Submitted:

11 October 2025

Posted:

13 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

- -

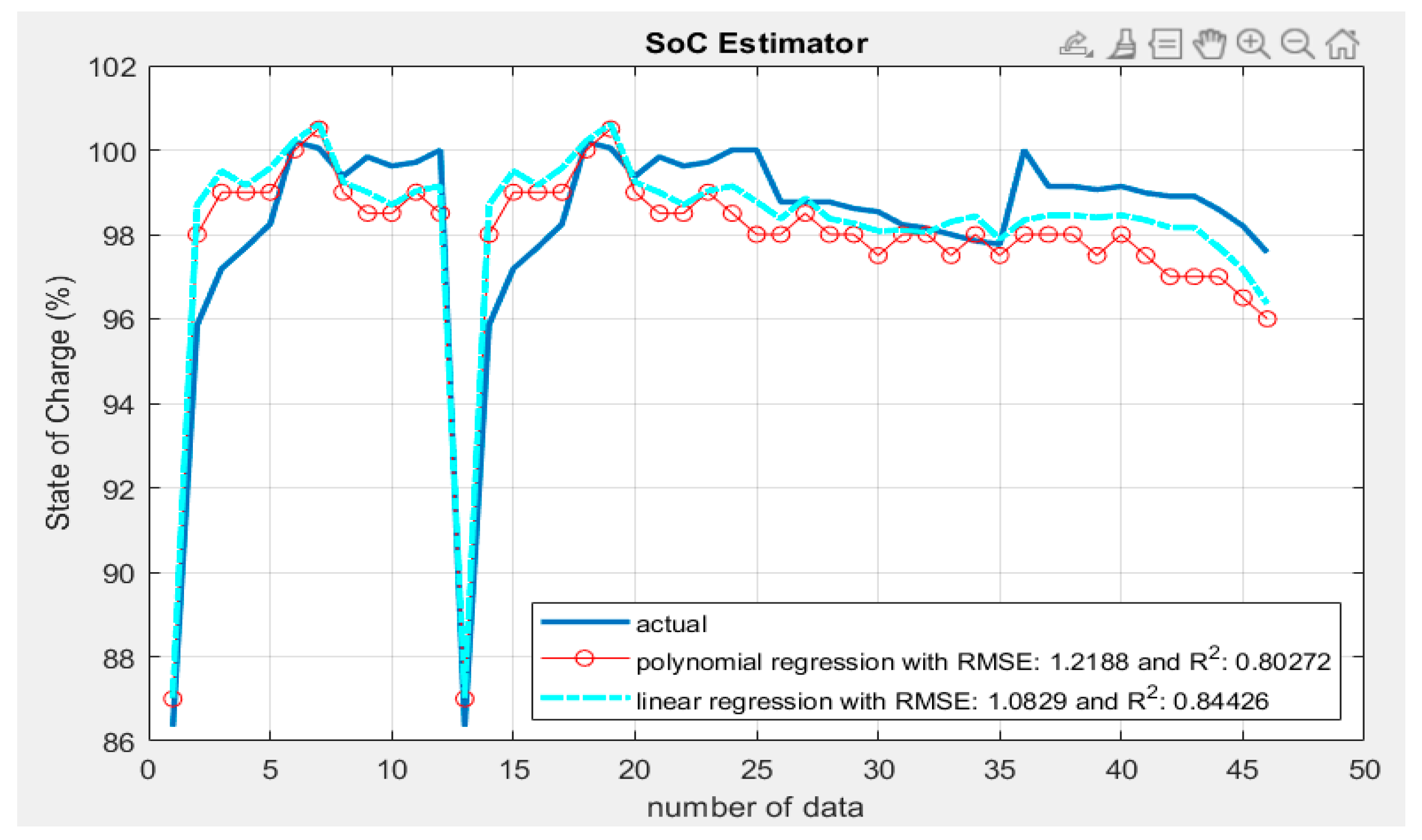

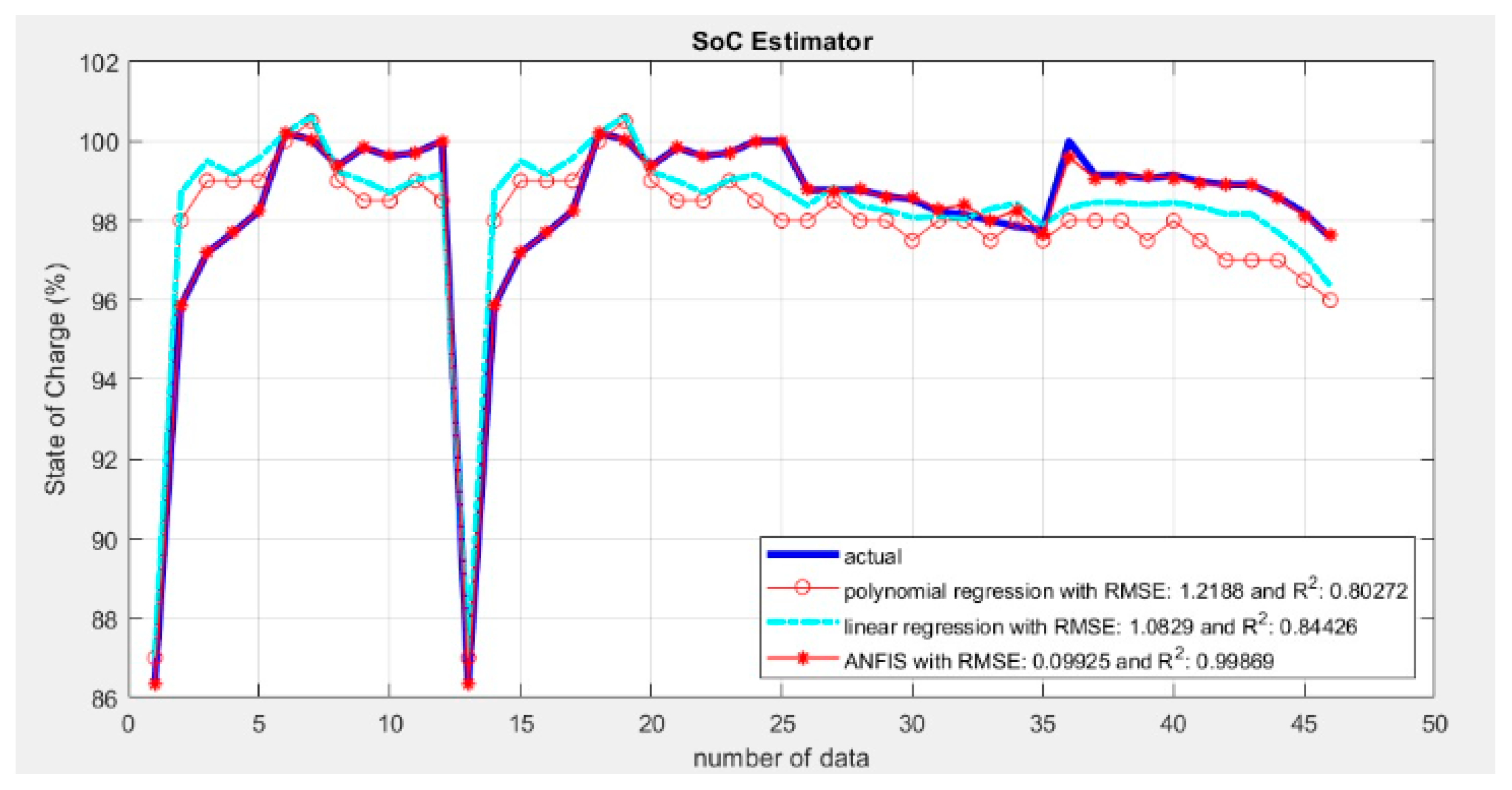

- This research proposes the estimation of the SOC parameter using a regression approach.

- -

- This research also includes a comparison with the other statistical method, i.e., the polynomial regression technique.

- -

- This research utilizes LiFePO4 batteries, whereas most other methods employ different types of lithium-ion batteries [29].

