1. Introduction

Injuries on duty (IOD) are defined as any unintentional occurrences of personal injury, death, or disability due to exposure in the workplace at specific dates, times, and places arising during the employee's employment [

1]. Injuries on duty pose a major public health and development problem in workplaces, and most workers prone to injuries on duty are those who work on farms, such as those who process chicken, or in agriculture, as their duties involve frequent use of knives and scissors, as well as machine operators and assemblers. The South African Department of Labour's regulations under the Occupational Health and Safety Act 85 of 1993 stress that employers must protect the health and safety of their workers as a proactive attempt by the government to provide and maintain a safe and healthy work environment for all, preventing unnecessary injury or illness due to injuries in the workplace [

1].

Globally, a lack of statistics on workplace injuries among employees in various industries was found, indicating that health and safety were not a priority for businesses and legislators in the past [

2]. Work-related accidents have the highest financial effects on the organization since they reduce productivity and necessitate spending money on the injured worker's medical care [

3]. This indicates that fatigue-related workplace accidents continue to be a problem on a global scale [

3]. Injuries on duty are often separated into two groups: reportable cases and non-reportable cases. Reportable cases are those that may result in disability or death like contusion or sprain, while non-reportable cases are minor injuries like paper cuts where the employee does not need to take time off from work and can be managed by first aiders at work [

4]. A report provided by the South African Poultry Association (SAPA) suggests that in 2020, 18% of the total agricultural gross value and 41% of animal product gross value came from poultry production, and it is estimated that the industry provides direct and indirect employment to over 110 000 people, which makes it the second largest consumer after maize [

5].

Poultry processing is the largest sector of the meat products industry, which is characterized by rapid line speeds and extreme division of labor [

6]. Furthermore, morbidity associated with the impact of workplace safety environments in this industry is growing fast [

6]. The employees who feel their workplace is safe are more likely to perform better than those who feel unsafe [

7]. According to United States Occupational Safety and Health Act 37 of 1970, the employer must take measures to protect his or her workers' health and safety against hazards that may result from the production, processing, use, handling, storage, or transportation of articles or substances [

8].

The likelihood of injuries occurring while working is linked to work experience, fatigue, health status, and a lack of ongoing formal induction or health talks. Generally, more experienced workers tend to have a better understanding of safety protocols and potential hazards, which can reduce their risk of injury. However, [

9] suggests that overconfidence can also set in with experience, leading to a higher likelihood of accidents. Additionally, certain job roles inherently carry higher risks, regardless of experience level [

9]. Fatigue, health status, and a lack of continued formal training have been linked to an increased risk of occupational injuries [

10]. Fatigue can impair cognitive function and physical coordination, making workers slower to react to hazards and prone to mistakes due to decreased concentration. Workers with underlying health concerns may be more susceptible to injuries because they have limits that enhance the risk of specific tasks. Poor health can also affect reaction times and physical capabilities, further elevating the risk of accidents. Additionally, the absence of regular training and updates on safety procedures can lead to worker complacency and ignorance of new hazards, exacerbating the likelihood of accidents [

10].

Occupational health and safety are a shared responsibility among various stakeholders; this includes government entities, industries across sectors, privately owned companies, and all individuals concerned with the well-being of their employees. This study is especially significant since it addresses a key knowledge gap about workplace injuries among general workers at a poultry processing farm in the Western Cape, South Africa. Understanding the extent of this issue is important for identifying workplace health and safety hazards, risks, and threats.

This study sought to identify predictors of workplace injuries among general workers at chicken processing farms in the Western Cape, South Africa. Furthermore, the study explored prominent forms and causes of injuries, analyzed demographic features linked with higher risk, and evaluated occupational hazards.

3. Results

3.1. Demographic Characteristics Associated with Injuries on Duty

The study investigated demographic characteristics to determine whether there is a relationship between injuries on duty and the level of education, gender, age, and work experience. Workers with matriculation or below education level had more injuries compared to undergraduates and postgraduates.

Table 1 indicates that females reported more injuries on duty than males.

The study shows that workers with three or more years of experience had more injuries compared to workers with less than two years of experience. Furthermore, statistics analysis on the probability of injuries on duty concerning demographic factors, including gender, level of education, age, and work experience, was conducted as shown in

Table 2.

