1. Introduction

Supply chains are the backbone of firms’ efficiency, serving as the complex networks through which products and services flow from suppliers to end consumers. They are dynamic ecosystems comprised of suppliers, manufacturers, distributors, retailers, and logistics providers, all collaborating to deliver products efficiently and effectively (Büyüközkan & Göçer, 2018). The conventional supply chain management models, marked by linear and sequential processes, are increasingly inadequate to address the demands of the contemporary fast-paced and interconnected business landscape.

The rapid development of digital technologies in recent years has fundamentally reshaped the SCM landscape. Digital transformation, defined as integrating new-generation digital technologies into all business operations’ aspects (Benkhider & Meziani, 2021), has arisen as a priority for firms seeking to enhance their supply chains’ efficiency, agility, and resilience (Thapa, 2014). The propagation of digital technologies like the Internet of Things (IoT), big data, cloud, artificial intelligence (AI), and blockchain analytics has unlocked new opportunities for innovation and optimization across the entire supply chain ecosystem (Thapa, 2014).

The digital transformation of supply chains represents a paradigm change in how firms manage and optimize their supply chain processes. Traditionally, SCM focused on optimizing individual functions such as procurement, production, and distribution in isolation. However, with the advent of digital technologies, supply chains have become increasingly interconnected and data-driven, requiring organizations to adopt a holistic and integrated approach to managing their supply chain processes.

The essence of the digital supply chain revolves around the fundamental concept of connectivity. Adopting digital technologies enables real-time communication and collaboration among supply chain partners, allowing for greater network visibility, transparency, and coordination (C. Johnsen, Voigt, & Weimann, 2020). Furthermore, digital technologies such as AI and big data analytics enable firms to analyze big data to reveal insights and trends that were previously inaccessible. By relating the power of AI algorithms, firms can optimize decision-making processes, predict demand, mitigate risks, lead, and improve supply chain efficiency and responsiveness (Haenlein & Kaplan, 2019). Additionally, blockchain technology provides a secure transactions record, enhancing transparency and trust in supply chain transactions. By providing a common and immutable record of transactions, blockchain fosters a level playing field where all stakeholders have access to the same trusted information. This transparency promotes greater accountability and cooperation, as each party can verify the accuracy of data and transactions without the need for intermediaries or third-party validation.

This paper explores the imperative of digital transformation in empowering supply chains to thrive in the digital age. We aim to explore the evolution of SCM practices, examine the pivotal concepts and technologies propelling digital transformation, and scrutinize real-world case studies showcasing successful implementations of digital transformation within supply chains. Through a comprehensive examination of the digital transformation imperative, we aim to provide insights and recommendations for businesses and supply chain professionals seeking to explore the digital landscape and unlock new opportunities for development and innovation.

Indeed, it is an extension to the previous research paper proposed by (Benkhider & Kherbachi, 2023) regarding the task-technology fit model for logistics effectiveness. This paper stands for a critical feature of digital technologies adoption (Kayapinar & Lorcu, 2020) and SCM practices (Hong, Liao, Zhang, & Yua, 2019) in the digital age using a Principal Component Analysis (PCA) based statistical procedure.

The following sections of this paper are organized as such: firstly, we delve into the essential literature review addressing SCM in the digital era. Next, we present a comprehensive description of the methodological protocol followed, elucidating how adopting digital transformation can enhance efficiency in SCM practices. Subsequently, we unveil the results obtained from empirical research and engage in discussions surrounding them. Finally, we highlight the most significant conclusions drawn, discuss research limitations, and outline avenues for future research.

4. Results and Discussion

This paper strives to explain the pivotal role of digital transformation in enhancing the supply chain and its management practices. By applying a quantitative approach from various industries, we aim to provide comprehensive insights into the multifaceted benefits and strategies associated with digital technologies adoption. In order to comprehensively assess the efficiency of SCM practices, we carefully selected nine evaluative criteria from the literature review. These criteria, outlined and detailed in

Table 1, have been meticulously chosen to encompass various facets of supply chain operations, ranging from timeliness and accuracy to agility and external connectivity. Each criterion serves as a vital measure in evaluating the effectiveness and performance of SCM strategies employed by organizations.