2. Materials and Methods

2.1. LiFePO4

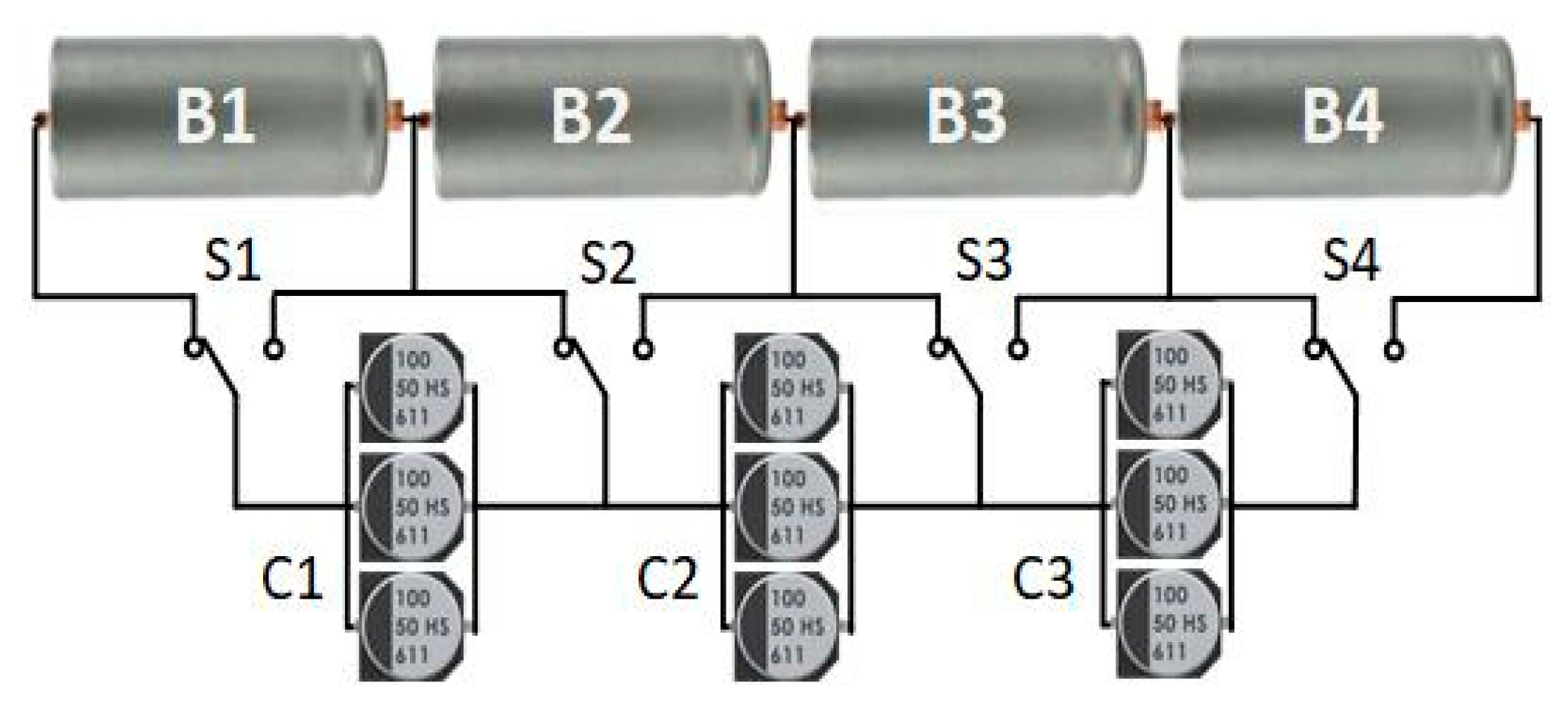

2.2. Flying Capacitor

2.3. Polynomial Regression

2.4. Linear Regression

2.5. Adaptive Neuro Fuzzy Inference System (ANFIS)

