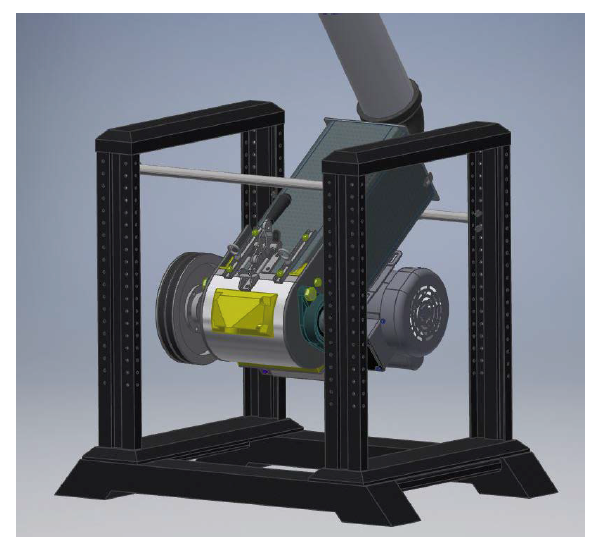

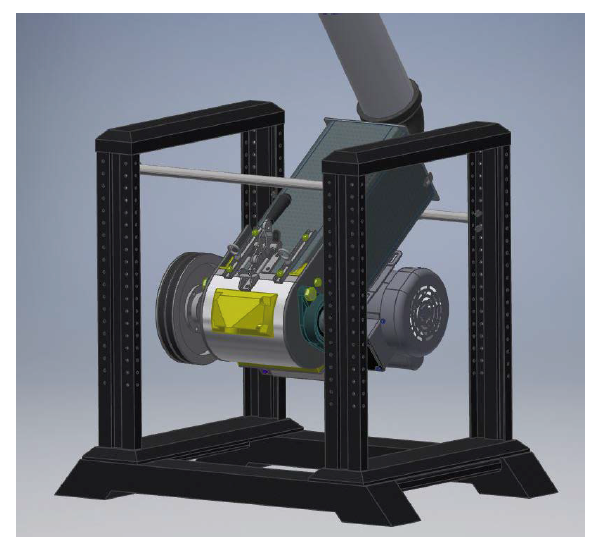

Abstract: In order to accelerate deployment of distributed recycling by providing low-cost feed stocks of granulated post-consumer waste plastic, this study analyzes an open source waste plastic granulator system. It is designed, built and tested for its ability to convert post-consumer waste, 3-D printed products and waste into polymer feedstock for recyclebots of fused particle/granule printers. The technical specifications of the device are quantified in terms of power consumption (380 to 404W for PET and PLA, respectively) and particle size distribution. The open source device can be fabricated for less than USD$2000 in materials. The experimentally-measured power use is only a minor contribution to the overall embodied energy of distributed recycling of waste plastic. The resultant plastic particle size distributions were found to be appropriate for use in both recyclebots and direct material extrusion 3-D printers. Simple retrofits are shown to reduce sound levels during operation by 4dB-5dB for the vacuum. These results indicate that the open source waste plastic granulator is an appropriate technology for community, library, makespace, fab lab or small business-based distributed recycling.