Submitted:

23 September 2025

Posted:

24 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

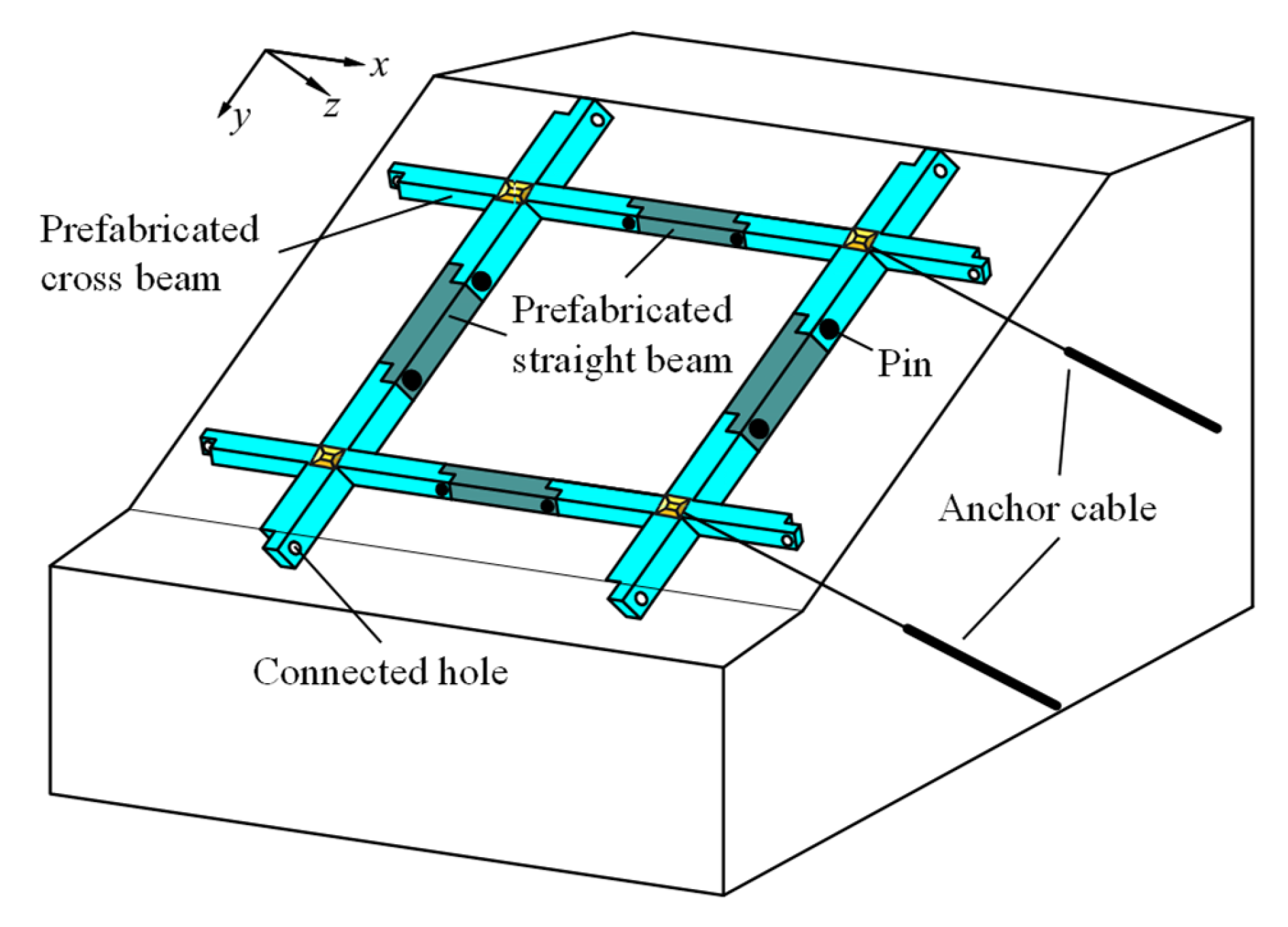

2. Structural Analysis Framework for HPFB Structures

2.1. Basic Assumptions

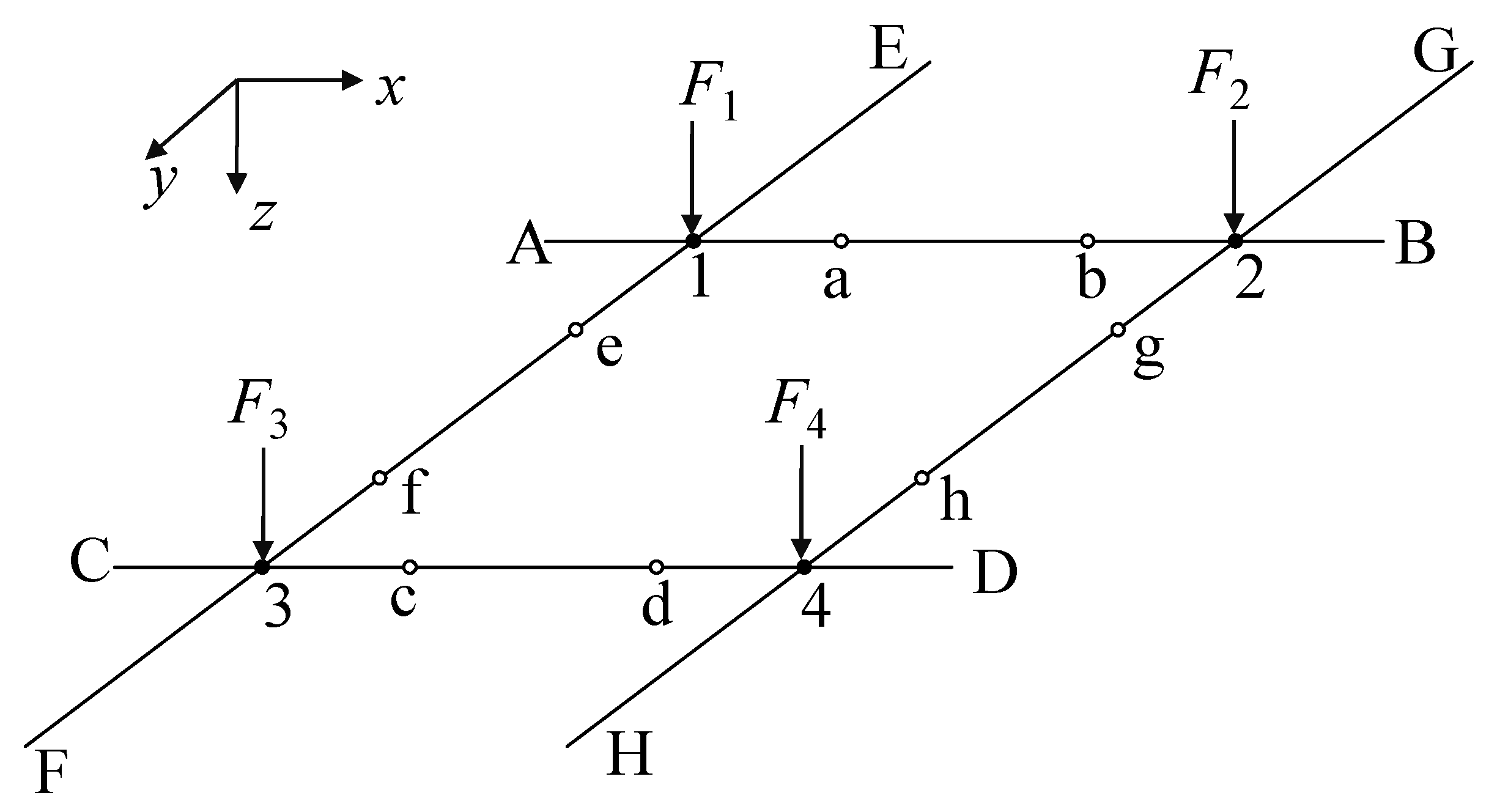

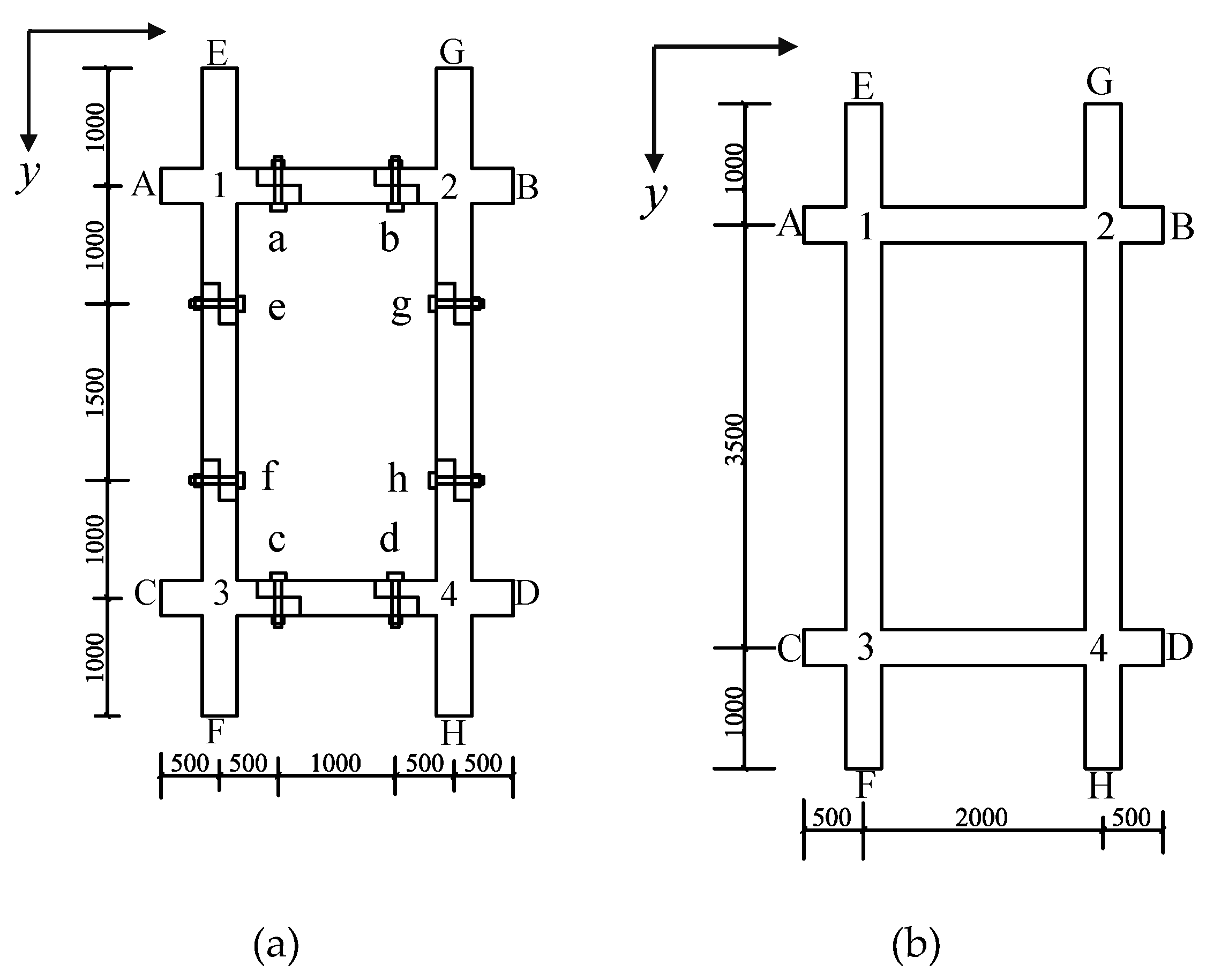

2.2. Structural Decomposition

- (1)

- Loads F1x, F2x, F3x, and F4x are allocated to the horizontal beams AB and CD;

- (2)

- Loads F1y, F2y, F3y, and F4y are assigned to the longitudinal beams EF and GH.