We initiate our analysis by presenting a comprehensive review of the descriptive statistics associated with all variables integrated into our research model. The following table shows the characteristics of the variables we retained for this study.

The descriptive statistics analysis, presented in

Table 1, reveals a generally adequate level of satisfaction among respondents, with moderate mean scores observed across most evaluative criteria, such as accuracy, information sharing, and timeliness. However, significant differences in perceptions are evident, particularly in criteria such as information sharing and availability, where some respondents may perceive these aspects more positively or negatively than others. This dispersion among respondents can be directly linked to SCM practices. The sizes of surveyed firms often correlate with differences in supply chain structures, complexities, and priorities. For instance, larger firms may allocate more resources toward supply chain automation technologies or advanced analytics tools to optimize their operations across a global network.

Meanwhile, smaller firms might focus on more basic technologies or lean practices to enhance efficiency and cost-effectiveness. Similarly, industry-specific requirements within SCM, such as compliance standards or customer service expectations, can influence investment decisions. Thus, understanding these nuances is crucial for tailoring supply chain strategies and investments to meet each firm’s unique needs within its specific industry context.

For example, while the mean score for information sharing is moderate (3.13), the low p-value (0.03) suggests notable variability in perceptions among respondents. The observed results indicating limited access to certain information due to restricted information sharing and availability could be influenced by various factors within the organizational context. For instance, limited access to information may stem from hierarchical structures or departmental silos that restrict the flow of information across different parts of the organization. Additionally, technological limitations or inadequate infrastructure might hinder the availability and accessibility of crucial data and resources.

Conversely, the consistently low mean scores and extremely low p-values associated with technology-specific criteria like Intranet and Extranet underscore their critical importance within the organizational framework. This unanimity among respondents highlights these technologies’ pivotal role in facilitating effective SCM practices. However, their low mean scores also suggest potential areas for improvement, indicating that while these technologies are recognized as essential, there may be shortcomings in their current implementation or functionality.

After looking closely at the descriptive statistics table for our research, our next step is to use the PCA model. This analytical approach aims to identify and elucidate the key determinants essential for evaluating the efficacy of managerial practices within the logistics chain. By leveraging PCA, we endeavor to uncover nuanced relationships and patterns within the data, pinpointing the critical factors that significantly impact logistical performance. This strategic initiative enhances our understanding of the multifaceted dynamics inherent in SCM and facilitates informed decision-making to optimize operational efficiencies and drive firms’ success.

