Introduction

Throughout human history, milk has played a crucial

role in meeting nutritional needs and preserving consumer health. Milk and its derivatives

are distinguished as excellent sources of superior quality proteins, vitamins,

carbohydrates, minerals, and fats. They also offer vital micronutrients,

bioactive compounds, lactic acid bacteria, and substances that enhance immunity

[1]. Camel milk is particularly significant in

providing nutrition and food security, especially for populations residing in semi-arid

and arid regions of Sub-Saharan Africa and Asian deserts. Camel milk possesses

unique chemical characteristics and intrinsic functional properties that are

distinct from the milk of other livestock. [2].

Although chemical composition of key nutrients in camel milk, such as water, protein

lactose, and fat, aligns closely with that of cow's milk, there are significant

differences in micronutrients. These include variations in immunoglobulin (IgG,

IgA), vitamins (A, C), as well as mineral salts [3,4].

Furthermore, the molecular structure of major components in camel milk differs

from that of bovine milk, posing a significant challenge for the dairy industry

in transforming camel milk into valuable dairy products [5,6]. Camel milk exhibits lower concentrations of carotene

and short-chain fatty acids but higher quantities of long-chain fatty acids [7]. In recent years, there has been a significant

increase in global interest and demand for camel milk and its dairy

derivatives, attributed to their exceptional medicinal benefits and

health-enhancing properties. This trend has prompted the dairy sector to

diversify its offerings, providing consumers with camel dairy products

characterized by advanced nutritional and functional qualities. Worldwide

production of camel milk is increasing up to 2% annually [8], driven by various factors including:

Its contribution in ensuring food security under challenging environmental conditions,

Growing market demand attributed to its exceptional functional properties,

Development of the camel dairy industry that offers potential advantages for camel proprietors.

In general, milk sourced globally undergoes diverse

processing methods employing contemporary technological approaches, aimed at

extending its shelf life and producing functional dairy products that possess

augmented nutritional value and health benefits. The conversion of milk into

both non-fermented and fermented dairy products is a widespread practice,

serving the dual purpose of preservation and enhancement of nutritional content

to meet increasing demands. The technological and functional qualities of milk,

encompassing aspects such as physical and chemical structure, foam generation

potential, solubility, emulsifying properties, gelation ability, and water

holding capacity, are recognized as pivotal factors in milk processing

techniques. These attributes play a significant role in the development of

innovative food products originating from animal sources [9].

The feasibility of utilizing camel milk for the development

of dairy products depends on its physicochemical and techno-functional

properties [8]. The functional properties of

food are subject to the influence of processing technologies, food quality, utilization

practices, formulation, and ultimately, their acceptability [10].

The conversion of camel milk into processed

products poses a significant challenge, requiring the application of appropriate

technologies. This is due to a range of factors including its distinctive

chemical constitution, the presence of a complex colloidal system, inherent

functionality, the dimensions of protein micelles and fat globules, and the

existence of antibacterial agents [1,11]. Lately,

the technological and functional properties of camel milk have attracted

significant attention from researchers, owing to the inadequacy of standard

technologies used for cow milk in processing camel milk into dairy products. Nevertheless,

overcoming these challenges could be feasible through the application of

innovative technologies, refinement of processing parameters, and modification

of its natural functionality by introducing synthetic compounds or fortifying

camel milk. The purpose of this review is to highlight contemporary progress in

the processing and conversion of camel milk into dairy products. Additionally,

it seeks to determine appropriate processing parameters that facilitate the

creation of novel dairy products on an industrial scale, based on insights from

existing literature.

Global Production and Technological Advancements in

Camel Milk Industry

In 2022, global camel milk production was reported

at approximately 4.11 million tons, though estimates suggest actual outputs

could be as high as 5.4 million tons annually due to underreporting in remote

areas where traditional herding dominates. Since the 1960s, camel milk production

has exhibited a consistent growth rate of 2.45% per year, leading to a

significant 6.5-fold increase by 2022 [12,13].

This growth is not attributed to enhanced productivity per animal, as the daily

yield per camel has remained constant. Instead, it reflects broader demographic

trends, including increases in camel populations and expanded dairy operations

across camel-rearing regions [12,14].

During the 1970s, the semi-automated milking

process was first introduced in the former Soviet Union and later adopted in other

parts of the world. This technology allowed for more efficient milking but

required specific adjustments to cater to the unique anatomy and behavior of

camels [15]. In 2002, a significant milestone

was achieved in Dubai with the establishment of a modern camel dairy farm. This

farm initially employed a single-camel milking stand, which was tested and

optimized in Oman. The development of the herringbone milking system, which

enables the simultaneous milking of five camels, represented a key advancement

in milking efficiency and animal handling [16,17].

Innovations in milking system design have also

included corridor and tandem systems, which provide camels with more space and

make it easier for handlers to manage the animals during milking. These designs

help prevent camels from sitting down during milking and allow calves easier

access to the udder, which is important for the welfare of both mother and calf

[18,19]. However, these systems typically

require larger milking parlors and more time to milk an equivalent number of

animals than the more compact herringbone design. The introduction of the

herringbone system necessitates specialized engineering solutions and a period

of acclimation for the camels, but ultimately yields a more streamlined and

efficient milking process [20].

Camel milk production is not uniformly distributed

globally; it is predominantly concentrated in Africa, the Middle East, and

parts of South Asia. The economic impact of camel milk is particularly

significant in arid and semi-arid regions where traditional cattle farming is

less viable. The commercialization of camel milk has provided substantial

economic benefits to rural communities, supporting livelihoods and contributing

to food security [21,22].

The future of camel milk production faces several

challenges, including the need for better breeding practices to enhance milk

yield and quality, and the adaptation of milking technologies to suit

small-scale producers. Moreover, there is a growing need for research into the

development of camel milk products, such as cheese and yogurt, which require

specialized processing techniques due to the unique properties of camel milk [23,24].

