Submitted:

24 May 2024

Posted:

27 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

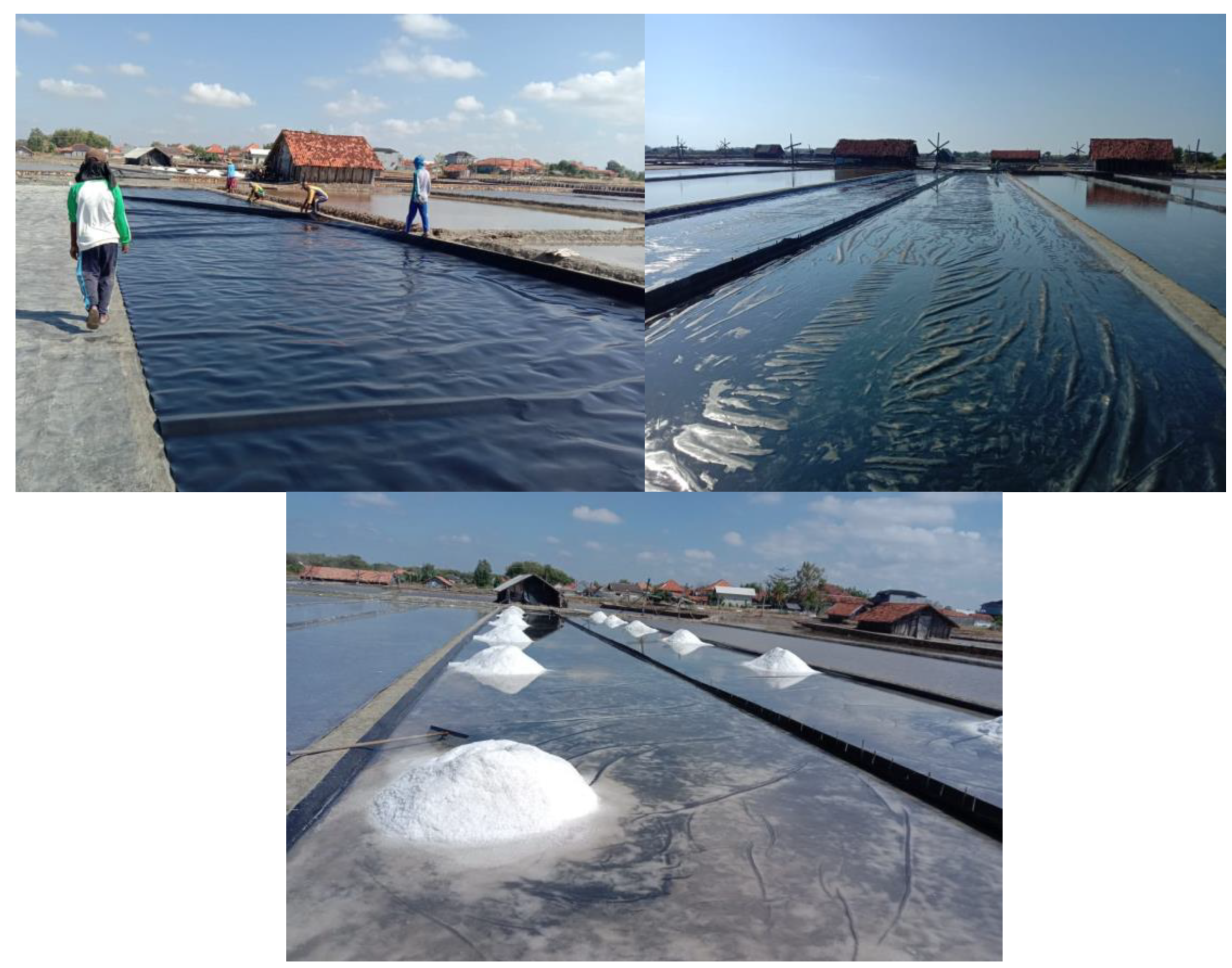

2. Materials and Methods

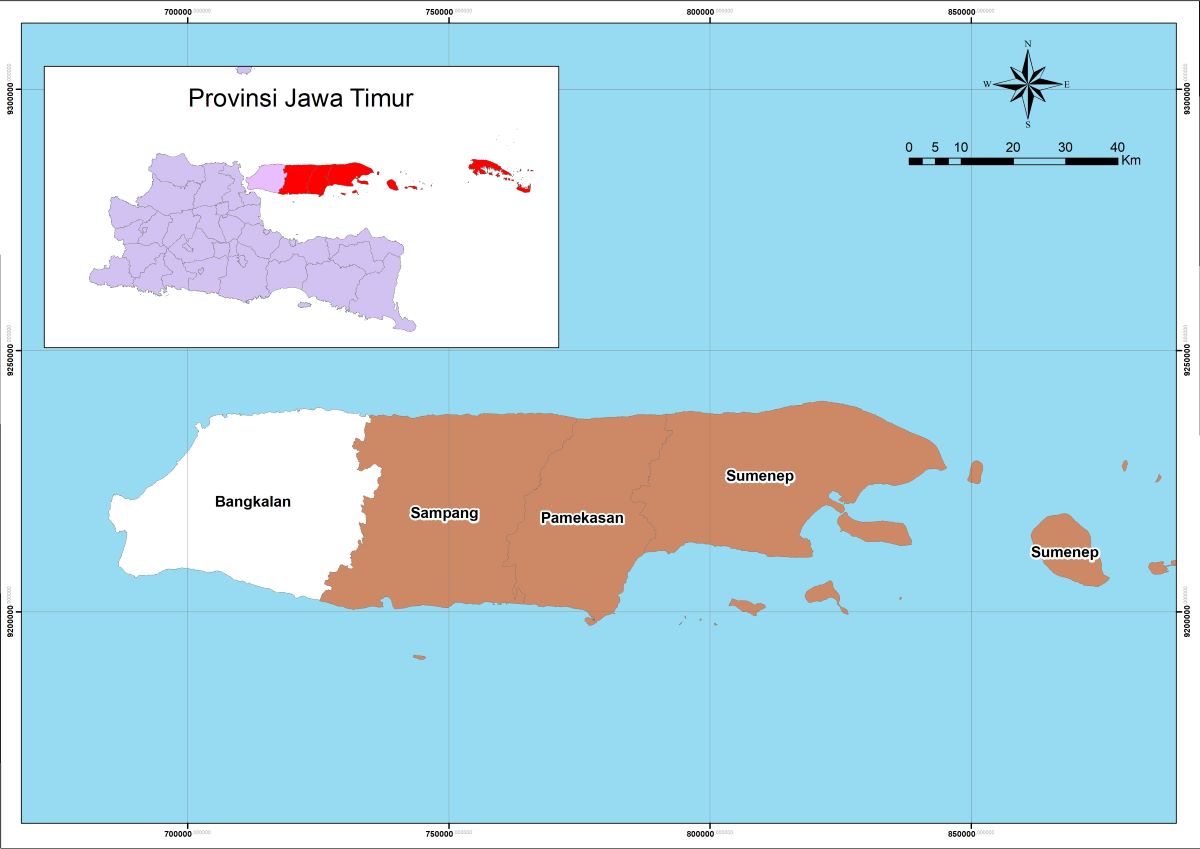

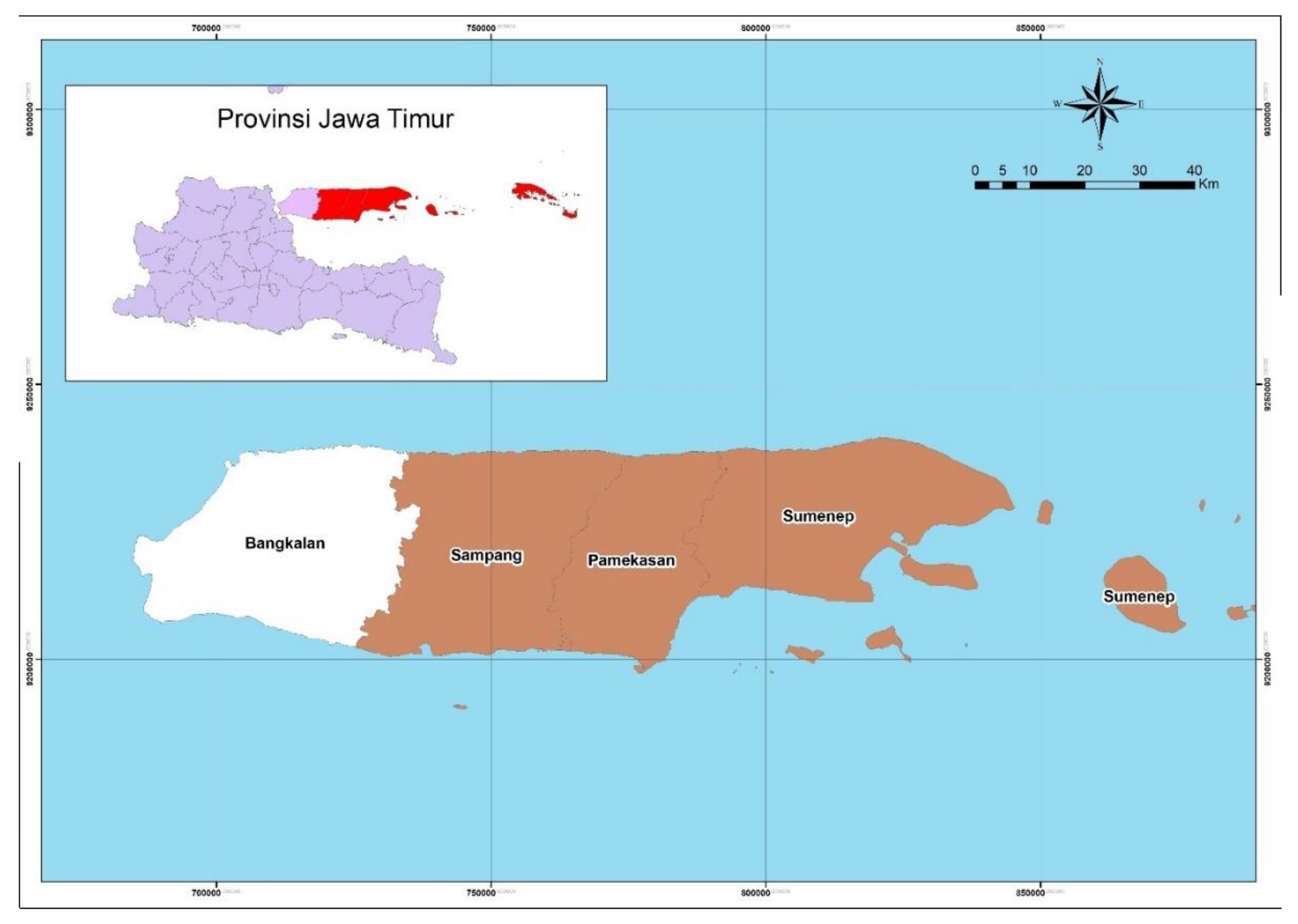

2.1. Research Data

2.2. Data Analysis

3. Results

3.1. Description of Research Variables

3.2. Mean Differences of Research Variables

3.3. Determinants of Adoption of Geomembrane as A Production Technology

3.4. Distribution of Technical Efficiency Scores

3.5. Impact of Adopting Geomembranes on Technical Efficiency

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sedivy, V.M. Environmental balance of salt production speaks in favour of solar saltworks. Global NEST Journal. 2009, 11, 41–48. [Google Scholar] [CrossRef]

- Ministry of Industry of the Republic of Indonesia. Industrial Salt Needs Soared 76.19% in 2018. Ministry of Industry of the Republic of Indonesia, Indonesia, 2018. Retrieved from https://kemenperin.go.id/.

- Adi, T. R., Supangat, A., Sulistiyo, B., Muljo, B., Amarullah, H., Prihadi, T. H., … Rustam, A. Salt and Artemia Integrated Business Development Guidebook. Jakarta (ID): Center for Research on Marine Areas and Non-Biological Resources, Marine and Fisheries Research Agency, Department of Maritime Affairs and Fisheries, Indonesia, 2006.

