1. Introduction

1.1. Electric Scroll Compressor

Since the early 2000s, growing concerns over global warming have necessitated the regulation of carbon dioxide emissions, leading South Korea to establish annual reduction targets after 2020 in accordance with the Paris Agreement, hence requiring a corresponding industrial response. In particular, the automotive industry has faced a relatively high reduction target of 17.4% by 2023, and is witnessing a trend of a decrease in the proportion of hydraulic components, while the development and application of electric components have emerged as a significant challenge.

In terms of automotive air conditioning systems, the electrification of refrigerant compressors for cooling systems is already underway, which implies the fact that as the prevalence of eco-friendly vehicles, including electric vehicles (EVs), increases, further technological development is essentially required. In general, the heating, ventilation, and air conditioning (HVAC) system in vehicle air conditioning is composed of several major components, respectively, Condenser, Compressor, Evaporator, Receiver, and Expansion device. While the HVAC system in conventional gasoline vehicles are powered by the engine, those in EVs operate on motor power driven by electric batteries, due to the absence of the engine as the power source of the vehicle. In regard to a Piston reciprocating compressor of gasoline vehicles are less likely to be favored due to their low compression efficiency, high torque, and significant noise and vibration. Therefore, the electric scroll compressors in EVs, which utilize two-scroll-shaped parts moving relative to each other to compress gas, are preferred within the global trend since their higher compression efficiency and lower power consumption.

1.2. Struture and Working Principle of Electric Scroll Compressor

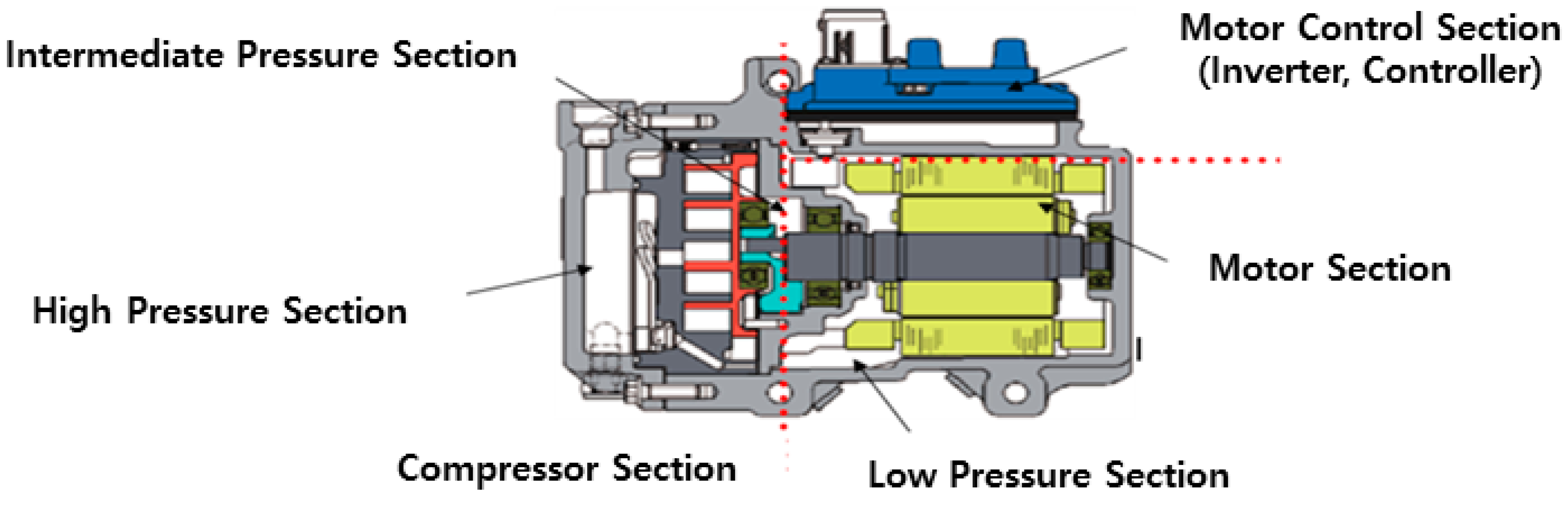

Electric Scroll compressors can be generally decomposed into three parts: The Compressor Section, the Motor Section, and the Motor Control Section.

Figure 1.

Structure of Electric Scroll Compressors.

Figure 1.

Structure of Electric Scroll Compressors.

The Compressor Section by interacting two scrolls (fixing, orbiting), compressing the refrigerant through progressively reducing the volume of a crescent-shaped suction space from the outer to the inner edges, thereby increasing pressure and discharging the refrigerant through a central outlet hole. Generally, such Electric Scroll Compressors divided by a Low Pressure Section where the refrigerant is drawn in, a High Pressure Section where the refrigerant is compressed and expelled, and an intermediate Pressure Section which is acting on the back of the orbiting scroll, pushing it tightly against the fixed scroll to ensure an efficient compression.

The Motor Section is composed of the stator (outer) and the rotor (inner). Typically, the rotor is attached to the rotating shaft and has multiple radially embedded permanent magnets, while the stator consists of multiple electromagnets, mainly coils wound around an iron core. These generate magnetic force by periodically getting supplied an alternating current (AC) from an external source. The interaction between such permanent magnets and electromagnets produces torque, which is eventually transmitted to the shaft.

The Motor Control Section, commonly known as an Inverter or controller, converts the direct current (DC) coming from the EV’s battery into AC. Such conversion enables the delivery of this AC to the motor’s Phase for controlling speed, thus it functions as a regulator that adjusts the amount of current in response to the load.

1.3. Features of Scroll Compressors

Scroll compressors perform minimal fluctuations in load torque and pressure pulsation, resulting in significantly reduced noise and vibration. Such high efficiency stands because compression, suction, and discharge occur simultaneously and continuously without the need of intaking or discharging valves, and the small pressure differential between adjacent compression chambers prevents leakage during compression. Moreover, the small operating radius of the moving parts is limited to millimeters, allowing for high-speed operation, and the number of components is about 1/4 that of reciprocating compressors, contributing to a compact and lightweight design.

As a result, the utilization of electric scroll compressors in EVs has been witnessed as a prominent industry trend, following this, it led to the development of proprietary electric scroll compressor models and the production of prototypes with undergone various internal evaluations. According to these assessments, the compressors’ performance and cooling capabilities have reached satisfactory levels compared to competitors' products, although the noise levels across all rotational speeds were found to be somewhat inferior.

In the shed of such findings, this study aims to analysis the causes of noise and vibration issues by conducting modal analysis and impact hammer modal measurements of the housing as well as noise and vibration measurements of the electric compressor, to examine the potential for resonance and the need for design modifications to reduce it.

