Submitted:

18 April 2025

Posted:

21 April 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results and Discussion

2.1. Alcohol Insoluble Solids Composition

2.2. Water Binding Capacity, Swelling, and Oil Holding Capacity

2.3. Sequential Polysaccharide Extraction

3. Materials and Methods

3.1. Plant Material and Method of Preparing the Material for Further Analysis

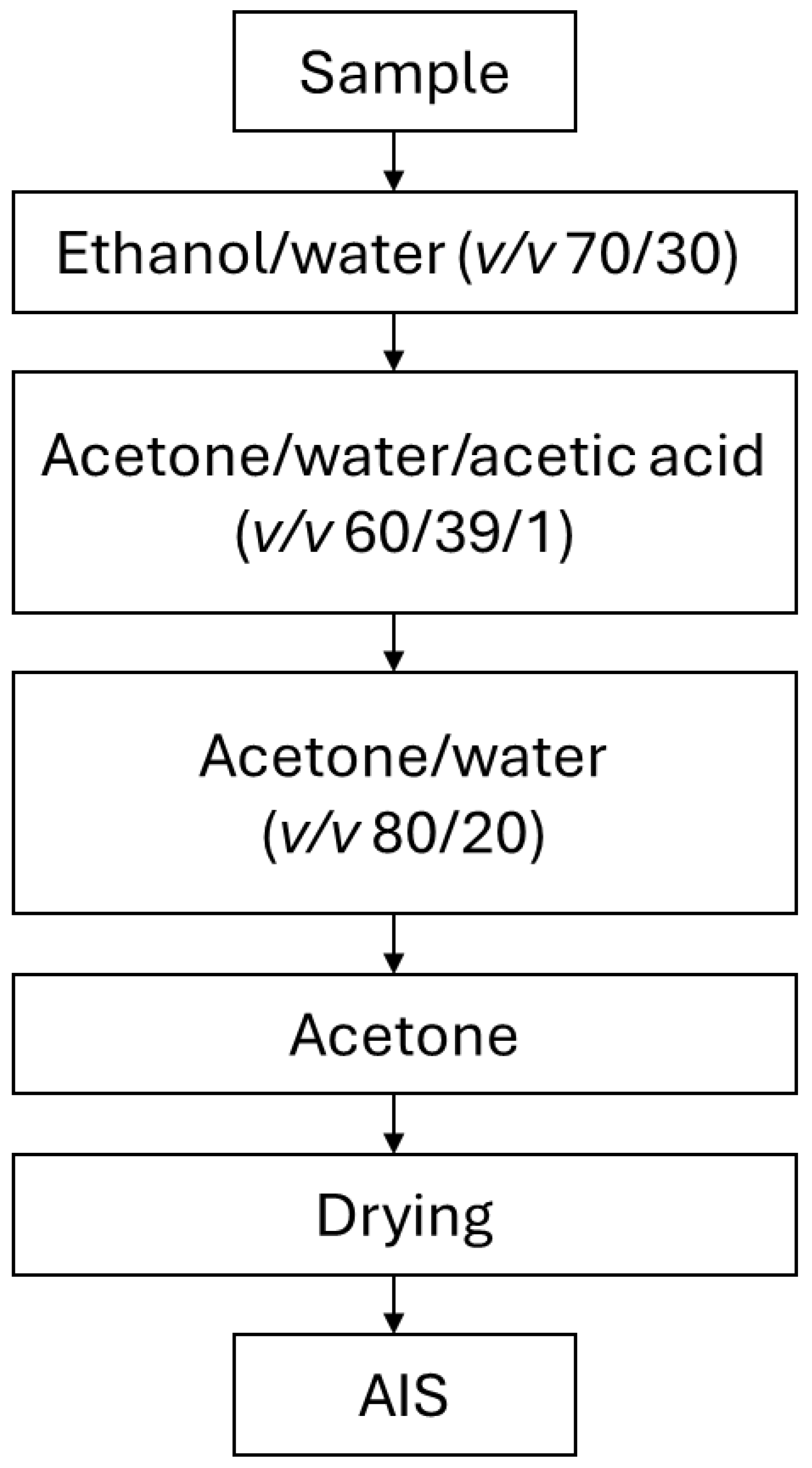

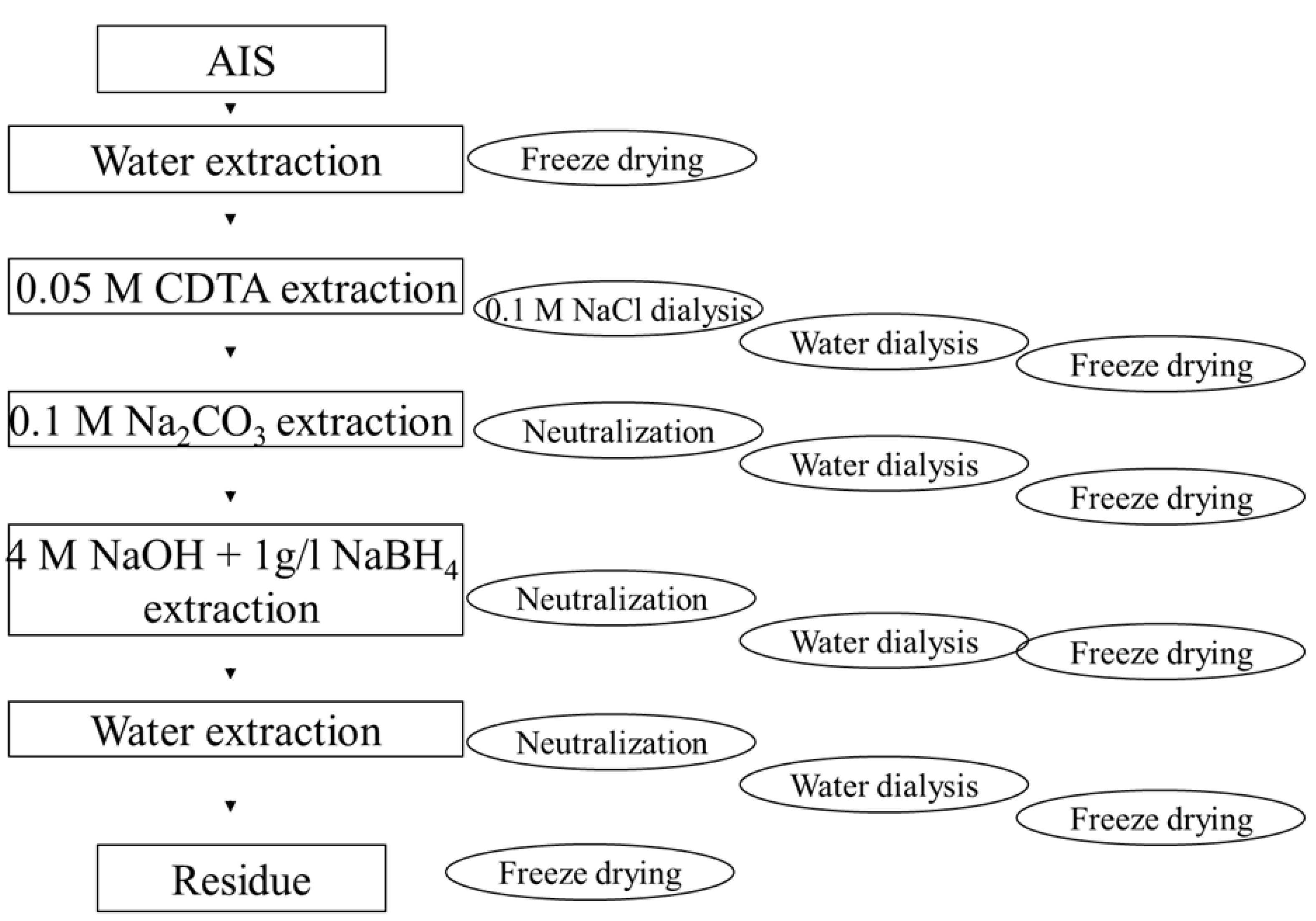

3.2. Alcohol Insoluble Solids (AIS) and Sequential Polysaccharide Extraction

3.4. Cell Walls Hydrolysis

3.5. Pectin Hydrolysis

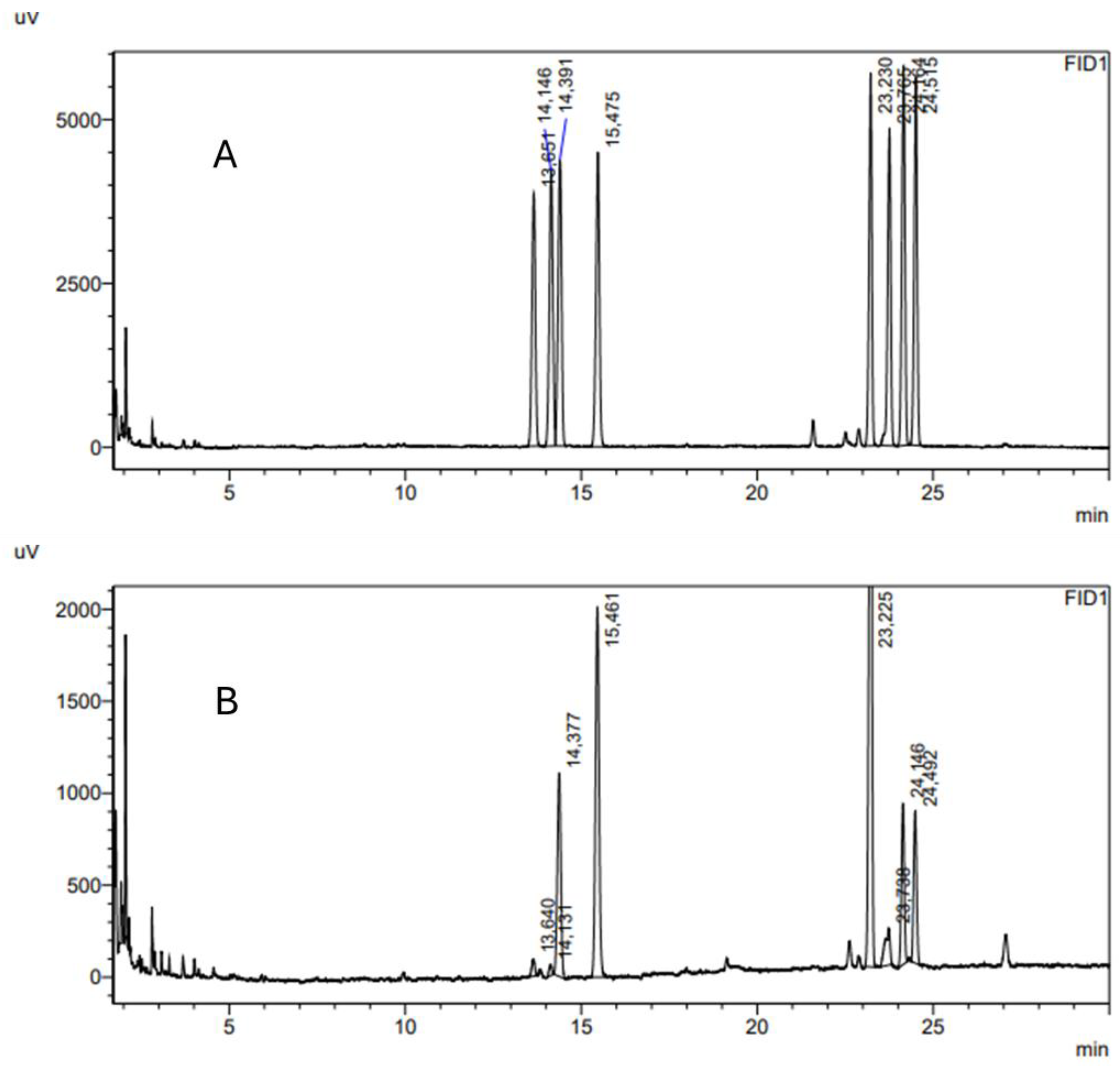

3.6. Derivatization and Gas Chromatography

3.7. Galacturonic Acid

3.8. Water Binding Capacity

3.9. Swelling

3.10. Oil Holding Capacity

3.11. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Ara | arabinose |

| CASP | concentrated alkali soluble polysaccharides |

| CDTA | trans-1,2-diaminocyclohexane-N,N,N′,N′-tetraacetic acid |

