Each study is analyzed in terms of its advantages and disadvantages. Advantages include increased forecasting accuracy and improved resource management due to the ability to identify complex patterns and dependencies in data. However, disadvantages include difficulty in interpreting results, high computational requirements, and the need for large amounts of data to train models.

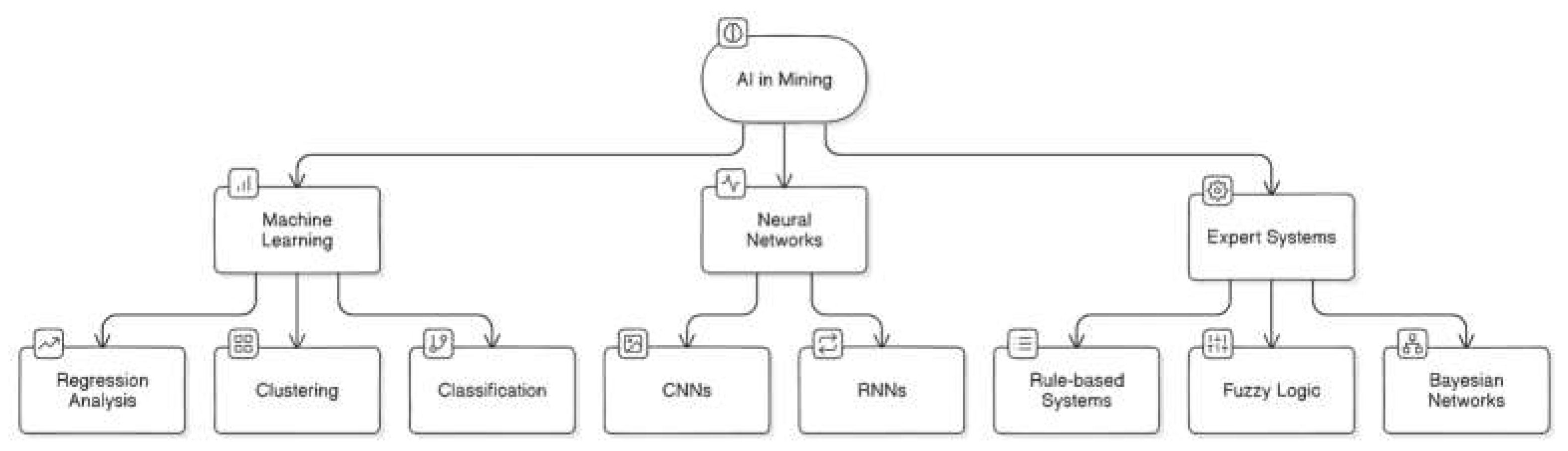

This review aims to provide a comprehensive overview of current advances in the application of Artificial Intelligence in the Mining Industry, highlight the potential and challenges of each of the reviewed techniques, and contribute to the further development of this important area of science and technology.

3.1. Classical Machine Learning Models

This paper uses Machine Learning to predict bolt failures in a mining environment. The advantages include the ability to analyze real data from underground mines. The authors applied different variations of the SVM model such as PCA-SVM and GTB-SVM to assess the failure risk of bolt supports in underground coal mines. The PCA-SVM model stands out and showed significant advantages over the other two approaches. By applying PCA-SVM, the authors were able to solve the problem of multicollinearity of features and select only the most important ones, as well as achieve an AUC Score of 0.85 on the training set and an AUC Score of 0.86 on the test set. The GTB model also reduced the number of features, but its AUC was 0.82 on the training set and 0.81 on the test set, indicating a significant loss of information after feature selection. The dataset used in the study includes both continuous data and discrete spatial data. In addition, the results showed that PCA, as a feature transformation method, allows for better extraction of complex data compared to the feature selection method. The authors also noted that their future work will be aimed at testing nonlinear feature transformation methods, such as autoencoders, as well as more complex datasets [

21].