3.2. Prevalence, Type, and Cause of the Injuries on Duty

Among the reported injuries, abrasions were the most common type, with n = 70 (16.7%), followed by punctures with n = 45 (10.7%). The primary causes reported by workers were cuts, accounting for 40 (30%) cases, and slips and falls, comprising 50 (37%) cases). The study's findings highlight that the most affected body parts were fingers, with n = 39 (27%), and hands, with n = 27 (19%). Abrasions (n = 70, 16.7%) and punctures (n = 45, 10.7%) ranked prominently among the identified injuries, as shown in

Table 3.

3.3. Association between Demographic, Organisational Factors, and Work-Related Injuries

In response to the section on "Causes of Injuries on Duty," the table reveals that slip-and-fall incidents (n = 50, 36%) were the most reported cause of injuries on duty. These incidents are frequently linked to wet floors in the processing farm environment. This finding shows the importance of implementing thorough safety measures and emphasizes wet floors as a significant hazard, indicating the need for the chicken processing farm to adopt mitigation strategies. Analyzing the section on "Body Parts Affected by Injuries," the researcher aimed to gain a thorough understanding to develop specific recommendations for reducing and preventing injuries. The results showed that fingers (n = 39, 27%) and hands (n = 27, 19%) were the most affected body parts. This prevalence can be linked to the types of tasks carried out by employees, which heavily involve the use of upper limbs for activities such as cutting and transferring meat between stations.

The analysis for “working hours” revealed a significant association between hours worked and back injuries (Pearson Chi-Square = 14.715, df = 2, p = 0.001). Specifically, employees working over 40 hours were more likely to experience back injuries compared to those working 40 hours or less (215 vs. 35, respectively). There was a statistically significant relationship between hours worked and puncture wounds (Pearson Chi-Square = 7.536, df = 2, p = 0.023). Employees working over 40 hours were more prone to puncture injuries compared to their counterparts working 40 hours or less (198 vs. 28, respectively). Similarly, a significant association was observed between hours worked and abrasions (Pearson Chi-Square = 9.956, df = 2, p = 0.007). Employees working more than 40 hours were more susceptible to abrasions compared to those working 40 hours or less (180 vs. 34, respectively).

The analysis did not reveal a substantial correlation between the number of hours worked and incidents of slips and falls (Pearson Chi-Square = 2.217, df = 2, p = 0.33). Both groups, comprising individuals working over 40 hours and those working 40 hours or fewer, demonstrated similar frequencies of slips and falls. However, the study did identify a noteworthy connection between hours worked and instances of being hit by objects (Pearson Chi-Square = 10.514, df = 2, p = 0.005). Employees working over 40 hours were more prone to being struck by objects compared to those working 40 hours or fewer (219 vs. 35, respectively).

3.4. Level of Education and Injuries on Duty

The analysis explored the relationship between the level of education and the occurrence of injuries among workers in chicken processing farms. There was no statistically significant association found between the level of education and the occurrence of abrasions (Pearson Chi-Square = 0.79, df = 2, p = 0.674). Both employees with a matriculation and below education level and those with an undergraduate education level exhibited similar rates of abrasions. However, a statistically significant relationship was observed between the level of education and finger injuries (Pearson Chi-Square = 7.145, df = 2, p = 0.028). Workers with a matriculation and below education level were more likely to suffer from finger injuries compared to their counterparts with undergraduate education (252 vs. 19, respectively), and finally the results showed no significant association between the level of education and slips and falls (Pearson Chi-Square = 0.229, df = 2, p = 0.892). Both educational groups demonstrated similar rates of slips and falls.

3.5. Personal Protective Equipment and Injuries on Duty

There is no statistically significant association found between the frequency of PPE usage and the occurrence of abrasions (Pearson Chi-Square = 1.377, df = 1, p = 0.241). Both employees who reported using PPE all the time and those who used it sometimes exhibited similar rates of abrasions. Similarly, no statistically significant association was found between the frequency of PPE usage and the occurrence of slips and falls (Pearson Chi-Square = 3.008, df = 1, p = 0.083). Although there seems to be a trend indicating fewer slips and falls among those who use PPE all the time, the association did not reach statistical significance, and lastly, no statistically significant association was found between the frequency of PPE usage and the occurrence of finger injuries (Pearson Chi-Square = 0.023, df = 1, p = 0.632). Both employees who reported using PPE all the time and those who used it sometimes demonstrated similar rates of finger injuries.

