1. Introduction

Arecanut (Areca catechu) is an important commercial crop that is popularly known as betel nuts. People widely use it for chewing, medicinal purposes, and traditional cultural practices. These betel nuts need to be dried for a few weeks that are ready to husk and sort. Once betel nuts are completely dried, the kernel seeds are required to be peeled off from the shell and people must remove the shells by hands. These processes cost times and may cause injury to the hands. Therefore, the previous researches aimed to develop various kinds of husking machines to reduce the operation time and prevent injury to users.

1.1. Related Work

The most efficient research related to husking machines were described in this section to understand the various kinds of husking machines. Nalawade et al. [

1] focused on developing the efficiency of a manually operated arecanut dehusker. The husking efficiency was 80-85% (650 to 700 arecanuts per hour). Kiran et al. [

2] also designed, developed, and tested a husking machine for three various sizes of arecanut. This prototype machine used a shearing blade mechanism to remove the husk. Their experimental results proved that a single blade provided higher peeling efficiency than a double blade (two blades spaced with a sleeve). Jarimopas et al. [

3] developed and tested a husking machine for dry betel nut. They designed and constructed a prototype using the principle of "tearing" the husk off with varying levels of friction applied to both sides of the betel nut through two sets of rubber wheels and curved sieves consecutively. However, the results of this study indicated that more than 15% of the nuts were either broken or remained unhusked. Madhusudhana et al. [

4] also designed and developed an arecanut de-husking machine for three sizes of arecanut. This research also used a tire and blades for de-husking. The partially de-husked Arecanut moved to the systems of gears, which were meshed tightly to pull the husk downwards, and the nuts were conveyed forward. The mechanism of this machine was powered by a 1HP single-phase motor. They evaluated the performance of the machine for a speed of 460-540 rpm, a tire pressure of 20-25 psi, and a clearance of 10-13 mm. Their results showed the optimum settings as a wheel’s rotating speed of 560 rpm, a tire’s pressure of 20 psi, and a clearance of 13 mm. Ravindra et al. [

5] evaluated the performances of three high-capacity green arecanut de-husking equipment. Their husking machine applied hook-tooth cutting blades fixed in a cutting wheel to dehusk the shell. They implemented this technique for the two-belt model, the four-belt model, and the six-belt model. Bulan et al. [

6] proposed a dry areca nut peeling machine combined with a fiber shredder. This machine tested various speeds of 800 rpm, 1000 rpm, and 1200 rpm on the parameters of engine capacity, engine efficiency, and fuel consumption during the test. The experimental results of this study showed that the best rotational speed of the dry arecanut peeling machine combined with a fiber shredder was 1000 rpm. Darmein et al. [

7] optimized the setting angle between the two cutter blades to improve the quality of the peeling results and increase the productivity of the machine. In addition, Sitorus et al. [

8] and Ertina et al. [

9] focused on design and development of cutting machines for fresh betel nuts. Tamrin et al. [

10] proposed a prototype that can separate various sizes of palm seeds. The seeds had fallen into the clearance between two steel bars in the form of a line. The small seeds had fallen first. They evaluated their machine using 300 palm seeds, which included 100 large-size seeds, 100 medium-size seeds, and 100 small-size seeds. The results showed 29.5% of large size, 30.8% of small size, and 28.2% of small size. Kumar et al. [

11] provided a comprehensive exploration of the evolving landscape of areca nut cutting machines, emphasizing technological advancements, market trends, and prospects in the future. Ajith et al. [

12] designed a low-cost separating machine for arecanut based on size and color. The large arecanut was separated by passing it through the sieves, while the quality of the arecanut was sorted by a camera with color detection to distinguish the color of the arecanut’s surface

1.2. Research Gaps and Contributions

The previous part of this study described the related works for husking and separating machines. Partial researchers used blades or hook-tooth to peel the shells of betel nuts. However, such methods require frequent maintenance to maintain their effectiveness, as the shells may become stuck to the teeth or blades. For this reason, some researchers designed husking machines using rubber tires that used the principle of tearing the husk off with varying levels of friction applied to both sides of the betel nut. However, their results indicated high ratio of broken and unhusked nuts. Moreover, there were no researchers who designed the separating machine that can automatically separate the full nuts off the broken nuts, and shells. Therefore, this study designed and implemented a low-cost machine to husk and separate full nuts, broken nuts, and shells simultaneously for dry betel nut. In addition, this study can also decrease the number of broken nuts from husking.

1.3. Outline of the Proposed Study

We organize the remainder of this study as follows:

Section 2 describes the proposed husking and separating machine for dry betel nuts. The experimental setup and results are provided in

Section 3. Finally,

Section 4 summarized the discussion and conclusions.