Factors influencing milk yield in camels.

Similar to other species, the principal

determinants influencing milk production in camels include age, breed,

seasonality, diet, parity, lactation and management aspect such as frequency of

milking. Nevertheless, in the case of machine milking, the critical factor

affecting milk yield is the effectiveness of milk extraction and the complete

evacuation of the mammary glands [25].

Previous findings demonstrated that residual milk

post-machine milking ranged from 15 to 42% and mostly depends on ambient

environmental settings [26]. This residual milk if not efficiently extracted, can lead

to engorgement of the mammary glands, reducing the animal's comfort and

subsequent milk yields. The hormonal regulation of milk production is another

vital area affecting yield. The process of milk let-down is closely associated

with the hormonal interplay, primarily involving oxytocin, which facilitates

the ejection of milk. The anatomical structure of the camel's udder and the

functionality of its mammary glands also dictate how effectively milk can be

extracted. Studies have indicated that a better understanding of these

physiological and anatomical features could lead to improvements in milking

practices and technology [27].

Despite its importance, research on the detailed

physiological, hormonal, and anatomical factors influencing camel milk production

is sparse. The lack of comprehensive studies on camel lactation physiology

impedes the development of optimized milking technologies and practices that

could enhance productivity. More research is needed to understand the dynamics

of milk secretion and ejection, as well as the development and functional

anatomy of the camel's udder. Future studies should focus on developing a

deeper understanding of the genetic factors influencing milk yield and quality

in camels. There is also a need for technological innovations in milking

systems designed specifically for camels, considering their unique anatomy and

milk production characteristics. Additionally, enhancing the nutritional

management of camels through the development of specialized feeds that improve milk

yield and quality during different seasons could provide significant benefits [28].

Camel Milk Processing and Challenges

It is reported that in average camel milk shares

similar chemical features with bovine milk (Table

1). Nevertheless, it is noted that molecular composition of proteins, distribution,

and content of fatty acids are documented to be distinct.

Cheese Production Process. Converting camel

milk into cheese is regarded as challenging and has been deemed impractical [29]. The amino acid composition and distribution of

caseins in camel milk differ from those in cow milk. Specifically, camel milk

casein exhibits a higher proportion of beta-casein (65% compared to 39%), a

lower percentage of alpha S1-casein (22% compared to 38%), and reduced kappa

casein (3.5% compared to 13%) in comparison to bovine milk caseins. Camel milk

has been documented to possess a higher whey protein to casein ratio in

comparison to cow milk, contributing to the formation of a delicate curd mass

easily digestible in the gastrointestinal tract [30].

The casein in camel milk is characterized by a larger micelle size, with an

average diameter of 380nm, in contrast to 150nm, 260nm, and 180nm observed in cow,

caprine, and ovine milk, respectively [11].

Small casein micelles in cow milk have been associated with improved gelation

properties [31]. Consequently, the lower

concentration of kappa-casein (k-CN), the elevated ratio of whey protein to

casein, and the greater micelle size found in camel milk have been identified

as factors contributing to the difficulties in cheese production. These characteristics

contribute to the formation of a softer coagulum and decreased yields in cheese

processing, as detailed in research conducted by [ornaz,Sahli[11] and Konuspayeva, Camier [32].

Table 1.

Comparative analysis of camel milk composition in relation to milk from other livestock species.

Table 1.

Comparative analysis of camel milk composition in relation to milk from other livestock species.

| Species |

Fat (%) |

Total solids (%) |

Lactose (%) |

Ash (%) |

Protein (%) |

| Camel* |

3.5 |

12.0 |

4.4 |

0.8 |

3.1 |

| Cow* |

3.7 |

12.7 |

4.8 |

0.7 |

3.4 |

| Ovine* |

7.4 |

19.3 |

4.8 |

1.0 |

4.5 |

| Equine |

1.21 |

13.2 |

6.4 |

0.42 |

2.1 |

Butter Production Process. The fat percentage in camel milk, which varies between 1.2% and 6.4%, is similar to the fat content found in bovine milk. The fat percentage in camel milk, which varies between 1.2% and 6.4% [

36], is similar to that of cow milk. However, the production of butter from camel milk is not a traditional practice and poses challenges when employing the same production technology as used for cow milk butter. High melting point [

37,

38] of camel milk fat (41–43℃) complicates the churning process at temperatures optimal for cow milk, which is between 10 and 14℃. The conversion of camel milk into butter is hindered by the milk's limited propensity to form cream, attributed to a deficiency in agglutinin, smaller fat globule dimensions, and a more robust membrane in fat globular.

Camel milk is characterized by a higher concentration of long-chain fatty acids and a diminished quantity of short-chain fatty acids. This composition accounts for the higher melting gradient of camel milk butter, attributable to the increased presence of long-chain fatty acids in its fatty acid composition. Nevertheless, the production of butter from camel milk is achievable with the right churning temperature and agitation technique. Berhe, Seifu [

39] have shown that the robust agitation of fermented camel milk in a vertical motion, as opposed to the conventional back-and-forth method, at a higher churning temperature, led to the successful extraction of butter. This approach is found to be efficient and exerts greater force to break the fat globule envelope, promoting the adhesion of the globules to each other. Farah, Streiff [

38] also documented the successful production of butter from camel milk at churning temperatures ranging from 15 to 36℃. According to their findings, the optimal fat recovery in butter production, attaining 85%, was achieved when churning run at 25℃.

Yoghurt Production Process. The production of yogurt or other processed dairy products from camel milk is acknowledged to be challenging. The coagulum formed from dromedary milk lacks the desired curd formation and firmness; instead, the curd exhibits fragility and heterogeneity, composed of dispersed flakes [

40]. The challenge associated with camel milk yogurt stems from its runny consistency and fragile texture. The texture of yogurt is a crucial factor that affects its visual appeal, mouthfeel, and general acceptance. Camel milk is recognized for its resistance to easy fermentation, primarily attributed to its antibacterial qualities. Despite this, it has been noted that commercial starter cultures are capable of developing in camel milk. However, the rate of acidification in camel milk is slower compared to that in cow milk [

41,

42].