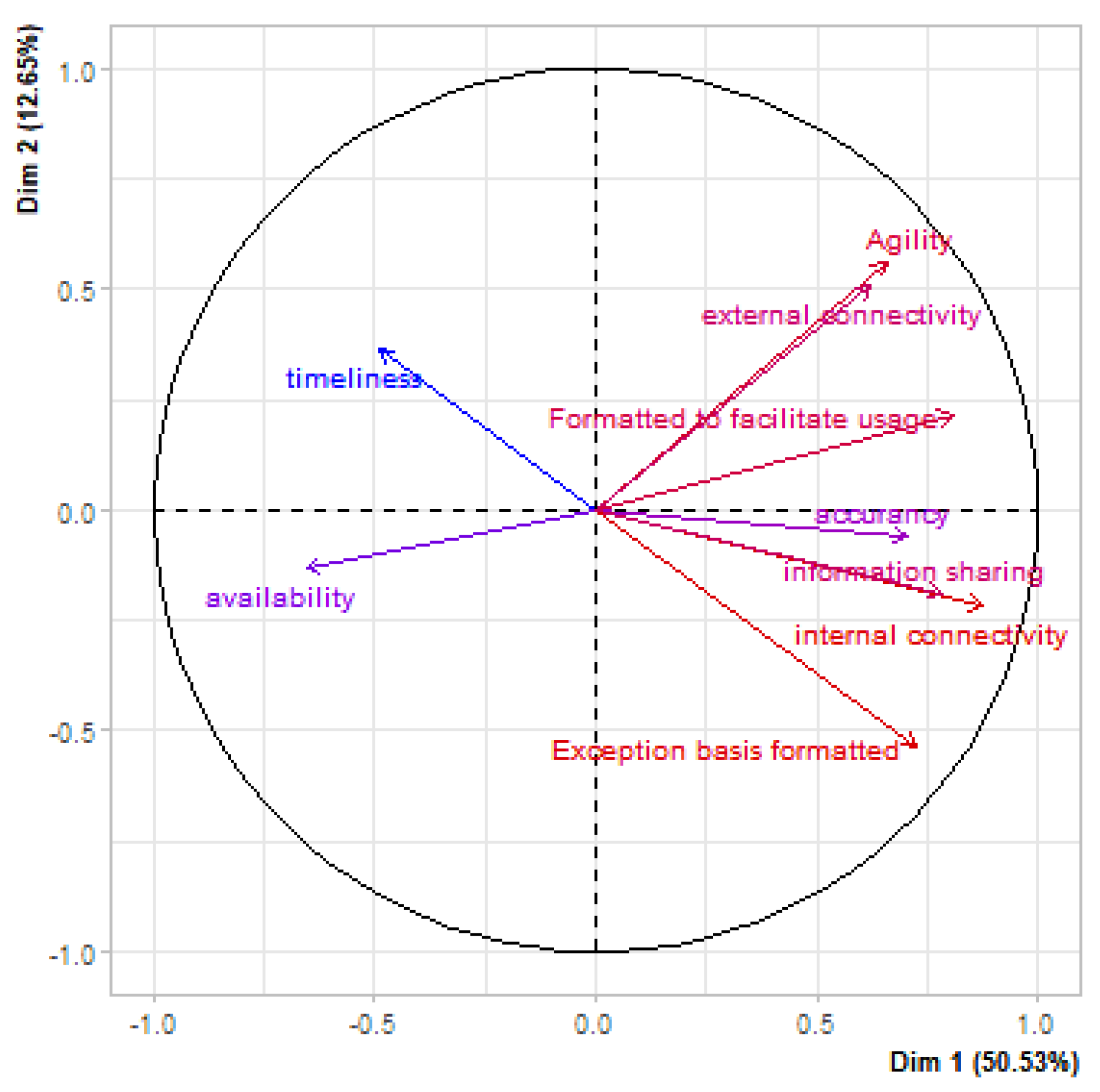

Figure 1 displays labeled variables crucial for constructing the plane, each color-coded by its category in SCM efficiency. These variables represent the highest influencers within the examined firms. The axes capture inertia equivalent to the 0.95-quintile of random distributions, explaining 63.18% of the total variance.

Dimension 1 opposes individuals such as 26, 24, 30, and 28 (to the right of the graph, characterized by a strongly positive coordinate on the axis) to individuals such as 6 and 21 (to the left of the graph, characterized by a strongly negative coordinate on the axis). The group in which individual 28 stands (characterized by a positive coordinate on the axis) shares low values for variables’ timeliness and availability (variables are sorted from the weakest). In addition, the group in which individuals 26, 24, and 30 stand (characterized by a positive coordinate on the axis) shares high values for the variables’ agility, internal connectivity, Exception basis formatted, formatted to facilitate usage, external connectivity, and information sharing (variables are sorted from the strongest). Moreover, it shares low values for variables’ availability and timeliness (variables are sorted from the weakest). The group where individuals 6 and 21 stand (characterized by a negative coordinate on the axis) shares low values for the variable internal connectivity.

These findings emphasize the critical importance of criteria like agility and connectivity in driving SCM efficiency. Agility enables organizations to swiftly adapt to changing market conditions, customer demands, and unforeseen disruptions, ensuring timely product delivery. Likewise, robust connectivity fosters synchronous communication and collaboration across the supply chain network, facilitating critical information exchange and aligning activities among stakeholders. However, identifying weaknesses in timeliness, availability, and internal connectivity highlights potential constraints that may hinder operational performance and responsiveness. Timeliness and availability issues can lead to delays in product delivery and stockouts, adversely affecting customer satisfaction and revenue generation. Meanwhile, deficiencies in internal connectivity may hinder the information flow and decision-making processes within firms, leading to inefficiencies and missed opportunities.

Addressing these weaknesses through targeted interventions, such as process optimization, technology integration, and workforce training, is crucial for enhancing supply chain resilience and responsiveness. By cultivating a more adaptive and interconnected supply chain ecosystem, organizations can better anticipate and respond to market fluctuations, customer preferences, and competitive pressures, ultimately driving sustainable growth and success in today’s dynamic business environment.