2. Materials and Methods

2.1. Dry Betel Nut Preparation

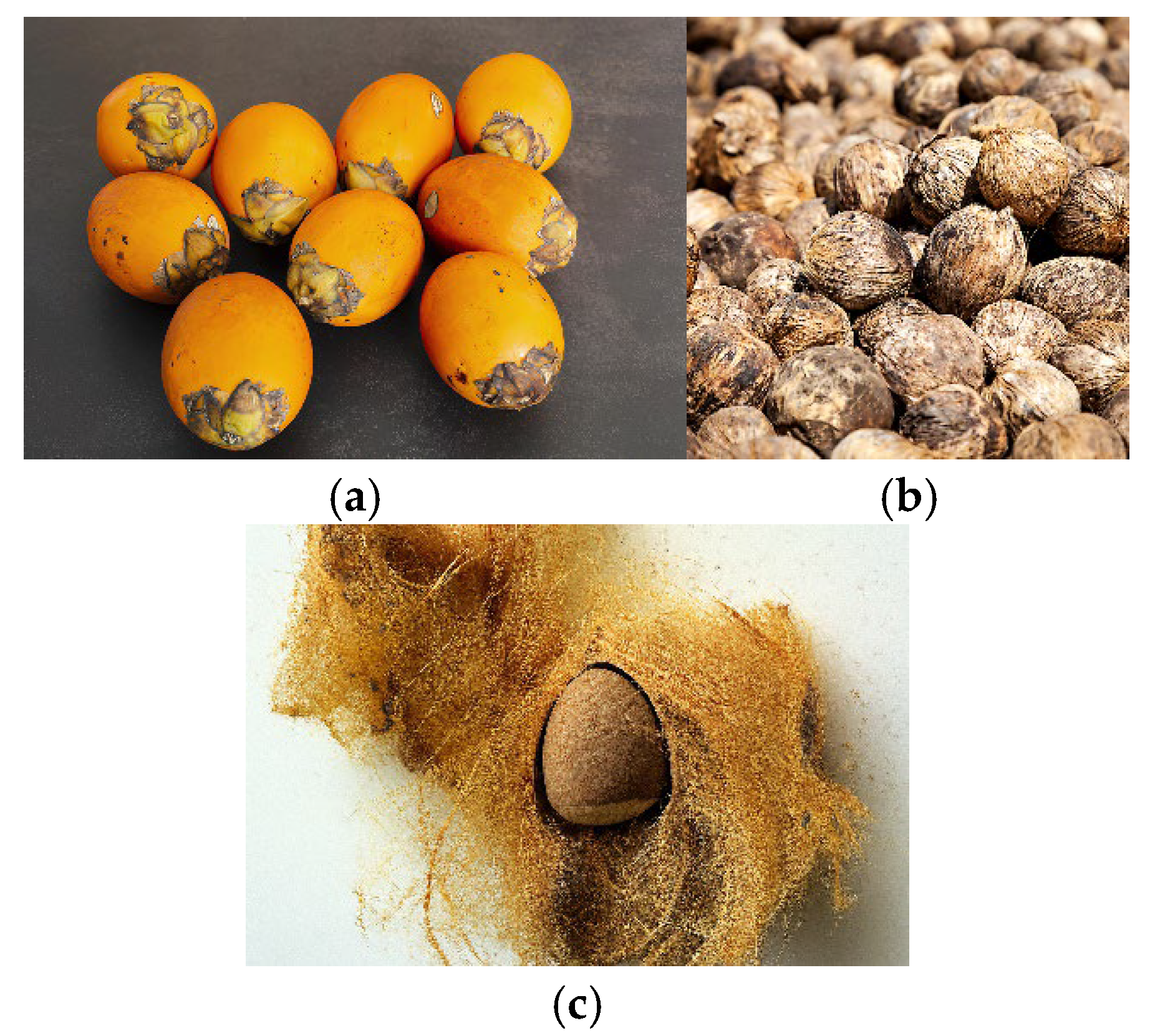

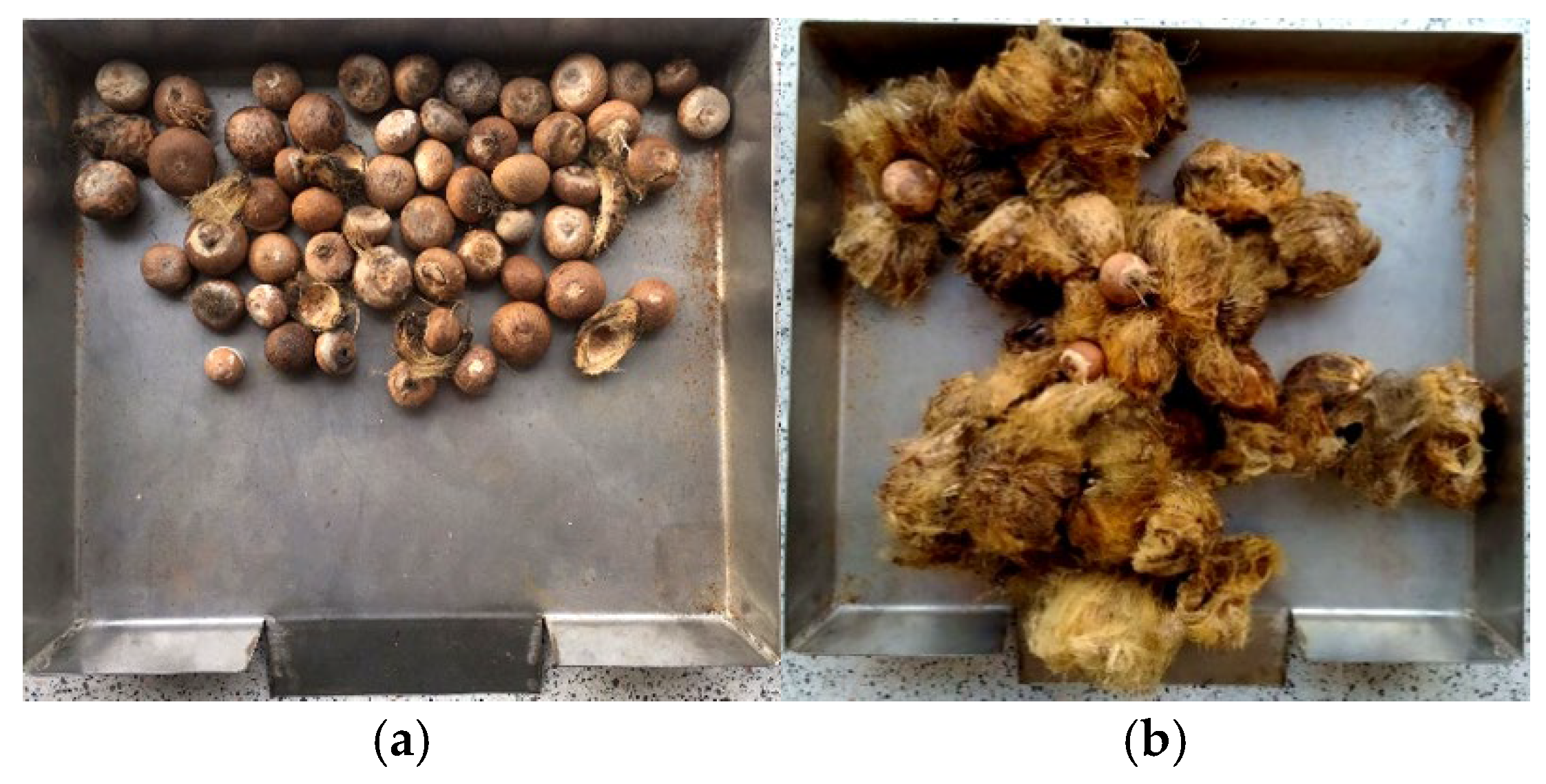

First, the whole ripe betel nuts as shown in

Figure 1a can be dried with the sunlight by laying them outdoors on solid ground or concrete for a few weeks. The betel nuts are not concerned about rain because after the nuts are wet and dry recursively, the shells of the nuts are decayed, which makes them easier to husk. Since there is a sound when the nuts (kernel) are shaken, that proves the nuts are completely dry as repe. Once the nuts and shells are completely dry as represented in

Figure 1b, the kernel nuts and shells are apart, which is expedient to be peeled as demonstrated in

Figure 1c. It means the betel nuts are ready for husking.