- Ihsannudin, I. & Pinuji, S. Empowering Land for People's Salt Farmers. Bangkalan (ID): UTM Press, 2020.

- Prihantini, C.I., Hanani, N., Asmara, R., & Syafrial.. The Relationship between the Sharecropping System, Informal Credit, and Productivity: The Empirical Evidence from the Madurese Traditional Solar Salt Business. ECSOFiM: Economic and Social of Fisheries and Marine Journal. 2024, 11, 02, 277-291. http://ecsofim.ub.ac.id/.

- Effendy, M., Zainuri, M., & Hafiludin. Intensification of people's salt fields in Sumenep district. In Presentation of the Marine Science Study Program for Madura Maritime. Bangkalan (ID): UTM Press, 2014.

- Mather, D. , Boughton, D., & Jayne, T.S. Explaining smallholder maize marketing in southern and eastern Africa: The roles of market access, technology and household resource endowments. Food Policy, 2013; 43, 248–266. [Google Scholar] [CrossRef]

- Wani, S.P. , Chander, G., & Sahrawat, K.L. Science-led interventions in integrated watersheds to improve smallholders’ livelihoods. NJAS–Wageningen Journal of Life Sciences, 2014; 70, 71–77. [Google Scholar] [CrossRef]

- Prihantini, C.I. , Syaukat, Y., & Fariyanti, A. Comparison of Profit at Different Sharecropping System in Traditional Salt Production in Pamekasan Regency, East Java. Jurnal Sosial Ekonomi Kelautan dan Perikanan, 2017; 12, 63–76. [Google Scholar] [CrossRef]

- Prihantini, C.I. ., Syaukat, Y., & Fariyanti, A. Comparison of Sharecropping System Salt Production Busineess in Pamekasan Regency, East Java. Jurnal Kebijakan Sosial Ekonomi Kelautan Dan Perikanan, 2017; 7, 77–90. [Google Scholar] [CrossRef]

- Abdulai, A. & Huffman, W.E. The Diffusion of New Agricultural Technologies: The Case of Crossbred-Cow Technology in Tanzania. Agricultural & Applied Economics Association. 2019; 87, 3, 645–659. [Google Scholar] [CrossRef]

- Mignouna, D.B. , Manyong, V.M., Rusike, J., Mutabazi, K.D.S., & Senkondo, E.M. Determinants of adopting imazapyr-resistant maize technologies and its impact on household income in Western Kenya. AgBioForum, /: 3, 158–163. https, 4462; 3. [Google Scholar]

- Samiee, A. , Rezvanfar, A., & Faham, E. Factors influencing the adoption of integrated pest management (IPM) by wheat growers in Varamin county, Iran. African Journal of Agricultural Research. 2009; 4, 5, 491–497. [Google Scholar]

- Murage, F. , Mugwe, J., Ngetich, K., Mucheru-Muna, M., & Mugendi, D. Adoption of Soybean by Smallholder Farmers in the Central Highlands of Kenya. African Journal of Agricultural Economics and Rural Development. 2019, 7, 5, 1–12. [Google Scholar]

- Obiero, K.O. , Waidbacher, H., Nyawanda, B.O., Munguti, J.M., Manyala, J.O., KaundaArara, B. Predicting uptake of aquaculture technologies among smallholder fish farmers in Kenya. Aquaculture International. 2019, 27, 1689–1707. [Google Scholar] [CrossRef]

- 16. Tegal Regency Fisheries Training and Extension Center [BPPP]. Making People's Salt Using Geomembrane Technology, Tegal Regency Fisheries Training and Extension Center, Indonesia. 2017.

- Scheirs, J. A Guide to Polymeric Geomembranes. John Wiley & Sons, Ltd. 2009. [CrossRef]

- Suhendra, A. Increasing the Productivity of Salt through HDPE Geomembrane — Indonesian Case History in Salt Evaporation Pond. Electronic Journal of Geotechnical Engineering, 2016, 21, 4273-4280.

