Submitted:

16 June 2024

Posted:

17 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

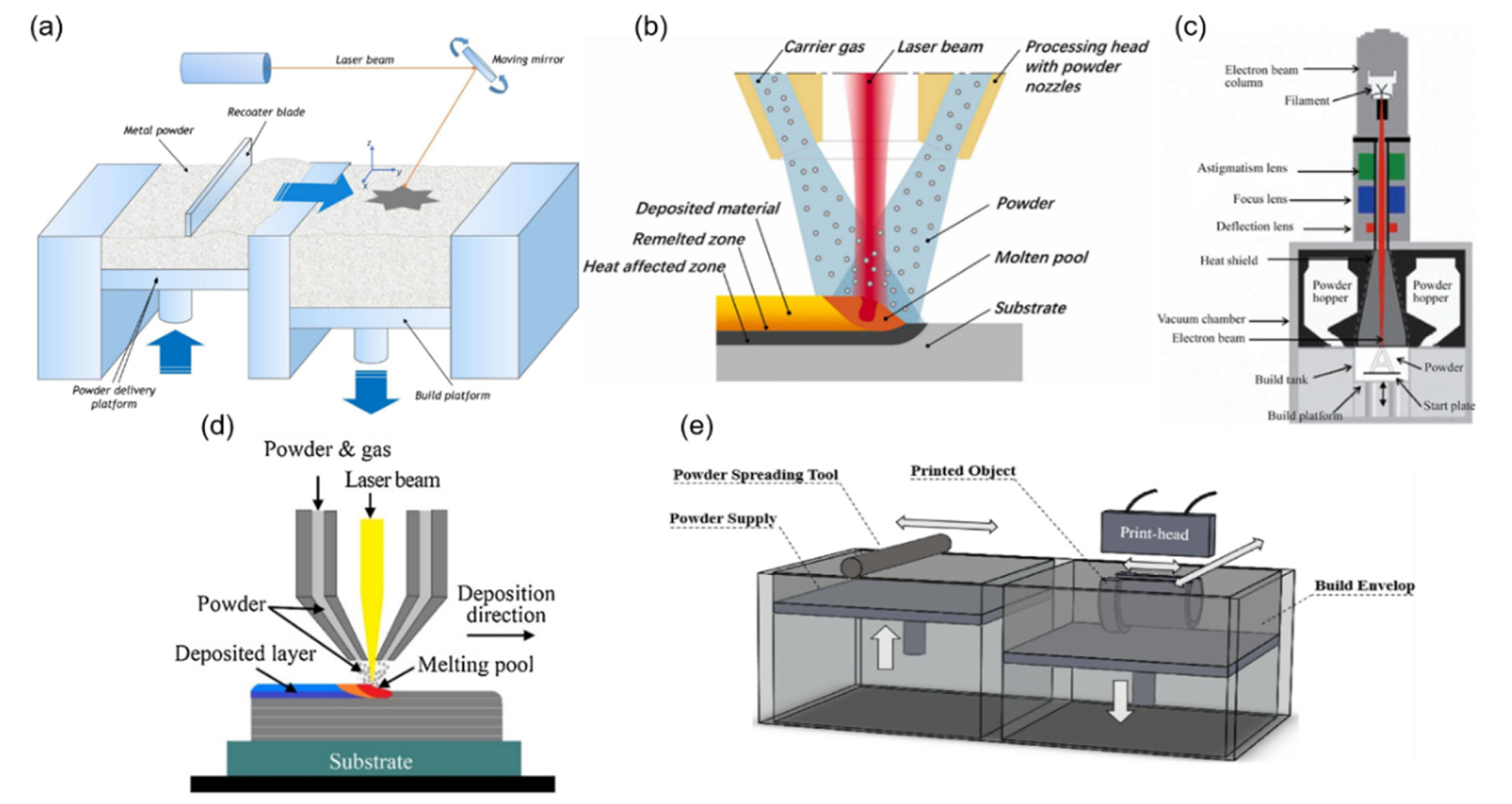

2. Techniques for Additive Manufacturing of Tungsten and Tungsten Alloys

3. Additively Manufactured Unalloyed Tungsten: Challenges, Determining Factors and Mitigating Strategies

3.1. Problems and Resolutions in Brief

| Challenges | Possible Strategy/Developments to Tackle the Challenge | Reference |

| The inherent brittleness and low ductility of W stem from 1) the high Peierls stress of its BCC crystal structure and, 2) weak grain boundary cohesion | Requires appropriate alloying to increase stacking fault energy for easier slip, and microstructural optimization. | [79] |

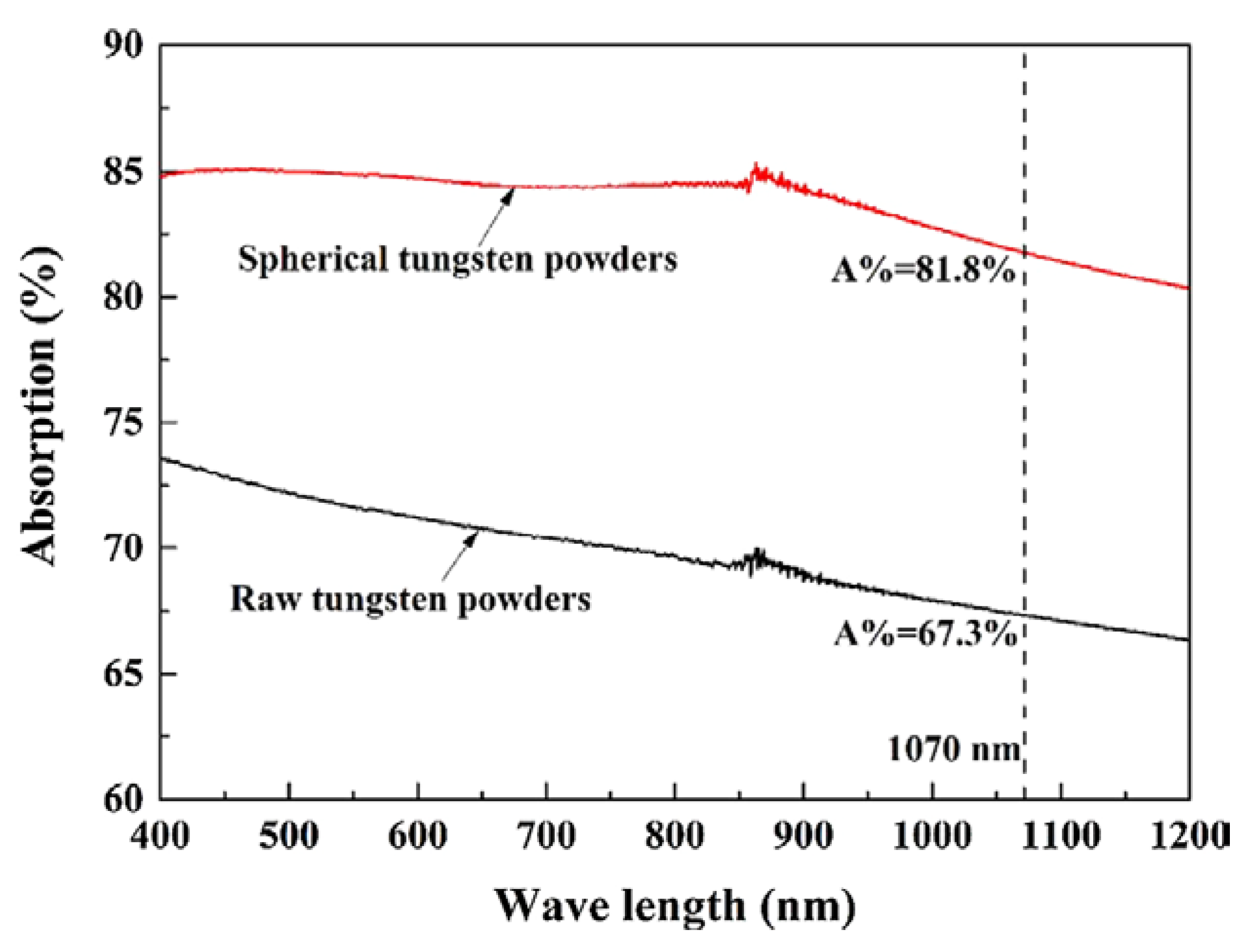

| High melting point, significant laser absorptivity (< 70% for SLM), pronounced viscosity, densification, porosities, balling, and deformation | Use of smaller, spherically shaped W powders to enhance laser absorptivity; Adjusting processing parameters to influence outcomes like defects, densification, and grain structures. Optimizing parameters like power and volumetric energy density have been found pivotal for improved W densification. |

[49,57,59,60,62,72,91,118] |

| Oxygen affinity and tungsten oxide segregation lead to hot cracking | Better quality starting material (powder, wire) production, optimized processing atmosphere, alloying. | [68] |