| ChSP | chelating agent soluble pectin |

| DASP | diluted alkali soluble pectin |

| Fuc | fucose |

| Gal | galactose |

| GalA | galacturonic acid |

| Glc | glucose |

| Man | mannose |

| MHDP | m-hydroxydiphenyl |

| OHC | Oil holding capacity |

| Rha | rhamnose |

| WBC | water binding capacity |

| WR | water residue |

| WSP | water soluble pectin |

| Xyl | xylose |

References

- Kotuła M., Kapusta-Duch J., Smoleń S., Doskocil I. Phytochemical composition of the fruits and leaves of raspberries (Rubus idaeus L.)—conventional vs. organic and those wild grown. Appl. Sci. 2022, 12, 11783. [CrossRef]

- Jiang H., Zhang W., Li X., Xu Y., Cao J., Jiang W. The anti-obesogenic effects of dietary berry fruits: a review. Food Res. Int. 2021, 147, 110539. [CrossRef]

- Krivokapić S., Vlaović M., Damjanović V.B., Perović A. Perović S. Biowaste as a potential source of bioactive compounds—a case study of raspberry fruit p . Foods. 2021, 10, 706.

- Sójka M., Macierzyński J., Zaweracz W., Buczek M. Transfer and mass balance of ellagitannins, anthocyanins, flavan-3- ols, and flavonols during the processing of red raspberries (Rubus idaeus L.) to juice. J. Agric. Food Chem. 2016, 64, 5549−5563. [CrossRef]

- Cechoviˇciene I., Šlepetiene A., Gumbyte M., Paulauskiene A., Taraseviˇciene Ž. Composition and physicochemical properties of pomace of various cultivars of blackberry (Rubus fruticosus L.). Horticulturae. 2024, 10, 38. [CrossRef]

- Álvarez E.E.; Sánchez P.G. La fibra dietética. Nutr. Hosp. 2006, 21, 61–72.

- Rivas M.Á., Casquete R., Córdoba M.D.G., Ruíz-Moyano S., Benito M.J., Pérez-Nevado F., Martín A. Chemical composition and functional properties of dietary fibre concentrates from winemaking by-products: skins, stems and lees. Foods. 2021, 10, 1510. [CrossRef]

- Tana C., Wei H., Zhao X., Xub C., Peng J. Effects of dietary fibers with high water-binding capacity and swelling capacity on gastrointestinal functions, food intake and body weight in male rats. Food Nutr. Res. 2017, 61, 1308118. [CrossRef]

- Gorlov I.F., Giro T.M., Pryanishnikov V.V., Slozhenkina M.I., Randelin A. V., Mosolova N.I., Zlobina E.Y., Kulikovskiy A.V. Using the fiber preparations in meat processing. Mod. Appl. Sci.; 2015, 9, 54- 64. [CrossRef]

- Milala J., Grzelak- Błaszczyk K., Sójka M., Kosmala M., Dobrzyńska-Inger A., Rój E. Changes of bioactive components in berry seed oils during supercritical CO2 extraction. J. Food Process. Preserv. 2018, 42, e13368. [CrossRef]

- Fotschki B., Juśkiewicz J., Jurgoński A., Rigby N., Sójka M., Kołodziejczyk K., Mackie A., Zduńczyk Z. Raspberry pomace alters cecal microbial activity and reduces secondary bile acids in rats fed a high-fat diet. J. Nutr. Biochem. 2017, 46, 13–20. [CrossRef]

- Demigné C., Morand C., Levrat M.A., Besson C., Moundras C., Rémésy C. Effect of propionate on fatty acid and cholesterol synthesis and on acetate metabolism in isolated rat hepatocytes. Br. J. Nutr. 1995 , 74, 209-219. [CrossRef]

