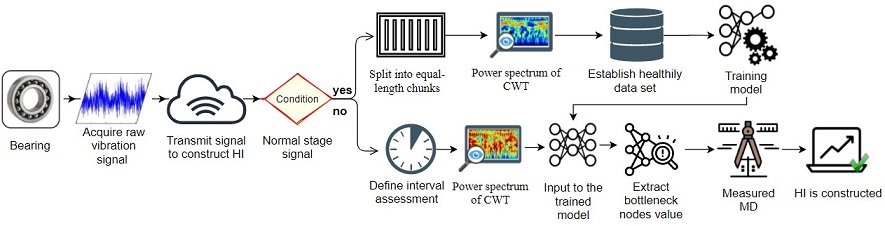

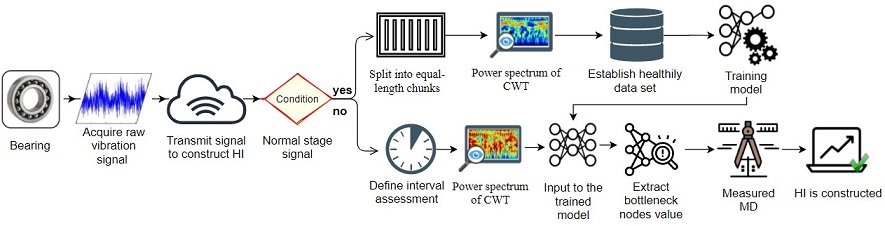

Estimating the remaining useful life (RUL) of components is a crucial task to enhance the reliability, safety, productivity, and to reduce maintenance cost. In general, predicting the RUL of a component includes constructing a health indicator ( ) to infer the current condition of the component, and modelling the degradation process, to estimate the future behavior. Although many signal processing and data-driven based methods were proposed to construct the , most of the existing methods are based on manual feature extraction techniques, and need the prior knowledge of experts, or rely on a large amount of failure data. Therefore, in this study, a new data-driven method based on the convolutional autoencoder (CAE) is presented to construct the . For this purpose, the continuous wavelet transform (CWT) technique is used to convert the raw acquired vibrational signals into a two-dimensional image; then, the CAE model is trained by the healthy operation dataset. Finally, the Mahalanobis Distance (MD) between the healthy and failure stages is measured as the . The proposed method is tested on a benchmark bearing dataset and compared with several other traditional construction models. Experimental results indicate that the constructed exhibits a monotonically increasing degradation trend and has a good performance to detect incipient faults.