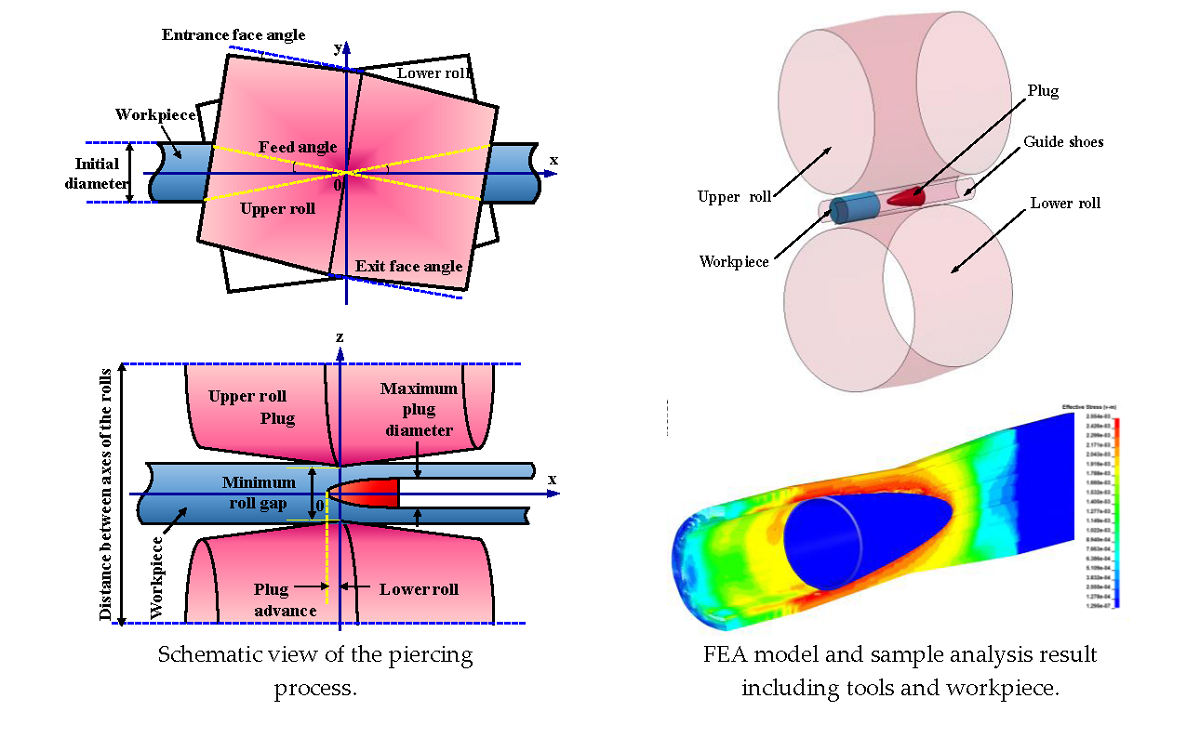

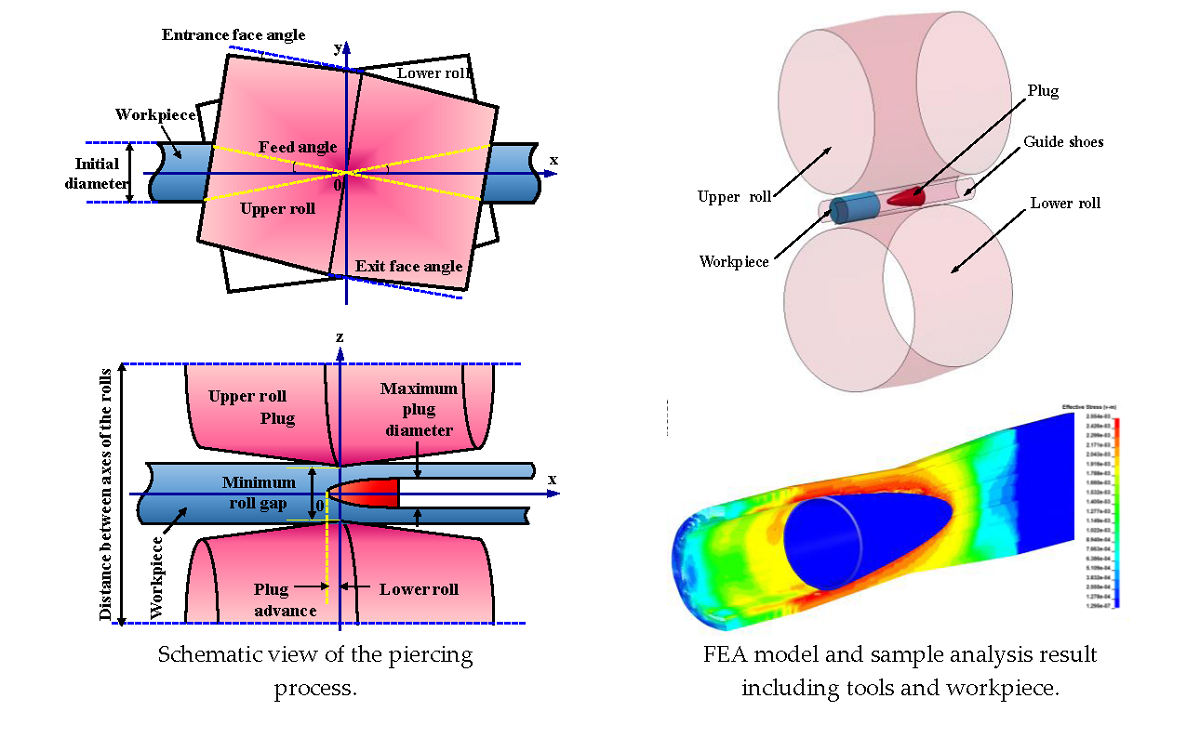

The development of numerical simulations is potentially useful in predicting the most suitable manufacturing process and ultimately improving product quality. Seamless pipes are manufactured by rotary piercing process in which round bars are fed between two rolls and pierced by a stationary plug. During this process, the material undergoes severe deformation which renders it impractical to be modelled and analysed with conventional finite element methods. In this paper, three dimensional numerical simulations of the piercing process are performed with Arbitrary Lagrangian-Eulerian (ALE) Formulation in LS DYNA software. Details about the material model as well as the elements formulations are elaborated here and mesh sensitivity analysis was performed. The results of the numerical simulations are in good agreement with experimental data found in the literature and the validity of the analysis method is confirmed. The effects of varying workpiece velocity, process temperature, and wall thickness on the maximum stress levels of the product material/pipes are investigated by performing simulations of sixty scenarios. Three dimensional surface plots are generated which can be utilized to predict the maximum stress value at any given combination of the three parameters.