- Kosmala M., Jurgoński A., Juśkiewicz J., Karlińska E., Macierzyński J., Rój E., Zduńczyk Z.. Chemical composition of blackberry press cake, polyphenolic extract, and defatted seeds, and their effects on cecal fermentation, bacterial metabolites, and blood lipid profile in rats. J. Agric. Food Chem. 2017, 65, 5470−5479. [CrossRef]

- Cui G., Zhang W., Wang Q., Zhang A, Mu H., Bai H., Duan J. Extraction optimization, characterization and immunity activity of polysaccharides from Fructus Jujubae. Carbohydr. Polym. 2014, 111, 245–255. [CrossRef]

- Dou J., Meng Y.H., Liu L., Li J., Ren D.Y., Guo Y.R. Purification, characterization and antioxidant activities of polysaccharides from thinned-young apple. Int. J. Biol. Macromol. 2015, 72, 31–40. [CrossRef]

- Yu Z., Liu L., Xu Y., Wang L., Tenga X., Li X, Dai J. Characterization and biological activities of a novel polysaccharide isolated from raspberry (Rubus idaeus L.) fruits. Carbohydr. Polym. 2015, 132, 180–186. [CrossRef]

- Lu J., Yang Y., Hong E.-K., Yin X., Wang X., Wang Y., Zhang D. Analyzing the structure-activity relationship of raspberry polysaccharides using interpretable artificial neural network model. Int. J. Biol. Macromol. 2024, 264, 130354. [CrossRef]

- Yang Y., Yin X., Zhang D., Lu J., Wang X. Isolation, structural characterization and macrophage activation activity of an acidic polysaccharide from raspberry pulp. Molecules. 2022, 27, 1674. [CrossRef]

- Li G., He Y., Liew A., Huang C., Song B., Jia X., Sathuvan M., Zhong S., Cheong K.-L. Dietary polysaccharides from dragon fruit pomace, a co-product of the fruit processing industry, exhibit therapeutic potential in high-fat diet-induced metabolic disorders. Food Res. Int. 2025, 203, 115818. [CrossRef]

- Chen F., Ran L., Mi J., Yan Y., Lu L., Jin B., Li X., Cao Y. Isolation, Characterization and antitumor effect on DU145 cells of a main polysaccharide in pollen of Chinese wolfberry. Molecules 2018, 23, 2430. [CrossRef]

- Khan T., Date A., Chawda, K., Patel K. Polysaccharides as potential anticancer agents—a review of their progress. Carbohydr. Polym. 2019, 210, 412-428. [CrossRef]

- eng H, He Y, Fu Y, Xiong H, Lu M, Zhang C, Ai C, Cao H, Zhong, S, Chen L. Effects of blackberry (Rubus spp.) polysaccharide on the structure and thermal behavior of the myofibrillar protein of chicken breast meat. Food Chem. X, 2023, 20, 100914. [CrossRef]

- Sójka M., Nowakowska A., Hejduk A. Influence of enzymatic clarification, filtration, and pasteurization on ellagitannin and anthocyanin content in raspberry juices. Eur. Food Res. Technol., 2024, 250, 351–359. [CrossRef]

- Renard C M.G.C., Ginies C. Comparison of the cell wall composition for flesh and skin from five different plums. Food Chem., 2009, 114, 1042-1049. [CrossRef]

- He Y., Zhang C., Zheng Y., Xiong H., Ai C., Cao H., Xiao J., El-Seedi H., Chen L., Teng H. (2023). Effects of blackberry polysaccharide on the quality improvement of boiled chicken breast. Food Chem. X, 2023, 18, 100623. [CrossRef]

- Elleuch M., Bedigian D., Roiseux O., Besbes S., Blecker C., Attia H. Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 2011, 124, 411–421. [CrossRef]

- Kosmala M., Milala J., Kołodziejczyk K., Markowski J., Mieszczakowska M., Ginies C., Renard C.M.G.C. Characterization of cell wall polysaccharides of cherry (Prunus cerasus var. Schattenmorelle) fruit and pomace. Plant Foods Hum Nutr. 2009, 64, 279–285. [CrossRef]

- Hotchkiss A.T., Chau H.K., Strahan G.D., Nunez A., Harron A., Simon S., White A.K., Dieng S., Heuberger E.R., Black I., Yadav M.P., Welchoff M., Hirsch J.. Structural characterization of strawberry pomace. Heliyon. 2024, 10, e29787. [CrossRef]

