Submitted:

05 March 2025

Posted:

06 March 2025

You are already at the latest version

Abstract

AI technologies are becoming increasingly prevalent in industrial workplaces, extending their applications beyond productivity to critical areas such as occupational safety. From our perspective, it is important to consider the safety of these AI systems for users already at the research and development stage, rather than only after deployment. Therefore, in this review, we synthesize publications that propose such AI-based safety systems to assess how potential risks are addressed early in their design and prototype stages. Consequently, we explore current advancements in AI-driven, sensor-based, and human-centered applications designed to enhance occupational safety by monitoring compliance, detecting hazards in real time, or assisting users. These systems leverage wearables and environmental sensing to proactively identify risks, support decision-making, and contribute to creating safer work environments. In this paper, we categorize the technologies according to the sensors used and highlight which features are preventive, reactive, or post-incident. Furthermore, we address potential risks posed by these AI applications, as they may introduce new hazards for workers. Through a critical review of current research and existing regulations, we identify gaps and propose key considerations for the safe and ethical deployment of trustworthy AI systems. Our findings suggest that in AI- and sensor-based research applications for occupational safety, some features and risks are considered notably less than others, from which we deduce that while AI is being increasingly utilized to improve occupational safety, there is a significant need to address regulatory and ethical challenges for its widespread and safe adoption in industrial domains.

Keywords:

1. Introduction

1.1. AI-Based Systems for Occupational Safety

1.2. Related Research

2. Materials and Methods

2.1. Publication Inclusion Criteria

- research papers that explore the application of AI-driven sensor systems published in English language

- the applications are built around the human operator and follow a human-centered design

- applications where the human operator is either assisted by the system or monitored by the system