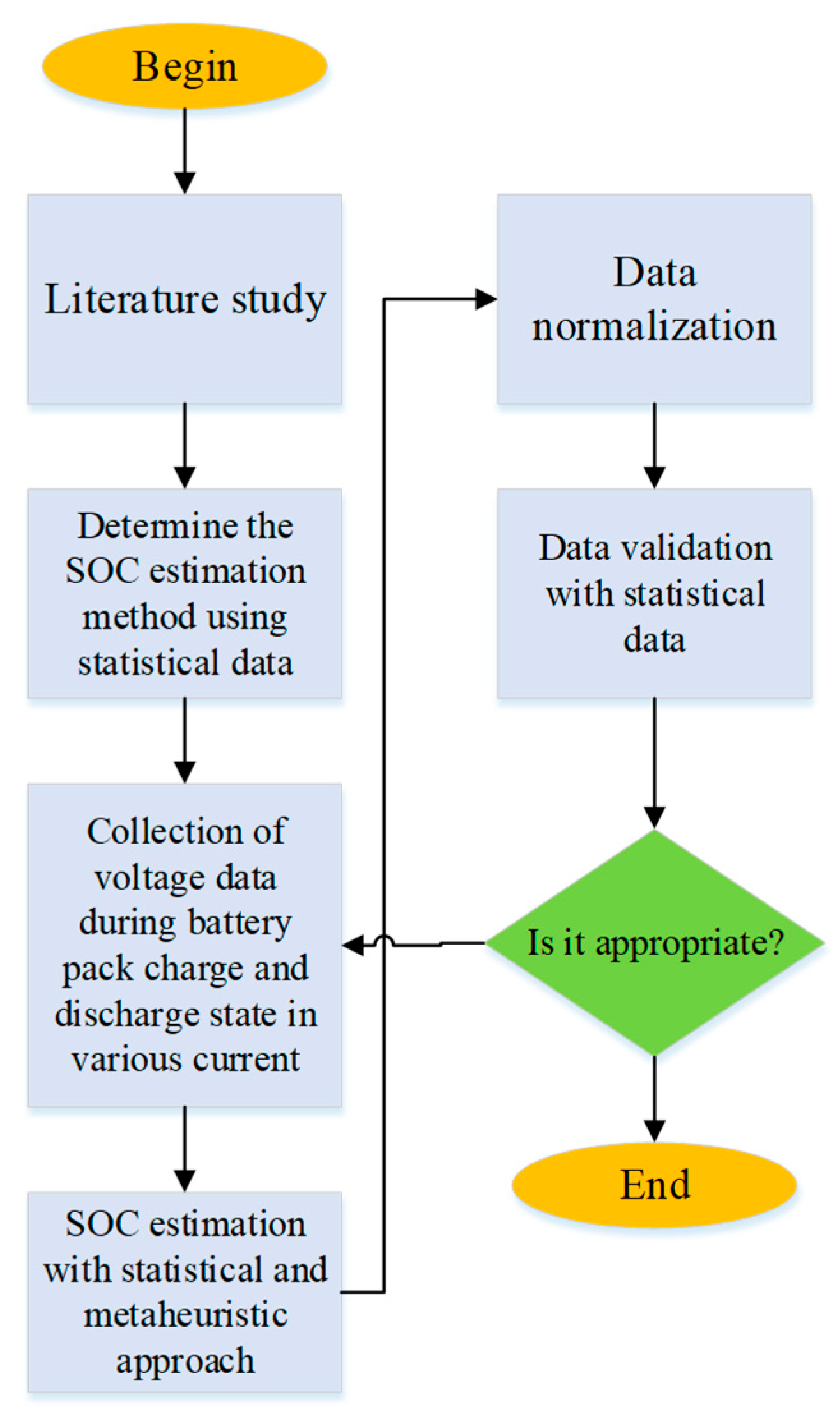

2.6. Research Flow

3. Results

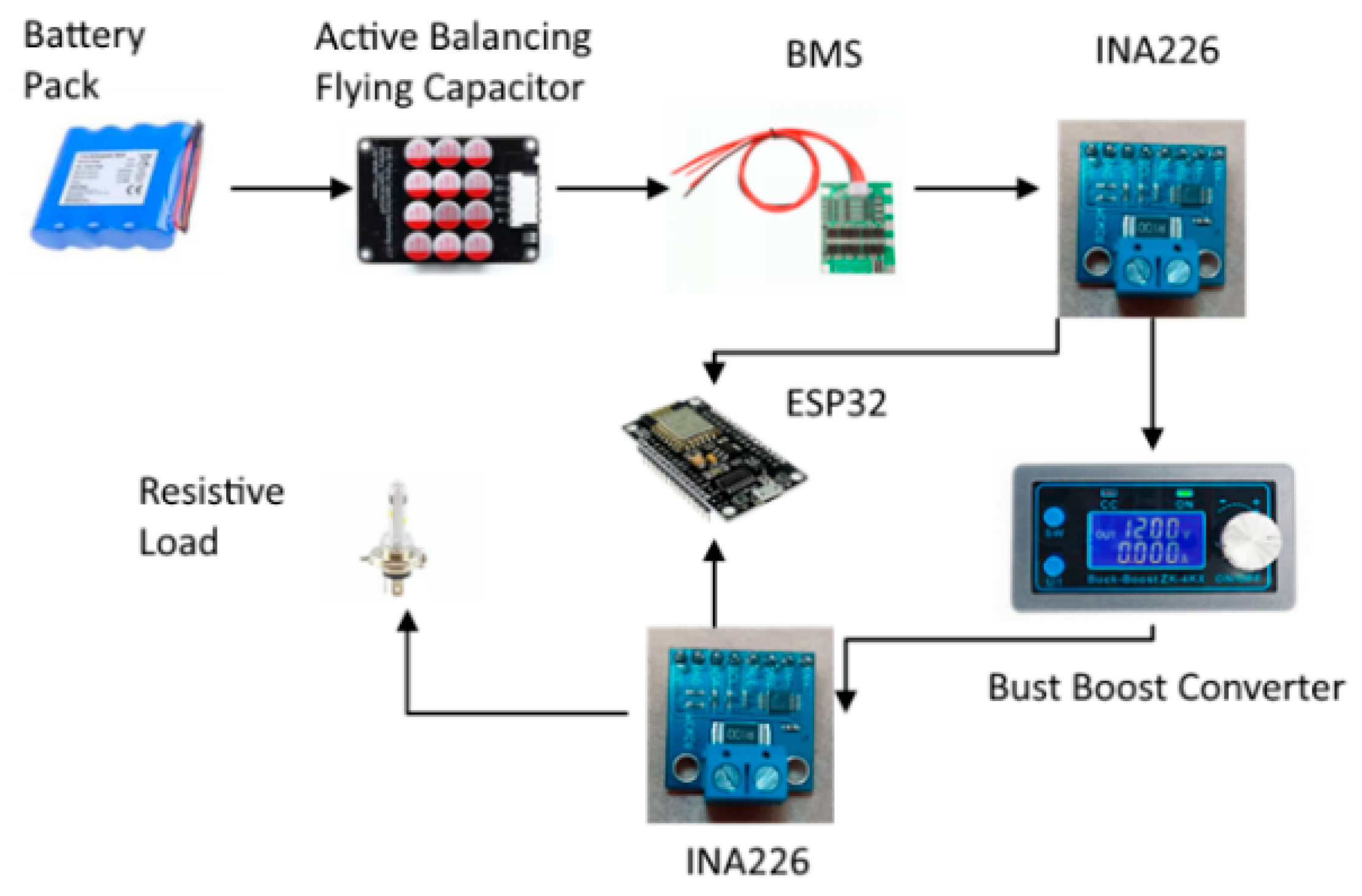

3.1. System Architecture

3.2. Dataset

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- J. B. Goodenough and K. S. Park, “The Li-ion rechargeable battery: A perspective,” J Am Chem Soc, vol. 135, no. 4, pp. 1167–1176, Jan. 2013. [CrossRef]