- Kosmala M., Kołodziejczyk, K., Markowski, J., Mieszczakowska, M., Ginies, C., Renard C.M.G.C. Co-products of black-currant and apple juice production: hydration properties and polysaccharide composition. LWT- Food Sci. Technol. 2010, 43, 173-180. [CrossRef]

- Renard C.M.G.C. Variability in cell wall preparations: quantification and comparison of common methods. Carbohydr. Polym. 2005, 60, 515-522. [CrossRef]

- Saeman J.F., Moore W.E., Mitchell R.L., Millet M.A. Techniques for the determination of pulp constituents by quantitative paper chromatography. TAPPI 1954, 37:336-343 ID: 102319861.

- Blumenkrantz N., Asboe-Hansen G. New method for quantitative determination of uronic acids. Anal. Biochem. 1973, 54, 484-489. [CrossRef]

- Renard C.M.G.C., Thibault J.-F. Composition and physico-chemical properties of apple fibres from fresh fruits and industrial products. Lebensm.- Wiss. Technol. 1991, 24,523-527 ID: 81105517.

|

Yield of AIS [mg/g] |

Rha [mg/g] |

Fuc [mg/g] |

Ara [mg/g] |

Xyl [mg/g] |

Man [mg/g] |

Gal [mg/g] |

Noncell Glc [mg/g] |

Cell Glc [mg/g] |

GalA [mg/g] |

|

| Raspberry | ||||||||||

| Fruit | 394±4f | 1±0c | 1±0cd | 16±5c | 39±9c | 6±1b | 12±4d | 12±0c | 64±6b | 305±21b |

| Pomace total | 812±10a | 1±0c | 1±0cd | 9±2e | 52±10ab | 6±3b | 9±1e | 5±2d | 66±13b | 219±52c |

| Pomace seedless fraction | 717±1d | 1±0d | 2±1b | 11±2de | 35±10c | 8±5ab | 18±3cd | 12±2c | 90±29ab | 177±32e |

| Pomace seed fraction | 775±11ab | 1±0cd | 1±0cd | 9±2e | 54±19ab | 4±1c | 7±2e | 3±0d | 49±3b | 172±14e |

| Juice | 38±0h | 9±1a | ND | 34±2b | 15±1e | 7±2b | 41±2a | 20±8b | ND | 278±16bc |

| Blackberry | ||||||||||

| Fruit | 333±11fg | 1±0c | 1±0cd | 20±3c | 46±14ab | 5±1bc | 10±1de | 3±0d | 59±17b | 247±20bc |

| Pomace total | 731±24cd | 1±0cd | 1±0c | 15±3c | 47±9ab | 5±2bc | 9±2e | 4±1d | 72±8ab | 176±22e |

| Pomace seedless fraction | 631±7e | 1±0cd | 3±0a | 31±4b | 25±9d | 8±5ab | 16±5cd | 12±7c | 102±12a | 236±30bc |

| Pomace seed fraction | 766±2bc | 1±0c | ND | 8±2e | 58±18a | 4±2c | 5±2e | 2±0d | 62±6b | 184±48e |

| Juice | 49±0h | 6±0b | ND | 67±2a | 3±1f | 10±2ab | 27±2b | 47±9a | ND | 363±59a |

