Submitted:

01 October 2025

Posted:

02 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

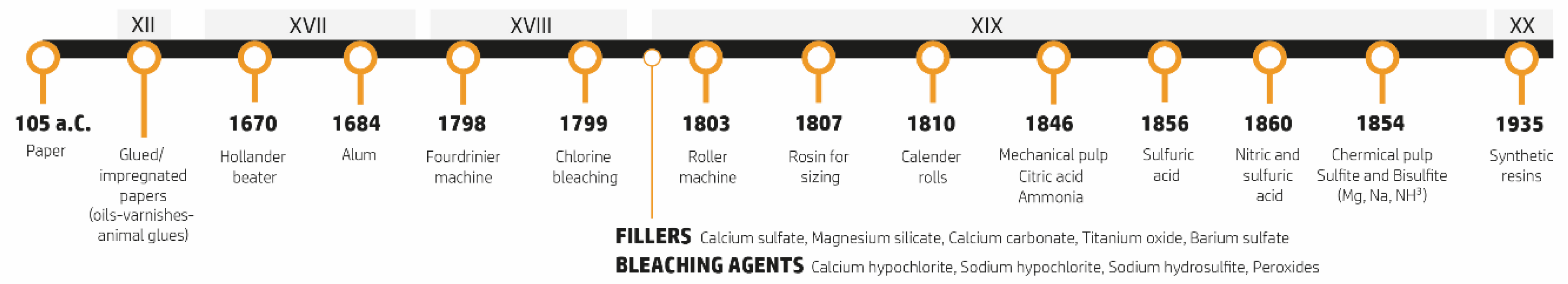

1.1. Evolution of Materials and Manufacturing Processes of Translucent Paper

1.2. Alterations and Conservation of Supports in Translucent Paper

-

Chemical alterations:Acidity: resulting from the use of highly acidic compounds and wood-based pulps. Acidity accelerates the degradation of the support, being enhanced by exposure to light, heat, and humidity.Yellowing: color change associated with lignin and cellulose degradation, accelerated by oxidation, hydrolysis, and light exposure. In translucent papers with added fatty substances, it is also due to the oxidation of the oils or varnishes used, reflecting the natural aging of the material.Darkening/opacity: loss of clarity and transparency of the paper due to surface dirt or chemical processes such as oxidation or hydrolysis.

-

Biological alterations:Fungi and microorganisms: although biological action is less frequent in translucent papers than in conventional ones, under extreme conditions of humidity, lack of ventilation, and high temperature, their proliferation can intensify the described alterations and contaminate other supports without direct contact.

-

Physical-mechanical alterations:Brittle and friable support: extreme fragility due to acidification processes, light exposure, handling, and variations in humidity and temperature.Abrasion: surface wear commonly caused by improper handling, lack of cleaning, weakening, or chemical alteration of the support.Deformation: alteration of the paper’s flatness due to environmental variations, especially humidity, as well as handling or improper storage (rolled, folded, etc.).Folds: deformations caused by improper handling or packaging. In fragile papers, folds can generate fractures and loss of support.Fracture: physical damage manifested as a broken line with microcracks in the cellulose fibres caused by folding. In translucent papers, these appear as light-toned lines.Tear: separation of the paper due to tension or localized fragility arising from folds or fractures, exposing and weakening the structural fibres of the support.Loss of support: loss of parts of the document, generally due to tears, metallic elements (staples), or incorrect handling. In this type of support, due to its characteristics and function, it is important to evaluate whether the missing material is the result of alteration or an original irregularity of the document.Surface dirt and stains: accumulation of external particles such as dust, environmental contaminants, or biological residues on the paper surface. This presence can result in localized stains or chromatic alterations caused by multiple factors: microorganisms, adhesives, metals, fats, humidity, or chemical degradation processes. The most frequent manifestations include:Tape stains: yellowing and darkening that are difficult to remove, caused by the degradation of tape adhesives. In this study, three types of tape are highlighted: paper tape with rubber adhesive, transparent cellulose acetate tape, and polypropylene packaging tape.Migration stains: caused by contact of the paper with water, which carries soluble substances, leaving an irregular dark edge.Contact stains: transfer of generally soluble compounds from one document to another due to direct contact.Stains from the addition of fatty substances: irregular application and absorption can, after aging and oxidation processes, produce yellowing, darkening, and heterogeneous stain appearance. In addition, these substances may create some surface stickiness, attracting dirt and facilitating adhesion and contamination of other documents in contact.Alterations from additives or anthropogenic causes: stains, tears, or loss of material caused by elements such as staples, clips, or other objects added later.