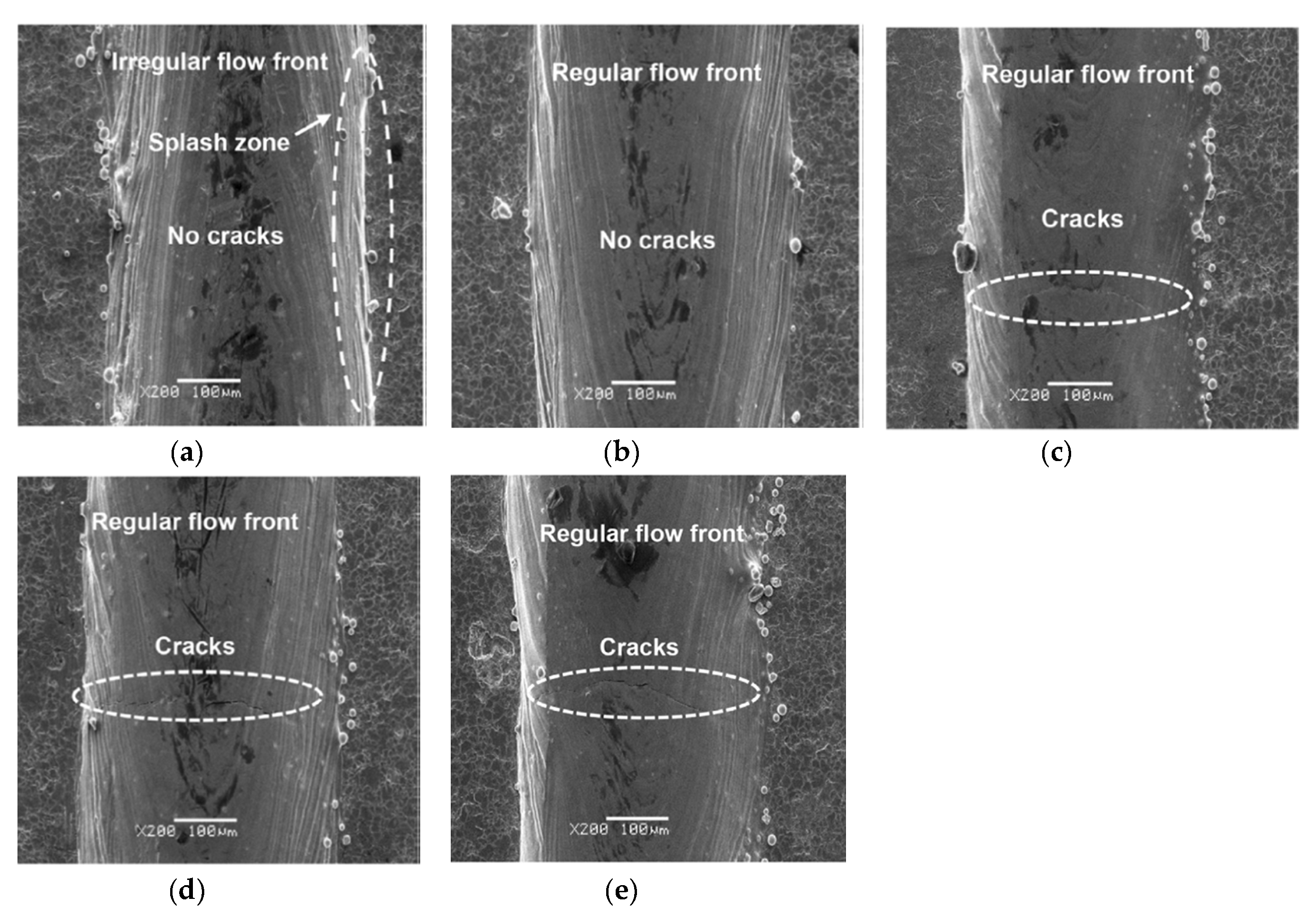

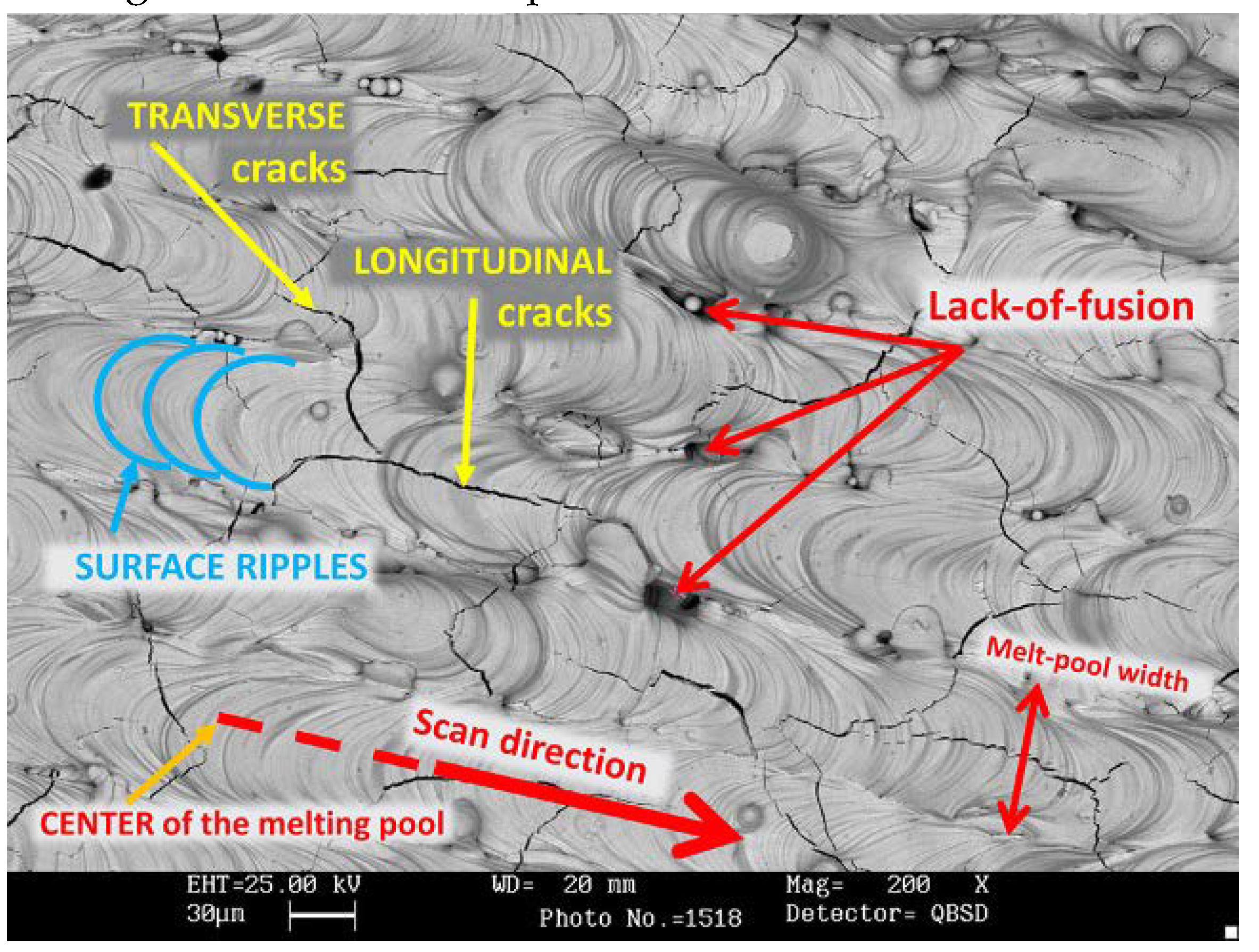

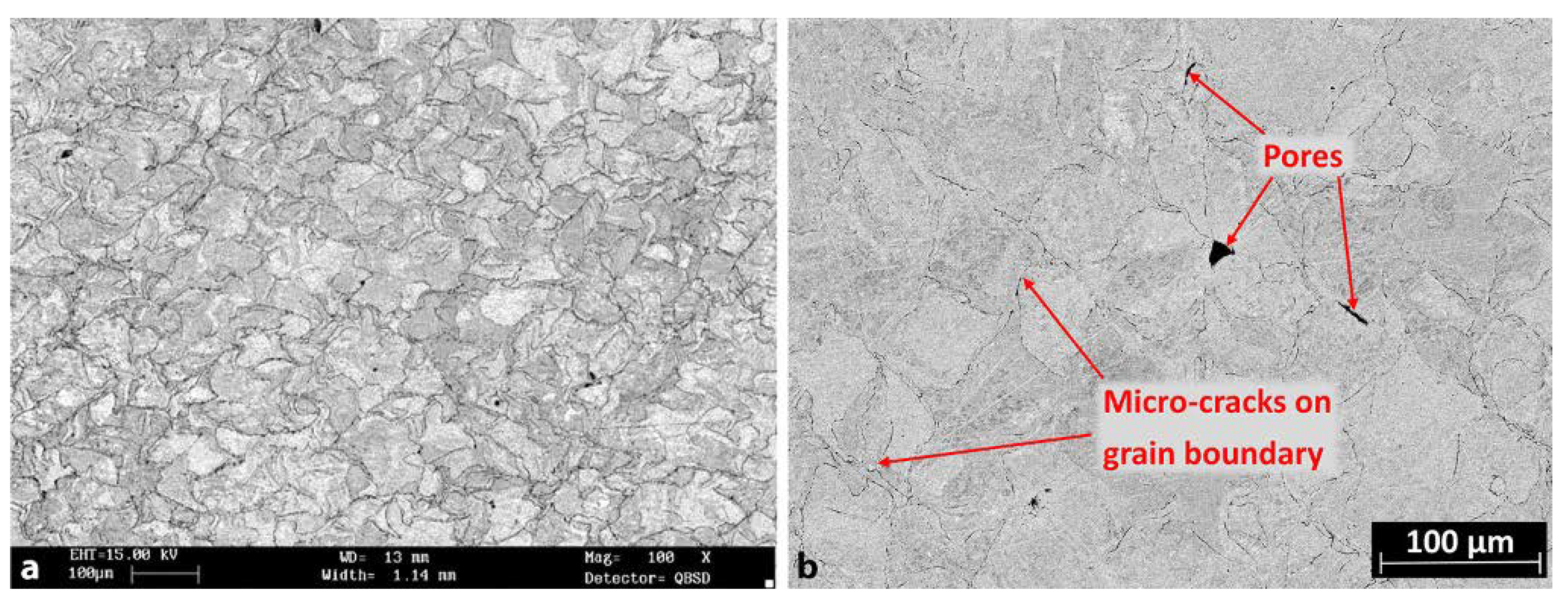

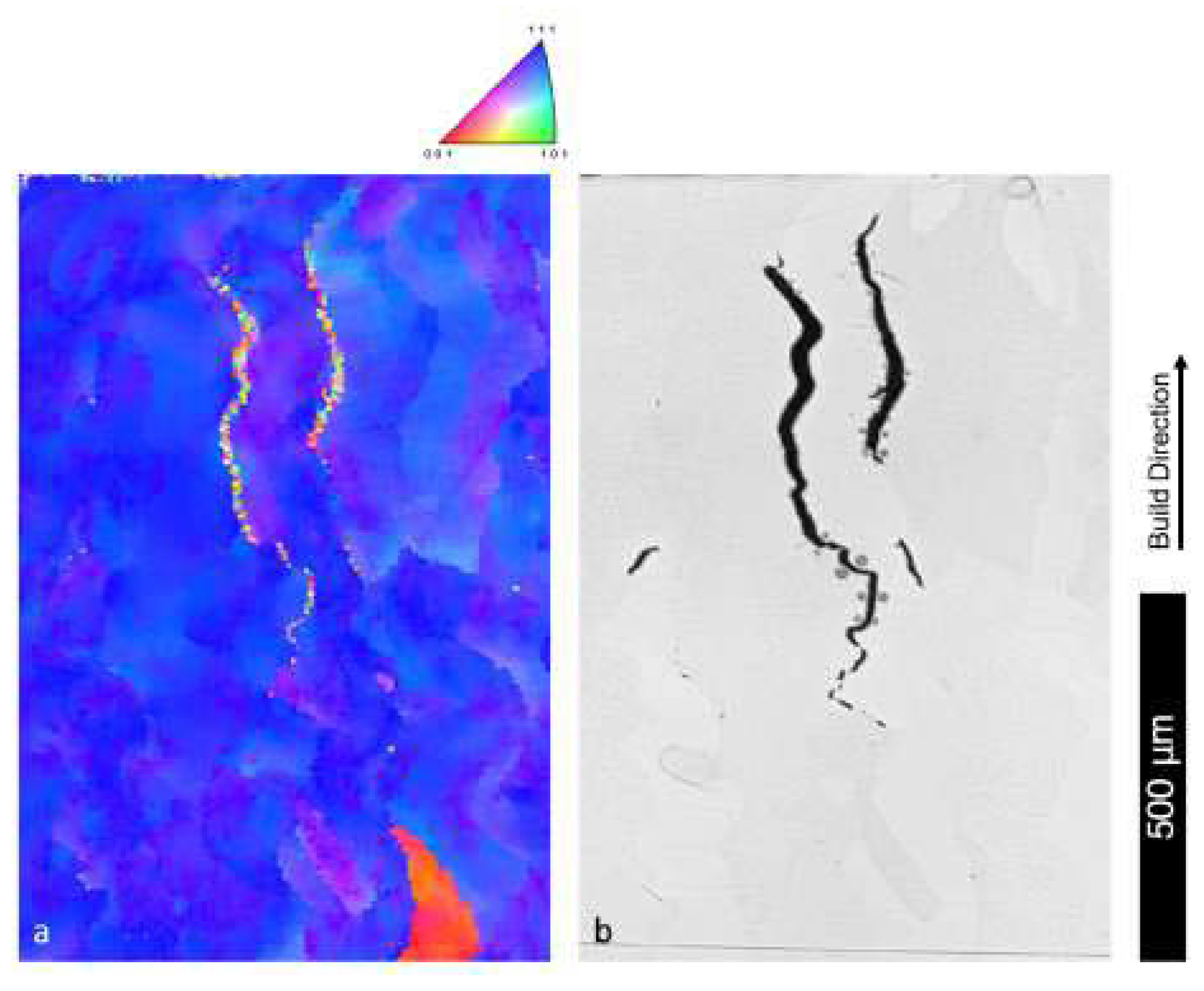

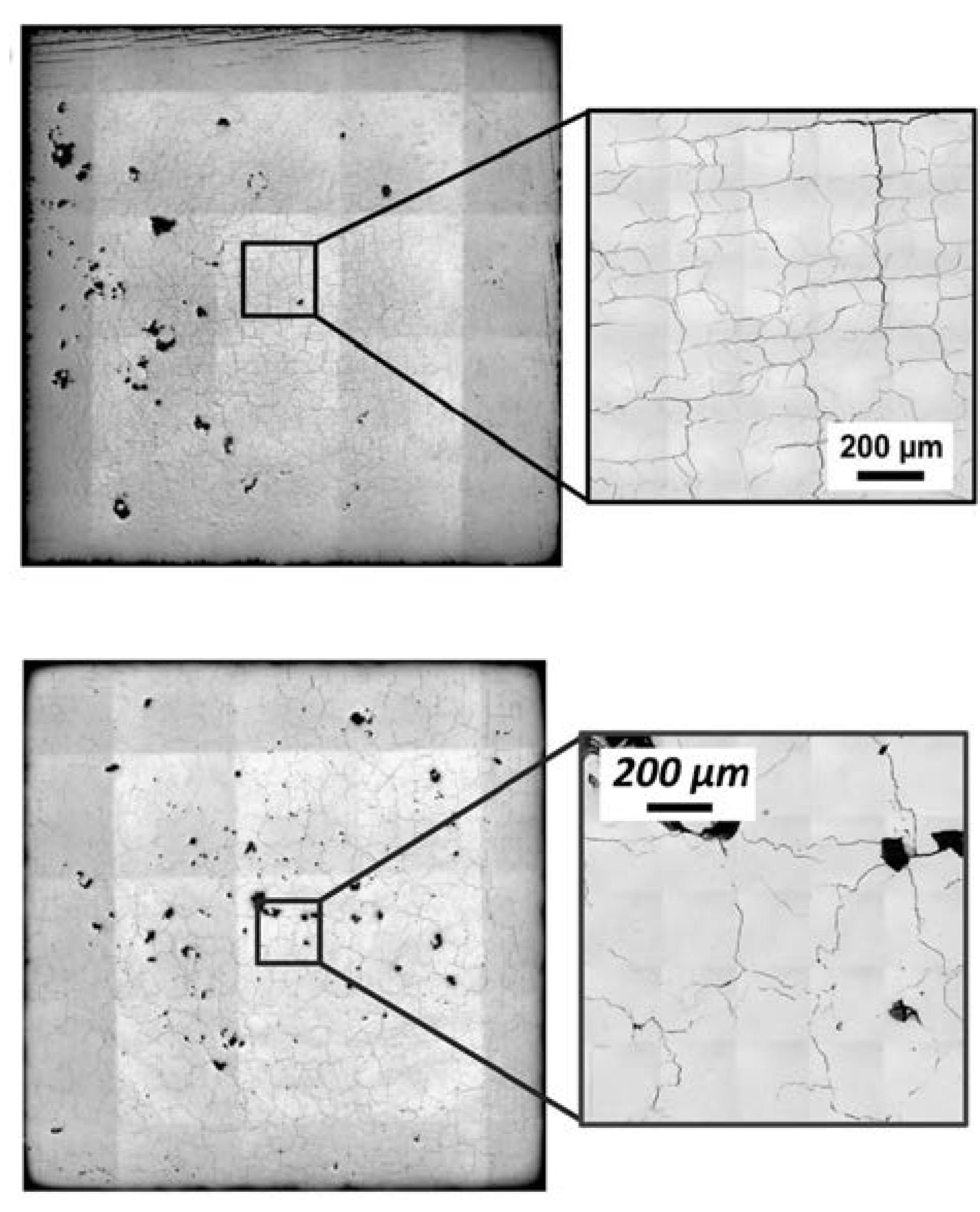

| Cracks due to: W embrittlement and high DBTT, thermal stress-induced, difficult-to-control crystallization, and oxygen-induced cracking along the grain boundaries | Adjusting laser speeds and reducing grain sizes; Techniques to adjust laser speeds and reduce grain sizes showed some positive results but did not completely resolve the issue. Scanning strategy optimization: speed, rotation, remelting |

[32,38,40,57,64,68] |

| Mechanical property issues (tensile strength and limited fracture toughness) especially in SLM-fabricated W | Alloying, introduction of reinforcements, process adjustments. | [68] |

3.2. High Melting Point, Related Challenges and Controlling Strategies

3.2.1. Melting

3.2.1.1. Particle Size and Morphology

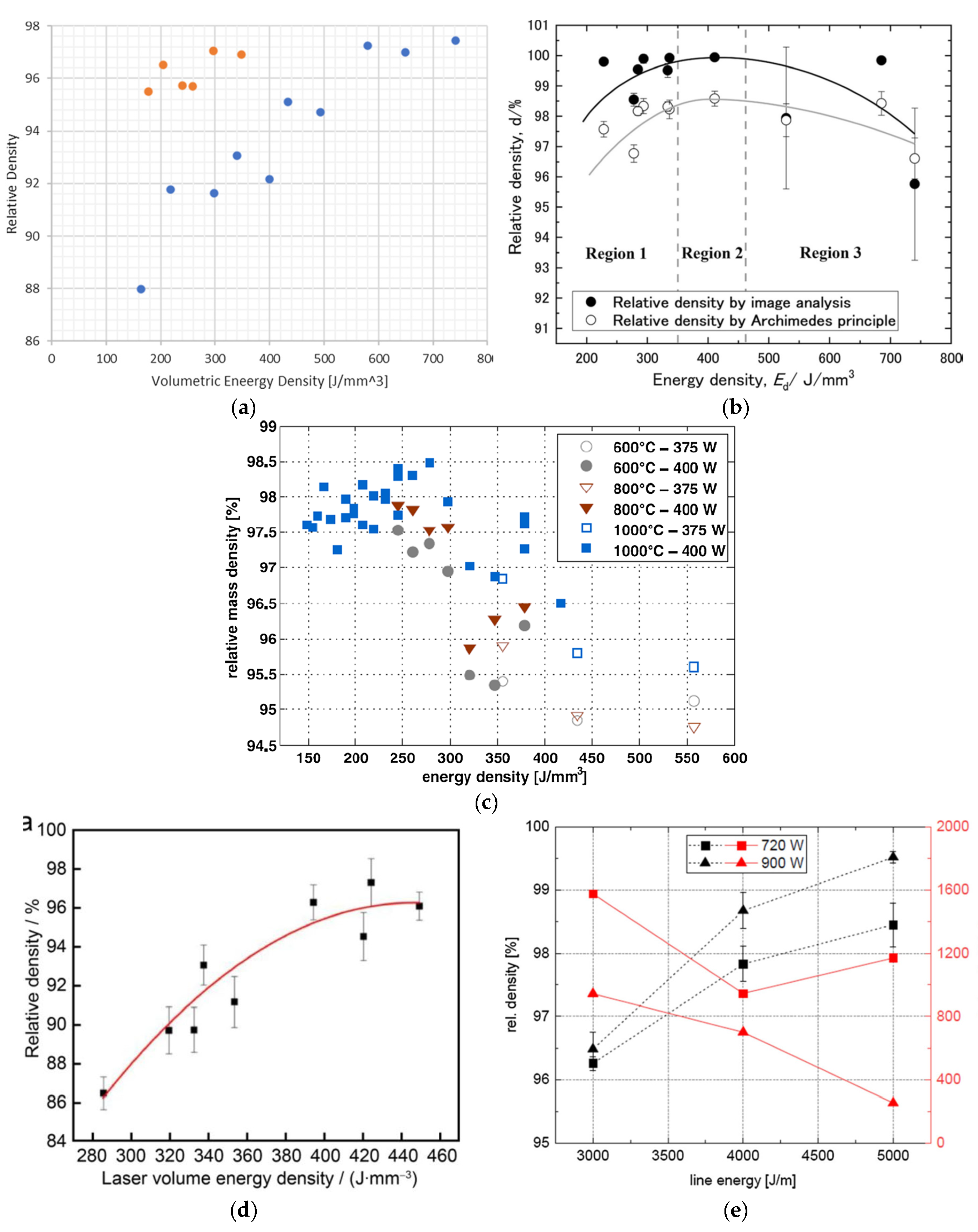

3.2.1.2. Power, Volumetric Energy Density, Layer Thickness

3.2.1.3. Other Scanning Variable and Strategies

| Scanning Parameters | Details | Reference |

|---|---|---|

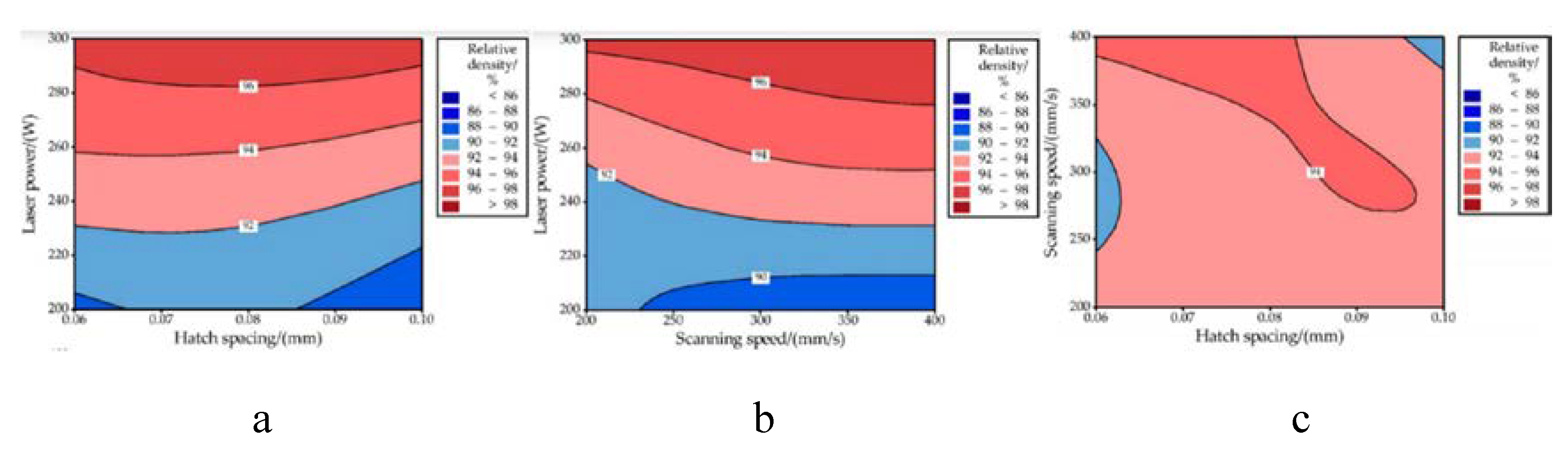

| Volumetric Energy Density | -Volumetric Energy Density: - Increased power in AM affects the molten pool via the Marangoni effect, with the severity proportional to laser energy. - can introduce gas, causing pore formation and pool instabilities, resulting in rough tracks - enhances the densification of manufactured parts - reduces residual stresses via annealing - volumetric energy density relates to pattern design. - Extremely high energy densities (> 300 J/mm3) have drawbacks: more porosity, excessive fusion risks, disrupted melt pools with stuck powder particles, vaporization of volatile elements due to W’s high melting point. These challenges impact printed part quality. Controlled melting has benefits: allows mixing of low melting point elements and improves interfacial bonding. Promotes growth of full columnar crystals in W AM parts. Techniques like EBM anneal W parts, decreasing cracks. |

