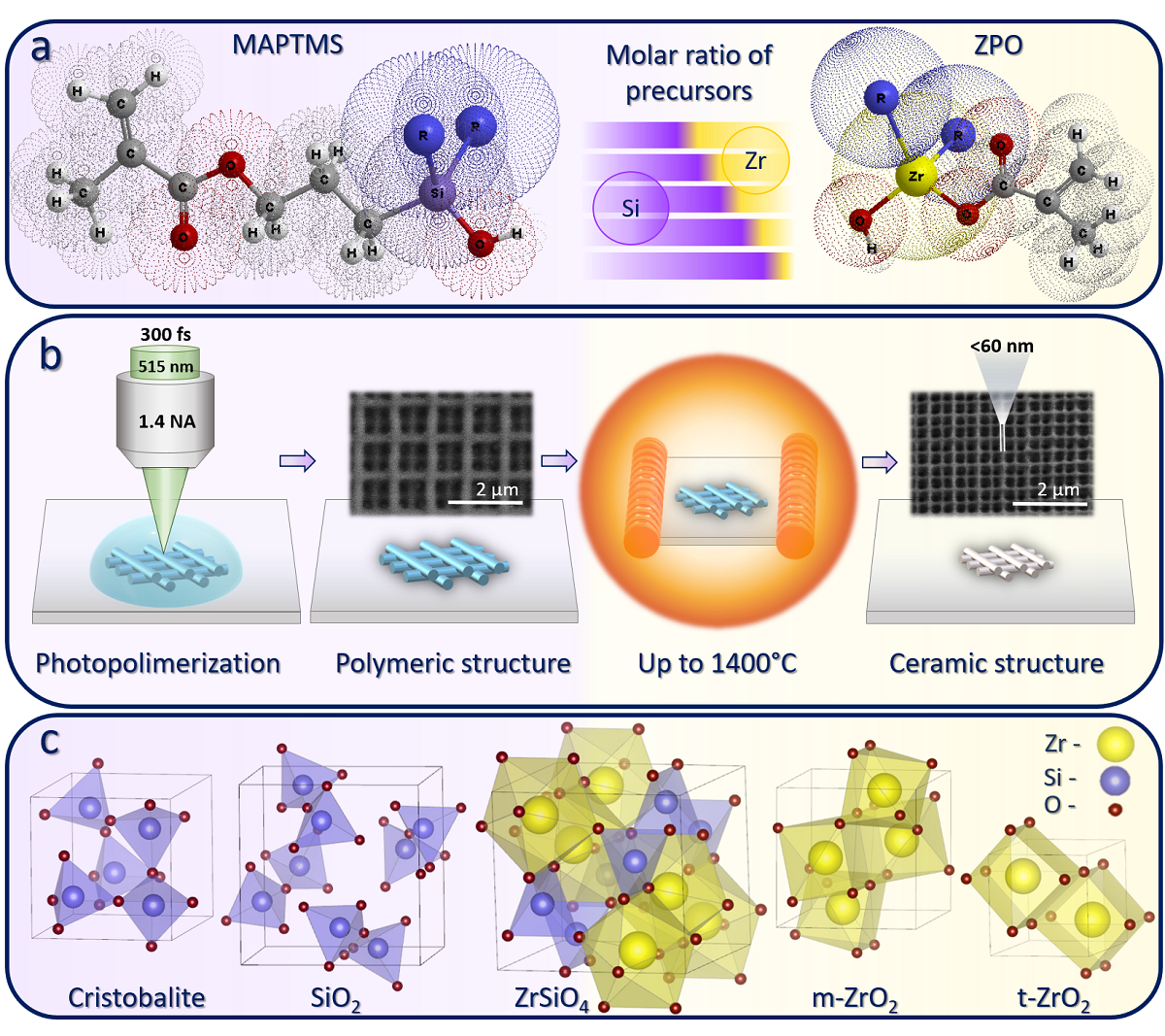

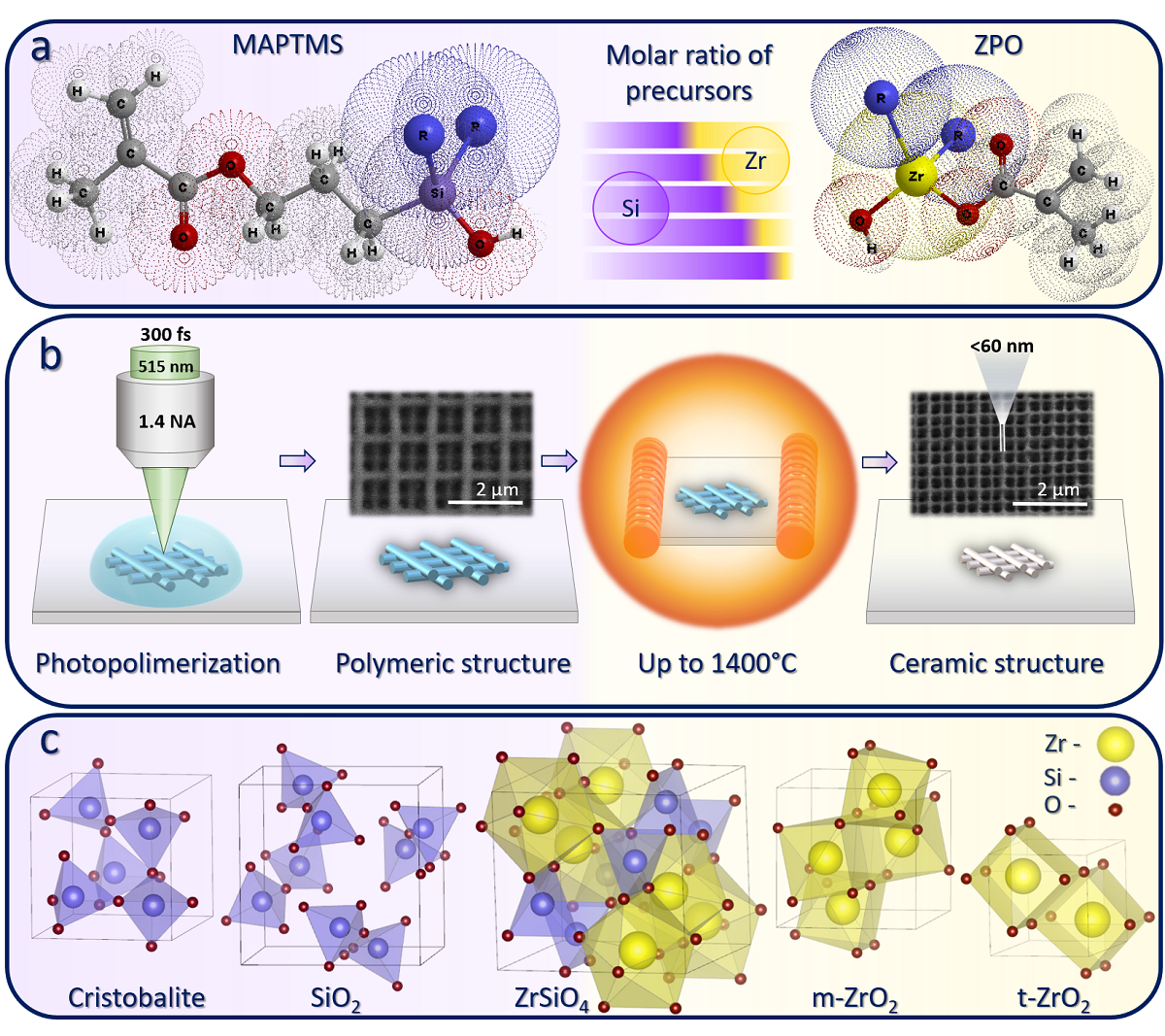

The current paper is focused on the rapidly developing field of nano-/micro three-dimensional production of inorganic materials. The fabrication method includes laserlithography of hybrid organic-inorganic materials with subsequent heat treatment lead-ing to a variety of crystalline phases in 3D structures. In this work, it was examineda series of organometallic polymer precursors with different silicon (Si) and zirconium (Zr) molar ratios, ranging from 9:1 to 5:5, prepared via sol-gel method. All mixtureswere examined for perspective used in 3D laser by manufacturing by fabricating nano-and micro-feature sized structures. Their deformation and surface morphology wereevaluated depending on chemical composition and crystallographic phase. The appear-ance of a crystalline phase was proven using single-crystal X-ray diffraction analysis,which revealed a lower crystallization temperature for microstructures compared tobulk materials. Fabricated 3D objects retain a complex geometry without any distortion after heat treatment up to 1400oC. Under the proper conditions, a zircon phase (ZrSiO4 - a highly stable material) can be observed. In addition, the highest newrecord of achieved resolution below 60 nm has been reached. The proposed prepara-tion protocol can be used to manufacture micro/nano-devices with high precision andresistance to high temperature and aggressive environment.