2. Materials and Methods

2.1. Materials

The materials used is the aluminum alloy ADC12, and the main material properties are as follows. The density is 2770 kg/m^3, Young’s modulus is 71 GPa, and the Poisson’s ratio is 0.33. Modal analysis were applied using such material properties, which were applied modal analysis.

Table 1.

Material Properties of ADC12 Aluminum Alloy.

Table 1.

Material Properties of ADC12 Aluminum Alloy.

| Material |

Density

[kg/m^3] |

Young Modulus

[GPa] |

Poisson’s Ratio |

| ADC12 |

2770 |

71 |

0.33 |

2.2. Methods

2.2.1. Housing Modal Analysis

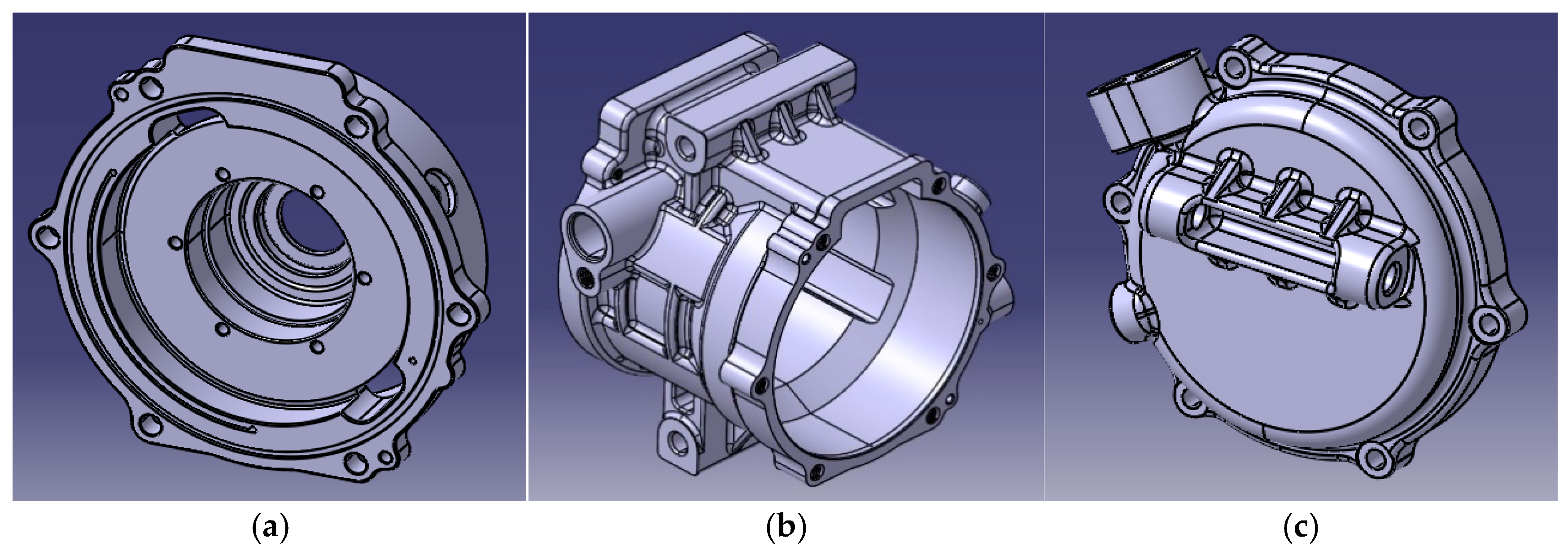

In order to process the modal analysis, 3D modelling of the Main Housing, Front Housing, and Rear Housing was carried out using the CATIA S/W.

Figure 2.

Modal Analysis of Housing. (a) Main Housing; (b) Front Housing; (c) Rear Housing.

Figure 2.

Modal Analysis of Housing. (a) Main Housing; (b) Front Housing; (c) Rear Housing.

The 3D modeled prototypes are implemented into the Ansys Workbench. And within this, the material property of the ADC12 aluminum alloy is applied, and the screw holes are set as the plate conditions and establishing boundary conditions. Then, the modal analysis is performed.

2.2.2. Housing Impact Hammer Modal Measurement

To establish the reliability of the Modal analysis for housings, modal measurements are conducted by using an impact hammer on each housing. The test of the Impact hammer implements an Accelerometer Sensor, Impact Hammer, and an FFT signal analyzer. The accelerometer sensor is attached to the housing, and when the housing is struck with the impact hammer, vibration data is collected through the sensor. The collected data was recorded into the FFT signal analyzer and processed by the dedicated S/W to create a result graph. On the result graph, the values showing significant spike correspond to the natural frequency.

To eliminate any effects from contact with surrounding objects in the process of the experiment, the housing is suspended in the air using a thread. Multiple measurements are taken to minimize potential minor errors and guarantee accurate readings. Furthermore, the sensor placement is varied with each measurement to verify the consistency of the test results.