The authors of [

22] considered premature failure of rock bolts in underground mines. It is becoming a major critical issue due to the complex mechanisms and multiple influencing factors, which makes laboratory predictions often unreliable. The study addresses this issue by using the categorical gradient boosting (Catboost) algorithm and SHapley Additive exPlanations (SHAP) to predict rock bolt failures with high accuracy and transparency. Using a dataset from an underground coal mine, the Catboost model demonstrated excellent prediction capabilities, with high AUC values and better performance than Random Forest. The SHAP analysis showed that "roadway length" is the main factor contributing to rock bolt failure, with increasing risks in roadways longer than 30 meters and in the presence of high-sulfur groundwater. Rock bolts younger than five years were found to be significantly less susceptible to failure. The study provides valuable insights into the complex relationships between rock bolt failures and various geotechnical and environmental variables, highlighting the importance of explainable Machine Learning to improve safety and reliability in underground mining. Thus, this study illuminates the complex relationships between rock bolt failures and the impact of geotechnical and environmental variables. The proposed approach has transparency and explainability, which can facilitate the implementation of explainable Machine Learning for rock bolt failure risk assessment in underground mines.

This review [

23] presents the current state of the art in applying Machine Learning to stress corrosion cracking risk assessment. There are many forms of corrosion, some of which carry minor risks while others can lead to catastrophic failures of engineering materials. Stress corrosion cracking (SCC) is one of the most severe forms of corrosion that is very difficult to detect. It occurs due to crack growth in a corrosive environment and the simultaneous application of tensile stress to metals or alloys. Identifying and predicting the occurrence of SCC is one of the pressing challenges faced by corrosion scientists and engineers. With the advancement of technology and the fourth industrial revolution, more data is available than ever before. Using this data to solve real-world problems has attracted a lot of attention in recent years. The availability of such data allows Artificial Intelligence (AI) and Machine Learning (ML) to be used as cutting-edge technologies to solve complex problems and gain insights that are not normally possible. Machine Learning is particularly useful in corrosion prediction applications, allowing the use of corrosion-influencing data such as environmental parameters (temperature and humidity), process conditions (flow conditions, pH, flow temperature and pressure), material characteristics (material type, material thickness, process device dimensions), existing corrosion protection measures, and visual conditions. All of these data can be modeled using Machine Learning algorithms to predict stress corrosion cracking occurrence and risk assessment. This paper attempts to review the available research on the application of Machine Learning to SCC. It also presents the current advances in Machine Learning and SCC, identifies existing knowledge gaps, and outlines future research directions in the field of corrosion risk assessment using Machine Learning.

This study [

24] aims to quickly and accurately predict gas explosions in coal mines using the real-time data collected by the intelligent mining system, including mine safety monitoring, personnel positioning and video surveillance. Initially, the coal mine accident prevention system is divided into subsystems considering accident contributing factors, surrounding conditions and vulnerable objects, which can establish an early warning index system for gas explosions. Then, a training data set is randomly selected from the known coal mine samples, which is analyzed and processed using Matlab software. Next, a learning model based on the random forest classification algorithm is built, which is optimized by the parameters Mtry and Ntree. As a result of comparing the built model with the support vector machine (SVM) classification model, specific coal mine cases are carried out to verify the applicability of the optimized gas explosion warning algorithm. The experimental results show that the optimized random forest model achieves 100% accuracy in predicting gas explosions in coal mines, while the accuracy of the SVM model is only 75%. The optimized model also shows lower model error and relative error, which proves its high performance in the early warning of coal mine gas explosions. The advantages of this approach include high prediction accuracy and reliability of the warning system, the ability to work in real time, and the use of multivariate data analysis to improve safety management in coal mines. However, the study has limitations, including the limited number of study samples and only focusing on the prevention of gas explosions, not covering other potential risks such as fires and geological disasters.

