Submitted:

31 May 2024

Posted:

31 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Providing the most comprehensive review about various technologies of the TFT gate drivers integrated in a display panel.

- Covering the circuit design methodologies of TFT gate drivers at all available TFT backplane technologies.

- Including special circuit implementations in TFT gate drivers for various functions, besides scanning pulse generation.

- Proposing future directions for researches on TFT gate drivers.

2. Scanning Pulse Generation Circuits for Integrated TFT Gate Drivers

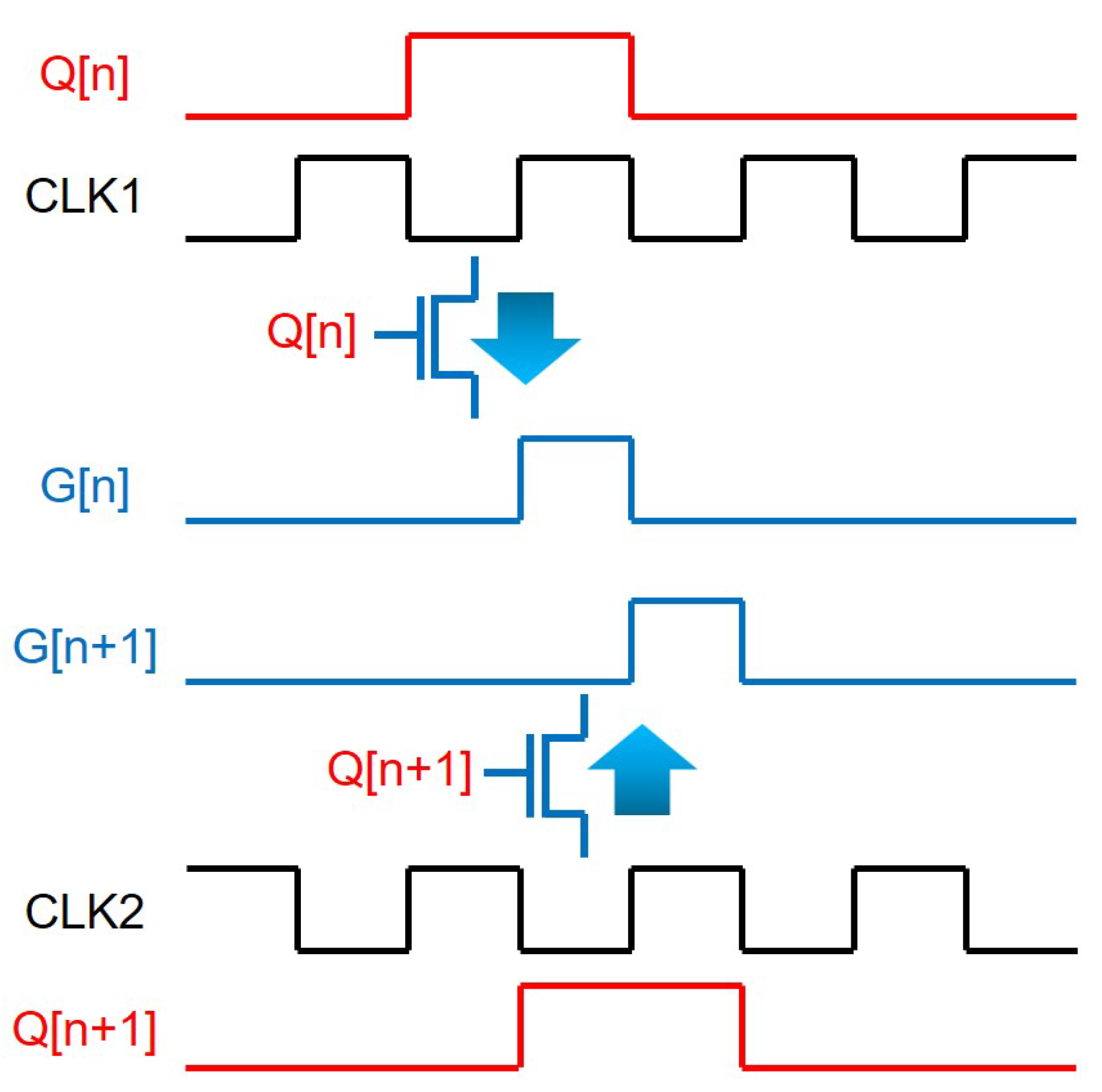

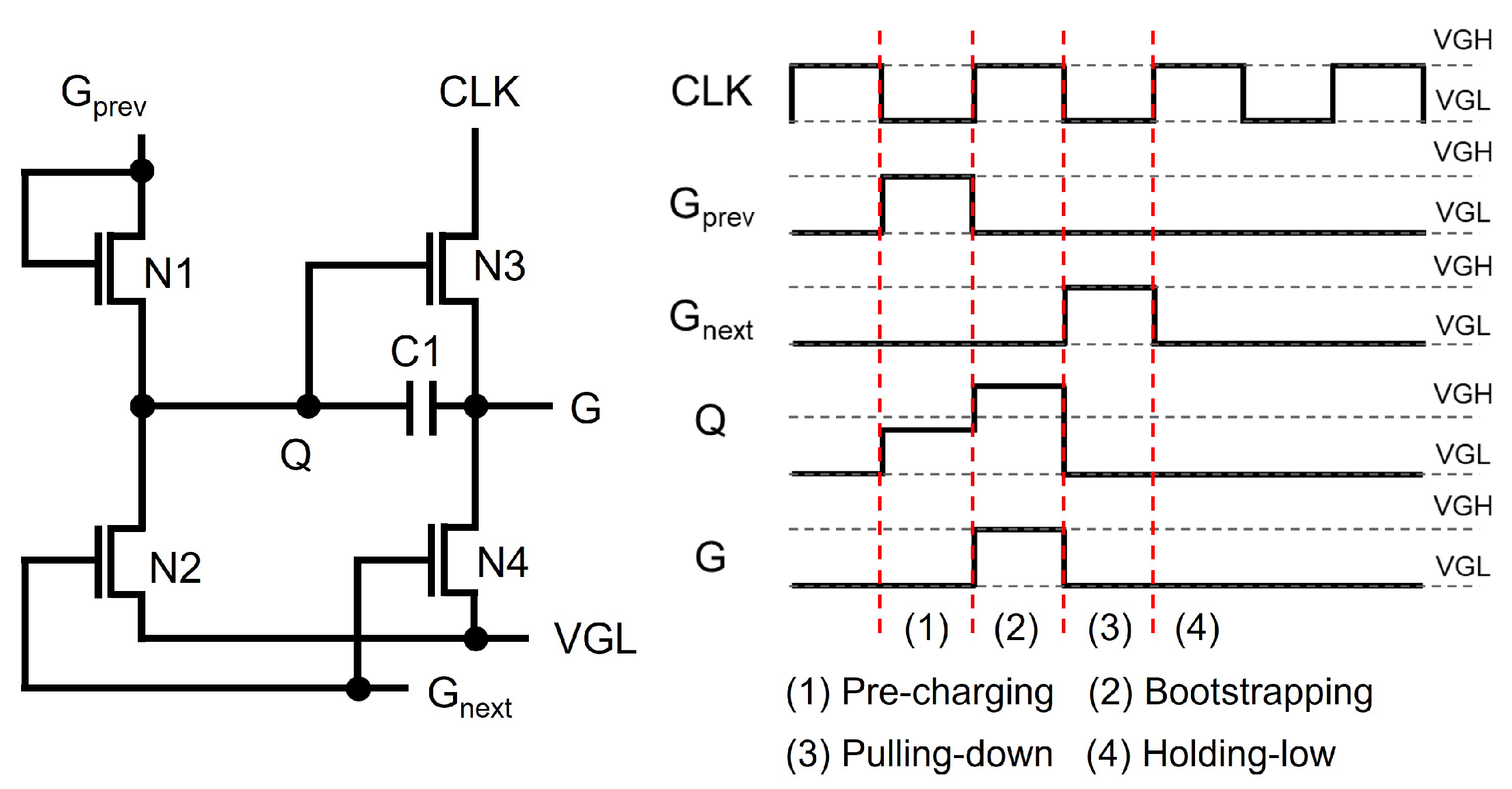

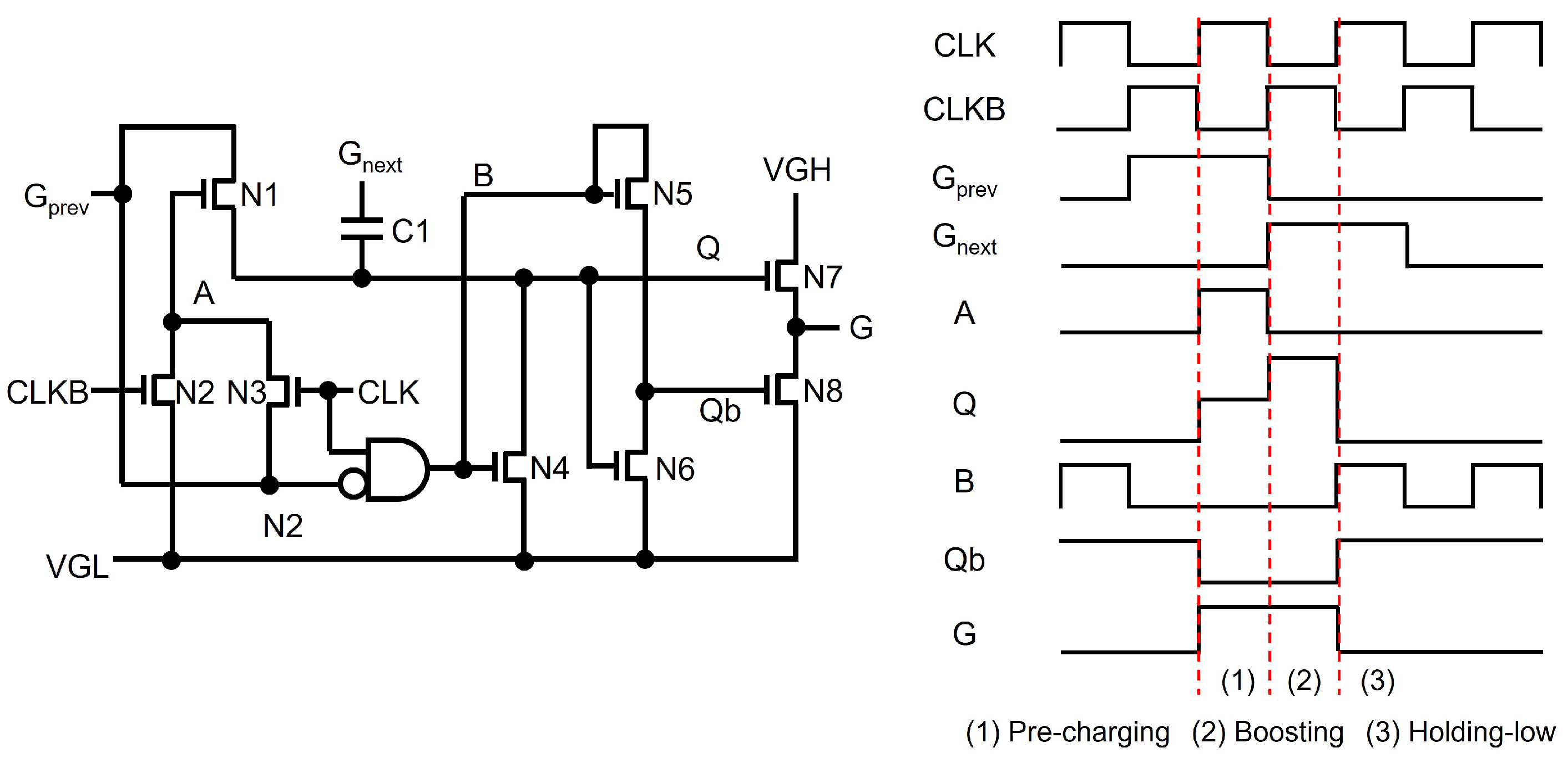

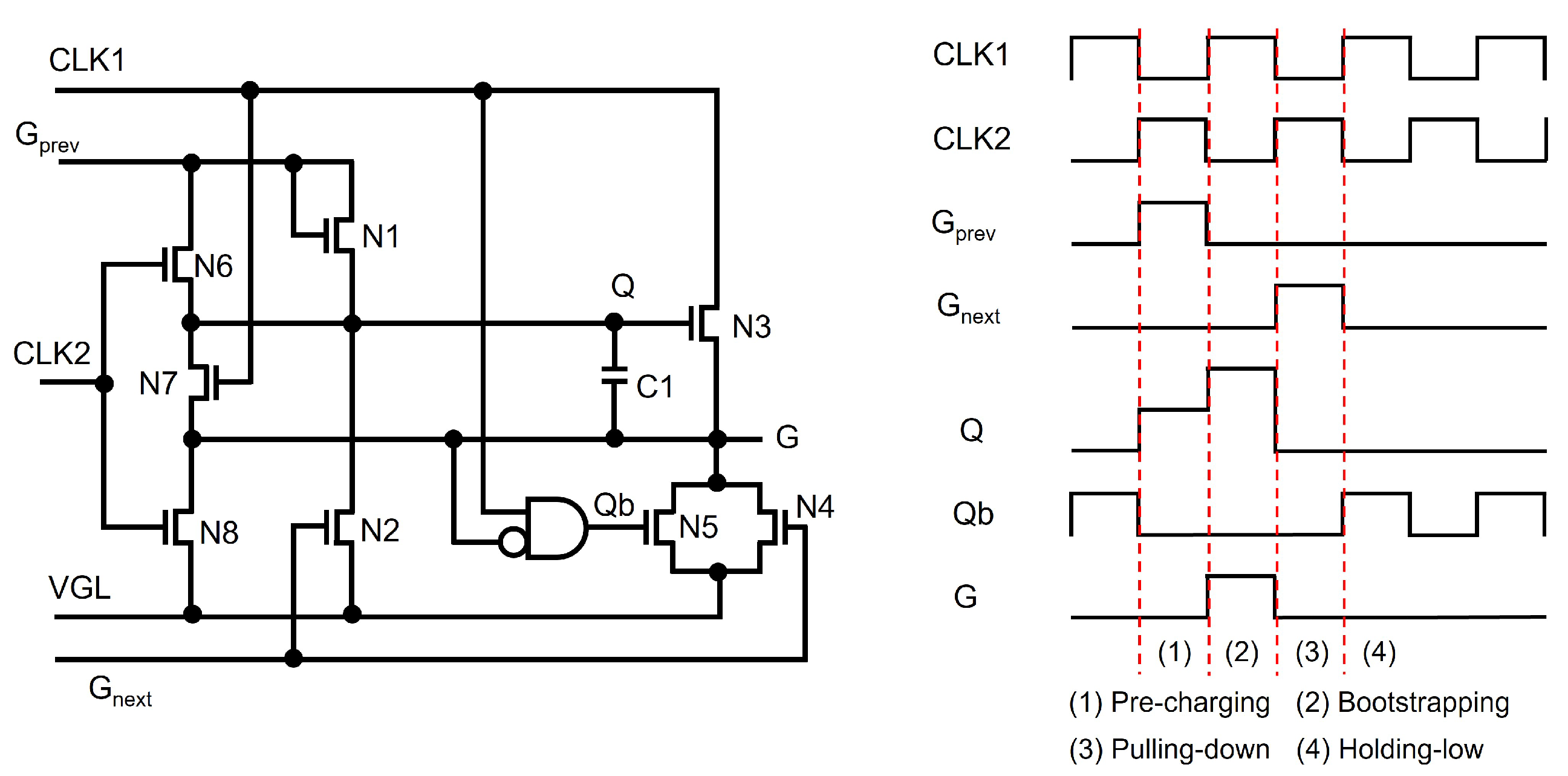

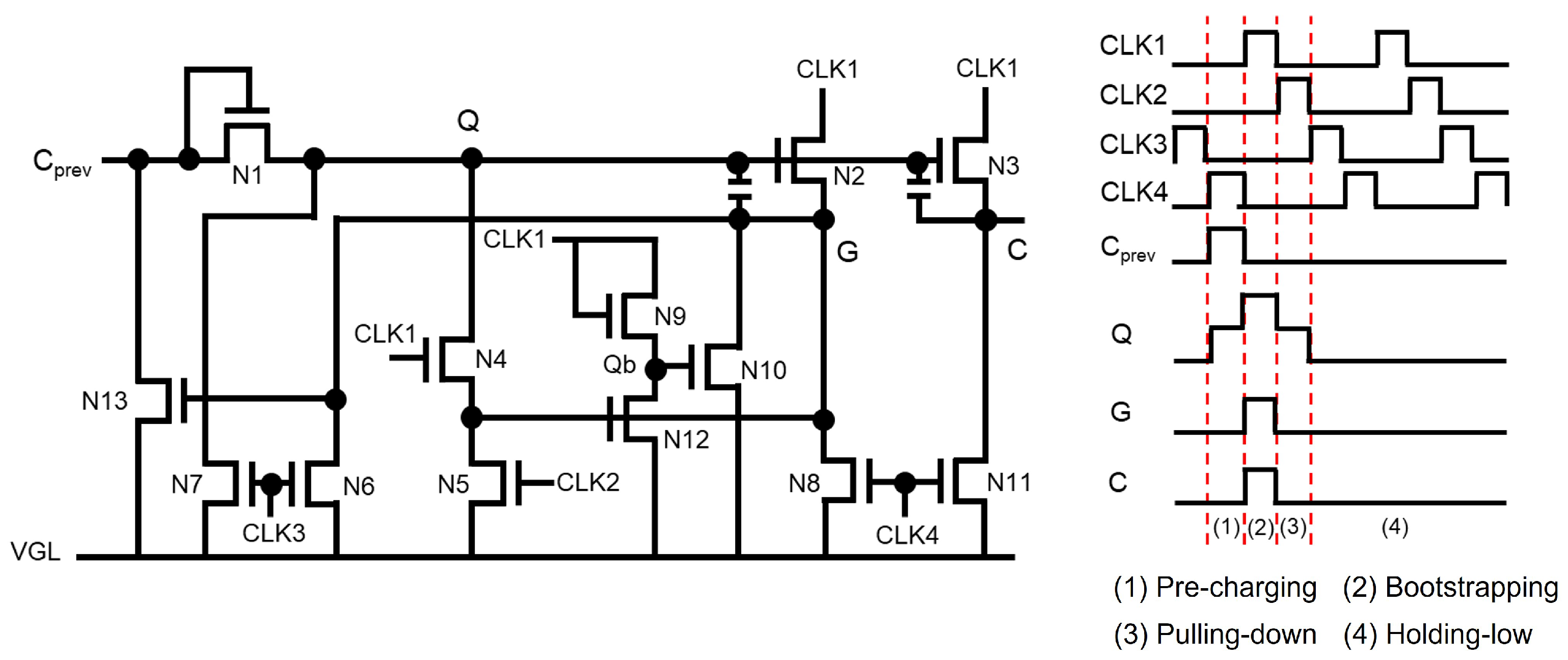

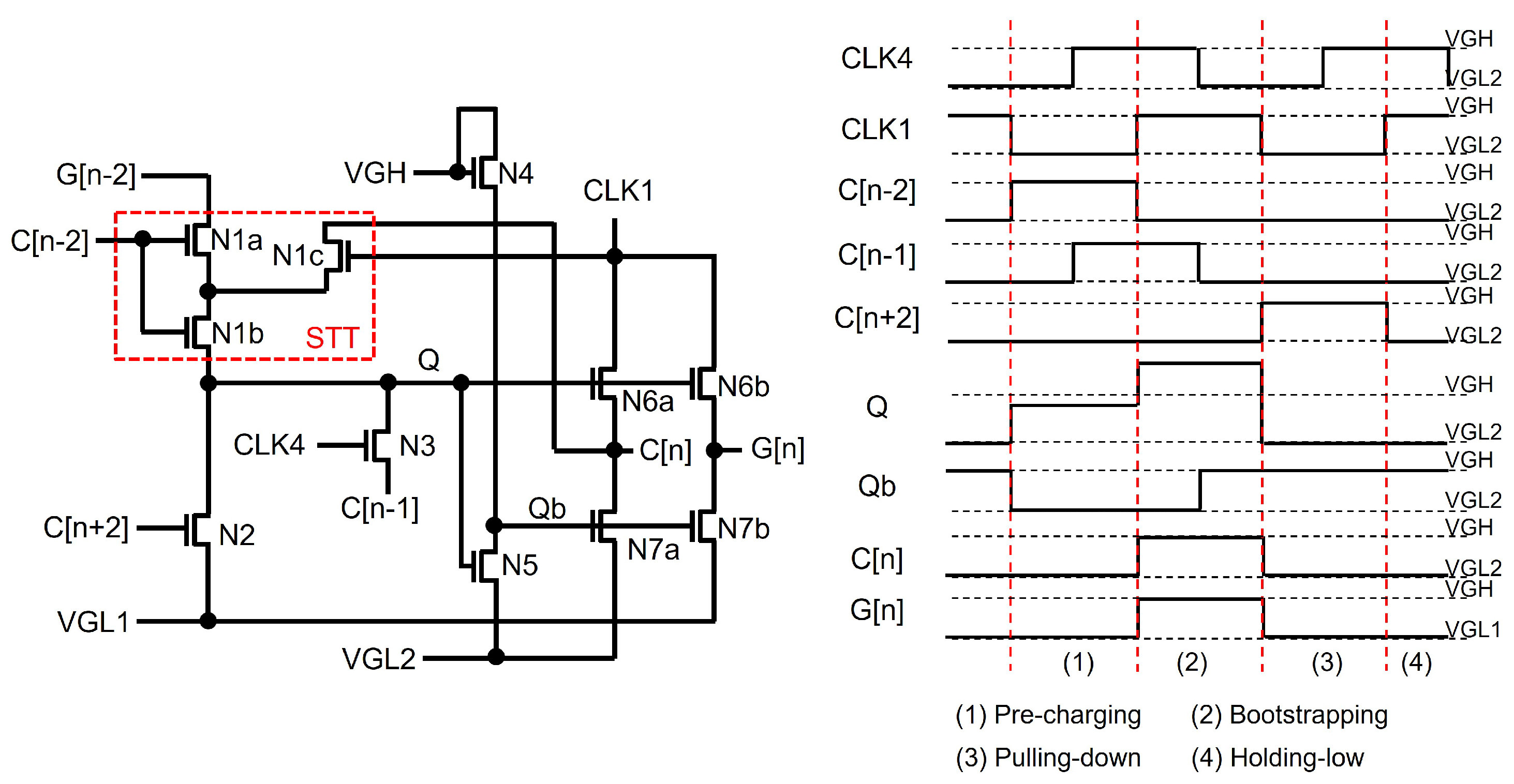

2.1. Basic Structure with N-type TFTs

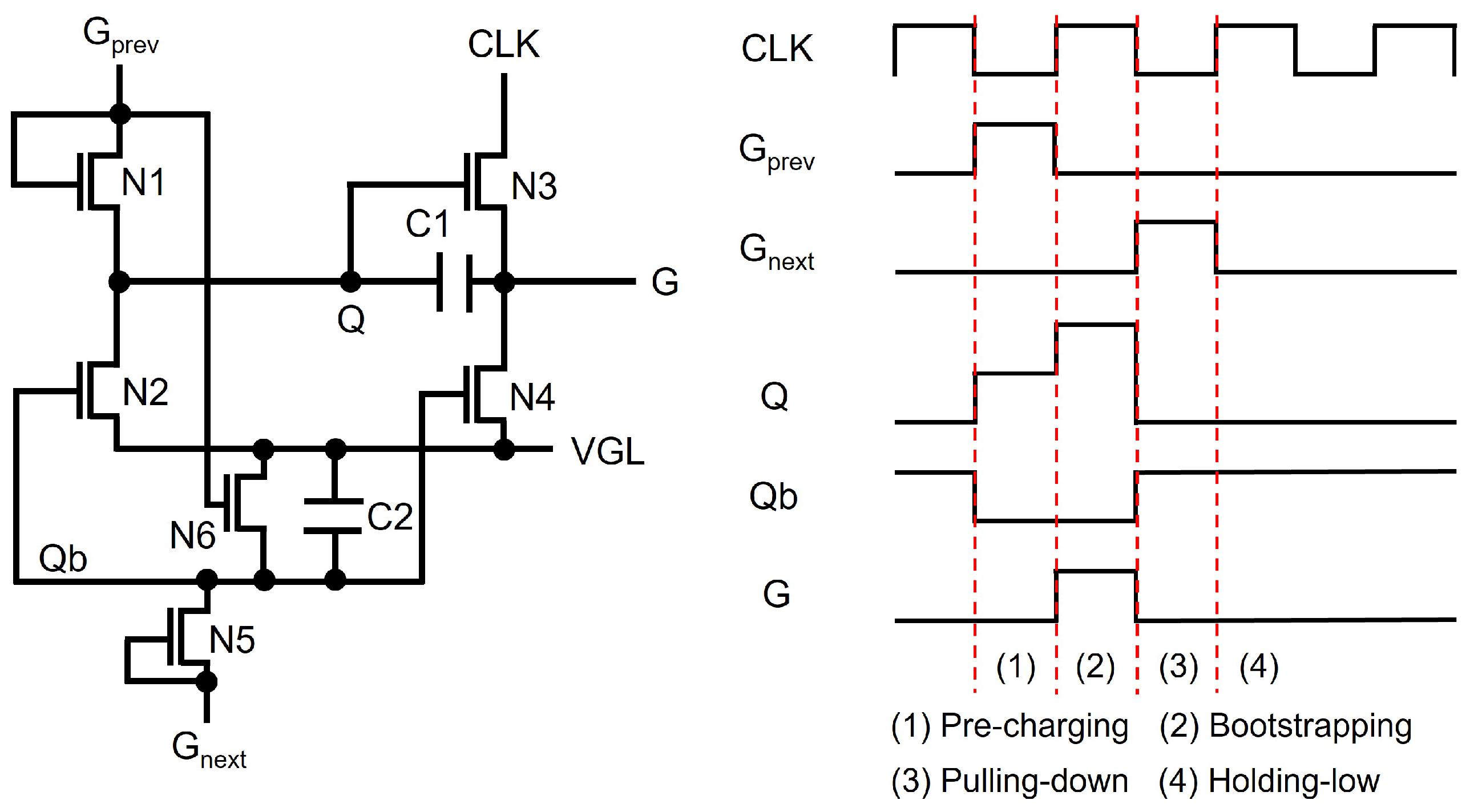

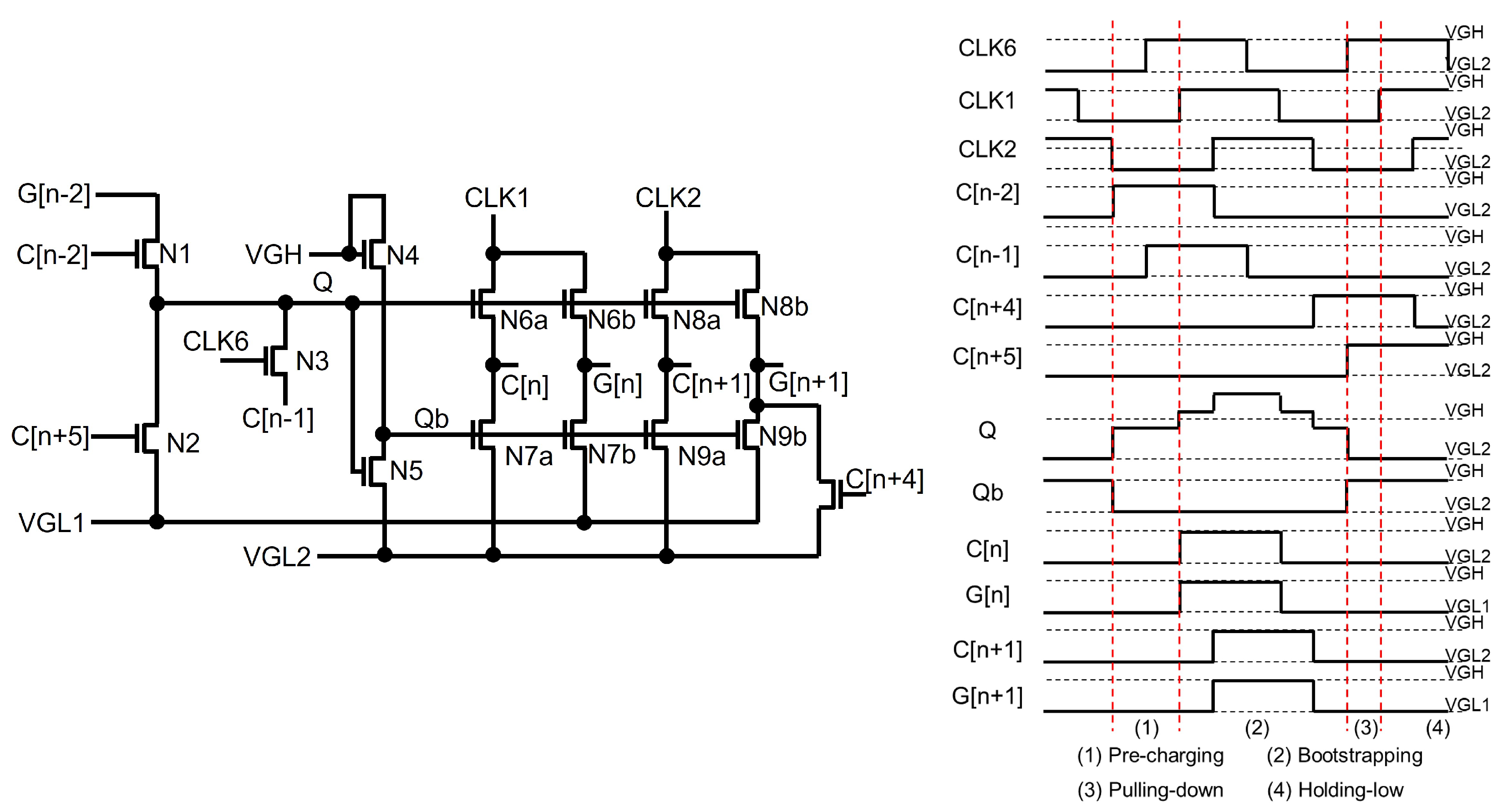

2.2. Fluctuation Reduction

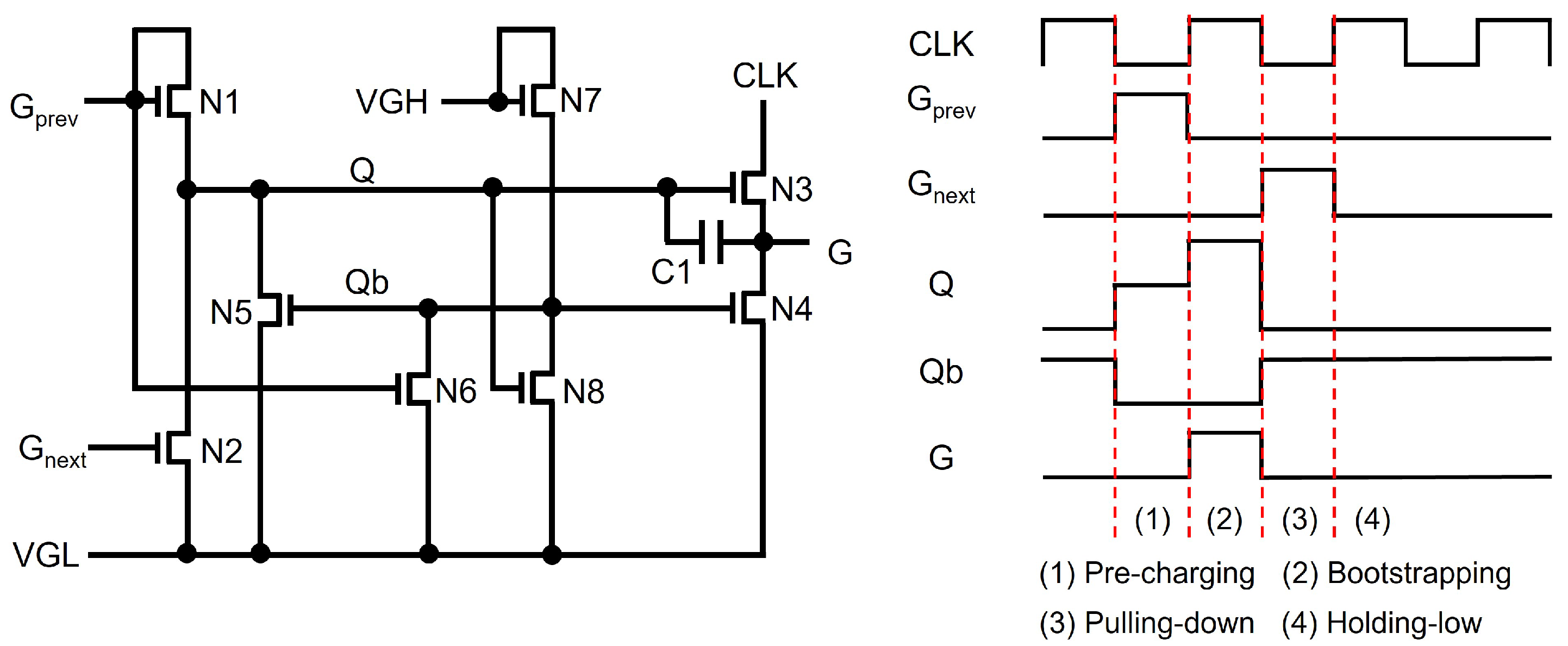