2. Materials and Methods

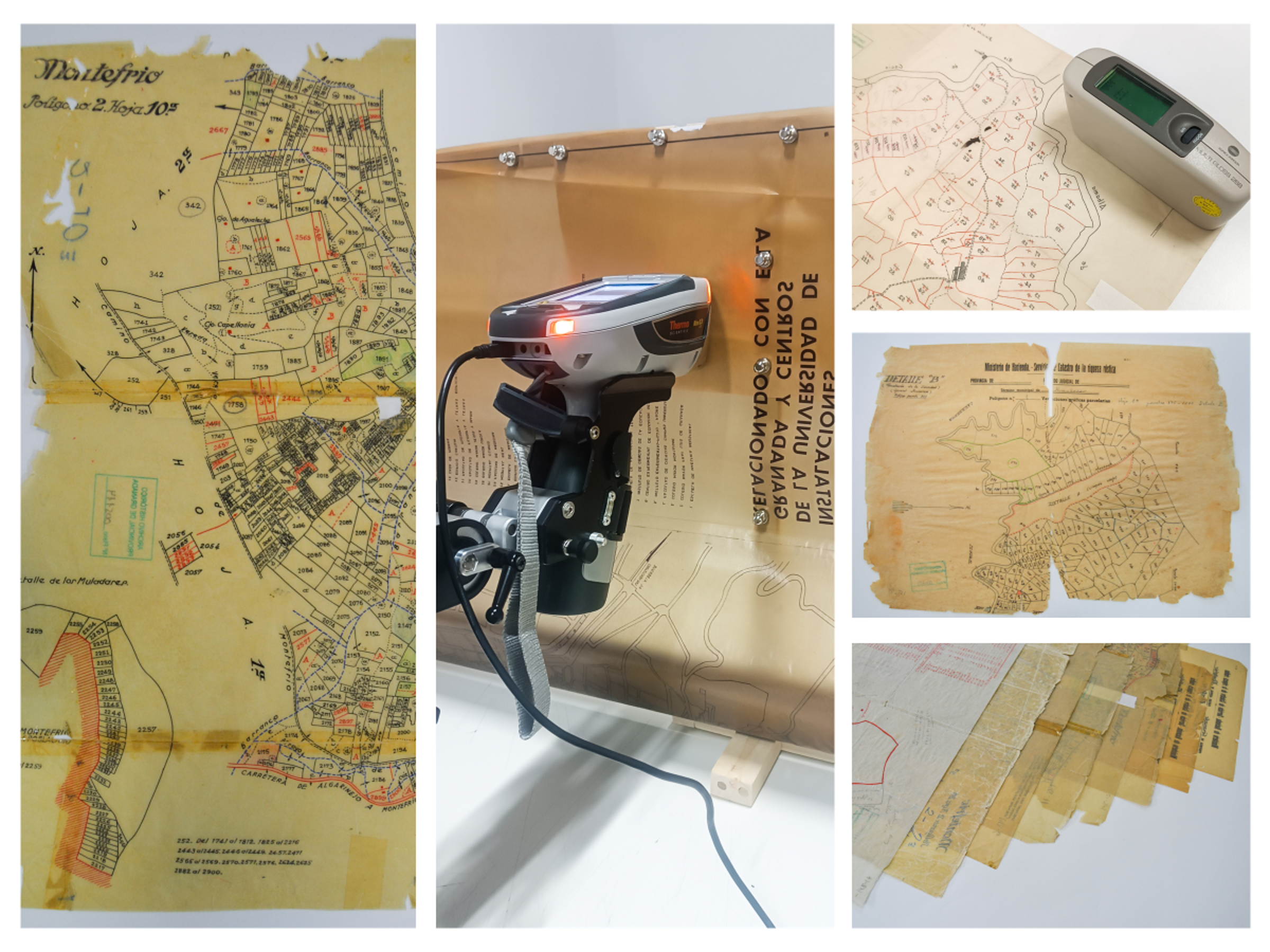

2.1. Equipment, Materials and Methodology

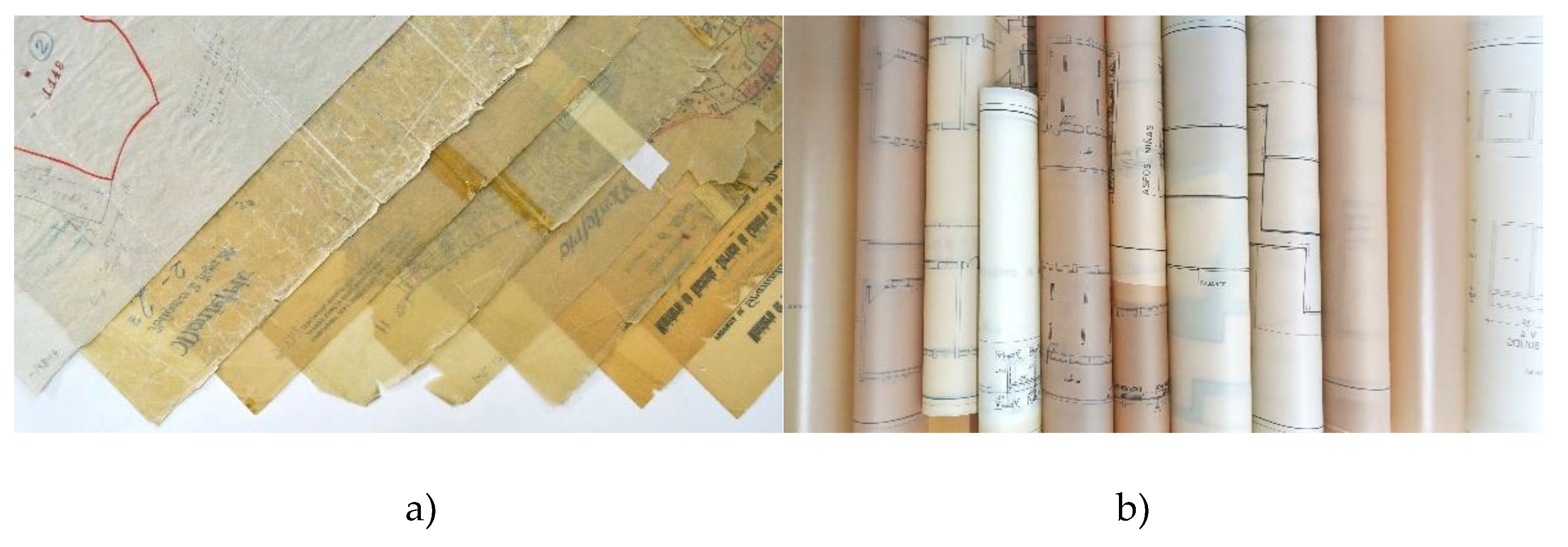

2.2. Study Collections

4. Results

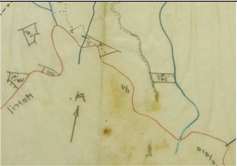

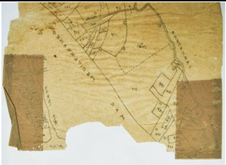

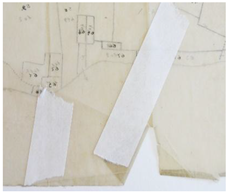

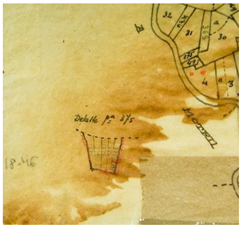

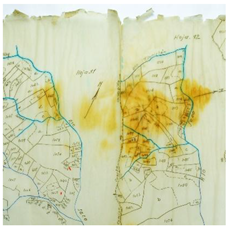

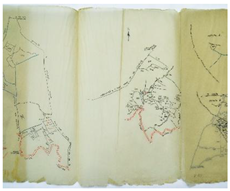

4.1. Visual Study and Photographic Recording of Characteristic Alterations in Plans on Translucent Paper

4.2. Evaluation of Types of Translucent Paper Based on Their State of Conservation and the Study of Physical Parameters. Color Study