- applications used in different occupational industrial environments

- articles published after 2022

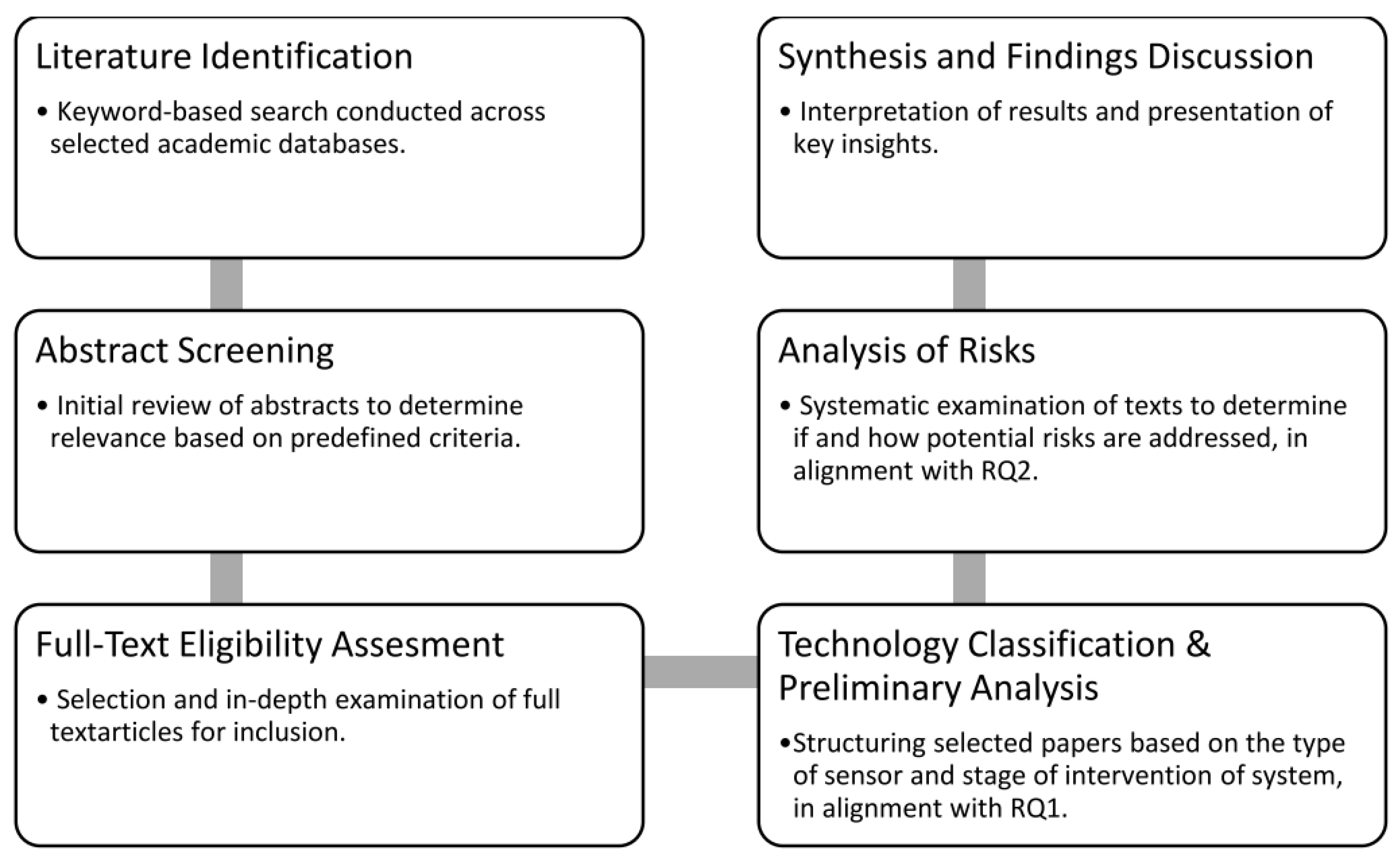

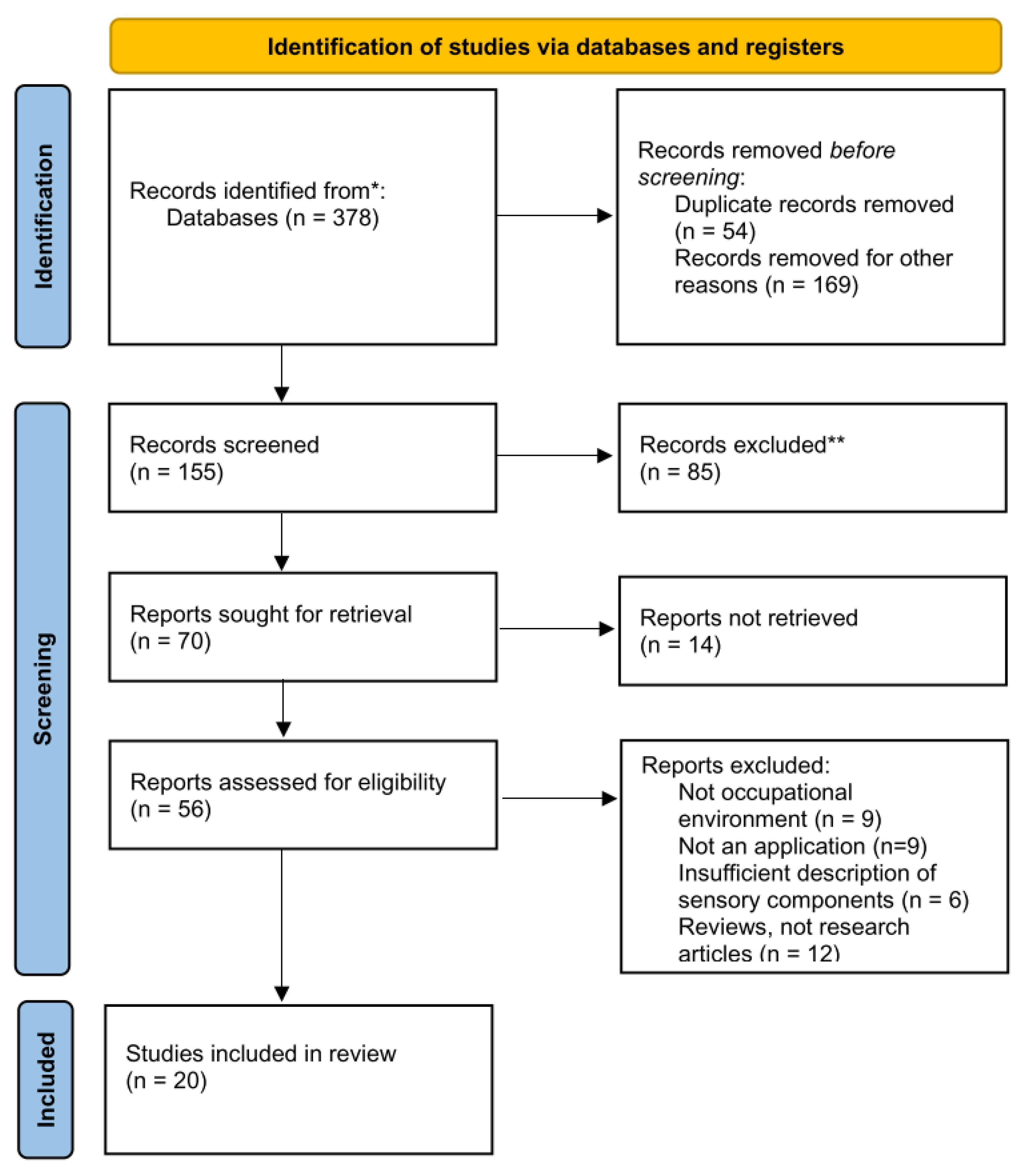

2.2. Publication Selection Process

2.3. Categorizing Publications and Formulating Research Questions

| Type of Sensor/Data Collected | |||

|---|---|---|---|

| R1 - Preventive | R2 - Reactive | R3 - Post-Incident | |

| Wearable Systems | |||

| Physiological Monitoring | [14] [15] [16] [17] | [15] [17] | |

| Environmental Monitoring | [18] [14] [15] [16] [19] [17] | [15] | |

| Movement and Posture Monitoring | [20] [18][21] [16] [17] [19] [22]* [23] | [17] [22]* [23] | [21][13] [24] [22]* |

| Proximity and Location Tracking | [14][21][16] [25] [22]* | [21] [25] [22]* | [21][13] [22]* |

| Systems Deployed in Environment | |||

| Image Sensors | [21] [26] [27] [28] [29] [30] [31] [32]* [22]* [33]* [34]* [35]* [36]* [37]* [38]* [39]* [40]* [23] | [32]* [22]* [33]* [34]* [35]* [37]* [38]* [39]* [40]* [23] | [32]* [22]* [33]* [34]* [35]* [37]* [38]* [39]* [40]* |

| Environmental Sensors | [41][16] [17] [19] [42] | [41] [17] [42] | |

| Motion and Proximity Sensors | [19] [22]* [35]* [37]* [39]* [40]* | [22]* [35]* [37]* [39]* | [22]* [35]* [37]* [39]* |

-

RQ1: How can AI-based systems and technologies implemented for occupational safety in industrial settings be categorized based on the following aspects?