3.6. Working Conditions, Job Satisfaction, Safety Culture Perception and Injuries on Duty

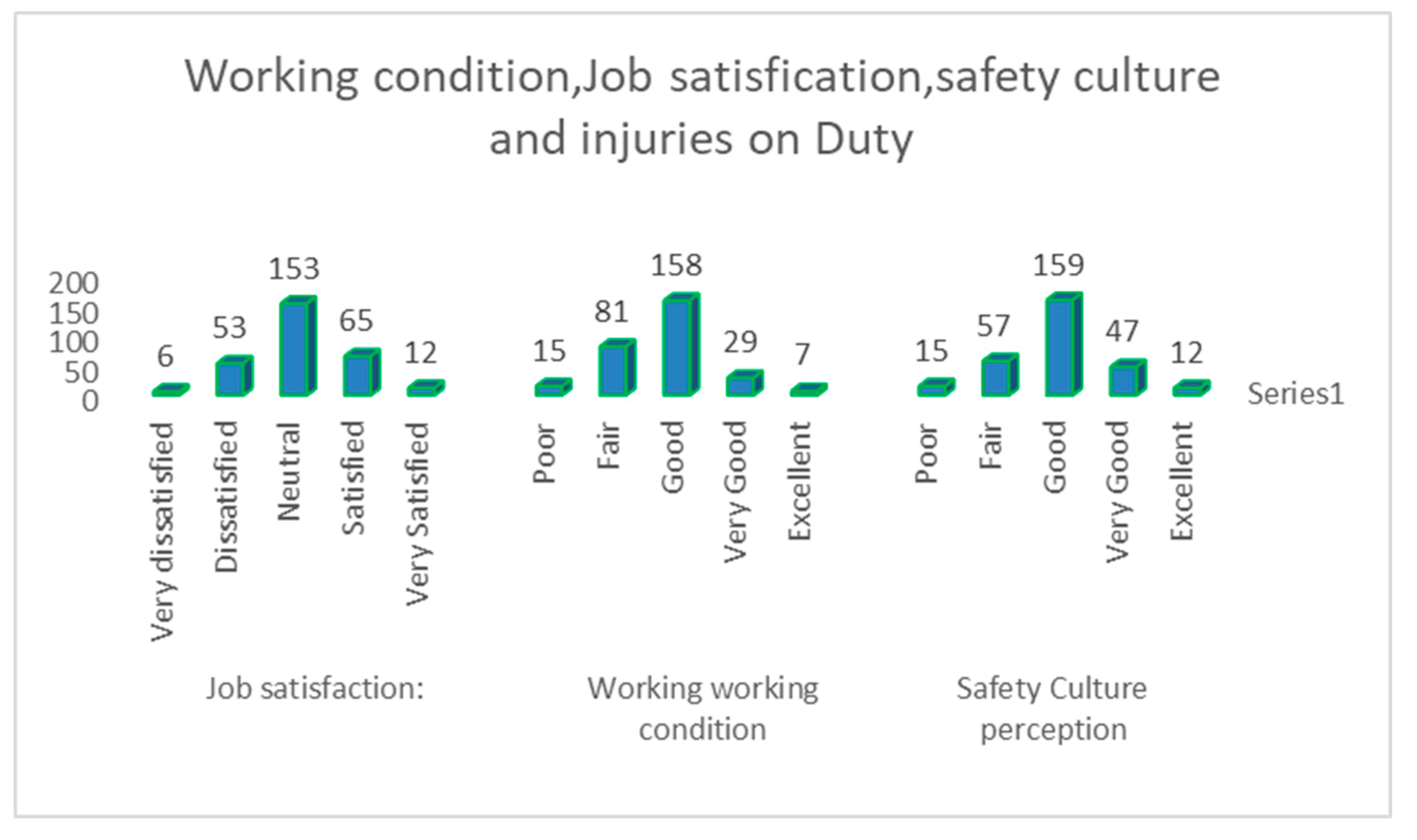

The study evaluated frequency distribution for injuries on duty in relation to working conditions such as work schedule, job satisfaction and working environment (

Figure 1).

The study could not find the association between the injuries and the safety culture, job satisfaction and work schedule as presented in

Table 4 below.