4.3. Studies Using X-Ray Fluorescence Spectroscopy (XRF) and Fourier Transform Infrared Spectroscopy (FTIR)

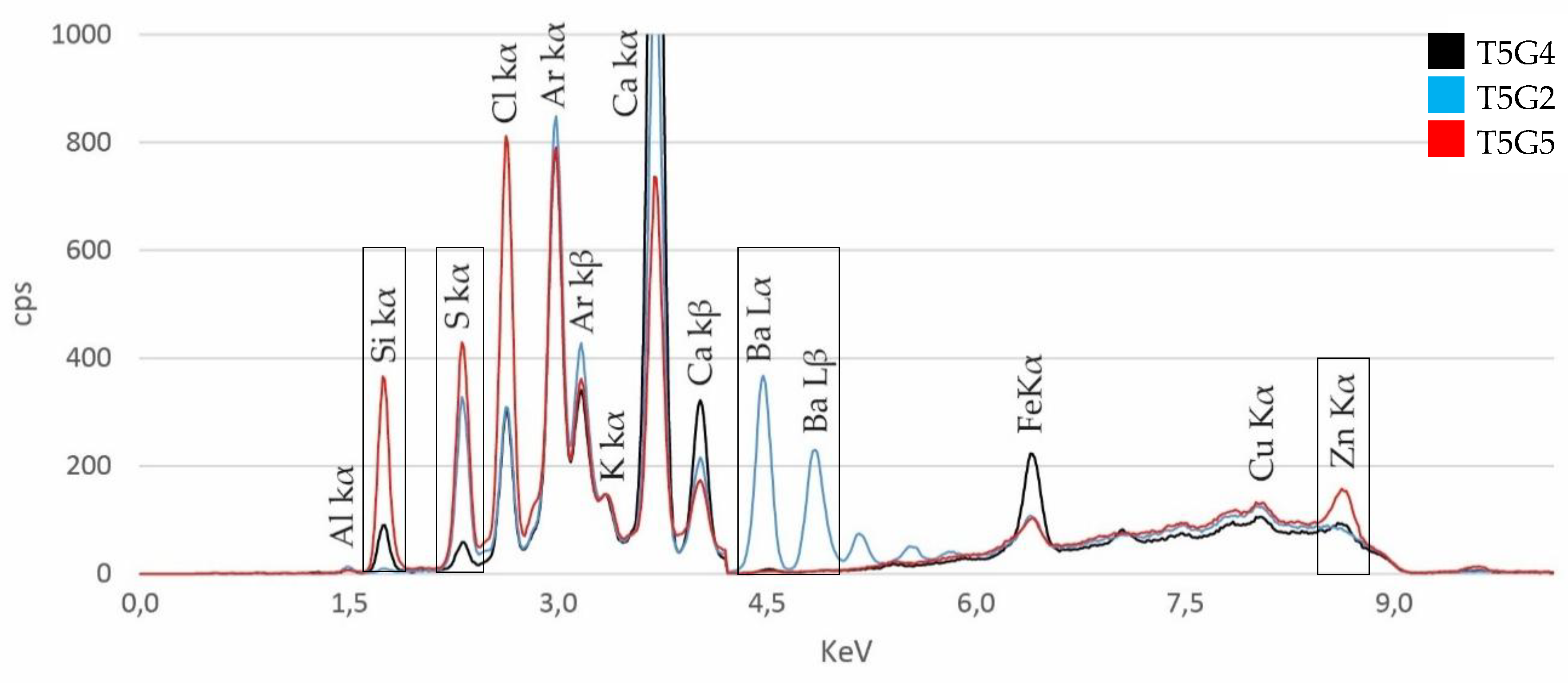

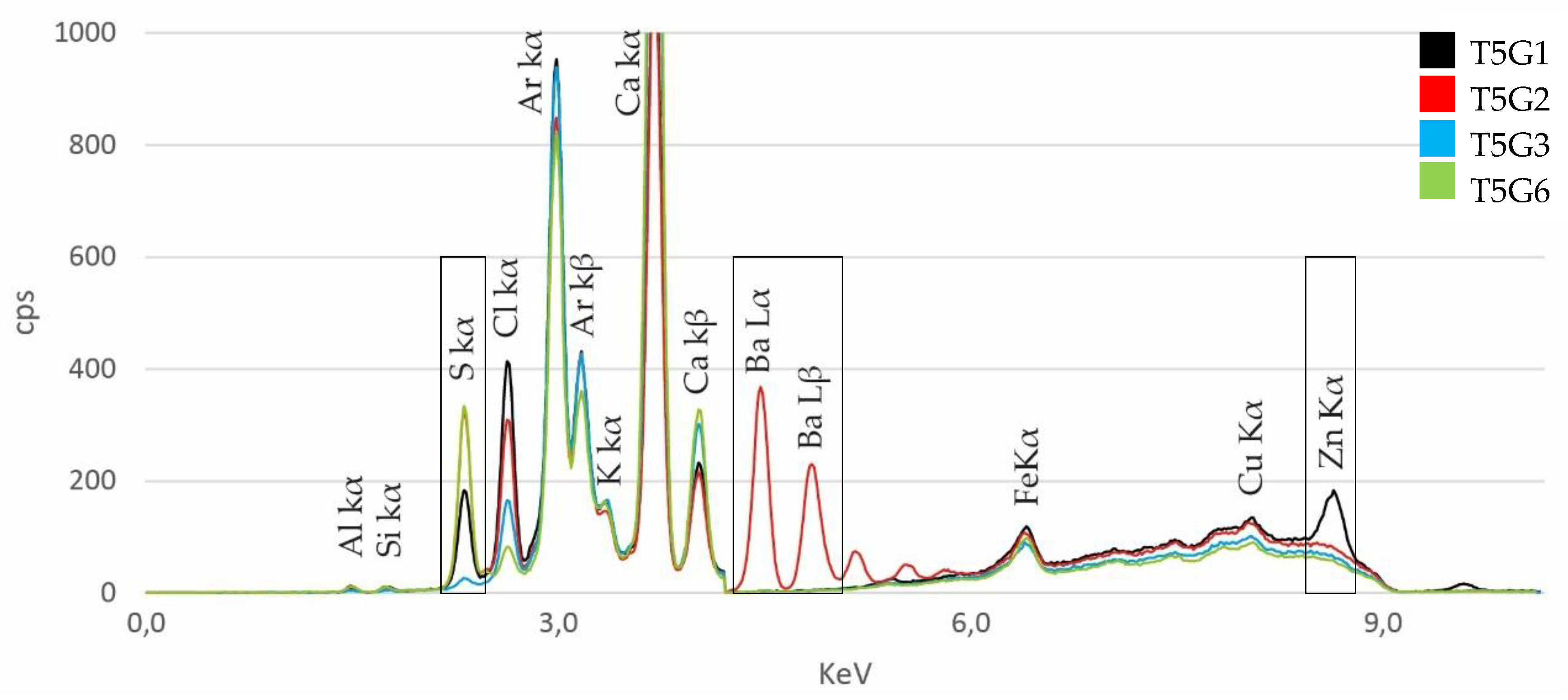

- Sulfur (S): this is a key element regarding the study of sulfurized papers (produced mainly through treatments with sulfuric acid); however, its use as an additive in paper manufacturing processes or in sulfite and bisulfite chemical pulps should also be considered [44]. In Figure 4, higher-intensity sulfur bands can be observed along with elements such as barium or zinc in their composition (T5G1 and T5G2). Among the documents containing sulfur accompanied only by elements common to the rest of the documents, intense sulfur bands were identified in only 2% of cases (T5G6) compared to 55% of papers showing weak sulfur bands (T5G3). It is noteworthy that the presence of sulfur accompanied by other elements could also be due to its action as sulfates or components of additives, ruling out its presence as an indicator of sulfuric acid use, which is typical of sulfurized translucent papers.