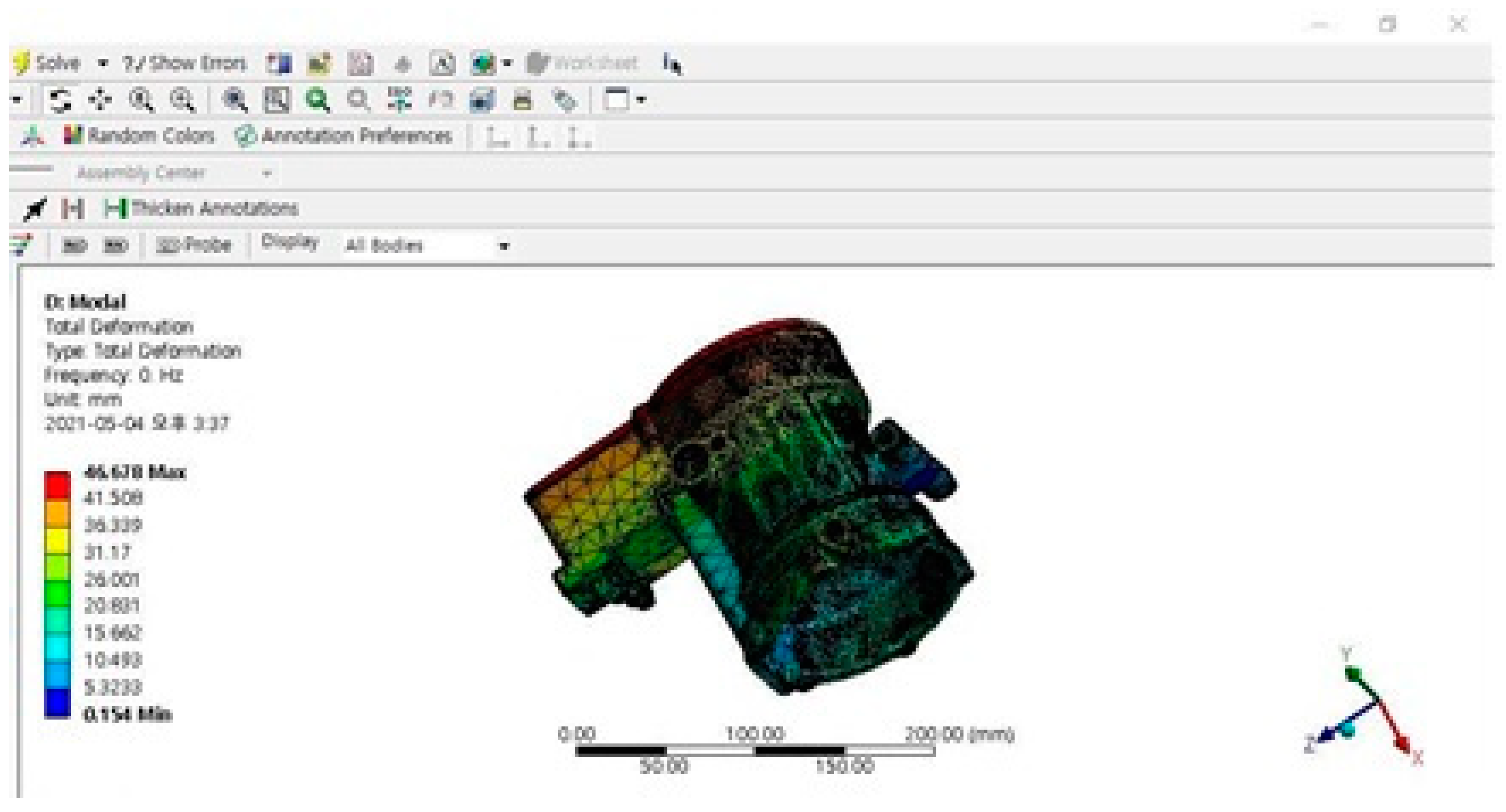

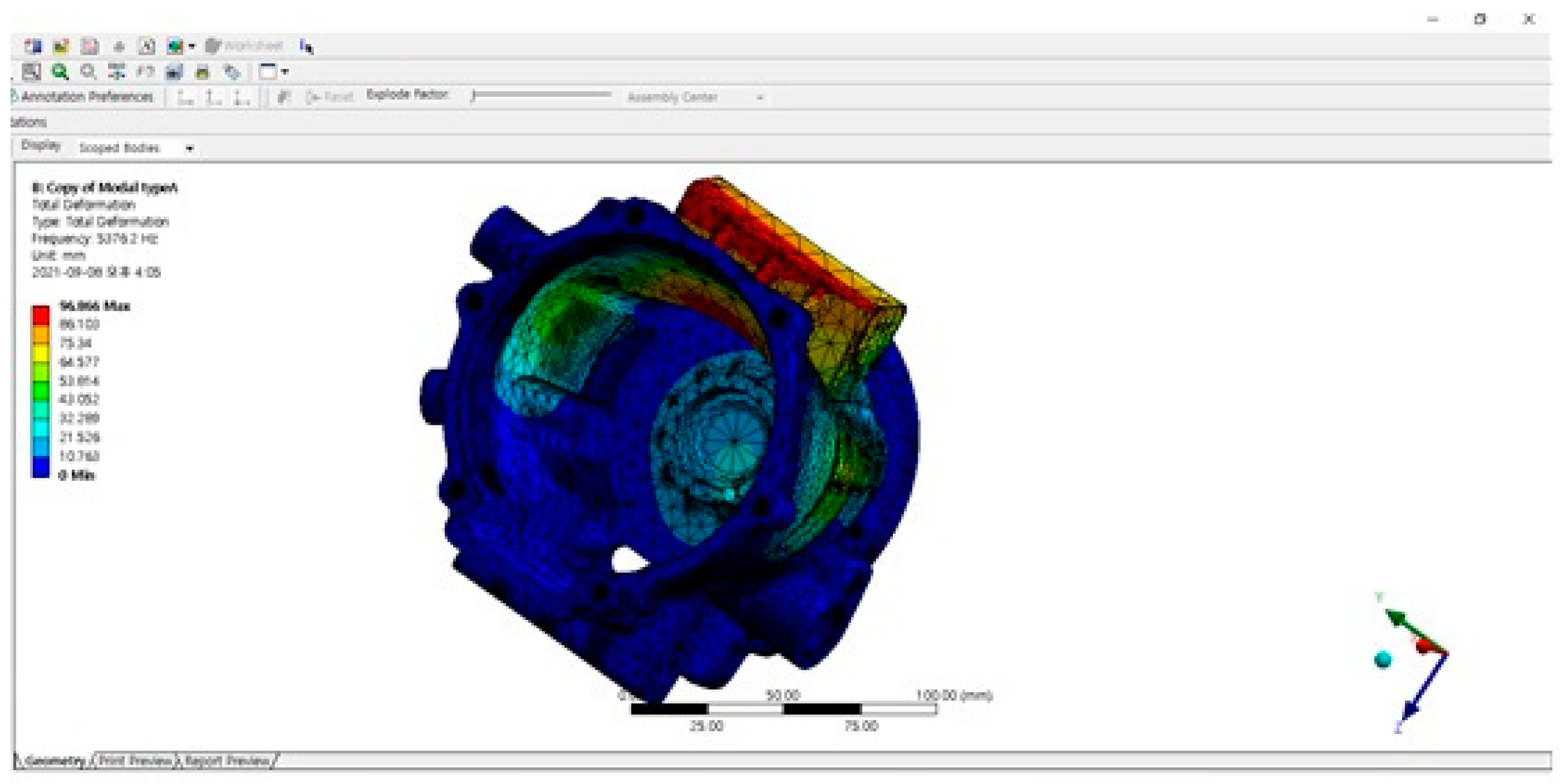

2.2.3. Modal Analysis of the Single and Assembly Status of the Electric Compressor

Modal analysis has conducted using the Modal tool of Ansys on both the single and the assembly status of the electric compressor.

Figure 3.

Modal analysis of the single status using the Ansys Workbench Modal tool.

Figure 3.

Modal analysis of the single status using the Ansys Workbench Modal tool.

Figure 4.

Modal analysis of the assembled status using the Modal tool in the Ansys Workbench.

Figure 4.

Modal analysis of the assembled status using the Modal tool in the Ansys Workbench.

2.2.4. Noise Measurement

Noise was measured at the x-axis, y-axis, z-axis, and z-axis relative to the origin point, using the electric compressor during operation as the reference point.

Figure 5.

Noise Measurement.

Figure 5.

Noise Measurement.