[38,48,51,57,69,79,80,82,94,110,123,124,125,126] |

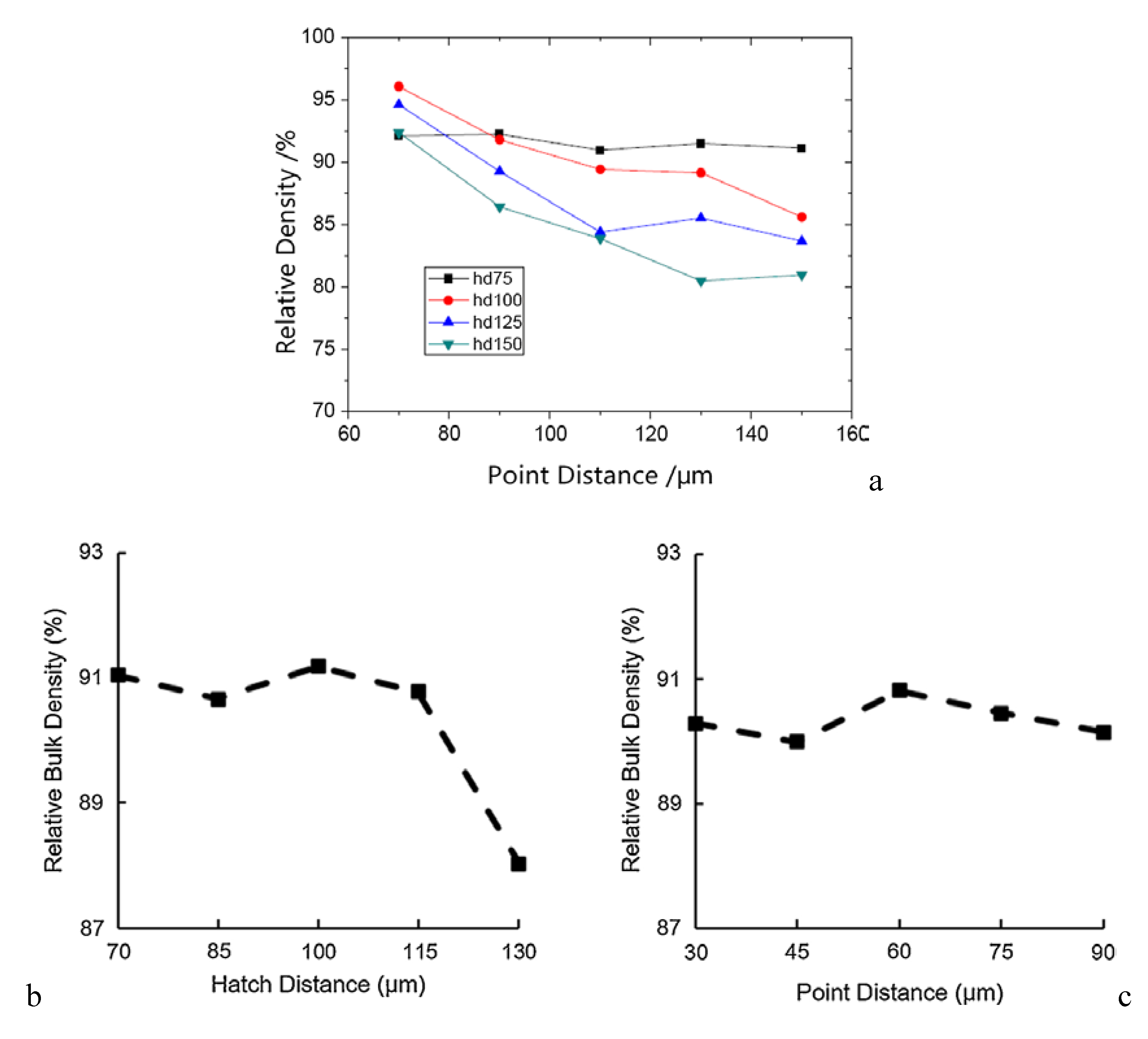

| Scanning Variables | - Direction & Angle: - EBM process allows multiple melting and re-melting at a single scanning point. - 90° alternating bidirectional scanning in SLM. - 67° alternating bidirectional scan. - Speed: scanning speed affects ~75% of W densification variation in SLM. - Hatch Spacing: affects ~7% of W densification variation. - Scan Track Width (w): a parameter in SLM. - Overlap Rate (φ): relationship between scan track characteristics and final W material densification is non-linear. Optimal overlap rate exists. |

[36,38,46,51,65,70,79,82] |

3.2.1.4. Wetting Behavior and Interfacial Characteristics

| Category | Description | Examples & Developments | References |

|---|---|---|---|

| Microscopic Wetting Behavior | Concerns internal heterogeneous boundaries in 3D-printed W materials. | - Temperature-dependent wettability of W - Introduction of Ni and Fe to improve wettability and AM quality |

[79,110,130,131,132] |

| Macroscopic W-Material/Substrate Interfacial Wetting and Reaction | Relates to interfaces between substrate and W material, affecting AM product quality. | - Use of stainless-steel interlayers containing nickel - Substituting substrates with Ti-based alloys, e.g., Ti–6Al–4V - Sandwich-structural printing sequences for W AM - Risks of diffusion-induced secondary phases and unwanted reactions |

[51,93,110,133] |

3.3. Oxygen, DBTT and Micro-cracking

3.3.1. Substrate Preheating

4. Additively Manufactured Tungsten Alloys and Composites

4.1. Alloying for Enhanced Densification

4.2. Alloying and Ceramic Dispersions for Microcrack Mitigation

4.2.1. Alloying Elements

4.2.2. Ceramic Dispersions (W Composites)

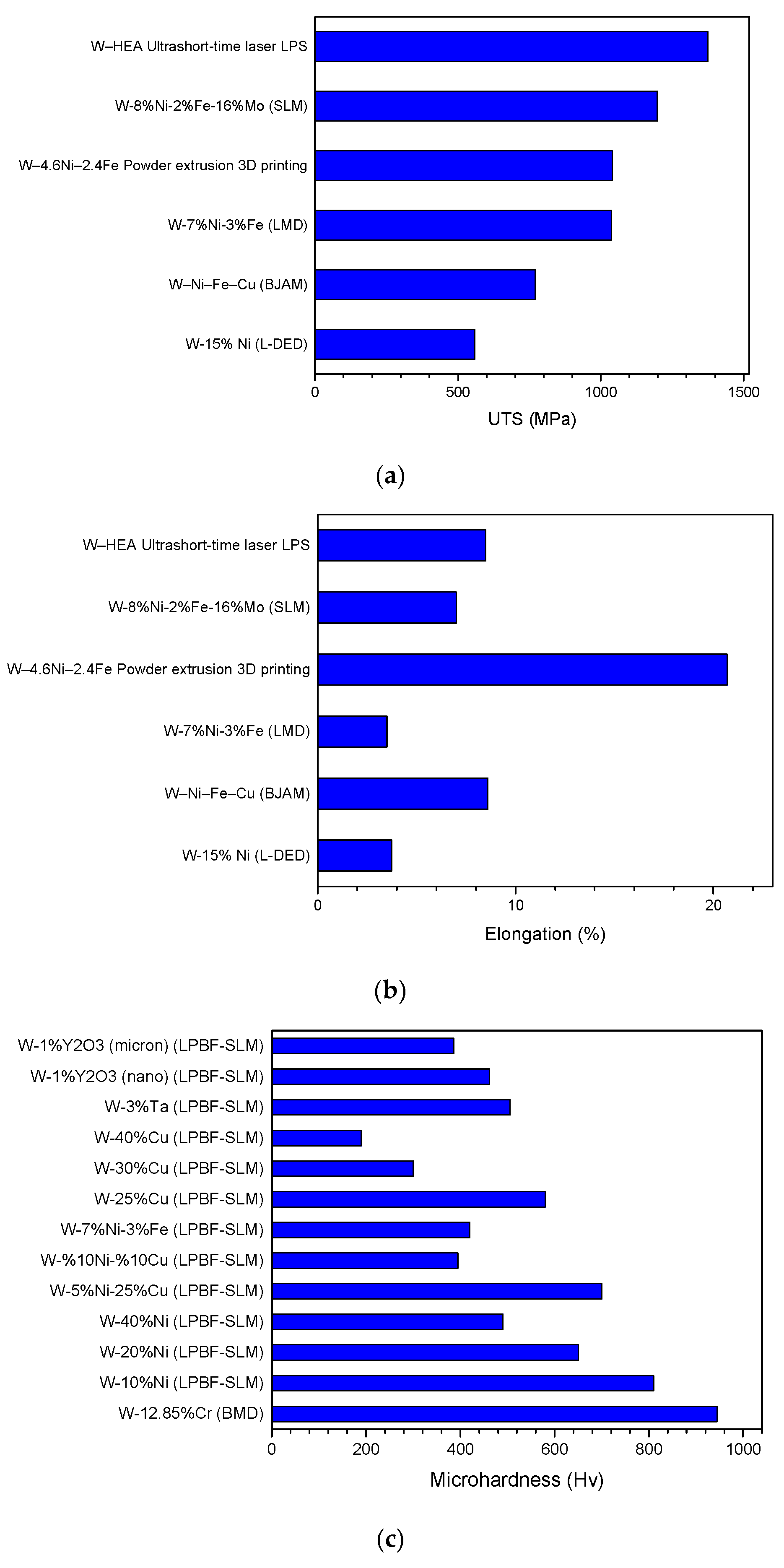

4.3. Alloying and Ceramic Dispersions for Adjustments to Mechanical Properties

4.4. Alloying for Other Specific Purposes

5. Future Directions

- 1.

- Atomic-Level Understanding: The Key to Tailored Properties

- 2.

- Thermodynamic Modeling: A Roadmap for Alloy Design

- 3.

- Harnessing the Power of Data Analytics: Machine Learning and In-situ Monitoring

- 4.

- Composite Design: Improved Innovative Composite

- 5.

- Sustainable Manufacturing: Hidden Cost of Oxidation of W

Acknowledgments

References

- M. Mani: J. Madan, J.H. Lee, K.W. Lyons, S.K. Gupta, Sustainability characterisation for manufacturing processes, Int J Prod Res 52 (2014) 5895–5912. [CrossRef]

- L. Valivullah, M. Mani, K.W. Lyons, S.K. Gupta, Manufacturing Process Information Models for Sustainable Manufacturing, in: Volume 1: Materials; Micro and Nano Technologies; Properties, Applications and Systems; Sustainable Manufacturing, American Society of Mechanical Engineers, 2014. [CrossRef]

- M. Mani, K.W. Lyons, S.K. Gupta, Sustainability Characterization for Additive Manufacturing, J Res Natl Inst Stand Technol 119 (2014) 419. [CrossRef]

- P. Moghimian, T. Poirié, M. Habibnejad-Korayem, J.A. Zavala, J. Kroeger, F. Marion, F. Larouche, Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys, Addit Manuf 43 (2021) 102017. [CrossRef]

- Mireles, O. Rodriguez, Y. Gao, N. Philips, Additive Manufacture of Refractory Alloy C103 for Propulsion Applications, in: AIAA Propulsion and Energy 2020 Forum, American Institute of Aeronautics and Astronautics, Reston, Virginia, 2020. [CrossRef]

- Zadpoor, Current Trends in Metallic Orthopedic Biomaterials: From Additive Manufacturing to Bio-Functionalization, Infection Prevention, and Beyond, Int J Mol Sci 19 (2018) 2684. [CrossRef]

- N. Li, S. Huang, G. Zhang, R. Qin, W. Liu, H. Xiong, G. Shi, J. Blackburn, Progress in additive manufacturing on new materials: A review, J Mater Sci Technol 35 (2019) 242–269. [CrossRef]

- K. Cho, H. Odo, K. Okamoto, H.Y. Yasuda, H. Nakashima, M. Takeyama, T. Nakano, Improving the Tensile Properties of Additively Manufactured β-Containing TiAl Alloys via Microstructure Control Focusing on Cellular Precipitation Reaction, Crystals (Basel) 11 (2021) 809. [CrossRef]

- M. Reith, M. Franke, C. Körner, Robust γ-TiAl Dual Microstructure Concept by Advanced Electron Beam Powder Bed Fusion Technology, Crystals (Basel) 13 (2023) 1348. [CrossRef]

- R. Zhang, F. Jiang, L. Xue, J. Yu, Review of Additive Manufacturing Techniques for Large-Scale Metal Functionally Graded Materials, Crystals (Basel) 12 (2022) 858. [CrossRef]

- Noh, J. Jeon, S.W. Lee, A Study on Metallographic and Machining Characteristics of Functionally Graded Material Produced by Directed Energy Deposition, Crystals (Basel) 13 (2023) 1491. [CrossRef]

- M.P. Behera, T. Dougherty, S. Singamneni, Conventional and Additive Manufacturing with Metal Matrix Composites: A Perspective, Procedia Manuf 30 (2019) 159–166. [CrossRef]

- S. Tang, R. Ummethala, C. Suryanarayana, J. Eckert, K.G. Prashanth, Z. Wang, Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review, Adv Eng Mater 23 (2021). [CrossRef]

- J. Shi, Y. Wang, Development of metal matrix composites by laser-assisted additive manufacturing technologies: a review, J Mater Sci 55 (2020) 9883–9917. [CrossRef]

- Y. Hu, W. Cong, A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites, Ceram Int 44 (2018) 20599–20612. [CrossRef]

- L. Jannesari Ladani, Applications of artificial intelligence and machine learning in metal additive manufacturing, Journal of Physics: Materials 4 (2021) 042009. [CrossRef]

- L. Meng, B. McWilliams, W. Jarosinski, H.-Y. Park, Y.-G. Jung, J. Lee, J. Zhang, Machine Learning in Additive Manufacturing: A Review, JOM 72 (2020) 2363–2377. [CrossRef]

- H. Ko, P. Witherell, Y. Lu, S. Kim, D.W. Rosen, Machine learning and knowledge graph based design rule construction for additive manufacturing, Addit Manuf 37 (2021) 101620. [CrossRef]

- J. Elambasseril, M. Brandt, Artificial intelligence: way forward to empower metal additive manufacturing product development – an overview, Mater Today Proc 58 (2022) 461–465. [CrossRef]

- C. Liu, W. Tian, C. Kan, When AI meets additive manufacturing: Challenges and emerging opportunities for human-centered products development, J Manuf Syst 64 (2022) 648–656. [CrossRef]

- B. Naghshineh, A. Ribeiro, C. Jacinto, H. Carvalho, Social impacts of additive manufacturing: A stakeholder-driven framework, Technol Forecast Soc Change 164 (2021) 120368. [CrossRef]

- F. Matos, C. Jacinto, Additive manufacturing technology: mapping social impacts, Journal of Manufacturing Technology Management 30 (2019) 70–97. [CrossRef]

- D. Landi, F.C. Zefinetti, C. Spreafico, D. Regazzoni, Comparative life cycle assessment of two different manufacturing technologies: laser additive manufacturing and traditional technique, Procedia CIRP 105 (2022) 700–705. [CrossRef]

- G. Felice, F. G. Felice, F. Lamperti, L. Piscitello, The employment implications of additive manufacturing, Ind Innov 29 (2022) 333–366. [CrossRef]

- M. Rieth, S.L. Dudarev, S.M. Gonzalez de Vicente, J. Aktaa, T. Ahlgren, S. Antusch, D.E.J. Armstrong, M. Balden, N. Baluc, M.-F. Barthe, W.W. Basuki, M. Battabyal, C.S. Becquart, D. Blagoeva, H. Boldyryeva, J. Brinkmann, M. Celino, L. Ciupinski, J.B. Correia, A. De Backer, C. Domain, E. Gaganidze, C. García-Rosales, J. Gibson, M.R. Gilbert, S. Giusepponi, B. Gludovatz, H. Greuner, K. Heinola, T. Höschen, A. Hoffmann, N. Holstein, F. Koch, W. Krauss, H. Li, S. Lindig, J. Linke, Ch. Linsmeier, P. López-Ruiz, H. Maier, J. Matejicek, T.P. Mishra, M. Muhammed, A. Muñoz, M. Muzyk, K. Nordlund, D. Nguyen-Manh, J. Opschoor, N. Ordás, T. Palacios, G. Pintsuk, R. Pippan, J. Reiser, J. Riesch, S.G. Roberts, L. Romaner, M. Rosiński, M. Sanchez, W. Schulmeyer, H. Traxler, A. Ureña, J.G. van der Laan, L. Veleva, S. Wahlberg, M. Walter, T. Weber, T. Weitkamp, S. Wurster, M.A. Yar, J.H. You, A. Zivelonghi, Recent progress in research on tungsten materials for nuclear fusion applications in Europe, Journal of Nuclear Materials 432 (2013) 482–500. [CrossRef]