- RQ1.1: Which AI-based wearable systems and technologies are implemented for occupational safety in industrial settings?

- RQ1.2: Which AI-based systems and technologies deployed in the environment are implemented for occupational safety in industrial settings?

- RQ1.3: Which preventive, reactive, and post-incident features of these AI-based safety applications can be identified?

- RQ2: Given that some AI-based applications for occupational safety inherently introduce new risks while others do not, does the respective scientific literature address these risks? Additionally, when considering both explicitly addressed risks and those not posed by the design of the respective systems, which applications can be considered safer or less safe overall?

3. Results

3.1. Table Summarizing Findings for RQ1

3.2. Findings for RQ1.1: Which AI-Based Wearable Systems and Technologies are Implemented for Occupational Safety in Industrial Settings?

3.2.1. Physiological Monitoring

3.2.2. Environmental Monitoring

3.2.3. Movement and Posture Monitoring

3.2.4. Proximity and Location Tracking

3.3. Findings for RQ1.2: Which AI-Based Systems and Technologies Deployed in the Environment Are Implemented for Occupational Safety in Industrial Settings?

3.3.1. Image Sensors

3.3.2. Environmental Sensors

3.3.3. Motion and Proximity Sensors

3.4. Findings for RQ1.3: Which Preventive, Reactive, and Post-Incident Features of These AI-Based Safety Applications Can Be Identified?