- Y. Ding, Z. P. Cano, A. Yu, J. Lu, and Z. Chen, “Automotive Li-Ion Batteries: Current Status and Future Perspectives,” Electrochemical Energy Reviews 2019 2:1, vol. 2, no. 1, pp. 1–28, Jan. 2019. [CrossRef]

- L. H. Saw, Y. Ye, and A. A. O. Tay, “Integration issues of lithium-ion battery into electric vehicles battery pack,” J Clean Prod, vol. 113, pp. 1032–1045, Feb. 2016. [CrossRef]

- H. A. Gabbar, A. M. Othman, and M. R. Abdussami, “Review of Battery Management Systems (BMS) Development and Industrial Standards,” Technologies 2021, Vol. 9, Page 28, vol. 9, no. 2, p. 28, Apr. 2021. [CrossRef]

- K. Liu, K. Li, Q. Peng, and C. Zhang, “A brief review on key technologies in the battery management system of electric vehicles,” Frontiers of Mechanical Engineering, vol. 14, no. 1, pp. 47–64, Mar. 2019. [CrossRef]

- M. Nasution, “Karakteristik Baterai Sebagai Penyimpan Energi Listrik Secara Spesifik | Nasution | JET (Journal of Electrical Technology).” Accessed: Nov. 07, 2024. [Online]. Available: https://jurnal.uisu.ac.id/index.php/jet/article/view/3797.

- Z. B. Omariba, L. Zhang, and D. Sun, “Review on Health Management System for Lithium-Ion Batteries of Electric Vehicles,” Electronics 2018, Vol. 7, Page 72, vol. 7, no. 5, p. 72, May 2018. [CrossRef]

- Z. B. Omariba, L. Zhang, and D. Sun, “Review of Battery Cell Balancing Methodologies for Optimizing Battery Pack Performance in Electric Vehicles,” IEEE Access, vol. 7, pp. 129335–129352, 2019. [CrossRef]

- B. Balasingam, M. Ahmed, and K. Pattipati, “Battery Management Systems—Challenges and Some Solutions,” Energies 2020, Vol. 13, Page 2825, vol. 13, no. 11, p. 2825, Jun. 2020. [CrossRef]

- H. S, “Overview of cell balancing methods for Li-ion battery technology,” Energy Storage, vol. 3, no. 2, p. e203, Apr. 2021. [CrossRef]

- M. Uzair, G. Abbas, and S. Hosain, “Characteristics of Battery Management Systems of Electric Vehicles with Consideration of the Active and Passive Cell Balancing Process,” World Electric Vehicle Journal 2021, Vol. 12, Page 120, vol. 12, no. 3, p. 120, Aug. 2021. [CrossRef]

- A. B. Ahmad, C. A. Ooi, D. Ishak, and J. Teh, “Cell Balancing Topologies in Battery Energy Storage Systems: A Review,” Lecture Notes in Electrical Engineering, vol. 547, pp. 2019. [CrossRef]

- S. L. Wu, H. C. Chen, and C. H. Chien, “A Novel Active Cell Balancing Circuit and Charging Strategy in Lithium Battery Pack,” Energies 2019, Vol. 12, Page 4473, vol. 12, no. 23, p. 4473, Nov. 2019. [CrossRef]

- K. P. Nivya and K. Deepa, “Active cell balancing for a 2s Lithium ion battery pack using flyback converter and push-pull converter,” IOP Conf Ser Mater Sci Eng, vol. 1070, no. 1, p. 012097, Feb. 2021. [CrossRef]

- Suhariningsih, F. Yulianda, E. Sunarno, and M. A. B. Nugroho, “Battery Management System dengan Fitur Adaptive Current Protection terhadap Suhu,” ELKOMIKA: Jurnal Teknik Energi Elektrik, Teknik Telekomunikasi, & Teknik Elektronika, vol. 12, no. 2, p. 498, Apr. 2024. [Google Scholar] [CrossRef]

- “Battery Minimum State Of Charge.” Accessed: Nov. 12, 2024. [Online]. Available: https://homerenergy.com/products/pro/docs/3.15/battery_minimum_state_of_charge.html.