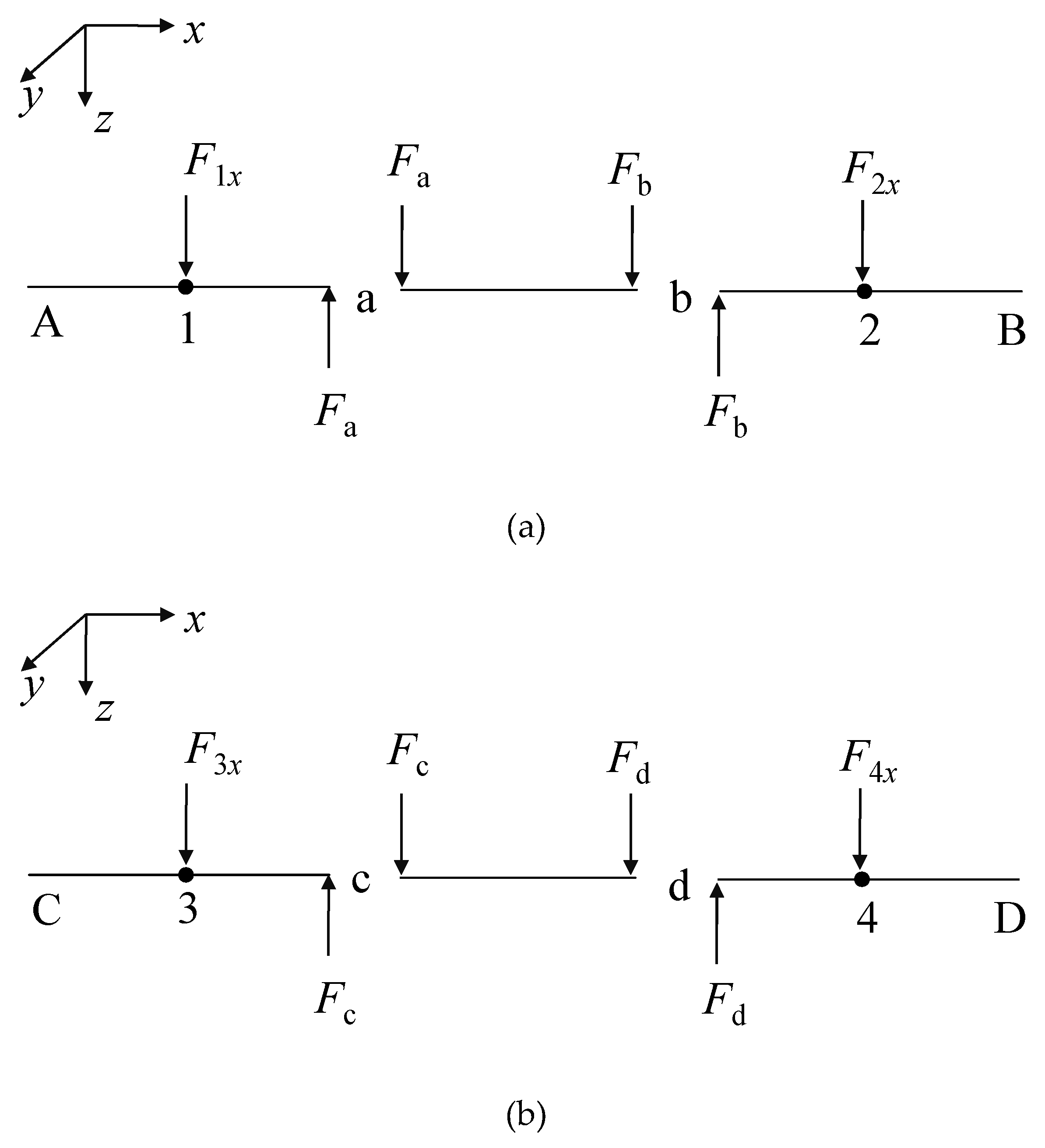

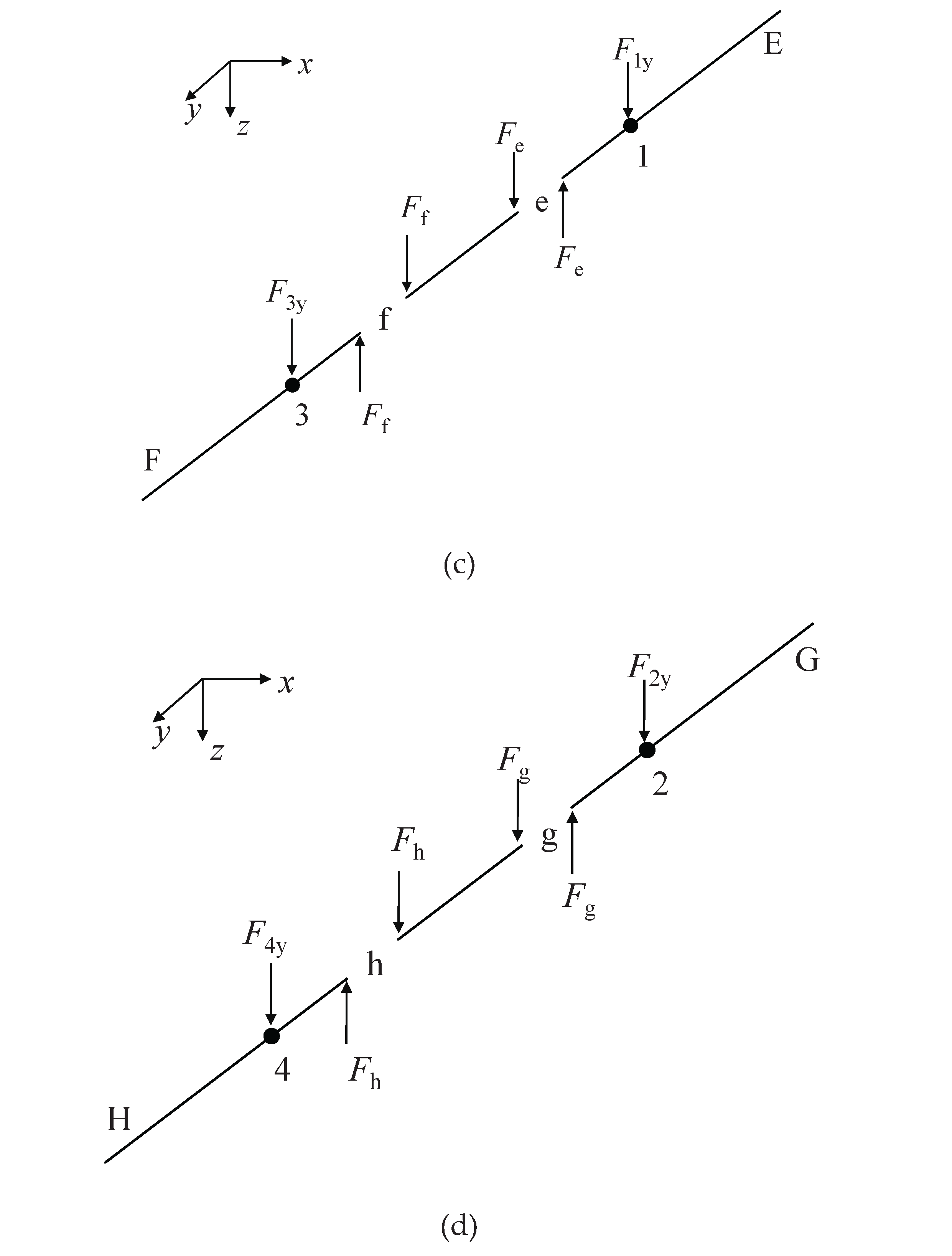

2.3. Load Distribution and Beam-end Shear Forces Determination

2.3.1. Analysis of Anchorage Points

2.3.2. Analysis of Hinge Points

2.3.3. Formulation and Solution of a System of Linear Equations

2.4. Analysis of Deformation and Internal Forces for Beam Segments

3. Case Study and Results

3.1. Project Overview

3.2. Comparative Analysis

3.2.1. Load Distribution and Verification of Deformation Compatibility

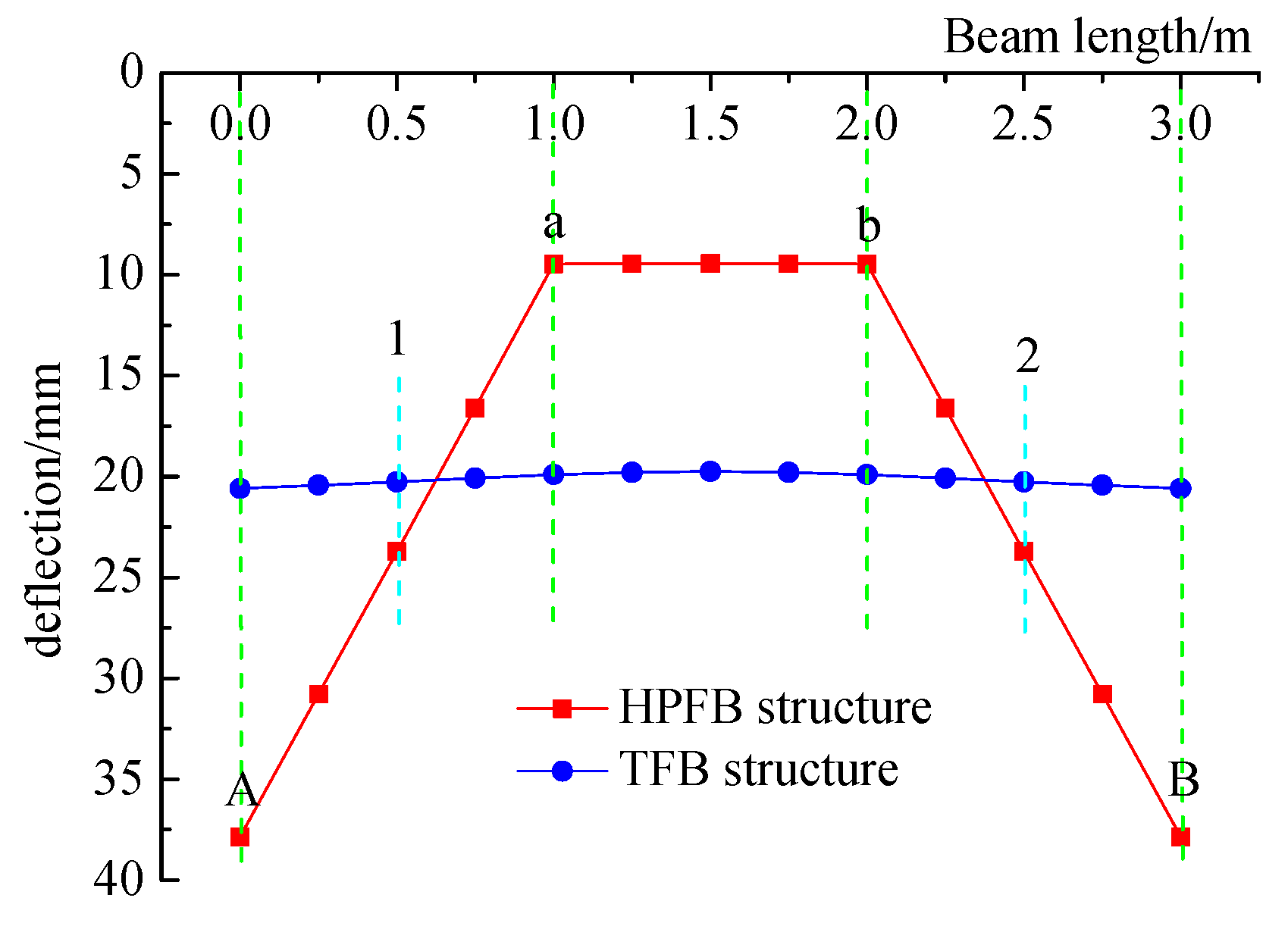

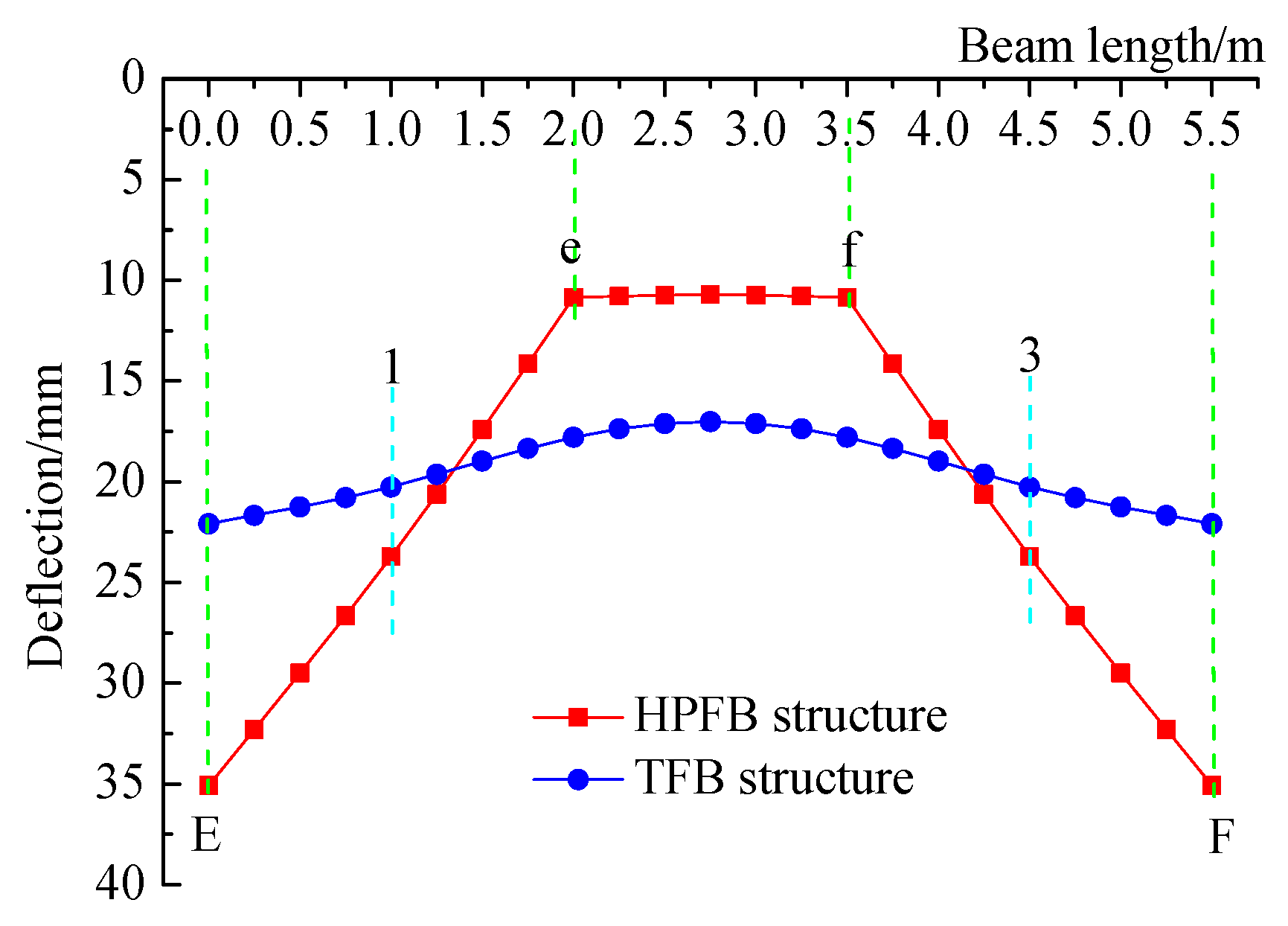

