Submitted:

01 March 2024

Posted:

04 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Present Contribution

2. Materials and Methods

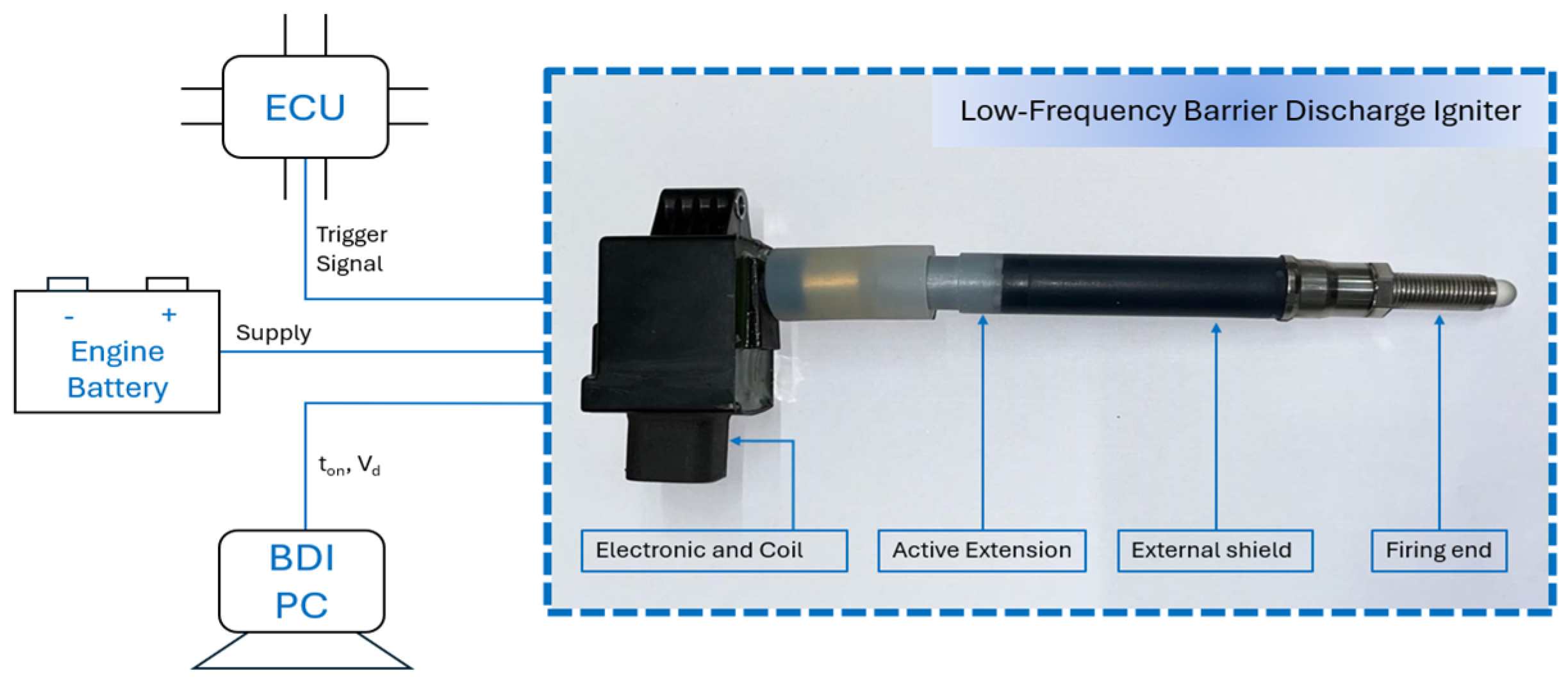

2.1. Igniter

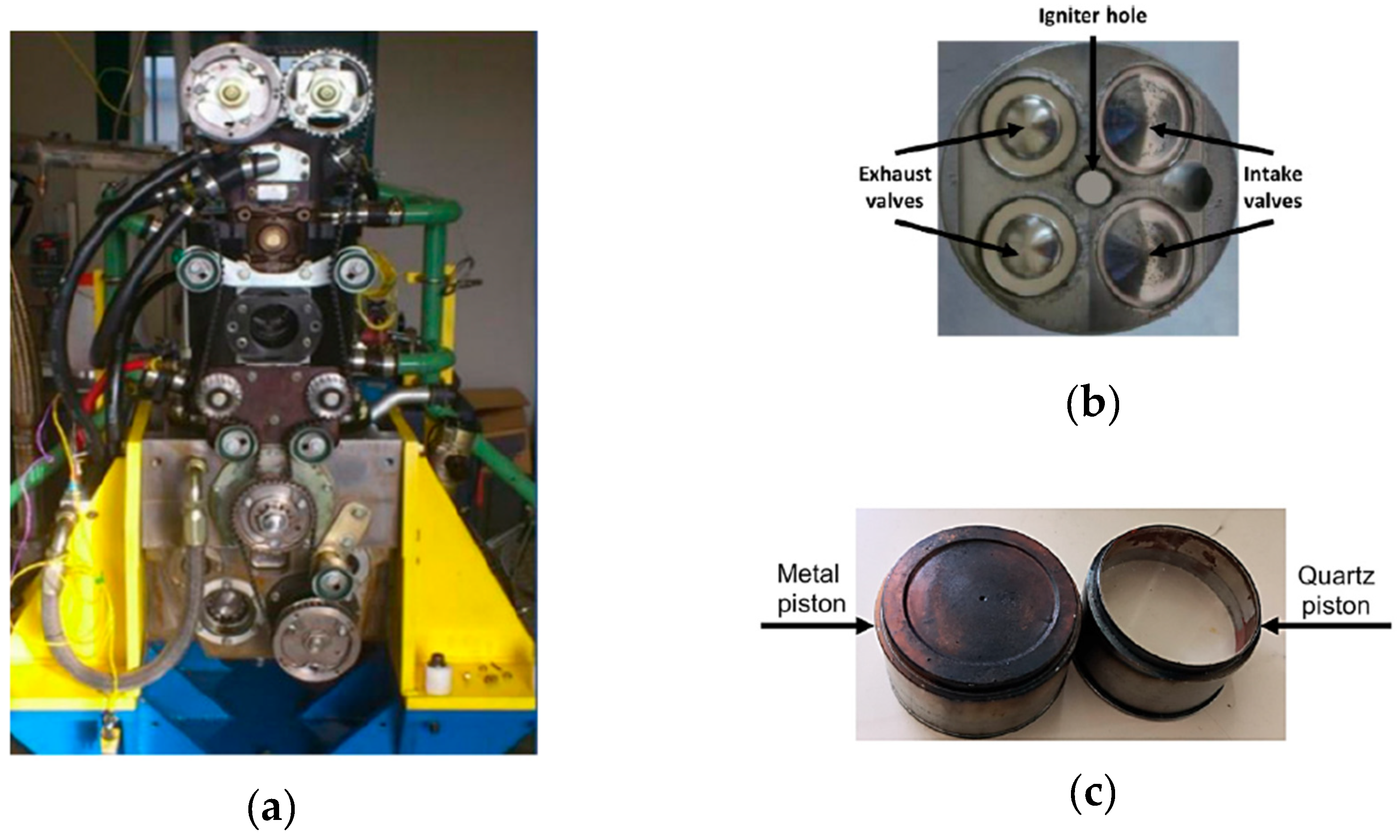

2.2. Single Cylinder Research Engine

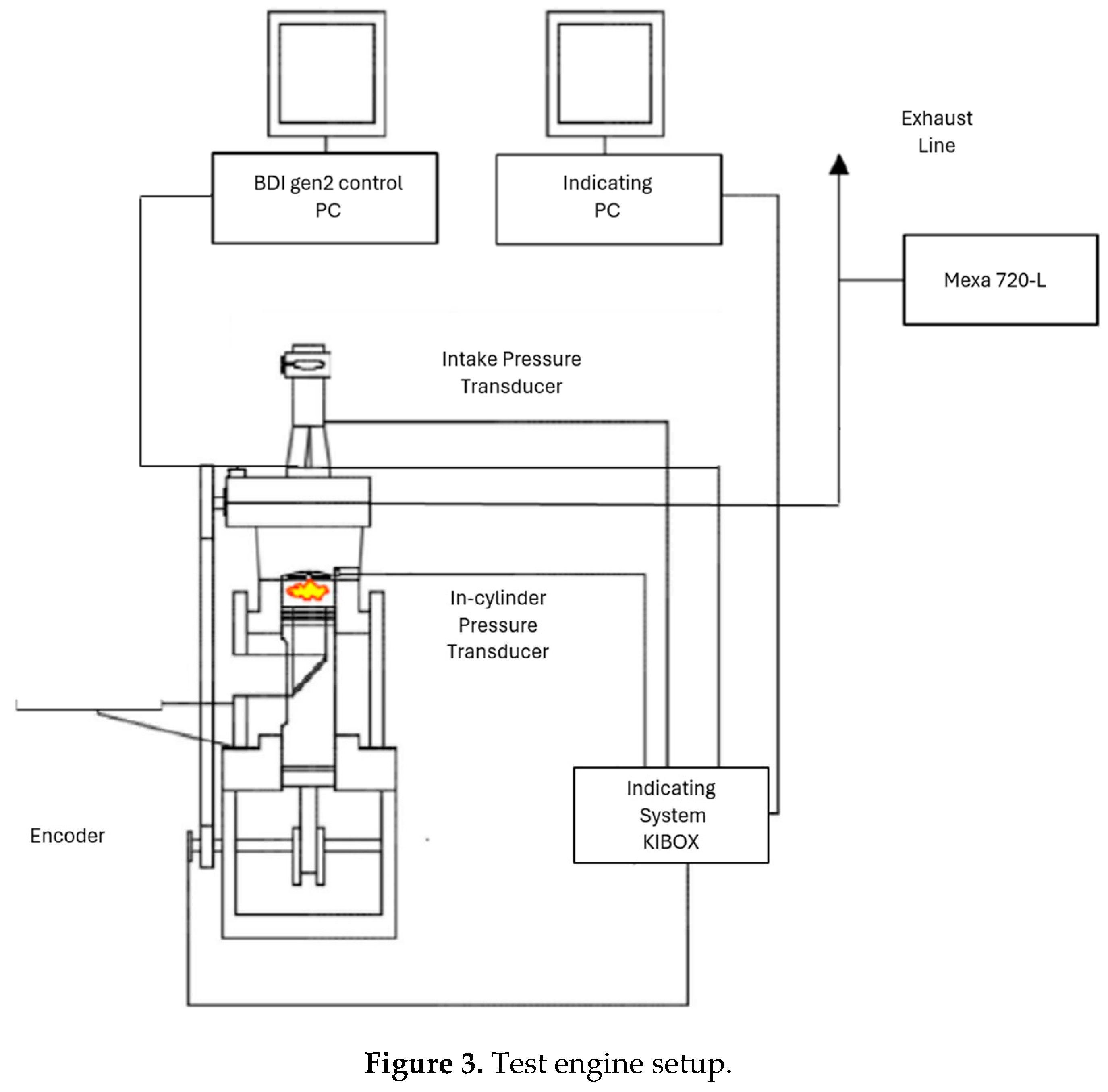

2.3. Test Campaign

3. Results and Discussions

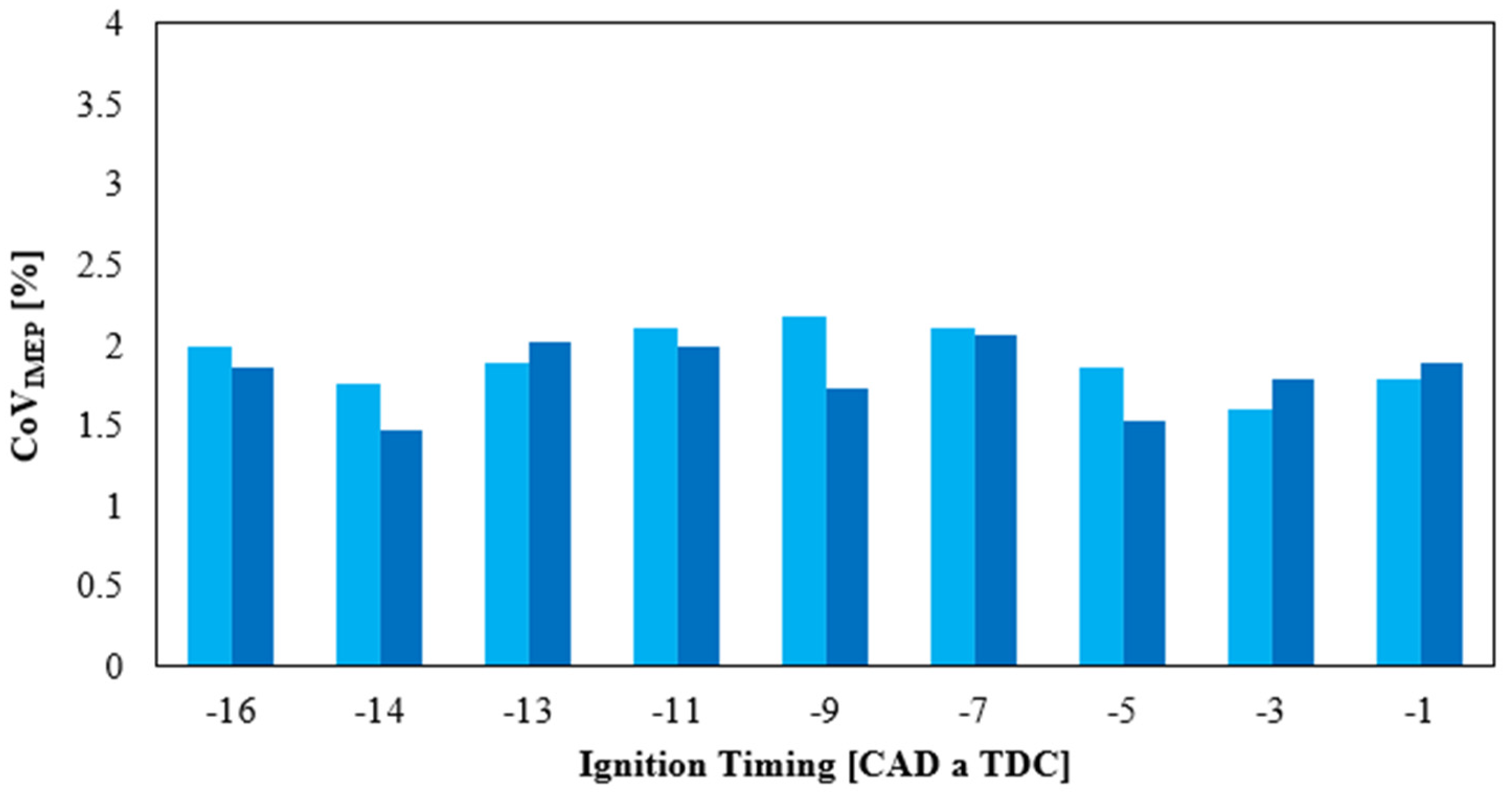

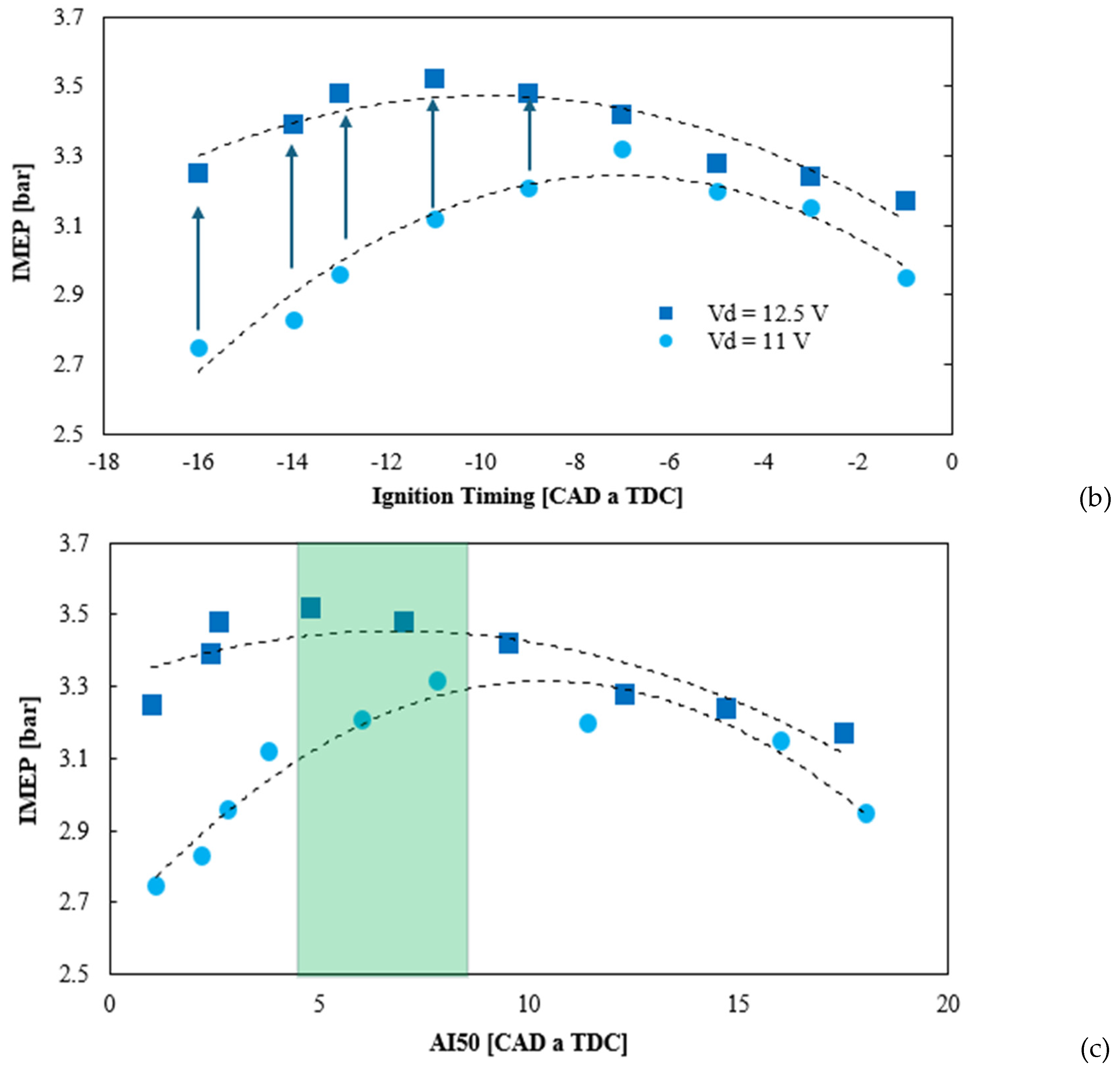

3.1. Optimization of the BDI Performance at λ = 1.6