2.3. Reliability Enhancement over Shifts

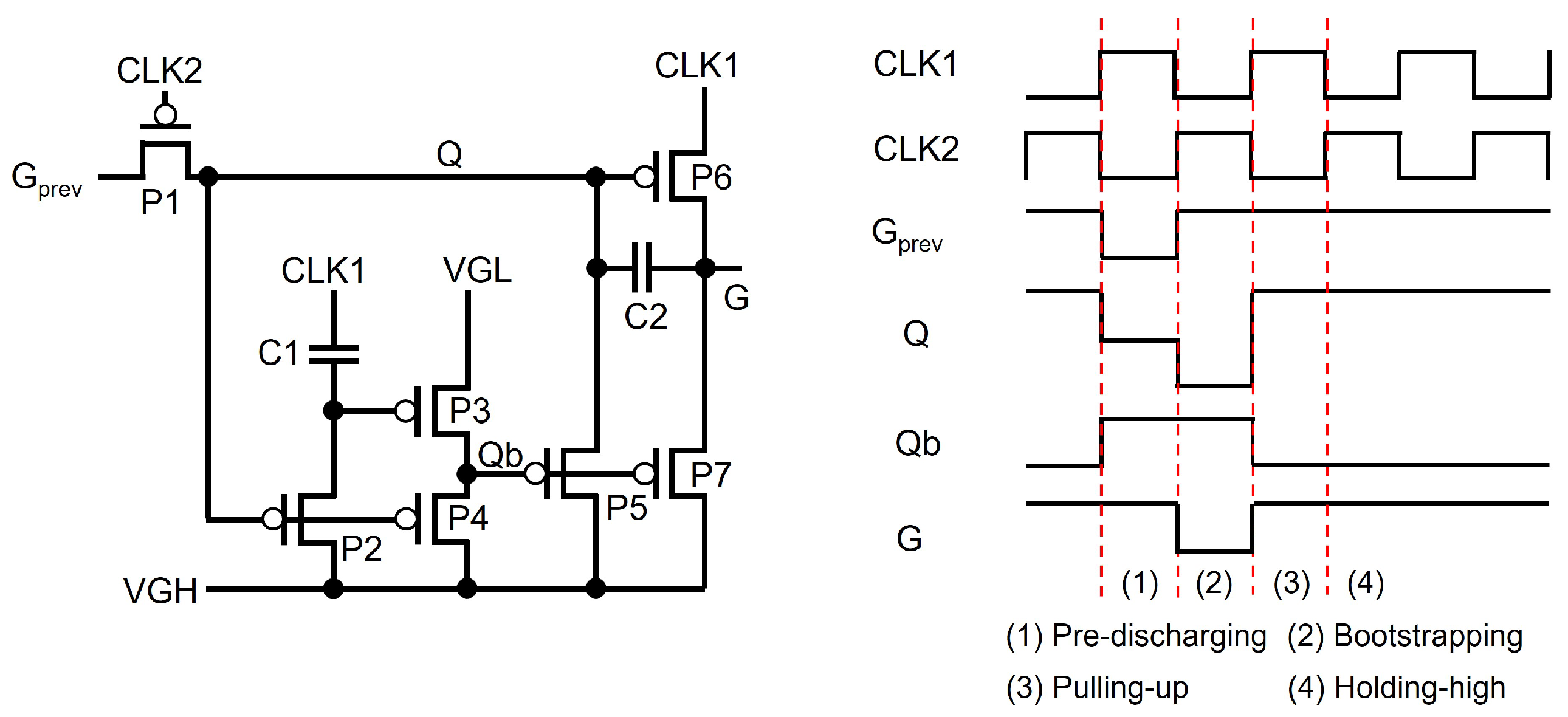

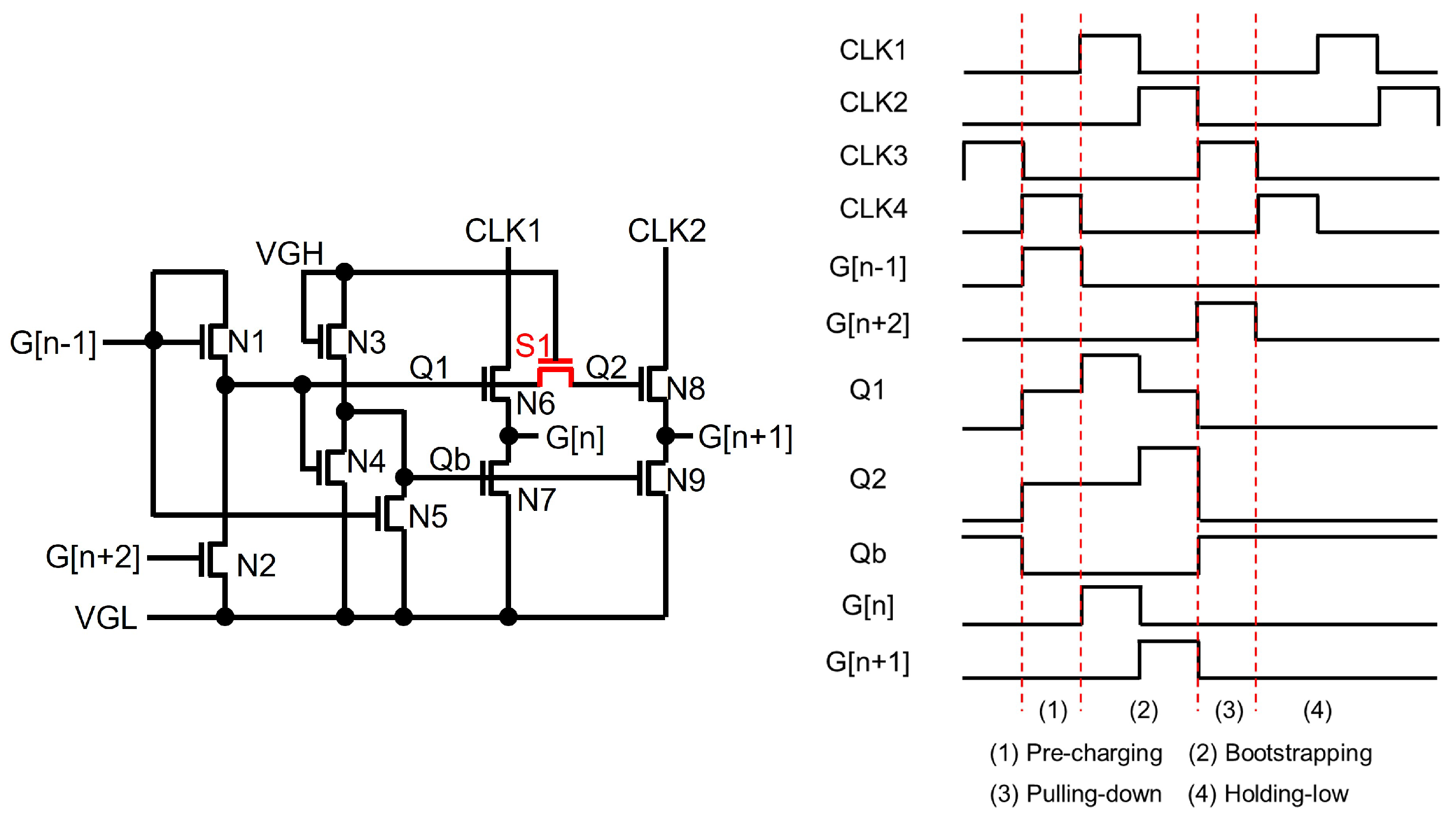

2.4. P-type TFT Circuit Implementation

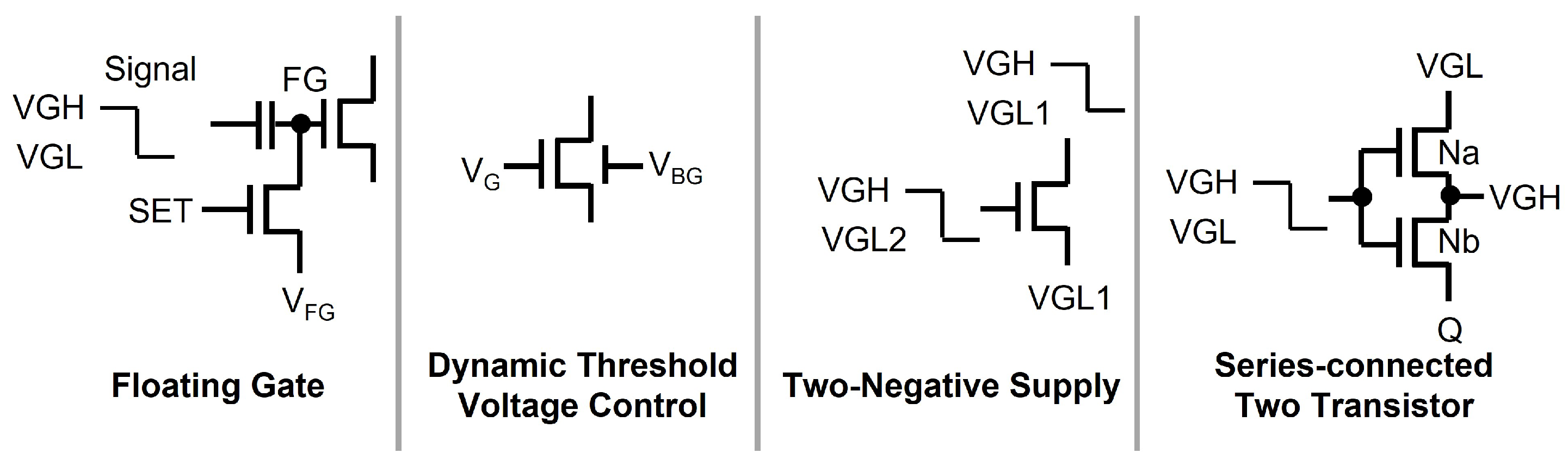

2.5. Depletion-mode TFT Circuit Implementation

2.6. Node-Sharing Schemes for Small Area Implementation

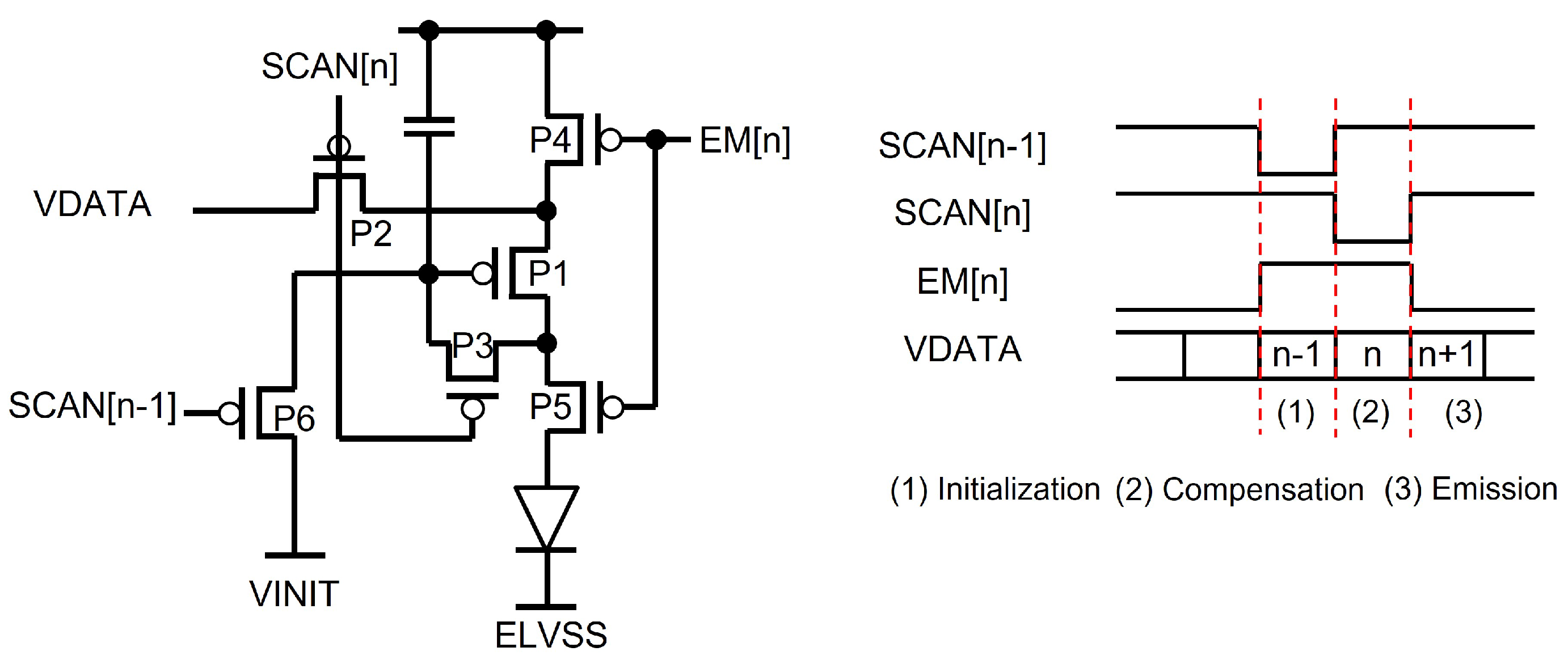

3. Special Gate Driver Circuits

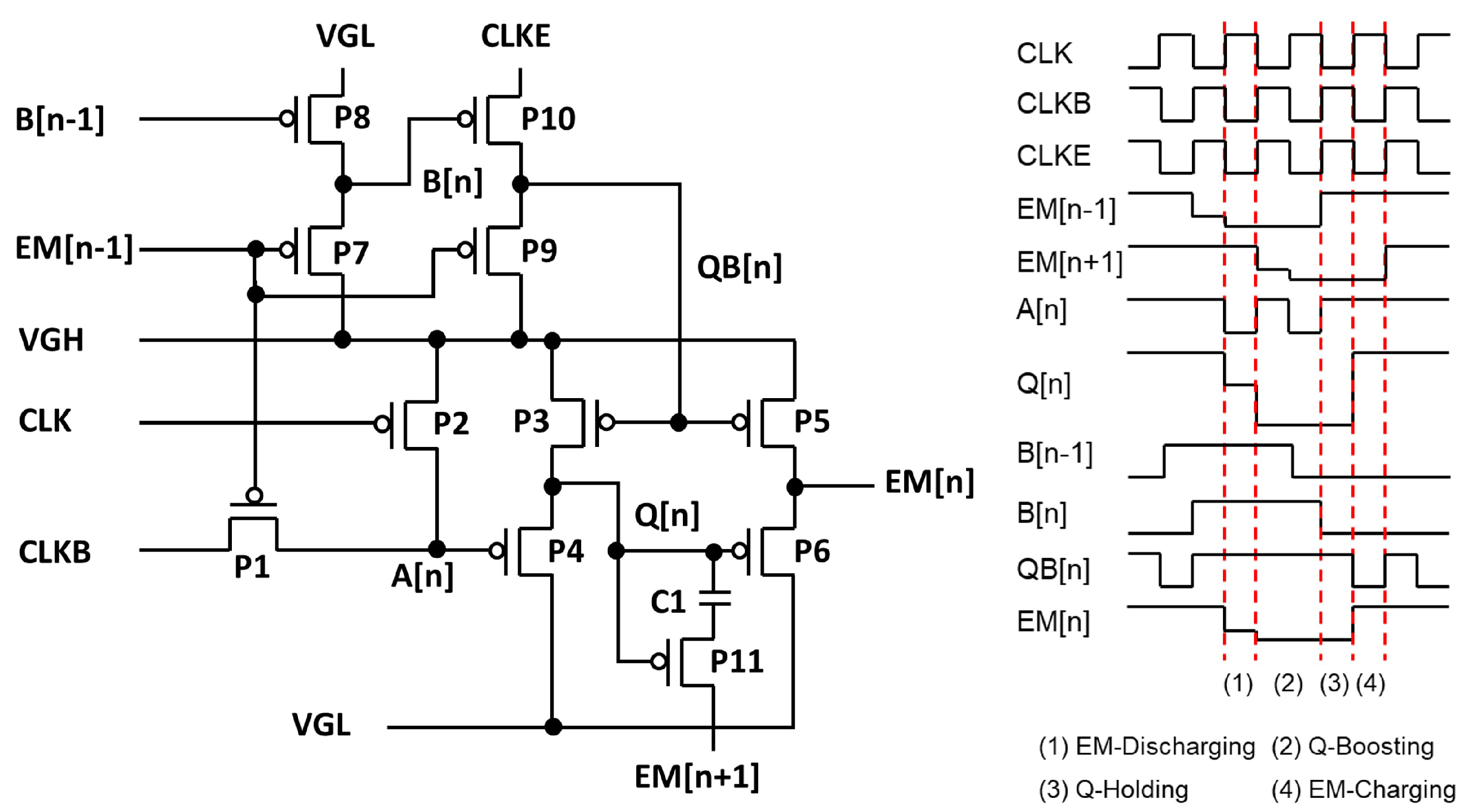

3.1. Emission Pulse (EM) Generation

3.2. Multi-Line Driving

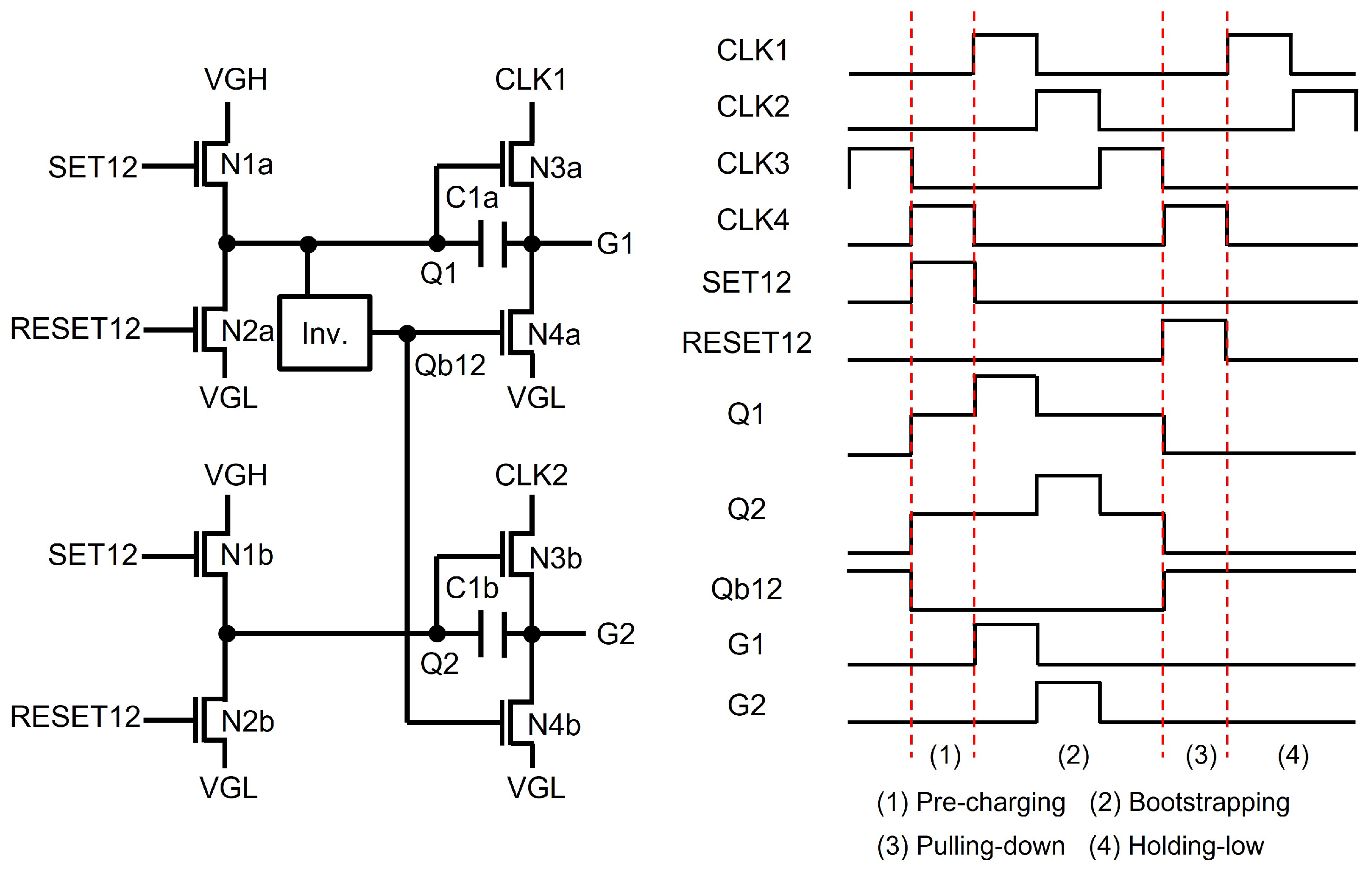