3.2.2. Comparative Analysis of Deflection curves

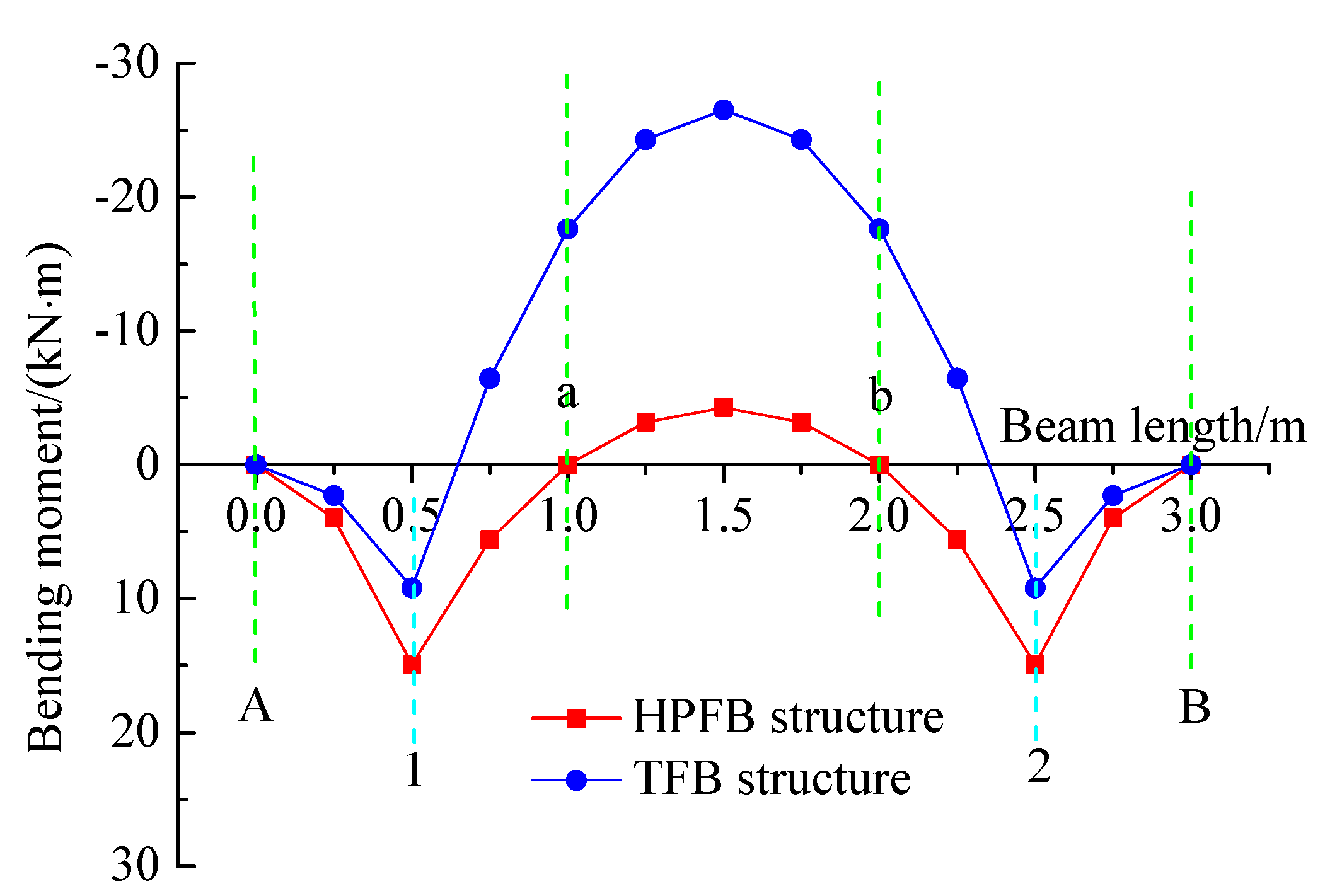

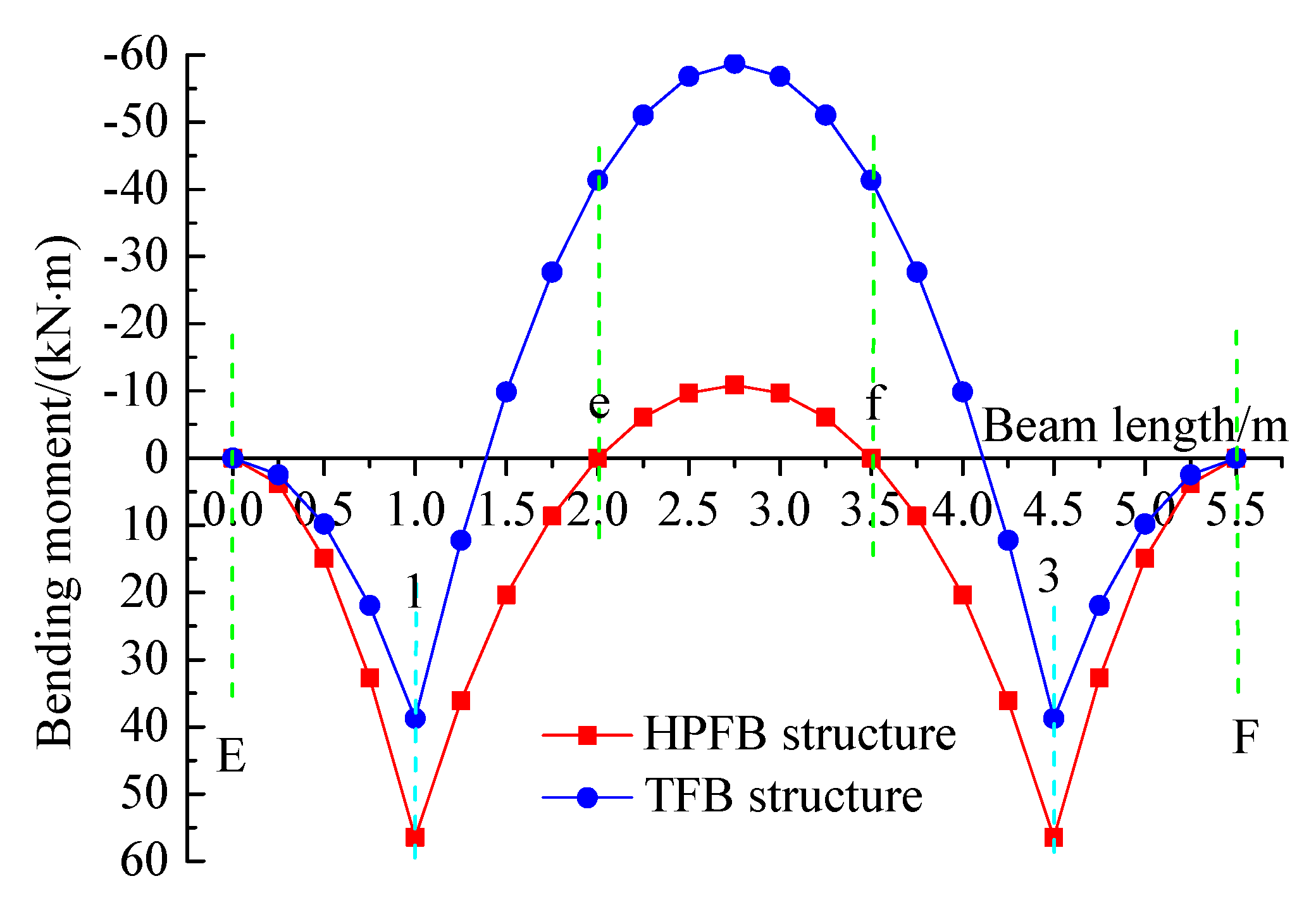

3.2.3. Comparative Analysis of Bending Moment Curves

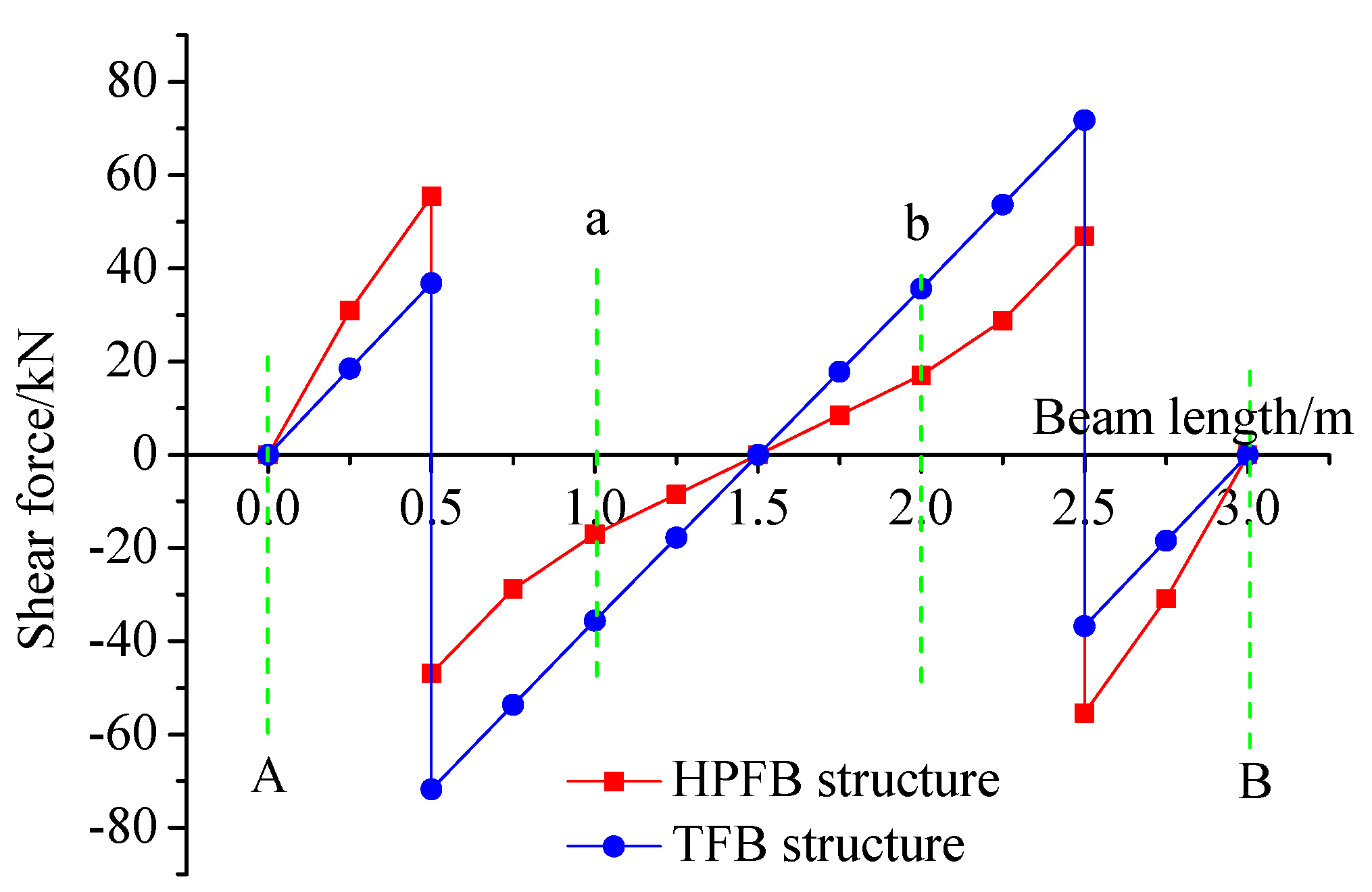

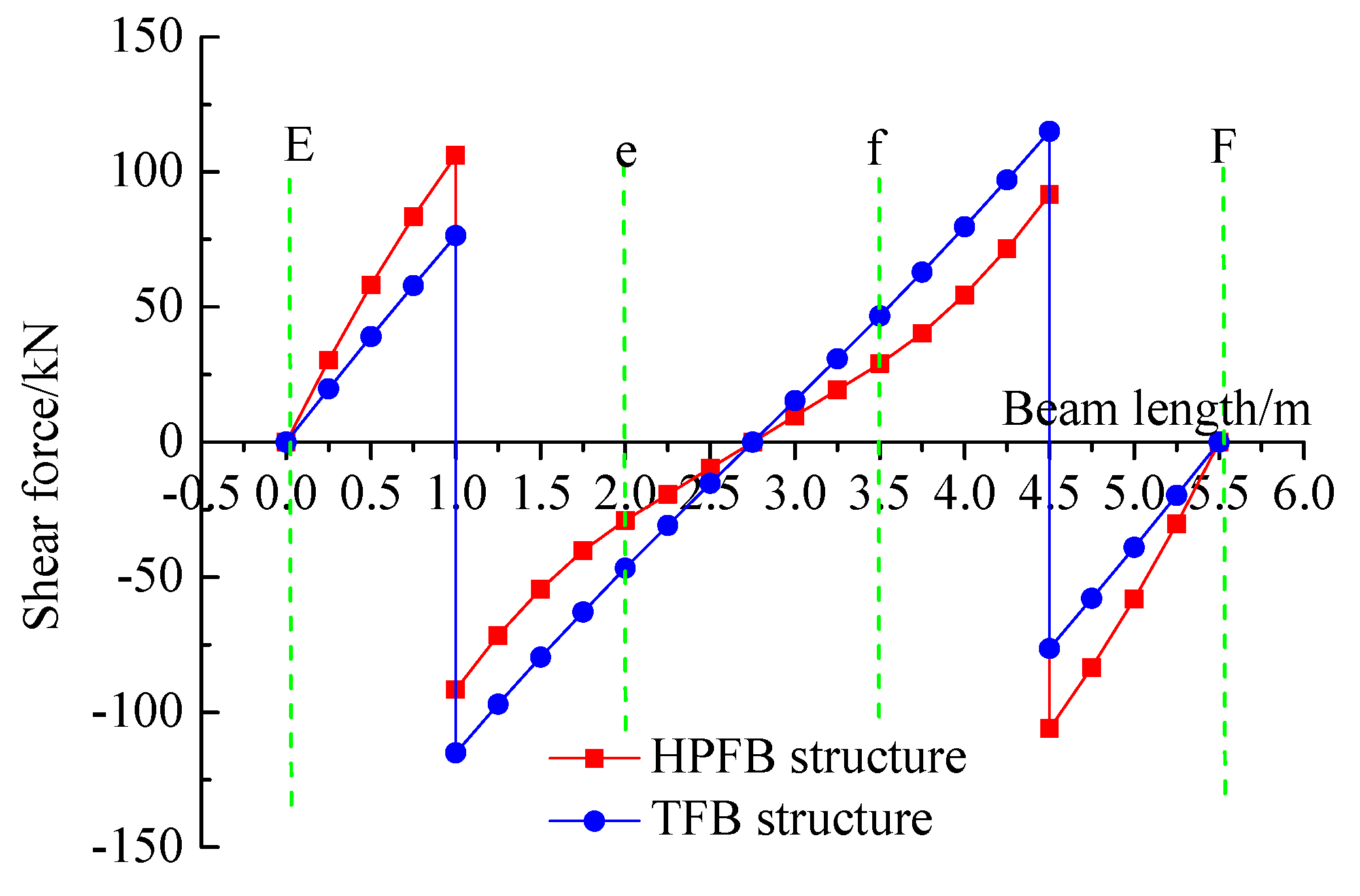

3.2.4. Comparative Analysis of Shear Force Curves

3.3. Sensitivity Analysis of Subgrade Reaction Coefficient on the Mechanical Response of HPFB Structures

3.3.1. Load Distribution and Determination of Beam-End Shear Forces

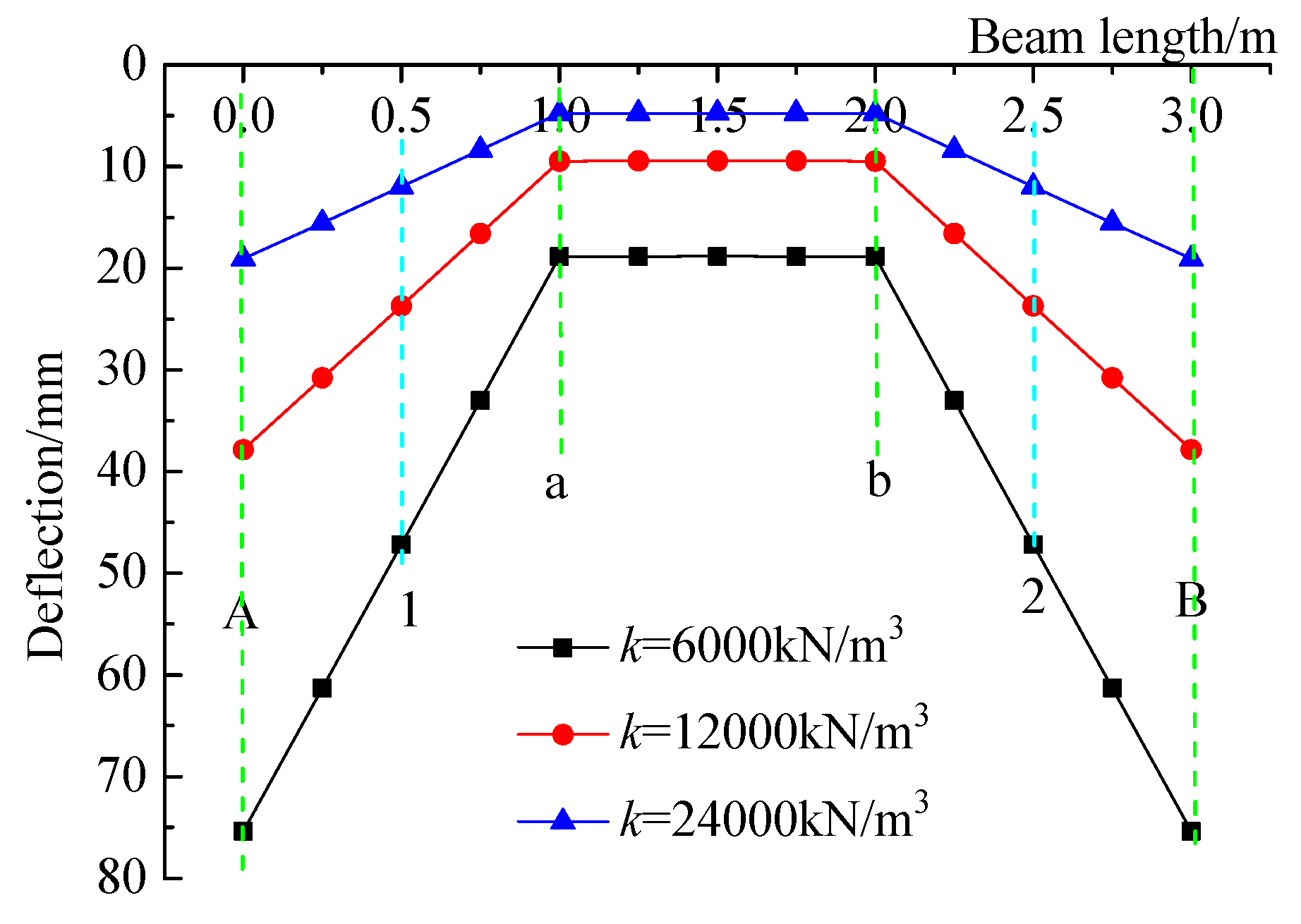

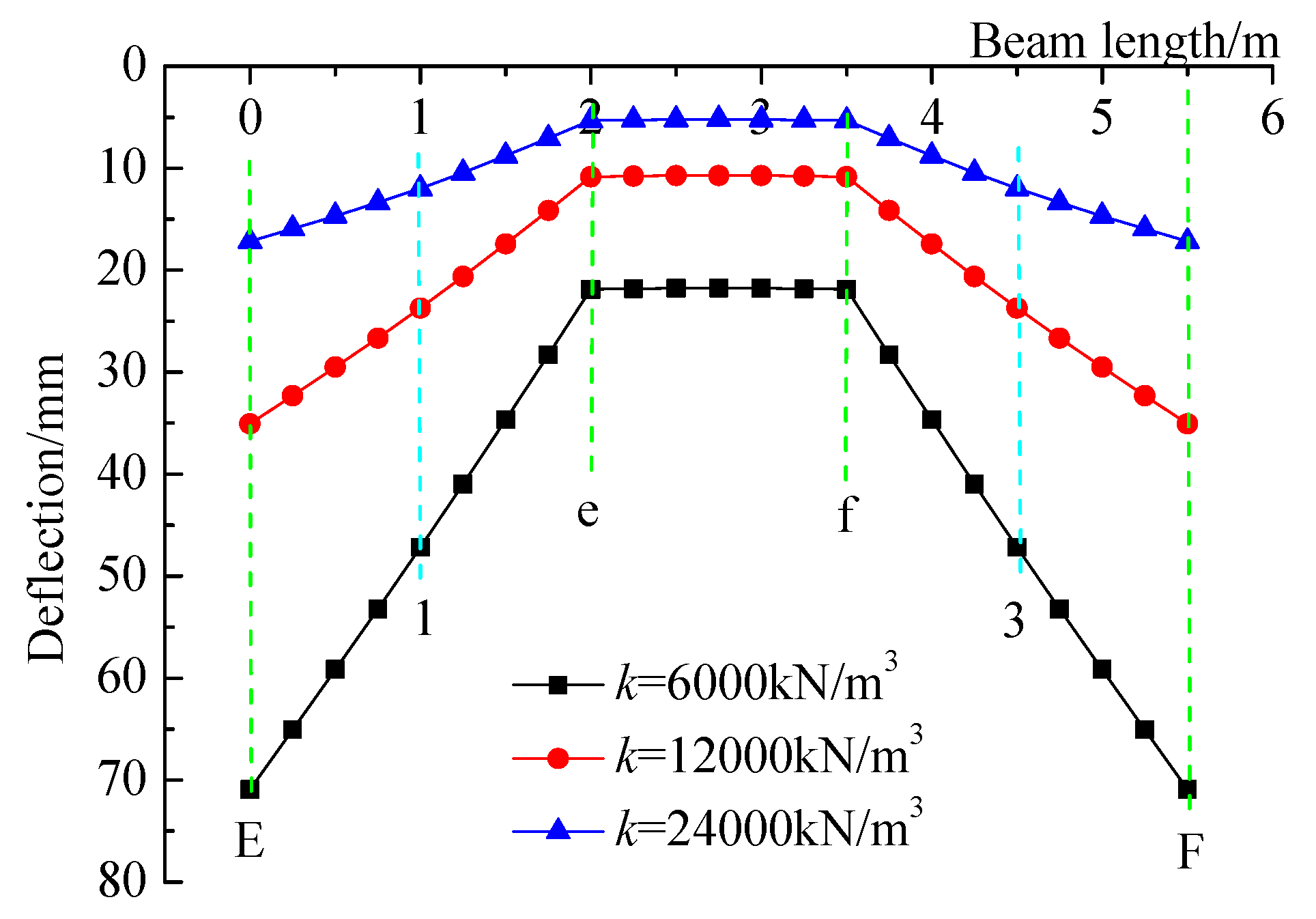