- J. Xie, H. Lu, J. Lu, X. Song, S. Wu, J. Lei, Additive manufacturing of tungsten using directed energy deposition for potential nuclear fusion application, Surf Coat Technol 409 (2021) 126884. [CrossRef]

- Y. Katoh, L.L. Snead, L.M. Garrison, X. Hu, T. Koyanagi, C.M. Parish, P.D. Edmondson, M. Fukuda, T. Hwang, T. Tanaka, A. Hasegawa, Response of unalloyed tungsten to mixed spectrum neutrons, Journal of Nuclear Materials 520 (2019) 193–207. [CrossRef]

- G. Wang, Y. Qin, S. Yang, Influence of Ni additions on the microstructure and tensile property of W-Cu composites produced by direct energy deposition, J Alloys Compd 899 (2022) 163272. [CrossRef]

- A.M. Engwall, S.J. Shin, J. Bae, Y.M. Wang, Enhanced properties of tungsten films by high-power impulse magnetron sputtering, Surf Coat Technol 363 (2019) 191–197. [CrossRef]

- S. Su, Y. Lu, Densified W Cu composite fabricated via laser additive manufacturing, Int J Refract Metals Hard Mater 87 (2020) 105122. [CrossRef]

- Oponowicz, M. Marciszko-Wiąckowska, A. Baczmański, M. Klaus, C. Genzel, S. Wroński, K. Kollbek, M. Wróbel, Gradient of Residual Stress and Lattice Parameter in Mechanically Polished Tungsten Measured Using Classical X-rays and Synchrotron Radiation, Metallurgical and Materials Transactions A 51 (2020) 5945–5957. [CrossRef]

- Iveković, N. Omidvari, B. Vrancken, K. Lietaert, L. Thijs, K. Vanmeensel, J. Vleugels, J.-P. Kruth, Selective laser melting of tungsten and tungsten alloys, Int J Refract Metals Hard Mater 72 (2018) 27–32. [CrossRef]

- Y. Jia, S. Chang, X. Du, S. Guo, Corrosion Performance of Commercial Alloys and Refractory Metals in Conditions for Electrorefining of Spent Nuclear Fuels, Crystals (Basel) 13 (2023) 817. [CrossRef]

- Q. Wei, K.T. Ramesh, B.E. Schuster, L.J. Kecskes, R.J. Dowding, Nanoengineering opens a new era for tungsten as well, JOM 58 (2006) 40–44. [CrossRef]

- S.J. Zinkle, L.J. Ott, D.T. Ingersoll, R.J. Ellis, M.L. Grossbeck, Overview of materials technologies for space nuclear power and propulsion, in: AIP Conf Proc, AIP, 2002: pp. 1063–1073. [CrossRef]

- X. Ren, H. Liu, F. Lu, L. Huang, X. Yi, Effects of processing parameters on the densification, microstructure and mechanical properties of pure tungsten fabricated by optimized selective laser melting: From single and multiple scan tracks to bulk parts, Int J Refract Metals Hard Mater 96 (2021) 105490. [CrossRef]

- S. Bai, J. Liu, P. Yang, H. Huang, L.-M. Yang, Femtosecond fiber laser additive manufacturing of tungsten, in: B. Gu, H. Helvajian, A. Piqué (Eds.), 2016: p. 97380U. [CrossRef]

- A. v. Müller, G. Schlick, R. Neu, C. Anstätt, T. Klimkait, J. Lee, B. Pascher, M. Schmitt, C. Seidel, Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 ∘C, Nuclear Materials and Energy 19 (2019) 184–188. [CrossRef]

- F. Feng, Y. Lian, J. Wang, J. Song, B. Yan, X. Liu, Mechanical Properties and Thermal Shock Performance of High-Energy-Rate-Forged W-1%TaC Alloy, Crystals (Basel) 12 (2022) 1047. [CrossRef]

- D.-Z. Wang, K.-L. Li, C.-F. Yu, J. Ma, W. Liu, Z.-J. Shen, Cracking Behavior in Additively Manufactured Pure Tungsten, Acta Metallurgica Sinica (English Letters) 32 (2019) 127–135. [CrossRef]

- E. Lassner, W.-D. Schubert, Tungsten, Springer US, Boston, MA, 1999. [CrossRef]

- R. Mitteau, J.M. Missiaen, P. Brustolin, O. Ozer, A. Durocher, C. Ruset, C.P. Lungu, X. Courtois, C. Dominicy, H. Maier, C. Grisolia, G. Piazza, P. Chappuis, Recent developments toward the use of tungsten as armour material in plasma facing components, Fusion Engineering and Design 82 (2007) 1700–1705. [CrossRef]

- Vrancken, R.K. Ganeriwala, M.J. Matthews, Analysis of laser-induced microcracking in tungsten under additive manufacturing conditions: Experiment and simulation, Acta Mater 194 (2020) 464–472. [CrossRef]

- A.H. Elsayed, M.A. Sayed, O.M. Dawood, W.M. Daoush, Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys, Crystals (Basel) 10 (2020) 825. [CrossRef]

- L. Wang, J. Wu, D. Zhang, Properties evolution of additive manufacture used tungsten powders prepared by radio frequency induction plasma, Int J Refract Metals Hard Mater 67 (2017) 90–97. [CrossRef]

- X. Zi, C. Chen, X. Wang, P. Wang, X. Zhang, K. Zhou, Spheroidisation of tungsten powder by radio frequency plasma for selective laser melting, Materials Science and Technology 34 (2018) 735–742. [CrossRef]

- D.D. Gu, W. Meiners, K. Wissenbach, R. Poprawe, Laser additive manufacturing of metallic components: materials, processes and mechanisms, International Materials Reviews 57 (2012) 133–164. [CrossRef]

- M. Guo, D. Gu, L. Xi, L. Du, H. Zhang, J. Zhang, Formation of scanning tracks during Selective Laser Melting (SLM) of pure tungsten powder: Morphology, geometric features and forming mechanisms, Int J Refract Metals Hard Mater 79 (2019) 37–46. [CrossRef]

- S. Wen, C. Wang, Y. Zhou, L. Duan, Q. Wei, S. Yang, Y. Shi, High-density tungsten fabricated by selective laser melting: Densification, microstructure, mechanical and thermal performance, Opt Laser Technol 116 (2019) 128–138. [CrossRef]

- O. Gokcekaya, T. Ishimoto, T. Todo, P. Wang, T. Nakano, Influence of powder characteristics on densification via crystallographic texture formation: Pure tungsten prepared by laser powder bed fusion, Additive Manufacturing Letters 1 (2021) 100016. [CrossRef]

- G. Yang, P. Yang, K. Yang, N. Liu, L. Jia, J. Wang, H. Tang, Effect of processing parameters on the density, microstructure and strength of pure tungsten fabricated by selective electron beam melting, Int J Refract Metals Hard Mater 84 (2019) 105040. [CrossRef]

- P.K. Gokuldoss, S. Kolla, J. Eckert, Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines, Materials 10 (2017) 672. [CrossRef]

- Klahn, B. Leutenecker, M. Meboldt, Design Strategies for the Process of Additive Manufacturing, Procedia CIRP 36 (2015) 230–235. [CrossRef]

- B. Vrancken, W.E. King, M.J. Matthews, In-situ characterization of tungsten microcracking in Selective Laser Melting, Procedia CIRP 74 (2018) 107–110. [CrossRef]

- A.T. Sidambe, Y. Tian, P.B. Prangnell, P. Fox, Effect of processing parameters on the densification, microstructure and crystallographic texture during the laser powder bed fusion of pure tungsten, Int J Refract Metals Hard Mater 78 (2019) 254–263. [CrossRef]

- P. Rebesan, M. Bonesso, C. Gennari, R. Dima, A. Pepato, M. Vedani, Tungsten Fabricated by Laser Powder Bed Fusion, BHM Berg- Und Hüttenmännische Monatshefte 166 (2021) 263–269. [CrossRef]

- C. Tan, K. Zhou, W. Ma, B. Attard, P. Zhang, T. Kuang, Selective laser melting of high-performance pure tungsten: parameter design, densification behavior and mechanical properties, Sci Technol Adv Mater 19 (2018) 370–380. [CrossRef]

- J. Chen, K. Li, Y. Wang, L. Xing, C. Yu, H. Liu, J. Ma, W. Liu, Z. Shen, The effect of hot isostatic pressing on thermal conductivity of additively manufactured pure tungsten, Int J Refract Metals Hard Mater 87 (2020) 105135. [CrossRef]

- A.C. Field, L.N. Carter, N.J.E. Adkins, M.M. Attallah, M.J. Gorley, M. Strangwood, The Effect of Powder Characteristics on Build Quality of High-Purity Tungsten Produced via Laser Powder Bed Fusion (LPBF), Metallurgical and Materials Transactions A 51 (2020) 1367–1378. [CrossRef]

- M. Guo, D. Gu, L. Xi, H. Zhang, J. Zhang, J. Yang, R. Wang, Selective laser melting additive manufacturing of pure tungsten: Role of volumetric energy density on densification, microstructure and mechanical properties, Int J Refract Metals Hard Mater 84 (2019) 105025. [CrossRef]

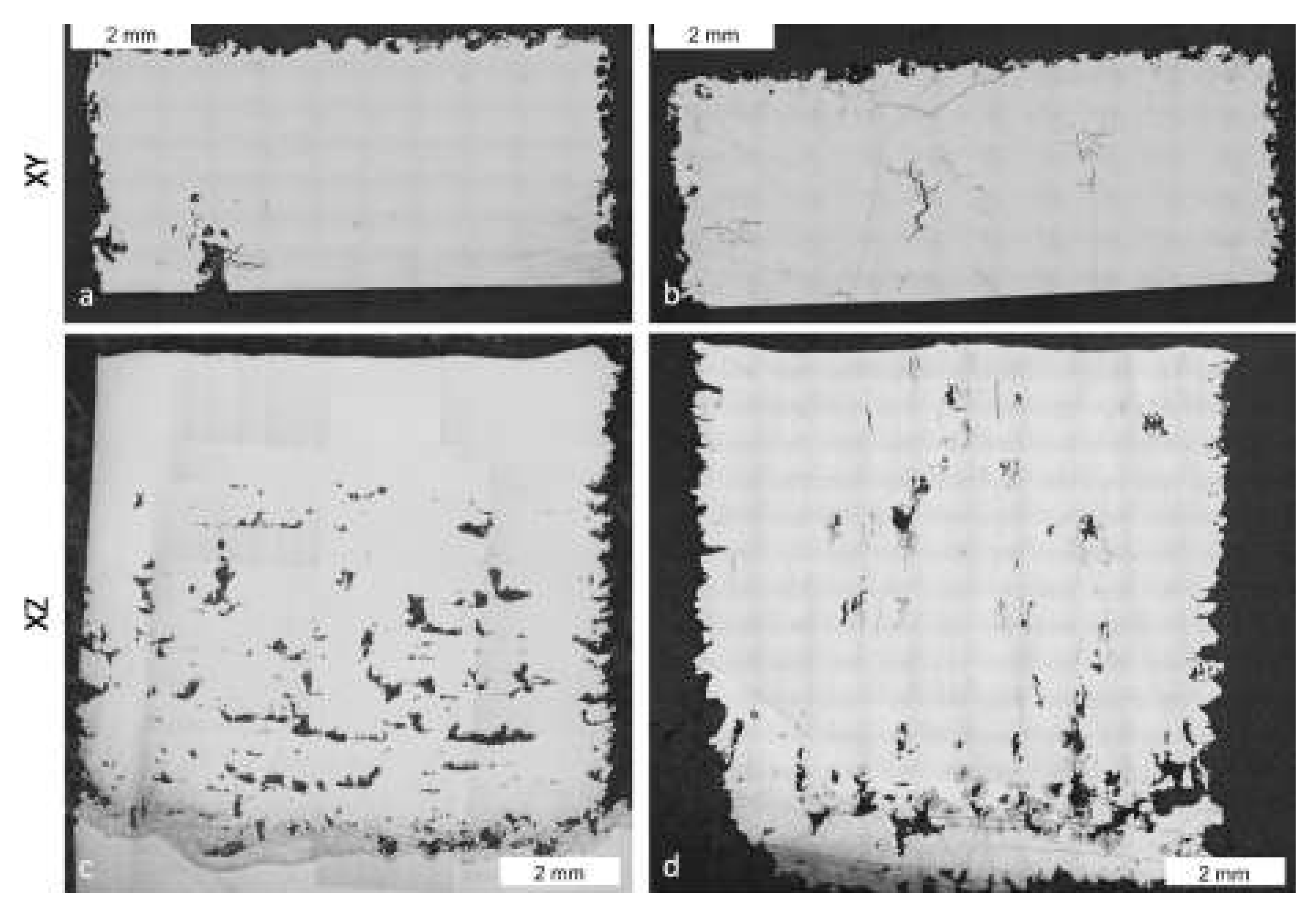

- Z. Hu, Y. Zhao, K. Guan, Z. Wang, Z. Ma, Pure tungsten and oxide dispersion strengthened tungsten manufactured by selective laser melting: Microstructure and cracking mechanism, Addit Manuf 36 (2020) 101579. [CrossRef]

- Wang, C. Yu, X. Zhou, J. Ma, W. Liu, Z. Shen, Dense Pure Tungsten Fabricated by Selective Laser Melting, Applied Sciences 7 (2017) 430. [CrossRef]

- B. Vrancken, R.K. Ganeriwala, A.A. Martin, M.J. Matthews, Microcrack mitigation during laser scanning of tungsten via preheating and alloying strategies, Addit Manuf 46 (2021) 102158. [CrossRef]

- Z. Xiong, P. Zhang, C. Tan, D. Dong, W. Ma, K. Yu, Selective Laser Melting and Remelting of Pure Tungsten, Adv Eng Mater 22 (2020). [CrossRef]

- X. Zhou, X. Liu, D. Zhang, Z. Shen, W. Liu, Balling phenomena in selective laser melted tungsten, J Mater Process Technol 222 (2015) 33–42. [CrossRef]

- Y. Wu, Manufacturing of tungsten and tungsten composites for fusion application via different routes, Tungsten 1 (2019) 80–90. [CrossRef]

- D. Wang, Z. Wang, K. Li, J. Ma, W. Liu, Z. Shen, Cracking in laser additively manufactured W: Initiation mechanism and a suppression approach by alloying, Mater Des 162 (2019) 384–393. [CrossRef]

- J. Braun, L. Kaserer, J. Stajkovic, K.-H. Leitz, B. Tabernig, P. Singer, P. Leibenguth, C. Gspan, H. Kestler, G. Leichtfried, Molybdenum and tungsten manufactured by selective laser melting: Analysis of defect structure and solidification mechanisms, Int J Refract Metals Hard Mater 84 (2019) 104999. [CrossRef]

- T. Yamamoto, M. Hara, Y. Hatano, Effects of fabrication conditions on the microstructure, pore characteristics and gas retention of pure tungsten prepared by laser powder bed fusion, Int J Refract Metals Hard Mater 95 (2021) 105410. [CrossRef]

- R.K. Enneti, R. Morgan, S. V. Atre, Effect of process parameters on the Selective Laser Melting (SLM) of tungsten, Int J Refract Metals Hard Mater 71 (2018) 315–319. [CrossRef]

- D. Zhang, Q. Cai, J. Liu, Formation of Nanocrystalline Tungsten by Selective Laser Melting of Tungsten Powder, Materials and Manufacturing Processes 27 (2012) 1267–1270. [CrossRef]

- J. Zhang, D. Gu, Y. Yang, H. Zhang, H. Chen, D. Dai, K. Lin, Influence of Particle Size on Laser Absorption and Scanning Track Formation Mechanisms of Pure Tungsten Powder During Selective Laser Melting, Engineering 5 (2019) 736–745. [CrossRef]

- K. Deprez, S. Vandenberghe, K. Van Audenhaege, J. Van Vaerenbergh, R. Van Holen, Rapid additive manufacturing of MR compatible multipinhole collimators with selective laser melting of tungsten powder, Med Phys 40 (2013). [CrossRef]

- A.T. Sidambe, D.S. Judson, S.J. Colosimo, P. Fox, Laser powder bed fusion of a pure tungsten ultra-fine single pinhole collimator for use in gamma ray detector characterisation, Int J Refract Metals Hard Mater 84 (2019) 104998. [CrossRef]