Shelf life. The development of fermented milk products likely originated from the necessity to prolong milk's shelf life in the absence of refrigeration, coupled with their nutritional value and potential health advantages. Traditional fermented camel milk, distinct from camel milk cheese, butter, and yogurt, is a commonly available camel dairy product. This fermented milk is known by various names globally, such as Dhanaan in Ethiopia, Suusac or susa in Kenya and Somalia, Gariss in Sudan, and Shubat in Turkey, Kazakhstan [

43]. The antimicrobial properties of the milk contribute to the reported relatively stable nature of fermented camel milk over an extended period at ambient temperatures.

Shubat is documented to exhibit heightened storage stability. Pastoralists in South and West Kazakhstan have noted that Shubat has a prolonged storage stability, remaining viable for several months, particularly when employing continuous back slopping. This method entails inoculating a fresh batch of milk with a sample from an previous batch, thereby extending its viability. Likewise, other [

44] reported that withdrawal of batch fermented accumulations and replacing with fresh camel milk can continue for several months. This extended storage duration may be attributed to the inherent antimicrobial characteristics of the milk. Notably, strains of potential probiotic lactic acid bacteria, isolated from fermented camel milk, exhibit bacteriocin activities capable of inhibiting pathogenic microbes. Additionally, yeasts are crucial in the fermentation process of camel dairy products, owing to their potent lipolytic and proteolytic enzymatic properties [

45,

46].

Thermal treatment applied to camel milk.

The molecular characteristics of whey proteins can be altered by factors such as heating temperature, pH, and salt content (NaCl) [

47]. Camel milk's lactoferrin (LF) and immunoglobulin G (IgG) exhibit higher heat resistance compared to their counterparts in bovine milk [

48]. The thermal denaturation of camel milk whey proteins is contingent upon the physical state of the proteins. While liquid forms of camel and cow milk whey proteins share similar thermal resistance, the process of drying has been reported to diminish the thermal stability of camel milk whey protein due to the absence of β-lactoglobulin (β-LG) in camel milk [

29,

49]. Consequently, in the production of camel milk powder, it is advisable to apply modified thermal treatment and atomization conditions. In the production of acidified milk products, the application of thermal treatment has been investigated through scanning electron microscopy. Specifically, in the production of labneh from camel milk, it was observed that a thermal treatment at 85 °C for 30 minutes resulted in acidified milk protein gels with smaller particles. In contrast, a more extensive heat treatment at 90 °C for 30 minutes caused casein particles to fuse, forming larger aggregates [

50]. Unheated milk exhibited a protein matrix that was more open, loose, and less dense. The higher abundance of α-lactalbumin (α-LA) in camel milk whey led to increased sensitivity in camel whey solubility to pH changes [

49], a phenomenon known to induce acid denaturation in bovine milk [

51]. Bovine α-LA forms aggregates in acidic conditions, unlike β-lactoglobulin (β-LG), which aggregates upon heating in both alkaline and acidic environments [

47]. Camel serum albumin (SA) has demonstrated lower heat sensitivity compared to SA from bovine or buffalo milk. Notably, denaturation of camel SA at 100 °C for 20 minutes was found to be comparable to the denaturation of bovine and buffalo SA heated at 85 °C for 20 minutes [

48]. However, the fouling properties, specifically the adherence of milk proteins to heated surfaces, in camel milk have been primarily attributed to α-LA and SA, whereas β-LG is identified as the main foulant in cow milk [

52].

Pasteurization. The pasteurization process for camel milk requires specific conditions and indicators. Previous research indicates that alkaline phosphatase, commonly utilized for cow milk [

53], is not a suitable marker for camel milk pasteurization due to its heat resistance even at 90°C [

54]. Consequently, it is. proposed using either glutamyltranspeptidase or leucine arylamidase as reliable indicators for camel milk pasteurization [

55]. In a growing body of literature, the indicators for pasteurization are vary considerably [

56,

57,

58,

59]. It should also be noted that there are no international standards established for the pasteurization processes of camel milk.

According to Wernery, Johnson [

60] should camel milk exposed to pasteurization at 72°C for 20 minutes, gamma-glutamyl transferase might be the most suitable indicator. On the other hand, Lorenzen, Wernery [

61] reported that gamma-glutamyl transferase remained detectable in pasteurized camel milk, suggesting that lactoperoxidase might serve as a more fitting indicator for pasteurization. Previous study [

62] verified that camel lactoperoxidase exhibits less heat resistance compared to its bovine counterpart. To date, comprehensive studies in this area remain inadequate, despite the introduction of pasteurized camel milk to the global market. This uncertainty regarding a suitable pasteurization indicator for camel milk poses a challenge in establishing an international standard. Therefore, the industrial-scale pasteurization of camel milk may be conducted improperly, leading to potential inaccuracies in its heat treatment.

Sterilization. Despite efforts by private companies, the sterilization of camel milk through extremely high-temperature processing has not yet been successfully implemented. Research focusing on the heat resistance of casein proteins and whey, vitamins, fat globules, and other components of camel milk is anticipated to aid in developing a technical resolution for this challenge [

63,

64,

65,

66,

67].

Camel milk undergoes separation into two distinct phases following high thermal processing. Thermal processing at 90°C for 5 minutes, 85°C for 5 minutes, 75°C for 5 minutes, 72°C for 30 seconds, 65°C for 30 minutes [

64], and at 72°C for 15 seconds and 90, 80, and 63°C for 30 minutes [

67] have shown that whey proteins in camel milk are highly sensitive and begin to denature. Various methods were experimented with to stabilize camel milk proteins after high thermal processing. These included the addition of bovine k-casein, disodium hydrogen orthophosphate, calcium chloride, sodium hydroxide, sodium dihydrogen phosphate anhydrous, however these attempts yielded unsatisfactory outcomes [

68]. Further work is required to establish the production of camel milk processed under high thermal conditions.