3.3. Robustness Improvement over Noises in In-Cell Touch Applications

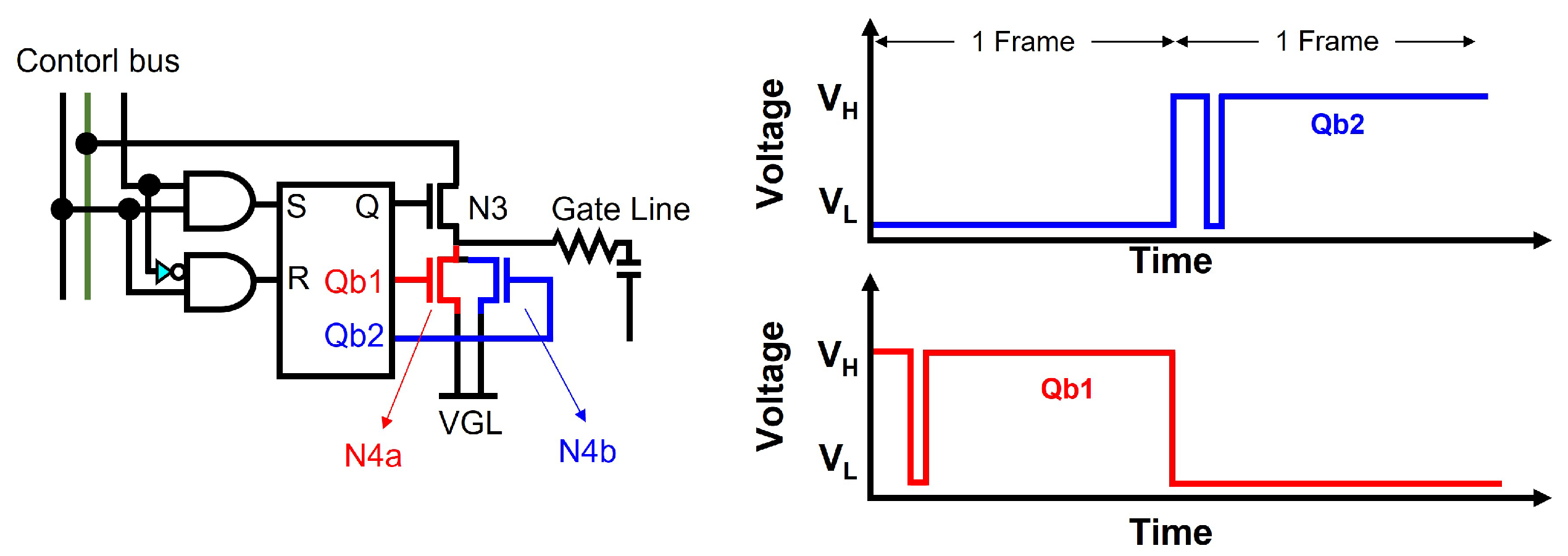

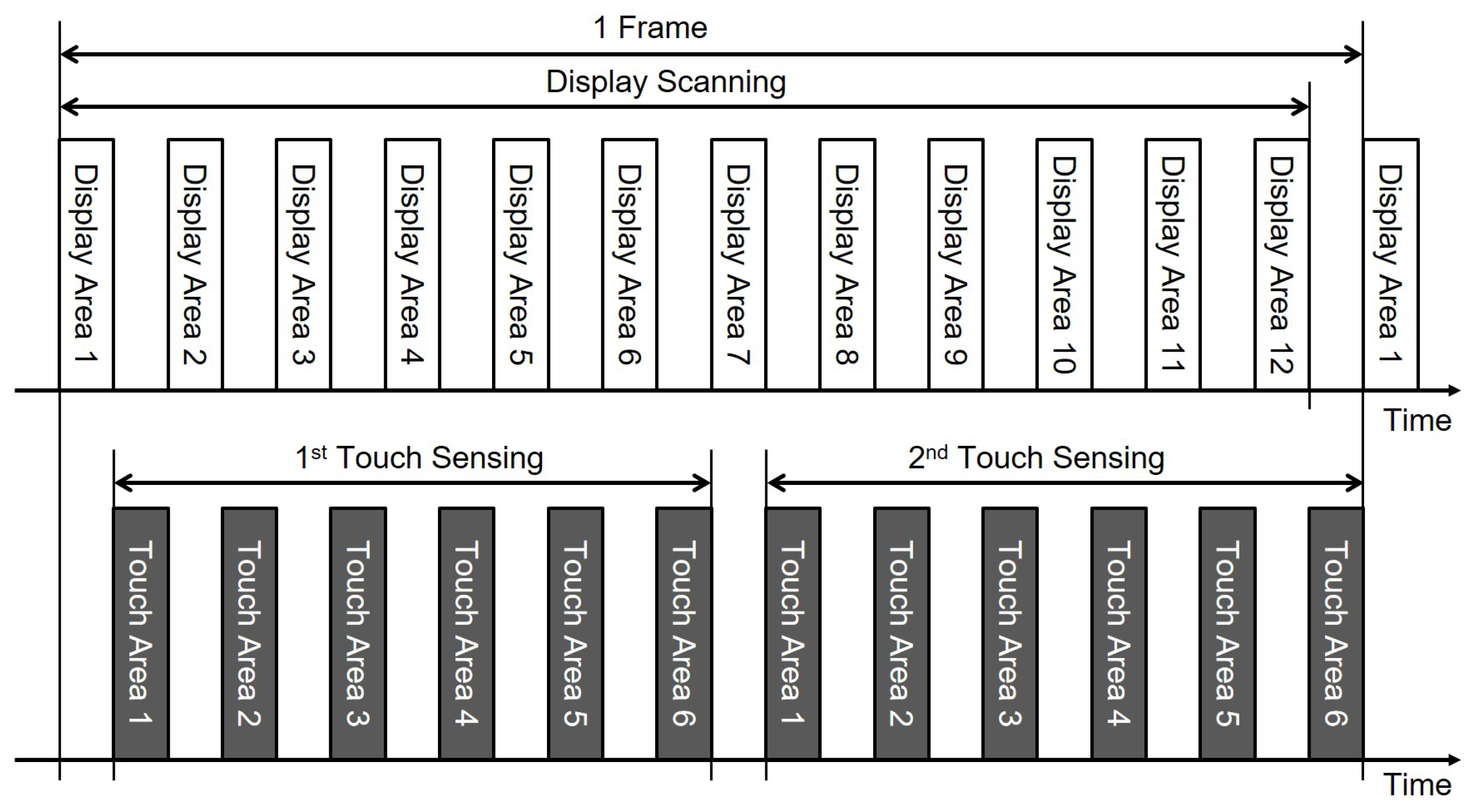

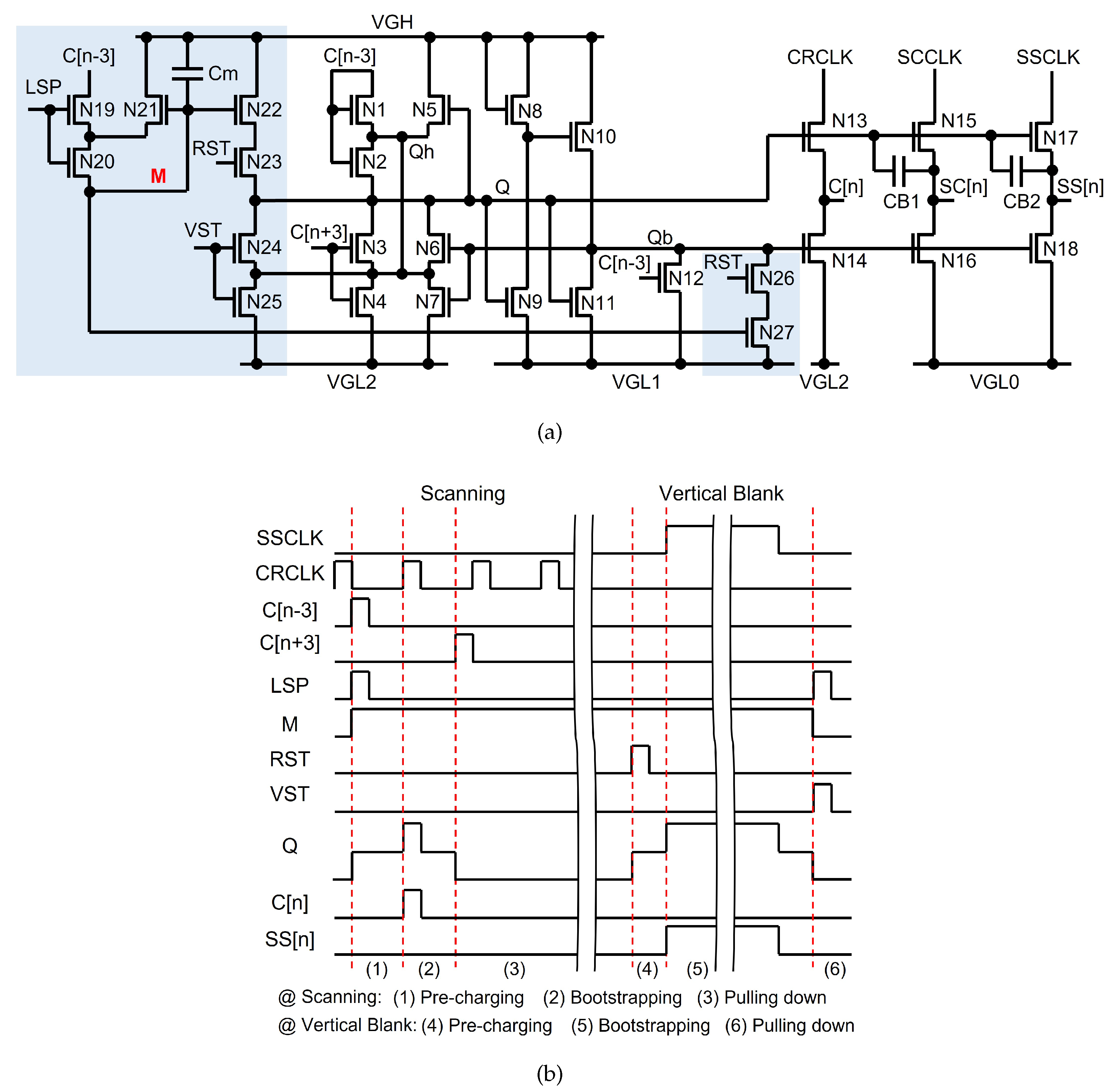

3.4. Random Sensing Pulse Generation for External Compensation in OLED Displays

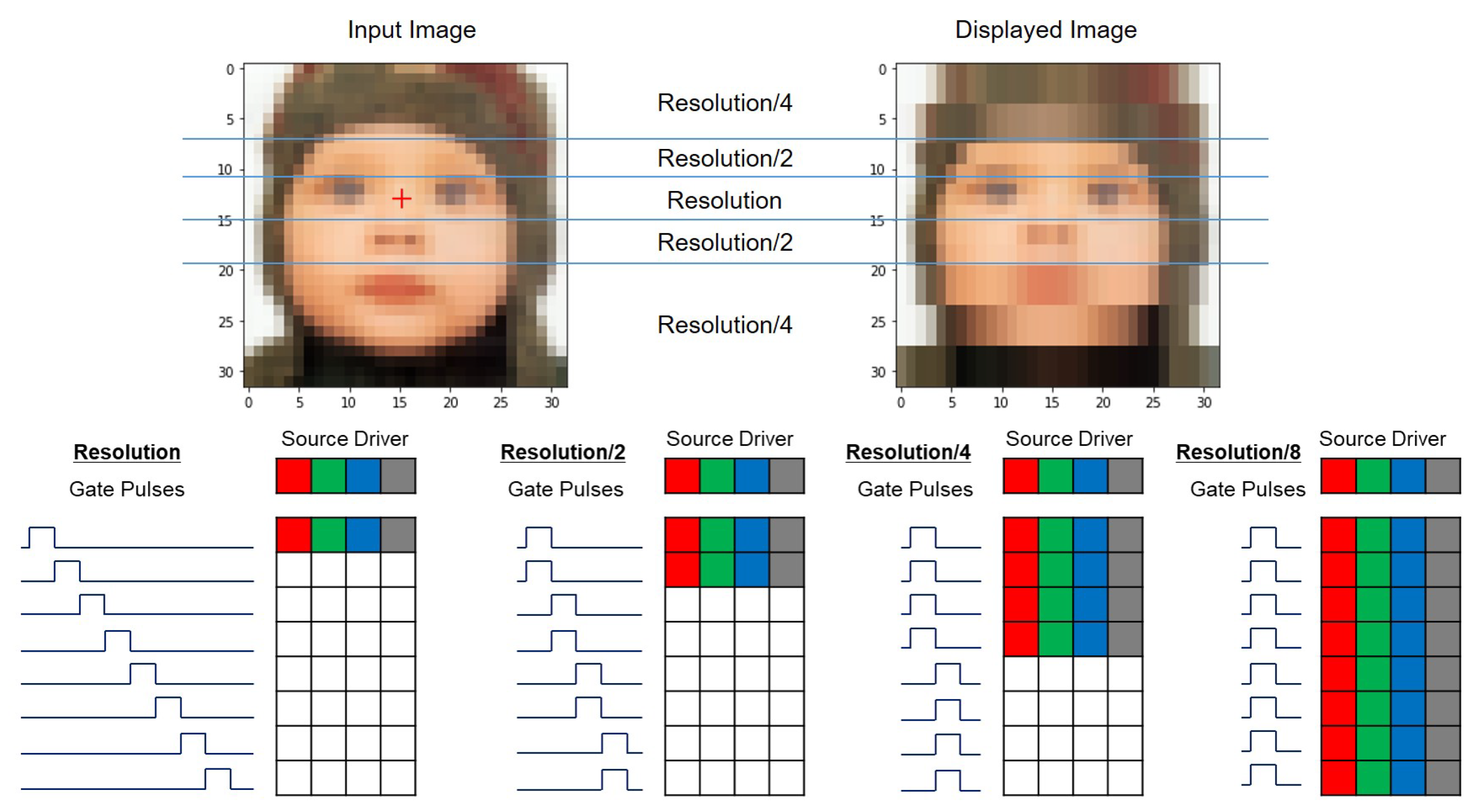

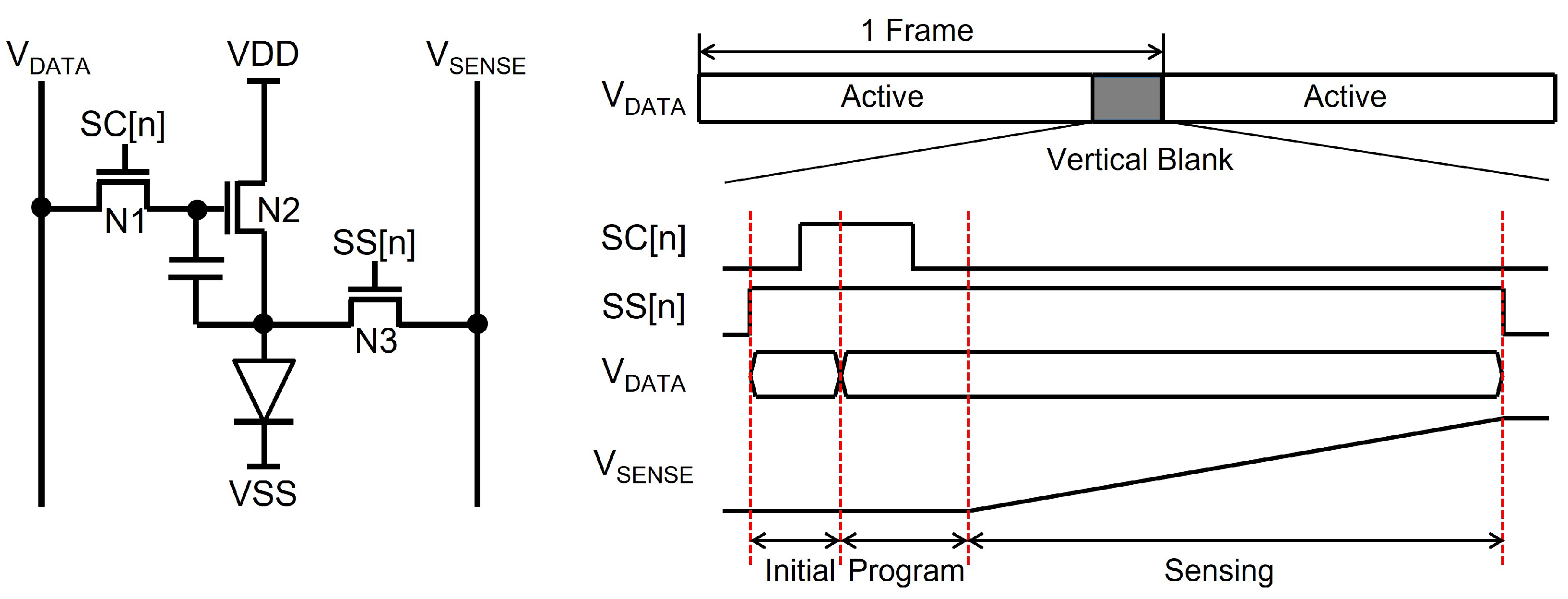

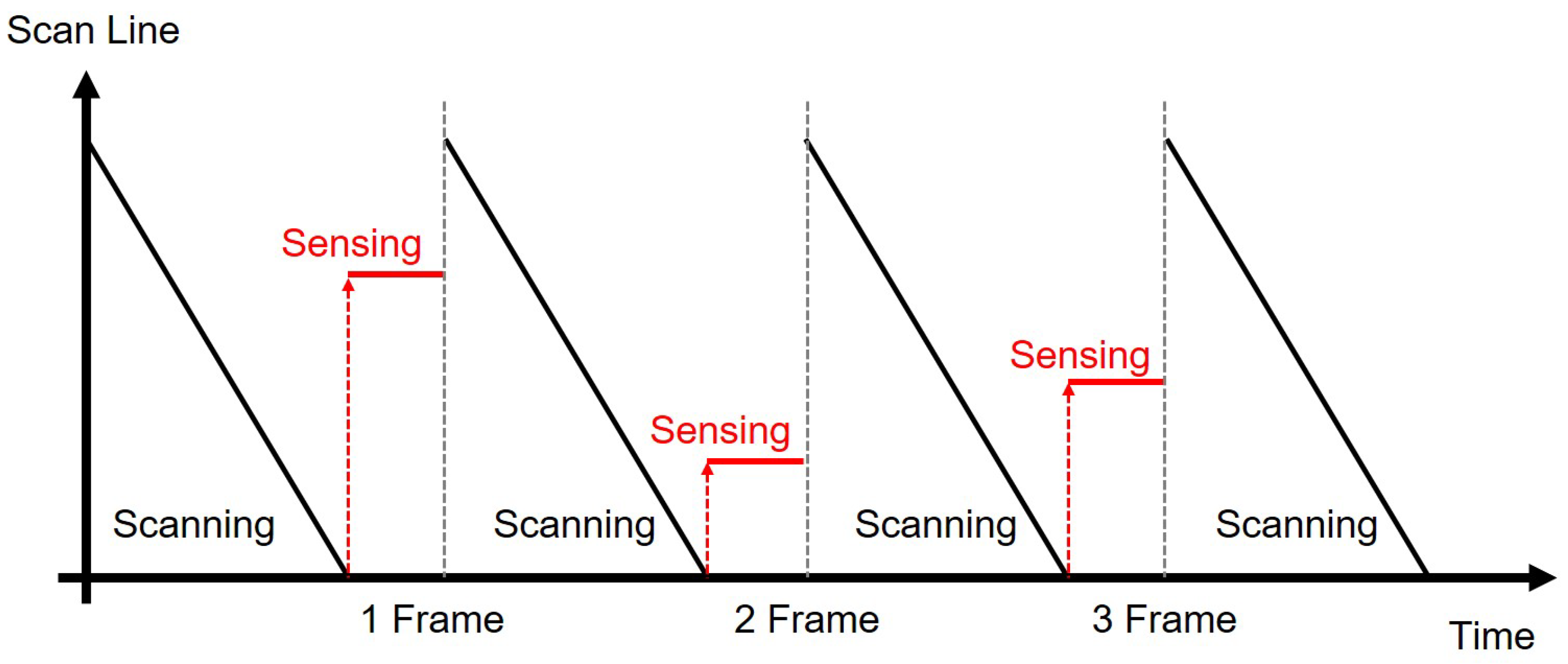

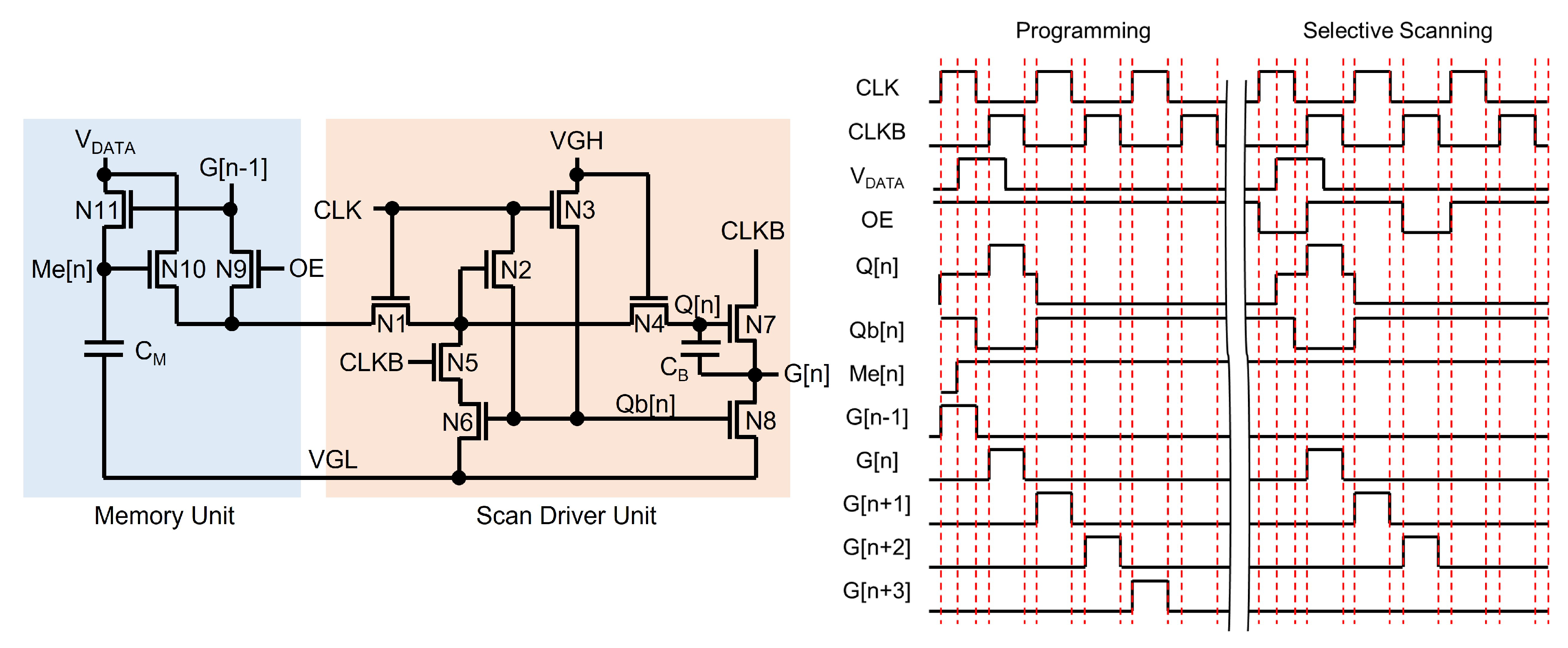

3.5. Adaptive Scanning Region Control

4. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, S. S.; Berkeley, B. H.; Kim, K.-H.; Song, J. K. New technologies for advanced LCD-TV performance. J. Soc. Inf. Disp. 2004, 12, 353–359. [Google Scholar] [CrossRef]

- Ishii, Y. The World of Liquid-Crystal Display TVs—Past, Present, and Future. J. Disp. Technol. 2007, 3, 351–360. [Google Scholar] [CrossRef]

- Nam, H.; Oh, K. Y.; Lee, S.-W. CCFL backlight solution for low-cost liquid crystal televisions without image artifacts. IEEE Trans. Consum. Electron. 2009, 55, 1021–1027. [Google Scholar] [CrossRef]