3.3.2. Sensitivity Analysis of Deflection to the Subgrade Reaction Coefficient

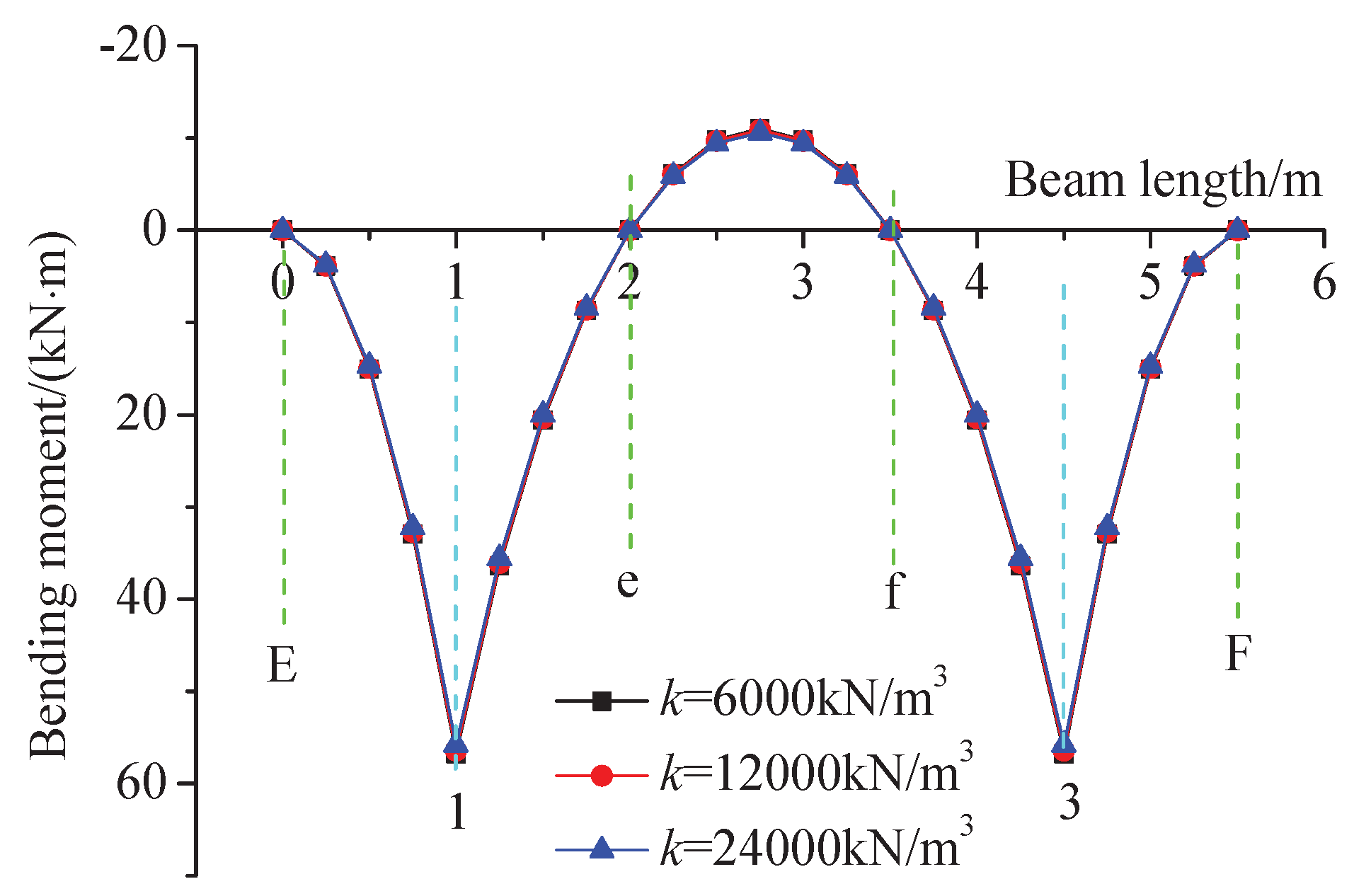

3.3.3. Sensitivity Analysis of Bending Moment to the Subgrade Reaction Coefficient

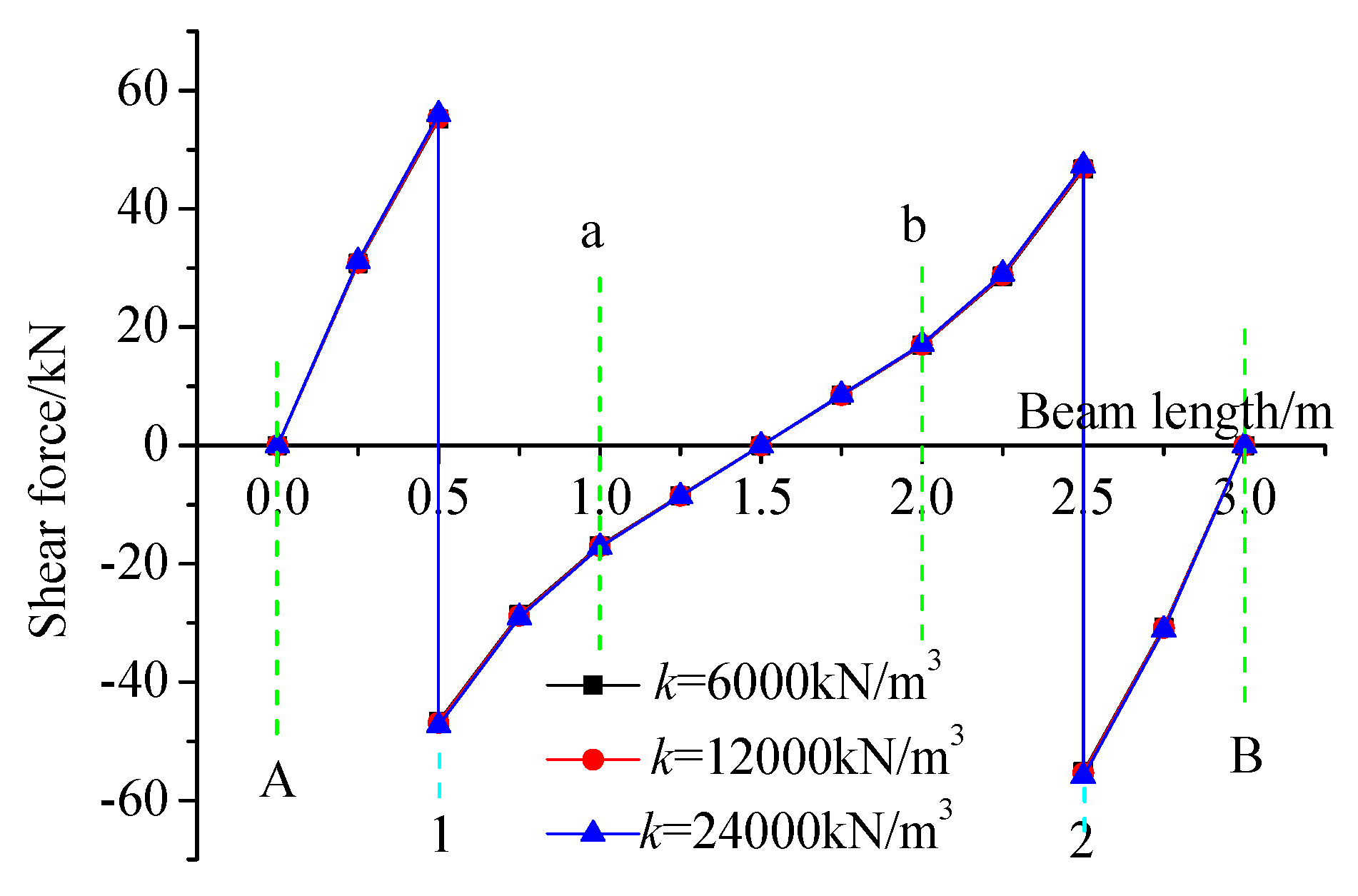

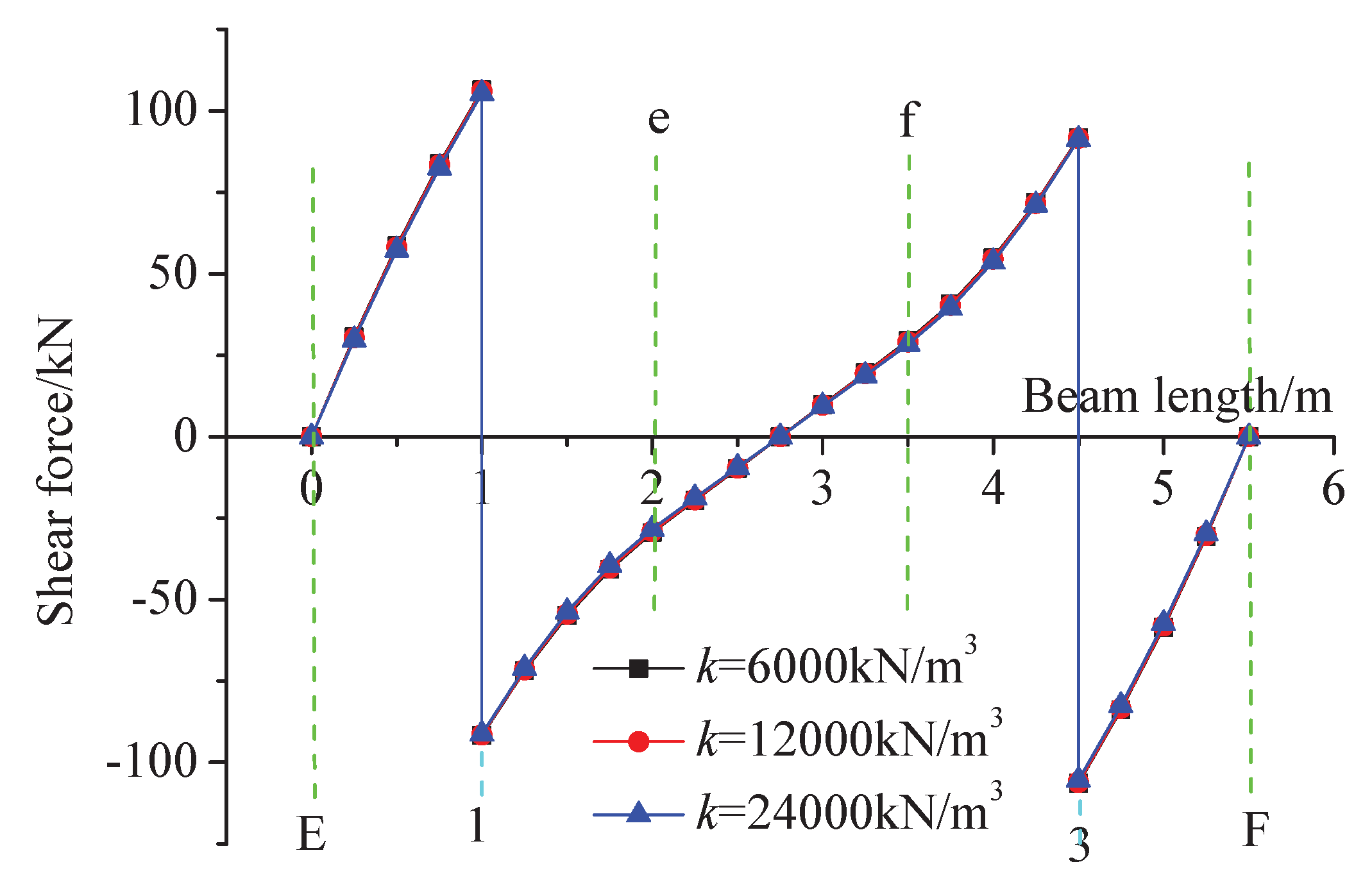

3.3.4. Sensitivity Analysis of Shear Force to the Subgrade Reaction Coefficient

4. Conclusions

- (1)

- Consistent with the load distribution observed in the TFB structure, the analytical framework proposed in this study allocates smaller concentrated loads to the shorter horizontal beam segments and larger