Mining activities cause negative changes in the environment, and such areas require continuous monitoring, which can be done using remote sensing data. The paper [

25] examines the impact of underground coal mining in the Bogdanka mine in southeastern Poland. Spectral indices, satellite radar interferometry, GIS tools and Machine Learning algorithms were used. A spatial model was developed that determines the statistical significance of the influence of various factors on the emergence of wetlands. The results show that changes in the NDVI index, terrain elevation, groundwater level and surface deformation significantly affect the emergence of wetlands. The Machine Learning model based on the Random Forest algorithm effectively identified potential flood zones with an accuracy of 76%. GWR (geographically weighted regression) analysis allowed us to identify local anomalies in the influence of the selected factors on the formation of wetlands, which helped to understand the reasons for their formation. The use of Random Forest and GWR allowed us to obtain accurate and detailed data on the influence of various factors on the formation of wetlands. The study takes into account various parameters (optical, radar, geological, hydrological and meteorological data), which allows us to obtain a comprehensive understanding of the problem. The use of available remote sensing data makes the methodology accessible and cost-effective for widespread use. The model can sometimes incorrectly classify flood zones, which requires additional data filtering efforts. The accuracy of Machine Learning models is highly dependent on the quality and volume of available data, which may limit their use in some regions. To improve the accuracy of the model, it is necessary to use more accurate geological and hydrological data, as well as expand the model with additional variables, which can complicate the analysis process.

Coal and gas emissions are one of the major causes of fatalities in underground coal mines and pose a threat to coal-fired power generation worldwide. Currently, methods such as monitoring methane levels using sensors, conducting geophysical surveys to identify geological structures and emission-prone zones, and empirical modeling to predict emissions are used to prevent them. However, with the development of industry 4.0 technologies, many studies have been conducted on the application of Artificial Intelligence methods to predict emissions. The proposed models and their results vary significantly in the literature. This study [

26] examines the application of Machine Learning (ML) to predict coal and gas emissions in underground mines using a mixed method. Most of the available literature focusing on the application of ML in predicting coal and gas emissions was reviewed in China. The results show that researchers proposed various ML models, mainly combining them with different optimization algorithms, including particle swarm analysis (PSO), genetic algorithm (GA), rough set theory (RS), and inverted fly optimization algorithm (IFOA) for emission forecasting. The number and type of input parameters for forecasting varied significantly, with initial gas velocity being the most significant parameter for gas emissions and coal seam depth being the most significant parameter for coal emissions. The training and testing datasets of the proposed ML models in the literature varied significantly, but were insufficient in most cases, which casts doubt on the reliability of some of the applied ML models. Future research should examine the impact of data size and input parameters on coal and gas emission forecasting. The advantages of applying Machine Learning methods to emission forecasting include the ability to handle large amounts of data and automatically improve models as new data becomes available, which improves the accuracy and reliability of forecasts. The disadvantages include the dependence on the quality and volume of input data, and the need for complex model tuning to obtain reliable results.

3.2. Deep Neural Networks

In [

27], an intelligent identification and positioning method for steel belt anchor hole in underground coal mine was proposed based on the improved YOLOv5s model. The main advantages of this approach include the improved detection accuracy of anchor holes by using super-resolution (SR) methods to enhance image clarity and implementing the coordinate attention (CA) module into the YOLOv5s backbone network. This can effectively extract the characteristics of small target objects and improve the detection success rate. In addition, the SR-CA-YOLOv5s model achieves high average detection accuracy (96.8%) and is capable of real-time operation while maintaining a high processing speed (166.7 fps), which meets the requirements for responsiveness. However, the disadvantages of the model include a decrease in the frame rate of 18.5 fps and the need for high-performance computing to train and operate the model in an underground mine environment.

This paper [

28] presents the results of a study on the application of artificial neural network (ANN) method to model the TBM advancement rate. The advancement rate of a tunnel boring machine (TBM) in rock conditions is a key parameter for the successful completion of a tunnel construction project. A database was created including the actual measured TBM advancement rates, uniaxial compressive strength of rock, distance between planes of weakness in rock mass, and rock quality index. The data were collected from three different TBM projects (Queens Water Tunnel, USA, Karaj-Tehran Water Supply Tunnel, Iran, and Gilgel Gibe II Hydroelectric Project, Ethiopia). A five-layer neural network with an architecture of three neurons in the input layer, 9, 7, and 3 neurons in the first, second, and third hidden layers respectively, and one neuron in the output layer was found to be optimal. The correlation coefficient determined for the advancement rate predicted by ANN was 0.94. The correlation coefficient of 0.94 indicates a high accuracy of TBM penetration rate predictions, which can significantly improve project planning and implementation. The model was trained on data from three different projects, which increases its applicability in different geological conditions. The study allowed us to determine the optimal structure of the neural network for this task, which improves its performance and reliability. As a drawback, we noted the dependence on data quality; the model requires high-quality and representative data for training, which can be difficult to provide. Tuning and optimizing the neural network parameters require significant computing resources and specialized knowledge. The model may be less effective when used on projects with geological conditions that are very different from those on which it was trained. Thus, the application of the artificial neural network method to TBM penetration rate modeling offers significant advantages in terms of accuracy and optimization, but requires taking into account the limitations associated with data quality and the complexity of model tuning.