- J.I. Gear, J. Taprogge, O. White, G.D. Flux, Characterisation of the attenuation properties of 3D-printed tungsten for use in gamma camera collimation, EJNMMI Phys 6 (2019) 1. [CrossRef]

- K. Zhou, W. Chen, Y. Yang, R. Li, L. Dong, Y.-Q. Fu, Microstructure and mechanical behavior of porous tungsten skeletons synthesized by selected laser melting, Int J Refract Metals Hard Mater 103 (2022) 105769. [CrossRef]

- P. Morcos, A. Elwany, I. Karaman, R. Arróyave, Review: additive manufacturing of pure tungsten and tungsten-based alloys, J Mater Sci 57 (2022) 9769–9806. [CrossRef]

- S. Omole, A. Lunt, S. Kirk, A. Shokrani, Advanced Processing and Machining of Tungsten and Its Alloys, Journal of Manufacturing and Materials Processing 6 (2022) 15. [CrossRef]

- S.-H. Pan, G.-C. Yao, Y.-N. Cui, F.-S. Meng, C. Luo, T.-Q. Zheng, G. Singh, Additive manufacturing of tungsten, tungsten-based alloys, and tungsten matrix composites, Tungsten 5 (2023) 1–31. [CrossRef]

- A. Talignani, R. Seede, A. Whitt, S. Zheng, J. Ye, I. Karaman, M.M. Kirka, Y. Katoh, Y.M. Wang, A review on additive manufacturing of refractory tungsten and tungsten alloys, Addit Manuf 58 (2022) 103009. [CrossRef]

- M. Galati, Electron beam melting process, in: Addit Manuf, Elsevier, 2021: pp. 277–301. [CrossRef]

- E.A.I. Ellis, M.A. Sprayberry, C. Ledford, J.P. Hankwitz, M.M. Kirka, C.D. Rock, T.J. Horn, Y. Katoh, R.R. Dehoff, Processing of tungsten through electron beam melting, Journal of Nuclear Materials 555 (2021) 153041. [CrossRef]

- H. Zhang, P.R. Carriere, E.D. Amoako, C.D. Rock, S.U. Thielk, C.G. Fletcher, T.J. Horn, Microstructure and Elevated Temperature Flexure Testing of Tungsten Produced by Electron Beam Additive Manufacturing, JOM 75 (2023) 4094–4107. [CrossRef]

- D. Dorow-Gerspach, A. Kirchner, Th. Loewenhoff, G. Pintsuk, T. Weißgärber, M. Wirtz, Additive manufacturing of high density pure tungsten by electron beam melting, Nuclear Materials and Energy 28 (2021) 101046. [CrossRef]

- J. Wang, D. Yao, M. Li, X. An, S. Li, W. Hou, X. Zhang, G. Yang, J. Wang, L. Wang, Hierarchical effects of multi-layer powder spreading in the electron beam powder bed fusion additive manufacturing of pure tungsten material, Addit Manuf 55 (2022) 102835. [CrossRef]

- X. Zhao, N. An, G. Yang, J. Wang, H. Tang, M. Li, J. Zhou, Enhancing standard finite element codes with POD for reduced order thermal analysis: Application to electron beam melting of pure tungsten, Mater Today Commun 29 (2021) 102796. [CrossRef]

- P. Fernandez-Zelaia, M. Kirka, Q. Campbell, J. Ortega Rojas, A. Marquez Rossy, C. Ledford, Electron Beam Powder Bed Fusion Additive Manufacturing of Refractory Metals, in: United States, 2021. https://www.osti.gov/biblio/1832704.

- W.-B. Liao, Z.-Y. Liu, M.-J. He, C. Feng, F. Wang, J. Huang, Effect of Electron Beam Remelting Treatments on the Microstructure and Properties of Atmospheric Plasma Sprayed Tungsten Coatings, Journal of Thermal Spray Technology 30 (2021) 2128–2137. [CrossRef]

- W. Jeong, Y.-S. Kwon, D. Kim, Three-dimensional printing of tungsten structures by directed energy deposition, Materials and Manufacturing Processes 34 (2019) 986–992. [CrossRef]

- G. Marinelli, F. Martina, H. Lewtas, D. Hancock, S. Mehraban, N. Lavery, S. Ganguly, S. Williams, Microstructure and thermal properties of unalloyed tungsten deposited by Wire + Arc Additive Manufacture, Journal of Nuclear Materials 522 (2019) 45–53. [CrossRef]

- Y.P. Wang, S.Y. Ma, X.S. Yang, Y.Z. Zhou, X. Liu, J.F. Li, J.J. Zhang, C. Li, X.Y. Wang, G.M. Le, Y. Zhang, Microstructure and strengthening mechanisms of 90W–7Ni–3Fe alloys prepared using laser melting deposition, J Alloys Compd 838 (2020) 155545. [CrossRef]

- G.-Y. Wang, S.-N. Gu, S. Yang, Microstructure and properties of tungsten heavy alloys fabricated by laser direct deposition, Materials Science and Technology 33 (2017) 415–420. [CrossRef]

- C. Li, S. Ma, X. Liu, J. Li, G. Le, Microstructures and properties of 80W-20Fe alloys prepared using laser melting deposition process, Int J Refract Metals Hard Mater 77 (2018) 113–119. [CrossRef]

- G. Wang, X. Sun, M. Huang, Y. Qin, Y. Yao, S. Yang, Influence of processing parameters on the microstructure and tensile property of 85 W-15Ni produced by laser direct deposition, Int J Refract Metals Hard Mater 82 (2019) 227–233. [CrossRef]

- S. Zhou, L. Wang, Y.-J. Liang, Y. Zhu, R. Jian, B. Wang, L. Wang, Y. Xue, F. Wang, H. Cai, Y. Ren, A strategy to achieve high-strength WNiFe composite-like alloys with low W content by laser melting deposition, Mater Des 190 (2020) 108554. [CrossRef]

- T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, W. Zhang, Additive manufacturing of metallic components – Process, structure and properties, Prog Mater Sci 92 (2018) 112–224. [CrossRef]

- C. Li, Y. Wang, S. Ma, X. Yang, J. Li, Y. Zhou, X. Liu, J. Tang, X. Wang, G. Le, Densification, microstructural evolutions of 90W-7Ni-3Fe tungsten heavy alloys during laser melting deposition process, Int J Refract Metals Hard Mater 91 (2020) 105254. [CrossRef]

- M.T. Stawovy, K. Myers, S. Ohm, Binder jet printing of tungsten heavy alloy, Int J Refract Metals Hard Mater 83 (2019) 104981. [CrossRef]

- V.V.K. Doddapaneni, K. Lee, H.E. Aysal, B.K. Paul, S. Pasebani, K.A. Sierros, C.E. Okwudire, C. Chang, A Review on Progress, Challenges, and Prospects of Material Jetting of Copper and Tungsten, Nanomaterials 13 (2023) 2303. [CrossRef]

- M. Ottensmeyer, H. Sabet, L. Furenlid, M. May, M. Kupinski, Collimator fabrication techniques: a comparative study, Journal of Nuclear Medicine 64 (2023) P1600. http://jnm.snmjournals.org/content/64/supplement_1/P1600.abstract.

- A. Bose, J.P. Reidy, N. Tuncer, L. Jorgensen, Processing of tungsten heavy alloy by extrusion-based additive manufacturing, Int J Refract Metals Hard Mater 110 (2023) 106021. [CrossRef]

- N. Huang, O.J. Cook, A.P. Argüelles, A.M. Beese, Review of Process–Structure–Property Relationships in Metals Fabricated Using Binder Jet Additive Manufacturing, Metallography, Microstructure, and Analysis 12 (2023) 883–905. [CrossRef]

- S. Zhou, Y.-J. Liang, Y. Zhu, B. Wang, L. Wang, Y. Xue, Ultrashort-time liquid phase sintering of high-performance fine-grain tungsten heavy alloys by laser additive manufacturing, J Mater Sci Technol 90 (2021) 30–36. [CrossRef]

- A. Bose, C.A. Schuh, J.C. Tobia, N. Tuncer, N.M. Mykulowycz, A. Preston, A.C. Barbati, B. Kernan, M.A. Gibson, D. Krause, T. Brzezinski, J. Schroers, R. Fulop, J.S. Myerberg, M. Sowerbutts, Y.-M. Chiang, A. John Hart, E.M. Sachs, E.E. Lomeli, A.C. Lund, Traditional and additive manufacturing of a new Tungsten heavy alloy alternative, Int J Refract Metals Hard Mater 73 (2018) 22–28. [CrossRef]

- Z.-Y. Du, Y.-Q. Lv, Y. Han, J.-L. Fan, L. Ye, Sintering densification behavior and kinetic mechanism of nano-tungsten powder prepared by sol-spray drying, Tungsten 2 (2020) 371–380. [CrossRef]

- Y. Han, J. Fan, T. Liu, H. Cheng, J. Tian, The effect of trace nickel additive and ball milling treatment on the near-full densification behavior of ultrafine tungsten powder, Int J Refract Metals Hard Mater 34 (2012) 18–26. [CrossRef]

- S.M. Thompson, L. Bian, N. Shamsaei, A. Yadollahi, An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics, Addit Manuf 8 (2015) 36–62. [CrossRef]

- T. Karafi, A. Tahiri, H. Chabba, M. Idiri, B. Boubeker, Effect of Grain-Size in Nanocrystalline Tungsten on Hardness and Dislocation Density: A Molecular Dynamics Study, Crystals (Basel) 13 (2023) 469. [CrossRef]

- N. V. Kozyrev, V. V. Gordeev, Thermodynamic Properties and Equation of State for Tungsten, Crystals (Basel) 13 (2023) 1470. [CrossRef]

- C. Wei, L. Liu, Y. Gu, Y. Huang, Q. Chen, Z. Li, L. Li, Multi-material additive-manufacturing of tungsten - copper alloy bimetallic structure with a stainless-steel interlayer and associated bonding mechanisms, Addit Manuf 50 (2022) 102574. [CrossRef]

- V. Griffiths, J.P. Scanlan, M.H. Eres, A. Martinez-Sykora, P. Chinchapatnam, Cost-driven build orientation and bin packing of parts in Selective Laser Melting (SLM), Eur J Oper Res 273 (2019) 334–352. [CrossRef]

- K. Ren, Y. Di, G. Wang, L. Wang, H. Wang, Y. Rong, Forward calculation model for utilization of energy and mass in laser-directed energy deposition, Addit Manuf 68 (2023) 103512. [CrossRef]

- A. Mohammadhosseini, S.H. Masood, D. Fraser, M. Jahedi, Dynamic compressive behaviour of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading, Adv Manuf 3 (2015) 232–243. [CrossRef]

- S.F. Yang, C.W. Li, A.Y. Chen, B. Gan, J.F. Gu, Microstructure and corrosion resistance of stainless steel manufactured by laser melting deposition, J Manuf Process 65 (2021) 418–427. [CrossRef]

- M. Ziaee, N.B. Crane, Binder jetting: A review of process, materials, and methods, Addit Manuf 28 (2019) 781–801. [CrossRef]

- T. Mukherjee, T. DebRoy, A digital twin for rapid qualification of 3D printed metallic components, Appl Mater Today 14 (2019) 59–65. [CrossRef]

- M. Matthews, J. Trapp, G. Guss, A. Rubenchik, Direct measurements of laser absorptivity during metal melt pool formation associated with powder bed fusion additive manufacturing processes, J Laser Appl 30 (2018). [CrossRef]

- R. Enneti, R. Morgan, T. Wolfe, A. Harooni, S. Volk, Direct Metal Laser Sintering (DMLS) of Tungsten Powders, in: Proceedings for Additive Manufacturing with Powder Metallurgy, 2017.

- J. Li, Z. Wei, B. Zhou, Y. Wu, S.-G. Chen, Z. Sun, Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting, Metals (Basel) 9 (2019) 884. [CrossRef]

- Y. Xia, Z. Dong, X. Guo, Q. Tian, Y. Liu, Towards a circular metal additive manufacturing through recycling of materials: A mini review, J Cent South Univ 27 (2020) 1134–1145. [CrossRef]

- P. Gradl, O.R. Mireles, N. Andrews, Introduction to Additive Manufacturing for Propulsion and Energy Systems, in: Propulsion Energy and Forum 2021, 2021.

- A. Sidambe, P. Fox, Analysis of melt pool during the laser powder bed fusion of tungsten, in: RAPDASA 2019 Conference and Exhibition, 2019.

- L.M. Sochalski-Kolbus, E.A. Payzant, P.A. Cornwell, T.R. Watkins, S.S. Babu, R.R. Dehoff, M. Lorenz, O. Ovchinnikova, C. Duty, Comparison of Residual Stresses in Inconel 718 Simple Parts Made by Electron Beam Melting and Direct Laser Metal Sintering, Metallurgical and Materials Transactions A 46 (2015) 1419–1432. [CrossRef]

- J. Xue, Z. Feng, J. Tang, C. Tang, Z. Zhao, Selective laser melting additive manufacturing of tungsten with niobium alloying: Microstructure and suppression mechanism of microcracks, J Alloys Compd 874 (2021) 159879. [CrossRef]

- G.K.L. Ng, A.E.W. Jarfors, G. Bi, H.Y. Zheng, Porosity formation and gas bubble retention in laser metal deposition, Applied Physics A 97 (2009) 641–649. [CrossRef]

- M. Zhong, W. Liu, G. Ning, L. Yang, Y. Chen, Laser direct manufacturing of tungsten nickel collimation component, J Mater Process Technol 147 (2004) 167–173. [CrossRef]

- J. Huang, M. Li, J. Wang, Z. Pei, P. Mclntyre, C. Ma, Selective laser melting of tungsten: Effects of hatch distance and point distance on pore formation, J Manuf Process 61 (2021) 296–302. [CrossRef]

- J. Li, Y. Wu, B. Zhou, Z. Wei, Laser Powder Bed Fusion of Pure Tungsten: Effects of Process Parameters on Morphology, Densification, Microstructure, Materials 14 (2020) 165. [CrossRef]

- J. Dong, S. Liu, H. Chen, D. Li, T. Zhang, C. Chen, K. Zhou, Effect of atmosphere on the microstructure and properties of additively manufactured tungsten, Materials Science and Technology 36 (2020) 1988–1996. [CrossRef]

- A.W. Adamson, Potential distortion model for contact angle and spreading. II. Temperature dependent effects, J Colloid Interface Sci 44 (1973) 273–281. [CrossRef]

- Y. Muramatsu, K. Halada, T. Dan, Y. Isoda, Solid-Liquid Interfacial Tension of the W-Cu System, Journal of the Japan Institute of Metals 54 (1990) 679–684. [CrossRef]

- S. Pan, Z. Guan, G. Yao, J. Yuan, X. Li, Mo-enhanced chemical stability of TiC nanoparticles in molten Al, J Alloys Compd 856 (2021) 158169. [CrossRef]

- C. Wei, H. Gu, Y. Gu, L. Liu, Y. Huang, D. Cheng, Z. Li, L. Li, Abnormal interfacial bonding mechanisms of multi-material additive-manufactured tungsten–stainless steel sandwich structure, International Journal of Extreme Manufacturing 4 (2022) 025002. [CrossRef]

- K. Li, D. Wang, L. Xing, Y. Wang, C. Yu, J. Chen, T. Zhang, J. Ma, W. Liu, Z. Shen, Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix, Int J Refract Metals Hard Mater 79 (2019) 158–163. [CrossRef]

- H. Kurishita, S. Matsuo, H. Arakawa, T. Sakamoto, S. Kobayashi, K. Nakai, H. Okano, H. Watanabe, N. Yoshida, Y. Torikai, Y. Hatano, T. Takida, M. Kato, A. Ikegaya, Y. Ueda, M. Hatakeyama, T. Shikama, Current status of nanostructured tungsten-based materials development, Phys Scr T159 (2014) 014032. [CrossRef]

