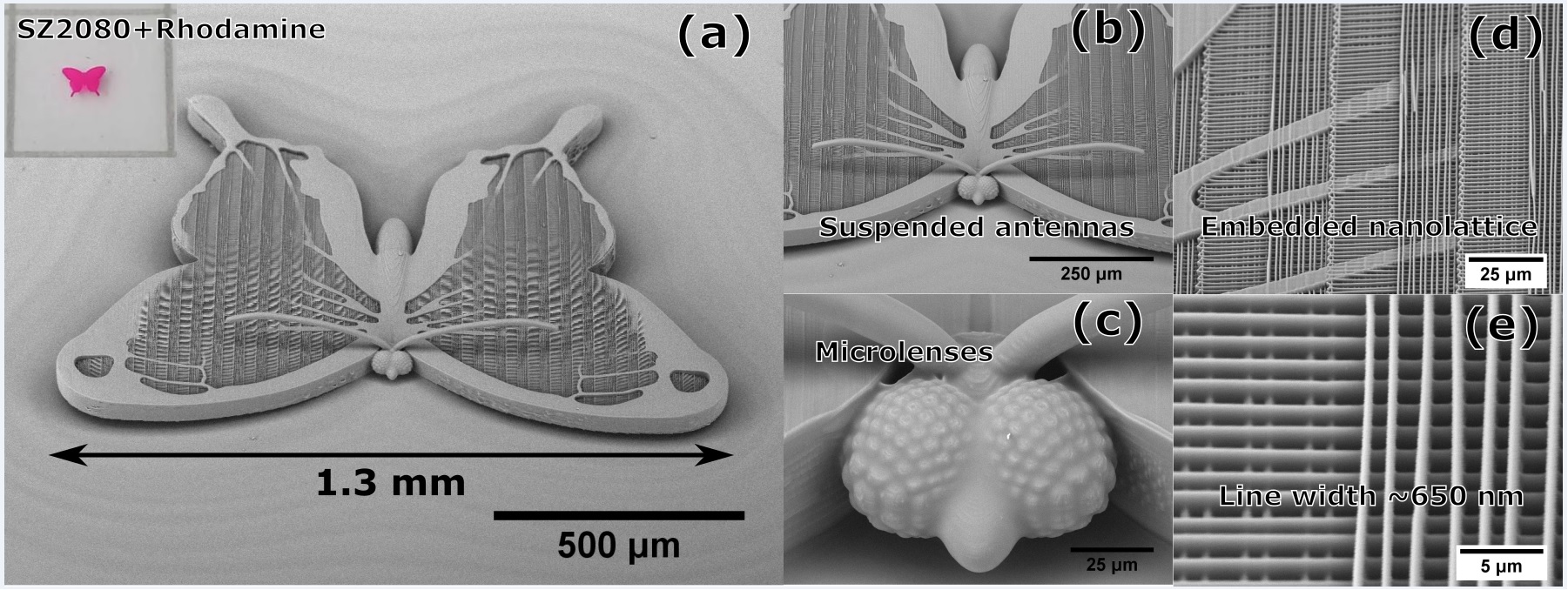

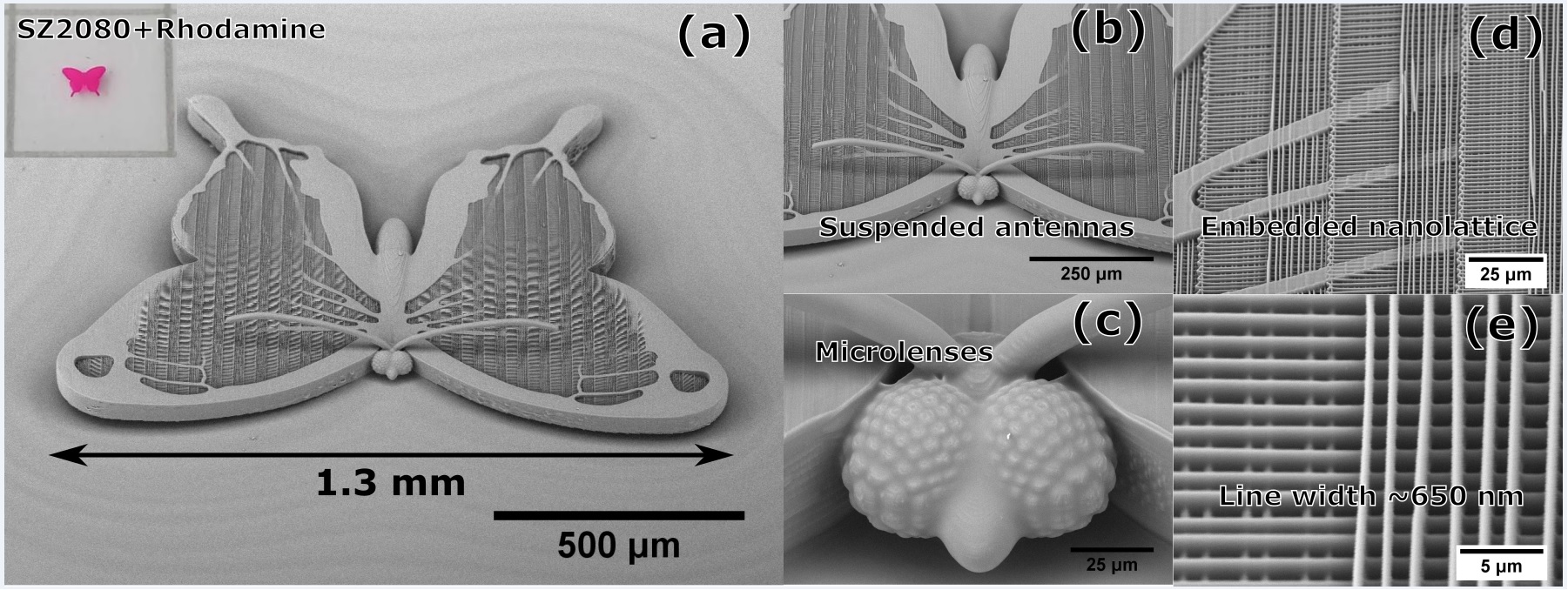

3D meso-scale structures that can reach up to centimeters in overall size but retain micro- or nano-features, proved to be promising in various science fields ranging from micro-mechanical metamaterials to photonics and bio-medical scaffolds. In this work we present synchronization of the linear and galvano scanners for efficient femtosecond 3D optical printing of objects at the meso-scale (from sub-μm to sub-cm spanning five orders of magnitude). In such configuration the linear stages provide stitch-free structuring at nearly limitless (up to tens-of-cm) working area, while galvo-scanners allow to achieve translation velocities in the range of mm/s-cm/s without sacrificing nano-scale positioning accuracy and preserving undistorted shape of the final print. The principle behind this approach is demonstrated, proving its inherent advantages in comparison to separate use of only linear stages or scanners. The printing rate is calculated in terms voxels/s, showcasing the capability to maintain an optimal feature size while increasing throughput. Full capabilities of this approach are demonstrated by fabricating structures that reach millimeters in size but still retain μm-scale features: scaffolds for cell growth, microlenses and photonic crystals. All this is combined into a benchmark structure: a meso-butterfly. Provided results show that synchronization of two scan modes is crucial for the end goal of industrial-scale implementation of this technology and makes the laser printing well aligned with similar approaches in nanofabrication by electron and ion beams.