2.2. Overview of the Proposed Machine Design

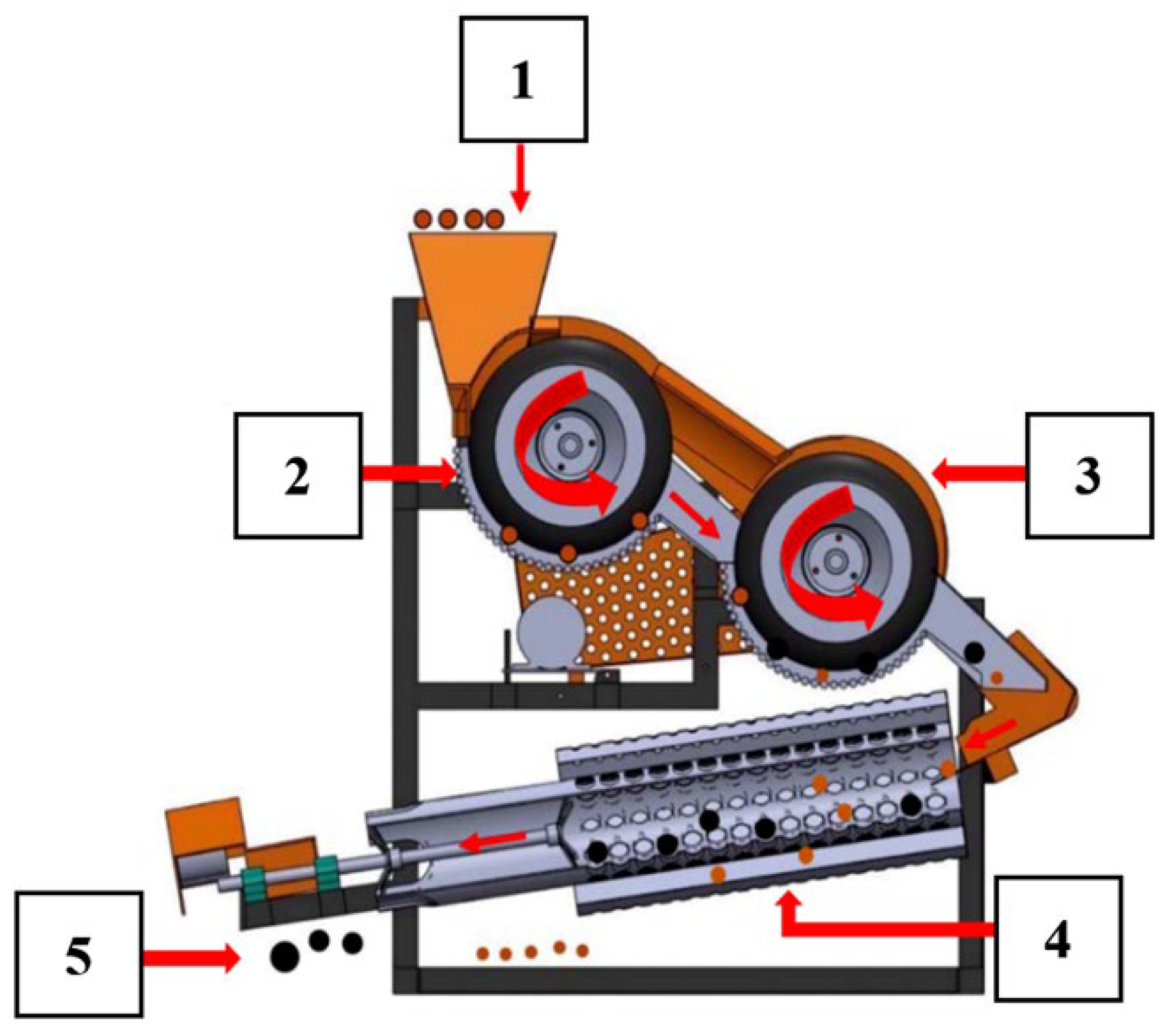

In this study, we designed two systems, as illustrated in

Figure 2 to husk and separate the nuts and shells simultaneously as follow: 1) the proposed husking system was used to tear the betel nuts’ shells, likely due to the structure of Jarimopas et al. [

3]. However, we applied a 750-Watt AC motor connecting with two all-terrain vehicle (ATV) wheels and metal sieves to husk the betel nuts instead of a 2.2 kW motor with two rubber tires; 2) the separating system is used to separate full nuts from broken nuts and shells by using a low-speed DC motor connecting to cylindrical parts with full holes.

As shown in

Figure 2, once dry betel nuts are put into the hopper (Number 1), the betel nuts are consecutively conveyed to the narrow passage between metal sieves and ATV tires that makes the shells are peeled (Numbers 2 and 3). In this process, the tire’s pressure and speed of both wheels, including the clearance between the tires and the metal sieves, significantly affect the performance of the husking system. Once, the nuts and shells are peeled and conveyed to the center of the separating system (Number 4). In the proposed separating system, the full nuts and broken nuts are sorted out of the shells. The shells are consecutively led to the destination (Number 5). The operation of separating system was described thoroughly in the next subsection.

