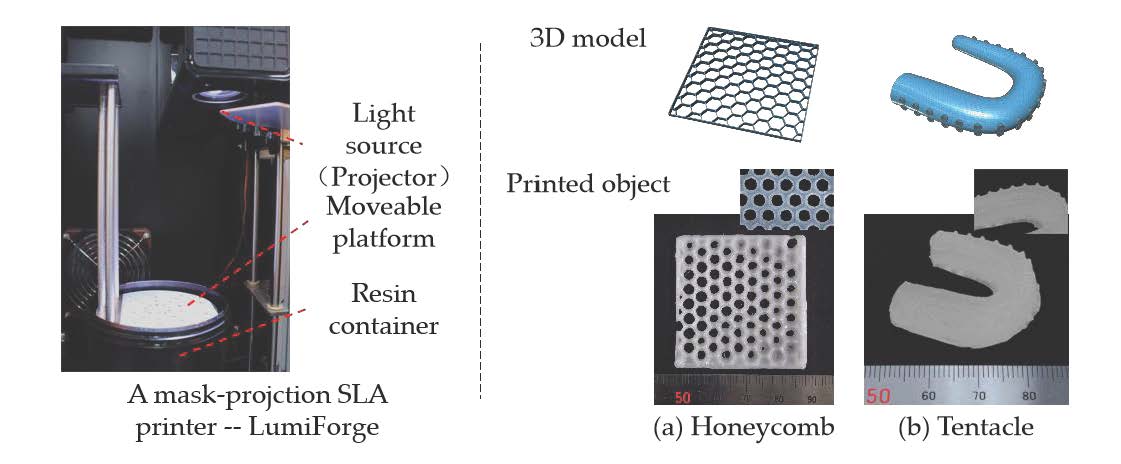

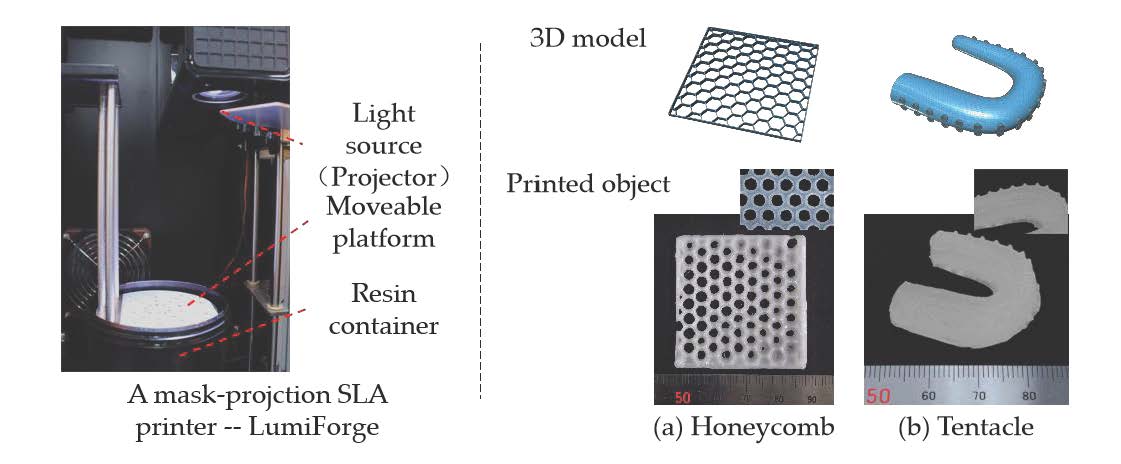

Most of the phase change materials (PCMs) have been limited to use as functional additions or sealed in containers, and extra auxiliary equipment or supporting matrix is needed. The emergence of 3D printing technique has dramatically advanced the developments of materials and simplified production processes. This study focuses on a novel strategy to model thermal energy storage crystalline gels with three-dimensional architecture directly from liquid resin without supporting materials through light-induced polymerization 3D printing technique. A mask-projection stereolithography printer was used to measure the 3D printing test, and the printable characters of crystalline thermal energy storage P(SA-DMAA) gels with different molar ratios were evaluated. For the P(SA-DMMA) gels with small fraction of SA, the 3D fabrication was realized with higher printing precision both on mili- and micro-meter scales. As a comparison of 3D printed samples, P(SA-DMAA) gels made by other two methods, post-UV curing treatment after 3D printing and UV curing using conventional mold, were prepared. The 3D printed P(SA-DMAA) gels shown high crystallinity. Post–UV curing treatment was beneficial to full curing of 3D printed gels, but did not lead to the further improvement of crystal structure to get higher crystallinity. The P(SA-DMAA) crystalline gel having the highest energy storage enthalpy that reached 69.6 J·g−1 was developed. Its good thermoregulation property in the temperature range from 25 to 40 °C was proved. The P(SA-DMAA) gels are feasible for practical applications as one kind of 3D printing material with thermal energy storage and thermoregulation functionality.