3.4.1. Preventive Features

3.4.2. Reactive Features

3.4.3. Post-Incident Features

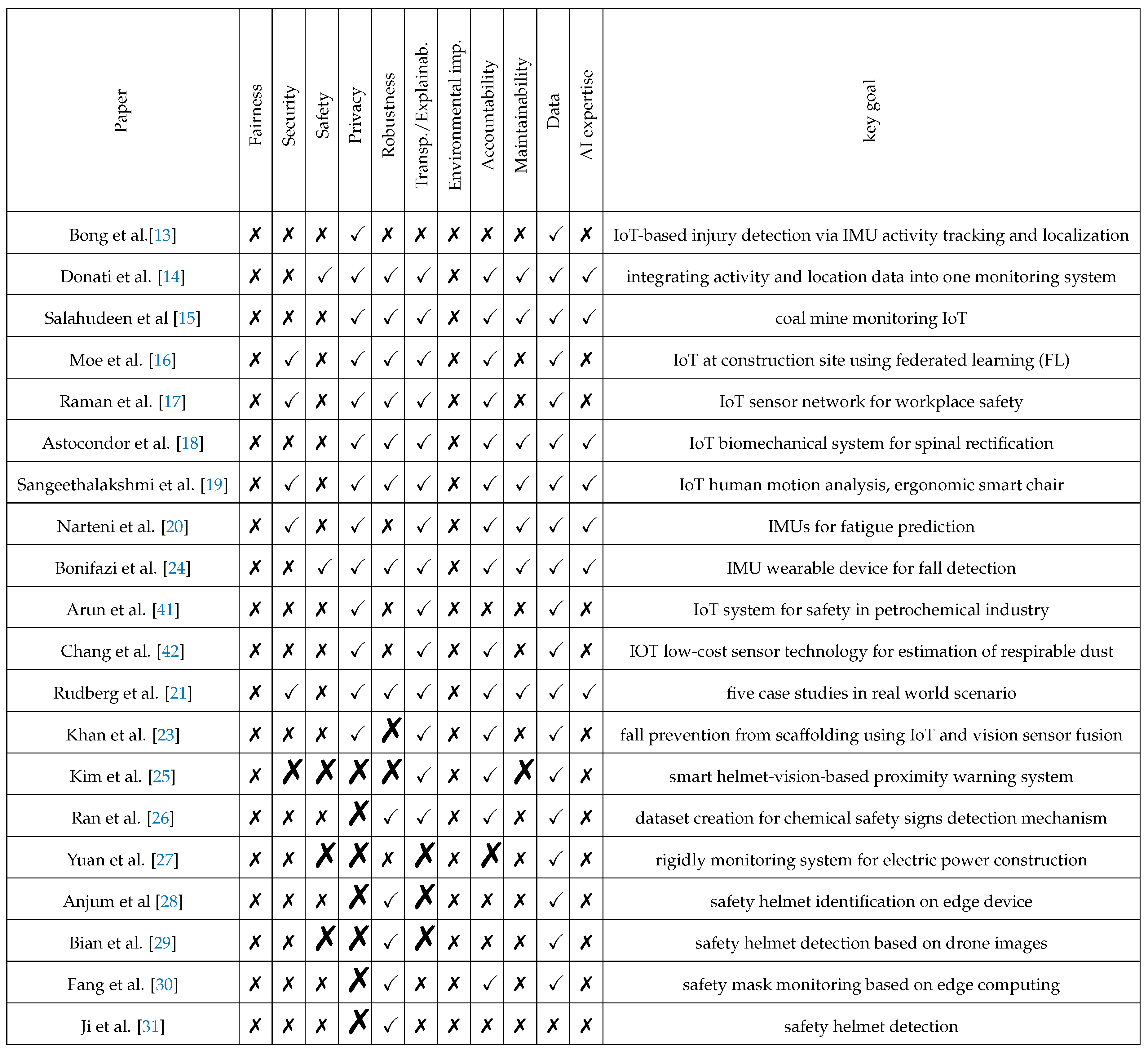

3.5. Findings for RQ2: Given That Some AI-Based Applications for Occupational Safety Inherently Introduce New Risks While Others Do Not, Does the Respective Scientific Literature Address These Risks? Additionally, When Considering Both Explicitly Addressed Risks and Those Not Posed by the Design of the Respective Systems, Which Applications Can Be Considered Safer or Less Safe Overall?

- Fairness: AI systems for automated decision-making can produce unfair outcomes due to biases in data, objective functions, and human input. Additionally, unfairness can arise from biases in the design, problem formulation, and deployment decisions of AI systems.

- Security: In AI, particularly in machine learning systems, new security issues such as data poisoning, adversarial attacks, and model stealing must be addressed in addition to traditional information and system security concerns. These emerging threats pose unique challenges that go beyond classical security measures.

- Safety: Safety relates to the expectation that a system does not, under defined conditions, lead to a state in which human life, health, property or the environment is endangered. Use of AI systems in automated vehicles, manufacturing devices, and robots can introduce risks related to safety.