- Barium (Ba): although theoretically not mentioned as a relevant element in the manufacture of translucent papers, there are references associating its use as a filler or in bleaching processes to improve surface properties in cellulosic supports [40]. Observing Table 5, and in the specific case of group T5G2, a significant presence of barium is found in relation to the other elements, associated in all cases with intense sulfur bands, absence of zinc, and the presence of silicon only as traces (Figure 5). Despite its absence in descriptions of translucent support manufacturing processes, its highly specific behavior suggests that it could act as a chemical marker for a specific type of translucent paper. Additionally, visually these papers show a tendency toward less yellowed and darker tones, especially compared to documents classified in group T3G1 of Table 3. However, this phenomenon cannot be attributed solely to the presence of barium, as documents without barium also exhibit similar characteristics.

- Silicon (Si): it is known in the paper industry for improving ink receptivity, strength, and filler compounds, and can be considered as an additive or derived from compounds used in pulp treatments and manufacturing [40,45]. In the case of translucent papers, although it appears mainly as traces in most documents, in a small number of cases (5%) it also shows particular band intensities. Unlike barium, the presence of considerable silicon bands has been associated with weak sulfur bands (group T5G4 in Table 5 and Figure 5). Only in group T5G5 has a high intensity of silicon and sulfur been related to the presence of other elements such as zinc or barium.

- Zinc (Zn): this element, detected in 24% of the documents, is associated with high sulfur bands (groups T5G1 and T5G5 in Table 5 and Figure 4 and Figure 5). However, in this specific case, the physical and visual analysis helps detect the relationship of both groups directly with a specific intaglio technique in which the translucent paper receives an emulsion. Therefore, the presence of zinc is related to those coatings applied to the translucent papers, providing not only an additional layer but also a gloss and texture that characterize both the technique and the support (relation to group T3G3 in Table 3). There are references to the use of zinc compounds for purposes similar to other elements such as aluminum, silicon, and phosphorus [19]. However, in this case, the intensities corresponding to zinc bands are much higher than in the cases of Al, Si, or P, and are characteristic only of the documents that contain this emulsion. Many patents developed throughout the 20th century mention the use of emulsions for the production of diazotypes with zinc compounds, such as US patent 4,478,926 by Muller and Mustacchi (1984), highlighting the use of zinc sulfonates offering significant advantages as stabilizers in diazotype materials (reproductions of plans or technical drawings obtained through a photochemical process using diazonium salts sensitive to ultraviolet light) [46,47].

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| XRF | X-ray fluorescence spectroscopy |

| FTIR | Fourier-transform infrared spectroscopy |

| CIE Lab* | Commission Internationale de l’Éclairage L*a*b* color space |

| RGB | Red, Green, Blue color space |

| AHP | Archivo Histórico Provincial de Granada (Provincial Historical Archive of Granada) |

| ETSAG | Escuela Técnica Superior de Arquitectura de Granada (Higher Technical School of Architecture of Granada) |

| T3G1 | Group 1 (G1) of Table 3 (T3) |

| T3G2 | Group 2 (G2) of Table 3 (T3) |

| T3G3 | Group 3 (G3) of Table 3 (T3) |

| T5G1 | Group 1 (G1) of Table 5 (T5) |

| T5G2 | Group 2 (G2) of Table 5 (T5) |

| T5G3 | Group 3 (G3) of Table 5 (T5) |

| T5G4 | Group 4 (G4) of Table 5 (T5) |

| T5G5 | Group 5 (G5) of Table 5 (T5) |

| T5G6 | Group 6 (G6) of Table 5 (T5) |

References

- Hubbe, M. A.; Venditti, R. A.; Rojas, O. J. What happens to cellulosic fibers during papermaking and recycling? A review. BioResources 2007, 2(4), pp. 739-788.

- Moreno, M. Microbiodeterioro por hongos en obras en papel: procesos de alteración y tratamientos de desinfección. MoleQla: revista de Ciencias de la Universidad Pablo de Olavide 2018, 32, pp. 1-3.

- Laroque, C. Diversity of transparent papers in public collections: A conservation challenge. Conservation Update 2023, 2, pp. 6–32. [CrossRef]

- González, V. F. Restauración de obra en papel transparente. Boletín de la Universidad del Museo Social Argentino 2017, pp. 135-152.

- El-Sharkawy, K.; Haavisto, S.; Koskenhely, K.; Paulapuro, H. Effect of fiber flocculation and filling design on refiner loadability and refining characteristics. BioResources 2008, 3(2), pp. 403-424.

- Wilson, H. A decision framework for the preservation of transparent papers. Journal of the Institute of Conservation, 2015, 38(1), pp. 54-64. [CrossRef]

- Hubbe, M. A.; Pawlak, J. J.; Koukoulas, A. A. Paper’s appearance: A review. BioResources 2008, 3(2), pp. 627-665. [CrossRef]

- Axelsson, K. Transparent papers: A review of the history and manufacturing processes. IPH Paper History 2016, 20(1), pp. 21-31.

- Lorente, R.; López, A.; Blanc, R. Planimetría en soportes traslúcidos de la Colección de Planos del Archivo del Patronato de la Alhambra y Generalife: Identificación mediante tecnología in situ no invasiva. Cuadernos de la Alhambra 2024, 53, pp.101-117.

- Teschke, K.; Demers, P. Industria del papel y de la pasta de papel sectores basados en recursos biológicos. Enciclopedia de salud y seguridad en el trabajo III, 2001, III (72), pp. 72.1-71.21.

- Viñas Lucas, R. El papel vegetal. Problemática y restauración. Pátina 1991, 5, pp. 54-60.

- Hermosín, R. Características de los distintos soportes sobre los que se reproducen planos y esferas. Revista ph 2011, 77, pp. 47-53. [CrossRef]

- Ioelovich, M.; Leykin, A. Structural investigations of various cotton fibers and cotton celluloses. BioResources 2008, 3(1), pp. 170-177. [CrossRef]

- Hubbe, M. A.; Heitmann, J. A. Review of factors affecting the release of water from cellulosic fibers during paper manufacture. BioResources 2007, 2(3), pp. 500-533. [CrossRef]

- Hubbe, M. A. Bonding between cellulosic fibers in the absence and presence of dry-strength agents–A review. BioResources 2006, 1(2), pp. 281-318. [CrossRef]

- Subramanian, R.; Kononov, A.; Kang, T., Paltakari, J.; Paulapuro, H. Structure and properties of some natural cellulosic fibrils. BioResources 2008, 3(1), pp. 192-203. [CrossRef]

- Porankiewicz, B.; Wieloch, G. Drill wear during the boring of particle board: A multi-factor analysis including effects of mineral contaminants. BioResources 2008, 3(2), pp. 425-436. [CrossRef]

- Shen, J.; Song, Z.; Qian, X.; Liu, W. Modification of papermaking grade fillers: a brief review. BioResources 2009, 4(3), pp. 1190-1209. [CrossRef]

- Gurnagul, N.; Howard, R. C.; Zou, X.; Uesaka, T.; Page, D. H. The mechanical permanence of paper: a literature review. Journal of pulp and paper science 1993, 19, pp. J160-J160.