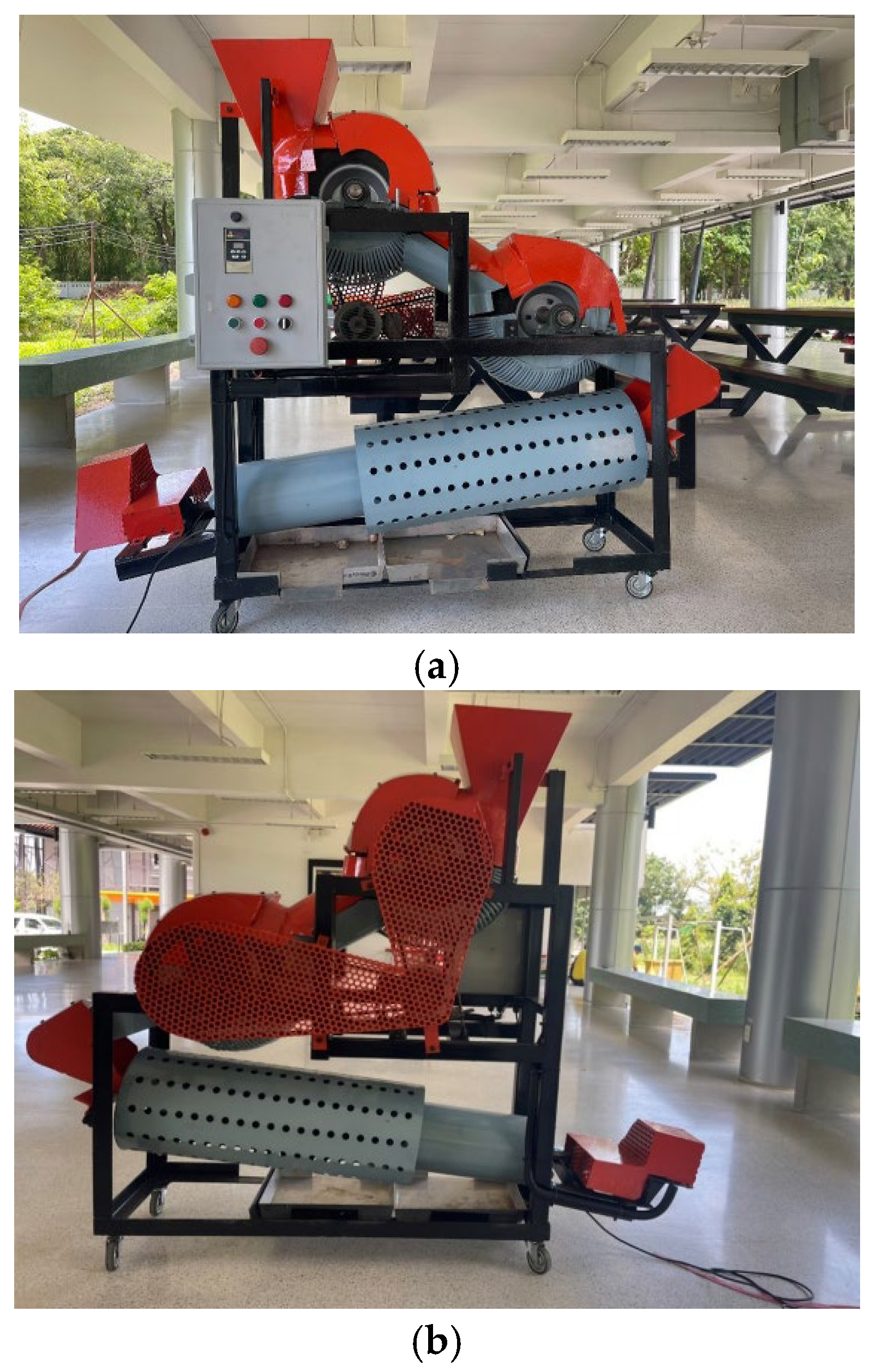

Figure 3a and

Figure 3b demonstrate our low-cost husking and separating machine for dry betel nuts in front side and back side, respectively.