concentrated loads to the longer longitudinal beam segments. Correspondingly, the hinged connections transfer smaller shear forces to the shorter horizontal segments and larger shear forces to the longer longitudinal segments.

- (2)

- The proposed analytical framework rigorously enforces the deformation compatibility conditions at both the anchorage points and hinged joints, thereby demonstrating the rationality and applicability of the HPFB structural analysis methodology presented in this study.

- (3)

- Compared to the TFB structure, the HPFB structure exhibits larger deflections near the beam ends and smaller deflections in certain intermediate regions. Furthermore, the deflection curves of both the horizontal and longitudinal beams in the HPFB structure exhibit clearly segmented, approximately linear distribution characteristics.

- (4)

- A comparative analysis of bending moment distributions under identical conditions indicates that, compared to the TFB structure, the HPFB exhibits higher positive bending moments at the anchorage points of both horizontal and longitudinal beams, along with substantially reduced moments in the mid-span regions of the precast straight beams. Furthermore, the bending moment curves in the HPFB structure display a smoother and more gradual variation along the beam length.

- (5)

- A comparative analysis of shear forces under identical conditions demonstrates that, relative to the TFB structure, the HPFB system exhibits lower maximum shear values at the anchorage points of both horizontal and longitudinal beams. Additionally, the shear force curves in the HPFB structure are characterized by distinctly convex profiles in the front segments and concave profiles in the rear segments of the beams.