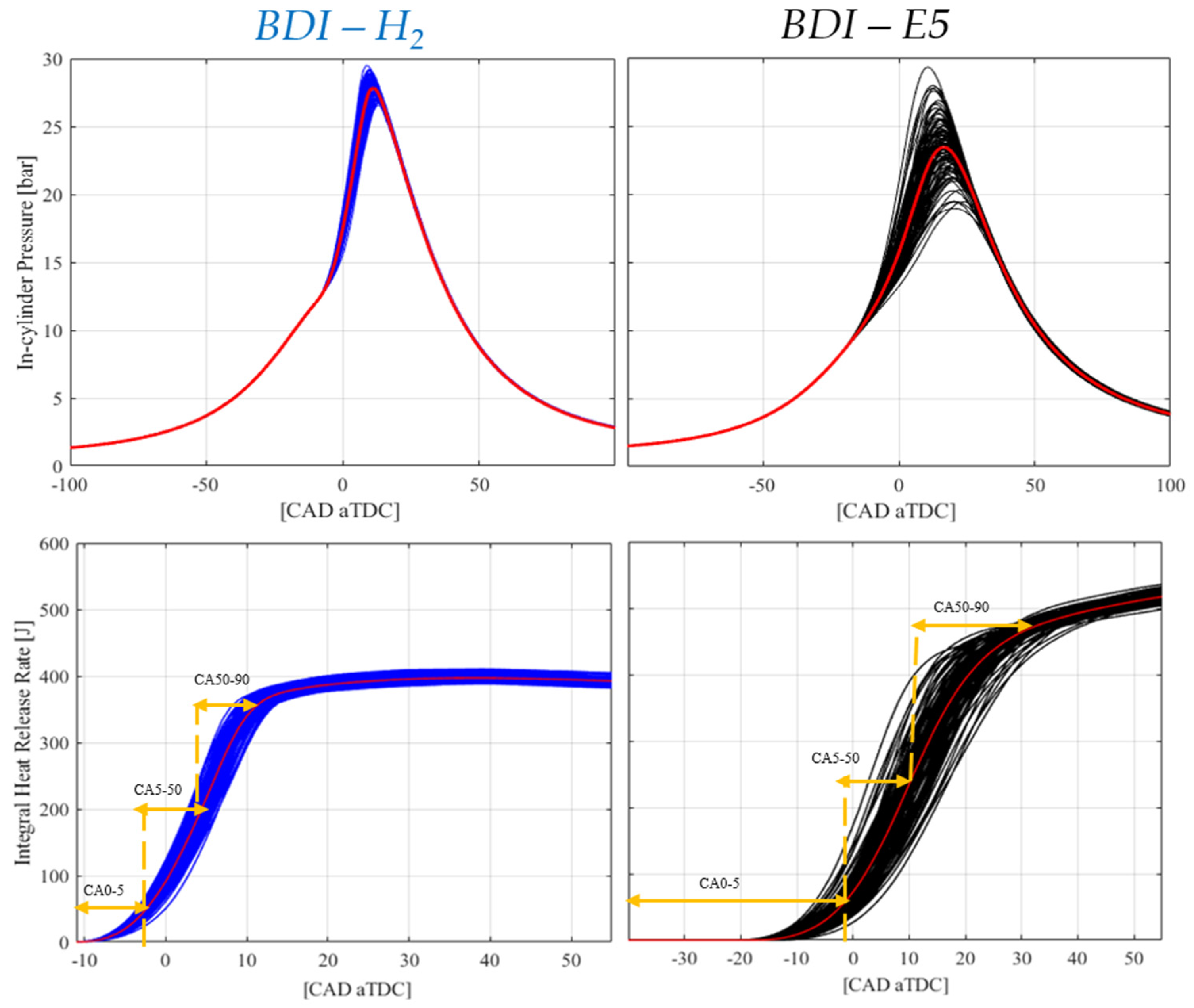

3.2. Analysis of the BDI’s Performance at λ = 1.6 in H2 and Conventional Gasoline E5

3.3. Comparison between Traditional Spark and BDI at the Same IT in H2

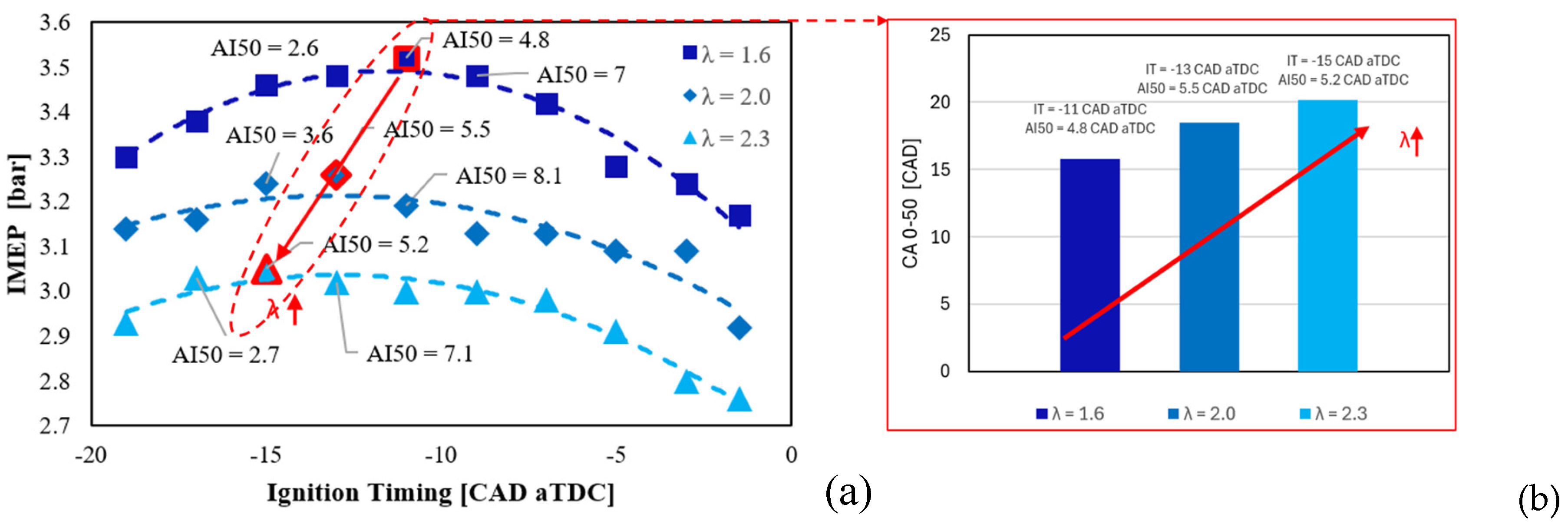

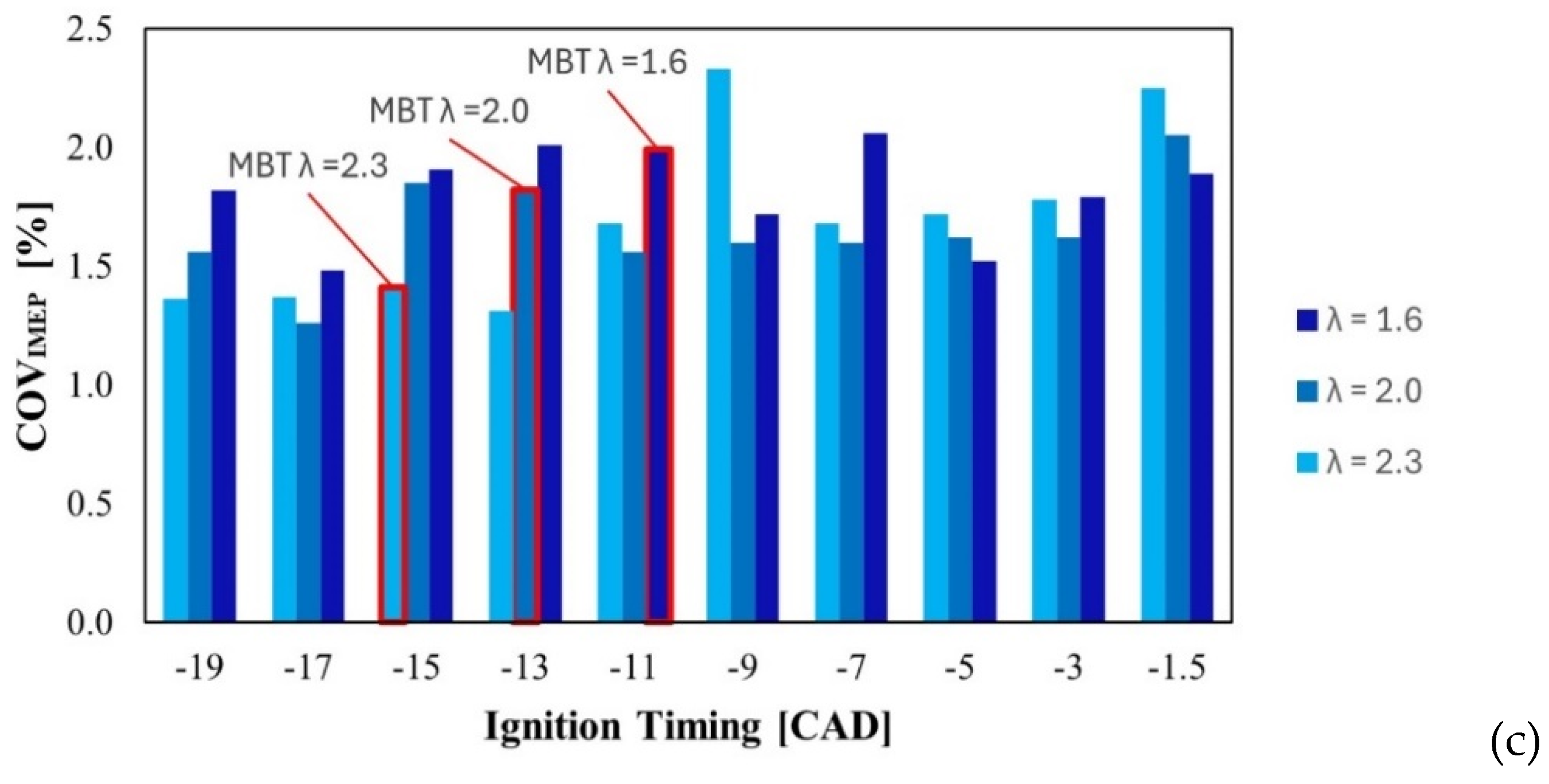

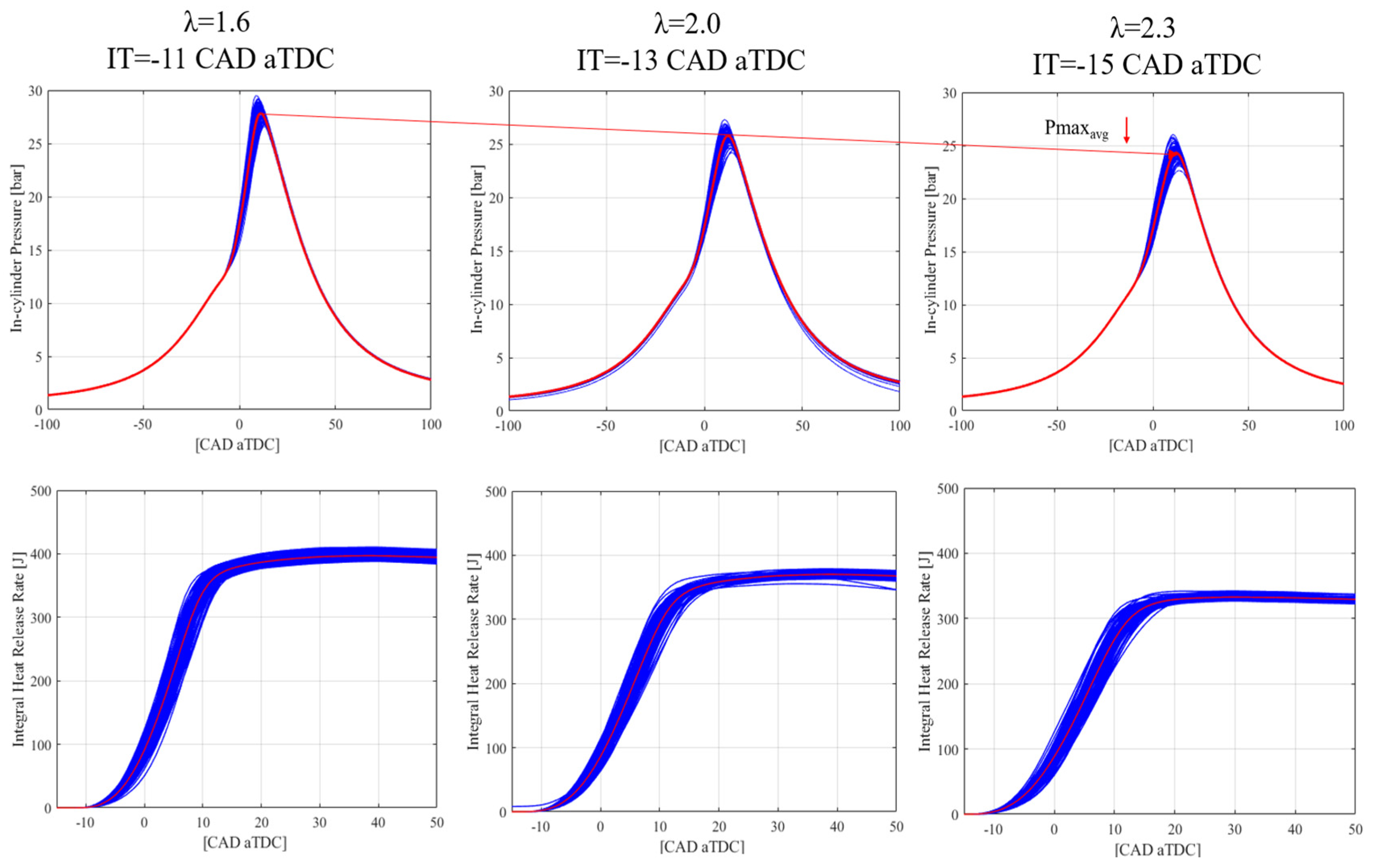

3.4. Extension of the BDI Lean Operating Condition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| aBDC | after Bottom Dead Center |