- Privacy: Privacy involves individuals controlling how their information is collected, stored, processed, and disclosed. Given that AI systems often rely on big data, particularly sensitive data like health records, there are significant concerns about privacy protection, potential misuse, and ethical impacts, including discrimination and freedom of expression.

- Robustness: Robustness is related to the ability of a system to maintain its level of performance under the various circumstances of its usage. In the context of AI systems, there are additional challenges due to its complex, nonlinear characteristics.

- Transparency and explainability: Transparency involves both the characteristics of organizations operating AI systems and the systems themselves. It requires organizations to disclose their use of AI, data handling practices, and risk management measures, while AI systems should provide stakeholders with information on their capabilities, limitations, and explainability to understand and assess their outcomes.

- Environmental impact: AI can impact the environment both positively, such as reducing emissions in gas turbines, and negatively, due to the high resource consumption during training phases. These environmental risks and their impacts must be considered when developing and deploying AI systems.

- Accountability: Accountability in AI involves both organizational responsibility for decisions and actions, and the ability to trace system actions to their source. The use of AI can change existing accountability frameworks, raising questions about who is responsible when AI systems perform actions.

- Maintainability: Maintainability is related to the ability of the organization to handle modifications of the AI system in order to correct defects or adjust to new requirements. Because AI systems based on machine learning are trained and do not follow a rule-based approach, the maintainability of an AI system and its implications need to be investigated.

- Availability and quality of training and test data: AI systems based on machine learning require high-quality, sufficiently diverse training and test data to ensure intended behaviour and strong predictive power. The data must be validated for currency and relevance. The amount will vary based on intended functionality and environment complexity.

- AI expertise: AI systems require inter-disciplinary specialists (difference to traditional software solutions) for their development, deployment and assessment. End users are strongly encouraged to familiarize themselves with the functionality of the system.

4. Discussion, Limitations and Future Work

4.1. Summarizing Findings

4.1.1. RQ1.1

4.1.2. RQ1.2

4.1.3. RQ1.3

4.1.4. RQ2

4.2. Limitations and Future Work

5. Conclusions

Funding

Conflicts of Interest

References

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Safety science 2018, 109, 403–411. [Google Scholar]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial artificial intelligence in industry 4.0-systematic review, challenges and outlook. IEEE access 2020, 8, 220121–220139. [Google Scholar]

- Pishgar, M.; Issa, S.F.; Sietsema, M.; Pratap, P.; Darabi, H. REDECA: a novel framework to review artificial intelligence and its applications in occupational safety and health. International journal of environmental research and public health 2021, 18, 6705. [Google Scholar] [PubMed]

- Zorzenon, R.; Lizarelli, F.L.; Daniel, B.d.A. What is the potential impact of industry 4.0 on health and safety at work? Safety science 2022, 153, 105802. [Google Scholar]

- Patel, V.; Chesmore, A.; Legner, C.M.; Pandey, S. Trends in workplace wearable technologies and connected-worker solutions for next-generation occupational safety, health, and productivity. Advanced Intelligent Systems 2022, 4, 2100099. [Google Scholar] [CrossRef]

- Guo, B.H.; Zou, Y.; Fang, Y.; Goh, Y.M.; Zou, P.X. Computer vision technologies for safety science and management in construction: A critical review and future research directions. Safety science 2021, 135, 105130. [Google Scholar] [CrossRef]

- Vukicevic, A.M.; Petrovic, M.N.; Knezevic, N.M.; Jovanovic, K.M. Deep learning-based recognition of unsafe acts in manufacturing industry. IEEE Access 2023. [Google Scholar] [CrossRef]

- Tran, T.a.; Abonyi, J.; Kovács, L.; Eigner, G.; Ruppert, T. Heart rate variability measurement to assess work-related stress of physical workers in manufacturing industries-protocol for a systematic literature review. In Proceedings of the 2022 IEEE 20th Jubilee International Symposium on Intelligent Systems and Informatics (SISY). IEEE; 2022; pp. 000313–000318. [Google Scholar]

- Flor-Unda, O.; Fuentes, M.; Dávila, D.; Rivera, M.; Llano, G.; Izurieta, C.; Acosta-Vargas, P. Innovative technologies for occupational health and safety: a scoping review. Safety 2023, 9, 35. [Google Scholar] [CrossRef]

- Fisher, E.; Flynn, M.A.; Pratap, P.; Vietas, J.A. Occupational safety and health equity impacts of artificial intelligence: a scoping review. International journal of environmental research and public health 2023, 20, 6221. [Google Scholar] [PubMed]