Therapeutic applications of Camel milk.

The acknowledgment of camel milk as a suitable alternative to cow milk in human nutrition has been widespread and enduring across various regions worldwide. Various bioactive compounds can be extracted from milk and its derivatives, offering the potential to combat various diseases [

69]. Camel milk exhibits antiviral, antimicrobial properties, and has demonstrated potential effects in mitigating tuberculosis and diabetes [

70]. The inhibitory effects of camel milk against Listeria monocytogenes, Staphylococcus aureus, and Escherichia coli are attributed to the presence of lactoperoxidase, hydrogen peroxide, and lysozyme, respectively. Additionally, the growth of Salmonella typhimurium is hindered by camel milk's lactoferrin, which binds iron, rendering it unavailable for bacterial growth [

71,

72]. Notably, camel lactoferrin has demonstrated greater efficiency in inhibiting Hepatitis C Virus (HCV) entry into human leukocytes compared to human or bovine lactoferrin [

73]. Fermented camel milk beverage known as Shubat, traditionally consumed in Kazakhstan, has been documented to elicit virus-inhibiting properties against both ortho- and paramyxoviruses [

74]. These properties endure following storage, and the suggested antiviral effectiveness of 'Shubat' is believed to be associated with the presence of metabolic byproducts and sialic conjugates derived from yeasts and lactic acid bacteria. In other study, Camel milk has been used to treat male patients who suffered from tuberculosis. The outcomes related to clinical, bacteriological, and radiological characteristics demonstrated a more pronounced improvement in the group supplemented with camel milk in comparison to the control group [

75]. The elevated concentration of insulin-like substances, notably half-cystine, in camel milk [

76], the impact of camel milk's small-sized immunoglobulins on b-cells [

77], and the absence of coagulation of camel milk in the human stomach collectively contribute to the hypoglycemic effect observed in individuals with type 1 diabetes [

78]. This effect has been noted in humans, rats [

79,

80], and alloxan-induced diabetic dogs [

81]. Furthermore, several studies have demonstrated the potential therapeutic effects of camel milk in treating rheumatoid arthritis and asthma [

82,

83]. These findings suggest that camel milk consumption may elicit anti-inflammatory actions and could be used as an adjunctive therapeutic approach for managing these conditions.

Prospects for the Production of Camel Milk Powder

The conversion of liquid camel milk into powder represents the most effective method for preserving camel milk, particularly when it is produced in distant regions with limited transportation and preservation facilities. Typically, two contemporary processing technologies employed for the production of camel milk powder include spray-drying and freeze-drying [

8].