- Susanto, H. , Rokhati, N., & Santosa, G.W. Development of Traditional Salt Production Process for Improving Product Quantity and Quality in Jepara District, Central Java, Indonesia. Procedia Environmental Sciences. Elsevier B.V. 2015, 175-178. [CrossRef]

- 20. Arwiyah, Zainuri, M., & Efendy, M. Study of Nacl Content in Raw Water and Their Salt Production and Productivity Using Different Table Salt Land. Jurnal Kelautan: Indonesian Journal of Marine Science and Technology, 2015, 8, 1, 1-9. [CrossRef]

- Balde, B.S. , Kobayashi, H., Nohmi, M., Ishida, A., Matsumura, I., Esham, M., & Tolno, E. Socio-economic Analysis of Small-scale Salt Production Techniques in the Coastal Area of Guinea: as an Alternative for Improving Livelihood Status and Sustainable Mangrove Forest Management. International Journal of Research in Engineering, IT and Social Sciences, 2013, 3, 9.

- Farrell, M. The Measurement of Productive Efficiency. Journal of the Royal Statistical Society. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Aigner, D. , Lovell, C. A. K., & Schmidt, P. Formulation and estimation of stochastic frontier production function models. Journal of Econometrics, 1977, 6, 21-37. [CrossRef]

- Meeusen, W. , & Broeck, V. D. Efficiency estimation from Cobb-Douglas production functions with composed error. International Economic Review, 1977, 18, 2, 435-444. [CrossRef]

- Charnes, A. , Cooper, W.W., & Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar]

- Coelli, T., Rao, P. and Battese, G.E. An Introduction to Efficiency and Productivity analysis. Massachusetts: Kluwer Academic Publishers, 1998.

- Ramanathan, R. An Introduction to data envelopment analysis: A tool for performance measurement. SAGE Publications, New Delhi, 2003. [CrossRef]

- Gujarati, D. N. Basic Econometrics. 4th Edition. McGraw-Hill, 2003.

- Prihantini, C.I. Profit Sharing Pattern for People’s Salt Business in Pamekasan Regency, East Java. [Thesis]. IPB University, 2016.

- Abdulai, S. , Zakariah, A., & Donkoh, S. A. Adoption of rice cultivation technologies and its effect on technical efficiency in Sagnarigu District of Ghana. Cogent Food & Agriculture, 2018, 4, 1424296. [CrossRef]

- Ariyani, A.H.M. , Harianto, Suharno, & Syaukat, Y. Factors Affecting Technology Adoption of Geoisolator on Solar Saltworks in East Java Province. AGRIEKONOMIKA. 2021, 9, 1. [Google Scholar] [CrossRef]

- Qu, R. , Wu, Y., Chen, J., Jones, G. D., Li, W., Jin, S., & Li, Z. Effects of agricultural cooperative society on farmers’ technical efficiency: Evidence from stochastic frontier analysis. Sustainability, 2020, 12, 19, 1-13. [CrossRef]

- Ma, W. , Renwick, A., Yuan, P., & Ratna, N. Agricultural cooperative membership and technical efficiency of apple farmers in China: An analysis accounting for selectivity bias. Food Policy, 2018, 81, 122-132. [CrossRef]

- Rahman, M.S. , Toiba, H., & Huang, W.-C. The impact of climate change adaptation strategies on income and food security: Empirical evidence from small-scale fishers in Indonesia. Sustainability, 2021, 13, 1-16. [CrossRef]

- 35. Syafrial, Toiba, H., Rahman, M.S., & Retnoningsih, D. The Effects of Improved Cassava Variety Adoption on Farmers’ Technical Efficiency in Indonesia. Asian Journal of Agriculture and Rural Development, 2021, 11, 4, 269-278. [CrossRef]

- Nabasirye, M. , Kiiza, B., & Omiat, G. Evaluating the impact of adoption of improved maize varieties on yield in Uganda: A propensity score matching approach. Journal of Agricultural Science and Technology, 2012, B, 4, 368-377.

- Ariyani, A.H.M., Harianto, H., Suharno, S., & Syaukat, Y. Impact of Application of Geoisolator in Saltworks Business in East Java Province: A Propensity Score Matching Approach. International Journal of Progressive Sciences and Technologies (IJPSAT). 2020, 22, 1, 40–47.