| ACIS | Advanced Corona Ignition System |

| AI05 | Crank angle degree after the Top Dead Center (TDC) for which 5% of the mass is burned |

| AI50 | Crank angle degree after the Top Dead Center (TDC) for which 50% of the mass is burned |

| AI90 | Crank angle degree after the Top Dead Center (TDC) for which 90% of the mass is burned |

| aTDC | after Top Dead Center |

| BDI | Barrier Discharge Igniter |

| CA 0-50 | Crank angle degree from IT to AI05 |

| CA 5-50 | Crank angle degree from AI05 to AI50 |

| CA 50-90 | Crank angle degree from AI50 to AI90 |

| CAD | Crank Angle Degree |

| CO | Carbon Monoxide |

| CoVIMEP | Coefficient of Variance of IMEP |

| DI | Direct Injection |

| D/GPF | High-efficiency Particulate Filters |

| E5 | Gasoline |

| E85 | Ethanol |

| ECU | Engine Control Unit |

| EGR | Exhaust Gas Recirculation |

| H2 | Hydrogen |

| HC | Hydrocarbons |

| ICE | Internal Combustion Engine |

| IHRR | Integral Heat Release Rate |

| IMEP | Indicated Mean Effective Pressure |

| IT | Ignition Timing |

| λ | Relative Air-Fuel ratio |

| LTC | Low-Temperature Combustion |

| LTP | Low-Temperature Plasma |

| MBT | Maximum Brake Torque |

| NOx | Nitrogen Oxides |

| O2 | Oxygen |

| PFI | Port Fuel Injection |

| SCR | Selective Catalytic Reducers |

| SI | Spark Ignition |

| ton | Activation Time |

| Vd | Driving Voltage |

References

- Suresh, D.; Porpatham, E. Influence of high compression ratio and hydrogen addition on the performance and emissions of a lean burn spark ignition engine fueled by ethanol-gasoline. Int. J. Hydrogen Energy 2023, 48, 14433–14448. [Google Scholar] [CrossRef]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Duan, X.; Xu, L.; Xu, L.; Jiang, P.; Gan, T.; Liu, H.; Ye, S.; Sun, Z. Performance analysis and comparison of the spark ignition engine fuelled with industrial by-product hydrogen and gasoline. J. Clean. Prod. 2023, 424. [Google Scholar] [CrossRef]