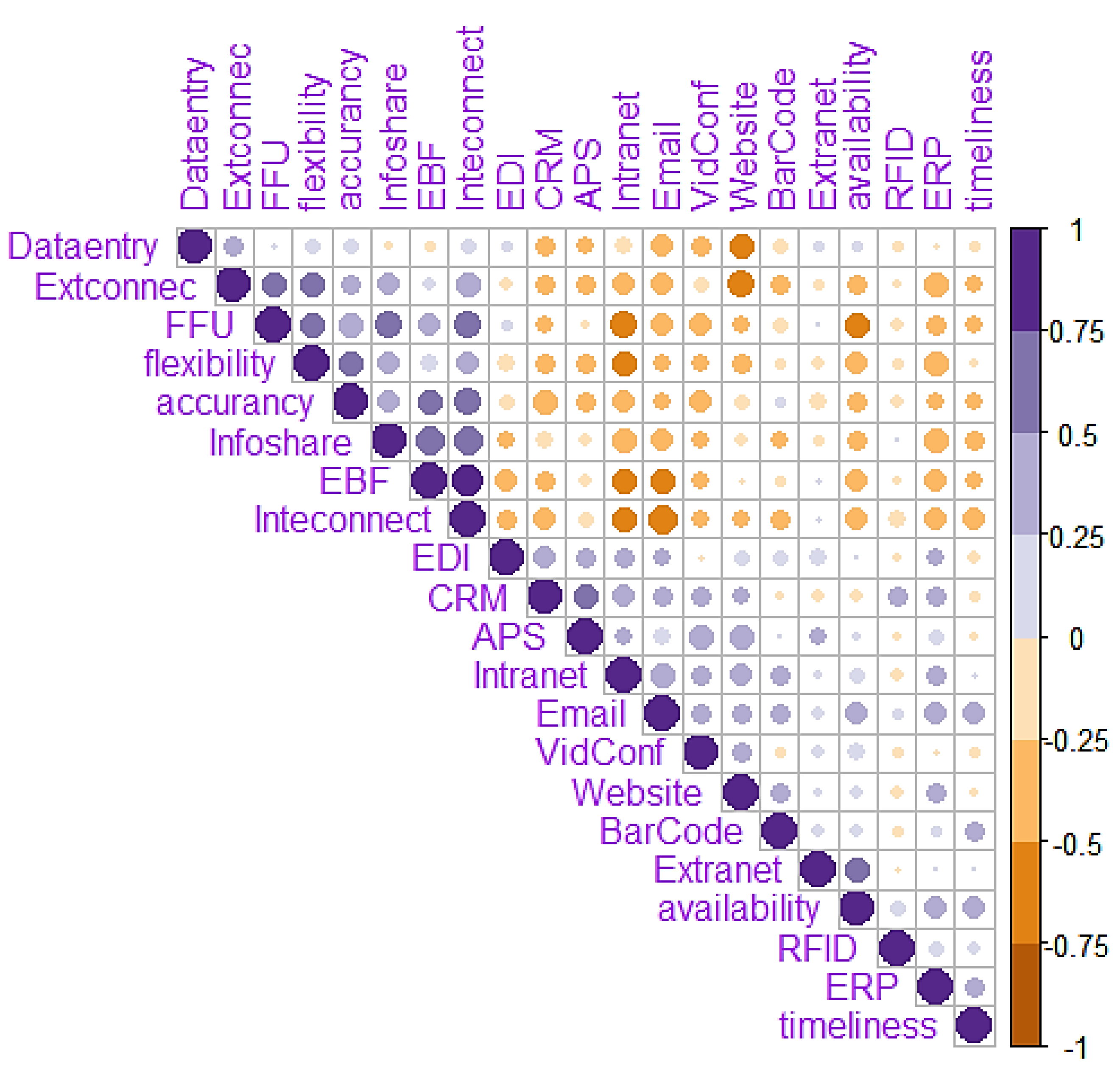

In this paper, we shed light on the contribution of digital transformation to improving SCM practices. We conducted an in-depth analysis by calculating the correlation matrix, elucidating the intricate relationships between these SCM practices and the digital technologies employed. This approach allows us to discern the extent to which specific practices align with and leverage the capabilities of various digital tools and platforms. By examining these correlations, we gain valuable insights into the synergies between operational strategies and technological advancements, thereby informing strategic decision-making processes to optimize supply chain performance and enhance organizational competitiveness.