- Sterflinger, K., & Pinzari, F. The revenge of time: fungal deterioration of cultural heritage with particular reference to books, paper and parchment. Environmental Microbiology 2012, 14(3), pp. 559-566. [CrossRef]

- Sequeira, S. O.; Cabrita, E. J.; Macedo, M. F. Fungal biodeterioration of paper: how are paper and book conservators dealing with it? An international survey. Restaurator 2014, 35(2), pp. 181-199. [CrossRef]

- Borrego, S.; Lavin, P.; Perdomo, I.; Gómez de Saravia, S.; Guiamet, P. Determination of indoor air quality in archives and biodeterioration of the documentary heritage. International Scholarly Research Notices 2012, 1, 680598. [Google Scholar] [CrossRef] [PubMed]

- Díaz de Miranda, D. La restauración de documentos gráficos: problemática y pautas de intervención. Patrimonio cultural: Documentación, estudios, información, 2008, 50, pp. 125-158.

- Daniels, V. The chemistry of translucent paper. The Paper Conservator 1996, 25, pp. 179–186. [CrossRef]

- Banik, G.; Brückle, I. Paper and water: A guide for conservators. Butterworth-Heinemann: Oxford, England, 2011.

- Mills, J. S.; White, R. The organic chemistry of museum objects (2nd ed.). Routledge: London, England, 1994.

- Karlovits, M.; Gregor-Svetec, D. Durability of cellulose and synthetic papers exposed to various methods of accelerated ageing. Acta Polytechnica Hungarica, 2012, 9(6), pp. 81-100. [CrossRef]

- Udina, R. Calcos y transparencias: papeles para copiar. Restauración de papeles vegetales impregnados. En Papeles en el balcón, 1st ed.; Universidad de Granada, Granada, España, 2021, pp. 42-67.

- Bojanoski, S.; Almada, M. Glosario ilustrado de conservación y restauración de obras en papel: deterioro y tratamientos—español, portugués, inglés, griego. Fino Traço Editora: Belo Horizonte, Brasil, 2021. [CrossRef]

- Homburger, H.; Korbel, B. Architectural drawings on transparent paper: modifications of conservation treatments. The book and paper group Annual. Available online: https://cool.culturalheritage.org/coolaic/sg/bpg/annual/v18/bp18-06.html (accessed on May 14, 2025).

- Muñoz Viñas, S. La restauración del papel. Tecnos Editorial: Madrid, España, 2010.

- Laroque, C. Transparent papers: a technological outline and conservation review. Studies in Conservation, 2000, 45(sup3), pp. 21-31. [CrossRef]

- Instituto del Patrimonio Cultural de España. Normas de conservación preventiva para la implantación de sistemas de control de condiciones ambientales en museos, bibliotecas, archivos, monumentos y edificios históricos. Ministerio de Cultura. Available online : https://www.cultura.gob.es/planes-nacionales/dam/jcr%3Aa8616b46-27cb-45fd-b121-79899d8d6907/ipce-normas-climatizacion.pdf (accesed on June 2, 2025).

- Chávez, A. Restauración de un plano con soporte de papel translúcido referente a la “Ruta del ferrocarril de Mérida a Sisal, Yucatán”. Boletín del Archivo General de la Nación, 2014, 8(02), pp. 91-109. [CrossRef]

- Dreyfuss-Deseigne, R. Nanocellulose films: Properties, development, and new applications for translucent and transparent artworks and documents. Book and Paper Group Annual, 2017, 36, pp. 108-114.

- De la Sancha Pérez, X.; Vargas López, A. K. Papel transparente, un reto de conservación. In Escuela Nacional de Conservación, Restauración y Museografía “Manuel del Castillo Negrete”, Guadalajara, Jalisco, México (November 7–9, 2018).

- Lorente, R.; López-Montes, A.; Blanc, R. La producción planimétrica de Leopoldo Torres Balbás como arquitecto conservador de La Alhambra. Restauración de la colección tras el conocimiento de sus materiales. In Comunicar la arquitectura: del origen de la modernidad a la era digital. Universidad de Granada: Granada, España, 2024, pp. 747-760.

- AENOR. UNE-EN ISO 18314-1 Colorimetría analítica. Parte 1: Medición práctica del color (ISO 1834-1:2015). Madrid: AENOR, 2019.

- Contreras, G.; Luna, J. Técnicas analíticas para la caracterización de documentos: una revisión bibliográfica. Ge-conservación, 2020, 17, pp. 251-266. [CrossRef]

- Suhr, M.; Klein, G.; Kourti, I.; Gonzalo, M. R.; Santonja, G. G.; Roudier, S.; Sancho, L. D. Best available techniques (BAT) reference document for the production of pulp, paper and board. Publications office of the European Union: Luxembourg, 2015. [CrossRef]

- Huang, X.; Shen, J.; Qian, X. Filler modification for papermaking with starch/oleic acid complexes with the aid of calcium ions. Carbohydrate Polymers, 2013, 98(1), pp. 931-935. [CrossRef]

- Felissia, F.; Area, M.; Barboza, O.; Bengoechea, D. Anti-scaling agents in kraft pulping. BioResources, 2007, 2(2), pp. 252-264. [CrossRef]

- Strlic, M.; Kolar, J. Ageing and stabilisation of paper. National and University Library: Michigan, United States, 2005.

- Sindall, R. W. The manufacture of paper. D. Van Nostrand: New York, United States, 1908.

- Lourenço, A.; Gamelas, J.; Sequeira, J.; Ferreira, P.; Velho, J. Improving paper mechanical properties using silica-modified ground calcium carbonate as filler. BioResources, 2015, 10(4), pp. 8312-8324. [CrossRef]

- García, P. Las cianotipias y diazotipias como métodos de duplicación de planos. Su conservación. Patrimonio cultural de España, 2009, 2, pp. 335-347.

- Muller, P.; Mustacchi, H. Zinc sulfonates and their use in diazotypy (U.S. Patent No. 4,478,926). U.S. Patent and Trademark Office, 1984.