In this paper [

29], the prediction of rock-induced stress during pillar extraction is investigated using Machine Learning methods such as Random Forest and Multilayer Perceptron. The models take into account factors such as working depth (H), panel width/length (W/L), pillar width/work height (w/h), goaf length, and extraction area. The paper highlights the importance of operational parameters over geological parameters. The correlation coefficient for rock-induced stress in the cases discussed in the paper is 0.85 for Random Forest and 0.76 for Multilayer Perceptron, which shows the advantage of Random Forest model. The developed models predict the stress conditions of pillars. Despite many advantages, Machine Learning also has its drawbacks. Machine Learning models require training on historical data to obtain accurate predictions, and the accuracy of the model depends on the amount and reliability of this data. However, Machine Learning is limited to be applied only to specific areas, and additional training of the model is required to work with new data. In this study, only four panels of continuous miners are analyzed, considering the limitations of data collection and the limitations of a single coal mine. In the future, more panels and different geomining conditions can be considered to improve the model. Therefore, stress prediction in underground coal mines remains one of the most important challenges for mining engineers, despite automation, advanced tools, and numerical modeling methods.

Effective prediction of ground vibration caused by blasting in opencast mining plays an important role in reducing environmental complaints. In this paper [

30], a novel hybrid evolutionary artificial neural network (ANN) optimized by genetic algorithm (GA) is proposed for peak particle velocity (PPV) prediction. The proposed GA-ANN model automatically selects the optimal ANN architecture including the number of neurons, activation functions, learning algorithm and the number of epochs. The data including maximum charge mass per delay, horizontal distance (HD), radial distance (RD) and a new modified radial distance (MRD) between the monitoring station and the blasting station were used to test the proposed approach in Sungun copper mine in Iran. The performance comparison of the GA-ANN model by statistical indicators shows its superiority over the empirical predictors and neuro-fuzzy inference system. An important result is that using MRD instead of traditional HD and RD distances improves the prediction accuracy. In summary, the results demonstrate the effectiveness of the proposed GA-ANN approach in finding the optimal ANN architecture for PPV forecasting. The advantages of using the new hybrid evolutionary artificial neural network (ANN) are: increased forecasting accuracy due to the use of MRD, optimization of the ANN architecture using GA provides higher model performance, and a systematic and automated approach to selecting ANN parameters. The disadvantages noted are: a large amount of data for training the model to achieve high accuracy, the model may be limited by the specificity of the application domain and not adapt to new conditions without additional training, a limited amount of data and tests may affect the generalization ability of the model and its applicability to other mining developments.

In [

31], an attempt was made to estimate and predict blast-induced ground vibration and frequency using rock parameters, blast modeling, and explosive parameters using an artificial neural network (ANN). A three-layer, feed-forward, back-propagation neural network having 15 hidden neurons, 10 input parameters, and two output parameters was trained using 154 experimental and monitoring blast records from a major surface coal mine in India. Twenty new blast datasets were used to validate and compare peak particle velocity (PPV) and frequency using ANN and other predictors. To improve the confidence in the proposed method, the same datasets were used to predict PPV using established vibration predictors as well as multivariate regression analysis (MVRA). The results were compared based on the correlation and mean absolute error (MAE) between the monitored and predicted PPV and frequency values. The ANN results showed a very close match with the field data, indicating high accuracy compared to traditional predictors and MVRA. ANN can learn new patterns not previously presented in the training dataset and update its knowledge over time when new training data is added. As a disadvantage, it is noted that the development and tuning of ANN requires significant computational resources and specialized knowledge to optimize the network architecture. Although ANN takes into account more parameters than traditional predictors, it may still not take into account all possible influencing factors, which may limit the accuracy of forecasts in some cases.