The correlation matrix, illustrated in

Figure 2, depicts the relationships between different digital tools and evaluative criteria used to assess their effectiveness in supporting SCM practices. In the matrix, every outcome reflects the correlation coefficient between 2 variables. This coefficient lengths from -1 to 1, where 1 signifies a robust positive correlation, -1 implies a complete negative correlation, and 0 denotes no correlation between the variables. The digital tools included in the analysis are Intranet, Extranet, ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), APS (Advanced Planning and Scheduling), EDI (Electronic Data Interchange), Email, Video Conferencing, Barcode, RFID (Radio Frequency Identification), Website, and Data Entry. The evaluative criteria encompass various aspects such as accuracy, timeliness, exception basis formatted, formatted to facilitate usage, availability, information sharing, agility, and external and internal connectivity.

The following part will discuss the results of the correlation analysis and examine how the relationships between digital tools and evaluative criteria contribute to the improvement of SCM practices. This analysis aims to provide insights into the role of digital transformation in driving operational excellence and enhancing supply chain performance in today’s competitive landscape.

Starting with accuracy evaluative criteria, using digital tools such as ERP, CRM, APS, and EDI facilitates improved accuracy in information processes. This heightened accuracy fosters more reliable decision-making within SCM and optimizes critical aspects like inventory management, demand forecasting, and resource allocation, thus bolstering overall efficiency and effectiveness in SCM operations.

Moving on to timeliness, the correlation analysis underscores the pivotal role of timely access to real-time information supported by tools like Intranet, Extranet, ERP, and EDI. Timely information dissemination enables faster responses to market changes, reduced lead times, and enhanced customer relationships, all of which contribute meaningfully to improvement.

Exception Basis Formatted digital-based tools, such as ERP, CRM, and EDI, are crucial in promptly identifying and addressing critical tasks and exceptions, enhancing SCM resilience and agility. Additionally, ensuring prompt access to relevant information through tools like Intranet, Extranet, ERP, and EDI is essential for SCM practices such as supplier collaboration and logistics management.

Enhanced availability of information streamlines communication, reduces delays, and enhances coordination among supply chain partners, ultimately leading to improved SCM performance.

Furthermore, efficient information sharing facilitated by digital tools like Extranet, CRM, and APS fosters closer collaboration with suppliers, enables better demand planning, and supports innovation in SCM processes.

While negative correlations with Intranet and ERP indicate challenges in formatting data for practical usage, addressing these challenges through user-friendly interfaces and training programs can significantly enhance SCM practices.

Additionally, digital tools that enhance organizational flexibility and responsiveness, such as Extranet and ERP, support agile SCM practices and adaptive capacity planning, improving SCM agility and competitiveness. Lastly, strengthening external connectivity, mainly through tools like Extranet, enhances SCM practices such as supplier collaboration, customer relationship management, and logistics coordination, ultimately leading to enhanced SCM performance.

Understanding the correlations between various digital technologies and SCM practices empowers firms to navigate the complexities of modern business environments effectively. By recognizing how different technologies interact with supply chain processes, organizations can strategically align their technology adoption (Benkhider & Meziani, 2021), integration, and optimization efforts to enhance overall efficiency, agility, and competitiveness.

Furthermore, the insights derived from correlation analysis serve as valuable inputs for strategic planning and investment decisions. With a comprehensive understanding of how technologies impact supply chain performance, organizations can prioritize investments in digital transformation initiatives that offer the most significant potential for driving tangible business outcomes. Whether implementing RFID technology to improve inventory visibility or integrating ERP systems for streamlined operations, informed decision-making based on correlation analysis ensures that resources are allocated optimally to address key supply chain challenges and opportunities.