| p | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 |

|

Water binding capacity [g water/g] |

Swelling [ml/g] |

Oil holding capacity [g oil/g] |

|

| Raspberry | |||

| Fruit | 6.5±0.9c | 4.8±0.2d | 16.5±0.3a |

| Pomace total | 8.5±0.2b | 3.7±0.0ef | 8.8±0.1ef |

| Pomace seedless fraction | 14.9±0.4a | 11.1±0.1a | 11.7±0.1c |

| Pomace seed fraction | 4.2±1.1d | 3.8±0.2e | 8.0±0.0g |

| Blackberry | |||

| Fruit | 6.7±0.9bc | 5.6±0.2c | 12.2±0.0b |

| Pomace total | 4.5±1.0d | 3.8±0.0e | 8.5±0.1f |

| Pomace seedless fraction | 13.0±1.7a | 8.5±0.3b | 9.5±0.1d |

| Pomace seed fraction | 2.7±0.3d | 3.3±0.1f | 9.0±0.0e |

| p | 0.000 | 0.000 | 0.000 |

|

Yield [mg/g] |

Rha [mg/g] |

Fuc [mg/g] |

Ara [mg/g] |

Xyl [mg/g] |

Man [mg/g] |

Gal [mg/g] |

Glc [mg/g] |

GalA [mg/g] |

||

| Raspberry fruit | WSP | 74 | 2±0c | 1±0d | 47±5a | 24±2h | 15±1c | 25±2cd | 6±2fc | 436±38a |

| ChSP | 220 | 1±0d | ND | 10±3f | 5±2i | 6±5d | 3±1h | 2±4gf | 177±0ef | |

| DASP | 224 | 1±0d | ND | 18±5d | 6±0i | 2±1f | 6±1h | 3±0gg | 111±24fgh | |

| CASP | 182 | 2±0c | 3±0c | 26±1d | 59±4f | 8±0d | 17±1e | 52±3ef | 7±0i | |

| WR | 58 | 2±0c | ND | 8±0f | 59±7f | 1±1g | 4±0h | 12±2f | 27±2i | |

| Residue | 304 | 1±0d | ND | 3±0g | 118±2b | 6±1d | 5±0h | 253±3c | 67±5ghi | |

| Raspberry pomace total | WSP | 57 | 1±0d | 1±0d | 20±3d | 34±5g | 8±2d | 18±3e | 16±2f | 317±0bc |

| ChSP | 49 | 1±0d | ND | 7±1f | 4±0i | 3±3f | 1±1i | 2±1g | 150±23f | |

| DASP | 83 | 1±0d | ND | 18±1d | 7±1i | 1±1g | 7±1h | 6±0f | 222±115de | |

| CASP | 168 | 2±0c | 5±0b | 31±1c | 88±2e | 22±0b | 28±1b | 64±13e | 68±0ghi | |

| WR | 56 | 2±0c | ND | 13±2e | 52±4f | 1±0g | 4±1h | 13±0f | 33±2hi | |

| Residue | 463 | 1±0d | ND | 6±0g | 104±10cd | 5±1e | 5±0h | 345±25b | 63±6ghi | |

| Raspberry pomace seedless | WSP | 64 | 1±0d | 2±0d | 18±2d | 40±4g | 8±1d | 23±2d | 18±1f | 252±18cd |

| ChSP | 70 | 1±1d | ND | 15±4d | 6±2i | 2±2f | 5±2h | 0±1g | 335±150b | |

| DASP | 99 | 1±0d | ND | 19±2d | 4±0i | 1±0g | 8±0g | 3±0g | 422±20a | |

| CASP | 243 | 1±0d | 7±0a | 16±0d | 106±1c | 38±0a | 41±1a | 103±1d | 65±10ghi | |

| WR | 39 | 3±1bc | 1±0d | 19±6d | 61±3f | 2±1f | 11±4f | 51±8e | 13±7i | |

| Residue | 223 | 1±0d | ND | 5±0g | 30±5gh | 5±0e | 4±0h | 605±14a | 43±5hi | |

| Raspberry pomace seed | WSP | 13 | 1±0d | 1±0d | 13±0e | 23±3h | 9±1d | 11±1f | 17±1f | 263±10cd |

| ChSP | 58 | 0±1d | 1±0d | 2±1g | 4±2i | 5±1e | 1±1i | ND | 122±1fg | |

| DASP | 69 | 1±0d | ND | 12±3e | 6±1i | 1±1g | 5±1h | 5±1f | 378±0ab | |

| CASP | 110 | 4±0b | 4±0c | 47±2a | 97±1de | 16±1c | 27±1bc | 48±7e | 52±3ghi | |

| WR | 30 | 6±3a | 0±1d | 37±6b | 145±21a | 3±0f | 11±4f | 9±1f | 78±5ghi | |

| Residue | 601 | 1±0d | ND | 3±0g | 111±6bc | 6±1d | 4±0h | 246±10c | 44±10ghi | |