2.2.5. Critical speed analysis using ARMD S/W

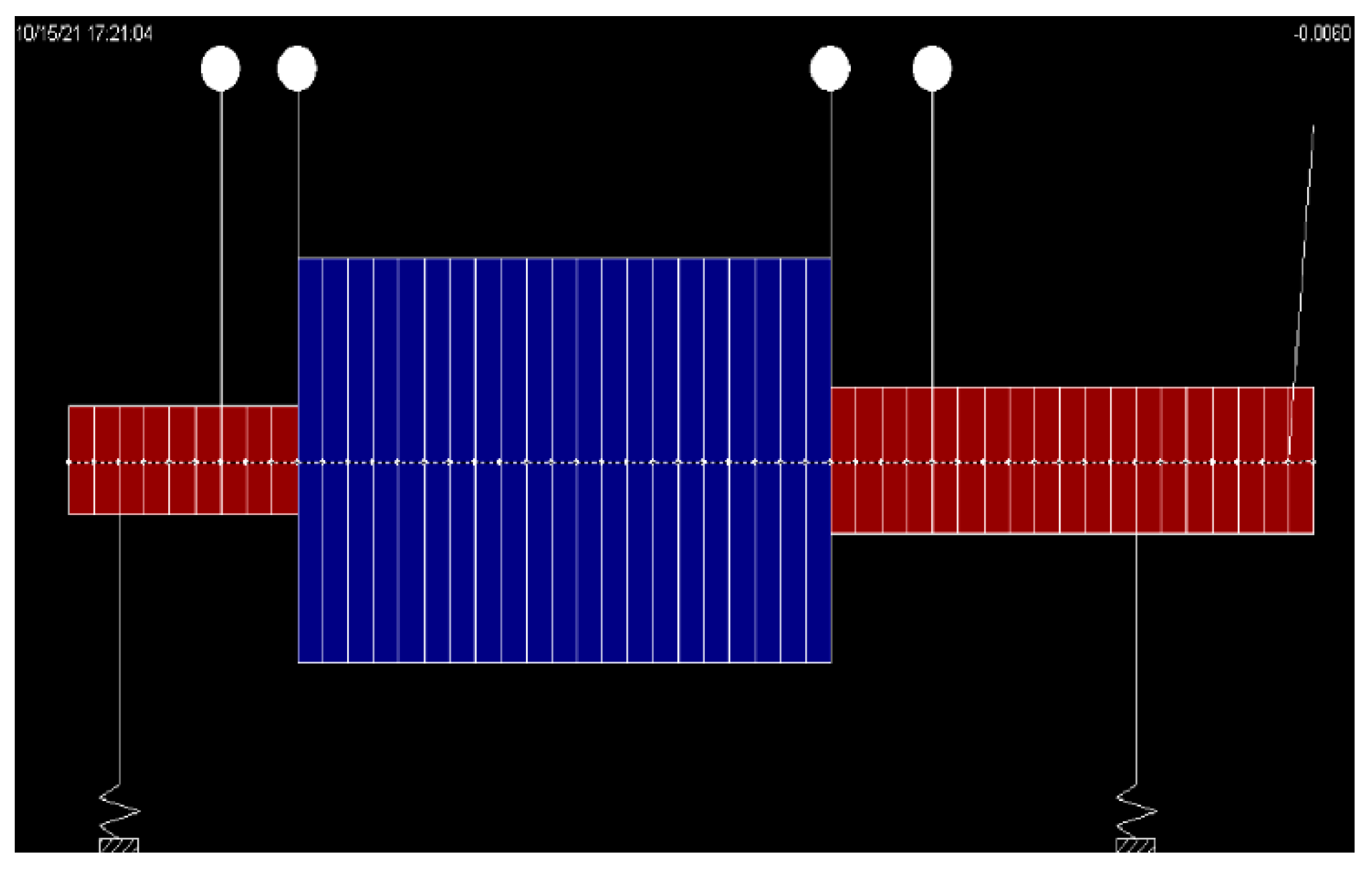

In order to identify the noise caused by vibration that possibly occurred during the rotational movement, the shaft and the critical speed were analyzed utilizing ARMD (Advanced Rotation Machinery) Dynamics. The analysis was performed with 49 elements, each having a length of 2mm, at 3,000rpm.

Figure 6.

Shaft modeled using ARMD S/W

Figure 6.

Shaft modeled using ARMD S/W

3. Results

3.1. Result of Housing Modal Analysis

The modal analysis of the Main Housing’s frequency for modes from 1 to 10 resulted as shown in the table below.

Table 2.

Main Housing ANSYS Modal Analysis Results.

Table 2.

Main Housing ANSYS Modal Analysis Results.

| Mode Number |

Frequency [Hz] |

| 1 |

0 |

| 2 |

0 |

| 3 |

3.9666E-3 |

| 4 |

350.64 |

| 5 |

516.74 |

| 6 |

2462.3 |

| 7 |

3498.6 |

| 8 |

5130.2 |

| 9 |

6986.3 |

| 10 |

7799 |

The modal analysis of the Front Housing’s frequency for modes from 1 to 20 resulted as shown in the table below.

Table 3.

Front Housing ANSYS Modal Analysis Results.

Table 3.

Front Housing ANSYS Modal Analysis Results.

| Mode Number |

Frequency [Hz] |

Mode Number |

Frequency [Hz] |

| 1 |

0 |

11 |

2727.5 |

| 2 |

1.47173E-3 |

12 |

3266.3 |

| 3 |

4.4004E-3 |

13 |

3331.5 |

| 4 |

230.92 |

14 |

3544.7 |

| 5 |

260 |

15 |

3692.6 |

| 6 |

705 |

16 |

4062.2 |

| 7 |

1275.1 |

17 |

4113.6 |

| 8 |

1654.6 |

18 |

4420.7 |

| 9 |

2010.1 |

19 |

4663.9 |

| 10 |

2188.6 |

20 |

4864 |

The modal analysis of the Rear Housing’s frequency for modes from 1 to 10 resulted as shown in the table below.

Table 4.

Rear Housing ANSYS Modal Analysis Results.

Table 4.

Rear Housing ANSYS Modal Analysis Results.

| Mode Number |

Frequency [Hz] |

| 1 |

0 |

| 2 |

2.4247E-3 |

| 3 |

7.063E-3 |

| 4 |

2568.3 |

| 5 |

3595.9 |

| 6 |

6708.6 |

| 7 |

7037.6 |

| 8 |

7670.8 |

| 9 |

8788.9 |

| 10 |

9026.2 |

3.2. The Result of the Modal Analysis

The impact hammer modal measurement result of the Main Housing, confirmed by conducting five measurements at each of the two sensor attachment positions, are such below.

Table 5.

Main Housing impact Hammer modal measurement results.