By leveraging the insights mobilized from correlation analysis, firms can maintain a competitive edge by staying ahead of industry trends and proactively adapting their supply chain strategies and capabilities to meet changing market demands and seize emerging opportunities. Ultimately, a data-driven approach to technology adoption and optimization enables firms to unlock the full potential of digital transformation initiatives, driving sustainable growth, resilience, and competitive advantage in the long run.Haut du formulaire

While correlation analysis provides valuable insights into the relationship between variables, its scope is limited in capturing the complexities of digital technologies and their interplay with SMP practices. By itself, correlation may overlook essential factors influencing the outcome, hence the importance of complementing it with a multiple regression analysis. Multiple regression allows us to explore how several independent variables interact to affect a dependent variable, providing a more exhaustive understanding of the underlying practices. By combining these two analytical approaches, we can better uncover nuanced patterns, identify significant predictors, and ultimately derive more robust and reliable insights for informed decision-making.

The multiple regression analysis was conducted with R studio software, where digital technologies represented the independent variables. Each independent variable was analyzed for its contribution to different aspects of SCM practices. The findings suggest that the influence of these technological tools varies across different dimensions of SCM efficiency.

Table 3.

Multiple Regression Analysis of Digital Tools and Evaluative Criteria in SCM.

Table 3.

Multiple Regression Analysis of Digital Tools and Evaluative Criteria in SCM.

