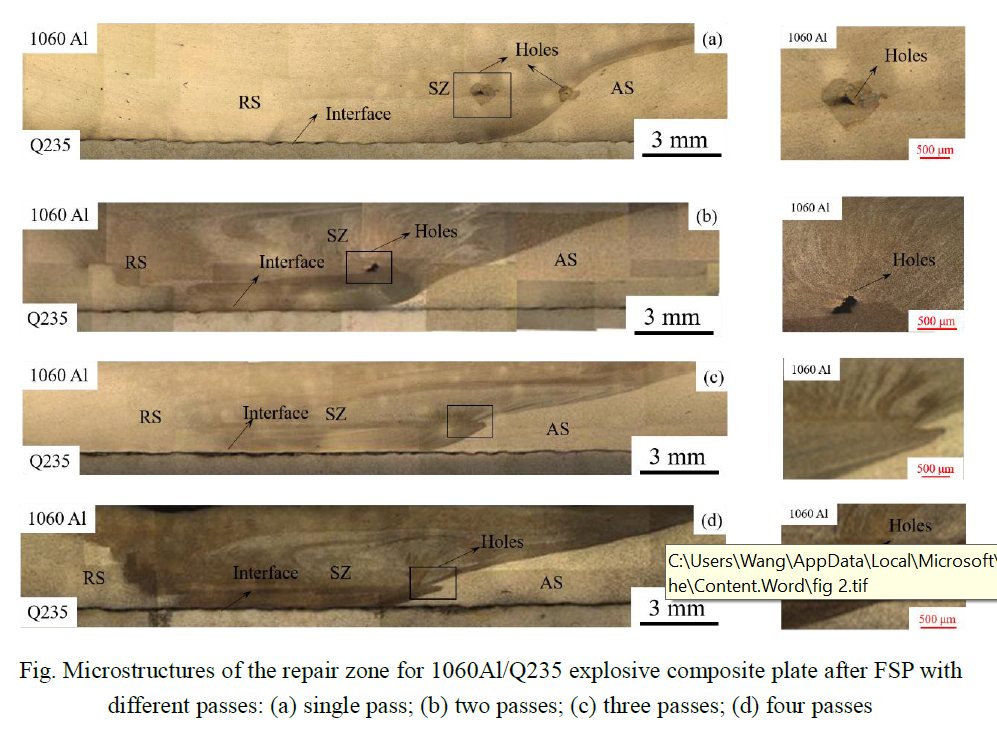

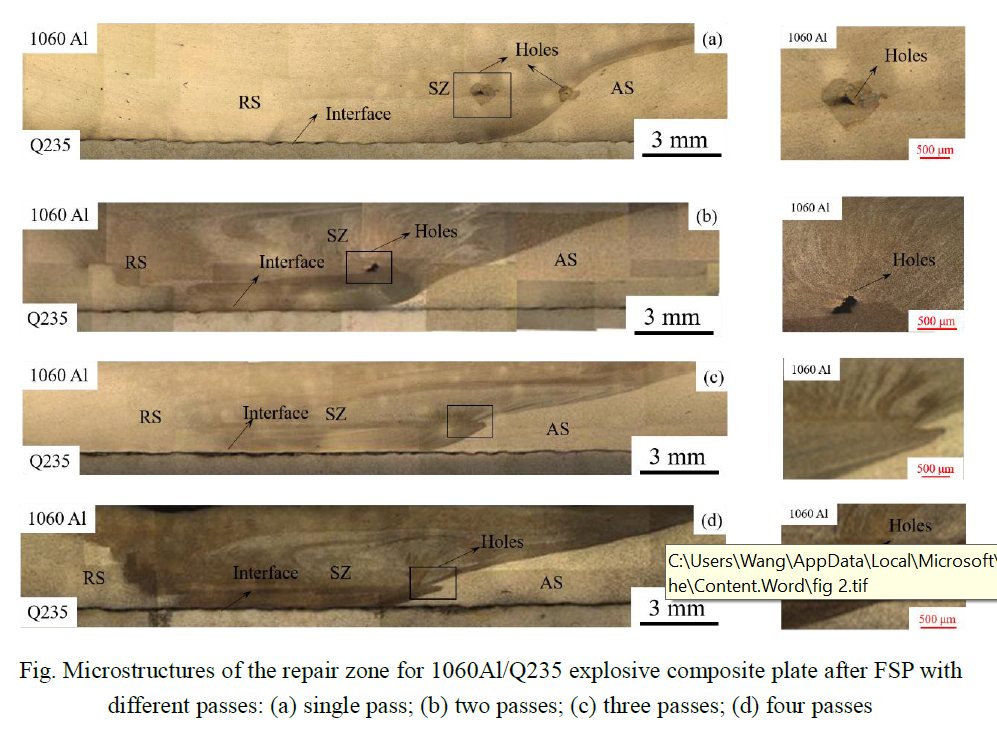

There always exist steel cuttings, holes and cracks at the interfaces in the explosive composite plate. Multi-pass friction stir processing (M-FSP) is proposed in this research to optimize the interface microstructure and the interface connection for 1060Al/Q235 explosive composite plate. Results show that the microstructures of 1060Al after M-FSP are fine and uniform owing to the strong stirring effect and recrystallization. Micro-defects formed by the explosive welding can be repaired by the M-FSP. However, M-FSP can also form tunnel defects in the aluminum, especially when the passes are one and two. The melting block and the melting lump in the composite plates are easy to become source of crack. The shear strengths and the bending properties for the 1060Al/Q235 explosive composite plate after M-FSP are the best when the passes are three, with the tool rotation speed of 1200rpm and the forward speed of 60mm/min. The optimized interfaces for the explosive composite plate after M-FSP are mainly by the metallurgical bondings, with a certain thickness and are discontinuous. Therefore, the crack extension stress is the largest and the mechanical properties are the best.