- 38. Rosanti, N, Sinaga, BM, Daryanto, A, & Kariyasa, K. Determinants of Farmer’s Participation in Contract Farming: Case Study of Coffee Farmers in Lampung. Jurnal Ekonomi Pertanian dan Agribsinis (JEPA), 2019, 3, 4, 853-863. [CrossRef]

- Fahad, S. , Wang, J., Hu, G., Wang, H., Yang, X., Shah, A.A., Huong, N.T.L., & Bilal, A. Empirical analysis of factors influencing farmers crop insurance decisions in Pakistan: Evidence from Khyber Pakhtunkhwa province. Land Use Policy, 2018, 75, 459-467. [CrossRef]

- Ramirez, A. Ramirez, A. The influence of social networks on agricultural technology adoption. Procedia-Social and Behavioral Sciences. 2013, 79, 101-116. 2013, 79, 101-116. [CrossRef]

- Nurwahyuni, E., Arianti, F., & Hindarwati, Y. The farmer’s response to the improvement of cropping index through intercropping of maize–soybean and groundnut monoculture in Pemalang. Paper presented at the IOP Conference Series: Earth and Environmental Science, 2021.

- Rahman, S. , Matin, M., & Hasan, M. Joint determination of improved variety adoption, productivity and efficiency of pulse production in Bangladesh: A sample-selection stochastic frontier approach. Agriculture & Food Security, 2018, 8, 7, 1-18. [CrossRef]

- Mwalupaso, G. E. , Wang, S., Rahman, S., Alavo, E. J.-P., & Tian, X. Agricultural informatization and technical efficiency in maize production in Zambia. Sustainability. 2019, 11, 1–17. [Google Scholar] [CrossRef]

- Abdul-Rahaman, A. , Issahaku, G., & Zereyesus, Y. A. Improved rice variety adoption and farm production efficiency: Accounting for unobservable selection bias and technology gaps among smallholder farmers in Ghana. Technology in Society, 2014, 64, 101471. [CrossRef]

- Ghimire, R. , Wen-Chi, H., & Shrestha, R. B. Factors affecting the adoption of improved rice varieties among rural farm households in Central Nepal. Rice Science. 2015, 22, 35–43. [Google Scholar] [CrossRef]

- Jaleta, M. , Kassie, M., & Marenya, P. Impact of improved maize variety adoption on household food security in Ethiopia: An endogenous switching regression approach. International Association of Agricultural Economists, 2015, 29, 1-26. [CrossRef]

- Shiferaw, B. , Kassie, M., Jaleta, M., & Yirga, C. Adoption of improved wheat varieties and impacts on household food security in Ethiopia. Food Policy. 2014, 44, 272–284. [Google Scholar] [CrossRef]

- Manda, J. , Alene, A. D., Tufa, A. H., Abdoulaye, T., Wossen, T., Chikoye, D., & Manyong, V. The poverty impacts of improved cowpea varieties in Nigeria: A counterfactual analysis. World Development, 2019, 122, 261-271. [CrossRef]

- Wossen, T., Alene, A., Abdoulaye, T., Feleke, S., Rabbi, I. Y., & Manyong, V. Poverty reduction effects of agricultural technology adoption: The case of improved cassava varieties in Nigeria. Journal of Agricultural Economics. 2019, 70, 2, 392-407. [CrossRef]

- Wu, H. , Ding, S., Pandey, S., & Tao, D. Assessing the impact of agricultural technology adoption on farmers’ well-being using propensity-score matching analysis in rural China. Asian Economic Journal, 2010, 24, 141-160. [CrossRef]