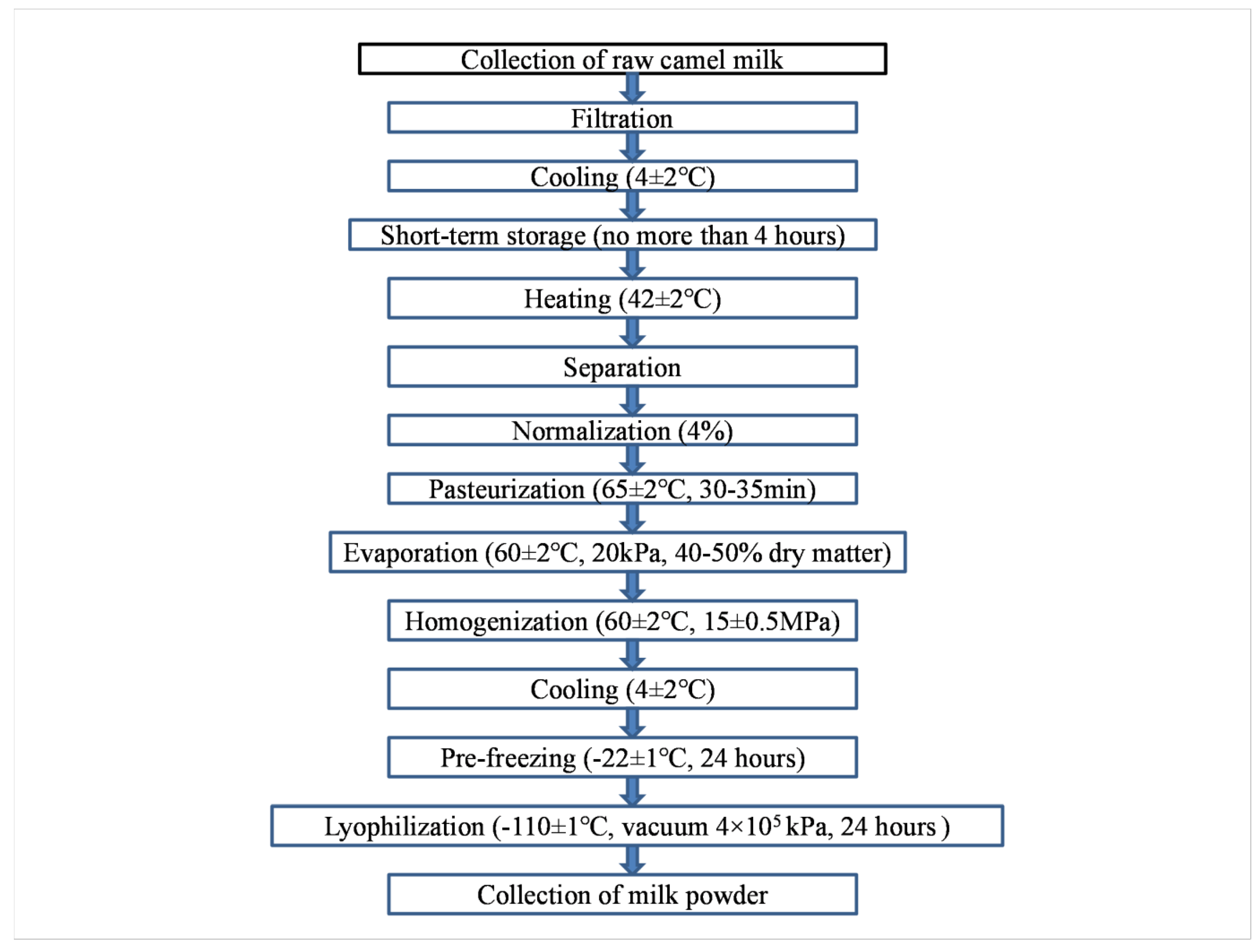

Recently, a laboratory-scale study was conducted to determine the optimal freeze-drying conditions (

Figure 1), with the objective of assessing the stability of camel milk powder and its components under various temperature settings using a freeze-drying method [

84,

85]. Findings revealed that the resulting camel milk powder exhibited enhanced stability at a humidity level of 11.3%. Likewise, another study investigated the impact of drying methods, particularly freeze-drying, on the nutritional value of camel milk compared to fresh camel milk. The study findings suggest that drying technology effectively preserved the comparative nutritional content and enhanced the stability of milk components, such as minerals and vitamins [

86]. In the context of spray-drying method, Sulieman, Elamin [

87] investigated the comparative physical characteristics of camel and cow milk powder produced using this technology. The findings highlighted that spray-drying markedly prolonged the shelf life of camel milk powder, primarily by eliminating the milk's water content.

In a recent study, a nutritional content of camel milk, including fatty acid and vitamin C profile has been further investigated under spray-drying and freeze-drying technologies [

88], [

85]. The findings indicated that the production output of milk powder is affected by variables like the feed flows, temperature, and the airflow of the processing apparatus. It was observed that elevated temperatures and increased airflow correlated with a notable reduction in the vitamin C concentration [

88]. In a recent study, the milk was subjected to fractionation through acid and enzymatic coagulation, followed by either freeze drying or spray drying coupled to gamma irradiation [

89]. This process enabled the production of dried milk fractions that exhibited a higher total phenolic content and greater antioxidant activities compared to corresponding skim milk. Authors concluded that gamma radiation within the range of 5–11 kGy may be employed to improve the preservation of powdered milk. However, it is important to note that implementing this technology in the dairy industry requires a substantial investment to install expensive milk roller driers and spray driers. Furthermore, employing spray-drying method for producing milk powder requires substantial energy consumption. Consequently, the development of a camel dairy industry calls for immediate actions to improve reproductive characteristics of camels and to establish extensive camel farming operations. This should be complemented by an efficient and widespread collection network linking these farms.

Figure 1.

Technological scheme for the production of camel milk powder using freeze-drying method.

Figure 1.

Technological scheme for the production of camel milk powder using freeze-drying method.

Conclusion and Perspectives

Camel milk and its derived products constitute an essential source of sustenance and economic livelihood for communities residing in exceptionally challenging environmental conditions, where traditional livestock farming is substantially impeded. Unlike conventional dairy sources, camel milk provides vital nutrition in arid and semi-arid regions, demonstrating its critical role in food security and community resilience.

Processing Challenges and Innovations. The processing of camel dairy products diverges markedly from traditional dairy methods, presenting unique challenges that stem from the inherent biochemical properties of camel milk. These challenges include the adaptation of pasteurization and fermentation techniques to accommodate the high mineral content and unique protein configuration of camel milk. Innovations in processing technology have enabled the production of camel milk derivatives such as pasteurized milk, milk powder, yogurt, butter, and cheese. However, each product requires specific adjustments to standard dairy processing protocols to preserve the nutritional value and improve the sensory attributes of the final products.

Enhancement of Organoleptic Properties. To address the distinct taste and textural characteristics of camel milk products, researchers have explored various biochemical modifications. These include altering the fat and protein content and adjusting the enzymatic activity during processing. Such modifications not only enhance the organoleptic properties of camel milk products but also aim to standardize these characteristics to appeal to a broader consumer base.

Persistent Limitations and Research Directions. Despite significant advancements, considerable processing limitations remain, underscored by the persistent variability in camel milk composition. The study and development of camel milk products thus represent a dynamic and evolving research area with immense potential. Ongoing investigations are required to refine processing techniques and develop protocols that can reliably produce high-quality camel milk products. Furthermore, there is a need for comprehensive research focusing on the scalability of production methods and the integration of novel technologies that can support the industrial processing of camel milk.

Future Perspectives and Global Implications. Looking forward, the camel dairy industry must not only address the technical challenges of milk processing but also embrace innovative strategies that cater to specific dietary and medical needs. This includes the development of specialized products such as lactose-free camel milk, high-calcium formulas, and hypoallergenic dairy products suitable for consumers with specific health conditions. Moreover, expanding the range of flavored and specialty camel milk products can enhance market penetration and consumer acceptance both locally and globally.

Conclusion. To compete effectively with products derived from other milk-producing species, camel milk products must meet stringent quality and safety standards. Establishing international guidelines and regulatory frameworks can facilitate the broader acceptance and integration of camel milk into global dairy markets. Additionally, strategic marketing efforts and consumer education are crucial in highlighting the unique benefits of camel milk, thereby fostering a sustainable market demand. As the camel milk industry continues to grow, its contributions to food security, economic stability, and dietary diversity will become increasingly significant, particularly in regions most affected by climate change and arid conditions. The future of camel milk and its derivatives lies in leveraging both scientific research and technological innovations to overcome existing challenges and unlock new opportunities in global dairy markets.

