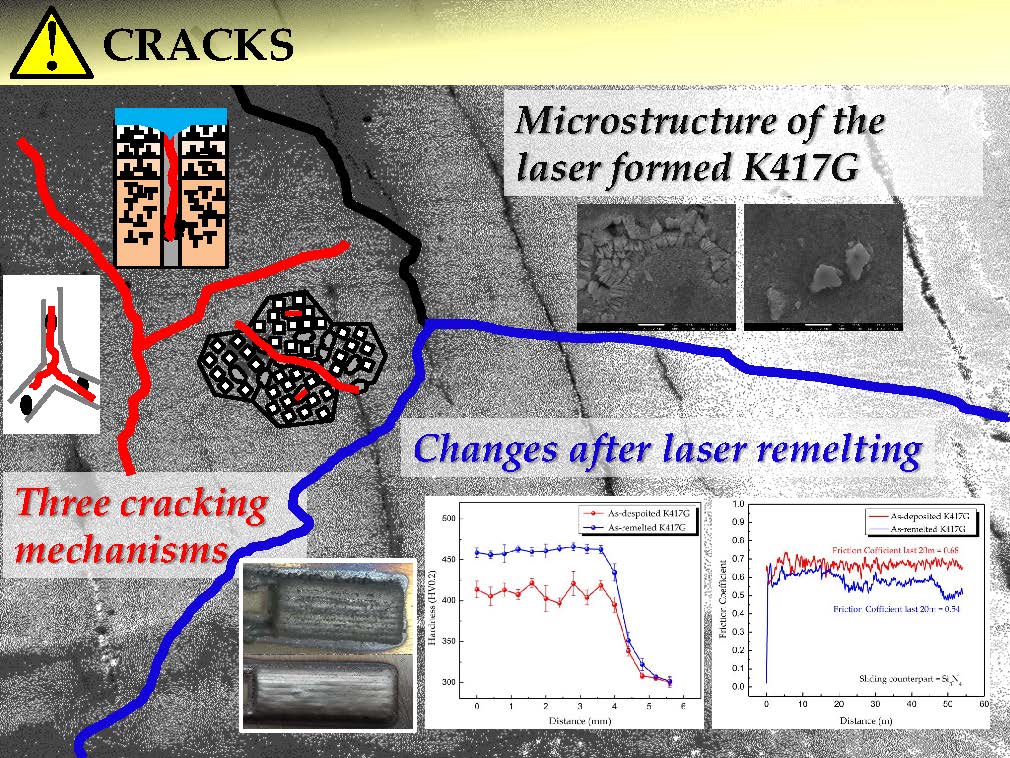

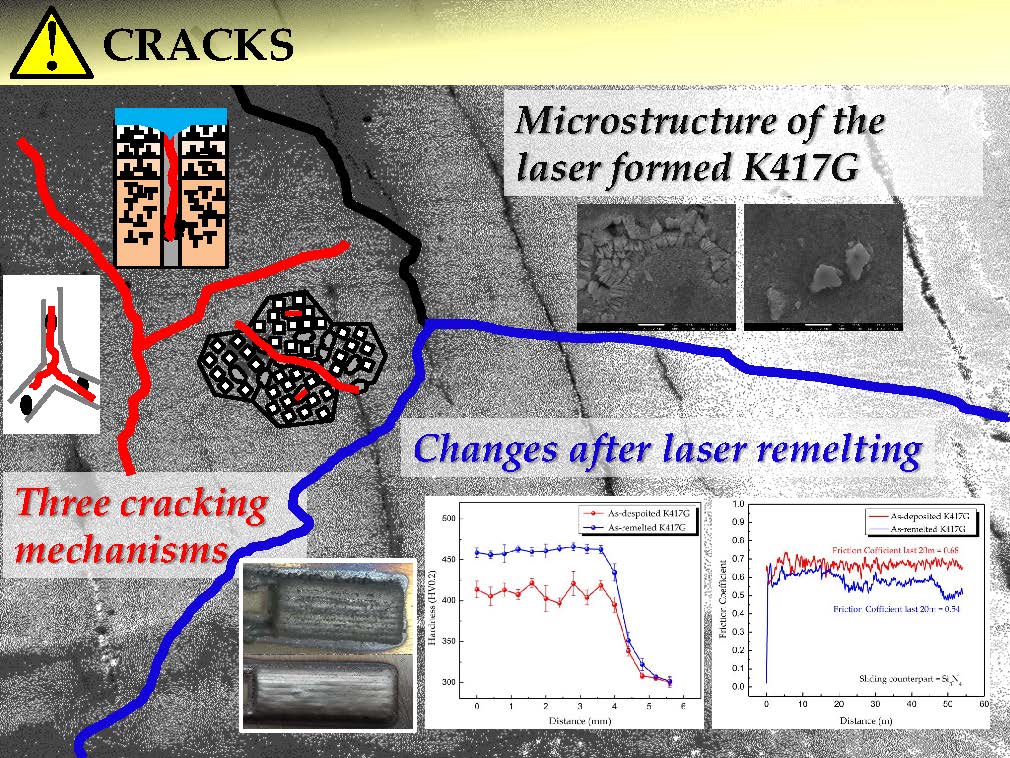

K417G Ni-based superalloy is widely used in aeroengine turbine blade for its excellent properties. However, the aeroengine rotor blade zigzag crown appears early failure frequently, which is because of the wear problems occurring in the working process. Laser forming repairing (LFR) is a promising technique to repair these damaged blades. Unfortunately, the laser formed Ni-based superalloys with high content of (Al + Ti) have a high cracking sensitivity. In this paper, the crack characterization of the LFRed K417G, the microstructure, microhardness and tribological properties of the coating before and after laser remelting are presented. The results show that the microstructure of as-deposited K417G consists of γ phase, γ′ precipitated phase, γ + γ′ eutectic and carbide. Cracking mechanisms including solidification cracking, liquation cracking and ductility dip cracking are proposed based on the composition of K417G and processing characteristics to explain the cracking behavior of the K417G superalloy during LFR. After laser remelting, the microstructure of the coating has been refined, and the microhardness and tribological properties has been improved. Laser remelting can decrease the size of the cracks in the LFRed K417G but not the number. Therefore, laser remelting can be applied as an effective method for strengthening coating and as an auxiliary method for controlling cracking.