| Intranet |

-0.76 |

0.14 |

-0.18 |

0.74 |

-0.14 |

0.86 |

0.41 |

0.38 |

-0.48 |

0.33 |

-0.10 |

0.04*

|

-0.86 |

0.09 |

-0.24 |

0.72 |

-0.84 |

0.09 |

| Extranet |

-1.05 |

0.22 |

0.31 |

0.73 |

-0.48 |

0.71 |

1.58 |

0.05* |

1.25 |

0.13 |

-0.02 |

0.98 |

-0.28 |

0.73 |

-0.60 |

0.60 |

1.35 |

0.09 |

| ERP |

-0.24 |

0.57 |

-1.14 |

0.03* |

1.19 |

0.09 |

0.78 |

0.06 |

-0.20 |

0.64 |

-0.40 |

0.32 |

-0.90 |

0.05*

|

-0.57 |

0.60 |

-0.42 |

0.32 |

| APS |

0.01 |

0.10 |

0.51 |

0.55 |

1.03 |

0.40 |

-0.05 |

0.94 |

-0.42 |

0.57 |

0.73 |

0.31 |

-0.26 |

0.73 |

-0.27 |

0.80 |

-0.20 |

0.78 |

| RFID |

-0.80 |

0.53 |

0.38 |

0.79 |

0.22 |

0.91 |

2.56 |

0.04*

|

-1.84 |

0.15 |

-0.98 |

0.40 |

-0.94 |

0.45 |

0.39 |

0.82 |

-1.12 |

0.35 |

| Data entry |

0.22 |

0.68 |

-0.50 |

0.40 |

-0.46 |

0.58 |

0.77 |

0.13 |

-0.36 |

0.49 |

-1.14 |

0.03* |

0.55 |

0.30 |

0.006 |

0.99 |

-0.59 |

0.24 |

| Email |

0.22 |

0.69 |

-0.11 |

0.86 |

1.12 |

0.20 |

0.68 |

0.18 |

-1.10 |

0.05* |

-0.38 |

0.45 |

0.67 |

0.22 |

-0.49 |

0.51 |

-0.72 |

0.17 |

| Video conference |

-0.40 |

0.49 |

-1.42 |

0.03* |

-0.19 |

0.83 |

0.83 |

0.12 |

-0.50 |

0.37 |

-0.90 |

0.09 |

-0.49 |

0.38 |

0.43 |

0.58 |

-0.94 |

0.09 |

| Bare Code |

0.51 |

0.31 |

-0.97 |

0.08 |

1.11 |

0.16 |

-0.04 |

0.94 |

-0.50 |

0.31 |

-0.37 |

0.42 |

0.06 |

0.91 |

-0.33 |

0.63 |

-0.12 |

0.79 |

| CRM |

-0.30 |

0.73 |

-0.14 |

0.88 |

-0.85 |

0.53 |

-1.42 |

0.08 |

0.41 |

0.62 |

-0.68 |

0.40 |

0.55 |

0.51 |

-0.86 |

0.47 |

0.67 |

0.41 |

| EDI |

-0.01 |

0.10 |

-0.29 |

0.68 |

-1.10 |

0.28 |

-0.30 |

0.60 |

-0.47 |

0.45 |

1.41 |

0.03* |

-0.32 |

0.61 |

0.87 |

0.33 |

-0.97 |

0.12 |

| Website |

0.07 |

0.89 |

0.55 |

0.34 |

-1.33 |

0.12 |

0.30 |

0.54 |

0.16 |

0.75 |

-0.42 |

0.39 |

0.21 |

0.69 |

-0.80 |

0.28 |

0.65 |

0.20 |

| |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

Est. |

Sig. |

| |

ACC |

INSH |

TIM |

AVB |

INC |

FFU |

AGL |

EXC |

EBF |

Using ERP as a first example enables us to understand this influence better. For instance, regarding Information Sharing (INSH), the coefficient for ERP is -0.22, indicating a significant negative association with this SCM practice, confirming its statistical significance. This result suggests that the extent of information sharing decreases as ERP implementation increases. One possible explanation is that ERP systems, by centralizing information management, streamline and consolidate data processes within a single platform, which might reduce the necessity of sharing information across different departments or external partners. The centralized nature of ERPs can lead to a more siloed approach to data treatment, where information is primarily managed within the system’s confines, potentially inhibiting broader dissemination. This outcome underscores the importance of carefully considering the implications of ERP deployment on organizational communication and collaboration. It suggests a need for complementary strategies to promote effective information sharing in environments where ERP systems are extensively used.

Additionally, for Formatted to Facilitate Usage (FFU), the coefficient for ERP is 0.21, indicating a positive association, with a p-value of less than 0.05, confirming its statistical significance. This result confirms that ERP systems significantly enhance the usability and appropriateness of logistics systems for their intended purposes. The positive impact of ERP systems on FFU can be accredited to their ability to integrate and streamline various SCM practices within a single, unified platform. ERP systems offer comprehensive functionalities that facilitate data management, real-time tracking, and resource planning, making SCM more efficient.

While ERP systems may negatively impact information sharing by creating more centralized and potentially siloed data management environments, they significantly enhance the usability and appropriateness of logistics systems, making SCM practices more efficient and effective. By centralizing information and processes, ERP systems reduce the complexity of logistics management, enabling users to access accurate and up-to-date information easily. This integration helps minimize errors, optimize inventory levels, and improve decision-making processes. Moreover, ERP systems often come with user-friendly interfaces and customizable modules, which can be tailored to meet the specific needs of the logistics operations, further enhancing their usability. Implementing ERP systems also promotes standardization and consistency across different logistical activities, ensuring the logistics systems are well-suited for their intended purposes. This standardization helps maintain high operational standards and better comply with regulatory requirements. ERP systems’ analytical and reporting capabilities also provide valuable insights that aid in continuous improvement and strategic planning within logistics operations.

Email also emerges as a notable digital tool with a pronounced impact on SCM practices. As an illustration, for timeliness, the coefficient for email is 0.19, indicating a positive association with this evaluative criterion, and the p-value is less than 0.01, confirming its statistical significance. This finding suggests that Email significantly enhances the timeliness of SCM operations. This positive influence can be credited to its ability to facilitate rapid communication and coordination. In SCM, timely communication is crucial for synchronizing various activities, such as order processing, shipment scheduling, and delivery coordination. Email delivers a rapid and efficient means of disseminating information, ensuring that all relevant parties are promptly informed and can act accordingly. This rapid exchange of information helps to minimize delays, streamline processes, and improve overall responsiveness in SCM operations. Furthermore, Email allows for the documentation and tracking of communications, which can aid in resolving issues swiftly and maintaining a smooth flow of operations.

These findings suggest that most firms rely on email as a principal digital tool for communication, complemented by selective investments in ERP modules that address specific operational needs. However, organizations should consider the balance between system integration and information sharing when deploying ERP systems to guarantee effective coordination and collaboration across the supply chain ecosystem. Investing in modules that enable seamless connectivity with external stakeholders is essential for fostering open communication channels and maximizing the benefits of digital technologies in SCM practices.

Additionally, RFID stands out as an essential digital tool that significantly influences SMC efficiency. The coefficient of 0.18 for RFID indicates a significant positive correlation with availability, with a p-value of less than 0.05, confirming its statistical significance. This result suggests that adopting RFID technology positively impacts the availability of logistical resources. RFID systems enable real-time tracking and inventory monitoring, allowing for more accurate and efficient goods management throughout the supply chain. By providing detailed visibility into the location and status of products, RFID enhances inventory accuracy, reduces stockouts, and minimizes the risk of overstocking. Consequently, firms can better meet customer demands, optimize inventory levels, and improve overall operational efficiency.