- Wordofa, M. G. , Hassen, J. Y., Endris, G. S., Aweke, C. S., Moges, D. K., & Rorisa, D. T. Adoption of improved agricultural technology and its impact on household income: A propensity score matching estimation in eastern Ethiopia. Agriculture & Food Security, 2021, 10, 1-12. [CrossRef]

| Variable | Description | Mean | Std. Deviation |

|---|---|---|---|

| Characteristics | |||

| Age | Age of salt farmer (years) | 48.53488 | 10.96671 |

| Experience | Salt business experience (years) | 19.17209 | 12.77641 |

| Education | Salt farmer’s last education (0 = not completed elementary school, 1 = elementary school, 2 = middle school, 3 = high school, 4 = Bachelor’s degree, 5 = postgraduate degree) | 1.581395 | 0.972341 |

| Gender | Salt farmer’s gender (1 = male, 0 = female) | 0.778689 | 0.416842 |

| Number of family members | Number of family members (people) | 3.269767 | 1.460306 |

| Profit sharing | Profit-sharing pattern (1= yes, 0= no) | 0.67757 | 0.468502 |

| Land ownership | Land ownership (1 = rented land/profit sharing, 0 = own land) | 0.409836 | 0.493831 |

| KUGAR | KUGAR participation (1= participate, 0= does not participate) | 0.697674 | 0.460337 |

| Mobile Phone Ownership | Mobile phone ownership (1 = yes, 0 = no) | 0.706977 | 0.456211 |

| Internet access | Access to the Internet (1=can or 0=cannot) | 0.427907 | 0.49593 |

| Assistance | Have you ever received assistance (1= yes, 0= no) | 0.688372 | 0.46424 |

| Demlot | Whether there is a demonstration plot (1 = exists, 0 = does not exist) | 0.297674 | 0.458303 |

| Capital Sources | Farming capital (1 = loan, 0 = own capital) | 0.27907 | 0.449589 |

| Geomembrane adoption | Geomembrane adoption decision (1 = geo, 0 = ground) | 0.827907 | 0.378342 |

| Inputs and outputs | |||

| Land area | Land area (M2) | 10179.35 | 4959.455 |

| Salt production | Total salt production (tons) | 94.96744 | 52.48145 |

| Harvest frequency | Number of harvests in 1 season | 13.2 | 3.305617 |

| Water volume | Water volume | 4282.842 | 2957.844 |

| Bozem percentage | Bozem percentage | 16.79401 | 12.09479 |

| Minian percentage | Minihan percentage | 54.98041 | 14.74632 |

| Salt table percentage | Percentage of salt table/crystallization | 28.22558 | 8.811714 |