- Dernotte, J.; Najt, P.M.; Durrett, R.P. Downsized-Boosted Gasoline Engine with Exhaust Compound and Dilute Advanced Combustion. SAE Int. J. Adv. Curr. Pr. Mobil. 2020, 2, 2665–2680. [Google Scholar] [CrossRef]

- Zembi, J.; Mariani, F.; Battistoni, M.; Irimescu, A.; Merola, S. Numerical Investigation of Water Injection Effects on Flame Wrinkling and Combustion Development in a GDI Spark Ignition Optical Engine. SAE WCX Digital Summit. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Zembi, J.; Battistoni, M.; Mariani, F.; Irimescu, A.; Vaglieco, B.; Merola, S. Investigations on the impact of port water injection on soot formation in a DISI engine through CFD simulations and optical methods. Fuel 2023, 337. [Google Scholar] [CrossRef]

- Dadam, S.R.; Jentz, R.; Lenzen, T.; Meissner, H. Diagnostic Evaluation of Exhaust Gas Recirculation (EGR) System on Gasoline Electric Hybrid Vehicle. WCX SAE World Congress Experience. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Ricci, F.; Martinelli, R.; Re, M.D.; Grimaldi, C.N. Comparative analysis of thermal and non-thermal discharge modes on ultra-lean mixtures in an optically accessible engine equipped with a corona ignition system. Combust. Flame 2024, 259. [Google Scholar] [CrossRef]

- Singh, A.P.; Kumar, V.; Agarwal, A.K. Evaluation of comparative engine combustion, performance and emission characteristics of low temperature combustion (PCCI and RCCI) modes. Appl. Energy 2020, 278, 115644. [Google Scholar] [CrossRef]

- Pielecha, J.; Skobiej, K.; Kurtyka, K. Exhaust Emissions and Energy Consumption Analysis of Conventional, Hybrid, and Electric Vehicles in Real Driving Cycles. Energies 2020, 13, 6423. [Google Scholar] [CrossRef]

- Anika, O.C.; Nnabuife, S.G.; Bello, A.; Okoroafor, E.R.; Kuang, B.; Villa, R. Prospects of low and zero-carbon renewable fuels in 1.5-degree net zero emission actualisation by 2050: A critical review. Carbon Capture Sci. Technol. 2022, 5, 100072. [Google Scholar] [CrossRef]

- Campos-Carriedo, F.; Bargiacchi, E.; Dufour, J.; Iribarren, D. How can the European Ecodesign Directive guide the deployment of hydrogen-related products for mobility? Sustain. Energy Fuels 2023, 7, 1382–1394. [Google Scholar] [CrossRef]

- Sementa, P.; Antolini, J.B.d.V.; Tornatore, C.; Catapano, F.; Vaglieco, B.M.; Sánchez, J.J.L. Exploring the potentials of lean-burn hydrogen SI engine compared to methane operation. Int. J. Hydrogen Energy 2022, 47, 25044–25056. [Google Scholar] [CrossRef]

- Luo, Q.-H.; Sun, B.-G. Inducing factors and frequency of combustion knock in hydrogen internal combustion engines. Int. J. Hydrogen Energy 2016, 41, 16296–16305. [Google Scholar] [CrossRef]

- Aydin, K.; Kenanoğlu, R. Effects of hydrogenation of fossil fuels with hydrogen and hydroxy gas on performance and emissions of internal combustion engines. Int. J. Hydrogen Energy 2018, 43, 14047–14058. [Google Scholar] [CrossRef]

- Srinivasan, C.B.; Subramanian, R. Hydrogen as a Spark Ignition Engine Fuel Technical Review. Int. J. Mech. Mechatron. Eng. IJMME-IJENS 2014, 14, 111–117. [Google Scholar]

- Ceviz, M.; Kaymaz, I. Temperature and air–fuel ratio dependent specific heat ratio functions for lean burned and unburned mixture. Energy Convers. Manag. 2005, 46, 2387–2404. [Google Scholar] [CrossRef]

- Verhelst, S.; Sierens, R.; Verstraeten, S. A Critical Review of Experimental Research on Hydrogen Fueled SI Engines. SAE 2006 World Congress & Exhibition. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Shi, C.; Ji, C.; Wang, S.; Yang, J.; Wang, H. Experimental and numerical study of combustion and emissions performance in a hydrogen-enriched Wankel engine at stoichiometric and lean operations. Fuel 2021, 291, 120181. [Google Scholar] [CrossRef]

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and emission characteristics of a hydrogen-diesel dual-fuel engine. Int. J. Hydrogen Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Wu, H.; Yu, X.; Du, Y.; Ji, X.; Niu, R.; Sun, Y.; Gu, J. Study on cold start characteristics of dual fuel SI engine with hydrogen direct-injection. Appl. Therm. Eng. 2016, 100, 829–839. [Google Scholar] [CrossRef]

- Serin, H.; Yıldızhan, Ş. Hydrogen addition to tea seed oil biodiesel: Performance and emission characteristics. Int. J. Hydrogen Energy 2018, 43, 18020–18027. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Song, P.; Tian, G.; Ma, C. Review of the backfire occurrences and control strategies for port hydrogen injection internal combustion engines. Fuel 2022, 307. [Google Scholar] [CrossRef]

- Huynh, T.C.; Kang, J.K.; Noh, K.C.; Lee, J.T.; Caton, J.A. Controlling Backfire Using Changes of the Valve Overlap Period for a Hydrogen-Fueled Engine Using an External Mixture. ASME 2007 Internal Combustion Engine Division Fall Technical Conference. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE. pp. 243–251.