Table 5.

Main Housing impact Hammer modal measurement results.

Strike Position

Number |

Sensor Position

Number |

Ave1

Frequency

[Hz] |

Ave2

Frequency

[Hz] |

Ave3

Frequency

[Hz] |

Ave4

Frequency

[Hz] |

Ave5

Frequency

[Hz] |

Total Ave

Frequency

[Hz] |

| 1 |

1 |

3207 |

3431 |

3216 |

3217 |

3216 |

3257 |

| 2 |

3413 |

3416 |

3417 |

3417 |

3416 |

3415 |

| 2 |

1 |

3223 |

3220 |

3219 |

3217 |

3215 |

3218 |

| 2 |

3418 |

3420 |

3420 |

3420 |

3418 |

3419 |

The impact hammer modal measurement result of the Front Housing, confirmed by conducting four measurements at each of the two sensor attachment positions, are such below.

Table 6.

Front Housing impact Hammer modal measurement results.

Table 6.

Front Housing impact Hammer modal measurement results.

Strike Position

Number |

Sensor Position

Number |

Ave1

Frequency

[Hz] |

Ave2

Frequency

[Hz] |

Ave3

Frequency

[Hz] |

Ave4

Frequency

[Hz] |

Total Ave

Frequency

[Hz] |

| 1 |

1 |

1566

4181 |

1565

2040

4178 |

1564

2040

4177 |

1656

2040

4177 |

1656

2040

4178 |

| 2 |

- |

- |

- |

- |

- |

| 2 |

1 |

- |

- |

- |

- |

- |

| 2 |

1180 |

1180 |

1180 |

1180 |

1180 |

| 1548 |

1548 |

1548 |

1548 |

1548 |

| 2022 |

2022 |

2022 |

2022 |

2022 |

| 2862 |

2862 |

2862 |

2862 |

2862 |

The impact hammer modal measurement result of the Rear Housing, confirmed by conducting four measurements at each of the two sensor attachment positions, are such below.

Table 7.

Rear Housing impact Hammer modal measurement results.

Table 7.

Rear Housing impact Hammer modal measurement results.

Strike Position

Number |

Sensor Position

Number |

Ave1

Frequency

[Hz] |

Ave2

Frequency

[Hz] |

Ave3

Frequency

[Hz] |

Ave4

Frequency

[Hz] |

Total Ave

Frequency

[Hz] |

| 1 |

1 |

1878 |

1875 |

1875 |

1874 |

1875 |

| 2 |

- |

- |

- |

- |

- |

| 2 |

1 |

- |

- |

- |

- |

- |

| 2 |

1795 |

1794 |

1795 |

1795 |

1795 |

3.3. Result of the Modal Analysis for the Single and Assembled Status of the Electric Compressor

The results of the modal analysis performed in the single status are shown in the table below.

Table 8.

Modal analysis results for single status.

Table 8.

Modal analysis results for single status.

| Mode Number |

Case Number |

Frequency with Mode No.

[Hz] |

| Main Housing |

1 |

3498.6 (mode 7) |

| Front Housing |

1 |

1275 (mode 7)

1654 (mode 5)

2010 (mode 9)

2188 (mode 9)

2821 (mode 10) |

| 2 |

| Rear Housing |

1 |

1415 (mode 6)

2929 (mode 7) |

| 2 |

- |

3

(VDA + current base) |

2150 (mode 6)

6056 (mode 6)

3079 (mode 7)

4256 (mode 8)

6600 (mode 10) |

4

(VAD port angle change + 122 OD) |

2356 (mode 6)

4221 (mode 7)

6025 (mode 8) |

The results of the modal analysis performed in the assembled status are shown in the table below.

Table 9.

Modal analysis results in Assembled status.

Table 9.

Modal analysis results in Assembled status.