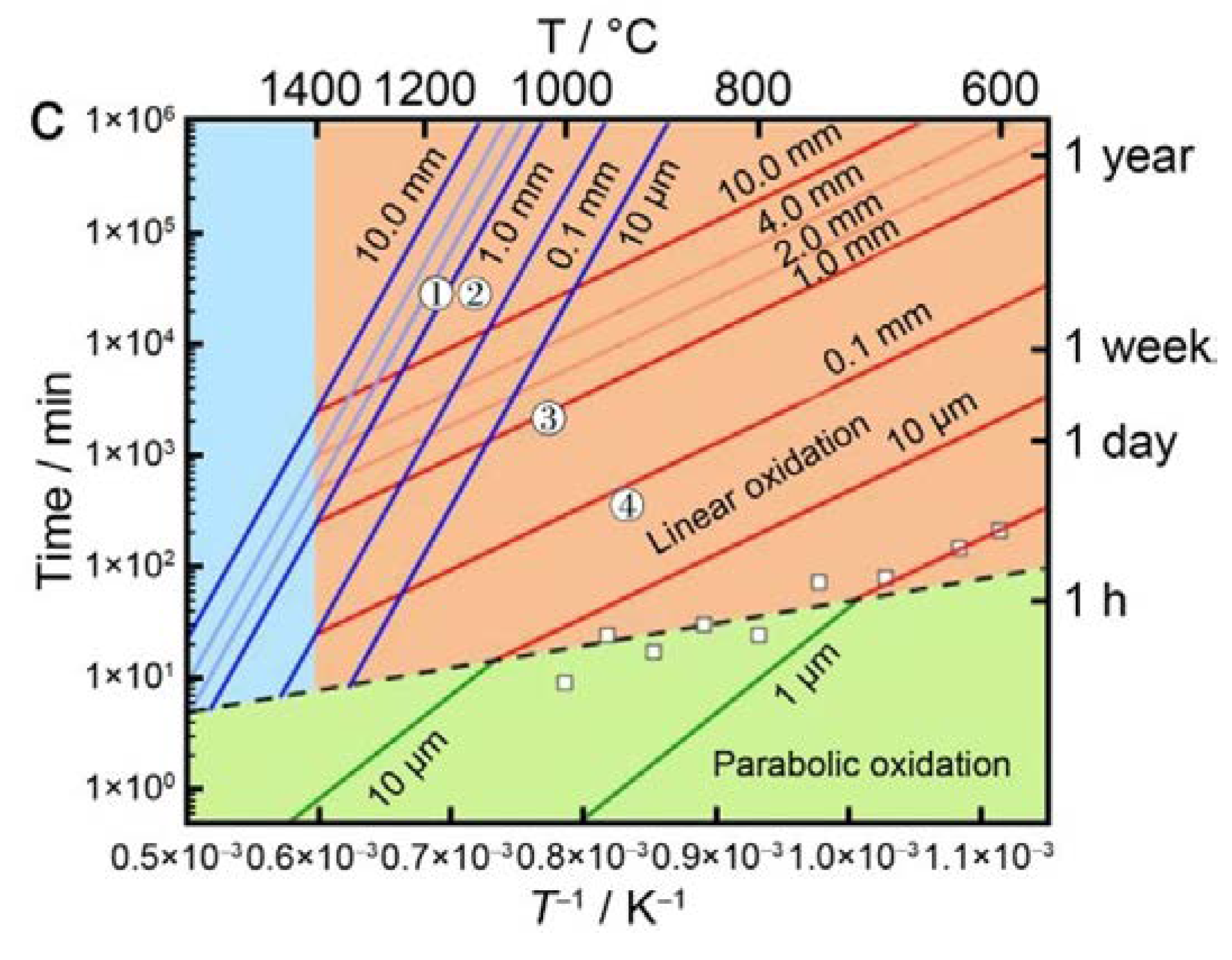

- D. Nagy, S.A. Humphry-Baker, An oxidation mechanism map for tungsten, Scr Mater 209 (2022) 114373. [CrossRef]

- A. Warren, A. Nylund, I. Olefjord, Oxidation of tungsten and tungsten carbide in dry and humid atmospheres, Int J Refract Metals Hard Mater 14 (1996) 345–353. [CrossRef]

- E.M. Savitskii, G.S. Burkhanov, Physical Metallurgy of Refractory Metals and Alloys, Springer US, Boston, MA, 1995. [CrossRef]

- C.C. Eckley, R.A. Kemnitz, C.P. Fassio, C.R. Hartsfield, T.A. Leonhardt, Selective Laser Melting of Tungsten-Rhenium Alloys, JOM 73 (2021) 3439–3450. [CrossRef]

- T. Yamamoto, M. Hara, Y. Hatano, Cracking behavior and microstructural, mechanical and thermal characteristics of tungsten–rhenium binary alloys fabricated by laser powder bed fusion, Int J Refract Metals Hard Mater 100 (2021) 105651. [CrossRef]

- W. Klopp, W. Witzke, P. Raffo, Mechanical properties of dilute tungsten-rhenium alloys, 1966.

- D.Q. Zhang, Z.H. Liu, Q.Z. Cai, J.H. Liu, C.K. Chua, Influence of Ni content on microstructure of W–Ni alloy produced by selective laser melting, Int J Refract Metals Hard Mater 45 (2014) 15–22. [CrossRef]

- D. Zhang, Q. Cai, J. Liu, R. Li, Research on Process and Microstructure Formation of W-Ni-Fe Alloy Fabricated by Selective Laser Melting, J Mater Eng Perform 20 (2011) 1049–1054. [CrossRef]

- A. Iveković, M.L. Montero-Sistiaga, K. Vanmeensel, J.-P. Kruth, J. Vleugels, Effect of processing parameters on microstructure and properties of tungsten heavy alloys fabricated by SLM, Int J Refract Metals Hard Mater 82 (2019) 23–30. [CrossRef]

- Z. Hu, Y. Liu, J. Wu, J. Dong, Z. Ma, Y. Liu, The simultaneous improvement of strength and ductility of the 93W-4.6Ni-2.4Fe prepared by additive manufacturing via optimizing sintering post-treatment, Addit Manuf 46 (2021) 102216. [CrossRef]

- H. Chen, X. Zi, Y. Han, J. Dong, S. Liu, C. Chen, Microstructure and mechanical properties of additive manufactured W-Ni-Fe-Co composite produced by selective laser melting, Int J Refract Metals Hard Mater 86 (2020) 105111. [CrossRef]

- M. Wang, R. Li, T. Yuan, C. Chen, M. Zhang, Q. Weng, J. Yuan, Selective laser melting of W-Ni-Cu composite powder: Densification, microstructure evolution and nano-crystalline formation, Int J Refract Metals Hard Mater 70 (2018) 9–18. [CrossRef]

- A. Yan, Z. Wang, T. Yang, Y. Wang, Z. Ma, Microstructure, thermal physical property and surface morphology of W-Cu composite fabricated via selective laser melting, Mater Des 109 (2016) 79–87. [CrossRef]

- R. Li, Y. Shi, J. Liu, Z. Xie, Z. Wang, Selective laser melting W–10 wt.% Cu composite powders, The International Journal of Advanced Manufacturing Technology 48 (2010) 597–605. [CrossRef]

- G. Wang, Y. Qin, S. Yang, Characterization of laser-powder interaction and particle transport phenomena during laser direct deposition of W‒Cu composite, Addit Manuf 37 (2021) 101722. [CrossRef]

- Z. Zhou, Z. Tan, D. He, Z. Zhou, L. Cui, Y. Wang, W. Shao, G. Wang, Fabrication of three-dimensional connected W-Cu10Sn composites by selective laser melting, Mater Lett 264 (2020) 127377. [CrossRef]

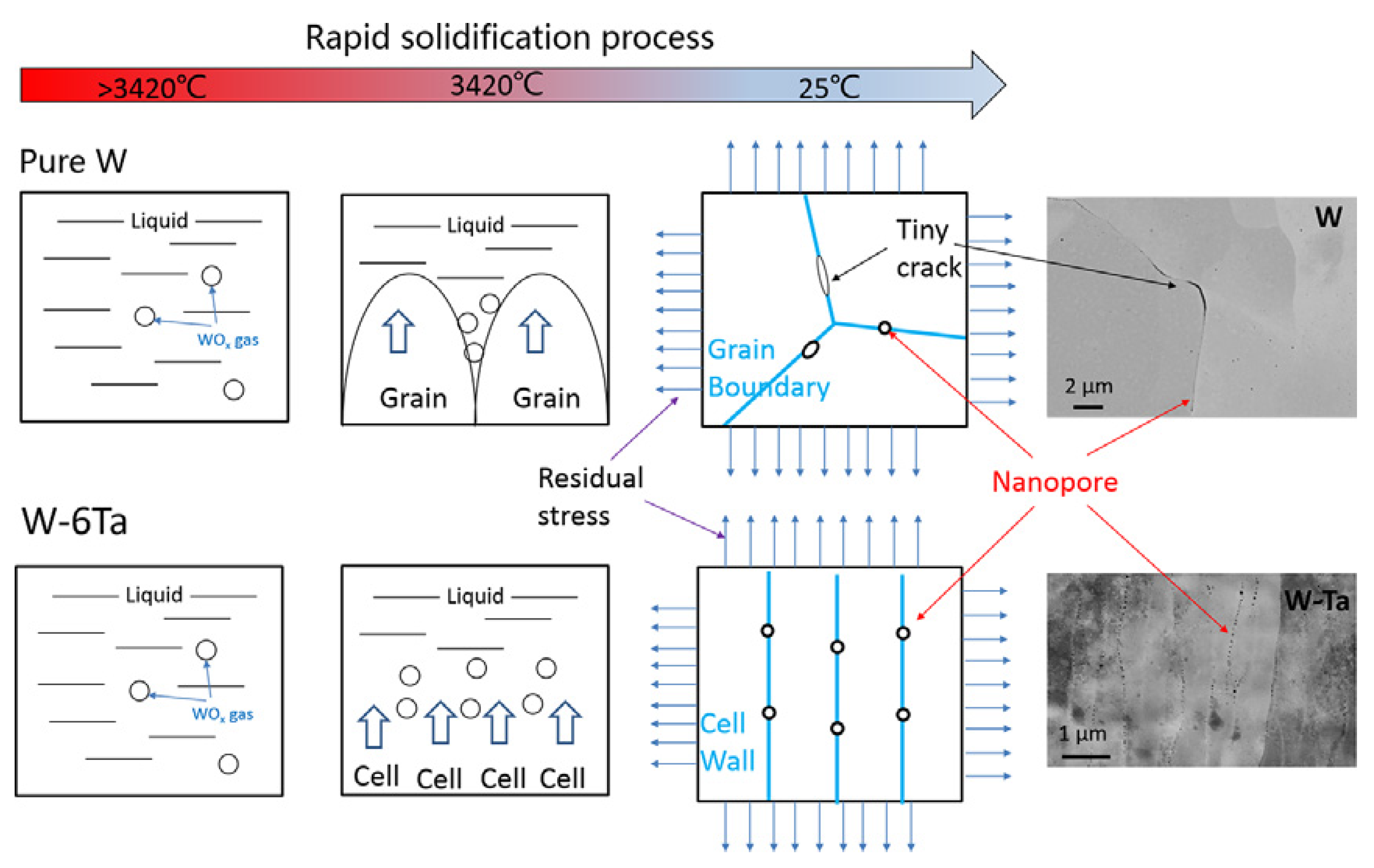

- K. Li, Y. Li, W. Chen, C. Zhao, Y. Yuan, L. Cheng, T.W. Morgan, W. Liu, Z. Shen, Effect of Ta addition on the fuzz formation of additively manufactured W-based materials, Nuclear Fusion 60 (2020) 064004. [CrossRef]

- K. Li, G. Ma, L. Xing, Y. Wang, C. Yu, J. Chen, J. Ma, G. Wu, W. Liu, Z. Shen, X. Huang, Crack suppression via in-situ oxidation in additively manufactured W-Ta alloy, Mater Lett 263 (2020) 127212. [CrossRef]

- Z. Guo, L. Wang, X.-Z. Wang, Additive manufacturing of W-12Ta(wt%) alloy: Processing and resulting mechanical properties, J Alloys Compd 868 (2021) 159193. [CrossRef]

- J. Li, Z. Wei, B. Zhou, Y. Wu, S.-G. Chen, Z. Sun, Preparation, microstructure, and microhardness of selective laser-melted W–3Ta sample, J Mater Res 35 (2020) 2016–2024. [CrossRef]

- B. Xiao, W. Jia, H. Tang, J. Wang, L. Zhou, Microstructure and mechanical properties of a newly developed WTaRe refractory alloy by selective electron beam melting, Addit Manuf 54 (2022) 102738. [CrossRef]

- B. Xiao, W. Jia, J. Wang, L. Zhou, High-temperature mechanical behaviors of a WTaRe refractory alloy manufactured by selective electron beam melting, Int J Refract Metals Hard Mater 116 (2023) 106371. [CrossRef]

- H. Chen, L. Ye, Y. Han, C. Chen, J. Fan, Additive manufacturing of W–Fe composites using laser metal deposition: Microstructure, phase transformation, and mechanical properties, Materials Science and Engineering: A 811 (2021) 141036. [CrossRef]

- Z. Tan, Z. Zhou, X. Wu, Y. Wang, W. Shao, X. Guo, Z. Zhou, Y. Yang, G. Wang, D. He, In situ synthesis of spherical W Mo alloy powder for additive manufacturing by spray granulation combined with thermal plasma spheroidization, Int J Refract Metals Hard Mater 95 (2021) 105460. [CrossRef]

- S. Lang, N. Sun, J. Cao, W. Yu, Z. Yang, S. Hou, Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method, Materials 14 (2021) 5865. [CrossRef]

- D. Gu, D. Dai, W. Chen, H. Chen, Selective Laser Melting Additive Manufacturing of Hard-to-Process Tungsten-Based Alloy Parts With Novel Crystalline Growth Morphology and Enhanced Performance, J Manuf Sci Eng 138 (2016). [CrossRef]

- J. Chen, C. Zhao, K. Li, M. Li, S. Sun, S. Zhang, J. Ma, W. Liu, Effect of TaC addition on microstructure and microhardness of additively manufactured tungsten, J Alloys Compd 897 (2022) 162978. [CrossRef]

- N.C. Cole, R.G. Gilliland, G.M. Slaughter, Weldability of tungsten and its alloys, in: American Welding Society 49th Annual Meeting, 1968.

- A. Bose, R.M. German, Microstructural refinement of W-Ni-Fe heavy alloys by alloying additions, Metallurgical Transactions A 19 (1988) 3100–3103. [CrossRef]

- A. Luo, D.L. Jacobson, K.S. Shin, Solution softening mechanism of iridium and rhenium in tungsten at room temperature, Int J Refract Metals Hard Mater 10 (1991) 107–114. [CrossRef]

- Y.K. Wang, Z.M. Xie, M.M. Wang, H.W. Deng, J.F. Yang, Y. Jiang, T. Zhang, X.P. Wang, Q.F. Fang, C.S. Liu, The superior thermal stability and tensile properties of hot rolled W-HfC alloys, Int J Refract Metals Hard Mater 81 (2019) 42–48. [CrossRef]

- T. Leonhardt, Properties of tungsten-rhenium and tungsten-rhenium with hafnium carbide, JOM 61 (2009) 68–71. [CrossRef]

- Ren, Z.Z. Fang, M. Koopman, B. Butler, J. Paramore, S. Middlemas, Methods for improving ductility of tungsten - A review, Int J Refract Metals Hard Mater 75 (2018) 170–183. [CrossRef]

- Calvo, K. Schlueter, E. Tejado, G. Pintsuk, N. Ordás, I. Iturriza, R. Neu, J.Y. Pastor, C. García-Rosales, Self-passivating tungsten alloys of the system W-Cr-Y for high temperature applications, Int J Refract Metals Hard Mater 73 (2018) 29–37. [CrossRef]

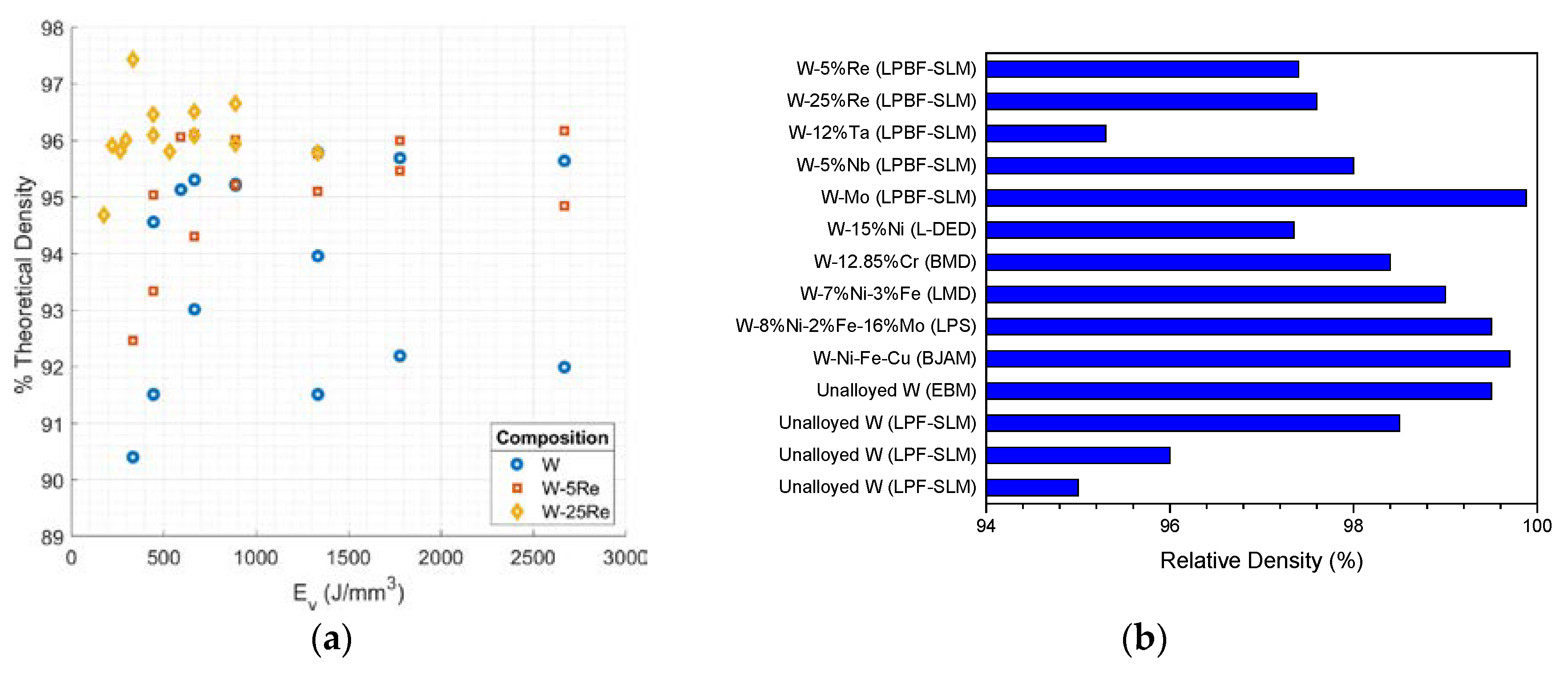

| AM Process | Energy (W) | Beam Size (µm) | Scan Speed (mm/s) | Temperature Gradient (°C/mm) | Cooling Rate (°C/s) | Relative Density (%) | Remark |