| p | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

|

Yield [mg/g] |

Rha [mg/g] |

Fuc [mg/g] |

Ara [mg/g] |

Xyl [mg/g] |

Man [mg/g] |

Gal [mg/g] |

Glc [mg/g] |

GalA [mg/g] |

||

| Blackberry fruit | WSP | 50 | 3±1cde | 1±0efgh | 67±2abcd | 10±1ijk | 5±1fg | 28±2bc | 18±0ef | 585±50c |

| ChSP | 82 | 1±0def | ND | 24±8hijk | 4±1k | ND | 6±2ghij | ND | 247±39efg | |

| DASP | 67 | 4±0cd | ND | 73±10abc | 5±0k | 2±0jk | 15±3de | 5±1f | 465±27cd | |

| CASP | 131 | 2±0def | 6±0e | 46±1efg | 73±2de | 18±1c | 26±1c | 73±3cde | 50±12hi | |

| WR | 44 | 8±2ab | ND | 44±7efg | 24±3i | 1±1jk | 12±2defg | 3±0f | 12±0i | |

| Residue | 502 | 1±0def | ND | 4±0kl | 107±8ab | 4±0fghij | 4±1ij | 266±15b | 64±7hi | |

| Blackberry pomace total | WSP | 23 | 1±0ef | 1±0e | 26±0ghij | 25±0ih | 9±1de | 15±0de | 23±1def | 355±41de |

| ChSP | 60 | 1±0ef | ND | 10±2jkl | 5±1k | 2±1ghijk | 2±0j | ND | 240±78efg | |

| DASP | 85 | 1±1def | ND | 12±5ijkl | 3±1k | 1±0jk | 4±2hij | 6±2f | 154±5fgh | |

| CASP | 114 | 3±0cd | 7±0b | 57±1bcde | 92±1bc | 25±1b | 33±1ab | 80±14cd | 45±13hi | |

| WR | 44 | 6±2b | ND | 32±1fghi | 21±2ij | 1±0jk | 17±2d | 15±1ef | 15±3i | |

| Residue | 577 | 1±0def | ND | 4±0kl | 115±5a | 4±0fghij | 4±0hij | 277±3b | 60±3hi | |

| Blackberry pomace seedless | WSP | 30 | 1±0def | 3±0d | 70±12abc | 49±7fg | 10±3e | 30±7bc | 14±2f | 793±154b |

| ChSP | 102 | 3±1cdef | ND | 76±20ab | 5±2jk | 2±1ghijk | 13±4def | 1±0f | 264±2ef | |

| DASP | 128 | 2±1def | ND | 48±8def | 3±0k | 2±1jk | 11±2defg | 7±2f | 927±0a | |

| CASP | 248 | 2±0def | 9±0a | 37±1efgh | 93±5bc | 40±1a | 38±2a | 110±5c | 42±19hi | |

| WR | 35 | 9±1a | 1±0efg | 81±9a | 23±3i | 2±0ijk | 32±3abc | 18±2ef | 11±5i | |

| Residue | 257 | 1±0def | ND | 13±2ijkl | 40±19gh | 6±1ef | 6±1fghij | 612±87a | 47±4hi | |

| Blackberry pomace seed | WSP | 28 | 1±0def | 1±0ef | 19±2hijkl | 17±1ijk | 12±2e | 9±0efghi | 26±2def | 241±6efg |

| ChSP | 65 | ND | ND | 3±0l | 5±1k | 1±1ijk | 1±0j | ND | 126±6ghi | |

| DASP | 60 | ND | ND | 3±0l | 3±0k | 1±0jk | 1±0j | 4±1f | 139±63fghi | |

| CASP | 49 | 4±0cd | 3±0d | 55±1cde | 62±2ef | 5±0fgh | 16±0d | 28±7def | 62±4hi | |

| WR | 25 | 5±2bc | ND | 30±5fghi | 81±5cd | 2±0ijk | 11±2defgh | 8±1f | 18±13i | |

| Residue | 503 | 1±0def | ND | 2±0l | 122±3a | 5±0fghi | 3±0ij | 263±6b | 45±4hi | |

| p | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).