| Housing |

Mode |

Test 1 Frequency

[Hz] |

Test 2 Frequency

[Hz] |

| Main Housing |

1 |

7170 |

9385 |

| 2 |

8463 |

10544 |

| 3 |

8981 |

12204 |

| 4 |

9591 |

12302 |

| 5 |

9837 |

12844 |

| 6 |

11223 |

13312 |

| 7 |

11339 |

14047 |

| 8 |

11461 |

14378 |

| 9 |

11777 |

14645 |

| 10 |

12478 |

15357 |

| Front Housing |

1 |

5376.2 |

5529.5 |

| 2 |

5460.5 |

5614.9 |

| 3 |

6133.6 |

5882.2 |

| 4 |

6791 |

6665.9 |

| 5 |

7484.4 |

7072.2 |

| 6 |

7609.5 |

7498.1 |

| 7 |

8088.7 |

7620.3 |

| 8 |

8238.8 |

8147.2 |

| 9 |

8804.7 |

8896.2 |

| 10 |

9520.9 |

9103.9 |

| Rear Housing |

1 |

6096 |

6096 |

| 2 |

6281 |

6281 |

| 3 |

7411 |

7411 |

| 4 |

9491 |

9491 |

| 5 |

10012 |

10012 |

| 6 |

10873 |

10873 |

| 7 |

11274 |

11274 |

| 8 |

12215 |

12215 |

| 9 |

12786 |

12786 |

| 10 |

13520 |

13520 |

| Fixed Scroll |

1 |

8458 |

5777 |

| 2 |

11342 |

6283 |

| 3 |

11485 |

6763 |

| 4 |

13563 |

8301 |

| 5 |

13802 |

8671 |

| 6 |

15564 |

10404 |

| 7 |

15897 |

11599 |

| 8 |

16777 |

11778 |

| 9 |

16875 |

12591 |

| 10 |

17076 |

12918 |

3.4. Result of the Noise Measurement

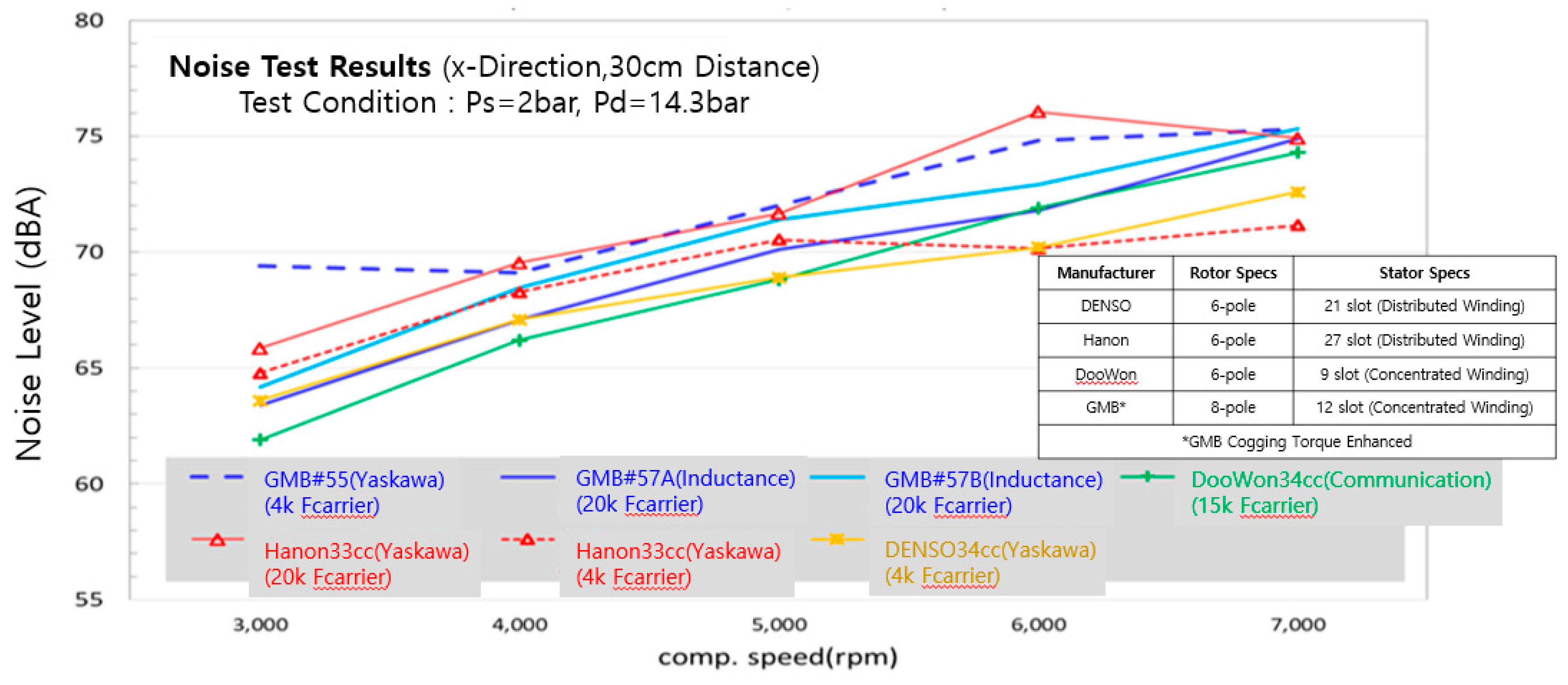

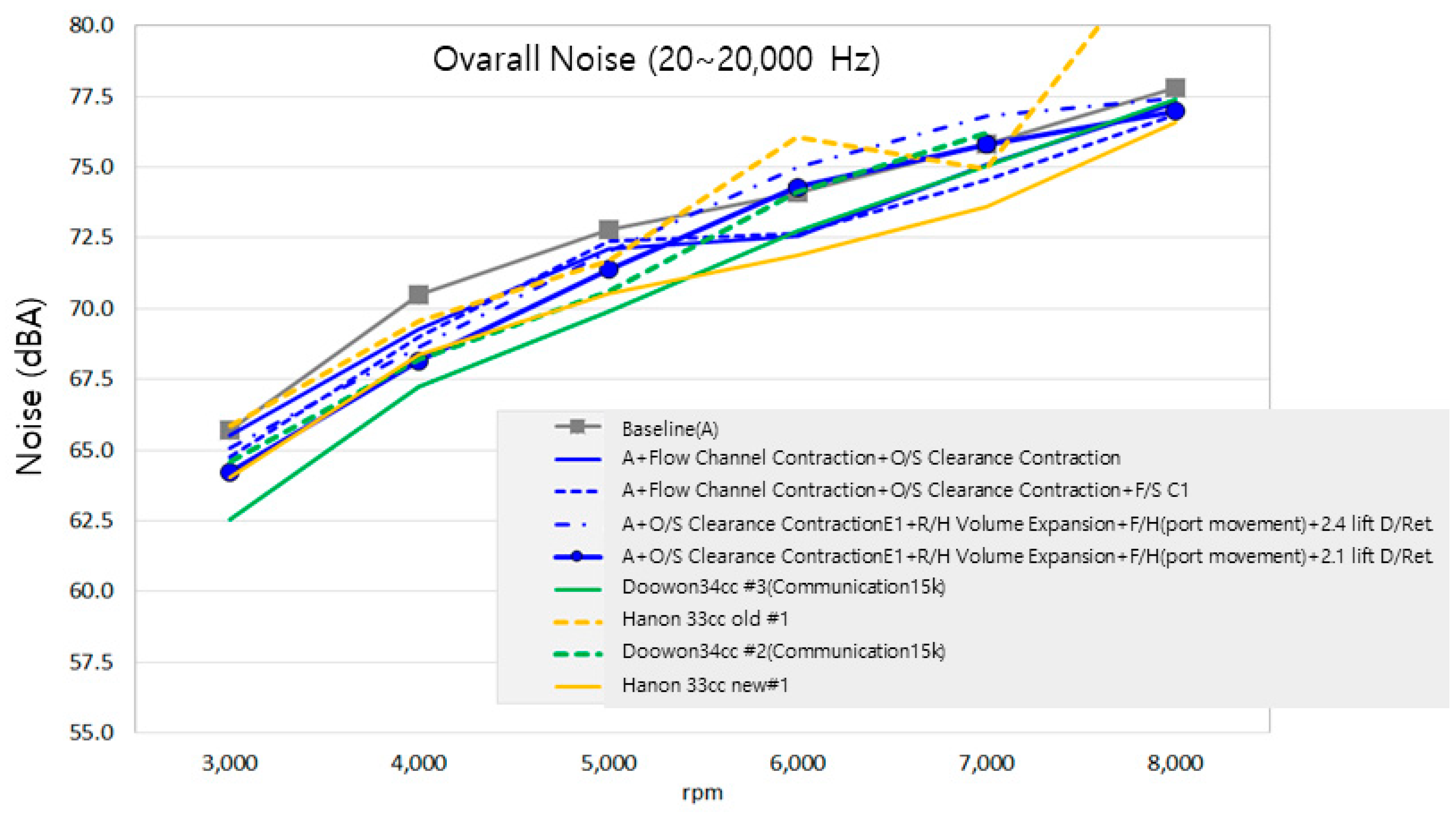

Figure 7.

Noise measurement Results for the Developed Product and Competitor Products.

Figure 7.

Noise measurement Results for the Developed Product and Competitor Products.