- Raudhatussyarifah, R.; Sediawan, W. B.; Azis, M. M.; Hartati, I. Microcrystalline cellulose production by acid hydrolysis of hydrotropic rice straw pulp. IOP Conference Series: Earth and Environmental Science, 2022, 963 (1), p. 012055). [CrossRef]

- Bosch, F. Yusa, D. Análisis químico instrumental ultravioleta-visible e infrarrojo aplicado al patrimonio cultural. Un enfoque práctico. Editorial Universitat Politècnica de València: Valencia, España, 2015.

- Derrick, M. R.; Stulik, D.; Landry, J. M. Infrared spectroscopy in conservation science. Scientific Tools for Conservation. The Getty Conservation Institute: Los Angeles, United States, 2000.

- Zulkifli, A.; Abd Halim, N.; Ibrahim, S.; Hamzah, N.; Saleh, S. Effect of sulphuric acid concentration on nanocellulose extraction from rice husk. Malaysian Journal of Chemistry, 2024, 26(5), pp. 562–571. [CrossRef]

- Stuart, B. Infrared spectroscopy: fundamentals and applications. John Wiley & Sons: New York, United States, 2004.

- Trafela, T.; Strlicˇ, M.; Kolar, J.; Lichtblau, D. A.; Anders, M.; Mencigar, D. P.; Pihlar, B. Nondestructive analysis and dating of historical paper based on IR spectroscopy and chemometric data evaluation. Analytical chemistry, 2007, 79(16), pp. 6319-6323. [CrossRef]

- Popescu, C.; Vasile, C.; Popescu, M.; Singurel, G.; Popa, V.; Munteanu, B. Analytical methods for lignin characterization. II. Spectroscopic studies. Cellulose chemistry and technology, 2006, 40(8), pp. 597-621.

- Wu, S.; Shi, S.; Liu, R.; Wang, C.; Li, J.; Han, L. The transformations of cellulose after concentrated sulfuric acid treatment and its impact on the enzymatic saccharification. Biotechnology for Biofuels and Bioproducts, 2023, 16(1), pp. 36. [CrossRef]

- Zervos, S. Natural and accelerated ageing of cellulose and paper: A literature review. In Cellulose: Structure and Properties, Derivatives and Industrial Uses. Nova Science Publishers, 2010, pp.155-203.

- van Velzen, S. T. J. The universe between felt and wire: A new look into the typology of Western made paper. PhD thesis, University of Amsterdam. Amsterdam School of Historical Studies, 2018. Available online: https://hdl.handle.net/11245.1/0b9e4e6a-266c-4fd1-9b2f-b95e7d179ce1 (accessed on May 22, 2025).

- Hubbe, M.; Maitland, C.; Nanjiba, M.; Horst, T.; Ahn, K.; Potthast, A. Archival performance of paper as affected by chemical components: A review. BioResources, 2023, 18(3), pp. 6430-6498. [CrossRef]

| Category | Materials/Substances | Properties | Aging | |

| Type of pulps | Rag pulp | Linen, hemp, cotton | Long fiber. Lignin-free—chemicals | Stable |

| Mechanical pulp | Groundwood / Bleaching agents |

With lignin, fragile, opaque, inexpensive | Yellows and becomes brittle | |

| Chemical pulp | Alkaline/Kraft/Sulfate: Sodium Hydroxide and Sodium Sulfide |

No lignin. Strong, stable, and slightly dark | Good (pH controlled) | |

| Acidic/Sulfite: Sodium, Calcium, Sulfur, Magnesium, Ammonium, etc. |

Low lignin. Whiteness, better for printing. More fragile | Due to residual acidity |

||

| Chemical-mechanical pulp | Chemical processes + Pulping | Cheap, stiff, low permanence | Variable | |

| Treatment | Translucency (foils) | Oils, Resins, Waxes, Starches, etc. | Fills spaces (refractive index similar to cellulose). Flexible | Oxidation of fats (yellowed, stiff, opaque) |

| Translucency (acids) | Sulfuric Acid, Nitric Acid, Zinc Chloride, Cuprammonium Solution | Chemically modifies. Resistant to oils/moisture | Very fragile | |

| Translucency (refining) | Short fibers (Hollander Beating) |

Very smooth | Low mechanical strength | |

| Additives | Softeners / Plasticizers | Glycerin, oils, synthetic resins. |

Improves feel, flexibility, and transparency | They oxidize or become sticky |

| Fillers | CaCO3, talc, starch, TiO2, etc. | Adjusts opacity, absorption, and pH. Smoother, less absorbent. | Good (alkaline fillers) Poor (acidic residues) |

|

| Bleaching | Chlorinated substances, NaOH, H2O2, SO2, etc. | Removes lignin. Increases brightness and whiteness. | Chemical degradation and cellulose yellowing |

| Alteration/Document | Photographic representation | Alteration/Document | Photographic representation |

|

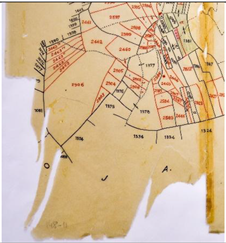

Yellowing All documents show yellowing, tonal changes, and varying degrees of opacity due to the aging of the support and exposure to light. |

|

Fungi ETSAGV3, ETSAGV4, ETSAGV6, ETSAGV7 |

|

|

Abrasion AHP5097, AHP5099 |

|

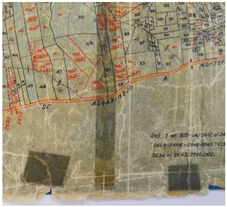

Deformation AHP508, AHP721, AHP729, AHP730, AHP733, AHP735, AHP790, AHP802, AHP832, ETSAGV3, ETSAGV4, ETSAGV6, ETSAGV7, ETSAGG1, to ETSAGG12, ETSAGP1 to ETSAGP37 |

|

|

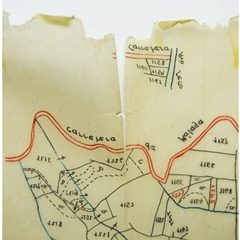

Folds AHP473, AHP474, AHP476, AHP508, AHP573, AHP711, AHP721, AHP729, AHP734, AHP790, AHP814, AHP832, AHP5097, AHP5099, AHP5101, AHP5110, AHP5112, AHP5114, AHP5117, AHP5119, AHP5148, AHP5156, ETSAGC1P14, ETSAGC1928P2, ETSAGC1D15, ETSAGC1D45, ETSAGC1D2 |

|

Tear AHP5097, AHP5099 |

|

|

Rips AHP473, AHP474, AHP484, AHP508, AHP530, AHP573, AHP585, AHP721, AHP729, AHP733, AHP755, AHP756, AHP822, AHP825, AHP832, AHP833, AHP5097, AHP5099, AHP5101, AHP5110, AHP5112, AHP5114, AHP5117, AHP5119, AHP5128, AHP5167, ETSAGB5, ETSAGB9 |