- Nam, H.; Lee, S.-W. Dithering artifacts in liquid crystal displays and analytic solution to avoid them. IEEE Trans. Consum. Electron. 2009, 55, 2211–2215. [Google Scholar] [CrossRef]

- Okumura, H. Birth of the Innovative Overdrive Technology for Liquid Crystal: Paving the Way for Practical Use of LCD Televisions. IEEE Consum. Electron. Mag. 2021, 10, 90–96. [Google Scholar] [CrossRef]

- Gao, Z.; Ning, H.; Yao, R.; Xu, W.; Zou, W.; Guo, C.; Luo, D.; Xu, H.; Xia, J. Mini-LED Backlight Technology Progress for Liquid Crystal Display. Crystals 2022, 12, 313. [Google Scholar] [CrossRef]

- Yin, K.; Hsiang, E.-L.; Zou, J.; Li, Y.; Yang, Z.; Yang, Q.; Lai, P.-C.; Lin, C.-L.; Wu, S.-T. Advanced liquid crystal devices for augmented reality and virtual reality displays: principles and applications. Light:Sci. Appl. 2022, 11, 161. [Google Scholar] [CrossRef] [PubMed]

- Geffroy, B.; le Roy, P.; Prat, C. Organic light-emitting diode (OLED) technology: materials, devices and display technologies. Polym. Int. 2006, 55, 572–582. [Google Scholar] [CrossRef]

- Nam, H.; Jeong, H. Data Supply Voltage Reduction Scheme for Low-Power AMOLED Displays. ETRI J. 2012, 34, 727–733. [Google Scholar] [CrossRef]

- Hong, G.; Gan, X.; Leonhardt, C.; Zhang, Z.; Seibert, J.; Busch, J. M.; Brase, S. A Brief History of OLEDs— Emitter Development and Industry Milestones. Adv. Mater. 2021, 33, 2005630. [Google Scholar] [CrossRef]

- Shin, H.-J.; Choi, S.-H.; Kim, D.-M.; Han, S.-E.; Bae, S.-J.; Park, S.-K.; Kim, H.-S.; Oh, C.-H. A Novel 88-inch 8K OLED Display for Premium Large-Size TVs. Proceedings of SID Display Week Symposium, Online, 17–21 May 2021; pp. 611–614. [Google Scholar]

- Seong, G.; Lee, Y.; Kwak, Y. Image Quality Comparison between LCD and OLED Display. Proceedings of Electronic Imaging, Online, 18–25 January 2021; p. 326. [Google Scholar]

- Prabha, A. Power Saving and Optimization of OLED Displays for Better System Design: A Survey. Proceedings of International Conference on Innovative Practices in Technology and Management, Pradesh, India, 22–24 February 2023. [Google Scholar]

- Lee, V. W.; Twu, N.; Kymissis, I. Micro-LED Technologies and Applications. Inf. Disp. 2016, 32, 16–23. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Chen, S.-W. H.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and Micro-LED: Promising Candidates for the Next Generation Display Technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef]

- Jung, T.; Choi, J. H.; Jang, S. H.; Han, S. J. Review of Micro-light-emitting-diode Technology for Micro-display Applications. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 12–17 May 2019; pp. 442–446. [Google Scholar]

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: present status and future perspectives. Light:Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Anwar, A. R.; Sajjad, M. T.; Johar, M. A.; Hernandez-Gutierrez, C. A.; Usman, M.; Lepkowski, S. P. Recent Progress in Micro-LED-Based Display Technologies. Laser Photonics Rev. 2022, 16, 2100427. [Google Scholar] [CrossRef]

- Ryu, J.-E.; Park, S.; Park, Y.; Ryu, S.-W.; Hwang, K.; Jang, H. W. Technological Breakthroughs in Chip Fabrication, Transfer, and Color Conversion for High-Performance Micro-LED Displays. Adv. Mater. 2022, 35, 2204947. [Google Scholar] [CrossRef] [PubMed]

- Rahman, R.; Wood, M. E.; Qian, L.; Price, C. L.; Johnson, A. A.; Osgood, G. M. Head-Mounted Display Use in Surgery: A Systematic Review. Surgical Innovation 2020, 27, 88–100. [Google Scholar] [CrossRef]

- Kawanishi, H.; Onuma, H.; Maegawa, M.; Ono, T.; Akase, S.; Yamaguchi, S.; Momotani, N.; Fujita, Y.; Kondoh, Y.; Kubota, K.; Yoshida, T.; Ikawa, Y.; Ono, T.; Higashisaka, H.; Hirano, Y.; Anzai, S. High-resolution and high-brightness full-colour “Silicon Display” for augmented and mixed reality. J. Soc. Inf. Disp. 2021, 29, 57–67. [Google Scholar] [CrossRef]

- Cheng, D.; Wang, Q.; Liu, Y.; Chen, H.; Ni, D.; Wang, X.; Yao, C.; Hou, Q.; Hou, G.; Wang, Y. Design and manufacture AR head-mounted displays: A review and outlook. Light Adv. Manuf. 2021, 2, 350–369. [Google Scholar] [CrossRef]

- Chung, J.-M. Emerging Metaverse XR and Video Multimedia Technologies; Apress: Berkeley, CA, USA, 2022; pp. 99–139. [Google Scholar]

- Broll, W.; Grimm, P.; Herold, R.; Reiners, D.; Cruz-Neira, C. VR/AR Output Devices. In Virtual and Augmented Reality (VR/AR); Doerner, R., Broll, W., Grimm, P., Jung, B., Eds.; Springer: New York, USA, 2022; pp. 149–200. [Google Scholar]

- Miao, W.-C.; Hsiao, F.-H.; Sheng, Y.; Lee, T.-Y.; Hong, Y.-H.; Tasi, C.-W.; Chen, H.-L.; Liu, Z.; Lin, C.-L.; Chung, R.-J.; Ye, Z.-T.; Horng, R.-H.; Chen, S.-C.; Kuo, H.-C.; He, J.-H. Microdisplays: Mini-LED, Micro-OLED, and Micro-LED. Adv. Opt. Mater. 2023, 12, 2300112. [Google Scholar] [CrossRef]

- Blankenbach, K. LCD Innovations vs. OLED Performance for Automotive Applications. In Proceedings of SID Display Week Symposium, Los Angeles, CA, USA, 21–26 May 2023; pp. 327–330. [Google Scholar]

- Tian, D.; Ma, H.; Huang, G.; Gao, M.; Cai, F.; Fang, Y.; Li, C.; Jiang, X.; Wang, A.; Wang, S.; Du, Z. A Review on Quantum Dot Light-Emitting Diodes: From Materials to Applications. Adv. Opt. Mater. 2023, 11, 2201965. [Google Scholar] [CrossRef]

- Wu, S. Y.-X. The Future of Automotive Displays and Technology: A Look Ahead. Proceedings of International Workshop on Active-Matrix Flatpanel Displays and Devices, Kyoto, Japan, 04–07 July 2023. [Google Scholar]

- Kim, J. H.; Pyun, Y. J.; Oh, J. H.; Song, K. H.; Kim, Y. N.; Cho, J. H.; Yoon, C. Y.; Han, Y. H.; Nam, H. Low Complexity Local Dimming Algorithm for High Quality Head Up Displays in Automotive Vehicles. J. Inf. Disp., 2024, 25, 197–210. [Google Scholar] [CrossRef]

- Ruckmongathan, T. N. Driving matrix liquid crystal displays. Pramana - J. Phys. 1999, 53, 199–212. [Google Scholar] [CrossRef]

- Hunze, A.; Scheffel, M.; Birnstock, J.; Blassing, J.; Kanitz, A.; Rajoelson, S.; Rogler, W.; Wittmann, G.; Hartmann, H.; Winnacker, A. Passive Matrix Displays Based on the New Red Emitting Dopant RedATDB. Proceedings of SID Display Week Symposium, Boston, MA, USA, 19–24 May 2002; pp. 1186–1189. [Google Scholar]

- Xiong, S.; Guo, B.; Wu, C.; Chen, Y.; Hao, Y.; Zhou, Z.; Yang, H. A Novel Design of Sub-frame and Current Driving Method for PM-OLED. Proceedings of SID Display Week Symposium, Boston, MA, USA, 19–24 May 2002; pp. 1174–1177. [Google Scholar]

- Ohta, S.; Chuman, T.; Miyaguchi, S.; Satoh, H.; Tanabe, T.; Okuda, Y.; Tsuchida, M. Active Matrix Driving Organic Light-Emitting Diode Panel Using Organic Thin-Film Transistors. Jpn. J. Appl. Phys. 2005, 44, 3678. [Google Scholar] [CrossRef]

- Park, I.-S.; Kim, T.-W.; Lee, J.-Y.; Choi, B.-D. Data driver architecture and driving scheme of AMOLED microdisplay for mobile projectors. IEEE Trans. Consum. Electron. 2009, 55, 2365–2371. [Google Scholar] [CrossRef]

- Blankenbach, K. Active Matrix Driving. In Handbook of Visual Display Technology; Chen, J., Cranton, W., Fihn, M., Eds.; Springer: Berlin, Heidelberg, Germany, 2012; pp. 441–458. [Google Scholar]

- Keum, N.-H.; Oh, K.; Hong, S.-K.; Kwon, O.-K. A Pixel Structure Using Block Emission Driving Method for High Image Quality in Active Matrix Organic Light-Emitting Diode Displays. J. Disp. Technol. 2016, 12, 1250–1256. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, D.-K. An Active-Matrix OLED Driver CMOS IC With Compensation of Non-Uniform Routing-Line Resistances in Ultra-Thin Panel Bezel. IEEE J. Solid-State Circuits 2017, 53, 484–500. [Google Scholar] [CrossRef]

- How To Drive Displays. Available online: https://rdotdisplays.com/articles/how-to-drive-displays (accessed on 10 March 2024).

- Hsia, S.-C.; Sheu, M.-H.; Chen, B.-Y. Area-efficient multi-channel active matrix micro-LED driver chip design. Analog Integr. Circ. Sig. Process. 2022, 111, 137–152. [Google Scholar] [CrossRef]

- 263 / 256 Channel TFT-LCD Gate Driver. Available online: https://pdf1.alldatasheet.com/datasheet-pdf/view/37875/SAMSUNG/S6C0657.html (accessed on 10 March 2024).

- den Boer, W. Select Line Driver for the Offset-Scan-and-Hold Dual Select Diode AMLCDs. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 3–8 June 2001; pp. 44–47. [Google Scholar]

- Kudo, Y.; Akai, A.; Furuhashi, T.; Atsudo, T.; Okota, Y. Low-power and High-integration Driver IC for Small-sized TFT-LCDs. Proceedings of SID Display Week Symposium, Baltimore, MD, USA, 18–23 May 2003; pp. 1244–1247. [Google Scholar]

- Shift Registers in Digital Logic. Available online: https://www.geeksforgeeks.org/shift-registers-in-digital-logic/ (accessed on 10 March 2024).

- Jeon, J.; Choo, K.-S.; Lee, W.-K.; Song, J.-H.; Kim, H.-G. Integrated a-Si Gate Driver Circuit for TFT-LCD Panel. Proceedings of SID Display Week Symposium, Seattle, WA, USA, 23–28 May 2004; pp. 10–13. [Google Scholar]

- Ha, Y.-M.; Hong, S.-K.; Jeong, H.; Park, J.-D.; Kim, B.-K.; Kim, W.-Y. P-type Low-Power Low-Temperature TFT-LCDs. Proceedings of SID Display Week Symposium, Seattle, WA, USA, 23–28 May 2004; pp. 1080–1083. [Google Scholar]

- Nam, W.-J.; Jung, S.-H.; Lee, J.-H.; Lee, H.-J.; Han, M.-K. A Low-Voltage P-type Poly-Si Integrated Driving Circuits for Active Matrix Display. Proceedings of SID Display Week Symposium, Boston, MA, USA, 24–27 May 2005; pp. 1046–1049. [Google Scholar]

- Lee, Y. S.; Park, H. W.; Moon, S.-H.; Kim, T.; Lee, K.-C.; Berkeley, B. H. ; Kim. S.-S. Advanced TFT-LCD Data Line Reduction Method. In Proceedings of SID Display Week Symposium, San Francisco, CA, USA, 4–6 June 2006; pp. 1083–1086. [Google Scholar]

- Yeh, S.-H.; Sun, W.-T.; Pai, C.-C.; Chou, H.-S.; Yang, C.-S. System-on-Glass LTPS LCD using P-type TFTs. Proceedings of SID Display Week Symposium, San Francisco, CA, USA, 4–6 June 2006; pp. 1177–1180. [Google Scholar]

- Ibaraki, N. a-Si TFT technologies for large-size and high-pixel-density AM-LCDs. Mater. Chem. Phys. 1996, 43, 220–226. [Google Scholar] [CrossRef]

- Nathan, A.; Servati, P.; Karim, K. S. TFT circuit integration in a-Si:H technology. Proceedings of International Conference on Microelectronics, Nis, Yugoslavia, 12–15 May 2002. [Google Scholar]

- Li, J.; Bansal, A.; Roy, K. Poly-Si Thin-Film Transistors: An Efficient and Low-Cost Option for Digital Operation. IEEE Trans. Electron Devices 2007, 54, 2918–2929. [Google Scholar] [CrossRef]

- Lih, J.-J.; Sung, C.-F.; Li, C.-H.; Hsiao, T.-H.; Lee, H.-H. Comparison of a-Si and Poly-Si for AMOLED displays. J. Soc. Inf. Disp. 2012, 12, 367–371. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef] [PubMed]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide Semiconductor Thin-Film Transistors: A Review of Recent Advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y. Thin Film Transistor Technology—Past, Present, and Future. Electrochem. Soc. Interface 2013, 22, 55. [Google Scholar] [CrossRef]

- Jang, J. Past, current and future TFT technologies for display manufacturing. Proceedings of International Workshop on Active-Matrix Flatpanel Displays and Devices, Kyoto, Japan, 02–05 July 2013. [Google Scholar]

- Mativenga, M.; Geng, D.; Jang, J. Oxide Versus LTPS TFTs for Active-Matrix Displays. Proceedings of SID Display Week Symposium, San Diego, CA, USA, 1–6 June 2014; pp. 1–4. [Google Scholar]

- Geng, D.; Wang, K.; Li, L.; Myny, K.; Nathan, A.; Jang, J.; Kuo, Y.; Liu, M. Thin-film transistors for large-area electronics. Nat. Electron. 2023, 6, 963–972. [Google Scholar] [CrossRef]

- Plus, D. Shift register useful as a select line scanner for liquid crystal display. US Patent 5,222,082, 1993. [Google Scholar]

- Lebrun, H.; Kretz, T.; Magarino, J.; Szydlo, N. Design of integrated Drivers with Amorphous Silicon TFTs for Small Displays. Basic Concepts. In Proceedings of SID Display Week Symposium, Boston, MA, USA, 24–27 May 2005; pp. 950–953. [Google Scholar]

- Oh, J. H.; Hur, J. H.; Son, Y. D.; Kim, K. M.; Kim, S. H. ; Kim. E. H; Choi, J. W., Hong, S. M., kim, J. O., Bae, B. S., Eds.; Jang, J. 2.0 inch a-Si: H TFT-LCD with Low Noise Integrated Gate Driver. In Proceedings of SID Display Week Symposium, Boston, MA, USA, 27 May 2005; pp. 942–945. [Google Scholar]

- Kim, C.-H.; Yoo, S.-J.; Kim, H.-J.; Jun, J.-M.; Lee, J.-Y. Integrated a-Si TFT row driver circuits for high-resolution applications. J. Soc. Inf. Disp. 2006, 14, 333–337. [Google Scholar] [CrossRef]