In terms of sound pressure (x-Direction), Doowon Co.,Ltd products signal-drive showed the lowest levels in the low-speed range (3k-4k), while GMB Korea Co.,Ltd products showed a significant noise reduction at lower speed range when the carrier frequency was changed (4k-20k). For Hanon Systems products, there was a prominent difference (1~6 dBA) between the general controller and the dedicated controller, with the distributed winding motor (For Hanon Systems, Denso) generally exhibiting lower noise levels at high speed (6k-7k). For GMB products, more efforts seem to be needed to reduce noise levels in the 3k-5k range.

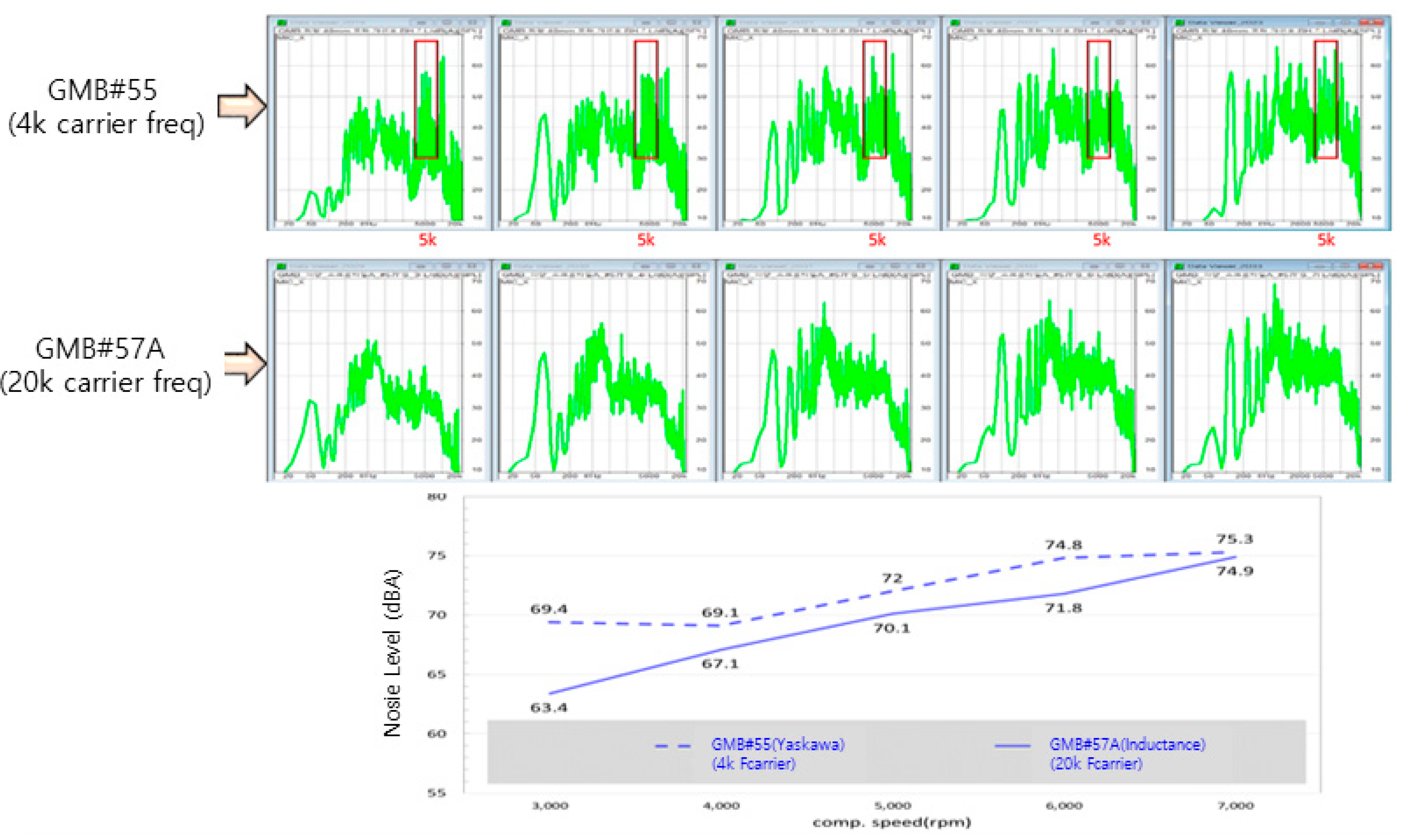

The influence of the carrier frequency of the inverter is explained below. As the carrier frequency of the inverter operates at a higher frequency, it is observed that higher frequency noise increases, and the sound pressure level increases accordingly.

Figure 8.

Effect of Carrier Frequency on High frequency Noise Level.

Figure 8.

Effect of Carrier Frequency on High frequency Noise Level.