| Number of workers (HOK) | Number of workers (HOK) | 133.7116 | 89.58418 |

| Amount of solar | Amount of diesel per day (litres) | 306.4791 | 214.9327 |

| MetaTE | Technical efficiency | 0.8085814 | 0.2220938 |

| Variable | Unmatched | Matched | ||||

|---|---|---|---|---|---|---|

| Adopting | Not Adopting | Diff. | Adopting | Not adopting | Diff. | |

| Age | 48.764 | 56.364 | 7.600* | 49.447 | 36.500 | 12.947*** |

| Experience | 23.600 | 31.455 | 7.855* | 23.904 | 16.181 | 7.723*** |

| Education | 1.882 | 1.546 | 0.336 | 1.830 | 2.660 | 0.830*** |

| Gender | 0.791 | 0.727 | 0.064 | 0.755 | 0.915 | 0.160*** |

| Family members | 4.182 | 3.364 | 0.818* | 4.064 | 3.075 | 0.989*** |

| Ln Land area | 8.968 | 9.183 | 0.215 | 9.001 | 9.115 | 0.114** |

| Ln Salt production | 4.281 | 4.299 | 0.018 | 4.313 | 4.676 | 0.363*** |

| Profit sharing | 0.509 | 0.818 | 0.309* | 0.553 | 0.170 | 0.383*** |

| Land ownership | 0.400 | 0.455 | 0.055 | 0.404 | 0.128 | 0.277*** |

| KUGAR | 0.727 | 0.455 | 0.273* | 0.702 | 0.915 | 0.213*** |

| Mobile ownership | 0.709 | 0.636 | 0.073 | 0.691 | 0.947 | 0.255*** |

| Internet access | 0.391 | 0.273 | 0.118 | 0.372 | 0.851 | 0.479*** |

| Assistance | 0.691 | 0.636 | 0.055 | 0.660 | 0.309 | 0.351*** |

| Demlot | 0.309 | 0.182 | 0.127 | 0.277 | 0.032 | 0.245*** |

| Capital sources | 0.227 | 0.091 | 0.136 | 0.170 | 0.043 | 0.128*** |

| Variable | Unmatched | Matched | ||||

|---|---|---|---|---|---|---|

| Adopting | Not Adopting | |Diff.| | Adopting | Not Adopting | |Diff.| | |

| ln Land area | 9.093 | 9.234 | 0.141* | 9.151 | 9.149 | 0.001 |

| Ln Harvest Frequency | 2.549 | 2.554 | 0.005 | 2.550 | 2.469 | 0.081*** |

| Ln Water volume | 8.098 | 8.416 | 0.318*** | 8.231 | 8.332 | 0.102 |

| Ln Percentage of Bozem | 2.503 | 2.693 | 0.189 | 2.605 | 2.435 | 0.170* |

| Ln Percentage of Minian | 3.969 | 3.940 | 0.028 | 3.943 | 4.000 | 0.056* |

| Ln Percentage of salt table | 3.292 | 3.272 | 0.020 | 3.298 | 3.301 | 0.003 |

| Ln Number of workers (HOK) | 4.677 | 4.611 | 0.066 | 4.658 | 4.627 | 0.032 |

| Ln Amount of diesel | 5.439 | 5.629 | 0.190 | 5.502 | 5.436 | 0.066 |

| Ln Salt production | 4.417 | 4.475 | 0.058 | 4.462 | 4.407 | 0.055 |

| Variable | Coefficient | P-Value | Odds Ratio (OR) |

|---|---|---|---|

| Constant | 7,137 | 0,049 | |

| Salt Farmer’s Age | 0,100 | 0,056* | 0,905 |

| Salt Farmer’s Experience | -0,014 | 0,704 | 0,986 |

| Salt Farmer’s Education | -0,619 | 0,277 | 0,538 |

| Number of Family Members | -0,436 | 0,016** | 1,546 |

| Salt Farmer’s Gender Dummy | 1,579 | 0,092* | 4,851 |

| Profit Sharing Dummy | 2,920 | 0,016** | 0,054 |

| Land Ownership Dummy | 1,321 | 0,093* | 3,745 |

| Mobile Phone Ownership Dummy | -0,715 | 0,446 | 0,489 |

| Internet Access Dummy | -0,205 | 0,834 | 0,815 |

| KUGAR Opt-in Dummy | 2,287 | 0,000*** | 9,846 |

| Demonstration Plot Dummy | 0,598 | 0,061* | 1,818 |

| Assistance Dummy | -0,900 | 0,407 | 0,045 |

| Efficiency Range | Adopters | Non-Adopters | Pooled Data | |||

|---|---|---|---|---|---|---|

| Frequency | Percent | Frequency | Percent | Frequency | Percent | |

| ≤0,50 | 2 | 1,12 | 6 | 16,22 | 26 | 14,61 |

| 0,51-0,60 | 4 | 2,25 | 7 | 18,92 | 22 | 12,36 |

| 0,61-0,70 | 13 | 7,30 | 8 | 21,62 | 23 | 12,92 |

| 0,71-0,80 | 14 | 7,87 | 5 | 13,51 | 17 | 9,55 |

| 0,81-0,90 | 28 | 15,73 | 1 | 2,70 | 14 | 7,87 |

| 0,91-1,00 | 117 | 65,73 | 10 | 27,02 | 76 | 42,69 |

| Total | 178 | 100 | 37 | 100 | 215 | 100 |

| Mean TE | 0,911 | 0,698 | 0,809 | |||

| Min. | 0,415 | 0,223 | 0,182 | |||

| Max. | 1,000 | 1,000 | 1,000 | |||

| Std. Dev. | 0,134 | 0,214 | 0,222 | |||

| Model | Not Adopting | Adopting | Diff. |

|---|---|---|---|

| Unmatched | |||

| Pooled | 0.607 | 0.908 | 0.301** |

| Separated | 0.668 | 0.955 | 0.287** |

| Matched | |||

| Pooled | 0.635 | 0.906 | 0.271* |

| Separated | 0.698 | 0.967 | 0.269** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).