2.3. Structure and Operation of the Proposed Separating System

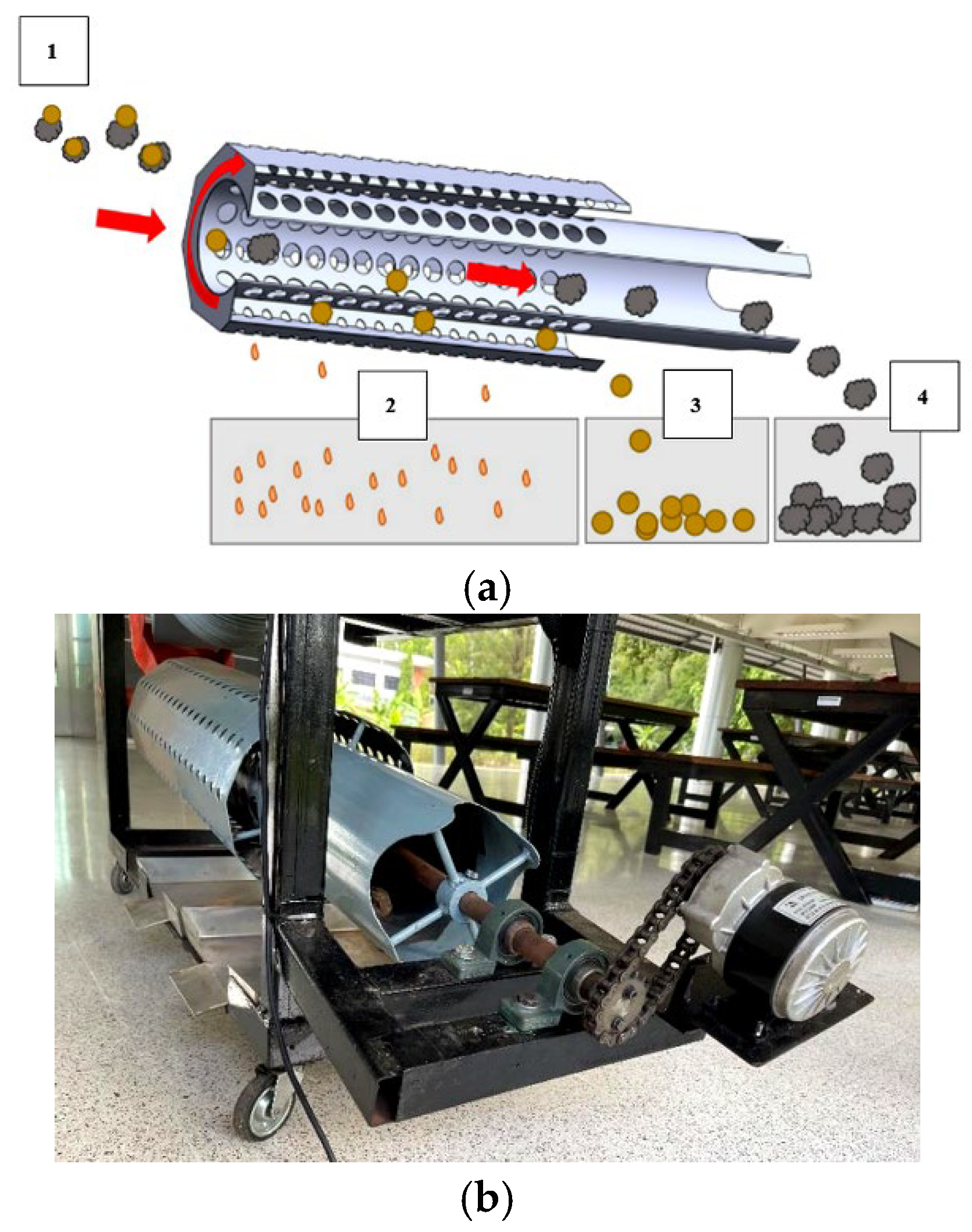

The previous section described that the former studies have not focused on simultaneous husking and separating processes. The proposed separating system illustrated in

Figure 4 can separate the full nuts, broken nuts, and shells individually. As represented in

Figure 4a: the frame of separating system consists of two layers: 1) the inner layer was a cylindrical frame (dimensions: 200 mm diameter and 1200 mm length); 2) the outside layer was an octagon frame (dimensions: 300 mm width and height; 800 mm length). Both layers were concentric assembling and set the angle of 10 degrees from the ground to conveyed the betel nuts to the destinations. The inner frame was used to separate both full nuts and broken nuts from shells by using 40 mm for 228 holes (12 rows x 19 holes) around the frame. While the outside frame was used to separate full nuts from broken nuts by using 20 mm for 240 holes (16 rows x 15 holes) around the frame. A 250-Watt 24V DC-Motor with 337 rpm speed and 6.65 Nm torque was used to the powertrain of this system. As shown in

Figure 4, once the betel nuts were husked, all of them were led into the separating machine (Number 1). The full nuts and broken nuts were sorted out of shells, and after that, the broken nuts, which were smaller size than full nuts, were dropped into the broken tray (Number 2). The full nuts were conveyed until the destination of the outside layer frame and dropped into the full nuts tray (Number 3), while the shells were led into the destination of the inner layer frame and fell onto the shells tray (Number 4). Our low-cost separating system was demonstrated in

Figure 4b.

3. Results

In this section, the experimental setup and results were presented to evaluate the performances of husking and separating systems of the proposed machine. The rotating speed and the pressure of the husking wheels, including the clearance between the husking wheels and sieves, were evaluated the performances of the proposed husking system. While the performance of the separating system was evaluated by the number of full nuts which were sorted off the shells and broken nuts using the input betel nuts with various size and mixed size. After all parameters were optimized, the performance of our husking and separating systems was simultaneously evaluated in term of the percentage of husking and separating, and operation time.

3.1. Experimental Setup

Before the husking and separating processes were evaluated, these parameters of our machine were optimized to reach the best performance: 1) the rotating speeds of wheels as 240, 280, 320, 360, 400, and 440 rpm were evaluated by 60 betel nuts, that showed the best result was 440 rpm; 2) the pressure of both wheels were considered of 10, 12.5, 15, 17.5, and 20 psi, which presented the best pressure as 20 psi; 3) the clearance between the wheels and the sieves was 15, 20, 25, and 30 cm, which was tested with the random-size betel nuts. The best husking performance was obtained from the gap of 20 cm. Once all optimized parameters were obtained, the husking and separating system performances of this machine were evaluated various number of betel nuts.