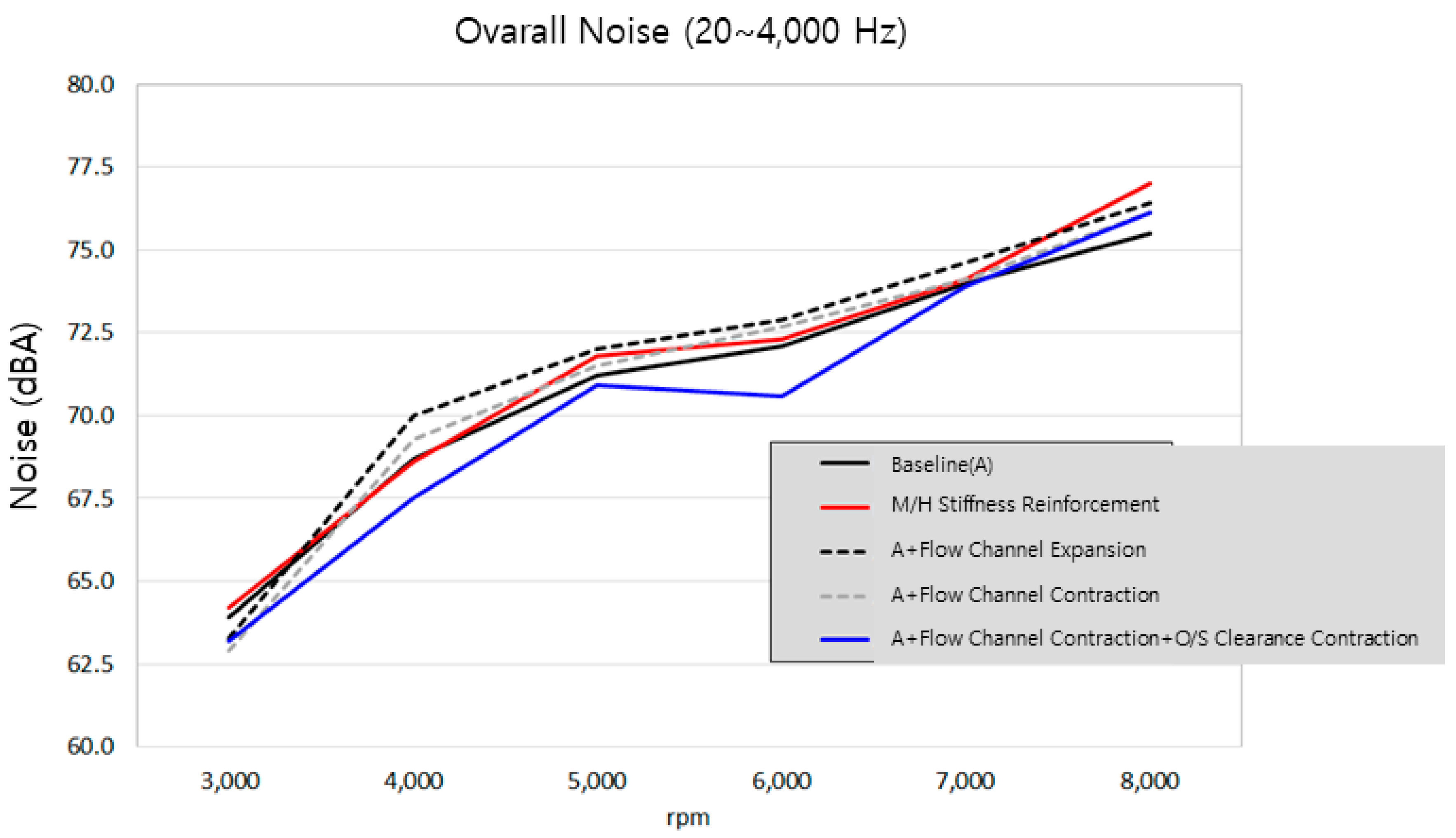

After analyzing the noise sources, it was figured that the noise was lowest in the ‘A+ Flow Contraction +O/S Clearance Contraction’, and the noise reduction has confirmed through

Figure 9 and

Figure 10.

After analyzing the noise sources, it was figured that the noise was lowest in the ‘A+ Flow Contraction +O/S Clearance Contraction’, and the noise reduction has confirmed through

Figure 9 and

Figure 10.

3.5. Result of Critical Speed Analysis Using ARMD S/W

The result of shaft’s critical speed analysis using ARMD S/W as such below.

Table 10.

Result of Shaft ARMD analysis.

Table 10.

Result of Shaft ARMD analysis.

| Mode Number |

Frequency [Hz] |

| 1 |

97.23 |

| 2 |

2889.2 |

| 3 |

15911.8 |

| 4 |

31950.3 |

| 5 |

61220 |

| 6 |

829212 |

4. Discussion

Analyzation of the impact hammer modal measurement results for the Main Housing represents slight variations in the readings depending on the sensor and impact locations. The measurements obtained from the impact hammer test at 3200Hz and 3410Hz closely match the mode7, 3498.6Hz value from the Ansys Modal analysis.

The analysis of the hammer modal measurement for the Front Housing shows that while the significant values varied depending on the sensor and impact locations, they commonly peaked near 1560Hz and 2030Hz. The impact hammer test results at these frequencies align closely with the Ansys Modal analysis's mode8, 1654.6Hz and mode9, 2010.1Hz, respectively, determining the reliability of the modal analysis results.

The Rear Housing’s impact hammer modal measurement results show slight differences due to changes in sensor and impact positions. However, there are no measurements from the impact hammer test that closely match any results from the Ansys Modal analysis, suggesting a need for reanalysis of the Ansys Modal data.

The noise measurement analysis suggests that noises above 10000 Hz are likely due to the motor inverter’s driving frequency. The noise within the 4000Hz to 5000Hz range is presumed to be generated from the discharge or suction paths, while the 600Hz to 800Hz range noise is likely due to resonance and harmonics with various components.

Observations indicate that the main shaft is not a major source of noise. This conclusion is supported by the significantly high frequency of vibrations caused by the main shaft at 3000 rpm compared to other test results.

5. Conclusion

Based on the minimal differences that have been shown in the analysis and measurement results of the Main Housing, Rear Housing, and Front Housing, the modal analysis is suggested as reliable. The modal analysis results for individual components and assemblies indicate that the natural frequencies of the components are not the direct cause of the noise. The identified main noise sources were in the 600~800Hz, 4,000-5,000 Hz, and 10,000 Hz frequency bands. Noise in the 10,000 Hz band could be reduced by altering the carrier frequency of the motor inverter. In the 4,000-5,000 Hz range, Significant improvements were demonstrated by adjusting the clearance at discharge, moreover, it was possible to reduce it to a limited extent by enlarging the internal space of the Rear Housing in the 600-800 Hz band’s noise, referencing comparative studies with competitors' products and relevant academic papers on refrigerator compressor scroll pumps.

References

- B. H. Ahn.; Y. S. Kim. A Study on Abnormal Noise Reduction of Scroll Compressor. 한국동력기계공학회지 제3권 제4호. 1999, 11, 28~35.

- Toyama, T.; Nishikawa, Y.; Yoshida, Y.; Hiodoshi, S.; and Shibamoto, Y., " Reduction Of Noise And Over-Compression Loss By Scroll Compressor With Modified Discharge Check Valve " (2002). International Compressor Engineering Conference. Paper 1587.

- Author Yanagisawa, M.; Uematsu, T.; Hiodoshi, S.; Saito, M.; and Era, S., " Noise Reduction Technology For Inverter Controlled Scroll Compressors " (2002). International Compressor Engineering Conference. Paper 1578.

- Rockwood, W. B., "Noise and Vibration Characterization and Statistical Energy Analysis of a Scroll Compressor" (1998). International Compressor Engineering Conference. Paper 1261.

- Jin. Kab. Lee. Identification of Noise Sources in Scroll Compressor for Air-Conditioner. KSME International Journal, Vol. 14, No. 6, 2000, 597~604.

- Motegi, Shuji and Nakashima, Shinji, "A Study on Noise Reduction in a Scroll Compressor" (1996). International Compressor Engineering Conference. Paper 1171.

- Chuang. Wang.; Zhen. Wang.; Weiguo. Yan.; Hongkun. Li.; Chunli. Yang. Study on Characteristics of the Vibration and Noise of High-Power Scroll Compressor. Hindawi Shock and Vibration Volume. 2021.

- Calhoun, John; Moore, James; and Forni, Ronald, "Stick-Slip Squeal in a Dry Scroll Vacuum Pump" (2016). International Compressor Engineering Conference. Paper 2470.

- Justin. Tharp. Moylan. Sound Reduction of Air Compressor Using a Systematic Approach. 2015.

- Miao. Qing.; Men. Yanru.; Wu. Jinxiang.; Gou. Xiang. Studies on Scroll Compressor Noise Improvement. Mechanics and Materials Vol. 694. 2014, 504~508.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).