This study [

32] focuses on the application of Machine Learning techniques, namely Random Forest and Multilayer Perceptron, to predict mining induced stress conditions in Indian underground coal mines. The focus is on predicting the behavior of strata in mining zones where the cobblestone and pillar method is used. The study revealed that operational parameters such as working depth, panel width and length, pillar width and working height, corrugation length and mining area play a key role in the models built to predict mining induced stress. As opposed to geological factors, operational parameters were found to be more important for the accuracy of predictions. The developed models exhibited high correlation coefficient (R2) reaching 0.85 for Random Forest and 0.76 for Multilayer Perceptron, indicating their effectiveness in predicting pillar stress conditions under different operating conditions. These findings help managers to take proactive measures to minimize risks in the coal industry including developing emergency response plans. The study also found that Random Forest demonstrated higher accuracy compared to Multilayer Perceptron, although the latter showed a higher mean absolute error. In the context of underground coal mining, the application of such Machine Learning tools is innovative and can significantly improve the safety and efficiency of processes. Future research can be aimed at improving the models, as well as exploring other numerical methods such as finite element method and finite difference method, which will allow for more in-depth and accurate predictions of rock behavior under different operating conditions. Thus, although the use of AI and Machine Learning methods for structural health monitoring offers significant benefits, it is important to consider their limitations to develop effective and reliable damage detection systems.

This study [

33] focuses on the use of explosives as a source of energy for breaking rock mass. Most of the blast energy is lost as earthquakes, noise, air bursts, and other factors. Earthquakes caused by blasts depend on many parameters such as rock mass composition, explosive characteristics, and blast design.

Prediction of blast-induced earthquakes using regression analysis methods is sometimes too conservative, which creates difficulties for efficient and safe mine operation. The scaled distance approach remains a reliable method for predicting vibrations, but there are other alternative approaches that show similar results with high correlation coefficient values.

Modern analysis and prediction tools such as Artificial Neural Networks (ANN) have proven to be an excellent method for vibration prediction, as confirmed by many researchers in their work. Another method used in the study is an ensemble learning method such as Random Forest, which builds multiple decision trees and shows good results in both classification and regression.

In this paper, an attempt was made to predict the maximum particle velocities in explosions at different distances using the Random Forest, ANN and scaled regression analysis methods. For each method, correlation coefficients were obtained using different initiation systems, which revealed that ANN demonstrates the highest values of correlation coefficients, showing the most accurate results among the three considered methods. Random Forest also showed good results, although lower than ANN, but higher than the scaled regression approaches.

The authors made the following useful conclusions:

- Among the three methods used to predict blast-induced vibrations, artificial neural networks (ANN) predicted the most accurate values with the highest correlation coefficients. This makes ANN the preferred tool for predicting blast-induced vibrations in mining.

- The highest correlation coefficient values for all three methods were achieved using the electronic initiation system. This demonstrates the accuracy of such a system, which contributes to a more accurate prediction of vibrations caused by explosions.

- Based on the conducted study, it can be concluded that it is recommended to use electronic detonators with the predictive ANN model to accurately predict the vibrations caused by blasts in controlled blasting operations to calculate the maximum charge in controlled blasting operations, instead of the Random Forest and scaled regression analysis methods. This can greatly help mine operators when conducting controlled blasting operations near populated areas.

The paper [

34] explores the use of deep learning to identify surface coal mines using satellite imagery, treating it as a land use and land cover classification problem. Using convolutional neural networks (CNN) and pre-trained VGG, ResNet and DenseNet architectures, a dataset of 3500 “coal mine” images and 3000 “non-coal mine” images was prepared. The VGG model using transfer learning achieved the highest classification accuracy of 98% on the validation dataset. These results indicate high accuracy and the possibility of using the model to detect coal mines in different countries. The model showed 98% accuracy on the validation dataset and more than 95% on test images from other countries, which demonstrates its reliability. Using CNN can greatly simplify the process of monitoring and detecting coal mines compared to traditional methods. The model can be updated and improved with new data, allowing it to remain relevant and effective. I would like to note that the model is prone to false positives, which can lead to additional work to filter out incorrect data. The model may misclassify other types of mines, such as copper, which requires additional data preprocessing measures.