3.2. Experimental Results

We evaluated the performance of the husking system as follows: 1) percentage of husking performance (full nuts; unhusked nuts; broken nuts) related to rotating speed and pressure of ATV wheels using a set of 60 dry betel nuts as represented in

Table 1 – 3; The percentage of husking performance related to the gaps between wheels and concave sieves using 300 random-size of dry betel nuts as illustrated in

Table 4. Once we obtained the optimized parameters (20 psi of tire pressure, 20 mm of the gap between the tires’ surface and the sieves, 442 rpm for husking tires)

3.2.1. Percentage of Husking Performance Related to Rotating Speed and Pressure of ATV Wheels Evaluated with 60 Dry Betel Nuts for an Experiment

In this part, the performance of husking system was evaluated in terms of percentages of full nut husking, unhusked nuts, and broken nuts as represented in

Table 1,

Table 2 and

Table 3, respectively. In

Table 1, the husking system was tested by using the rotating speed of ATV wheels from 239 rpm to 442 rpm, while the pressure of the tires was tested with 10 psi to 20 psi. The husking system performed the best performance for full nut husking by using the rotating speed of 442 rpm and the pressure of 20 psi.

Table 2 presented the percentage of unhusked nuts related to rotating speed and pressure of ATV wheels. The high percentage of unhusked nut demonstrated from the husking system using low rotating speed and low pressure. The best performance that performed the lowest unhusked nuts, was obtained by the husking system using 442 rpm and 20 psi as same as the best performance showed in

Table 1. Finally, the percentage of broken nuts related to rotating speed and pressure of ATV wheels was evaluated in

Table 3. Unfortunately, the experimental results in

Table 3 did not show significant of the husking performance for the broken nuts. However, the high rotating speed or high torque may affect to high percentage of the broken nuts. For this reason, the proposed study used only 750W AC motor for the husking system.

The percentage of husking performance related to the gaps between wheels and concave sieves using random size of dry betel nuts was evaluated in

Table 4. These results were obtained by using 442 rpm rotating speed and 20 psi for the pressure of both tires. For an experiment, 300 betel nuts was used to test the performance for a distance between wheels and concave sieves. The experimental results in

Table 4 proved that the best distance between wheels and concave sieves was 20 mm. Using the smaller gap performed high percentage of broken nuts, while the bigger gap performed high percentage of unhusked nuts.

Table 4.

Percentage of husking performance related to the gaps between wheels and concave sieves using random size of dry betel nuts.

Table 4.

Percentage of husking performance related to the gaps between wheels and concave sieves using random size of dry betel nuts.

| Gaps between wheels and concave sieves (mm) |

Husking performance (%) |

| Full nuts |

Unhusked nuts |

Broken nuts |

| 15 |

64.33 |

17.67 |

18.00 |

| 20 |

83.00 |

7.33 |

9.67 |

| 25 |

68.00 |

17.67 |

14.33 |

| 30 |

53.33 |

47.00 |

6.33 |

The percentage of husking performance related to diameter of dry betel nuts. This experiment was evaluated using 442 rpm rotating speed and 20 psi for the pressure of both tires, including 20 mm of the gaps between wheels and concave sieves. In this experiment, the proposed study used the betel nuts with the diameter of less than 30 mm, 30-45 mm, and greater than 45 mm to tested the husking performance. The results in

Table 5 indicated that the proposed husking system used the gap of 20 mm. was suitable for husking the betel nuts with the diameter less than 30 mm. However, the betel nuts with the diameter between 30-45 mm were moderately used for the proposed study. In case of betel nuts with diameter greater than 45 mm can be used for the proposed husking system, but the gap between wheels and concave sieves should be bigger than 20 mm. The average diameter of the betel nuts should approximately not be greater than 1.5 times of the gap.

3.2.2. Performance of Separating Process

The performance of the proposed separating system, that presented in

Table 6, was evaluated in various size as follow: 1) 150 betel nuts with diameter less than 25 mm; 2) 150 betel nuts with diameter between 25-30 mm; 3) 150 betel nuts with diameter greater than 30 mm; 4) 450 betel nuts with mixed size. The results of the separating system was demonstrated the full nut complete separating in

Figure 5a and the full nuts were mixed in the shell tray in

Figure 5b.

3.2.3. Performance of Husking and Separating Process

The husking and separating processes performances of our machine were evaluated by testing with 100 betel nuts for five times (500 betel nuts). The results of full nuts, unhusked nuts, and broken nuts were illustrated thoroughly in

Table 7. The husking and separating performances demonstrated full nuts of 80.2%, unhusked nuts of 13.8%, and broken nuts of 6% within 158.4 seconds. Nevertheless, most of the unhusked nuts appeared because of uneven shrinkage. The outcomes of the proposed machine were presented as in

Figure 6. The full nuts (

Figure 6a) were separated from the broken nuts (

Figure 6b), and unhusked nuts (

Figure 6c).