- Akyıldız, C. Integration of digitalization into occupational health and safety and its applicability: a literature review. The European Research Journal 2023, 9, 1509–1519. [Google Scholar] [CrossRef]

- Auernhammer, J. Human-centered AI: The role of Human-centered Design Research in the development of AI. In Proceedings of the Synergy - DRS International Conference 2020; Boess, S.; Cheung, M.; Cain, R., Eds., Held online, August 2020. 11-14 August. [Google Scholar] [CrossRef]

- Bong, P.C.; Tee, M.K.T.; Jo, H.S. Exploring the Potential of IoT-based Injury Detection and Response by Combining Human Activity Tracking and Indoor Localization. In Proceedings of the 2022 International Conference on Computer and Drone Applications (IConDA). IEEE; 2022; pp. 28–33. [Google Scholar]

- Donati, M.; Olivelli, M.; Giovannini, R.; Fanucci, L. RT-PROFASY: Enhancing the well-being, safety and productivity of workers by exploiting wearable sensors and artificial intelligence. In Proceedings of the 2022 IEEE International Workshop on Metrology for Industry 4.0 &, 2022, IoT (MetroInd4. 0&IoT). IEEE; pp. 69–74.

- Salahudeen, M.; Rahul, K.; Kurian, N.S.; Vardhan, H.; Amirthavalli, M. Smart PPE using LoRaWAN Technology. In Proceedings of the 2023 International Conference on Inventive Computation Technologies (ICICT). IEEE; 2023; pp. 1272–1279. [Google Scholar]

- Moe, S.J.S.; Kim, B.W.; Khan, A.N.; Rongxu, X.; Tuan, N.A.; Kim, K.; Kim, D.H. Collaborative Worker Safety Prediction Mechanism Using Federated Learning Assisted Edge Intelligence in Outdoor Construction Environment. IEEE Access 2023. [Google Scholar]

- Raman, R.; Mitra, A. IoT-Enhanced Workplace Safety for Real-Time Monitoring and Hazard Detection for Occupational Health. In Proceedings of the 2023 International Conference on Artificial Intelligence for Innovations in Healthcare Industries (ICAIIHI), Vol. 1; 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Astocondor-Villar, J.; Grados, J.; Mendoza-Apaza, F.; Chavez-Sanchez, W.; Narciso-Gomez, K.; Grados-Espinoza, A.; Pascual-Panduro, P. Low-cost Biomechanical System for Posture Rectification using IoT Technology. In Proceedings of the Proceedings of the 2023 6th International Conference on Electronics, Communications and Control Engineering, 2023, pp.

- Sangeethalakshmi, K.; Lakshmi, V.V.; Malathi, N.; Velmurugan, S.; et al. Smart Ergonomic Practices With IoT and Cloud Computing for Injury Prevention and Human Motion Analysis. In Proceedings of the 2023 International Conference on Artificial Intelligence for Innovations in Healthcare Industries (ICAIIHI). IEEE, Vol. 1; 2023; pp. 1–6. [Google Scholar]

- Narteni, S.; Orani, V.; Cambiaso, E.; Rucco, M.; Mongelli, M. On the Intersection of Explainable and Reliable AI for physical fatigue prediction. IEEE Access 2022, 10, 76243–76260. [Google Scholar]

- Rudberg, M.; Sezer, A.A. Digital tools to increase construction site safety. In Proceedings of the ARCOM Association of Researchers in Construction Management; 2022. [Google Scholar]

- TrioMobil. TrioMobil. https://www.triomobil.com/en, 2024. Accessed: 2024-07-11.

- Khan, M.; Khalid, R.; Anjum, S.; Tran, S.V.T.; Park, C. Fall prevention from scaffolding using computer vision and IoT-based monitoring. Journal of Construction Engineering and Management 2022, 148, 04022051. [Google Scholar]

- Bonifazi, G.; Corradini, E.; Ursino, D.; Virgili, L.; Anceschi, E.; De Donato, M.C. A machine learning based sentient multimedia framework to increase safety at work. Multimedia tools and applications 2022, 81, 141–169. [Google Scholar] [PubMed]

- Kim, Y.; Choi, Y. Smart helmet-based proximity warning system to improve occupational safety on the road using image sensor and artificial intelligence. International journal of environmental research and public health 2022, 19, 16312. [Google Scholar] [PubMed]