The relationship between stress levels and on-duty injuries was investigated through thorough analysis using the Pearson correlation test. The analysis was broken down into three categories: 3-6 months, 6-12 months, and 12-36 months spanning the years, 2021 to2023 in order to get detailed information regarding the stress levels at work and at home and analyse hazards at that specific time. The Pearson Correlation test was conducted to determine the correlation between high prevalence injury type, causes of injuries on duty and occupational stress (

Table 5).

4. Discussion

Poultry processing is the largest sector within the meat products industry, characterized by high line speeds and extensive division of labor [

6]. Furthermore [

6], state that morbidity resulting from workplace safety issues in this industry is rapidly increasing. The employees who perceive their workplace as safe are more likely to perform better compared to those who feel unsafe [

7]. In accordance with the United States Occupational Safety and Health Act 37 of 1970, employers are obligated to take measures to protect their workers' health and safety from hazards arising from the production, processing, use, handling, storage, or transportation of articles or substances [

8].

Occupational health and safety is a fundamental practice that prioritizes and safeguards the overall well-being of workers, encompassing their mental, physical, and social states within any organization [

11]. Furthermore, occupational health and safety plays a pivotal role in the work environment, focusing on all aspects of health and safety, with specific attention given to proactive prevention of upper and lower limb injuries [

12].

Regarding injury prevalence within a chicken processing farm, abrasions and punctures were prominently highlighted risks associated with knife usage. The results indicate that fingers and hands were the most injured body parts due to heavy reliance on upper limb usage. For example, chicken processing requires workers to cut the chickens, pack the chicken pieces in boxes, and move the boxes to the storeroom. The results of this study, along with those from the research conducted by [

13], emphasized the necessity for thorough safety measures to prevent injuries on duty associated with upper limb usage in processing farms [

13]. This study's discovered that there is no significant difference in the distribution of injuries on duty between males and females (P-value 0.912), even though there were more females than males who participated in the study. However, the findings by [

14] indicate that female workers have a higher prevalence of injuries on duty, and the study further expands on this by clarifying that there are differences between men and women, such as body size and shape, muscle anatomy and function, metabolism of toxic compounds, hormones, and immunological responses, but the actual factors that predispose female workers to injuries on duty are still unclear [

14].

This study finding further suggests that workers with matriculation or a lower level of education experienced more injuries, with a significant difference observed in comparison to those with undergraduate or postgraduate degrees. Similarly to the finding from the study conducted by [

15], which indicates that workers with lower educational levels experienced more injuries due to various factors such as potentially receiving less comprehensive safety training, encountering difficulties in understanding safety protocols, or being assigned to more physically demanding tasks without adequate support or supervision. Additionally, indicating socioeconomic barriers limit their access to proper safety equipment, thus resulting in increasing their vulnerability to injuries on duty [

15].

Furthermore, the study findings suggest that workers with three or more years of experience had more injuries as compared to those with less than two years of experience; this could be influenced by factors such as overconfidence in their skills and knowledge of the job and the fact that workers have become accustomed to certain work practices or developed habits that increase their risk of injury. However, the findings from the study conducted by [

16] contradict this, as the results from their study suggest that having more experience decreases the risk of injuries on duty [

16]. Therefore, it is crucial for chicken processing farms to implement targeted safety measures, particularly addressing hazards related to knife usage, wet floors, and tasks involving hand movements, and to focus on demographic factors such as gender and education level that may influence injury prevalence, as suggested by the findings.

Furthermore, the study findings suggest that workers with three or more years of experience had more injuries as compared to those with less than two years of experience; this could be influenced by factors such as overconfidence in their skills and knowledge of the job and the fact that workers have become accustomed to certain work practices or developed habits that increase their risk of injury. However, the findings from the study conducted by [

16] contradict this, as the results from their study suggest that having more experience decreases the risk of injuries on duty [

16]. Therefore, it is crucial for chicken processing farms to implement targeted safety measures, particularly addressing hazards related to knife usage, wet floors, and tasks involving hand movements, and to focus on demographic factors such as gender and education level that may influence injury prevalence, as suggested by the findings.

Furthermore, findings suggest that there is no significant association identified between the level of education and occurrences of abrasions, slips, and falls; however, there was a correlation between education level and finger injuries (p = 0.028). Workers with higher education levels exhibit lower rates of finger injuries due to their enhanced awareness, training, and access to resources, compared to those with lower education levels who may face greater occupational hazards. These results are consistent with [

18], study findings that indicate that workers with a lower level of education (matriculation and below) were more likely to suffer from injuries as compared to those with undergraduate education due to variations in perceiving safety training, job roles, and access to resources, and recommended the need for targeted interventions and training programs to improve workplace safety, especially for workers with lower levels of education [

18].