As the core of Artificial Intelligence, Machine Learning has significant advantages in multi-criteria intelligent evaluation and decision making. The level of sustainable development is of great importance for assessing the safety of coal mining enterprises. In this work [

35], the BP neural network method is used to make decisions on the level of sustainable development and assess the safety of coal mining enterprises. Based on the analysis of methods for assessing the sustainable development of coal enterprises, a system of evaluation indices is created and a multilayer forward neural network is built based on the backpropagation algorithm. Based on the human-machine-environment-control system theory and taking the four individual elements and the entire coal mine system as the research object, a system analysis and research is carried out to evaluate and continuously improve the internal safety of mines.

The advantages of BP neural network are that it avoids the subjectivity and complex mathematics of traditional estimation methods, and can produce stable and accurate results even in the presence of some missing data and parameter drift. It provides scientific and theoretical guidance for decision-making on sustainable development of coal mining enterprises and has some research value. The disadvantages of the method are the dependence on the quality of the initial data and the need to fine-tune the model to achieve high accuracy.

Future research will focus on two aspects: optimizing the processing process of the proposed algorithm to further improve its accuracy and efficiency, and using big data technologies to analyze text data recorded in the production process of coal mines to improve the ability of predictive control of industrial safety risks. coal mines.

The goal of coal producers is to provide a sufficient volume of coal of the required quality with minimal costs for its extraction. Therefore, predicting energy characteristics is one of the most important tasks aimed at optimal use of the energy value of coal. The goal of the authors' work [

36] is to identify, investigate, and evaluate the most influential Artificial Intelligence algorithms widely used in the mining community on a real-world coal quality prediction problem. The study was based on data obtained in laboratory conditions over a period of five years (2005-2010), including 33,256 coal samples from the Kreka Coal Mine company. It was aimed at building a prediction model based on the described data, which will be used to predict the quality class of unknown coal samples. As part of the work, four algorithms were identified: C4.5, kNN, Naive Bayes and multilayer perceptron (MLP).

The idea was to find the best model through the following steps: each of the algorithms is calibrated to determine suitable model partitioning techniques that maximize the performance of the algorithms, the importance of the input attributes is assessed, and finally the algorithms are compared on their performance. The final evaluation of the results identified MLP as the best forecasting method for this domain with an optimal structure for the input, hidden and output layers.

The predictive model for this domain achieved the optimal structure (14-24-7) for the input layer, hidden layer and output layer. The results show that this neural network can be an important tool for predicting coal quality. New knowledge can be a valuable aid in decision making and management of complex systems, ensuring product and production quality. For future work, it is planned to study the possibility of introducing the resulting predictive model into an online monitoring system of the actual values of the content of coal moving along the conveyor, which will provide information about the quality of coal in real time.

This study [

37] highlights the critical vulnerability of coal mines due to insufficient air flow, which poses significant risks to safety and human resources. Therefore, continuous monitoring of air flow in underground mines is essential to detect potential disasters.