- Garmsiri, S. Study of an internal combustion engine to burn hydrogen fuel and backfire elimination using a carburetor fuel delivery method. UOIT 2010.

- Ye, Y.; Gao, W.; Li, Y.; Zhang, P.; Cao, X. Numerical study of the effect of injection timing on the knock combustion in a direct-injection hydrogen engine. Int. J. Hydrogen Energy 2020, 45, 27904–27919. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Balducci, E.; Cavina, N.; Rojo, N.; Calogero, L.; Poggio, L. Experimental observations of engine piston damage induced by knocking combustion. Mater. Des. 2017, 114, 312–325. [Google Scholar] [CrossRef]

- Diéguez, P.; Urroz, J.; Sáinz, D.; Machin, J.; Arana, M.; Gandía, L. Characterization of combustion anomalies in a hydrogen-fueled 1.4 L commercial spark-ignition engine by means of in-cylinder pressure, block-engine vibration, and acoustic measurements. Energy Convers. Manag. 2018, 172, 67–80. [Google Scholar] [CrossRef]

- Tsujimura, T.; Suzuki, Y. The utilization of hydrogen in hydrogen/diesel dual fuel engine. Int. J. Hydrogen Energy 2017, 42, 14019–14029. [Google Scholar] [CrossRef]

- Falfari, S.; Cazzoli, G.; Mariani, V.; Bianchi, G.M. Hydrogen Application as a Fuel in Internal Combustion Engines. Energies 2023, 16, 2545. [Google Scholar] [CrossRef]

- Zembi, J.; Ricci, F.; Grimaldi, C.; Battistoni, M. Numerical Simulation of the Early Flame Development Produced by a Barrier Discharge Igniter in an Optical Access Engine. 15th International Conference on Engines & Vehicles. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Ricci, F.; Cruccolini, V.; Discepoli, G.; Petrucci, L.; Grimaldi, C.; Papi, S. Luminosity and Thermal Energy Measurement and Comparison of a Dielectric Barrier Discharge in an Optical Pressure-Based Calorimeter at Engine Relevant Conditions. SAE WCX Digital Summit. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Starikovskaia, S.M. Plasma assisted ignition and combustion. J. Phys. D: Appl. Phys. 2006, 39, R265–R299. [Google Scholar] [CrossRef]

- Zembi, J.; Cruccolini, V.; Mariani, F.; Scarcelli, R.; Battistoni, M. Modeling of thermal and kinetic processes in non-equilibrium plasma ignition applied to a lean combustion engine. Appl. Therm. Eng. 2021, 197. [Google Scholar] [CrossRef]

- Idicheria, C.A.; Najt, P.M. Potential of advanced corona ignition system (ACIS) for future engine applications. In ; : ; . p. –. In Ignition Syst. Gasol. Engines.; Springer International Publishing: Cham, 2017; pp. 315–331. [Google Scholar] [CrossRef]

- Martinelli, R.; Ricci, F.; Zembi, J.; Battistoni, M.; Grimaldi, C.; Papi, S. Lean Combustion Analysis of a Plasma-Assisted Ignition System in a Single Cylinder Engine fueled with E85. Conference on Sustainable Mobility. LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Ricci, F.; Discepoli, G.; Cruccolini, V.; Petrucci, L.; Papi, S.; Di Giuseppe, A.; Grimaldi, C. Energy characterization of an innovative non-equilibrium plasma ignition system based on the dielectric barrier discharge via pressure-rise calorimetry. Energy Convers. Manag. 2021, 244, 114458. [Google Scholar] [CrossRef]

- Cruccolini, V.; Discepoli, G.; Ricci, F.; Petrucci, L.; Grimaldi, C.; Papi, S.; Re, M.D. Comparative Analysis between a Barrier Discharge Igniter and a Streamer-Type Radio-Frequency Corona Igniter in an Optically Accessible Engine in Lean Operating Conditions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Azeem, N.; Beatrice, C.; Vassallo, A.; Pesce, F.; Davide, G.; Guido, C.; Rossi, R. Comparative Analysis of Different Methodologies to Calculate Lambda (λ) Based on Extensive And systemic Experimentation on a Hydrogen Internal Combustion Engine. WCX SAE World Congress Experience. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE.

- Wang, L.; Yang, Z.; Huang, Y.; Liu, D.; Duan, J.; Guo, S.; Qin, Z. The effect of hydrogen injection parameters on the quality of hydrogen–air mixture formation for a PFI hydrogen internal combustion engine. Int. J. Hydrogen Energy 2017, 42, 23832–23845. [Google Scholar] [CrossRef]

- Shinde, B.J.; K. , K. Recent progress in hydrogen fuelled internal combustion engine (H2ICE) – A comprehensive outlook. Mater. Today: Proc. 2021, 51, 1568–1579. [Google Scholar] [CrossRef]

| Feature | Value | Unit |

| Displaced volume | 500 | cc |

| Stroke | 88 | mm |

| Bore | 85 | mm |

| Connecting rod length | 139 | mm |

| Compression ratio | 8.8:1 | - |

| Number of valves | 4 | - |

| Exhaust valve open | -13 | CAD aBDC |

| Exhaust valve close | 25 | CAD aBDC |

| Intake valve open | -20 | CAD aBDC |

| Intake valve close | -24 | CAD aBDC |

| Features | H2 | E5 |

| IT [CAD aTDC] | -11 | -38 |

| CoVIMEP [%] | 1.56 | 2.8 |

| IMEP [bar] | 3.52 | 4.49 |

| AI05 [CAD aTDC] | -1.2 | -2.7 |

| AI50 [CAD aTDC] | 7.1 | 10 |

| AI90 [CAD aTDC] | 13.8 | 31.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).