Author Contributions

A.I.: Conceptualization, funding acquisition, data curation, methodology, formal analysis, investigation, supervision, writing – original draft, writing – review & editing.

Funding

The author gratefully acknowledge the financial support provided by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant Numbers: BR21881957).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Arain, M.A. , et al., Nutritional significance and promising therapeutic/medicinal application of camel milk as a functional food in human and animals: a comprehensive review. Animal Biotechnology, 2023. 34(6): p. 1988-2005.

- Muthukumaran, M.S. , et al., A comprehensive review on health benefits, nutritional composition and processed products of camel milk. Food Reviews International, 2023. 39(6): p. 3080-3116.

- Hammam, A.R. , Compositional and therapeutic properties of camel milk: a review. Emirates Journal of Food and Agriculture, 2019: p. 148-152.

- Mullaicharam, A. , A review on medicinal properties of camel milk. World Journal of Pharmaceutical Sciences, 2014: p. 237-242.

- Baig, D. , et al., Technological challenges in production of camel milk cheese and ways to overcome them–A review. International Dairy Journal, 2022. 129: p. 105344.

- Ho, T.M., Z. Zou, and N. Bansal, Camel milk: A review of its nutritional value, heat stability, and potential food products. Food Research International, 2022. 153: p. 110870.

- Al-Nasseri, R.H. , et al., Lipids derived from Camel milk regulate NLRP3 inflammasome-dependent inflammatory responses in human macrophages. Functional Foods in Health and Disease, 2019. 9(4): p. 224-240.

- Konuspayeva, G. and B. Faye, Recent advances in camel milk processing. Animals, 2021. 11(4).

- Shokri, S. , et al., Effects of ultrasound on the techno-functional properties of milk proteins: A systematic review. Ultrasonics sonochemistry, 2022. 83: p. 105938.

- Mahajan, A. and S. Dua, Salts and pH induced changes in functional properties of amaranth (Amaranthus tricolor L.) seed meal. Cereal Chemistry, 2002. 79(6): p. 834-837.

- Bornaz, S. , et al., Physicochemical characteristics and renneting properties of camels’ milk: A comparison with goats’, ewes’ and cows’ milks. International Journal of Dairy Technology, 2009. 62(4): p. 505-513.

- FAO, FAOSTAT. Crops and livestock products. 2022, Food and Agriculture Organization of the United Nations.

- Faye, B. Dairy productivity potential of camels. In: R.Cardellion, A. Rosati, C. Mosconi (eds), Current Status of Genetic Resources, Recording and Production Systems in African, Asian and American Camelids, ICAR technical series No. 11. in Proceedings of the ICAR/FAO Seminar,. 2008. Sousse,Tunisia, Rome, : ICAR.

- Faye, B. and G. Konuspayeva, The sustainability challenge to the dairy sector–The growing importance of non-cattle milk production worldwide. International dairy journal, 2012. 24(2): p. 50-56.

- Yagil, R. , Camels and camel milk.. Animal Production and Health, 1982. 26: p. 1–69.

- Wernery, U., J. Juhasz, and P. Nagy, Milk yield performance of dromedaries with an automatic bucket milking machine. Journal of Camel Practice and Research, 2004. 11(1): p. 51-57.

- Wernery, U. , et al. In Milk production of dromedaries milked with an automatic milking machine: milk yield, quality control and udder hygiene. in Proceedings of the International Scientific Conference on Camels, Qassim, KSA. 2006. [Google Scholar]

- Hammadi, M. , et al., Training period and short time effects of machine milking on milk yield and milk composition in Tunisian Maghrebi camels (Camelus dromedarius). Journal of Camel Practice and Research, 2010. 17(1): p. 1-7.

- Ayadi, M. , et al., Evaluation of teat condition and udder health of dairy dromedary camel's machine milked under intensive Saudi Arabian condition. 2015.

- Nagy, P. and J. Juhasz, Review of present knowledge on machine milking and intensive milk production in dromedary camels and future challenges. Tropical Animal Health and Production, 2016. 48(5): p. 915-926.

- Konuspayeva, G. and B. Faye. New Opportunities in the Camel Milk Valorization. in In Proceedings of the 5th Conference ISOCARD Recent Advances in Camelids Biology, Health and Production. 2018. Laâyoune, Morocco: IAV Hassan II: Rabat, Morocco, 2018.

- Soni, V. and M. Goyal, Potential of using camel milk for ice cream making. Journal of Camel Practice and Research, 2013. 20(2): p. 271-275.

- Jafarpour, A. , Feasibility of manufacture and investigation of physicochemical properties of camel milk–based ice cream. Journal of Scientific Agriculture, 2017. 1: p. 300-302.

- Ipsen, R. , Opportunities for producing dairy products from camel milk: A comparison with bovine milk. East African Journal of Sciences, 2017. 11(2): p. 93-98.

- Musaad, A., B. Faye, and A.A. Nikhela, Lactation curves of dairy camels in an intensive system. Tropical Animal Health and Production, 2013. 45: p. 1039-1046.

- Atigui, M. , et al., Effect of changes in milking routine on milking related behaviour and milk removal in Tunisian dairy dromedary camels. Journal of Dairy Research, 2014. 81(4): p. 494-503.

- Ayadi, M. , et al., Machine milking parameters for an efficient and healthy milking in dairy camels (Camelus dromedarius). Journal of Camel Practice and Research, 2018. 25(1): p. 81-87.

- Cherifa, B., S. Oumelkheir, and E. Amar, Influence of feeding on some physicochemical and biochemical characteristics of camel milk (Camelus dromadarius). Emirates Journal of Food and Agriculture, 2018: p. 251-255.

- Merin, U. , et al., A comparative study of milk serum proteins in camel (Camelus dromedarius) and bovine colostrum. Livestock Production Science, 2001. 67(3): p. 297-301.