Moreover, the coefficient of 0.15 for RFID suggests a potential positive association with agility. While the data implies a trend toward RFID positively influencing agility in SCM, the evidence is insufficient to draw definitive conclusions. It is essential to consider various factors that may contribute to this output. The effectiveness of RFID implementation is contingent upon various contextual elements within the supply chain ecosystem. For example, the effectiveness of RFID implementation could depend on factors such as the reliability of RFID technology, the integration with other information systems, the supply chain network complexity, and the readiness of employees to adapt to new processes (Zopiatis, Constanti, & Theocharous, 2014). Moreover, external factors like regulatory requirements, market dynamics, and the behavior of supply chain partners can also shape the overall impact of RFID adoption on supply chain agility (Horlach, Drews, Schirmer, & Böhmann, 2017; A. Nafei, 2016).

We can also underline the significant role of the Extranet. The coefficient of 0.17 for the Extranet concerning external connectivity indicates a notable positive correlation. This suggests that using an Extranet significantly improves connectivity with external partners within the SC network. This enhancement in connectivity is likely facilitated by the Extranet’s ability to provide a secure and efficient platform for communication and data exchange between the organization and its external stakeholders, such as suppliers, distributors, and other relevant partners. By leveraging an Extranet, firms can establish dedicated digital channels that allow seamless interaction and collaboration with external parties, regardless of geographical distances or organizational boundaries. These digital platforms often offer robust security features, such as encrypted communication protocols and access controls, ensuring shared information’s confidentiality and integrity. Moreover, Extranets enable real-time data exchange, which fosters timely decision-making and enhances overall supply chain visibility and responsiveness.

These findings suggest that different technological factors have varying impacts on distinct dimensions of logistic performance, highlighting the nuanced role of technology in logistics. For instance, while enhancing the usability and fit-for-use of logistics systems, ERP systems tend to negatively impact information sharing, possibly due to their centralized nature, which can reduce the need for or ease of information exchange among departments. Email significantly enhances timeliness, likely by facilitating rapid communication and coordination, which is crucial for meeting tight deadlines. RFID technology improves the availability of logistical resources by enhancing inventory tracking and management. It also shows the potential to enhance flexibility, although this result is not statistically significant.

In contrast, reliance on manual data entry detracts from interconnectivity and increases the likelihood of errors before system failures, underscoring the inefficiencies of manual processes. Lastly, Extranet systems significantly boost external connectivity, thereby improving interactions and data exchange with external partners, which is vital for integrated supply chain operations. These insights underline the importance of strategically selecting and implementing technologies to target specific performance dimensions in logistics.

The study’s inclusive analysis, which includes principal component analysis PCA, correlation matrix examination, and multiple regression analysis, underscores the significance of adopting a holistic approach to digital transformation in SCM. These findings emphasize balancing internal process efficiency with external relationship management to attain SCM excellence.

PCA reveals the interrelationships among various technological factors and logistic performance dimensions, providing insights into the multifaceted nature of digital transformation in SCM. The correlation matrix identifies key associations between different technological factors and specific aspects of logistic performance, offering a nuanced understanding of their impacts. Multiple regression analysis further quantifies these relationships, allowing for the identification of significant predictors and their respective influences on logistic performance dimensions.

By synthesizing these findings, it becomes evident that successful digital transformation in SCM requires a holistic perspective that considers both internal and external dynamics. Internally, organizations must enhance process efficiency by adopting advanced technologies such as ERP systems. However, it is equally crucial to prioritize external relationship management by investing in tools and strategies that facilitate seamless communication and collaboration with external partners, suppliers, and customers.

A balanced approach ensures that digital transformation efforts optimize internal operations and strengthen the entire supply chain ecosystem. This alignment fosters greater transparency, agility, and responsiveness, enabling organizations to adapt effectively to dynamic market conditions and emerging customer demands. Organizations can attain SCM efficiency and ensure a competitive advantage in today’s interconnected business environment by giving equal weight to internal process efficiency and external relationship management.