- (6)

- As the subgrade reaction coefficient increases multiplicatively, the concentrated loads assigned to the shorter horizontal beam segments show a gradual increasing trend, while those allocated to the longer longitudinal beam segments exhibit a gradual decreasing trend. Correspondingly, the end shear forces transferred through the hinged connections to the shorter horizontal segments increase gradually, whereas those transferred to the longer longitudinal segments decrease gradually.

- (7)

- With a multiplicative increase in the subgrade reaction coefficient, the deflections of both the horizontal and longitudinal beams in the HPFB structure decrease correspondingly, while their deflection curves exhibit a progressively flatter profile. This trend clearly demonstrates the considerable influence of the subgrade reaction coefficient on the deflection behavior of the beams.

- (8)

- Sensitivity analysis reveals that a multiplicative increase in the subgrade reaction coefficient exerts a negligible influence on both the bending moments and shear forces within the HPFB structure. This finding suggests that, provided beam deflection meets design requirements, it is feasible to adopt a unified set of design parameters for slopes with varying subgrade stiffness.

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Lu, Y.; Cheng, Q. Numerical simulation of reinforcement for rock slope with rock bolt (anchor cable) frame beam. J. Highw. Transp. Res. Dev. (Engl. Ed.) 2008, 3, 65–71. [CrossRef]

- Cheng, Z.; Wang, Z.; Xi, H.; Zou, L.; Zhou, Z.; Zhou, C. Recent advances in high slope reinforcement in China: Case studies. J. Rock Mech. Geotech. Eng. 2016, 8, 775–788. [CrossRef]

- Deng, D.P.; Zhao, L.H.; Li, L. Limit-equilibrium analysis on stability of a reinforced slope with a grid beam anchored by cables. Int. J. Geomech. 2017, 17, 06017013.

- Liu, Z.; Shi, K.Y.; Wu, X.P.; Dai, S.L. Coupled calculation model for anchoring force loss in a slope reinforced by a frame beam and anchor cables. Eng. Geol. 2019, 260, 105245. [CrossRef]

- Chen, M.; Zhang, Z.; Liu, G.; et al. Experimental and numerical evaluation of creep and coupling mechanism with lattice structure of the deposits coarse-grained soils in reservoir area. KSCE J. Civ. Eng. 2025, 29, 100026. [CrossRef]

- Fan, J.; Yang, S.; Deng, B.; et al. A New Technique of Lattice Beam Construction with Pre-Anchoring for Strengthening Cut Slope: A Numerical Analysis of Temporary Stability during Excavation. Buildings 2022, 12, 1930. [CrossRef]

- Zhang, S.; Pei, X.; Wang, S.; Huang, R.; Zhang, X. Centrifuge model testing of loess landslides induced by excavation in Northwest China. Int. J. Geomech. 2020, 20, 04020022. [CrossRef]

- Wang, Z.; Gu, D.; Zhang, W. Influence of excavation schemes on slope stability: A DEM study. J. Mt. Sci. 2020, 17, 1509–1522.

- Li, Q.; Wang, Y.M.; Zhang, K.B.; et al. Field investigation and numerical study of a siltstone slope instability induced by excavation and rainfall. Landslides 2020, 17, 1485–1499. [CrossRef]

- Yubonchit, S.; Chinkulkijniwat, A.; Horpibulsuk, S.; et al. Influence factors involving rainfall-induced shallow slope failure: Numerical study. Int. J. Geomech. 2017, 17, 04016158.

- Lee, L.M.; Gofar, N.; Rahardjo, H. A simple model for preliminary evaluation of rainfall-induced slope instability. Eng. Geol. 2009, 108, 272–285. [CrossRef]

- Rahimi, A.; Rahardjo, H.; Leong, E.C. Effect of antecedent rainfall patterns on rainfall-induced slope failure. J. Geotech. Geoenviron. Eng. 2011, 137, 483–491. [CrossRef]

- Wu, T.; Zhou, C.; Jiang, N.; et al. Stability analysis for high-steep slope subjected to repeated blasting vibration. Arab. J. Geosci. 2020, 13, 828.

- Xu, J.; Yan, C.; Zhao, X.; et al. Monitoring of train-induced vibrations on rock slopes. Int. J. Distrib. Sens. Netw. 2017, 13, 1550147716687557.

- Budhu, M.; Gobin, R. Seepage-induced slope failures on sandbars in Grand Canyon. J. Geotech. Geoenviron. Eng. 1995, 121, 601–609.

- Yu, L.; Zheng, X.; Liu, Z.; et al. Multiscale modelling of the seepage-induced failure of a soft rock slope. Acta Geotech. 2022, 17, 4717–4738. [CrossRef]

- Xu, J.; Wang, Z.; Ren, J.; et al. Mechanism of slope failure in loess terrains during spring thawing. J. Mt. Sci. 2018, 15, 845–858.

- Paranunzio, R.; Laio, F.; Nigrelli, G.; et al. A method to reveal climatic variables triggering slope failures at high elevation. Nat. Hazards 2015, 76, 1039–1061. [CrossRef]

- Sato, A.; Hatakeyama, O. Characteristics of slope surfaces deformed by frost heaving. In Transportation Soil Engineering in Cold Regions, Volume 1: Proceedings of TRANSOILCOLD 2019; Springer: Singapore, 2019; pp. 9–17.

- Qin, M.; Dou, G.; Yang, J.; Wei, S. Field Test and Numerical Study of Three Types of Frame Beams Subjected to a 600 kN Anchoring Force. Buildings 2024, 14, 401.

- Liao, H.J.; Chen, H.M. Cut Slope Failure of Mudstone Formations in Southern Taiwan. In Advances in Geotechnical Engineering: The Skempton Conference, Proceedings of the Skempton Conference on Geotechnical Engineering, Royal Geographical Society, London, UK, 29–31 March 2004; Institution of Civil Engineers: London, UK, 2004; Volume 2, pp. 868–880. ISBN 978-0727732483.

- Qin, M.; Yang, J.; Wei, S. Calculation of precast prestressed beam with variable cross-sections on Pasternak foundation under anchoring force. KSCE J. Civ. Eng. 2024, 28, 3941–3950.

- Dai, X.; Cao, Y.; Wei, S.; Wei, P.; Huo, H.; Cai, J.; Li, Y. Analysis of reinforcement effect of different anchoring forces on slope stabilised by prefabricated anchorage cable frame beams. Structures 2024, 69, 107476.

- Zhang, J.; Zhou, Q.; Li, F.; Zhang, S. Case study of field application of prefabricated anchoring frame beam structure in slope supporting projects. J. Constr. Eng. Manag. 2022, 148, 05022008. [CrossRef]

- Le, X. Stability Analysis of Red Clay Slope of Jiang-yu Expressway in Guizhou Province and Support of Fabricated Frame Beam. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2019.(in Chinese).

- Zhou, Q. Study on Node Mechanical Properties and Shear Behavior of Hinged Prefabricated Anchoring Frame Beam Structure. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2022.(in Chinese).

- DB43/T 2938-2024;Technical specification for the anchoring of hinged assembled frame beam structure; Administration for Market Regulation of Hunan Province: Changsha, China, 2024.(in Chinese).

- Li, J.B.; Zhu, Y.P.; Ye, S.H.; M, X.R. Internal force analysis and field test of lattice beam based on Winkler theory for elastic foundation beam. Math. Probl. Eng. 2019, 2019, 5130654.

- Fan, J.; Yang, S.; Deng, B.; Sun, B.; Liu, T. A comparison of load distribution methods at the node and internal force analysis of the lattice beam based on the winkler foundation model. Buildings 2023, 13, 1731. [CrossRef]

- Zhang, J., Zhou, S., Zhang, S., Li, F. Stress-induced deformation characteristics of a hinged prefabricated anchor frame beam .J Changsha Univ Sci Tech (Nat Sci), 2025, 22(1): 1-14.(in Chinese).

- Dinev, D. Analytical solution of beam on elastic foundation by singularity functions. Eng. Mech. 2012, 19, 381–392.

- Papusha, A.N. Beam Theory for Subsea Pipelines: Analysis and Practical Applications, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015.

- Bowles, J.E. Foundation Analysis and Design, 5th ed.; McGraw-Hill: New York, NY, USA, 1996.

| HPFB structure | TFB structure | ||||

| F1x/kN | F1y/kN | Fa/kN | Fe/kN | F1x/kN | F1y/kN |

| 102.331 | 197.699 | 17.0278 | 29.0528 | 108.557 | 191.443 |

| HPFB structure | TFB structure | ||||||

| w1x/mm | w1y/mm | waAa/mm | waab/mm | weEe/mm | weef/mm | w1x/mm | w1y/mm |

| 23.7151 | 23.7151 | 9.4738 | 9.4739 | 10.8409 | 10.8409 | 20.2595 | 20.2595 |

| k=6000kN/m3 | k=12000kN/m3 | k=24000kN/m3 | |

| F1x/kN | 101.833 | 102.331 | 103.305 |

| F1y/kN | 198.167 | 197.669 | 196.695 |

| Fa/kN | 16.9585 | 17.0278 | 17.1622 |

| Fe/kN | 29.4237 | 29.0528 | 28.3292 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).