- Shamsia, S. , Nutritional and therapeutic properties of camel and human milks. International journal of genetics and molecular biology, 2009. 1(2): p. 52-58.

- Glantz, M. , et al., Importance of casein micelle size and milk composition for milk gelation. Journal of dairy science, 2010. 93(4): p. 1444-1451.

- Konuspayeva, G. , et al., Some parameters to process camel milk into cheese. Emirates Journal of Food and Agriculture, 2014. 26(4): p. np.

- Al Kanhal, H.A. , Compositional, technological and nutritional aspects of dromedary camel milk. International Dairy Journal, 2010. 20(12): p. 811-821.

- Jastrzebska, E. , et al., Nutritional Value and Health-Promoting Properties of Mare's Milk - a Review. Czech Journal of Animal Science, 2017. 62(12): p. 511-518.

- Fox, P.F., P. L. Mcsweeney, and L. Paul, Dairy chemistry and biochemistry. Second Edition ed. 2015.

- Konuspayeva, G., B. Faye, and G. Loiseau, The composition of camel milk: a meta-analysis of the literature data. Journal of food composition and analysis, 2009. 22(2): p. 95-101.

- Berhe, T., E. Seifu, and M.Y. Kurtu, Physicochemical properties of butter made from camel milk. International Dairy Journal, 2013. 31(2): p. 51-54.

- Farah, Z., T. Streiff, and M. Bachmann, Manufacture and characterization of camel milk butter. Milchwissenschaft, 1989. 44(7): p. 412-414.

- Berhe, T. , et al., Processing Challenges and Opportunities of Camel Dairy Products. International Journal of Food Science, 2017. 2017.

- Attia, H., N. Kherouatou, and A. Dhouib, Dromedary milk lactic acid fermentation: microbiological and rheological characteristics. Journal of industrial Microbiology and biotechnology, 2001. 26(5): p. 263-270.

- Berhe, T. , et al., Comparison of the acidification activities of commercial starter cultures in camel and bovine milk. Lwt-Food Science and Technology, 2018. 89: p. 123-127.

- AbuTarboush, H.M. , Comparison of associative growth and proteolytic activity of yogurt starters in whole milk from camels and cows. Journal of Dairy Science, 1996. 79(3): p. 366-371.

- Arain, M.A. , et al., A Review on Processing Opportunities for the Development of Camel Dairy Products. Food Science of Animal Resources, 2023. 43(3): p. 383-401.

- Sulieman, A.M.E.H., A. A. Ilayan, and A.E.A.E. Faki, Chemical and microbiological quality of Garris, Sudanese fermented camel's milk product. International journal of food science & technology, 2006. 41(3): p. 321-328.

- Takeda, S. , et al., The investigation of probiotic potential of lactic acid bacteria isolated from traditional Mongolian dairy products. Animal Science Journal, 2011. 82(4): p. 571-579.

- Maurad, K. and K.H. Meriem, Probiotic characteristics of Lactobacillus plantarum strains from traditional butter made from camel milk in arid regions (Sahara) of Algeria. Grasas Y Aceites, 2008. 59(3): p. 218-224.

- Boye, J.I. , et al., Factors affecting molecular characteristics of whey protein gelation. International Dairy Journal, 1995. 5(4): p. 337-353.

- El-Agamy, E. , Effect of heat treatment on camel milk proteins with respect to antimicrobial factors: a comparison with cows' and buffalo milk proteins. Food Chemistry, 2000. 68(2): p. 227-232.

- Laleye, L., B. Jobe, and A. Wasesa, Comparative study on heat stability and functionality of camel and bovine milk whey proteins. Journal of Dairy Science, 2008. 91(12): p. 4527-4534.

- Desouky, M.M., S. M. Shalaby, and K. Soryal, Compositional, rheological and organoleptic qualities of camel milk labneh as affected by some milk heat treatments. World Journal of Dairy & Food Sciences, 2013. 8(2): p. 118-130.

- Paulsson, M., P. -O. Hegg, and H. Castberg, Thermal stability of whey proteins studied by differential scanning calorimetry. Thermochimica Acta, 1985. 95(2): p. 435-440.

- Felfoul, I. , et al., Fouling behavior of camel and cow milks under different heat treatments. Food and Bioprocess Technology, 2015. 8: p. 1771-1778.

- Rankin, S. , et al., Invited review: The application of alkaline phosphatase assays for the validation of milk product pasteurization. Journal of Dairy Science, 2010. 93(12): p. 5538-5551.

- Elagamy, E. , Effect of heat treatment on camel milk proteins with respect to antimicrobial factors: a comparison with cows' and buffalo milk proteins. Food Chemistry, 2000. 68(2): p. 227-232.

- Loiseau, G. , et al., Enzymes ability to serve as markers of pasteurized camel milk. 2002.

- Rahman, M.S. , et al., Thermal characteristics of freeze-dried camel milk and its major components. Thermochimica Acta, 2012. 549: p. 116-123.

- Alhaj, O. , et al., Chemical characterisation of oligosaccharides in commercially pasteurised dromedary camel (Camelus dromedarius) milk. International Dairy Journal, 2013. 28(2): p. 70-75.

- Hassan, R., I. E. El Zubeir, and S. Babiker, Effect of pasteurization of raw camel milk and storage temperature on the chemical composition of fermented camel milk. Int. J. Dairy Sci, 2007. 2(2): p. 166-171.

- Ibtisam, E. and I.I. Marowa, Effect of pasteurization of milk on the keeping quality of fermented camel milk (Gariss) in Sudan. Livestock Research for Rural Development, 2009. 21(2).

- Wernery, U., B. Johnson, and R. George, Gamma-glutamyl transferase (GGT), a potential marker for the evaluation of heat treatment of dromedary milk. Journal of Camel Practice and Research, 2007. 14(1): p. 9-9.