- T. Huria, M. Ceraolo, J. Gazzarri, and R. 2012 IEEE International Electric Vehicle Conference, IEVC 2012, 2012. [CrossRef]

- S. Piller, M. Perrin, and A. Jossen, “Methods for state-of-charge determination and their applications,” J Power Sources, vol. 96, no. 1, pp. 113–120, Jun. 2001. [CrossRef]

- V. Pop, H. J. Bergveld, P. H. L. Notten, and P. P. L. Regtien, “State-of-the-art of battery state-of-charge determination,” Meas Sci Technol, vol. 16, no. 12, p. R93, Oct. 2005. [CrossRef]

- G. L. Plett, “Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 1. Background,” J Power Sources, vol. 134, no. 2, pp. 252–292, Aug. 2004. [CrossRef]

- M. Chen and G. A. Rincón-Mora, “Accurate electrical battery model capable of predicting runtime and I-V performance,” IEEE Transactions on Energy Conversion, vol. 21, no. 2, pp. 504–511, Jun. 2006. [CrossRef]

- Y. Muratoglu and A. Alkaya, “Unscented Kalman Filter based State of Charge Estimation for the Equalization of Lithium-ion Batteries on Electrical Vehicles,” Engineering, Technology & Applied Science Research, vol. 9, no. 6, pp. 4876–4882, Dec. 2019. [CrossRef]

- Y. Zhang, W. Song, S. Lin, and Z. Feng, “A novel model of the initial state of charge estimation for LiFePO4 batteries,” J Power Sources, vol. 248, pp. 1028–1033, Feb. 2014. [CrossRef]

- K. S. Ng, Y. F. Huang, C. S. Moo, and Y. C. INTELEC, International Telecommunications Energy Conference (Proceedings), 2009. [CrossRef]

- L. Zhong, C. Zhang, Y. He, and Z. Chen, “A method for the estimation of the battery pack state of charge based on in-pack cells uniformity analysis,” Appl Energy, vol. 113, pp. 558–564, Jan. 2014. [CrossRef]

- R. Zhang et al., “State of the Art of Lithium-Ion Battery SOC Estimation for Electrical Vehicles,” Energies 2018, Vol. 11, Page 1820, vol. 11, no. 7, p. 1820, Jul. 2018. [CrossRef]

- J. C. Alvarez Anton, P. J. Garcia Nieto, C. Blanco Viejo, and J. A. Vilan Vilan, “Support vector machines used to estimate the battery state of charge,” IEEE Trans Power Electron, vol. 28, no. 12, pp. 5919–5926, 2013. [CrossRef]

- E. Chemali, P. J. Kollmeyer, M. Preindl, R. Ahmed, and A. Emadi, “Long Short-Term Memory Networks for Accurate State-of-Charge Estimation of Li-ion Batteries,” IEEE Transactions on Industrial Electronics, vol. 65, no. 8, pp. 6730–6739, Aug. 2018. [CrossRef]

- A. H. Pandyaswargo, A. D. Wibowo, M. F. N. Maghfiroh, A. Rezqita, and H. Onoda, “The Emerging Electric Vehicle and Battery Industry in Indonesia: Actions around the Nickel Ore Export Ban and a SWOT Analysis,” Batteries 2021, Vol. 7, Page 80, vol. 7, no. 4, p. 80, Nov. 2021. [CrossRef]

- L. Lu, X. Han, J. Li, J. Hua, and M. Ouyang, “A review on the key issues for lithium-ion battery management in electric vehicles,” J Power Sources, vol. 226, pp. 272–288, Mar. 2013. [CrossRef]

- W. J. Zhang, “Structure and performance of LiFePO4 cathode materials: A review,” J Power Sources, vol. 196, no. 6, pp. 2962–2970, Mar. 2011. [CrossRef]