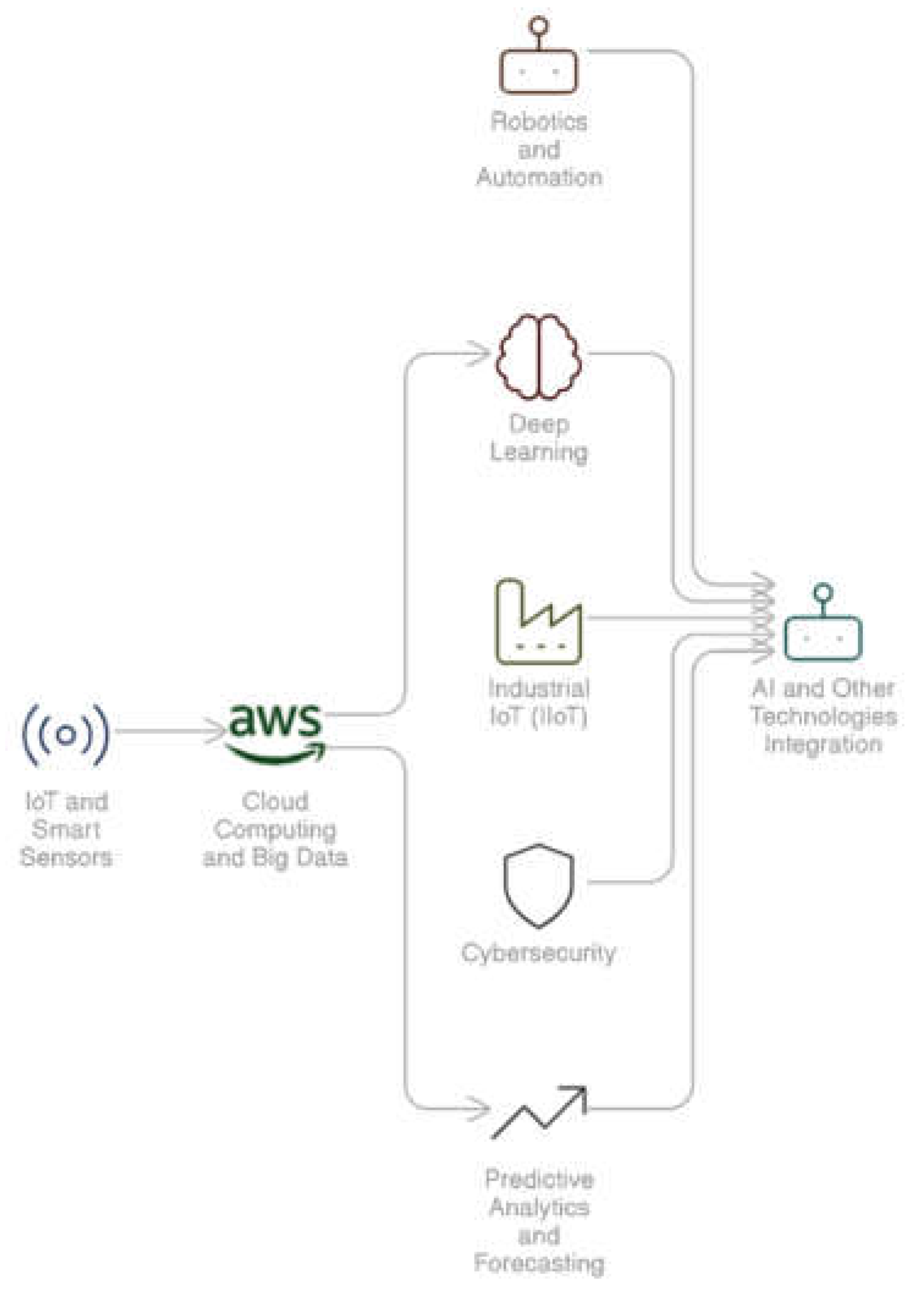

Various Artificial Intelligence methods are used to estimate nonlinear air flow parameters in mines, but often encounter problems such as local minima and low convergence speed.

This paper proposes a new algorithm that integrates adaptive neuro-fuzzy interface system (ANFIS) with genetic algorithm (GA) to predict energy consumption and air flow in underground mine ventilation systems. GA is used to automate the discovery and configuration of network architectures, reducing the need to manually configure optimal network design. As a comparison, two predictive benchmark models, particle swarm optimization (PSO) and Bayesian optimization (BO), are introduced to demonstrate the effectiveness of GA in identifying the best hyperparameters for ANFIS and ANN models.

Experimental analysis validates the proposed model against several baseline approaches using statistical parameters such as root mean square error (RMSE), mean absolute error (MAE), and coefficient of determination (R square). The results show that the proposed model outperforms the baseline models on these performance metrics.

Thus, this work advances ventilation and monitoring technologies in mines with the goal of improving operational reliability, improving safety and health conditions, reducing energy and operating costs, and increasing overall mine productivity.

This study also demonstrates a unique hybrid neuro-genetic system (ANFIS-GA) for optimizing model structures, which not only reduces computation time and cost, but also leverages the potential of GA to create more efficient model architectures.