- Nam, H.; Song, E. Oxide TFT inverter with wide output dynamic range. Electron. Lett. 2012, 48, 791–792. [Google Scholar] [CrossRef]

- Song, E.; Nam, H. Shoot-through current reduction scheme for low power LTPS TFT programmable shift register. J. Soc. Inf. Disp. 2014, 22, 18–22. [Google Scholar] [CrossRef]

- Liu, S.-E.; Kung, C.-P.; Hou, J. Estimate Threshold Voltage Shift in a-Si:H TFTs Under Increasing Bias Stress. IEEE Trans. Electron Devices 2009, 56, 65–69. [Google Scholar] [CrossRef]

- Jeong, J. K.; Yang, H. W.; Jeong, J. H.; Mo. Y.-G.; Kim, H. D. Origin of threshold voltage instability in indium-gallium-zinc oxide thin film transistors. Appl. Phys. Lett. 2008, 93, 123508. [Google Scholar] [CrossRef]

- Wei, C.-C.; Lin, W.-C.; Lo, S.-H.; Chang, C.-J.; Wu, W.-E. Integrated Gate Driver Circuit Using a-Si TFT. Proceedings of International Display Workshops, Takamatsu, Japan, 06–09 December 2005. [Google Scholar]

- Koo, J. H.; Choi, J. W.; Kim, Y. S.; Kang, M. H.; Ahn, K. W.; Lee, S. W.; Jang, J. Nobel a-Si:H Gate Drivers with High Reliability. Proceedings of International Display Workshops, Otsu, Japan, 06–08 December 2006. [Google Scholar]

- Moon, S.-H.; Lee, Y.-S.; Lee, M.-C.; Berkeley, B. H.; Kim, N.-D.; Kim, S.-S. Integrated a-Si:H TFT Gate Driver Circuits on Large Area TFT-LCDs. Proceedings of SID Display Week Symposium, Long Beach, CA, USA, 20–25 May 2007; pp. 1478–1481. [Google Scholar]

- Shih, C. J.; Hsu, C. Y.; Kuo, C. C.; Ku, C. P.; Yu, C. K.; Tsai, C. H. 5” WQVGA a-Si TFT LCD with High Reliability Integrated Gate Driver. Proceedings of International Display Workshops, Sapporo, Japan, 05–07 December 2007. [Google Scholar]

- Hwang, I.; Moh, S.; Lee, M.-C.; Lee, E.-S. Design of Integrated a-Si Gate Driver Circuits for Low Power Consumption. Proceedings of SID Display Week Symposium, Los Angeles, CA, USA, 18–23 May 2008; pp. 842–845. [Google Scholar]

- Lin, C.-L.; Tu, C.-D.; Chuang, M.-C.; Yu, J.-S. Design of Bidirectional and Highly Stable Integrated Hydrogenated Amorphous Silicon Gate Driver Circuits. J. Disp. Technol. 2011, 7, 10–18. [Google Scholar] [CrossRef]

- Lin, C.-L.; Chen, M.-H.; Tu, C.-D.; Chuang, M.-C. Highly Reliable Integrated Gate Driver Circuit for Large TFT-LCD Applications. IEEE Electron Device Lett. 2012, 33, 679–681. [Google Scholar] [CrossRef]

- Kim, B.; Jang, Y. H.; Yoon, S. Y.; Chun, M. D.; Cho, H. N.; Cho, N. W.; Sohn, C. Y.; Jo, S. H.; Choi, S. C.; Kim, C.-D.; Chung, I.-J. a-Si Gate Driver Integration with Time Shared Data Driving. Proceedings of International Display Workshops, Takamatsu, Japan, 06–09 December 2005. [Google Scholar]

- Yoon, S. Y.; Jang, Y. H.; Kim, B.; Chun, M. D.; Cho, H. N.; Cho, N. W.; Sohn, C. Y.; Jo, S. H.; Kim, C.-D.; Chung, I.-J. Highly Stable Integrated Gate Driver Circuit using a-Si TFT with Dual Pull-down Structure. Proceedings of SID Display Week Symposium, Boston, MA, USA, 24–27 May 2005; pp. 348–351. [Google Scholar]

- Yeh, S.-H.; Sun, W.-T.; Pai, C.-C.; Chou, H.-S.; Yang, C.-S. System-on-Glass LTPS LCD using P-type TFTs. Proceedings of SID Display Week Symposium, San Francisco, CA, USA, 4–9 June 2006; pp. 1177–1180. [Google Scholar]

- Nam, W.-J.; Lee, J.-H.; Lee, H.-J.; Shin, H.-S.; Han, M.-K. Peripheral circuit designs using low-temperature p-type poly-Si thin-film transistors. J. Soc. Inf. Disp. 2006, 14, 403–409. [Google Scholar] [CrossRef]

- Zhao, L.-Q.; Wu, C.-Y.; Hao, D.-S.; Yao, Y.; Meng, Z.-G.; Xiong, S.-Z. An integrated driving circuit implemented with p-type LTPS TFTs for AMOLED. Optoelectron. Lett. 2009, 5, 104–107. [Google Scholar] [CrossRef]

- Jung, M-H. ; Chung H.-J.; Park, Y.-J.; Kim, O. A Full p-Type Poly-Si TFT Shift Register for Active Matrix Displays. MRS Online Proceedings Library 2009, 1245, 1906. [Google Scholar] [CrossRef]

- Tsai, Y.-S.; Liu, C.-Y.; Tseng, C.-C.; Shih, L.-W. A Slim Border Design for Wearable Display: Using Novel P-type Shift Register and Optimal Layout Arrangement. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 31 May–4 June 2015; pp. 64–66. [Google Scholar]

- Chen, M.; Lei, J.; Huang, S.; Liao, C.; Deng, L. Poly-Si TFTs integrated gate driver circuit with charge-sharing structure. J. Semicond. 2017, 38, 055001. [Google Scholar] [CrossRef]

- Kang, C.-K.; Park, Y.-S.; Park, S.-I.; Mo, Y.-G.; Kim, B.-H.; Kim, S. S. Integrated Scan Driver with Oxide TFTs Using Floating Gate Method. Proceedings of SID Display Week Symposium, Los Angeles, CA, USA, 15–20 May 2011; pp. 25–27. [Google Scholar]

- Park, Y.-S.; Chung, B.-Y.; Kang, C.-K.; Park, S.-I.; Im, K.-J.; Jeong, J. H.; Kim, B.-H.; Kim, S. S. Oxide TFT Scan Driver with Dynamic Threshold Voltage Control. Proceedings of SID Display Week Symposium, Los Angeles, CA, USA, 15–20 May 2011; pp. 718–721. [Google Scholar]

- Kim, B.; Ryoo, C.-I.; Kim, S.-J.; Bae, J.-U.; Seo, H.-S.; Kim, C.-D.; Han, M.-K. New Depletion-Mode IGZO TFT Shift Register. IEEE Electron Device Lett. 2011, 32, 158–160. [Google Scholar] [CrossRef]

- Kim, B.; Choi, C. C.; Lee, S.-Y.; Kuk, S.-H.; Jang, Y. H.; Kim, C.-D.; Han, M. K. A Depletion-Mode a-IGZO TFT Shift Register With a Single Low-Voltage-Level Power Signal. IEEE Electron Device Lett. 2011, 32, 1092–1094. [Google Scholar] [CrossRef]

- Kim, B.; Choi, S. C.; Lee, J.-S.; Kim, S.-J.; Jang, Y.-H.; Yoon, S.-Y.; Kim, C.-D.; Han, M.-K. A Depletion-Mode In–Ga–Zn–O Thin-Film Transistor Shift Register Embedded With a Full-Swing Level Shifter. IEEE Trans. Electron Devices 2011, 58, 3012–3017. [Google Scholar] [CrossRef]

- Kim, B.; Cho, H. N.; Choi, W. S.; Kuk, S.-H.; Jang, Y. H.; Yoo, J.-S.; Yoon, S. Y.; Jun, M.; Hwang, Y.-K.; Han, M.-K. Highly Reliable Depletion-Mode a-IGZO TFT Gate Driver Circuits for High-Frequency Display Applications Under Light Illumination. IEEE Electron Device Lett. 2012, 33, 528–530. [Google Scholar] [CrossRef]

- Song, E.; Kang, B.; Han, I.; Oh, K.; Kim, B.; Nam, H. Depletion Mode Oxide TFT Shift Register for Variable Frame Rate AMOLED Displays. IEEE Electron Device Lett. 2015, 36, 247–249. [Google Scholar] [CrossRef]

- Cho, H. N.; Kim, H. Y.; Il, C. R.; Choi, S. C.; Kim, B.; Jang, Y. H.; Yoon, S. Y.; Chun, M. D.; Park, K.-S.; Moon, T.; Cho, N. W.; Jo, S. H.; Kim, S. K.; Kim, C.-D.; Kang, I. B. Amorphous-silicon gate-driver circuits of shared-node dual pull-down structure with overlapped output signals. J. Soc. Inf. Disp. 2008, 16, 77–81. [Google Scholar] [CrossRef]

- Kim, B.; Cho, H. N.; Choi, W. S.; Kuk, S.-H.; Yoo, J.-S.; Yoon, S. Y.; Jun, M.; Hwang, Y.-K.; Han, M.-K. A Novel Depletion-Mode a-IGZO TFT Shift Register With a Node-Shared Structure. IEEE Electron Device Lett. 2012, 33, 1003–1005. [Google Scholar] [CrossRef]

- Shin, H.-J.; Chang, M.-K.; Kim, Y.-H.; Choi, S.-H.; Bae, S.-J.; Shin, W.-S.; Lee, H.-W. An Improved Gate Driver Using Oxide TFTs for Large OLED Displays. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 501–504. [Google Scholar]

- Kim, Y. I.; Park, S.-J.; Nam, H. Node-sharing low-temperature poly silicon TFT shift register without bootstrapping degradation for narrow bezel displays. Electron. Lett. 2018, 54, 1162–1164. [Google Scholar] [CrossRef]

- Kim, Y. I.; Nam, H. Clocked control scheme of separating TFTs for a node-sharing LTPS TFT shift register with large number of outputs. J. Soc. Inf. Disp. 2020, 28, 825–830. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Kim, E.; Jung, E. K.; Hong, S.; Im, H.; Kim, Y.-S. Indium–Gallium–Zinc Oxide Thin-Film Transistor-Based Scan Driver Circuit Using Separate Driving Structure for Multiple Output Signals. IEEE Trans. Electron Devices 2023, 70, 3605–3610. [Google Scholar] [CrossRef]

- Hack, M.; Brown, J. J.; Mahon, J. K.; Kwong, R. C.; Hewitt, R. Performance of high-efficiency AMOLED displays. J. Soc. Inf. Disp. 2001, 9, 191–195. [Google Scholar] [CrossRef]

- Kowalsky, W.; Becker, E.; Benstem, T.; Dobbertin, T.; Heithecker, D.; Johannes, H.-H.; Metzdorf, D.; Neuner, H. OLED matrix displays: technology and fundamentals. Proceedings of International IEEE Conference on Polymers and Adhesives in Microelectronics and Photonics. Incorporating POLY, PEP & Adhesives in Electronics, Potsdam, Germany, 21–24 October 2001. [Google Scholar]

- Sakariya, K.; Servati, P.; Striakhilev, D.; Nathan, A. Vt-Shift Compensating Amorphous Silicon Pixel Circuits for Flexible OLED Displays. Proceedings of MRS Fall Meeting & Exhibit, Boston, MA, USA, 1–5 December 2002. [Google Scholar]

- Sanford, J. L.; Libsch, F. R. Vt Compensated voltage-data a-Si TFT AMOLED pixel circuits. J. Soc. Inf. Disp. 2004, 12, 65–73. [Google Scholar] [CrossRef]

- Han, M.-K. AM backplane for AMOLED. Proceedings of Asian Symposium on Information Display, New Delhi, India, 8–12 October 2006. [Google Scholar]

- Lin, J.-T.; Wne, C.-N.; Lin, P.-H. A compensation threshold voltage shift pixel circuit for active matrix organic light emitting diode. Proceedings of International Conference on Microelectronics, Nis, Serbia and Montenegro, 11–14 May 2008. [Google Scholar]

- Onoyama, Y.; Yamashita, J.; Kitagawa, H.; Hasegawa, E.; Makita, A.; Yokoyama, S.; Asaki, R.; Kambe, E.; Nishimura, T.; Yamada, J.; Uchino, K.; Makimura, S.; Shiraishi, Y.; Urabes, T. 0. 5-inch XGA Micro-OLED Display on a Silicon Backplane with High-Definition Technologies. In Proceedings of SID Display Week Symposium, Boston, MA, USA, 5–8 May 2012; pp. 950–953. [Google Scholar]

- Chung, B.-Y.; Kwon, O.-K.; Matsueda, Y.; Kim, H.-D. An Emission Control Driver Using P-type TFTs for AMOLED Displays. Proceedings of International Technical Conference on Circuits/Systems, Computers and Communication, Shimonoseki, Japan, 6–9 July 2008; pp. 1009–1012. [Google Scholar]

- Song, E.; Nam, H. Programmable Pulse Width LTPS TFT Shift Register for High Resolution and High Frame Rate Active Matrix Flat Panel Displays. Proceedings of SID Display Week Symposium, Vancouver, Canada, 19–24 May 2013; pp. 473–477. [Google Scholar]

- Song, E.; Nam, H. Low Power Programmable Shift Register With Depletion Mode Oxide TFTs for High Resolution and High Frame Rate AMFPDs. J. Disp. Technol. 2014, 10, 834–838. [Google Scholar] [CrossRef]

- Song, E.; Song, S.-J.; Nam, H. Pulse-width-independent low power programmable low temperature poly-Si thin-film transistor shift register. Solid-State Electron. 2015, 107, 35–39. [Google Scholar] [CrossRef]

- Chang, M.-K.; Kim, J.-H.; Nam, H. Fine-Tunable Emission Pulse Generation Circuit Based on p-Type Low-Temperature Poly-Si Thin-Film Transistors for Active Matrix Organic Light-Emitting Diode Displays. IEEE Trans. Electron Devices 2023, 70, 3092–3099. [Google Scholar] [CrossRef]

- Lee, B.-W.; Ji, I.-H.; Han, S.-M.; Sung, S.-D.; Shin, K.-S.; Lee, J. D.; Kim, B. H.; Berkeley, B. H.; Kim, S. S. Novel Simultaneous Emission Driving Scheme for Crosstalk-free 3D AMOLED TV. Proceedings of SID Display Week Symposium, Seattle, WA, USA, 25–28 May 2010; pp. 758–761. [Google Scholar]

- Bastani, B.; Turner, E.; Vieri, C.; Jiang, H.; Funt, B.; Balram, N. Foveated pipeline for AR/VR head-mounted displays. Inf. Disp. 2017, 33, 14–35. [Google Scholar] [CrossRef]

- Bhowmik, A. K. Advances in virtual, augmented, and mixed reality technologies. Inf. Disp. 2018, 34, 18–21. [Google Scholar] [CrossRef]

- Albert, R.; Patney, A.; Luebke, D.; Kim, J. Latency requirements for foveated rendering in virtual reality. ACM Trans. Appl. Percept. 2017, 14, 1–13. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y. I.; Nam, H. Foveation-based reduced resolution driving scheme for immersive virtual reality displays. Opt. Express 2019, 27, 29594. [Google Scholar] [CrossRef] [PubMed]

- Nam, H.; Kang, H. Complexity-Reduced Super Resolution for Foveation-based Driving Head Mounted Displays. IEEE Access 2021, 9, 140042–140049. [Google Scholar] [CrossRef]

- Bae, J.; Lee, J.; Nam, H. Variable Clock and EM Signal Generation Scheme for Foveation-based Driving OLED Head-Mounted Displays. Electron. 2021, 10, 538. [Google Scholar] [CrossRef]