|

Loss of support AHP473, AHP474, AHP573, AHP574, AHP578, AHP711, AHP729, AHP734, AHP735, AHP755, AHP756, AHP790, AHP817, AHP818, AHP822, AHP825, AHP832, AHP5097, AHP5099, AHP5101, AHP5110, AHP5112, AHP5114, AHP5116, AHP5117, AHP5119, AHP5128, AHP5156, AHP5167, ETSAGB5 |

|

|

Surface dirt AHP508, AHP553, AHP560, AHP790, AHP814, AHP818 |

|

Tape stains -Polypropylene- AHP817, AHP822 |

|

|

Tape stains -Cellulose acetate- AHP721, AHP802, AHP817, AHP825, AHP829, AHP833, AHP1537, AHP5097, AHP5099, AHP5101, AHP5110, AHP5112, AHP5114, AHP5117, AHP5119, AHP5167, ETSAGC1, ETSAGC2, ETSAGC3, ETSAGC4 |

|

Tape stains -Rubber adhesive- AHP484, AHP508, AHP530, AHP585, AHP721, AHP729, AHP733, AHP755, AHP802, AHP814, AHP817, AHP818, AHP825, AHP829, AHP832, AHP833, AHP805, AHP5112, AHP5114, AHP5117, AHP5128 |

|

|

Staining from migration AHP729, AHP734, AHP817, AHP818, AHP822, ETSAGV3, ETSAGV4, ETSAGV6, ETSAGV7, ETSAGG1, ETSAGG2, ETSAGG3, ETSAGG4, ETSAGG5, ETSAGG6, ETSAGG7, ETSAGG8, ETSAGG9, ETSAGG10, ETSAGG11, ETSAGG12, ETSAGP4, ETSAGP5, ETSAGP8, ETSAGP9, ETSAGP14, ETSAGP16, ETSAGP28, ETSAGP29, ETSAGP32, ETSAGP33, ETSAGP34 |

|

Contact stains AHP790, AHP814 |

|

|

Staple tears: additions AHP578, AHP583, AHP585, AHP756, AHP5148, AHP5156 |

|

Loss of support due to staples: additions AHP574, AHP578, AHP585 |

|

|

Deformation from storage: anthropogenic ETSAGV1 to ETSAGV10, ETSAGVi1 to ETSAGVi4, ETSAGB1 to ETSAGB22, ETSAGBA1 to ETSABA25, ETSAGG1 to ETSAGG13, ETSAGC1 to ETSAGC4, ETSAGP1 to ETSAGP37, ETSAGR |

|

Storage marks: anthropogenic AHP473, AHP484, AHP508, AHP530, AHP552, AHP553, AHP560, AHP721, AHP733, AHP734, AHP735, AHP790, AHP814, AHP817, AHP818, AHP805, AHP1537, AHP1543, AHP5097, AHP5099, AHP5117, AHP5119, AHP5128, ETSAGC1D13, ETSAGC1D3, ETSAGC1P14, ETSAGC1928P2 |

|

| Characteristics | T3G1 (35%) | T3G2 (45%) | T3G3 (20%) |

| Thickness | M/L | M/L | H |

| Conservation | P/F | P/F | G |

| Texture | Matte, smooth, and regular surface | Matte, less smooth, and regular surface |