- Ran, S.; Weise, T.; Wu, Z. Chemical safety sign detection: a survey and benchmark. In Proceedings of the 2022 International Joint Conference on Neural Networks (IJCNN). IEEE; 2022; pp. 1–7. [Google Scholar]

- Yuan, W.; Zaixin, C.; Qing, W.; Huihui, J.; Tao, D.; Li, C. Safety Risk Control System for Electric Power Construction Site Based on Artificial Intelligence Technology. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE). IEEE; 2023; pp. 1695–1699. [Google Scholar]

- Anjum, S.; Zaidi, S.F.A.; Khalid, R.; Park, C. Artificial Intelligence-based Safety Helmet Recognition on Embedded Devices to Enhance Safety Monitoring Process. In Proceedings of the 2022 IEEE International Conference on Artificial Intelligence in Engineering and Technology (IICAIET). IEEE; 2022; pp. 1–4. [Google Scholar]

- Bian, H.; Liu, Y.; Shi, L.; Lin, Z.; Huang, M.; Zhang, J.; Weng, G.; Zhang, C.; Gao, M. Detection method of helmet wearing based on uav images and yolov7. In Proceedings of the 2023 IEEE 6th Information Technology, Networking, 2023, Vol. 6, Electronic and Automation Control Conference (ITNEC). IEEE; pp. 1633–1640.

- Fang, D.; Tian, L.; Li, M.; Wang, Y.; Liu, J.; Chen, X. Factory Worker Safety Mask Monitoring System Based on Deep Learning and AI Edge Computing. In Proceedings of the 2022 5th International Conference on Mechatronics, Robotics and Automation (ICMRA). IEEE; 2022; pp. 96–100. [Google Scholar]

- Ji, N.; Ren, G.; Li, S.; Wei, W.; Zhang, M.; Liu, M.; Jiang, B. Improved Yolov5 for Safety Helmet Detection with Hybrid Attention. In Proceedings of the 2023 4th International Conference on Electronic Communication and Artificial Intelligence (ICECAI). IEEE; 2023; pp. 57–61. [Google Scholar]

- Intenseye. Intenseye. https://www.intenseye.com/, 2024. Accessed: 2024-07-11.

- Chooch. Chooch. https://www.chooch.com/, 2024. Accessed: 2024-07-11.

- 3motionAI. 3motionAI. https://3motionai.com/, 2024. Accessed: 2024-07-11.

- Eyyes. Eyyes. https://www.eyyes.com/, 2024. Accessed: 2024-07-11.

- EWIworks. EWIworks. https://ewiworks.com/, 2024. Accessed: 2024-07-11.

- Nirovision. Nirovision. https://www.nirovision.com/, 2024. Accessed: 2024-07-11.

- Geutebrueck. Geutebrueck. https://www.geutebrueck.com/de/index.html, 2024. Accessed: 2024-07-11.

- ProtexAI. ProtexAI. https://www.protex.ai/, 2024. Accessed: 2024-07-11.

- AssertAI. AssertAI. https://www.assertai.com/, 2024. Accessed: 2024-07-11.

- Arun, S.; Karthik, S.; et al. Using Artificial Intelligence to Enhance Hazard Assessment and Safety Measures in Petrochemical Industries: Development and Analysis. In Proceedings of the 2023 3rd International Conference on Pervasive Computing and Social Networking (ICPCSN). IEEE; 2023; pp. 823–830. [Google Scholar]

- Chang, T.Y.; Chen, G.Y.; Chen, J.J.; Young, L.H.; Chang, L.T. Application of artificial intelligence algorithms and low-cost sensors to estimate respirable dust in the workplace. Environment International 2023, 182, 108317. [Google Scholar] [PubMed]

- Pavón, I.; Sigcha, L.; Arezes, P.; Costa, N.; Arcas, G.; López, J. Wearable technology for occupational risk assessment: Potential avenues for applications. In Occupational safety and hygiene VI; CRC Press, 2018; pp. 447–452.

- High-Level Expert Group on Artificial Intelligence. Ethics Guidelines for Trustworthy AI. Technical report, European Commission, 2019. Accessed: 2024-10-08.

- for Standardization, I.O.; Commission, I.E. Information technology — Artificial intelligence — Guidance on risk management. Technical Report ISO/IEC 23894:2023, ISO/IEC, Geneva, Switzerland, 2023.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).