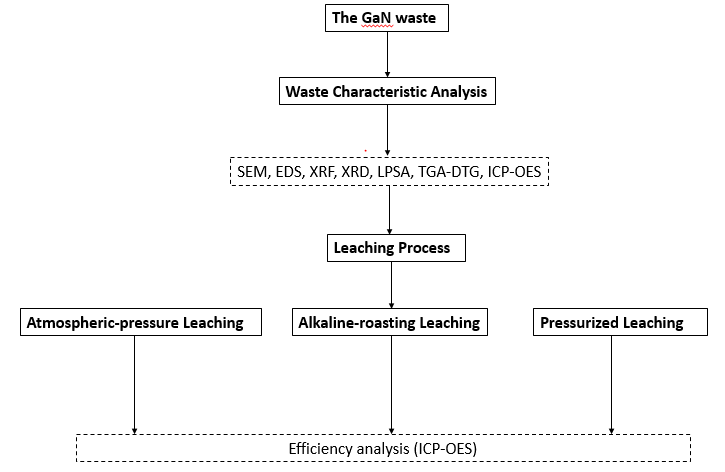

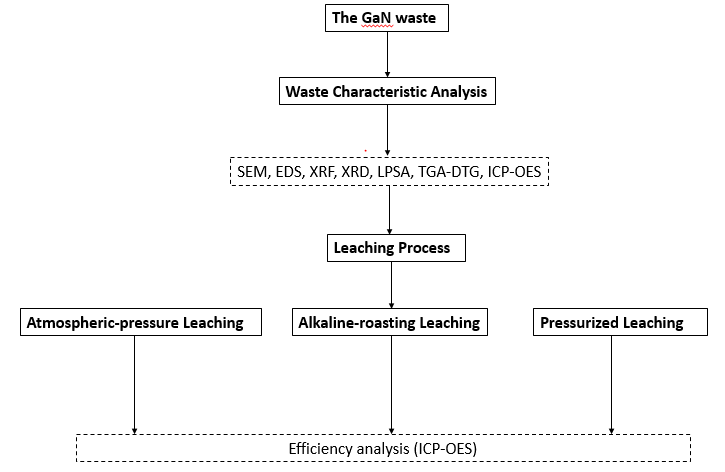

In recent years, with the increasing research and development of the LED industry which contains GaN, it is expected that there will be a large amount of related wastes in the future. Especially the gallium has extremely high value of economic, therefore, it is necessary to establish the recycling system of the GaN waste. However, GaN is a direct-gap semiconductor and with high energy gap, high hardness, and high melting point make it difficult to recycle. Therefore, this study will analyze the physical characteristics of LED wastes containing GaN and carry out various leaching method to leach the valuable metals from the waste optimally. Different acids are used to find out the best reagent for leaching the gallium. Different experimental parameters are discussed such as the effect of the different acid agents , concentration, pressure, solid-liquid mass ratio, temperature, and time which influence the leaching efficiency of the gallium. In this study, various leaching methods which effect the leaching efficiency of the gallium are compared and the advantages and disadvantages are discussed. Finally, pressurized acid leaching method is preferred to leach the GaN waste, and hydrochloric acid is used as the leaching solution because of its better leaching efficiency of gallium. Eventually, the leaching efficiency of the gallium can reach to 98%.