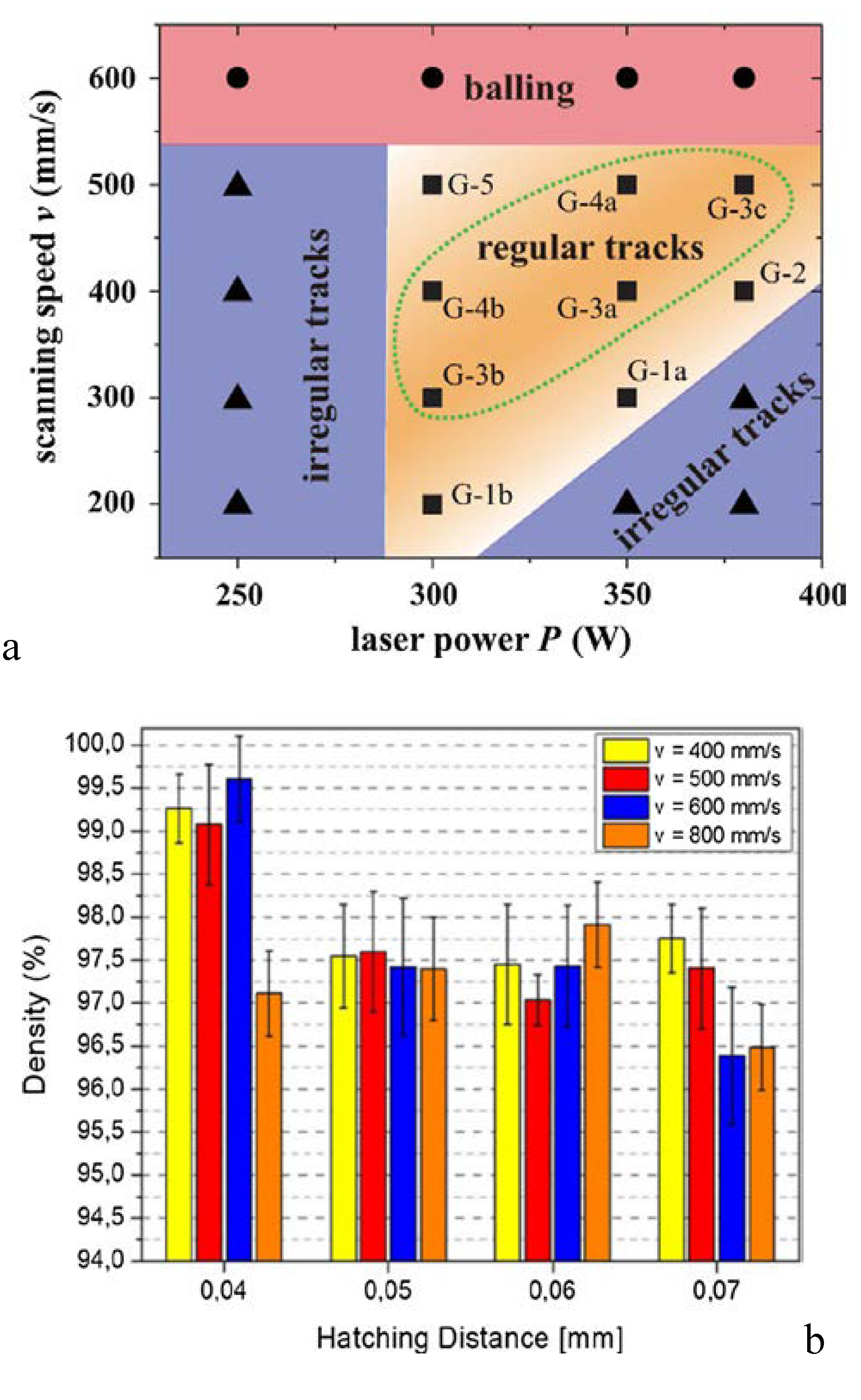

| LPBF- SLM | 102-103 (normally below 1000 [79,80,116]) | 30-200 [80,116] | 10-103 [116] | 106-107 [80,116] ; | 105-107 [80,116] | 95 [66,73] and max. ~98.71 [49] | A general processing window exists for SLM-fabrication of W (Figure 4b [36]). Laser techniques, like femtosecond fiber laser, are advantageous for AM of W [37]. The double melt strategy improves W densification in LPBF [65]. SLM can be merged with other processes, e.g., infiltration, for W-based materials [38]. |

| L-DED | 102-104 [91,116] (normally between 600-4000 [80]) | 102 -103 [80,116] | 10-102 [80,116] | 104-106 [80,91,116] | 102-105 [116], mostly on the order of 104 °C/s [38] | More than 99 for W [26]: even higher for W alloys [50] | In L-DED, the relationship between molten pool size and powder flow is crucial (Figure 5b, d) [28]. Increased laser energy widens the molten pool, but if the molten pool exceeds the flow of the powder, it can result in the reduction in the percentage of W entering [26]. L-DED surpasses EBM and LPBF in fabricating larger parts [26]. |

| EBM | 102-103 [80,116] (Normally more than 1000W up to 3000 W [51,79,82] but can be as high as 6000 | 102 -103 [80,116] | 10-103 [116] | 103-104 [80,91,116] | ~99.5 in W [51] | EBM requires a high vacuum level post He/N2 purge due to electron travel [51,82]. The EBM processing window is depicted using scanning speed and current (or current density) in Figure 4a [51,79]. EBM, with appropriate preheating, can address cracking issues in AM for W materials [51,80,81]. EBM-fabricated W show promising results [51,79,81]. EBM has been adapted for W surface treatment to enhance quality, due to its controlled beam size and thermal influence on parts [88]. |

|

| LMD (Laser melting Deposition) | 102-103 [91,96] | 103 [91,96] | 10-103 [96] | less than L-PBF-SLM | 103-104 [80,96] | 99 [91] to Nearly 100 [97] for WHA | LMD provides comparatively large melt pools (on the order of several millimeters) versus SLM (on the order of 100 µm). [91,96] LMD’s larger melt pools and slower cooling rates [96,116] aid in W particle organization and decrease porosity [92,93,94,95] |

| BJ (Binder Jetting) | 99.7 for WHA [98] | Uses a flowable powder and polymer adhesive on a build platen, with successive layers bound together, then cured in an oven before post-processing. This technique enables the creation of intricate designs [98,99,100,101,102] |

| Factor/Parameter | Details/Effects | References |

|---|---|---|

| Contaminants in AM | Oxygen, nitrogen, hydrogen | [36,134,135,136] |

| Adverse Effects | - Embrittlement - Shifts in DBTT - Strength reduction - Cause cracking especially at high angle grain boundaries |

[36,40,134,135,136] |

| Sources of Oxygen in W Materials | - Oxidized powder surface - Residual oxygen in the chamber - Substrates due to high thermal energy inputs |

[38,68] |

| Oxygen Sensitivity in W Materials | - Molten W is sensitive to oxygen - Oxide layer formation (1 nm thick within an hour) - Potential for intergranular cracking upon cooling |

[67,82,137,138] |

| Oxygen Control Techniques in AM | - Higher beam power - Enhanced volumetric energy density - Radio frequency induction plasma treatment |

[45,82] |

| Material Design for Reduced Oxygen Sensitivity | Introduction of alloying elements such as Ta to W | [67] |

| Important Studies and Findings | Oxidation mechanism map for AM applications exists | [136] |

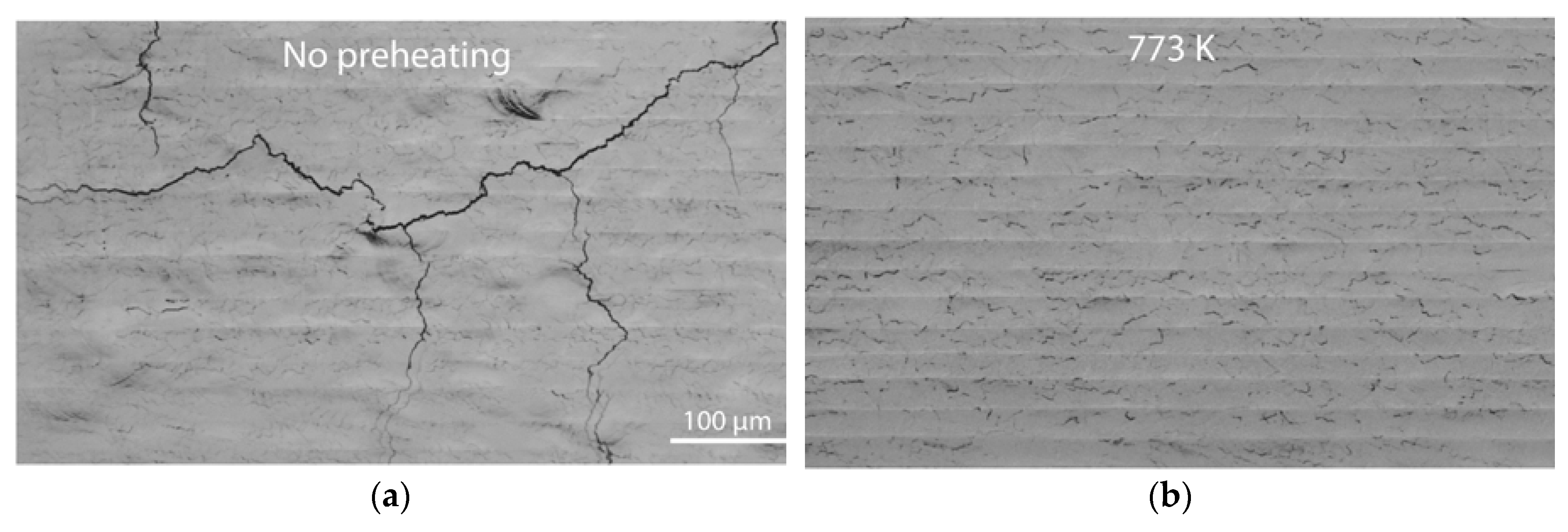

| Preheating Effects | Information/Description | Reference |

|---|---|---|

| Purpose | Used before the process to enhance AM results | |

| Benefits | ||

| - Mitigation of Stress | Reduces built-up thermal stresses | [118] |

| - Melt Pool Dynamics | Controls cooling rate and thermal gradient during solidification | |

| - Delay/Avoidance of DBTT | Delays or prevents DBTT, crucial for materials with a high DBTT like W | [63] |

| - Annealing Effect | Simulates the annealing process, refining W microstructure | [123] |

| - Enhanced Density & Reduced Microcracks | Increases part density and reduces microcrack formation, especially with preheating up to 1000°C in SLM, and more in EBM | [38,82] |

| Optimal Preheating Range | ||

| - Observation | Low preheating temperatures below 400°C are insufficient for microcrack mitigation of W materials | [32,51] |

| - General Findings | Higher preheating temperatures minimize high DBTT effects and enhance mass density of additively manufactured W parts | [38] |

| Drawbacks of Excessive Preheating | ||

| - Recrystallization | Extremely high temperatures trigger recrystallization in material | [82] |

| - Grain Vulnerabilities | Larger recrystallized grains are prone to intergranular cracking, acting as pathways for cracks near grain boundaries | [79,135] |

| - Counter-productiveness | Very high preheating temperatures can be counterproductive | [79,82] |

| Materials | References |

|---|---|

| W Alloys | |

| W-1-25%Re | [140,163] |

| W-0.1-40%Ni | [94,142] |

| W-7%Ni-3%Fe | [91,92,95,97,98,101,103,119,143,144] |

| W-4.6%Ni-2.4%Fe | [145] |

| W-6%Ni-2%Fe-2%Co | [146] |

| W-12%Ni-4%Fe-4%Co | [146] |

| W-18%Ni-6%Fe-6%Co | [146] |

| W- 8.7%(Ni-Fe-Cu) | [98] |

| W-5%Ni-15%Cu | [27] |

| W-5%Ni-25%Cu | [147] |

| W-10%Ni-10%Cu | [147] |

| W-10%-40%Cu | [28,30,148,149,150] |

| W-20%(Cu10Sn) | [151] |

| W-1-12%Ta | [32,152,153,154,155] |

| W-14.8%Ta-17.2%Re | [156,157] |

| W-5%Nb | [124] |

| W-14-79%Fe | [93,158] |

| W-50%Mo | [159] |

| W-12.85%Cr | [104] |

| W Matrix Composites | |

| W-0.5-2.5%TiC | [160,161] |

| W-0.5%ZrC | [134] |

| W-5%TaC | [162] |

| W-5%La2O3 | [63] |

| W-2%CeO2 | [63] |

| W-1.75%La2O3-0.12%ZrO2-0.12%Y2O3 | [63] |

| Y2O3 | [61,80] |

| Effects on W in AM | Alloying Element(s) | Specifics/Notes | Ref |

|---|---|---|---|

| Enhanced Densification | Ni, Fe, Co, Mo, Re, Ta, etc. | Due to lower melting points of alloying phases promote densification. For SLM, the melting of Ni, Fe and Co enhances dissolution of W particles. |

[38,60,94,104,142,146,147,148,149,150] |

| Cu | Due to role of alloying elements in forming binding phases. Good wetting allows the molten copper (Cu) to spread and adheres strongly to the W particles. Surface smoothing also contribute to a denser final structure | [28,30] | |

| Ni, Cu, Ta, Fe, Mo | Modifications in laser absorption, melt viscosity, and fluidity. Ni works better than Cu. Ta Increases recrystallization temperature and decreases thermal conductivity. Ni, and Fe for improved wettability of W. |