Glossy, smooth, and regular surface. It has emulsion |

|

Color |

|

|

|

| Groups Table 3 | Color | ΔE*ab | ΔL* | Δa* | Δb* |

| T3G1 | White | 7,09 | -5,82 | -2,72 | 2,99 |

| T3G1 | Gray | 22,05 | -13,10 | -3,10 | 17,47 |

| T3G2 | Yellow | 41,61 | -20,05 | 4,20 | 36,22 |

| T3G3 | Violet | 23,96 | -20,48 | 0,55 | 12,42 |

| T3G3 | Ochre | 40,05 | -30,82 | 3,87 | 25,28 |

| T3G3 | Green | 40,13 | -34,28 | -3,31 | 20,59 |

| S | Ba | Si | Al | Cl | Ca | K | Zn | Fe | Cu | Ni | Ti | P | |

| T5G1 (20%) | M | - | tr | tr | M | M | m | M | m | m | m | - | -/tr |

| T5G2 (14%) | M | M | tr | tr | M | M | m | - | m | m | m | - | - |

| T5G3 (55%) | m | - | tr | tr | M | M | m | - | m | m | m | -/tr | -/tr |

| T5G4 (5%) | m | - | M | tr | M | M | m | - | m | m | m | - | - |

| T5G5 (4%) | M | - | M | tr | M | M | m | M | m | m | m | - | - |

| T5G6 (2%) | M | - | tr | tr | M | M | m | - | m | m | m | - | - |

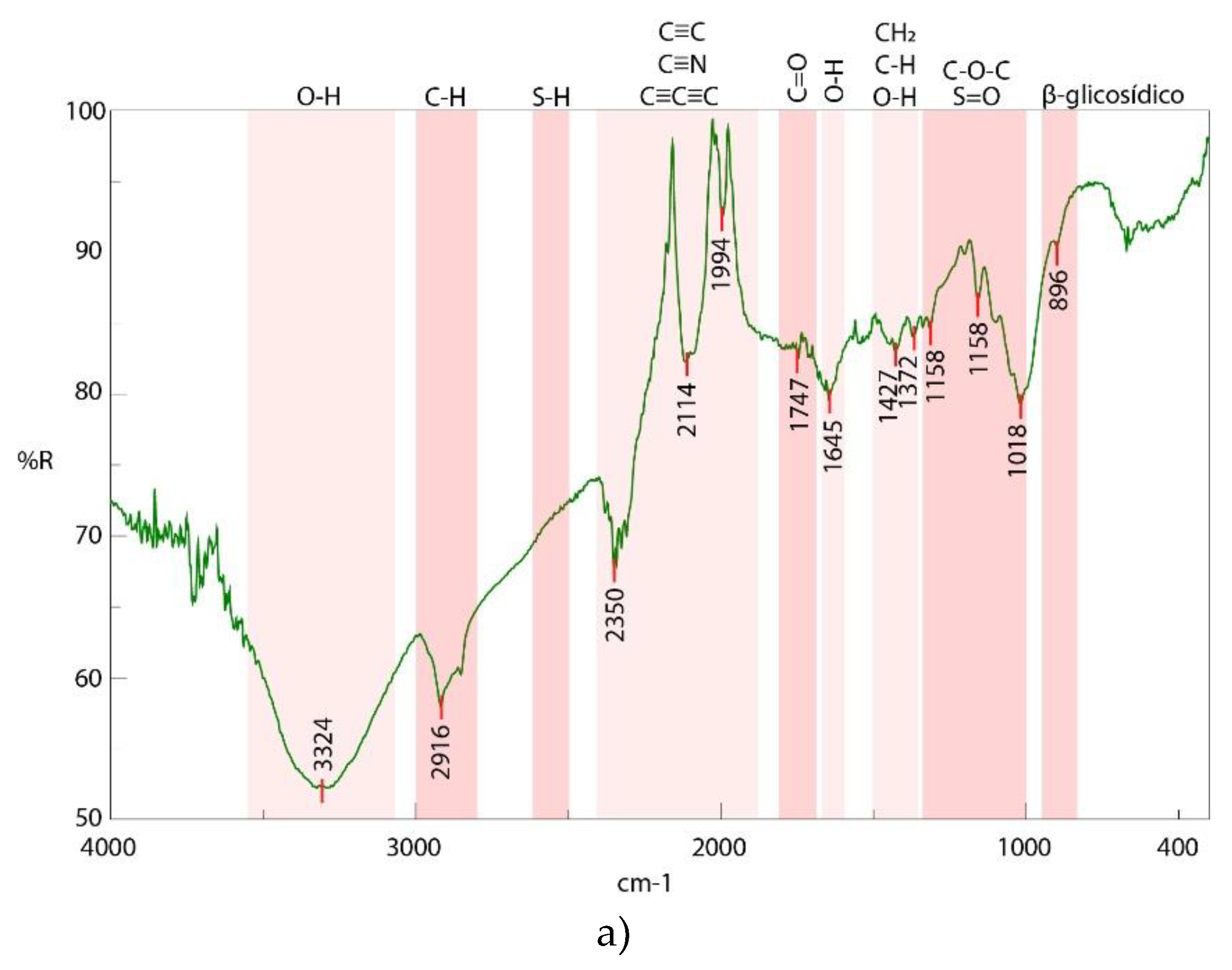

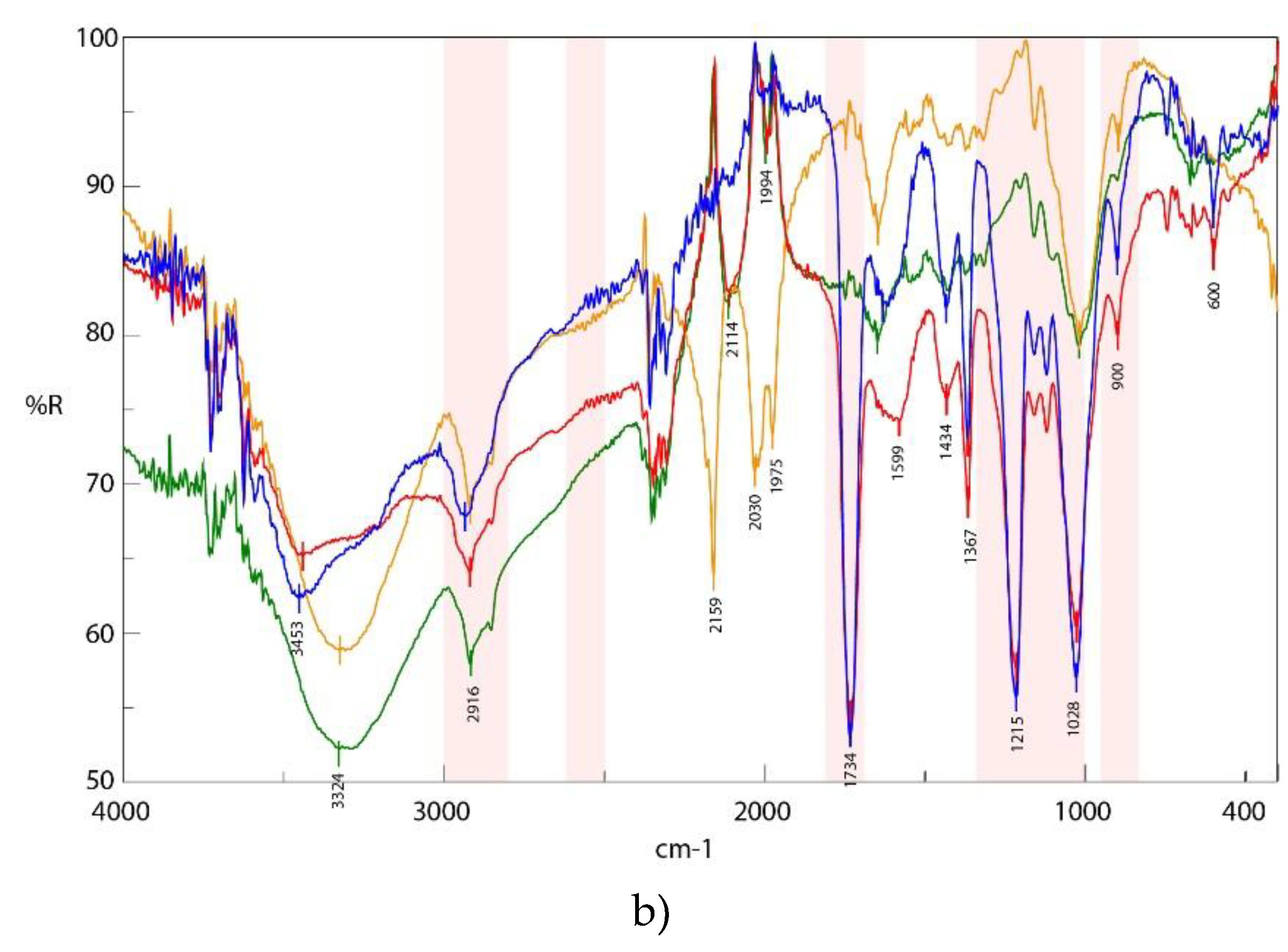

| FTIR Band (cm-1) | Groups of documents | Observations | ||||

| T6G1 (71%) | T6G2 (8%) | T6G3 (2%) | T6G4 (19%) | |||

| 3420-3330 | O-H | S | S | S/M | M | Cellulose |

| 2920- 2850 | C-H | M | M/S | S/M | M | Cellulose/Oils |

| 2600-2550 | S-H | - | - | - | - | Sulfur degradation |

| 2159-1975 | - | M | - | - | Triple bonds, cellulose, contamination | |

| 2114 | M | - | M | - | ||

| 1740-1730 | C=O | W | W | S | S | Oils |

| 1710 | C=O | - | - | - | - | Oxidation |

| 1650–1600 | O-H | W/M | W/M | M | W/M | Absorbed water |

| 1540-1370 | CH2, C-H, O-H Bending | W | W | M | M | Acids/oils/oxidation |

| 1200–1000 | C-O-C | M | M/W | S | S | Cellulose/ Oils |

| 1040 | S=O | - | - | - | - | Sulfurized |

| 900-895 | β-glycosidic | -/W | -/W | M | W | Amorphous cellulose |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).