- Lorenzen, P.C. , et al., Evaluation of indigenous enzyme activities in raw and pasteurised camel milk. Small Ruminant Research, 2011. 97(1-3): p. 79-82.

- Tayefi-Nasrabadi, H., M. A. Hoseinpour-fayzi, and M. Mohasseli, Effect of heat treatment on lactoperoxidase activity in camel milk: A comparison with bovine lactoperoxidase. Small Ruminant Research, 2011. 99(2-3): p. 187-190.

- Kherouatou, N., M. Nasri, and H. Attia, A study of the dromedary milk casein micelle and its changes during acidification. Brazilian Journal of Food Technology, 2003. 6(2): p. 237-244.

- Farah, Z. , Effect of heat treatment on whey proteins of camel milk. Milchwissenschaft, 1986. 41(12): p. 763-765.

- Farah, Z. and D. Atkins, Heat coagulation of camel milk. Journal of Dairy Research, 1992. 59(2): p. 229-231.

- Momen, S. , et al., The techno-functional properties of camel whey protein compared to bovine whey protein for fabrication a model high protein emulsion. LWT, 2019. 101: p. 543-550.

- Hattem, H. , et al., A study on the effect of thermal treatment on composition and some properties of camel milk. Slovak Journal of Animal Science, 2011. 44(3): p. 97-102.

- Alhaj, O.A., A. A. Metwalli, and E.A. Ismail, Heat stability of camel milk proteins after sterilisation process. Journal of Camel Practice and Research, 2011. 18(2): p. 277-282.

- Dziuba, B. and M. Dziuba, Milk proteins-derived bioactive peptides in dairy products: molecular, biological and methodological aspects. Acta Scientiarum Polonorum Technologia Alimentaria, 2014. 13(1): p. 5-26.

- Singh, R. , et al., Camel Milk: An Important Natural Adjuvant. Agricultural Research, 2017. 6(4): p. 327-340.

- El Sayed, I. , et al., Antibacterial and antiviral activity of camel milk protective proteins. Journal of Dairy Research, 1992. 59(2): p. 169-175.

- Ochoa, T.J. and T.G. Cleary, Effect of lactoferrin on enteric pathogens. Biochimie, 2009. 91(1): p. 30-34.

- Redwan, E.R.M. and A. Tabll, Camel lactoferrin markedly inhibits hepatitis C virus genotype 4 infection of human peripheral blood leukocytes. Journal of immunoassay & immunochemistry, 2007. 28(3): p. 267-277.

- Chuvakova, Z. , et al. Chemical composition, microbial control and antiviral properties of freshly made and conserved shubat “Bota”. in Proc. 2nd International Camelid Conference Agro economics of Camelid Farming, Almaty, Kazakhstan. 2000.

- Mal, G. , et al., Therapeutic value of camel milk as a nutritional supplement for multiple drug resistant (MDR) tuberculosis patients. Israel Journal of Veterinary Medicine, 2006. 61(3/4): p. 88.

- Beg, O.U. , et al., A camel milk whey protein rich in half-cystine: primary structure, assessment of variations, internal repeat patterns, and relationships with neurophysin and other active polypeptides. European Journal of Biochemistry, 1986. 159(1): p. 195-201.

- Agrawal, R.P. , et al., Effect of camel milk on residual β-cell function in recent onset type 1 diabetes. Diabetes research and clinical practice, 2007. 77(3): p. 494-495.

- Agrawal, R.P. , et al., Camel milk as an adjunct to insulin therapy improves long-term glycemic control and reduction in doses of insulin in patients with type-1 diabetes. A 1 year randomized controlled trial. Diabetes Research and Clinical Practice, 2005. 68(2): p. 176-177.

- Sahani, M. , et al., Hypoglycemic activity of camel milk in straptozotocin induced hyperglycemia in rats. 2005.

- Dikhanbayeva, F. , et al., The effect of camel milk curd masses on rats blood serum biochemical parameters: Preliminary study. Plos One, 2021. 16(9).

- Sboui, A. , et al., Anti-diabetic effect of camel milk in alloxan-induced diabetic dogs: a dose–response experiment. Journal of animal physiology and animal nutrition, 2010. 94(4): p. 540-546.

- Arab, H.H. , et al., Camel Milk Attenuates Rheumatoid Arthritis Via Inhibition of Mitogen Activated Protein Kinase Pathway. Cellular Physiology and Biochemistry, 2017. 43(2): p. 540-552.

- Bakhtiari, E. , et al., Effect of camel milk in asthmatic children: A double-blind randomized pilot study. Pediatric Pulmonology, 2022. 57(11): p. 2834-2838.

- Zhang, B.Y. , et al., Fouling characterization of camel milk with comparison to bovine milk. Journal of Food Engineering, 2020. 285.

- Aralbayev, N.A. , RESEARCH AND DEVELOPMENT OF TECHNOLOGY OF DRY DAIRY PRODUCTS BASED ON CAMEL MILK, in Technology of Food Products. 2022, Almaty Technological University: Almaty. p. 44.

- Ibrahim, A.H. and S.A. Khalifa, Effect of freeze-drying on camel's milk nutritional properties. International Food Research Journal, 2015. 22(4): p. 1438-1445.

- Sulieman, A.M.E. , et al., Comparison of physicochemical properties of spray-dried camel’s milk and cow’s milk powder. International Journal of Food Science and Nutrition Engineering, 2014. 4(1): p. 15-19.

- Habtegebriel, H., M. Wawire, and D. Sila, The Effect of Pretreatment (Spray Drying) on the Yield and Selected Nutritional Components of Whole Camel Milk Powder. Journal of Food Science, 2018. 83(12): p. 2983-2991.

- Harizi, N. , et al., Effects of Spray Drying, Freeze Drying and Gamma Irradiation on the Antioxidant Activities of Camel and Cow Milk Fractions. Processes, 2023. 11(3).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).