[28,30,32,94,142,147,148,149,150,152,153,154,155] | |

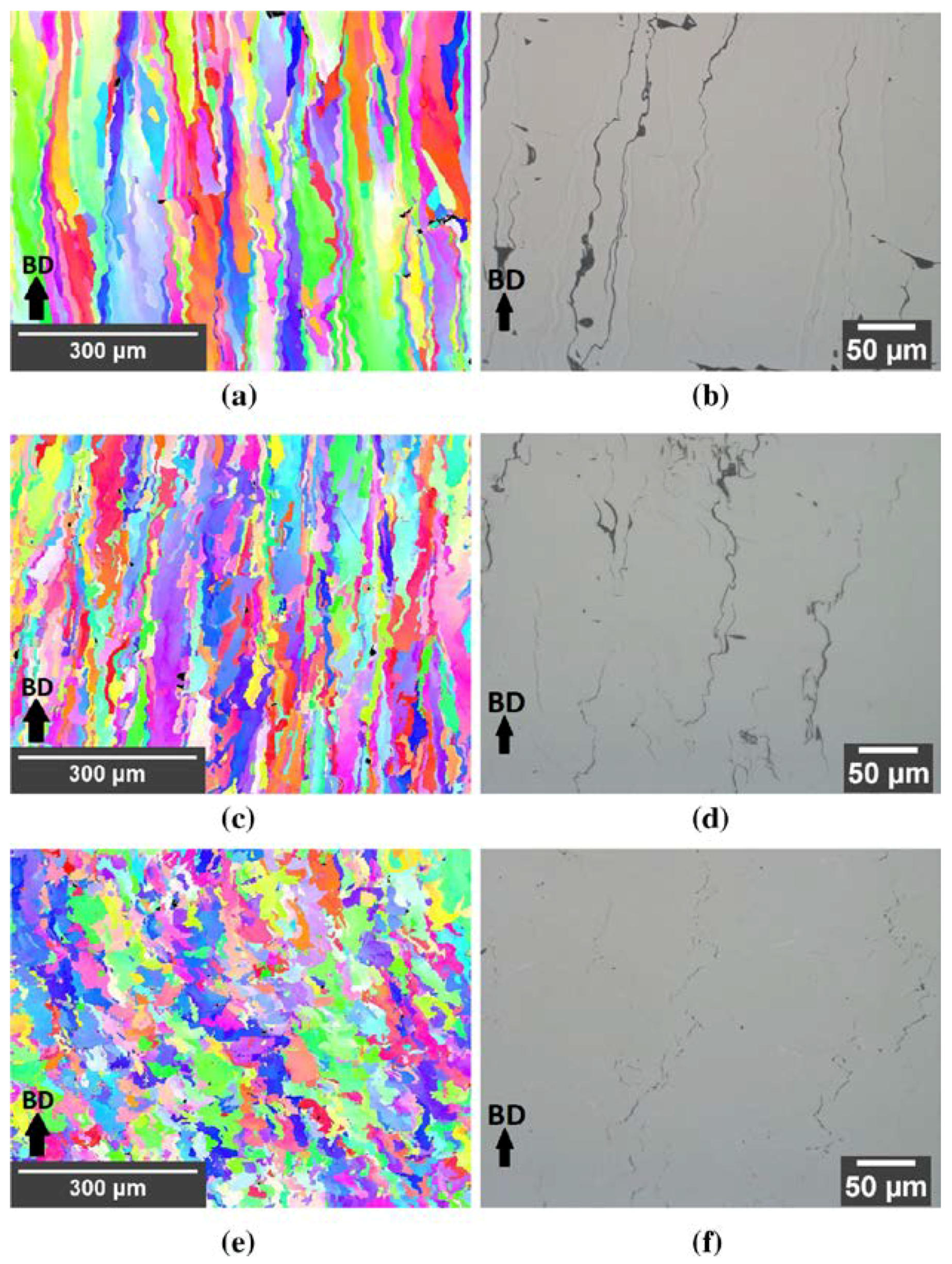

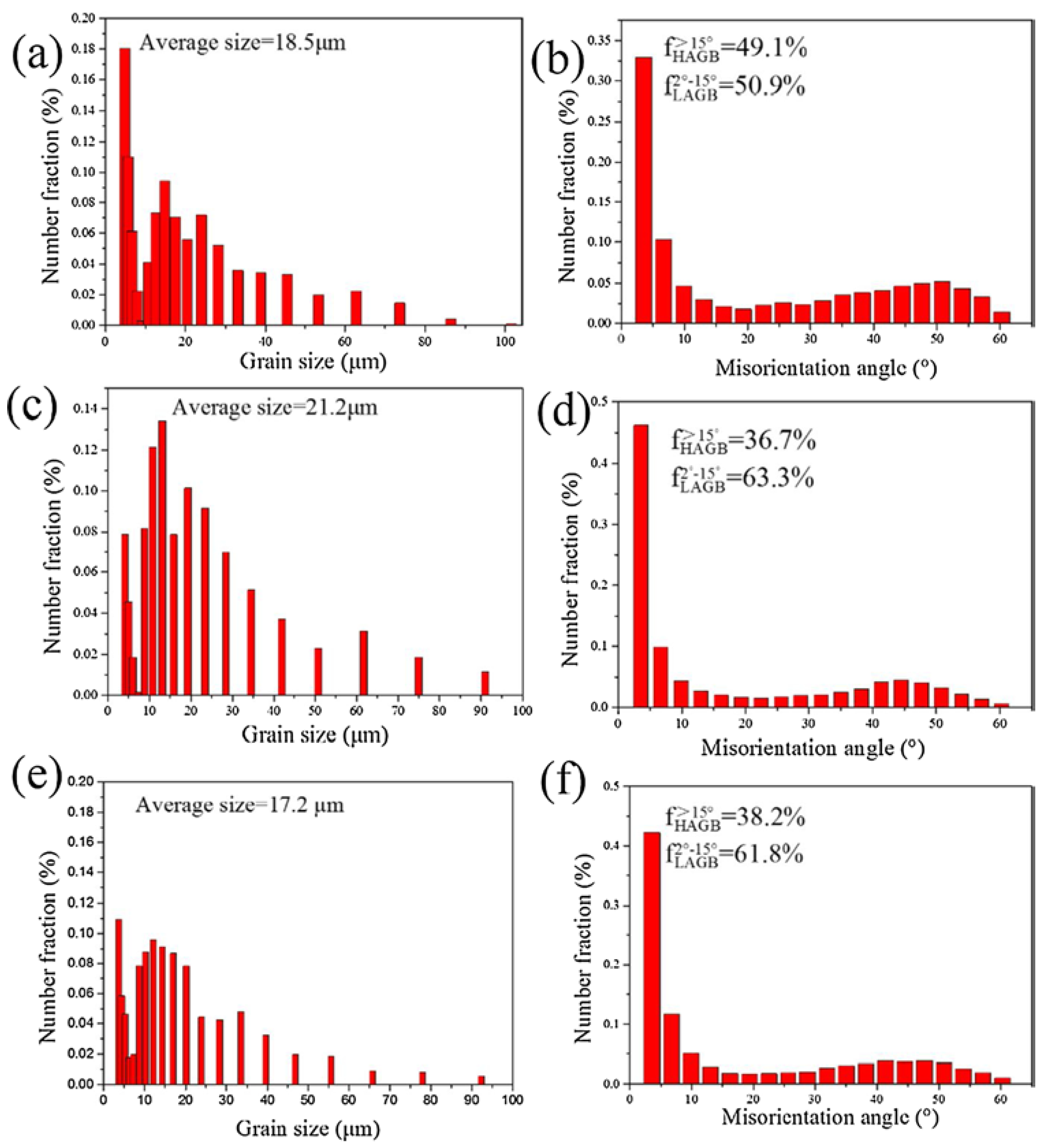

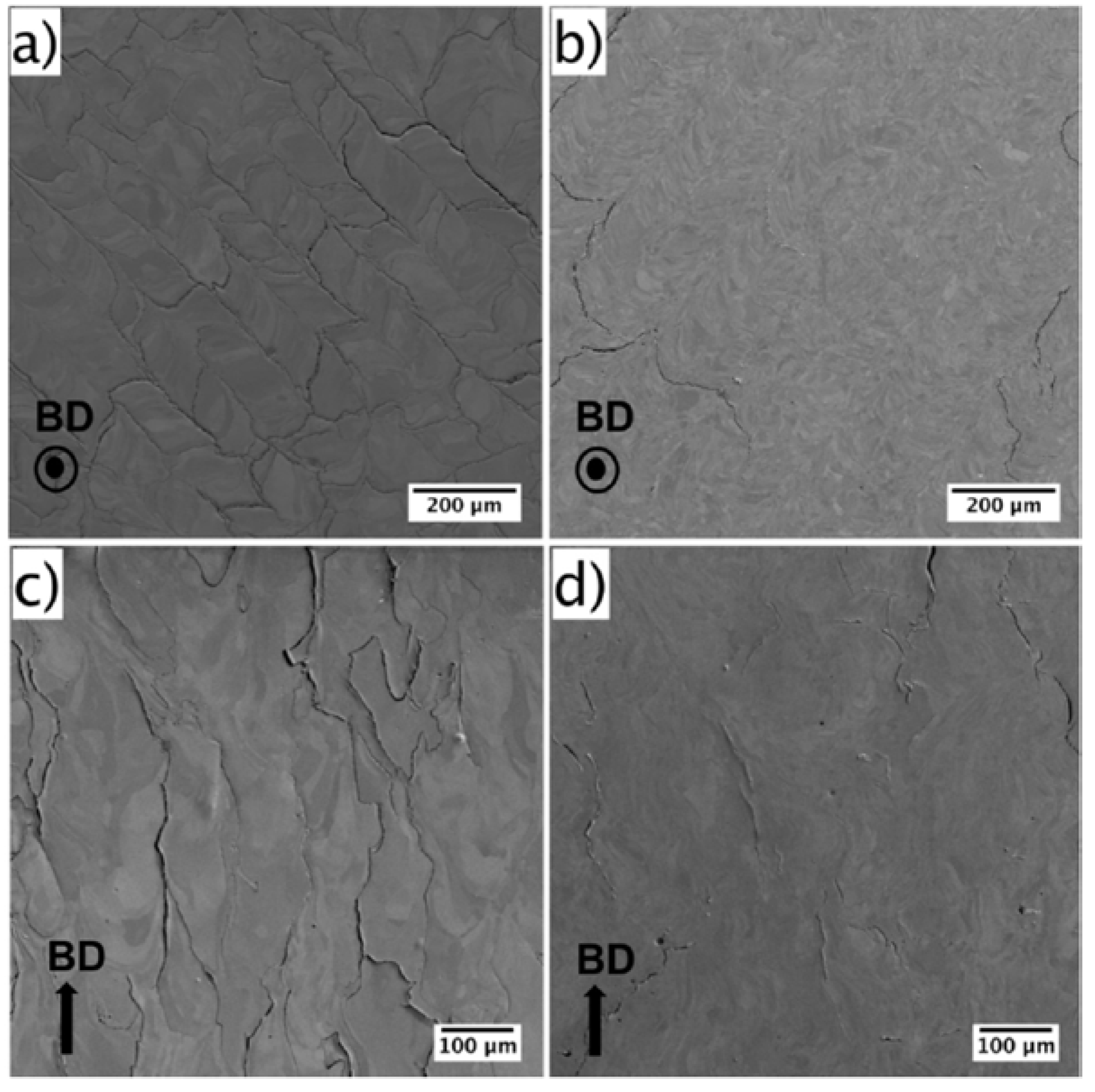

| Microcrack Mitigation | Re, Ta, Nb, Mo, Cr, Ti , Ir | Re lowers the DBTT of tungsten alloys, significantly reduce their tendency to crack during AM processes. Ta forms a special cellular structure that keeps tiny air pockets (nanopores) separated from each other. This reduces the overall tendency of the material to crack. Ta also oxidizes more easily than tungsten (W) during the printing process. As a result, fewer nanopores form in the final tungsten alloy, and the risk of microcracks is reduced. Nb improves the intergranular bonding of the alloy via solid solution strengthening. Adding certain elements (alloying) to tungsten can be a powerful tool to prevent the formation of tiny cracks (microcracks) during 3D printing. Tungsten’s high melting point presents a challenge. It solidifies first, causing stress within the material. Alloying elements help to lessen this stress by essentially acting as a buffer. Grain refinement of W, Improved grain boundary strengthening, modified grain structure, better pore distribution. Cr forms Cr-rich Cr-W phase and causes grain refinement. Ti (in conventional manufacturing of W) gives rise to a heterogeneous chemical distribution to prevent nanostructured microstructure from coarsening Ir (in conventional manufacturing of W) strengthens grain boundary cohesion, optimizes dislocation mobility, and reduce cracking. |

[28,63,67,104,124,139,140,141,153,154,155,156,164,165] |

| Re | Enhancement of grain boundary cohesion Boosting dislocation mobility and lowering DBTT, reducing embrittlement W when alloyed with rhenium (Re) showcases a reduced DBTT and increased low-temperature ductility. This improvement is attributed to rhenium’s high solubility in tungsten and its capability as a solution hardener |

[139,140,141] | |

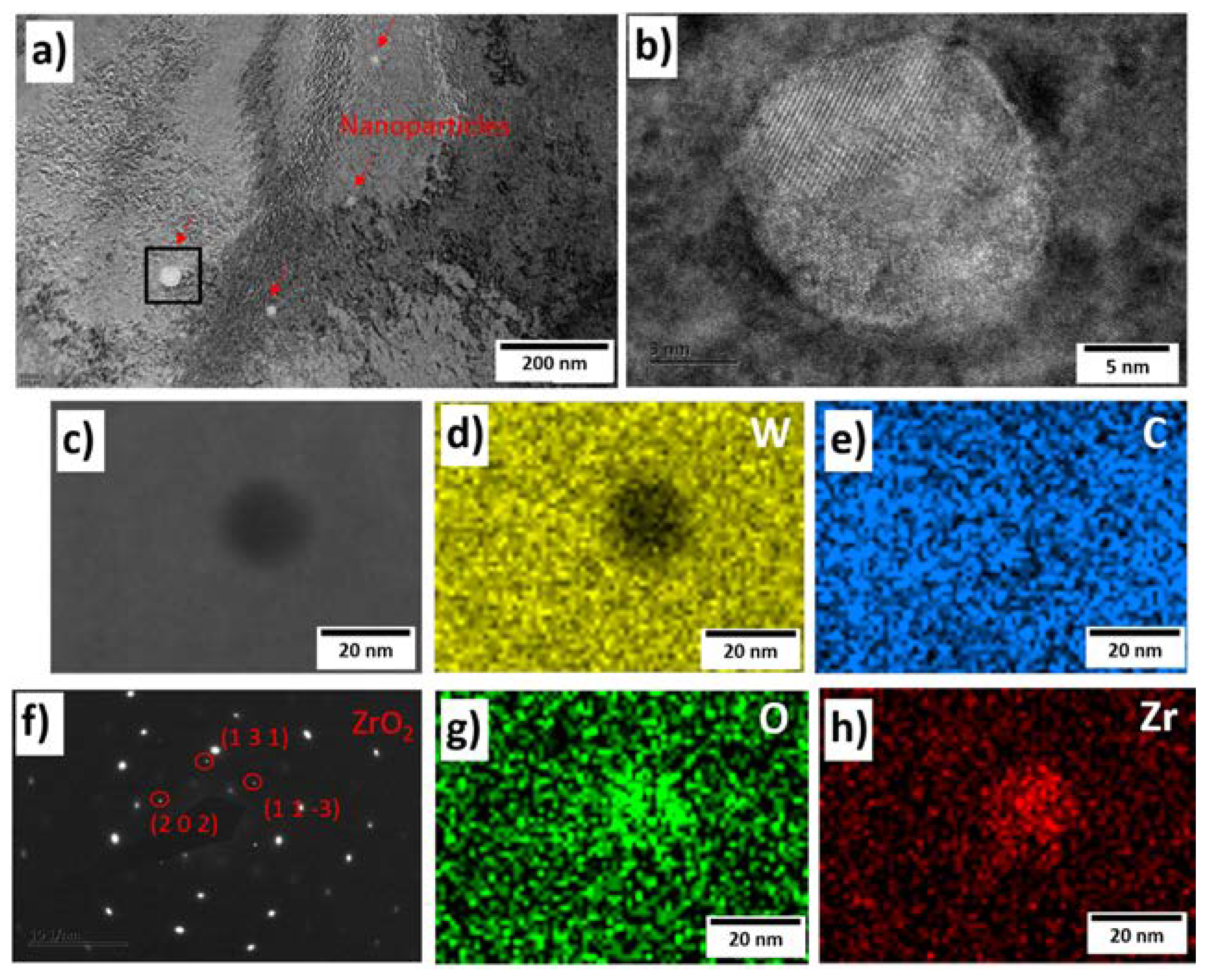

| TiC, ZrC, TaC, Y2O3, La2O3, etc. | Y2O3 Oxide leads to more low-angle grain boundaries (LAGBs) and reduces cracking. W–Y2O3 has 3.6 μm grain size and better low-temperature ductility and supress cracking. the integration of lanthanum oxide (La2O3) not only bolsters radiation resistance but also provides an indirect solution to these interstitial contamination challenges. Incorporating ZrC nanoparticles decreases crack density due to finer grains and increased grain-boundary length. ZrC also captures oxygen to form ZrOy, reducing embrittlement. TaC supports the formation of W2C phases within the material, further increase the overall strength and crack resistance. TaC reacts with any oxygen present, forming TaOx, effectively removing oxygen from the system. TiC enhances hardness. |

[61,66,134,153,162] | |

| Mechanical Properties Adjustments |

Fe | Strengthening by formation of secondary or precipitated phases during AM. The non-equilibrium solidification between Fe and W allows for the potential formation of intermetallic phases like Fe7W6 and Fe2W, improving the hardness. | [93,156,158] |

| Ni | Tensile strength and fracture toughness enhancement | [94,142] | |

| Ti, Ir, Hf (if used in AM) | Increase recrystallization temperatures. As potent carbide formers mitigate the adverse effects of carbon impurities on the alloy’s mechanics, Elevate the recrystallization temperatures and improve W’s low temperature ductility and high temperature strength. Ir can improve mechanical properties by increasing grain boundary cohesion. |

[164,165,166,167,168] | |

| Ta, Nb, and other group V and IV transition metals | Improvement of Intrinsic ductility of W alloys Ta can increase hardness. Solid solution strengthening by Nb |

[124,153,154,155,156] | |

| Others | Ta | Fuzz Formation Reduction: fuzz reduction during He plasma irradiation; suitable for nuclear applications. | [152] |

| Cr-Y | Self-passivation behavior for high-temperature applications | [169] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).