4. Discussion and Conclusions

The objective of this study was to create a low-cost machine for the simultaneous husking and separating of betel nuts to prevent the dangers of husking betel nuts by hand and increase the productivity of manual separating by humans. Because prior researchers were focused on husking machines or separating machines individually. The proposed husking system used to peel the betel nuts’ shells. Once the betel nuts were put into the gaps between the ATV wheels (power-transmitted from an AC electric motor with 750 Watts) and metal sieves, the shells were grazed and conveyed to the center of the separating system. The proposed separating system was designed to be two layers. The inner layer was a cylindrical frame, which was around 40 mm for 228 holes (12 rows x 19 holes), used to separate full nuts and broken nuts from shells. The outer layer was an octagonal frame, measuring approximately 20 mm and containing 240 holes (16 rows x 15 holes), which was used to separate full nuts from broken nuts. We evaluated the husking and separating performances of our machine using 500 betel nuts. The husking and separating performances demonstrated for full nuts of 80.2%, unhusked nuts of 13.8%, and the broken nuts of 6%.

Author Contributions

Conceptualization, A.P. and N.C.; methodology, A.P. and N.C.; validation, A.P and N.C.; resources, P.V. and C.J.; data curation, P.V. and C.J.; writing—original draft preparation, A.P., N.C., P.V. and C.J.; writing—review and editing, A.P., N.C., P.V. and C.J.; supervision, A.P. and N.C.; project administration, A.P. and N.C.; funding acquisition, A.P.

Funding

This research was funded by King Mongkut’s University of Technology North Bangkok, Contract no. KMUTNB-66-KNOW-09.

Acknowledgments

We would like to gratefully acknowledge our research assistants as Seksan Khampa, Sirawit Kaewchoo, and Watee Phoodinkaw for their valuable support in resources and data curation.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.:

References

- Nalawade, S.; Gajakos, A.V.; Kad, V.P. Development of manually operated areca nut dehusker. Quarterly Journal in Science, Agriculture Engineering. 2018, 7, 346–348. [Google Scholar]

- Kiran, K. Design, Development and Testing of an Areca nut Dehusking Agri-machine. Int. Journal of Engineering Research and Applications. 2014, 4, 109–115. [Google Scholar]

- Jarimopas, B.; Jaisin, C.; Singh, G. Development and testing of a husking machine for dry betel nut (Areca catechu Linn.). Biosystems Engineering. 2009, 102, 83–89. [Google Scholar] [CrossRef]

- Madhusudhana, H.K.; Satish, G.J.; Vijayakumar, N.; Sachin, P. Design and Optimization of Operating Parameters for Areca Nut De-Husker. IOP Conference Series: Materials Science and Engineering. 2020, 872, 12011. [Google Scholar] [CrossRef]

- Ravindra, N.; Sadvatha, R.H.; Senthilkumar, T.; Balaji, V. Performance evaluation of high capacity mechanised dehusking equipment for green arecanut (Areca catechu L.). Journal of Plantation Crops 2020, 126–136. [Google Scholar] [CrossRef]

- Bulan, R.; Idkham, M.; Dhafir, M.; Lubis, A. , Safwan, and Ziurrakhman U. Design and performance testing of a dry areca nut peeling machine combined with its fiber shredder. IOP Conference Series: Earth and Environmental Science. 2025, 1477, 012061. [Google Scholar]

- Darmein, Usman R, and Rusli. Angle Setting Between Two Cutters’ Blades of Dried Areca Nut Peeling Machines to Increase Its Production. IOP Conference Series: Materials Science and Engineering. 2019, 536, 12091. [Google Scholar] [CrossRef]

- Sitorus, A.; Nugraha, D.; Rustamli, D.; Muslimin, M.; Hasan, A.R.; Bulan, R. (2019). Design and Construction of Cutting Machines for Fresh Betel Nut (Areca catechu Linn). In Proceedings of the 5th International Conference on Computing Engineering and Design (ICCED). pp. 1–4. [CrossRef]

- Ernita, Y.; Novita, S.A.; Herdian, F.; Hasman, E.; Melly, S.; Yuliana, F. Design and Development of Young Areca Nut Slicing Machine. IOP Conference Series: Earth and Environmental Science. 2022, 1097, 12053. [Google Scholar] [CrossRef]

- Tamrin, T.; Budianto, L.; Warji, W.; Nasrullah, N. Design of Palm Seeds Sorting Machine. IOP Conference Series: Earth and Environmental Science. 2020, 537, 012032. [Google Scholar] [CrossRef]

- Kumar, M.; Dsouza, P.M.; Moses, S.C.; Aalam, R.N.; Paul, A. A review on areca nut processing machine. International Journal of Agriculture Extension and Social Development. 2024, 7, 417–426. [Google Scholar] [CrossRef]

- Ajith, B.S.; Pramod, B.C.; Impha, Y.D.; Rakshith, H.S.; Sudeep, K.; Padavu, P. Modeling, Fabrication and Automation of Areca Nut Sorting Machine. Journal of Mechanical Engineering and Automation. 2017, 7, 99–102. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).