3.3. Recurrent Neural Networks

The authors of [

38] proposed a deep learning model based on Unified Manifold Approximation and Projection (UMAP) and Long Short-Term Memory (LSTM) methods to predict fire status in sealed zones of underground coal mines. This model protects the lives of miners by providing early warning of impending dangers. The proposed forecasting model graphically displays the fire status in the form of an Ellicott expansion plot. The performance of the proposed forecasting model is experimentally measured in comparison with existing Machine Learning models such as support vector machine (SVR) and autoregressive integrated moving average (ARIMA). It was found that the UMAP-LSTM model has the lowest root mean square error in forecasting the concentrations of gases O2, CO, CH4, CO2, H2, N2 and C2H4: 0.288, 0.006, 0.0995, 0.902, 0.238, 0.452 and 0.006, respectively, which indicates a higher efficiency of the proposed forecasting models. Fires in mines often lead to gas and coal dust explosions, which pose a danger to the lives of miners and complicate rescue efforts. Therefore, it is necessary to monitor the state of the gas mixture in sealed areas and study trends in the explosiveness of the gas mixture over time. Knowledge of future gas concentrations allows immediate action to be taken to eliminate the hazard.

This study [

39] presents a deep neural network for predicting gas concentrations in sealed areas of underground coal mines using various IoT sensors installed in a metal gas chamber. Air is automatically drawn at preset intervals from the sealed area using a solenoid valve, suction pump and programmable microprocessor. Gas sensors monitor gas levels in a coal mine and transmit gas concentration information to a server room on the surface via a wireless network and cloud data storage. In this study, a forecasting model t-SNE_VAE_bi-LSTM is proposed, combining t-SNE, VAE and bi-LSTM networks. The t-SNE model method aims to minimize the dimensionality of recorded gas concentrations, the VAE layer reconstructs the internal characteristics of low-dimensional gas concentrations, and the Bi-LSTM layer predicts the gas concentrations of CH4, CO2, CO, O2 and H2. The advantages of the proposed t-SNE_VAE_bi-LSTM model for predicting gas concentrations in sealed areas of coal mines include high prediction accuracy, as evidenced by low mean square error (MSE) values compared to alternative ARIMA and CHAOS models. The model is able to effectively account for the complex relationships between the concentrations of various gases and time, which makes it more adaptive to changes in the mine environment. In addition, the use of t-SNE and VAE technologies can reduce data dimensionality and extract important features, which improves the overall performance of the model. However, the model also has disadvantages. In particular, the complexity of setting up and interpreting the results can be high due to the use of several complex algorithms (t-SNE, VAE, bi-LSTM) that require deep understanding and experience in Machine Learning and geology. In addition, the model requires significant computational resources and training time due to its deep architecture and the need to process large amounts of data.

Early diagnosis of cracks makes it possible to take timely measures to eliminate them and ensure the safety of personnel and equipment in open coal mines. Monitoring cracks in such sections is important for the safety of workers and the security of national resources. Digital twins (DTs) play a key role in crack detection in open-pit coal mines, providing continuous, real-time monitoring of mine and environmental conditions. Various sensors and Internet of Things (IoT) devices collect ground motion and stress data. Integrating this data into DT allows the identification and analysis of anomalies that may indicate crack formation or propagation. This work [

40] proposes a deep neural network with dense connectivity and low weight embedded in DT for crack detection and predictive maintenance decision making by integrating historical data, real-time sensor data and predictive models.

The proposed DT system can predict the formation of cracks, which allows proactive measures to eliminate them. Comparing the performance of our network with other models showed that it outperforms all state-of-the-art deep neural networks in terms of accuracy, recall, overall accuracy, average accuracy, F1-measure, and kappa coefficient. Our network also performed better in terms of average accuracy and outperformed models such as U-Net and recurrent neural networks in terms of training and prediction time.

The benefits of the proposed system include a comprehensive approach to crack detection through the integration of real-time monitoring, predictive analytics, modeling, visualization and decision support. This allows mine operators to improve safety, optimize maintenance efforts and minimize risks associated with cracking and structural instability. Disadvantages of the system may include difficulty in setting up and the need for a large amount of data to ensure high accuracy and reliability of forecasts.