The study did not find any significant association between the frequency of PPE usage and the occurrence of abrasions, slips and falls, or finger injuries. However, findings from this study identified a noticeable trend suggesting that consistent usage of PPE might have protective effects against slips and falls in the workplace. Workers who consistently used PPE appeared to experience fewer slip and fall incidents compared to those who did not. Although this trend was observed, it did not achieve statistical significance, indicating that the association between PPE usage and reduced slip and fall occurrences was not strong enough to be considered conclusive based on the available findings. However, the trend provides evidence that use of PPE has the potential to prevent workplace accidents, particularly slips and falls.

In addition to exploring factors such as working hours, education level, and the use of personal protective equipment, the study also examined various other aspects of the work environment to grasp their connection with on-duty injuries in chicken processing farms. This investigation encompassed an analysis of job satisfaction levels, which unveiled a diverse range of sentiments among workers. While most workers expressed either a neutral or satisfied stance, notable proportions also reported dissatisfaction. This indicates that a portion of the workforce is not entirely content, emphasizing the importance of understanding the underlying reasons for this discontentment in the context of safety management within the chicken processing farm. However, according to the study by [

19], they found a significant negative correlation between job satisfaction and incidence of unsafe acts, P < 0.05 [

19]. This implies that when job satisfaction decreases, the likelihood of engaging in unsafe acts and experiencing occupational accidents increases. Given that the findings from this study suggest a correlation slightly above neutral, it underscores the importance of addressing these concerns to enhance overall employee satisfaction. This, in turn, could potentially lead to increased productivity, reduced turnover rates, and ultimately contribute to a safer work environment.

The findings highlight the importance of considering various aspects of the work environment, including job satisfaction, working conditions, and safety culture perception, in understanding the determinants of injuries on duty in chicken processing farms. As indicated by [

20], organizations fostering safe, welcoming, and supportive workplaces tend to enjoy enhanced financial stability, productivity, and communication [

20]. Furthermore, research by [

21] suggests that employees' interactions with their work environment contribute to their working conditions, encompassing both physical and psychological aspects [

21]. Addressing these factors is vital for enhancing overall workplace well-being and mitigating the risk of injuries, particularly since many workers in this study expressed neutral to positive attitudes, while a significant proportion reported dissatisfaction or concerns.

The unfavorable emotional reaction that people may experience in or out of their workplace when they believe they are unable to adequately respond to a perceived threat is known as "stress," and it causes them to feel frustrated and anxious [

22]. According to [

23], a number of things can lead to stress, including work environments that are detrimental to one's health and productivity, work overload, an inability to handle demands at work or voice complaints due to a fear of losing employment, a lack of engagement, and a work-life balance [

22,

24,

25].

Ineffective management of stress can have adverse effects on productivity and work performance, and it's challenging to maintain a clear boundary between work and personal life in any profession. Moreover, employees often find themselves torn between fulfilling multiple roles both at work and at home, such as being an employee, spouse, parent, or child, which frequently leads to stress in managing these responsibilities, ultimately impacting work performance. This study confirms the correlation between work-related stress and family obligations, as some participants struggled to balance work and family demands, particularly during peak seasons, leading to on-duty injuries. These findings align with previous research conducted by [

26,

27,

28], which also identified a significant association between work-family conflicts and stress [

26,

27,

28]. The results of the current study demonstrate a strong association between workplace and family-related stress and injuries. This finding is in line with prior research indicating that stress and conflicts between work and family life negatively impact the workplace [

24].

The study’s findings suggest that the conflict between work and family responsibilities is linked to stress, corroborating the findings of [

29]. While some injuries were potentially exacerbated by heightened stress levels, participants in our study exhibited varying experiences concerning their work environments, family stressors, and occupational stress. This mirrors the observations of [

23], whose study suggested that excessively demanding workloads may contribute to increased stress levels [

23]. Moreover, research conducted by [

30] suggested that stressed employees exhibit poor performance due to a lack of motivation and potential health issues [

30]. The working conditions and environment play an important role, as individuals dissatisfied with their workplace are more susceptible to stress-related illnesses, leading to decreased concentration at work and an increased likelihood of sustaining injuries [

31].