- H. Chen, “Research on battery pack dynamic equalization technology with improved flying capacitor,” International Journal of Low-Carbon Technologies, vol. 16, no. 1, pp. 199–204, Mar. 2021. [CrossRef]

| Id | State (Charge = 1, Discharge = 0) | |||||||

| Time | V1 | V2 | V3 | V4 | Tot V | SOC | State | |

| 1 | 0 | 2.74 | 2.74 | 3.19 | 2.94 | 11.61 | 86 | 1 |

| 2 | 10 | 2.74 | 2.74 | 3.19 | 2.94 | 11.61 | 86 | 1 |

| 3 | 20 | 3.23 | 3.22 | 3.23 | 3.21 | 12.89 | 96 | 1 |

| 4 | 30 | 3.27 | 3.28 | 3.249 | 3.27 | 13.069 | 97 | 1 |

| 5 | 40 | 3.289 | 3.293 | 3.275 | 3.28 | 13.137 | 98 | 1 |

| 6 | 50 | 3.328 | 3.294 | 3.288 | 3.301 | 13.211 | 98 | 1 |

| 7 | 60 | 3.325 | 3.52 | 3.31 | 3.318 | 13.473 | 100 | 1 |

| 8 | 70 | 3.356 | 3.446 | 3.306 | 3.345 | 13.453 | 100 | 1 |

| 9 | 80 | 3.354 | 3.337 | 3.329 | 3.343 | 13.363 | 99 | 1 |

| 10 | 90 | 3.372 | 3.356 | 3.351 | 3.346 | 13.425 | 100 | 1 |

| ... | ... | ... | ... | ... | ... | ... | ... | ... |

| 25 | 0 | 3.25 | 3.24 | 3.25 | 3.25 | 12.99 | 100 | 0 |

| 26 | 12 | 3.2 | 3.2 | 3.22 | 3.21 | 12.83 | 99 | 0 |

| 27 | 24 | 3.21 | 3.2 | 3.21 | 3.21 | 12.83 | 99 | 0 |

| 28 | 36 | 3.2 | 3.2 | 3.22 | 3.21 | 12.83 | 99 | 0 |

| 29 | 48 | 3.2 | 3.19 | 3.22 | 3.2 | 12.81 | 99 | 0 |

| Id | State (Charge = 1, Discharge = 0) | |||||||

| Time | V1 | V2 | V3 | V4 | Tot V | SOC | State | |

| 30 | 60 | 3.19 | 3.19 | 3.22 | 3.2 | 12.8 | 99 | 0 |

| 31 | 72 | 3.18 | 3.18 | 3.21 | 3.19 | 12.76 | 98 | 0 |

| 32 | 84 | 3.18 | 3.18 | 3.21 | 3.18 | 12.75 | 98 | 0 |

| 33 | 96 | 3.18 | 3.17 | 3.2 | 3.18 | 12.73 | 98 | 0 |

| 34 | 108 | 3.17 | 3.17 | 3.19 | 3.18 | 12.71 | 98 | 0 |

| 35 | 120 | 3.16 | 3.17 | 3.2 | 3.17 | 12.7 | 98 | 0 |

| ... | ... | ... | ... | ... | ... | ... | ... | ... |

| 46 | 120 | 3.08 | 3.1 | 3.18 | 3.11 | 12.47 | 98 | 0 |

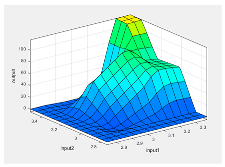

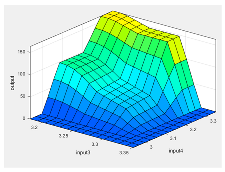

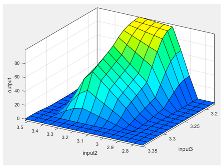

| 1 | V1, V2, SOC |  |

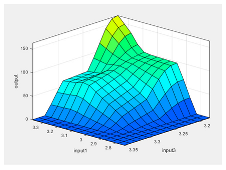

| 2 | V1, V3, SOC |  |

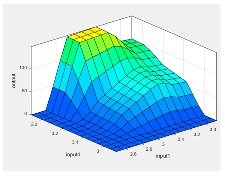

| 3 | V1, V4, SOC |  |

| Id | Relation | Surface View |

| 5 | V3, V4, SOC |  |

| 6 | V2, V3, SOC |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).