- Sugita, Y.; Kida, K.; Yamagishi, S. In-Cell Projected Capacitive Touch Panel Technology. IEICE Trans. Electron. 1384. [Google Scholar] [CrossRef]

- Moon, S.-H.; Haruhisa, I.; Kim, K.; Park, C.-W.; Chung, H.-J.; Kim, S.-H.; Kim, B.-K.; Kim, O. Highly Robust Integrated Gate-Driver for In-Cell Touch TFT-LCD Driven in Time Division Driving Method. J. Disp. Technol. 2015, 12, 435–441. [Google Scholar] [CrossRef]

- Lin, C.-L.; Lai, P.-C.; Lai, P.-C.; Chu, T.-C.; Lee, C.-L. Bidirectional Gate Driver Circuit Using Recharging and Time-Division Driving Scheme for In-Cell Touch LCDs. IEEE Trans. Ind. Electron. 2017, 65, 3585–3591. [Google Scholar] [CrossRef]

- Seo, J.; Nam, H. Robust integrated shift register circuit over clock noises for in-cell touch applications. J. Soc. Inf. Disp. 2017, 25, 537–543. [Google Scholar] [CrossRef]

- Seo, J.; Nam, H. Low power and low noise shift register for in-cell touch display applications. IEEE J. Electron Devices Soc. 2018, 6, 726–732. [Google Scholar] [CrossRef]

- Shen, S.; Liao, C.; Yang, J.; Jiao, H.; Zhang, S. Capacitor Reused Gate Driver for Compact In-Cell Touch Displays. IEEE J. Electron Devices Soc. 2021, 9, 533–538. [Google Scholar] [CrossRef]

- Tai, Y.-H.; Chen, B.-T.; Kuo, Y.-J.; Tsai, C.-C.; Chiang, K.-Y.; Wei, Y-J. ; Chen, H.-C. A new pixel circuit for driving organic light-emitting diode with low temperature polycrystalline silicon thin-film transistors. J. Disp. Technol. 2005, 1, 100–104. [Google Scholar] [CrossRef]

- Han, N.-K. AM backplane for AMOLED. Proceedings of Asian Symposium on Information Display (ASID), New Delhi, India, 8–12 October 2006; pp. 53–58. [Google Scholar]

- Lee, J.-H.; Nam, W.-J.; Kim, B.-K.; Choi, H.-S.; Ha, Y.-M.; Han, M.-K. A new Poly-Si TFT current-mirror pixel for active matrix organic light emitting diode. IEEE Electron Device Lett. 2006, 27, 830–833. [Google Scholar] [CrossRef]

- In, H. J.; Oh, K. H.; Lee, I.; Ryu, D. H.; Choi, S. M.; Kim, K. N.; Kim, H. D.; Kwon, O. K. An advanced external compensation system for active matrix organic light-emitting diode displays with poly-Si thin-film transistor backplane. IEEE Trans. Electron Devices 2010, 57, 3012–3019. [Google Scholar] [CrossRef]

- Song, S.-J.; Chen, Y.; Jang, J.; Nam, H. Hybrid Voltage and Current Programming Pixel Circuit for High Brightness Simultaneous Emission AMOLED Display. J. Disp. Technol. 2015, 11, 255–260. [Google Scholar] [CrossRef]

- Takasugi, S.; Shin, H.-J.; Chang, M.-K.; Ko, S.-M.; Park, H.-J.; Lee, J.-P.; Kim, H.-S.; Oh, C.-H. Advanced compensation technologies for largesized UHD OLED TVs. J. Soc. Inf. Disp. 2016, 24, 410–418. [Google Scholar] [CrossRef]

- Kwon, J.; Lee, C.; Chae, Y.; Murmann, B. Design Considerations for External Compensation Approaches to OLED Display Degradation. Proceedings of IEEE International Symposium on Circuits and Systems (ISCAS), Seville, Spain, 12–14 October 2020. [Google Scholar]

- Park, K.; Oh, S.; Choi, D.; Shin, K.; Cho, H.; Bien, F. Real-Time External Compensation System With Error Correction Algorithm for High-Resolution Mobile Displays. IEEE Trans. Circuits Syst. I: Regul. Pap. 2023, 70, 1121–1132. [Google Scholar] [CrossRef]

- Kim, I. J.; Noh, S.; Ban, M. H.; Son, K.; Han, I.; Shin, H. K.; Oh, K.; Kim, B.; Kang, I. B. Integrated gate driver circuit technology with IGZO TFT for sensing operation. J. Soc. Inf. Disp. 2019, 27, 313–318. [Google Scholar] [CrossRef]

- Kim, Y.-D.; Han, K.-L.; Park, J.-S.; Choi, B.-D. A Random Access Gate Driver Using a-IGZO TFTs for External Compensation of High-Resolution, High-Frame-Rate AMOLEDs. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 8–13 May 2022; pp. 32–35. [Google Scholar]

- Nam, H.; Lee, S. W. Low-Power Liquid Crystal Display Television Panel with Reduced Motion Blur. IEEE Trans. Consum. Electron. 2010, 56, 307–311. [Google Scholar] [CrossRef]

- Yonebayashi, R.; Tanaka, K.; Okada, K.; Yamamoto, K.; Yamamoto, K.; Uchida, S.; Aoki, T.; Takeda, Y.; Furukawa, H.; Ito, K.; Katoh, H.; Nakamura, W. High refresh rate and low power consumption AMOLED panel using top-gate n-oxide and p-LTPS TFTs. Proceedings of SID Display Week Symposium, Online, 3–7 August 2020; pp. 355–358. [Google Scholar]

- You, B.; Nam, H.; Lee, H. Image Adaptive Refresh Rate Technology for Ultra Low Power Consumption. Proceedings of SID Display Week Symposium, Online, 3–7 August 2020; pp. 676–679. [Google Scholar]

- Slavenburg, G.; Janseens, M.; Lucas, L.; Schutten, R. J.; Verbeure, T. Variable Refresh Rate Displays. Proceedings of SID Display Week Symposium, Online, 3–7 August 2020; pp. 669–672. [Google Scholar]

- Kwon, S.; Kim, S.; Yoon, C.; Kim, T.; Yang, J.; Choi, Y.; Choe, W. Multi-Frequency driving of OLED for low power consumption. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 8–13 May 2022; pp. 155–158. [Google Scholar]

- Jo, J.-H.; Jeong, W.-B.; Joung, Y.-S.; Lee, S.-W. Selective Scan Driver for Low-Power Consumption Using Oxide Thin Film Transistors. IEEE Electron Device Lett. 2022, 43, 1263–1266. [Google Scholar] [CrossRef]

- Yuan, Z.; Han, Y.; Meng, S.; Gu, X.; Liu, X.; Li, Y.; Xu, P.; Yuan, C.; Cheng, X.; Yan, G.; Yu, J.; Dong, X. An Innovative Decoder-type GOA for Intelligent Split-Screen and External Compensation Technology. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 513–516. [Google Scholar]

- Huang, Z.; Xu, J.; Pan, Z.; Yang, Y.; Zhang, L.; Dang, P. l Shen, Y. ; Zhu, X. Gate Driver Circuit to generating Multi-Frequency Pulses using LTPO Technology. In Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 1664–1666. [Google Scholar]

- Chang, T.-K.; Lin, C.-W.; Chang, S. LTPO TFT Technology for AMOLEDs. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2019; pp. 545–548. [Google Scholar]

- Chung, U.-J.; Choi, S.-C.; Noh, S. Y.; Kim, K.-T.; Moon, K.-J.; Kim, J.-H.; Park, K.-S.; Choi, H.-C.; Kang, I.-B. Manufacturing Technology of LTPO TFT. Proceedings of SID Display Week Symposium, Online, 3–7 August 2020; pp. 545–548. [Google Scholar]

- Qiu, H.; An, J.; Wang, K.; Liao, C.; Dai, C.; Zhang, X.; Zhang, S. A Low Power and IR Drop Compensable AMOLED Pixel Circuit Based on Low-Temperature Poly-Si and Oxide (LTPO) TFTs Hybrid Technology. IEEE J. Electron Devices Soc. 2022, 10, 51–58. [Google Scholar] [CrossRef]

- Fu, J.; Peng, Z.; Liao, C.; Zheng, X.; An, J.; Liang, J.; Dai, C.; Zhang, X.; Zhang, S. High Performance AMOLED Pixel Circuit Using Interleaved Emit Signals Based on Low-Temperature Poly-Si and Oxide (LTPO) TFTs. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 8–13 May 2022; pp. 132–135. [Google Scholar]

- An, J.; Liao, C.; Zhu, Y.; Zheng, X.; Dai, C.; Zhang, X.; Zhang, S. Gate Driver on Array With Multiple Outputs and Variable Pulse Widths for Low-Temperature Polysilicon and Oxide (LTPO) TFTs Driven AMOLED Displays. IEEE Trans. Circuits Syst. II Express Briefs 2022, 70, 934–938. [Google Scholar] [CrossRef]

- Kim, J.; Billah, M. M.; Jang, J. Ultra-Low Power, Emission Gate Driver With Pulse Width Modulation Using Low-Temperature Poly-Si Oxide Thin-Film Transistors. IEEE Electron Device Lett. 2022, 43, 236–239. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, M.; Kim, B.; Jang, J. 38μm-Pitch, 3-Output Gate Driver Using Low-Temperature Poly-Si Oxide TFTs for High Resolution Display. IEEE Electron Device Lett. 2022, 43, 1471–1474. [Google Scholar] [CrossRef]

- Kim, J.; Lee, H.; Jang, J. Emission Gate Driver With Five Low-Temperature Poly-Si Oxide TFTs Without Capacitor for Narrow-Bezel AMOLED Display. IEEE J. Solid-State Circuits 2022, 6, 53–56. [Google Scholar] [CrossRef]

- Xu, Y.; Ruan, C.-P.; Zhou, L.; Zou, J.-H.; Xu, M.; Wu, W.-J.; Wang, L.; Peng, J.-B. A 256 × 256, 50-μm Pixel Pitch OPD Image Sensor Based on an IZO TFT Backplane IEEE Sensor J. 2021, 21, 20824–20832. 21. [CrossRef]

- Zhuo, R.; Lin, P.; Wu, Y.; Wu, Z.; Ye, D.; Huangfu, J. Sensorless LED display screen interaction and object recognition. J. Soc. Inf. Disp. 2021, 30, 141–158. [Google Scholar] [CrossRef]

- Yamada, N.; Nakanotani, H.; Takagi, A.; Mamada, M.; Balijapalli, U.; Ichikawa, T.; Hirata, E.; Kaizu, S.; Tanaka, A.; Itonaga, K.; Adachi, C. Three-dimensional sensing of surfaces by projection of invisible electroluminescence from organic light-emitting diodes. Sci. Adv. 2024, 10, eadj6583. [Google Scholar] [CrossRef]

- Tai, Y.-H.; Tu, C.-C.; Yuan, Y.-C.; Chang, Y.-J.; Hsu, M.-H.; Chuang, C.-Y. Light-Controlled Gap-Type TFT Used for Large-Area Under-Screen Fingerprint Sensor. IEEE J. Electron Devices Soc. 2021, 9, 517–520. [Google Scholar] [CrossRef]

- Yin, P.-H.; Lu, C.-W.; Wang, J.-S.; Chang, K.-L.; Lin, F.-K.; Chen, P. A 368 × 184 Optical Under-Display Fingerprint Sensor Comprising Hybrid Arrays of Global and Rolling Shutter Pixels With Shared Pixel-Level ADCs. IEEE J. Solid-State Circuits 2021, 56, 763–777. [Google Scholar] [CrossRef]

- Jeon, D.-H.; Jeong, W.-B.; Chung, H.-J.; Lee, S.-W. Novel Micro-LED Display Featuring Fingerprint Recognition Without Additional Sensors. IEEE Access 2022, 10, 74187–74197. [Google Scholar] [CrossRef]

- Jeon, D.-H.; Jeong, W.-B.; Lee, S.-W. Novel Active-Matrix Micro-LED Display With External Compensation Featuring Fingerprint Recognition. IEEE Electron Device Lett. 2022, 43, 1483–1486. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hatsumi, R.; Nakazawa, Y.; Idojiri, S.; Kamada, T.; Kubota, D.; Okazaki, K.; Yamagata, S.; Yamazaki, S. Organic Light-Emitting Diode Display Constituted Side-by-Side OLED and Organic Photodiode Pixels Integrated in the Same Plane by Adopting MML (Metal Mask-Less Lithography) Technology. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 138–141. [Google Scholar]

- Bae, K. S.; Kim, G. H.; Park, H. A.; Park, J.; Ahn, T.; Lee, D.-Y.; Moon, S.; Kim, J.-K.; Kim, C.; Kim, Y. Full Screen Fingerprint Display with Embedded Organic Photo-detectors. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 142–145. [Google Scholar]

- Ku, N.; Hwang, J. C.; Oh, B.; Park, J.-U. Smart Sensing Systems Using Wearable Optoelectronics. Adv. Intell. Syst. 2020, 2, 1900144. [Google Scholar] [CrossRef]

- Chen, Y.; Lee, S.; Kim, H.; Lee, J.; Geng, D.; Jang, J. In-pixel temperature sensor for high-luminance active matrix micro-light-emitting diode display using low-temperature polycrystalline silicon and oxide thin-film-transistors. J. Soc. Inf. Disp. 2020, 28, 528–534. [Google Scholar] [CrossRef]

- Mu, G.; Rao, T.; Qi, Y.; Ma, S.; Hao, Q.; Chen, M.; Tang, X. Color-Tunable Organic Light-Emitting Displays for Interactive Multi-Signal Visualization. Adv. Funct. Mater. 2023, 33, 2301280. [Google Scholar] [CrossRef]

- Miao, W.-C.; Hsiao, F.-H.; Sheng, Y.; Lee, T.-Y.; Hong, Y.-H.; Tsai, C.-W.; Chen, H.-L.; Liu, Z.; Lin, C.-L.; Chung, R.-J.; Ye, Z.-T.; Horng, R.-H.; Chen, S.-C.; Kuo, H.-C.; He, J.-H. Microdisplays: Mini-LED, Micro-OLED, and Micro-LED. Adv. Opt. Mater. 2023, 12, 2300112. [Google Scholar] [CrossRef]

- Yu, S.; Park, T. H.; Jiang, W.; Lee, S. W.; Kim, E. H.; Lee, S.; Park, J.-E.; Park, C. Soft Human–Machine Interface Sensing Displays: Materials and Devices. Adv. Mater. 2023, 35, 2204964. [Google Scholar] [CrossRef]

- Ye, H.; Wang, Q. SpiderWeb: Enabling Through-Screen Visible Light Communication. In Proceedings of the ACM Conference on Embedded Networked Sensor Systems, Coimbra, Portugal, 15–17 November 2021; pp. 316–328. [Google Scholar]

- Chaleshtori, Z. N.; Zvanovec, S.; Ghassemlooy, Z.; Khalighi, M.-A. Visible light communication with OLEDs for D2D communications considering user movement and receiver orientations. Appl. Opt. 2022, 61, 676–682. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Choi, J.; Hwangbo, S.; Kwon, D.-H.; Jang, B.; Ji, S.; Kim, J.-H.; Han, S.-K.; Ahn, J.-H. Flexible micro-LED display and its application in Gbps multi-channel visible light communication. npj Flex. Electron. 2023, 6, 100. [Google Scholar] [CrossRef]

- Zhao, Z.; Qiu, Y.; Zou, G.; Weng, J.; Yang, B.-R.; Qin, Z. Mini-LED LCDs Integrated with High-capacity MIMO Visible Light Communication. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 212–215. [Google Scholar]

- Sung, S. H.; Kho, Y.-S.; Park, S. 60kHz Ultrasonic Actuators for Animal-Friendly Haptic Displays. Proceedings of SID Display Week Symposium, San Jose, CA, USA, 13–17 May 2024; pp. 1338–1340. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).